Page 1

Dustless Circular Saw

Model C 5YC

Handling Instructions

Note:

Before using this Electric Power Tool, carefully read through these

HANDLING INSTRUCTIONS to ensure efficient, safe operation. It is

recommended that these INSTRUCTIONS be kept readily available

as an important reference when using this power tool.

Page 2

2

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including

the following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause

fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children and infirm persons away. Do not let

visitors touch the tool or extension cord. All visitors

should be kept away from work area.

5. Store idle tools. When not in use, tools should be

stored in a dry, high or locked up place, out of reach

of children and infirm persons.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool. Do

not use tools for purposes not intended; for example,

do not use circular saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or

jewelry, they can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended

when working outdoors. Wear protecting hair

covering to contain long hair.

9. Use eye protection. Also use face or dust mask if

the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by the

cord or yank it to disconnect it from the receptacle.

Keep the cord away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work.

It is safer than using your hand and it frees both

hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades,

bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a pluggedin tool with a finger on the switch. Ensure switch is

off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will operate

properly and perform its intended function. Check

for alignment of moving parts, free running of

moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A

guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not

use the tool if the switch does not turn it on and off.

21. Warning

The use of any accessory or attachment, other than

those recommended in this handling instructions,

may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

PRECAUTIONS ON USING CIRCULAR SAW

1. Do not use saw blades which are deformed or

cracked.

2. Do not use saw blades made of high speed steel.

3. Do not use saw blades which do not comply with

the characteristics specified in these instructions.

4. Do not stop the saw blades by lateral pressure on

the side surface of disc.

5. Always keep the saw blade sharp.

6. Ensure that the lower guard moves smoothly and

freely.

7. Never use the circular saw with its lower guard

fixed in the open position.

8. Ensure that the retraction mechanism of the guard

system operates accurately.

9. Never operate the circular saw with grasping the

saw blade upside down or to the lateral direction.

10. Ensure that the material is free of foreign matters

such as nails.

11. For model C5YC, the saw blade’s diameters which

can be mounted are 125 mm or less.

12. Be careful of brake kickbac.

This circular saw incorporates an electric brake that

functions when the switch is released. As there is

some kickback when the brake functions, be sure to

hold the main body securely.

Page 3

3

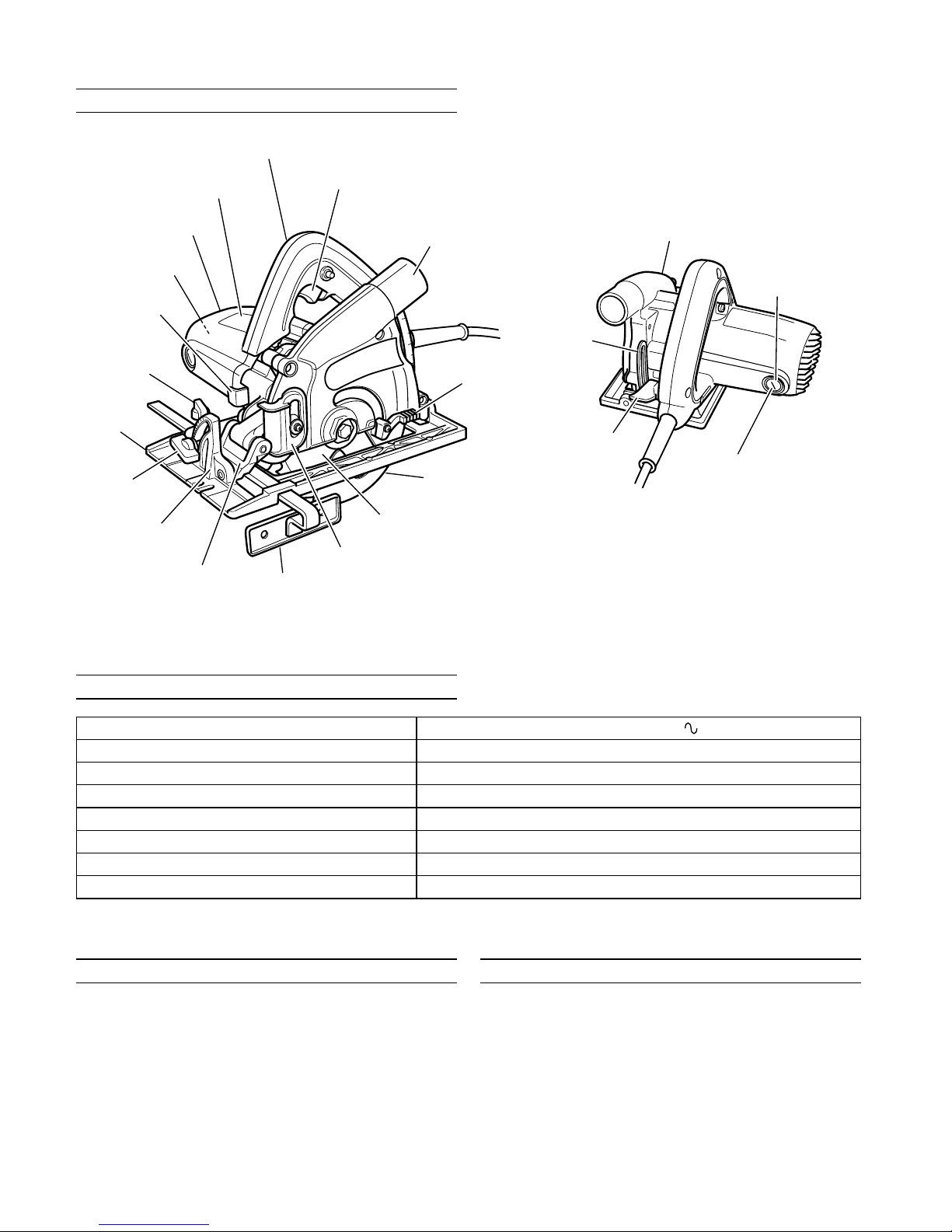

NAME OF PARTS

SPECIFICATIONS

Voltage (by areas)* (230 V, 240 V)

Cutting Depth 35 mm Max.

Power Input* 1010 W

Capacity 125 mm Max. Hole diam. 20 mm

Full Load Amp.* 4.7 A, 4.6 A

Dimensions (Length × Height × Width) 284 mm × 208 mm × 320 mm

No Load Speed 9600/min

Weight (without cord) 2.9 Kg

STANDARD ACCESSORIES

(1) Box wrench ............................................................... 1

(2) Guide .......................................................................... 1

(3) Dust bag .................................................................... 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

䡬 Carbide Tipped Saw Blade (Dia. 125 mm) for the

gypsum board.

Optional accessories are subject to change without

notice.

Handle

Switch

Saw cover

Lever

Lower guard

Saw blade

Slide cover

Guide

Bevel piece

Inclined gauge

Wing bolt

Lock lever

Motor

Housing

Name plate

Gear cover

Brush holder

Brush cap

Clamp lever

Link

Wing bolt

Base

* Be sure to check the nameplate on product as it is subject to change by areas.

Page 4

4

APPLICATION

(1) Cutting the hard boards types T9 and T7.

(ex. harditex, hardiflex, etc.)

(2) Cutting the gypsum board.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

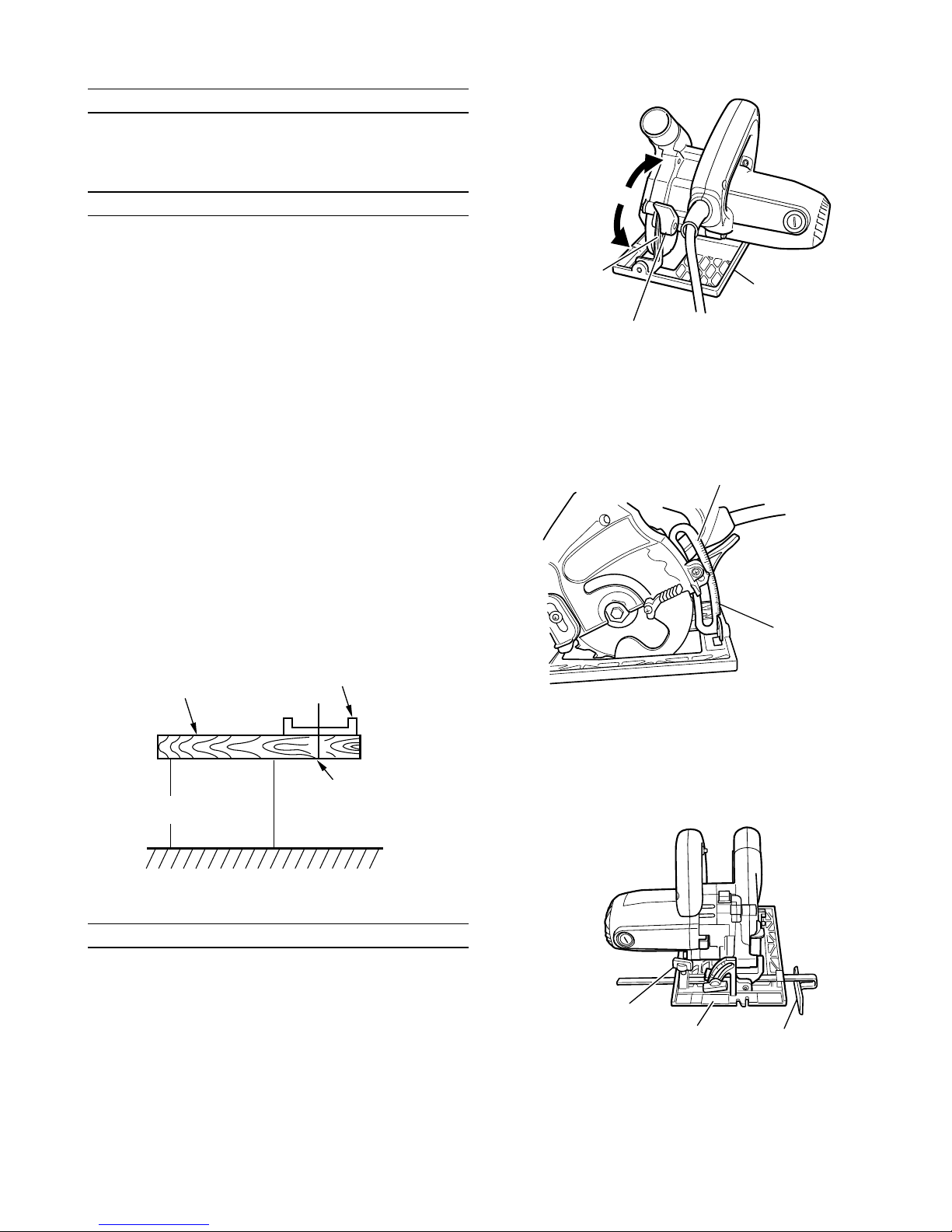

4. Prepare a wooden workbench (Fig. 1)

Since the saw blade will extend beyond the lower

surface of the lumber, place the lumber on the

workbench prior to cutting. If a square block is

utilized as the workbench, adjust leveling to ensure

that it is properly stabilized. An unstable workbench

will result in hazardous operation.

CAUTION

● To avoid possible accident, remains always ensure

that the portion of workpiece after cutting is securely

anchored or held in position.

Fig. 1

ADJUSTING THE SAW PRIOR TO USE

1. Adjusting the cutting depth (Fig. 2)

CAUTION

If the clamp lever is loose, injury can result.

Tighten it securely after adjustment.

To adjust cutting depth, loosen the clamp lever and,

while holding the base with one hand, move the

main body up and down to obtain the prescribed

cutting depth. After adjusting to the prescribed

cutting depth, tighten the clamp lever securely.

Fig. 2

(2) When a base and saw blade are right-angled, it cuts

deeply using the scale of a link part, and the depth

can be adjusted (Fig. 3).

Fig. 3

3. Regulating the guide (Fig. 4)

The cutting position can be regulated by moving

the guide to the left or right after loosening its

wing-bolt. The guide may be mounted on either the

right or left side of the base.

Fig. 4

Loosen

Tighten

Link

Clamp lever

Base

Workpiece

Base

Workbench

Saw blade

Link

Scale link

Wing bolt

Base Guide

Page 5

5

CUTTING PROCEDURES

CAUTION

䡬 During use, when the body is out of condition or there

is unusual sound, please turn off a switch immediately.

䡬 During cutting, please do not pry the body or do not

push too much strongly. Please carry forward the

body calmly straightly.

It becomes the cause of an injury in response to

restitution. Moreover, while unreasonableness starts

a motor part, the life of saw blade is shortened.

䡬 Please do not carry out usage which made saw blade

facing up and sideways.

It becomes the cause of an injury.

䡬 Please use protection glasses.

䡬 Please use the protection implement of an ear.

䡬 Surely, the time of work discontinuation and after

work should turn off and put a switch, and should

pull out a lump plug from a power supply wall socket.

䡬 Be careful by rotating saw blade not to cut a code.

NOTE

䡬 Before beginning cutting, rotation of saw blade should

become the maximum high speed.

䡬 Extrusion fabrication cement building materials

should not cut 1 time of the cut depth with the speed

of 40 cm or less in 20 mm or less and 1 minute.

When using the cut depth, making it shallow, in order

that edge of a blade may open, dust-collecting power

declines.

1. The body (base) is carried on work piece and guide

slot of the base front part is united with a premarked

line.

When you do not incline, please follow large guide

slot as a guide, and when you incline (45°), follow

small guide slot as a guide (Fig. 5, Fig. 6, Fig. 7).

(It is the figure seen from the top)

Fig. 5

(When not inclined)

Fig. 6

(When inclined 45°)

Fig. 7

2. Saw blade turns on a switch in the state where work

piece cannot be touched.

This state is maintained until it carries forward the

body ahead slowly and finishes cutting it then.

For pulling and cleaning the skin, it advances straightly

with fixed speed.

MOUNTING AND DISMOUNTING THE SAW

BLADE

As for this body, saw blade is not attached to the body at

the time of factory shipments.

Please carry out attachment and removal of saw blade in

the following procedure in the case of use.

CAUTION

䡬 Surely, please turn off and put a switch in the case of

attachment and removal of saw blade, and pull out a

lump plug from a power supply wall socket.

It becomes the basis of the unexpected accident.

䡬 Attachment and detachment of a hexagonal flange

bolt should work with an attached box spanner.

If tools other than attachment are used, it will become

past [a bundle] and the shortage of bolting, and will

become the cause of an injury.

When not

inclined

Premarked line Work piece

Large guide slot

Small guide slot

When inclined 45°

Wing bolt

Guide

Cutting position

(in the case of 45°)

Wing bolt

Inclination scale

Page 6

6

1. How to attach (Fig. 8)

(1) The cut depth is made into the minimum.

A lever is loosened, a base is made into the minimum

cut depth, and a lever is fastened.

Fig. 8

(2) Two projection parts of a slide cover are pressed

down with a finger, and it moves up (Fig. 9).

Fig. 9

(3) A washer (A) is removed (Fig. 10).

Pushing in a lock lever, a hexagonal flange bolt is

loosened with an attached box spanner, and a washer

(A) is removed.

Since a hexagonal flange bolt is a left screw, it will

loosen, if it turns clockwise.

After removing, the garbage adhering to the spindle

or the washer (A) is often wiped off.

Fig. 10

(4) Saw blade is attached (Fig. 11)

A lower guard is carried out to full open, and saw

blade is attached.

It is made in agreement [the direction of an arrow of

saw blade] with the direction of an arrow of saw

cover.

Fig. 11

(5) A hexagonal flange bolt is tightened (Fig. 12).

A washer (A) and a hexagonal flange bolt are attached

in order of the left figure, and a hexagonal flange bolt

is fully bound tight using an attached box spanner,

pushing a lock lever.

Fig. 12

USE OF DUST BAG

CAUTION

䡬 To avoid serious accident, ensure the switch is

in the OFF position, and disconnect the plug from

the receptacle.

䡬 Never attempt to saw any material like metal and

so on that give off sparks. Such action can lead

to fire or injury.

1. Mounting the dust bag

Hold the clasp of the dust bag and insert it into

the adapting mouth of the body while opening the

thrusting mouth (Fig. 13).

Loosens

Tighten

Base

Clamp lever

Lever

Saw blade

Lower guard

Loosens

A hexagonal flange

bolt is turned with

a box spanner

A lock lever is

pushed in

Tighten

Projection part

Slide cover

Saw blade

Spindle

Hexagonal flange boIt

Washer (A)

Washer (B)

Page 7

7

Fig. 13

2. Dumping sawdust and cleaning the inside of dust

bag

NOTE

䡬 If too much sawdust is accumulated inside the

dust bag, the dust collector will run low on

power. Attempt to dump the sawdust as early

as you can and clean the dust bag thoroughly

so that you can enjoy your work with strong dust

collecting power.

(1) Hold the clasp, open the thrusting mouth of the

dust bag, and pull it off from the body.

(2) Open the fastener (Fig. 14) and dump the sawdust.

Fig. 14

MAINTENANCE AND INSPECTION

1. Inspecting the saw blade

Since use of a dull saw blade will degrade efficiency

and cause possible motor malfunction. Resharpen and

replace the saw blade as soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and replacement

on this tool should ONLY be performed by a Hitachi

Authorized Service Center.

5. Replacing supply cord

If the supply cord of Tool is damaged, the Tool

must be returned to Hitachi Authorized Service

Center for the cord to be replaced.

6. Adjusting the base and saw blade to maintain

perpendicularity

The angle between the base and the saw blade has

been adjusted to 90°, however should this

perpendicularity be lost for some reason, adjust in

the following manner:

(1) Placing a square against the base of the tool,

determine the angle desired and lightly tighten the

M4 screw (See Fig. 15).

(2) Turn the angle adjustment screw until the end of

the screw touches the bevel plate (See Fig. 4).

(3) After all adjustments have been made, firmly tighten

the M4 screw.

(For inclination adjustment)

Fig. 15

7. Service parts list

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized

Service Center.

Especially laser device should be maintained by the

authorized agent by laser manufacturer.

Always assign the repair of laser device to Hitachi

Authorized Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without

prior notice.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

Dust bag

Adapting mouth

Clasp

Fastener

Square

Wing bolt

Slotted set screw

Base

Page 8

8

Page 9

9

ITEM

NO.

PART NAME

1SAW COVER

2 BOLT (LEFT HAND) W/WASHER M7 × 17.5

3WASHER (A)

4WASHER (B)

5 DUST WASHER

6 O-RING (1AP-20)

7 MACHINE SCREW (W/WASHER) M4 × 14

8 RETAINING RING FOR D30 SHAFT

9 LEVER

10 RETURN SPRING

11 LOWER GUARD

12 SEAL LOCK FLAT HD. SCREW M4 × 14

13 BEARING HOLDER

14 SLEEVE

15 BALL BEARING 6094DDPS2L

16 SPINDLE AND GEAR SET

17 BALL BEARING 606ZZC2PS2L

18 MACHINE SCREW M4 × 8

19 GEAR COVER

20 SPACER

21 MACHINE SCREW M4 × 10

22 LED CASE (D)

23 MACHINE SCREW (W/SP. WASHERS) M4 × 20

24 PINION

25 BALL BEARING 629VVC2PS2L

26 RUBBER RING

27 LOCK LEVER

28 ARMATURE

29 FAN GUIDE

30 HEX. HD. TAPPING SCREW D5 × 65

31 STATOR ASSAY

32 BRUSH TERMINAL

33 FLAT HD. SCREW M5 × 20

34 CUSHION

35 DEPTH LIMITED

36 CLEAR COVER

37 WASHER (A)

38 BALL BEARING 608VVC2PS2L

39 HOUSING ASSAY

40 TAPPING SCREW (W/FLANGE) D4 × 20

41 NAME PLATE

42 MACHINE SCREW (W/SP. WASHERS) M5 × 35

43 BASE ASSAY

44 ROLL PIN D& × 45

45 WING BOLT M6 × 16.5

46 LOCK SPRING

ITEM

NO.

PART NAME

47 SUPER LOCK WASHER M6

48 WING BOLT (A)

49 HANDLE COVER

50 SWITCH

51 SLOTTED HD. SET SCREW (SEAL LOCK) M6 × 6

52 BOLT WASHER M8

53 LOCK BOLT M8

54 LOCK LEVER

55 MACHINE SCREW (W/SP.WASHERS) M4 × 12

56 TAPPING SCREW (W/WASHER) D4 × 16

57 CORD CLIP

58 CORD

59 CORD ARMOR

60 BRUSH CAP

61 CARBON BRUSH

62 BRUSH HOLDER

63 HEX. SOCKET SET SCREW M5 × 8

501 GUIDE

502 BOX WRENCH 10MM

503 DUST BAG

504 SPACER

Page 10

10

Page 11

11

Page 12

505

Code No. C99120611 N

Printed in Japan

Hitachi Koki Co., Ltd.

Loading...

Loading...