Page 1

POWER TOOLS

TECHNICAL DATA

AND

SERVICE MANUAL

CIRCULAR SAWS

C 6SE, C 7SE

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

LIST Nos. C 6SE: 0587

C 7SE: 0588

Sep. 1999

C

MODELS

C 6SE

C 7SE

C 6SE

C 7SE

Page 2

REMARK:

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s)

is(are) used in the place of company name(s) and model name(s) of our

competitor(s). The symbol(s) utilized here is(are) as follows:

Symbol Utilized

Competitor

Company Name

Model Name

C --- 1 MAKITA

5606B

C 6SE

Symbol Utilized

Competitor

Company Name

Model Name

C --- 2 MAKITA

5806B

C 7SE

Page 3

Page

CONTENTS

[ Business Section ]

1. PRODUCT NAME

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

2. MARKETING OBJECTIVE

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

3. APPLICA TIONS

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

4. SELLING POINTS

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

4-1. Selling Point Descriptions

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

2

5. SPECIFICATIONS

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

3

6. COMPARISONS WITH SIMILAR PRODUCTS

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

4

7. PRECAUTIONS IN SALES PROMOTION

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

4

7-1. Handling Instructions

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

4

[ Service Section ]

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

5

8-1. Disassembly

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

5

8-2. Reassembly

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

6

8-3. Insulation Tests

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

10

8-4. Deflection of Saw Blade

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

10

8-5. Cleaning the Case

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

10

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

11

[ Appendix ]

Assembly Diagram for C 6SE

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

12

Assembly Diagram for C 7SE

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

16

Page 4

--- 1 ---

1. PRODUCT NAME

Hitachi Circular Saw, Model C 6SE [165 mm (6-1/2") ]

Hitachi Circular Saw, Model C 7SE [190 mm (7-1/2")]

2. MARKETING OBJECTIVE

The Models C 6SE and C 7SE have been developed based on the current Models C6 and C7. The key features

of the Models C 6SE and C 7SE are as follows:

(1) Double-insulated construction. No grounding required

(2) Power-plus heavy-duty motor

(3) High performance 40-tooth tungsten carbide tipped (TCT) saw blade as standard

(C 6SE: 165 mm, C 7SE: 190 mm)

(4) Improved operability with large front grip, large plastic wing bolt & nut for base adjustment, and large lever on

the safety cover

(5) Convenient cutting depth scale on the safety cover

3. APPLICA TIONS

Cutting of various wood materials

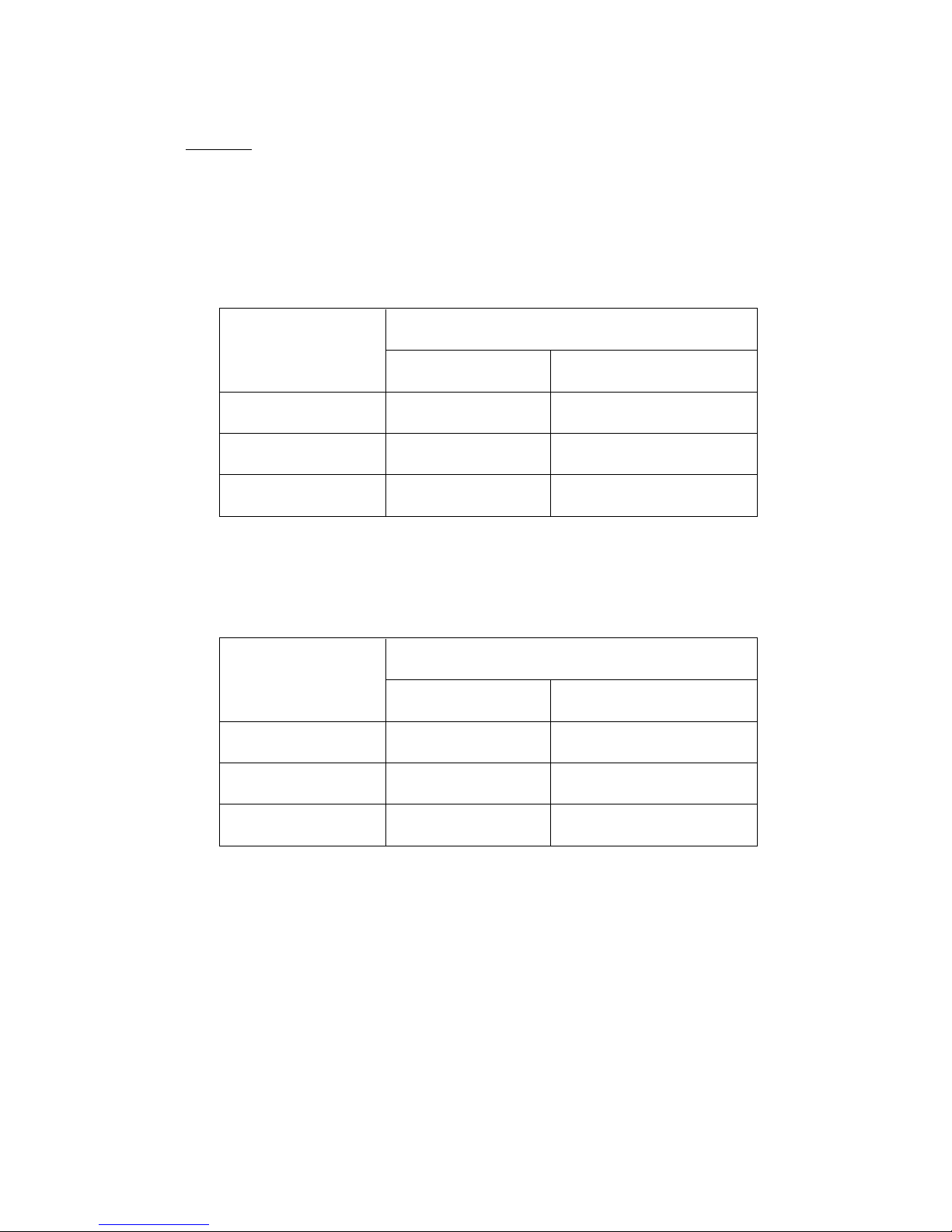

4. SELLING POINTS

Double-insulated

construction

Cutting depth scale

on the safety cover

Large front grip

High performance

40T TCT saw blade

C 6SE: 165 mm dia.

C 7SE: 190 mm dia.

Power-plus heavy duty motor

C 6SE: Input 960 W

C 7SE: Input 1,080 W

Large plastic wing bolt & nut for

easy base adjustment

Large lever on the safety cover

Page 5

--- 2 ---

4-1. Selling Point Descriptions

(1) Double-insulated construction

Grounding is not required because of the double-insulated construction.

(2) Power-plus heavy duty motor

Powerful motor provides greater input and output than those of the Models C6 and C7.

(3) High performance 40-tooth tungsten carbide tipped (TCT) saw blade as standard

High performance TCT saw blade (40 teeth) is provided as standard instead of the conventional combination

blade. The Models C 6SE and C 7SE provide greater maximum cutting depth than the conventional models

by using a 165 mm dia. TCT saw blade and a 190 mm dia. TCT saw blade respectively.

(4) Improved operability with large front grip, large plastic wing bolt & nut for base adjustment, and large lever on

the safety cover

The circular saw can be stably handled with both hands because the front grip is formed with the housing as

one piece. The inclination adjusting wing bolt and cutting depth adjusting wing nut were changed from steel to

plastic for better operability. A large safety cover knob is adopted for easier opening and closing of the safety

cover.

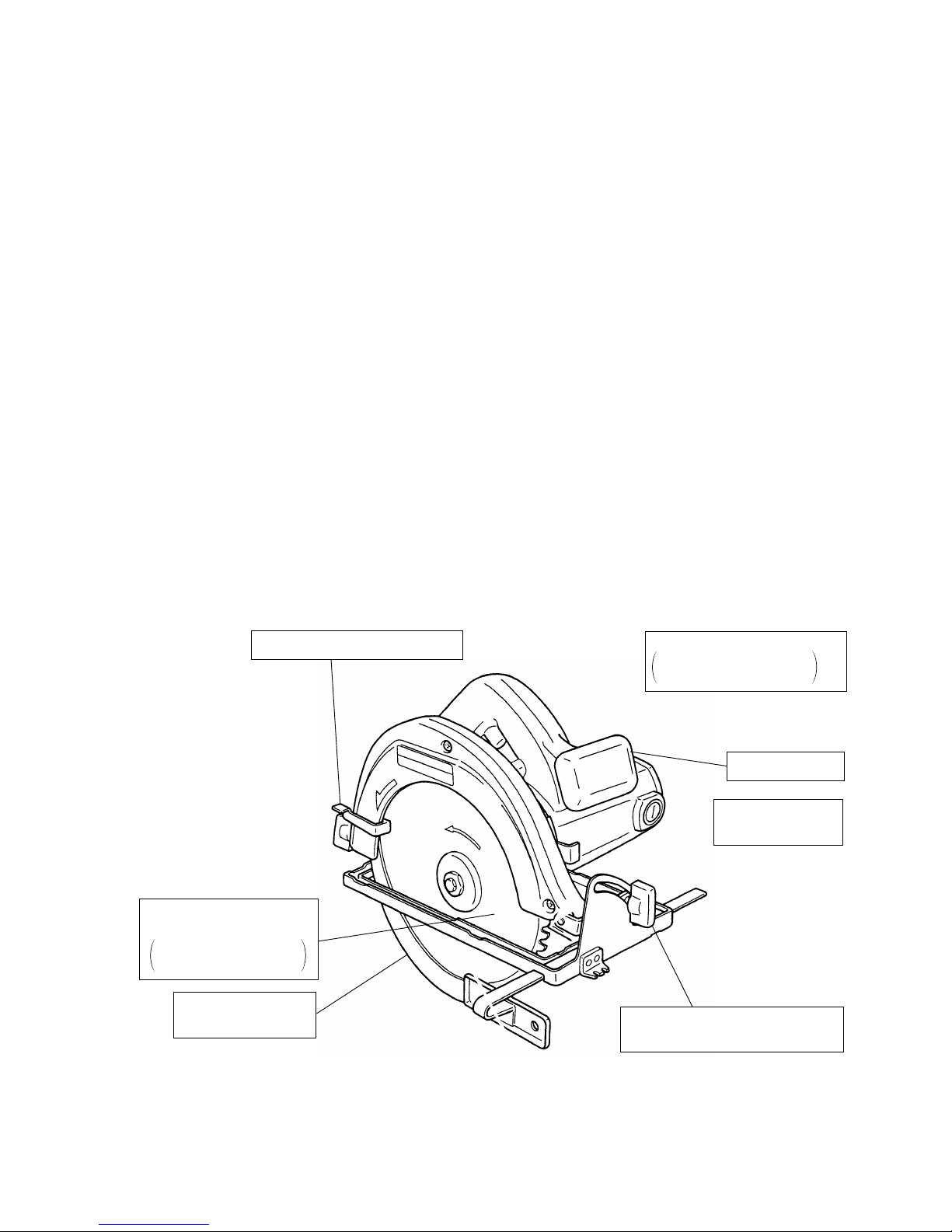

(5) Convenient cutting depth scale on the safety cover

A cutting depth scale is marked in millimeters on

the safety cover. By aligning the bottom of the

base with the scale, you can easily set the

desired cutting depth. The inner scale is for a

160 mm dia. saw blade on the C 6SE or for a

185 mm dia. saw blade on the C 7SE, and the

outer scale is for a 165 mm dia. saw blade on the

C 6SE or for a 190 mm dia. saw blade on the

C 7SE. Both scales are graduated in 3

millimeters. An example, when the cutting depth

is adjusted to 30 mm, is shown in Fig. 1.

Notes on using the cutting depth scale

• This scales should only be used as a rough guide. If more accurate adjustment is required, instruct the

customers to measure the saw blade tip directly from the bottom surface of the base.

• As the scale indicates a cutting depth when the saw blade is at a right angle to the base, it cannot be used

for inclined cutting.

Fig. 1

Page 6

--- 3 ---

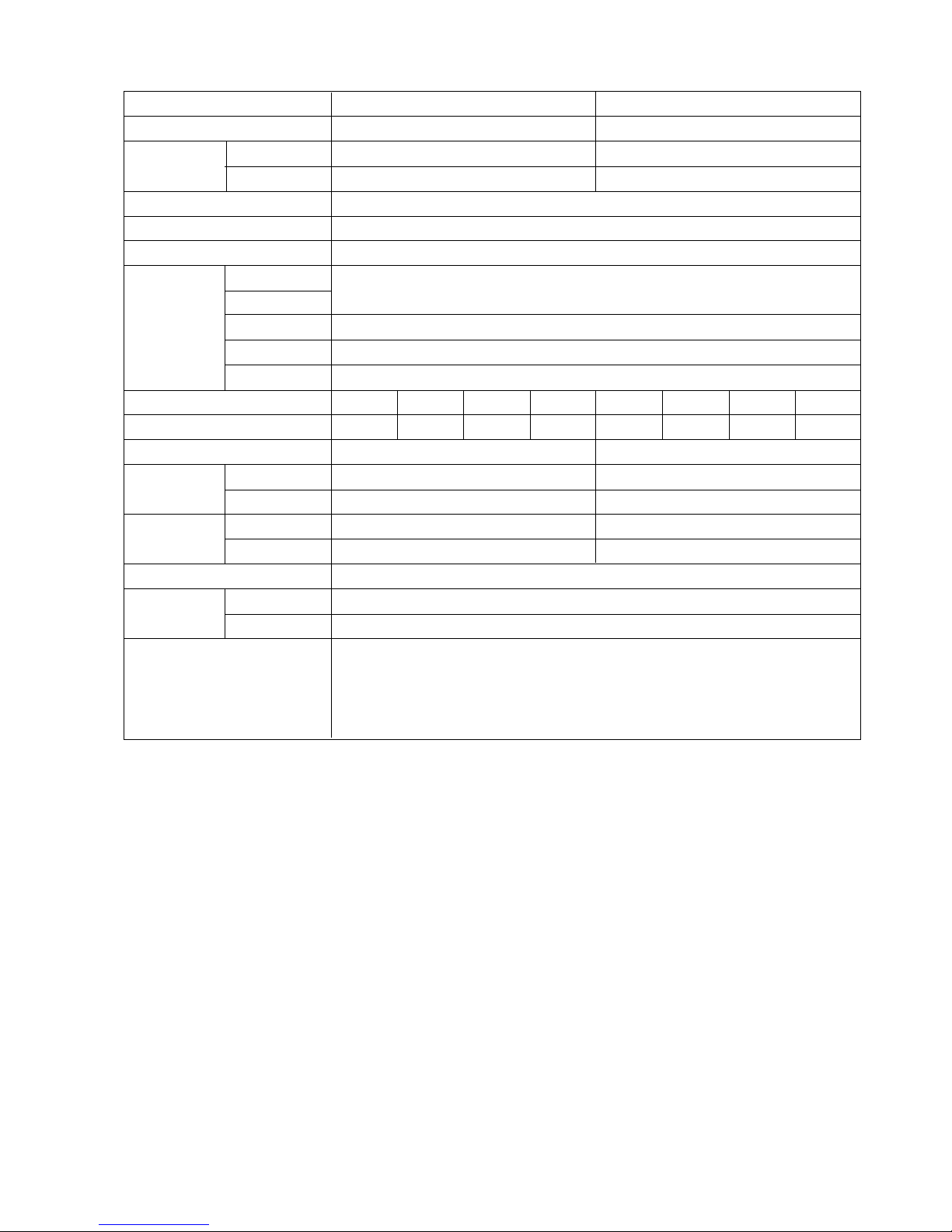

5. SPECIFICATIONS

Model

Saw blade diameter

Cutting depth

at 90˚

at 45˚

Power source

Type of motor

Type of switch

Housing

Handle cover

Enclosure Gear cover

Safety cover

Base

* Voltage (V)

* Current (A)

Power input

Rotation

No-load

speed

Full-load

Weight

Net

Gross

Packaging

Cord

Type

Overall length

Standard equipment

C 6SE C 7SE

165 mm (6-1/2") 190 mm (7-1/2")

0 --- 56 mm (0 --- 2-7/32") 0 --- 67 mm (0 --- 2-5/8")

Max. 37 mm (1-15/32") Max. 44 mm (1-23/32")

AC single phase 50/60 Hz

AC single phase commutator motor

Trigger switch

Polycarbonate resin

Cast aluminum

Sheet metal

Sheet metal

960 W 1,080 W

5,000 /min 5,000 /min

4,260 /min 3,900 /min

3.2 kg (7.1 lbs) 3.7 kg (8.2 lbs)

4.8 kg (10.6 lbs) 5.3 kg (11.7 lbs)

Corrugated cardboard box

Two core cabtire cable

2.5 m (8.2 ft.)

Tungsten carbide tipped (TCT) saw blade

•••••••••••••••••••••••••••••••••••••••••••••••••••

1

Box wrench

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

Parallel guide

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

Wing bolt

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

110 220 230 240 110 220 230 240

9.2 4.6 4.4 4.3 10.3 5.2 4.9 4.7

* Check the tool name plate to confirm the rating, as it is subject to change by area.

Page 7

--- 4 ---

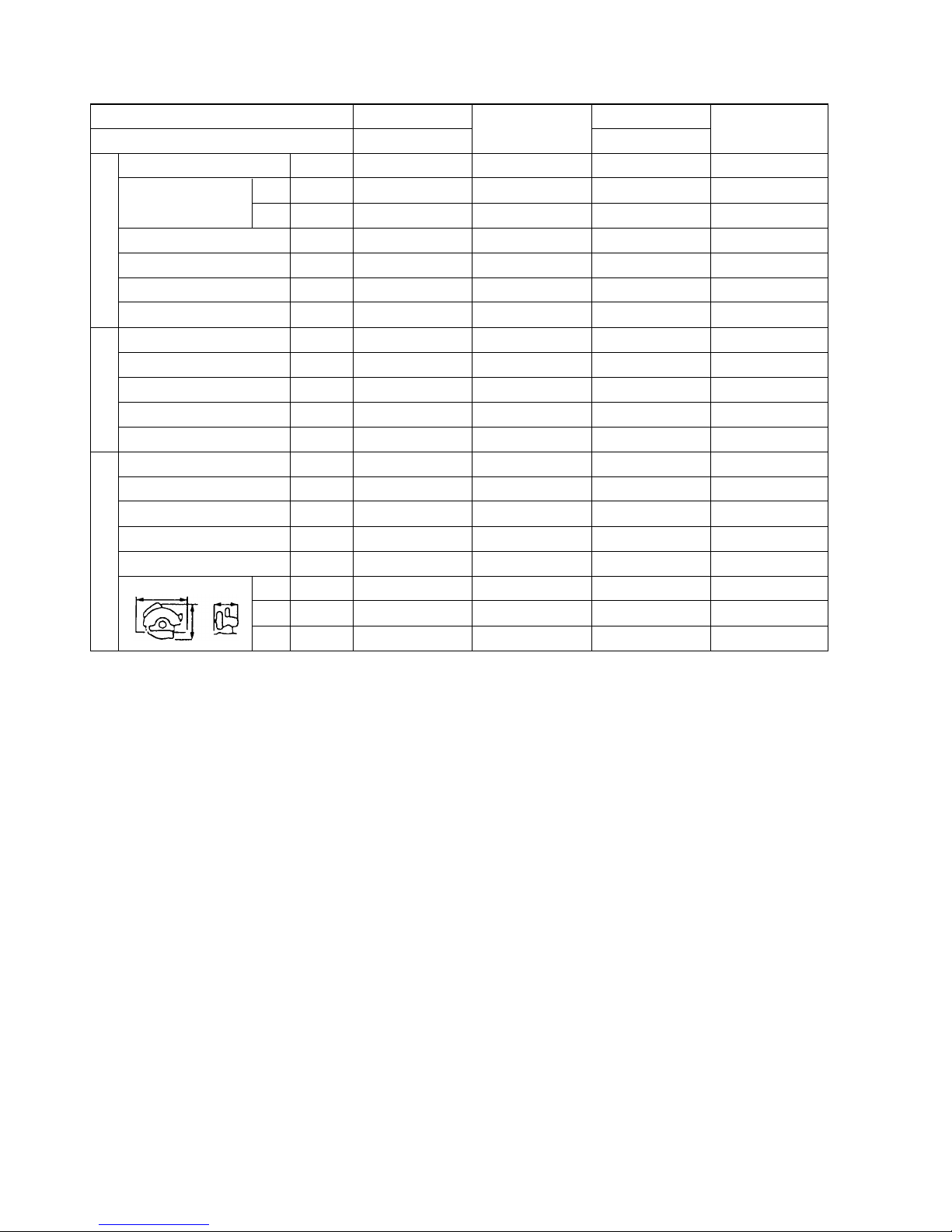

Maker

Model

Saw blade diameter mm

Max. cutting

90˚ mm

depth

45˚ mm

Power input W

No-load rotation speed /min

Overall length mm

Weight kg

No-load rotation speed /min

Full-load rotation speed /min

Full-load output W

Max. output W

No-load noise dB

Insulation --Standard saw blade --Front grip or side handle --Material of wing bolt/nut --Scales on safety cover ---

Lmm

Hmm

Wmm

6. COMPARISONS WITH SIMILAR PRODUCTS

Catalog specifications

Characteristics*

Structure

HITACHI

C --- 1

HITACHI

C --- 2

C 6SE C 7SE

165 (6-1/2") 160 (6-1/4") 190 (7-1/2") 185 (7-1/4")

56 (2-7/32") 55 (2-5/32") 67 (2-5/8") 66 (2-19/32")

37 (1-15/32") 36 (1-3/8") 44 (1-23/32") 44 (1-23/32")

960 950 1,080 1,050

5,000 4,700 5,000 4,700

278 268 294 282

3.2 (7.1 lbs) 3.3 (7.3 lbs) 3.7 (8.2 lbs) 3.7 (8.2 lbs)

5,400 5,300 5,350 5,130

4,260 3,660 3,960 3,330

560 545 730 700

1,410 1,340 1,530 1,500

87 82 87 84

Double Double Double Double

TCT blade TCT blade TCT blade TCT blade

Provided Optional Provided Optional

Plastic Steel Plastic Steel

Provided None Provided None

278 268 294 282

224 230 241 240

218 225 221 230

L

W

H

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Models C 6SE and C 7SE Circular Saws by all

of our customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer

seriously recognizes the importance of the contents of the Handling Instructions.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture, and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric tool cannot be completely eliminated. Accordingly,

general precautions and suggestions for the use of electric power tools, and specific precautions and suggestions

for the use of the Circular Saw are listed in the Handling Instructions to enhance the safe and efficient use of the

tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling Instructions to

be able to offer appropriate guidance to the customer during sales promotion.

* Figures are based on 230 V motors

Page 8

--- 5 ---

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The disassembly and reassembly procedures for the Model C 6SE and C 7SE are essentially the same. The [ ]

numbers in descriptions below correspond to the item numbers in the parts list and exploded assembly diagram

for the Model C 6SE, and the < > numbers for the Model C 7SE. During disassembly and reassembly, and at all

times as well, sufficient care must be exercised in handling to ensure that there is no deviation in the flatness of

the bottom surface of the base and in its perpendicularity with relation to the saw blade.

8-1. Disassembly

Before disassembly, be sure to remove the TCT Saw Blade [14] <14> to

prevent damage to the teeth or personal injury.

(1) Removing the Safety Cover [6] <6>

Remove the Return Spring [7] <7> from the Safety Cover [6] <6>. Remove the three Machine Screws [11]

<10>, Bearing Cap [9] <9> and Safety Cover [6] <6>.

(2) Removing the Bearing Holder [4] <4>

Remove the two Seal Lock Flat Hd. Screws [5] <5> and remove the Bearing Holder [4] <4> together with the

Spindle and Gear Set [2] <2>.

(3) Removing the Spindle and Gear Set [2] <2>

Hold the Bearing Holder [4] <4> in a cylindrical jig with an inside diameter 49 mm, and remove the Spindle

and Gear Set [2] <2> from the Bearing Holder [4] <4> by pushing the end of the spindle.

(4) Removing the Armature [30] <29>

Loosen the Brush Cap [40] <39> and remove the two Carbon Brushes

[39] <38>.

Loosen and remove the three M5 x 45 Machine Screws [23] <22> to

separate the Housing Ass’y [25] <24> from the Gear Cover Ass’y [34]

<33>. The Armature [30] <29> can be removed by tapping around the

Housing Ass’y [25] <24> lightly with a wooden or plastic hammer. Be

careful not to tap the fan of the Armature [30] <29>.

(5) Removing the Base Ass’y [63] <62>

Remove the D6 x 30 Roll Pin [61] <60> to separate the Base Ass’y [63] <62> from the Gear Cover Ass’y [34]

<33>.

Fig. 2

Jig

Push

49 mm

60 mm

Page 9

--- 6 ---

8-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, particular

attention should be given to the following items.

(1) Tightening torquer for fastening screws and bolts

• M3 Machine Screws

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

0.8 0.2 N•m (8 2 kgf•cm)

• M4 Machine Screws

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1.8 0.4 N•m (18 4 kgf•cm)

• M5 Machine Screws

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

3.4 0.7 N•m (35 7 kgf•cm)

• M7 x 17.5 Bolt [16] (16)

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

9.8 2.0 N•m (100 20 kgf•cm)

• D4 Tapping Screws

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

2.0 0.5 N•m (20 5 kgf•cm)

• D5 Tapping Screws

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

2.9 0.5 N•m (30 5 kgf•cm)

• Brush Caps

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

0.98 0.5 N•m (10 5 kgf•cm)

• M4 x 10 Seal Lock Flat Hd. Screw

•••••••••••••••••••••••••••••••••••••••••••••

1.8 0.4 N•m (18 4 kgf•cm)

• M5 x 10 Seal Lock Flat Hd. Screw

•••••••••••••••••••••••••••••••••••••••••••••

3.4 0.7 N•m (35 7 kgf•cm)

• M3.5 Bind Screws

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

0.6 0.15 N•m (6 1.5 kgf•cm)

• D4 FT Screws

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

3.0 0.5 N•m (30 5 kgf•cm)

(2) Reassemble the Armature [30] <29>

Prior to assembling the Armature [30] <29>, ensure that the Bearing Lock [33] <32> is properly inserted into

the groove of the bearing case within the Gear Cover Ass'y [34] <33>.

(3) Reassemble the Lock Lever [31] <30> (See Fig. 3.)

A. Position the Lock Lever [31] <30> between the fan and the Ball Bearing [32] <31> of the Armature [30]

<29>, and carefully assemble it together with the Armature [30] <29> into the Gear Cover Ass'y [34] <33>.

B. Ensure that both ends of the spring on

the Lock Lever [31] <30> are properly

supported inside the ribs of the Gear

Cover Ass'y [34] <33>.

C. When assembly of the Lock Lever [31]

<30> has been completed (when the

Gear Cover Ass'y [34] <33> is

assembled to the Housing Ass'y [25]

<24> and fastened with the M5 x 45

Machine Screws [23] <22>), push the

Lock lever [31] <30> by hand and

ensure that it returns to its original

position when released.

[34] <33>

[31] <30>

[30] <29>

Rib

Fig. 3

Page 10

--- 7 ---

(4) Reassemble the Stator Ass'y [28] <27>

As shown in Fig. 4, insert a guide bar [J-132 stator press pins (Special repair tool, Code No. 970911) are

recommended] into the Stator Ass'y [28] <27> and the Housing Ass’y [25] <24> to accurately align the screw

hole on the Stator Ass'y [28] <27> with the corresponding hole on the Housing Ass’y [25] <24>. Press-fit the

Stator Ass'y [28] <27> into the Housing Ass’y [25] <24> so that the internal wire faces the Name Plate. Hook

the carbon brush terminals in the brush holders. Be careful not to put the internal wires in the ribs of the Stator

Ass'y [28] <27> in the Housing Ass’y [25] <24>. Fix the Stator Ass'y [28] <27> to the Housing Ass’y [25] <24>

with the two Hex. Hd. Tapping Screws [46] <45>. If the noise suppressor is provided, fix the Terminal [52]

<51> at the tip of the internal wire coming out of the noise suppressor with one of the two Hex. Hd. Tapping

Screws [46] <45>. (See Fig. 5.)

Guide bar

(J-132 stator

press pins)

[28] (27)

Brush holder

Name plate side

[25] <24>

[52] <51>

[46] <45>

Fig. 4

Fig. 5

Page 11

--- 8 ---

(5) Wiring

Wiring should be performed as shown below. Be careful not to sandwich the internal wires between the

Handle Cover [57] <56> and the Housing Ass'y [25] <24>.

1. Wiring diagram

[A] For Australia and New Zealand

Black or blue

Stator

Noise

suppressor

Switch

Blue

Power

source

Brown

Black or blue

Blue

Stator

Noise

suppressor

Switch

Blue

Power

source

Brown

Blue

Armature

Armature

Connector

Stator

Switch

Power

source

Black or brown

White, blue or black

Armature

Connector

White or blue

White, blue or black

[B] For Korea

[C] For other countries [ASEAN, M.E. Asia, Taiwan]

Page 12

--- 9 ---

[A] For Australia [B] For New Zealand

Blue

Black

Brown

Blue

Blue

Brown

[C] For Korea [D] For other countries [ASEAN, M.E. Asia, Taiwan]

Brown

Blue

Blue

Black or brown

White, blue

or black

White or blue

2. Schematic diagram

Page 13

--- 10 ---

(6) Lubrication

The Gear Cover Ass'y [34] <33>

•••••••••••••••••••

Apply Nippeco Grease (SEP-3A) 8 g

Code No. 930035

Amply rub grease into the teeth of gear and pinion.

8-3. Insulation Tests

On completion of disassembly and repair, measure the insulation resistance and conduct dielectric strength test.

Insulation resistance: 7MΩ or more with DC 500 V Megohm Tester

Dielectric strength: AC 4000 V/1 minute, with no abnormalities

8-4. Deflection of Saw Blade

Allowable deflection level of the saw blade shall be as follows.

8-5. Cleaning the Case

When the unit becomes soiled, clean it with a clean soft rag moistened with soapy water. Since chloric solvents,

gasoline and thinner tend to melt plastic material, their use for cleaning is absolutely avoided.

Model Measuring point Allowable level

C 6SE, C 7SE 150 0.5 mm max.

Page 14

--- 11 ---

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40 50 60 min.

Fixed

Variable

Work Flow

Switch

Cord

Saw Blade

Safety Cover

Return Spring

Armature

Ball Bearing

(608VV)

Ball Bearing

(6000VV)

Gear Cover

Ass’y

Spindle and

Gear Set

Bearing Holder

Ball Bearing

x 2

Housing Ass’y

Stator Ass’y

General Assembly

Base Ass’y

C 6SE

C 7SE

Page 15

--- 12 ---

Assembly Diagram for C 6SE

Page 16

--- 13 ---

PARTS

C 6SE

: ALTERNATIVE PARTS

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

1 606-ZZM BALL BEARING 606ZZC2PS2L 1

2 317-932 SPINDLE AND GEAR SET 1

3 873-095 O-RING (P-16) 1

4 941-048 BEARING HOLDER 1

5 990-430 SEAL LOCK FLAT HD. SCREW M4X10 2

6 317-930 SAFETY COVER 1

7 957-062 RETURN SPRING 1

8 620-2VV BALL BEARING 6202VVCMPS2L 1

9 941-049 BEARING CAP 1

10 949-451 SPRING WASHER M3 (10 PCS.) 3

11 949-203 MACHINE SCREW M3X8 (10 PCS.) 3

12 961-366 DISTANCE PIECE 1

* 13 993-598 WASHER (A) 1

* 13 315-968 WASHER (A) 1 FOR TPE

* 14 317-452 TCT SAW BLADE 165MM-D20 HOLE-NT40 1

* 14 317-937 TCT SAW BLADE 165MM-D25.4 HOLE-NT40 1 FOR TPE

15 957-064 WASHER (B) 1

16 957-749 BOLT (W/WASHER) M7X17.5 1

17 317-933 SAW COVER 1

18 HITACHI LABEL 1

19 949-219 MACHINE SCREW M4X16 (10 PCS.) 3

20 986-723 MACHINE SCREW (W/WASHERS) M4X8 1

21 301-653 TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 2

22 961-732 TAIL COVER 1

23 302-434

MACHINE SCREW (W/WASHERS) M5X45 (BLACK)

3

* 24 NAME PLATE 1

* 25 317-935 HOUSING ASS’Y 1 INCLUD.36,38

* 25 317-936 HOUSING ASS’Y 1 INCLUD.36,38 FOR NZL

26 608-VVM BALL BEARING 608VVC2PS2L 1

27 930-703 BRUSH TERMINAL 2

* 28 340-447C STATOR ASS’Y 110V 1 INCLUD.27

* 28 340-447E STATOR ASS’Y 220V-230V 1 INCLUD.27

* 28 340-447F STATOR ASS’Y 240V 1 INCLUD.27

* 28 340-447G STATOR ASS’Y 220V-230V 1 INCLUD.27 FOR NZL,KOR

* 28 340-447H STATOR ASS’Y 240V 1 INCLUD.27 FOR AUS

29 987-980 FAN GUIDE 1

* 30 360-500C ARMATURE 110V 1

* 30 360-500E ARMATURE 220V-230V 1

* 30 360-500F ARMATURE 240V 1

31 987-981 LOCK LEVER 1

32 600-0VV BALL BEARING 6000VVCMPS2L 1

33 931-701 BEARING LOCK 1

34 317-931 GEAR COVER ASS’Y 1 INCLUD.33,47,48

* 35 500-455Z CORD 1 (CORD ARMOR D8.8)

* 35 930-054 CORD 1 (CORD ARMOR D10.1) FOR TPE

* 35 500-234Z CORD 1 (CORD ARMOR D8.8) FOR INA,KOR

* 35 500-423Z CORD 1 (CORD ARMOR D8.8) FOR SIN,KUW

* 35 500-439Z CORD 1 (CORD ARMOR D8.8) FOR NZL,AUS

36 938-477 HEX. SOCKET SET SCREW M5X8 2

37 307-028 TAPPING SCREW (W/FLANGE) D4X25 (BLACK) 4

38 957-051 BRUSH HOLDER 2

*

6

----

99

Page 17

--- 14 ---

PARTS

C 6SE

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

39 999-043 CARBON BRUSH (1 PAIR) 2

40 935-829 BRUSH CAP 2

* 41 980-063 TERMINAL 2 FOR CORD

* 42 981-373 TUBE (D) 2 FOR CORD

* 43 953-327 CORD ARMOR D8.8 1

* 43 938-051 CORD ARMOR D10.1 1

44 937-631 CORD CLIP 1

45 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

46 953-174 HEX. HD. TAPPING SCREW D5X55 2

47 961-729 CUSHION 1

48 949-794 FLAT HD. SCREW M6X20 (10 PCS.) 1

49 948-167 SUPER LOCK WASHER M6 2

* 50 980-063 TERMINAL 2 FOR NZL,KOR

* 51 981-373 TUBE (D) 2 FOR AUS

* 52 959-144 TERMINAL 50051 (10 PCS.) 1 FOR NOISE SUPPRESSOR

* 53 994-273 NOISE SUPPRESSOR 1 FOR NZL,AUS,KOR

* 54 305-499 MACHINE SCREW (W/WASHER) M3.5X6 4 EXCEPT FOR AUS

* 55 957-747 SWITCH (A) (1P SCREW TYPE) W/LOCK 1

* 55 302-470 SWITCH (C) (1P SCREW TYPE) W/O LOCK 1 FOR NZL

* 55 963-756Z SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 FOR AUS

* 56 959-140 CONNECTOR 50091 (10 PCS.) 1 EXCEPT FOR NZL,AUS

57 302-320 HANDLE COVER 1

58 301-806 WING BOLT M6X15 1

59 947-859 LOCK SPRING 1

60 302-459 WING BOLT M6X17 1

61 949-515 ROLL PIN D6X30 (10 PCS.) 1

62 314-620 BOLT ASS’Y (SQUARE) M6X22 1 INCLUD.49

63 317-934 BASE ASS’Y 1 INCLUD.49,58-60,62

: ALTERNATIVE PARTS

*

6

----

99

Page 18

--- 15 ---

: ALTERNATIVE PARTS

*

STANDARD ACCESSORIES

C 6SE

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

501 940-543 BOX WRENCH 10MM 1

502 316-106 GUIDE WITH WING BOLT AND SPRING 1

6

----

99

Printed in Japan

(990625 N)

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

601 949-172 SAW BLADE (COMBINATION) 160MM-D19 HOLE 1

602 879-096 PLANER SAW BLADE 160MM-D19 HOLE 1

603 879-097 SAW BLADE 160MM-D19 HOLE FOR PLASTIC 1

604 879-098 SAW BLADE 160MM-D19 HOLE FOR ALUMINUM 1

605 939-156 CUT-OFF WHEELS 150MM (10 PCS.) 1

606 961-734 CORD HANGER 1

Page 19

--- 16 ---

Assembly Diagram for C 7SE

Page 20

--- 17 ---

PARTS

C 7SE

: ALTERNATIVE PARTS

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

1 626-VVM BALL BEARING 626VVC2PS2L 1

2 317-925 SPINDLE AND GEAR SET 1

3 873-095 O-RING (P-16) 1

4 940-867 BEARING HOLDER 1

5 990-299 SEAL LOCK FLAT HD. SCREW M5X10 2

6 317-923 SAFETY COVER 1

7 957-062 RETURN SPRING 1

8 620-2VV BALL BEARING 6202VVCMPS2L 1

9 940-868 BEARING CAP 1

10 307-635 MACHINE SCREW (W/SP. WASHER) M4X10 3

11 986-723 MACHINE SCREW (W/WASHERS) M4X8 1

12 961-366 DISTANCE PIECE 1

* 13 993-598 WASHER (A) 1

* 13 315-968 WASHER (A) 1 FOR TPE

* 14 317-928 TCT SAW BLADE 190MM-D20 HOLE-NT40 1

* 14 317-929 TCT SAW BLADE 190MM-D25.4 HOLE-NT40 1 FOR TPE

15 957-064 WASHER (B) 1

16 957-749 BOLT (W/WASHER) M7X17.5 1

17 317-926 SAW COVER 1

18 HITACHI LABEL 1

19 949-219 MACHINE SCREW M4X16 (10 PCS.) 3

20 301-653 TAPPING SCREW (W/FLANGE) D4X20 (BLACK) 2

21 961-732 TAIL COVER 1

22 302-434

MACHINE SCREW (W/WASHERS) M5X45 (BLACK)

3

23 NAME PLATE 1

* 24 317-935 HOUSING ASS’Y 1 INCLUD.35,37

* 24 317-936 HOUSING ASS’Y 1 INCLUD.35,37 FOR NZL

25 608-VVM BALL BEARING 608VVC2PS2L 1

26 930-703 BRUSH TERMINAL 2

* 27 340-448C STATOR ASS’Y 110V 1 INCLUD.26

* 27 340-448E STATOR ASS’Y 220V-230V 1 INCLUD.26

* 27 340-448F STATOR ASS’Y 240V 1 INCLUD.26

* 27 340-448G STATOR ASS’Y 220V-230V 1 INCLUD.26 FOR NZL,KOR

* 27 340-448H STATOR ASS’Y 240V 1 INCLUD.26 FOR AUS

28 987-940 FAN GUIDE 1

* 29 360-501C ARMATURE 110V 1

* 29 360-501E ARMATURE 220V-230V 1

* 29 360-501F ARMATURE 240V 1

30 987-981 LOCK LEVER 1

31 600-1VV BALL BEARING 6001VVCMPS2L 1

32 931-701 BEARING LOCK 1

33 317-924 GEAR COVER ASS’Y 1 INCLUD.32,46,47

* 34 500-455Z CORD 1 (CORD ARMOR D8.8)

* 34 500-234Z CORD 1 (CORD ARMOR D8.8) FOR INA

* 34 500-423Z CORD 1 (CORD ARMOR D8.8) FOR SIN,KUW

* 34 500-439Z CORD 1 (CORD ARMOR D8.8) FOR NZL,AUS

* 34 930-054 CORD 1 (CORD ARMOR D10.1) FOR TPE

35 938-477 HEX. SOCKET SET SCREW M5X8 2

36 307-028 TAPPING SCREW (W/FLANGE) D4X25 (BLACK) 4

37 957-051 BRUSH HOLDER 2

38 999-043 CARBON BRUSH (1 PAIR) 2

*

6

----

99

Page 21

--- 18 ---

PARTS

C 7SE

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

39 935-829 BRUSH CAP 2

* 40 980-063 TERMINAL 2 FOR CORD

* 41 981-373 TUBE (D) 2 FOR CORD

* 42 953-327 CORD ARMOR D8.8 1

* 42 938-051 CORD ARMOR D10.1 1

43 937-631 CORD CLIP 1

44 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

45 961-501 HEX. HD. TAPPING SCREW D5X60 2

46 961-729 CUSHION 1

47 949-794 FLAT HD. SCREW M6X20 (10 PCS.) 1

48 948-167 SUPER LOCK WASHER M6 2

* 49 980-063 TERMINAL 2 FOR NZL,KOR

* 50 981-373 TUBE (D) 2 FOR AUS

* 51 959-144 TERMINAL 50051 (10 PCS.) 1 FOR NOISE SUPPRESSOR

* 52 994-273 NOISE SUPPRESSOR 1 FOR NZL,AUS,KOR

* 53 305-499 MACHINE SCREW (W/WASHER) M3.5X6 4 EXCEPT FOR AUS

* 54 957-747 SWITCH (A) (1P SCREW TYPE) W/LOCK 1

* 54 302-470 SWITCH (C) (1P SCREW TYPE) W/O LOCK 1 FOR NZL

* 54 963-756Z SWITCH (2P PILLAR TYPE) W/SAFETY LOCK 1 FOR AUS

* 55 959-140 CONNECTOR 50091 (10 PCS.) 1 EXCEPT FOR NZL,AUS

56 302-320 HANDLE COVER 1

57 301-806 WING BOLT M6X15 1

58 947-859 LOCK SPRING 1

59 302-459 WING BOLT M6X17 1

60 949-515 ROLL PIN D6X30 (10 PCS.) 1

61 314-620 BOLT ASS’Y (SQUARE) M6X22 1 INCLUD.48

62 317-927 BASE ASS’Y 1 INCLUD.48,57-59,61

: ALTERNATIVE PARTS

*

6

----

99

Page 22

--- 19 ---

: ALTERNATIVE PARTS

*

STANDARD ACCESSORIES

C 7SE

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

501 940-543 BOX WRENCH 10MM 1

502 316-106 GUIDE WITH WING BOLT AND SPRING 1

6

----

99

Printed in Japan

(990625 N)

OPTIONAL ACCESSORIES

ITEM

NO.

CODE NO. DESCRIPTION

NO.

USED

REMARKS

601 940-878 SAW BLADE (COMBINATION) 185MM-D19 HOLE 1

602 879-099 SAW BLADE (RIP) 185MM-D19 HOLE-NT36 1

603 879-101 PLANER SAW BLADE 185MM-D19 HOLE 1

604 879-100 SAW BLADE 185MM-D19 HOLE FOR PLASTIC 1

605 879-102 SAW BLADE 185MM-D19 HOLE FOR ALUMINUM 1

606 939-156 CUT-OFF WHEELS 150MM (10 PCS.) 1

607 961-734 CORD HANGER 1

Loading...

Loading...