Page 1

MODEL C 15FB

1. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY:

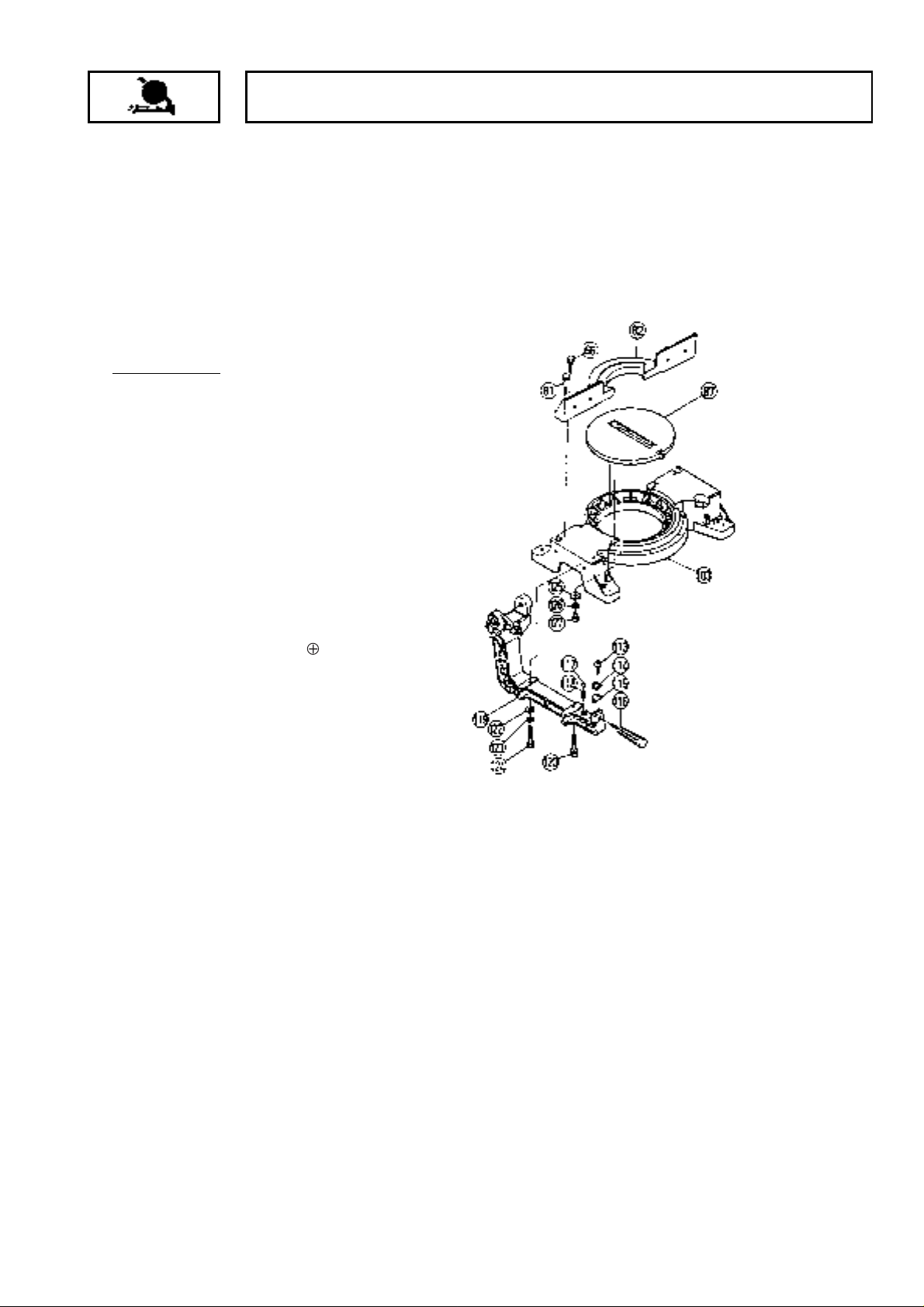

The circled numbers in the descriptions below correspond to the item numbers in the Parts List and exploded

assembly diagram.

[CAUTION] Prior to commencing disassembly (including replacement of the saw blade), ensure that the

plug is disconnected from the power source.

1-1. Disassembly:

(1) Disassembly of the Base and Turn Table:

Tools Required:

17 mm Box Spanner

•

A. After removing the M10 x 65 Bolt [120] and

M10 x 65 Screw (G) [124] which fix the Hinge

[119], the Hinge [119] and upper portions

(Gear Case, etc.) can be separated from the

main body.

B. Remove the four M10 x 40 Bolts [66] which

fix Vise (B) [82], and separate Vise (B) [82]

from the Base Ass'y [103].

C. Remove the two M6 x 16 -Hd. Machine

Screws [127]. The Turn Table [87] can then

be removed by pushing it up lightly from the

rear portion of the Base Ass'y [103].

[NOTE] When removing the Hinge [119], be

very careful not to lose the D12.7 Steel

Ball [117] and Sprint (C) [118].

--- 1 ---

Page 2

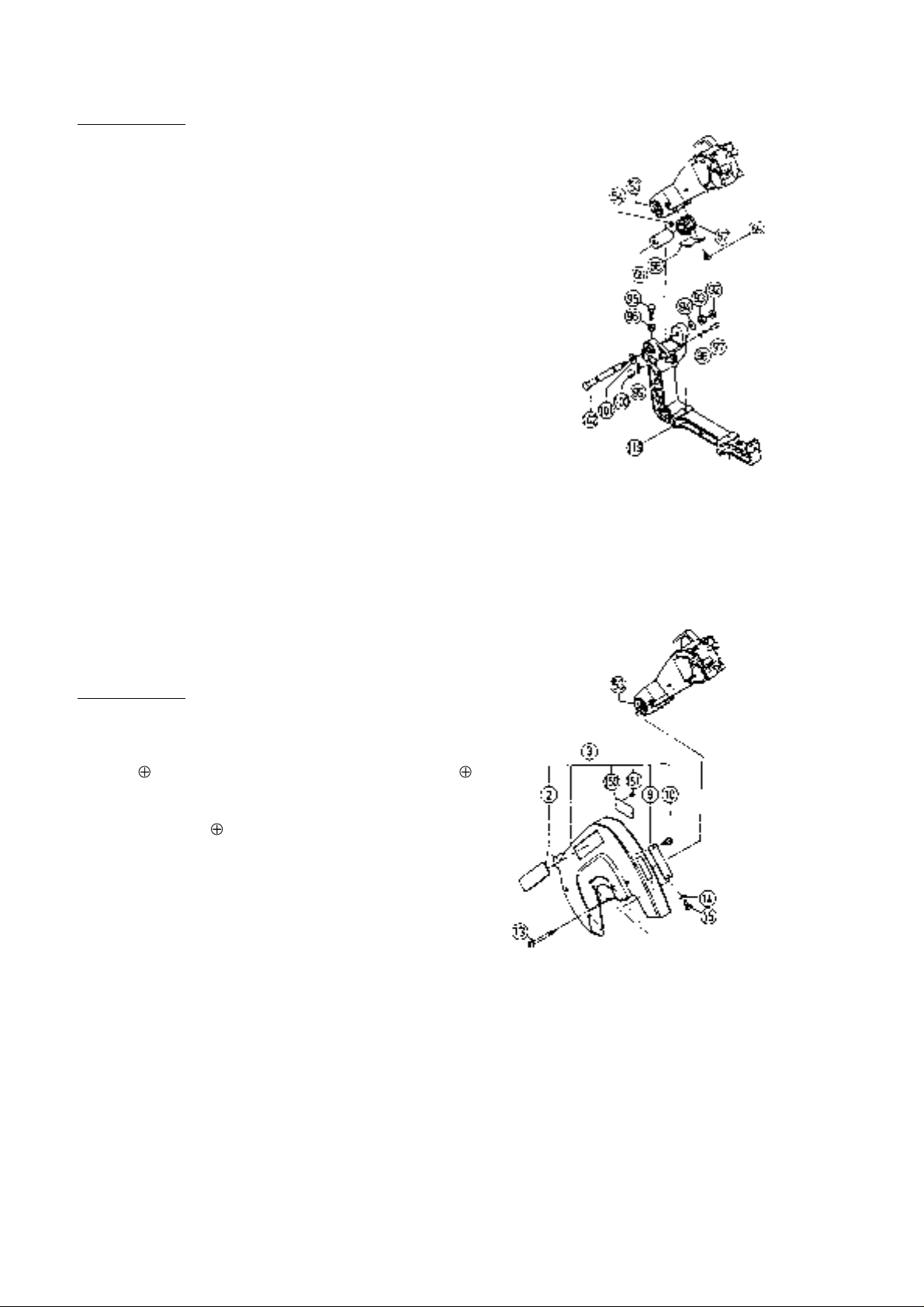

(2) Disassembly of the Spring Section and the Sleeve:

Tools Required:

17 mm Wrench, 10 mm Wrench, 6 mm Hex. Bar Wrench, and

•

Plus Screwdriver

A. This step of disassembly is dangerous and requires close

attention at all times. Particular caution is necessary after

releasing the fixing device (paragraph D.).

B. Push the Gear Case [53] forward and down to its lowered

position, and lock it in that position with the fixing device

(push in the Set Pin [97] to engage the Grip [100]).

C. Loosen the M10 Lock Nut [96], and screw the M10 x 40 Bolt

[95] fully into the Hinge [119].

D. Being very careful as cautioned above, release the fixing

device (Set Pin [97] and Grip [100]) and slowly and carefully

raise the Gear Case [53].

E. Loosen the two M6 x 10 Hexagon Socket Hd. Set Screws

[54], and remove the M12 Lock Nut [92] and M12 Nut [93].

Next, gently pull out the Hinge Shaft [102]. Finally, loosen

the two M4 x 10 Flat Hd. Screws [65], take off the Spring

Cover [68], and take out the Spring [67] and Sleeve [69].

(3) Disassembly of the Saw Cover Section:

Tools Required:

Plus Screwdriver

•

The Saw Cover Ass'y [3] can be disassembled by removing the

M4 x 10 -Hd. Machine Screws [15] and four D5 x 90 -Hd.

Tapping Screws [13] However, please note that to remove two

of the four D5 x 90 -Hd. Tapping Screws [13] it is necessary

to insert the screwdriver through the holes at either end of the

Arrow Mark on the Saw Cover which indicates the rotational

direction of the saw blade.

Insert screwdriver through

Arrow Mark holes for

disassembly and reassembly.

--- 2 ---

Page 3

(4) Disassembly of the Switch and Handle Section:

Tools Required:

Plus Screwdriver

•

A. When only the Switch [22] must be disassem-

bled, first loosen the two M5 x 20 -Hd.

Machine Screws [18] and M5 x 16 -Hd.

Machine Screw [16] which fix the Handle [20].

Then loosen the two M5 x 12 -Hd. Machine

Screws [27] and two D4 x 25 Tapping Screws

[35] which fix the Handle Cover [25]. The

Handle [20] can then be removed from the

Gear Case [53].

B. After loosening the D4 x 10 -Hd. Tapping

Screws [21], the Switch [22] can be separated

from the Handle [20].

(5) Disassembly of the Spindle Section and stopper Pin:

Tools Required:

Plus Screwdriver, Pliers, Wooden or Plastic Hammer

•

A. Remove the Saw Cover Ass'y [3] by following the disassem-

bly procedures in paragraph (3), above.

B. After extracting the D7 E-Type Retaining Ring [37] from the

Stopper Pin [52], the Stopper Pin [52] and Gauge Spring

[38] can be taken out.

C. After loosening the three M6 x 25 Flat Hd. Screws [74],

gently tap on the saw cover side of the Gear Case [53] to

loosen and remove the Spindle Gear Ass'y [75].

--- 3 ---

Page 4

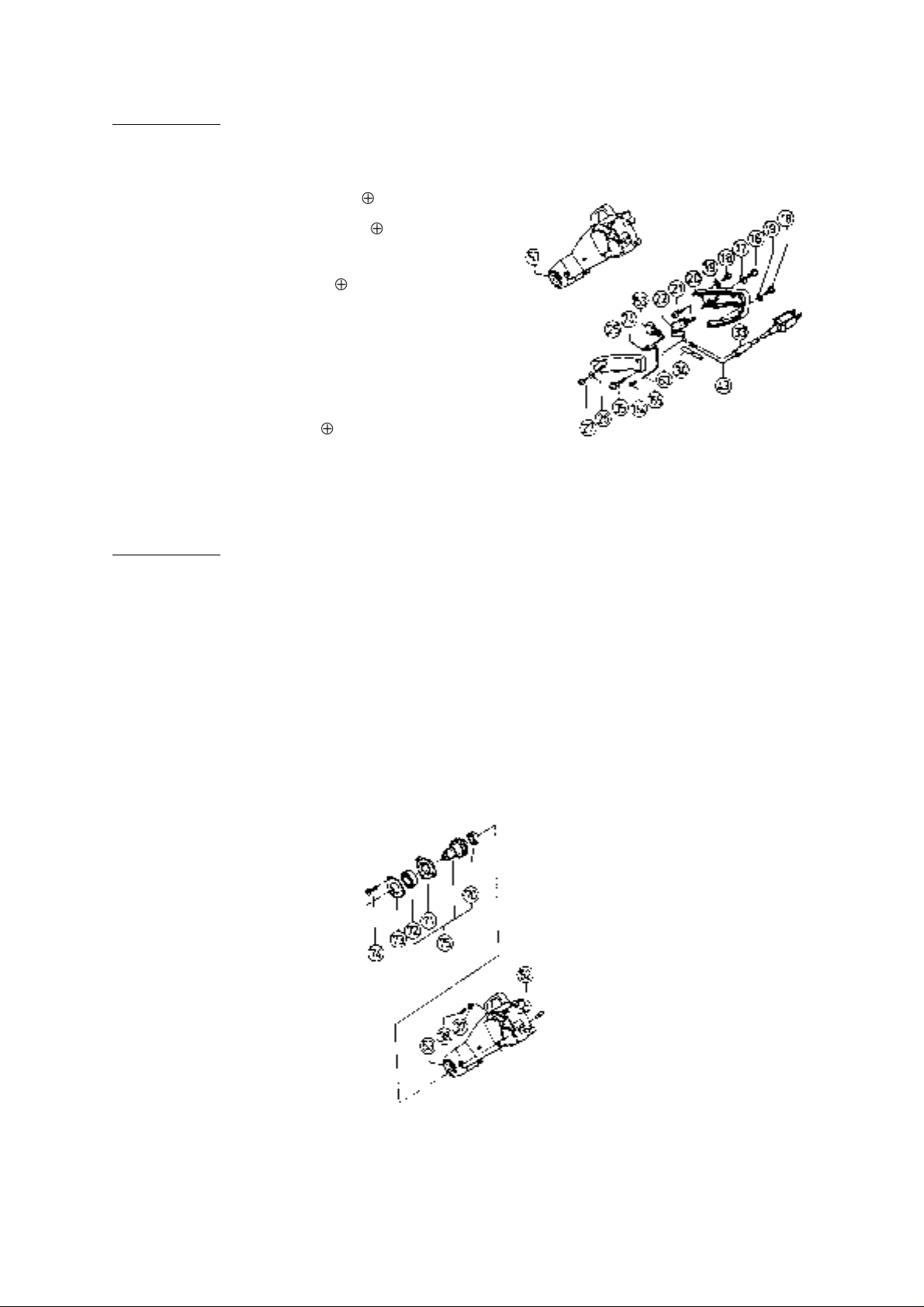

(6) Disassembly of the Armature Ass'y and Stator Ass'y:

Tools Required:

Plus Screwdriver, Nippers, Wooden or Plastic Hammer

•

1. Disassembly of the Armature Ass'y:

A. Remove the Saw Cover Ass'y [3] and handle Cover [25] by following the disassembly procedures in

paragraphs (3) and (4), above.

B. Remove the two leadwires of the Stator Ass'y [46] from the Switch [22]. As there is another leadwire

connected at the Connector [24], cut off the wires as closely to the Connector as possible.

C. Remove the two Brush Caps [55] from the Housing Ass'y [84], and take out the two Carbon Brushes

[40].

D. Remove the Armature Ass'y [36] from the Housing Ass'y [84].

2. Disassembly of the Stator Ass'y:

A. Loosen the two D4 x 10 -Hd. Tapping Screws [41], and remove the Tail Cover [42] from the Housing

Ass'y [84].

B. Disconnect the two Stator Brush Terminal Ass'ys [158] from the Brush Holders [56].

C. Loosen the two M5 x 75 -Hd. Machine Screws [48] which fix the Stator Ass'y [46]. Then tap gently on

the Gear Case mounting end of the Housing Ass'y [84] to loosen and remove the Stator Ass'y [46].

1-2. Reassembly:

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

(1) If the Armature, Stator, Switch or any other electrical component has been replaced, conduct the following

tests:

--- 4 ---

Page 5

A. With the main switch turned ON, measure the insulation resistance between the plug prongs and exposed

metal portions of the frame with a 500V DC Megohm Tester. The reading should be in excess of 7

megohms.

B. If possible, a dielectric strength test should be conducted. With a Dielectric Withstand Voltage Tester, apply

4,000 volts between the plug prongs and exposed metal portions of the frame for one (1) minute with the

main switch turned ON. Confirm that there is no "flashover" or breakdown of the insulation.

C. After electrical testing has been completed, connect the plug to the power source and confirm the following:

There is no irregular noise.

•

Commutation of the Commutator portion is not excessive.

•

There is no abnormal vibration.

•

(2) Ensure that the thickness of the vinyl tube which covers the leadwires from the Stator is in excess of 1.2 mm,

and ensure that the vinyl tube completely covers the Stator leadwires all the way up to the polycarbonate

portion of the Switch Handle.

(3) If the M12 Nut and M12 Lock Nut on the Hinge Shaft are tightened excessively, it may interfere with the

smooth movement of the Gear Case. If they are not tightened sufficiently, the Gear Case may move and

vibrate on the Hinge, causing uneven cutting of the workpiece. Be very careful to ensure that the M12 Nut and

M12 Lock Nut tightened properly to prevent vibration of the Gear Case, yet allow smooth movement of the

Gear Case.

1-3. Assemblies Requiring Careful Adjustment:

(1) Perpendicularity Adjustment of the Saw Blade (or Dummy Disc) and Vise (B):

If the Hinge is disassembled from and then reassembled to the Turn Table, it is necessary to perform

necessary adjustments to ensure the perpendicularity of the Saw Blade (or Dummy Disc) and Vise (B).

A. Mount the D12.7 Steel Ball [117] and Spring (C) [118] onto the Hinge [119], and temporarily fix the Hinge

onto the Turn Table [87] with the M10 x 65 Bolt [120] and M10 x 65 Screw (G) [124]. At this time, the Table

Insert [86] and Guard [61] should be removed from the Turn Table [87].

B. Perform adjustment as necessary so that the Saw

Blade (or Dummy Disc) is positioned exactly in

the center of the Table Insert mounting groove, as

Table Insert

Mounting Groove

Turn Table

Position Saw Blade

(or Dummy Disc) in

exact center.

illustrated left, and tighten the M10 x 65 Bolt [120]

and M10 x 65 Screw (G) [124]. At this time,

confirm without fail that the D12.7 Steel Ball [117]

is properly engaged in the 0˚ setting hole in the

Base Ass'y [103].

Square

Vise (B)

Saw Blade (or Dummy Disc)

--- 5 ---

C. As illustrated, left, fit a square to the side surface

of the Saw Blade (or Dummy Disc), and adjust

Vise (B) as necessary to ensure it is exactly

perpendicular to the Saw Blade. Then thoroughly

tighten the four M10 x 40 Bolts [66].

Page 6

D. Finnally, ensure that the arrow mark on the Indicator [114] is properly aligned with the 0˚ setting of the Scale

[89], and tighten the two M5 x 10 -Hd. Machine Screws [113].

(2) Cutting Depth Adjustment:

The adjustment procedures and dimensions described below are based on the use of a 380 mm diameter Saw

Blade.

A. Cutting depth adjustment procedures are described in the Instruction Manual. If the M10 x 40 Bolt [95] is

not properly adjusted, the following may occur:

Maximum machine cutting capacity cannot be obtained.

•

The Saw Blade could cut into the Turn Table [87].

•

B. To obtain maximum machine cutting dimensions, set the Turn Table [87] to the 0˚ setting, lower the Saw

Blade, and perform adjustment with the M10 x 40 Bolt [95] so that the appropriate dimension between the

surface of Vise (B) and Point A (where the Saw Blade intersects the surface of the Turn Table) is

obtained, as illustrated below.

Vise (B)

90˚

(0˚ Scale

Setting)

185 mm

Saw Blade

(Point A)

Check this dimension

at 0˚ Scale Setting

185 mm

(Point A)

C. On completion of the above adjustment, lower the Saw Blade and ensure that it does not come in contact

with the Turn Table.

(3) Saw Blade Height Setting Adjustment:

When the Gear Case [53] has been disassembled and then

Saw Blade

reassembled, adjust the M10 x 40 Bolt [95] without fail to

set the Saw Blade at the most appropriate height (H) above

the Turn Table for the operator to conveniently perform

Workpiece

H

normal cutting operations. Details concerning adjustment

procedures are listed in the Instruction Manual; study them

Vise (B)

carefully, and set the height in accordance with cutting

Saw Blade

needs.

1-4. Confirmation of Appropriate Insulation:

When making leadwire connections, do not remove any more of the insulation covering than is absolutely

necessary. For example, ensure there are no exposed wire cores projecting from connectors, terminals, etc. In

particular, carefully confirm that there are no exposed wire cores at the terminals of the Switch. In addition,

carefully avoid pinching leadwires between the Handle and Handle Cover during reassembly.

--- 6 ---

Page 7

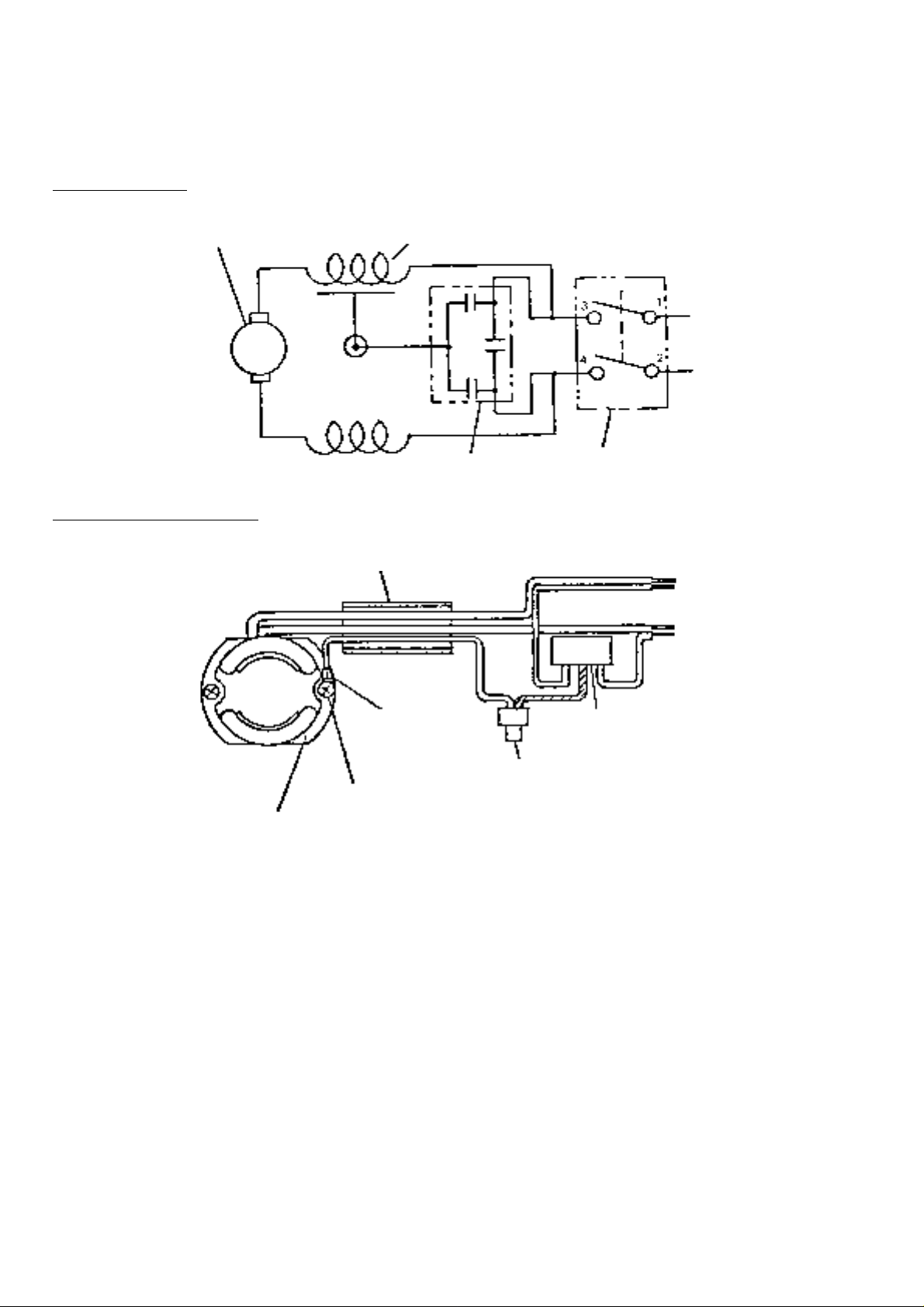

1-5. Wiring Diagrams and Leadwire Arrangements:

Perform wiring work as illustrated below.

(1) For Products with a Dynamic Brake (115V Specification Products for the U.S. and Canada Only):

WIRING DIAGRAM

Armature

Ass'y

LEADWIRE ARRANGEMENT

Stator Ass'y

Brown

Tube (A)

Switch

White

Black

Cord

White

Connector

Noise Suppressor

Connector

Switch

Cord

Cord Armor

--- 7 ---

Page 8

(2) For Products with a Noise Suppressor:

[NOTE] The wiring diagram for products without a Noise Suppressor is the same as that illustrated below with the

exception of the Noise Suppressor section.

WIRING DIAGRAM

Armature

Ass'y

LEADWIRE ARRANGEMENT

Stator Ass'y

Vinyl Tube

Noise Suppressor

Black

Red

Switch

Black

Red

Stator Core

Green

Terminal

(w/o insulation

tube)

M5 x 75 Machine Screw

Noise

Suppressor

Yellow/Green

Connector

--- 8 ---

Page 9

2. TROUBLESHOOTING GUIDE:

The circled numbers in the descriptions below correspond to the item numbers in the Parts List and exploded

assembly diagram.

(All Dimensions in Millimeters)

Item Phenomenon Possible Cause (s) Standard Countermeasure (s)

1.

Inaccurate cutting.

(Unable to obtain accurate

perpendicularity of cut

surface.)

(Mitered joints cannot be

accurately aligned.)

Fig. 1

0.1

80

Fig. 2

0.1

Perpendicularity

Standard:

0.2/90

A. Improper perpendicularity

between Vise (B) [82] and the

Base Ass'y [103] causes

inclined bevel cutting, resulting

in inaccurate angles.

B. Improper perpendicularity

between Saw Blade and Turn

Table [87] causes Saw Blade

to cut into Workpiece at

inclined angle.

C. Excessive deflection of the

Saw Blade.

(Excessive vibration)

D. Turn Table [87] is not

properly fixed with the Side

Handle [116], and moves

during the cutting operation.

Within

0.1/80

(Fig. 2)

0.2/190

(Fig. 1)

0.26/φ 370

(With

Dummy

Disc)

----

Adjust or replace Vise (B) [82].

Adjust M12 Nut [93] and M12

•

Lock Nut [92] to eliminate gap

and vibration between Hinge

[119] and Gear Case [53].

Replace Hinge [119].

•

(If Hinge damaged or deformed)

Replace Gear Case [53].

•

(If Gear Case damaged or deformed)

Replace Turn Table [87].

•

(If Turn Table damaged or deformed)

Replace the Saw Blade.

•

Replace Washer (A) [28] and/or

•

Washer (B) [29].

Securely fix the Turn Table [87]

with the Side Handle [116] and

recheck after next cutting.

Within 0.1

Fig. 3

Within 0.1

Fig. 4

E. Surface of Vise (B) uneven

(worn or damaged) and

causes uneven cutting of the

workpiece.

F. Surface of Turn Table [87]

uneven (worn or damaged)

and causes uneven cutting of

the workpiece.

G. Excessive looseness or excessive tightening of the turn

connection between the Hinge

[119] and Gear Case [53]

which causes either vibration

or irregular movement of the

Saw Blade, and subsequent

uneven cutting.

H. Excessively fast cutting

operation speed causes

deflection of the Saw Blade,

and subsequent uneven

cutting.

Within 0.1

(Fig. 3)

Within 0.1

(Fig. 4)

----

----

Replace Vise (B) [82].

Replace the Turn Table [87].

Check for material (chips, dust,

•

etc.) in the joints of the Hinge

[119], Gear Case [53] and

Hinge Shaft [102], and clean as

necessary.

Readjust M12 Nut [93] and M12

•

Lock Nut [92] to ensure proper

movement of the Gear Case

[53].

Reduce cutting operation

•

speed.

(Appropriate cutting time for a

100 mm (4") workpiece is 10 --15 seconds.

Use a Tungsten Carbide Tipped

•

Saw Blade for wood or aluminum (Code No. 959024).

I. Excessive pressure is

applied because of a dull Saw

Blade.

--- 9 ---

----

Resharpen or replace the Saw

•

Blade.

Page 10

Item Phenomenon Possible Cause (s) Standard Countermeasure (s)

Inaccurate cutting.

(Unable to obtain accurate

perpendicularity of cut

surface.)

(Mitered joints cannot be

accurately aligned.)

2.

Cutting operation results in

rough cutting surfaces

A = 0.02/60

J. The workpiece is not properly secured, and moves during the cutting operation.

K. Curved or rough surface of

the Workpiece causes

workpiece movement during

cutting operation.

A. Excessive deflection of the

Saw Blade.

(Inherent Saw Blade deflection

will cause rough surfaces.)

B. Incorrect selection of Saw

Blade, or dull Saw Blade.

(While a regular TCT Saw

Blade provides faster cutting

speed, it also produces

rougher surfaces than a TCT

Saw Blade for wood or

aluminum.)

C. Improper perpendicularity

between Saw Blade and Turn

Table [87] causes Saw Blade

to cut into workpiece at slightly

inclined angle, and cause

rough cutting surface.

----

----

0.26/φ 370

----

0.2/190

(Fig. 1)

Secure the workpiece with Vise

(A), and check cutting accuracy.

Plane the surface of the workpiece to remove defects, and

recheck the cutting accuracy.

Replace the Saw Blade. (To obtain very fine cutting surfaces,

Hitachi's TCT Saw Blade for

wood or aluminum (Code No.

959024) is recommended.)

Replace the regular TCT Saw

•

Blade with a TCT Saw Blade for

wood or aluminum (code No.

959024).

Resharpen the Saw Blade.

•

Adjust M12 Nut [93] and M12

•

Lock Nut [92] to eliminate gap

and vibration between Hinge

[119] and Gear Case [53].

Replace Hinge [119]

•

(If damaged or deformed).

Replace Gear Case [53]

•

(If damaged or deformed).

Replace Turn Table [87]

•

(If damaged or deformed).

Fig. 5

Fig. 6: Left Bevel Cutting

Fig. 7: Right Bevel Cutting

D. Washers (A) and (B) not

parallel because of surface

defects or other damage.

E. Improper perpendicularity

between Vise (B) and the

Base Ass'y [103] causes

improper support of the

workpiece.

F. Surface of Vise (B) uneven

and causes improper support

of the workpiece.

G. Excessively fast cutting

operation speed.

H. When the Saw Blade cuts

against the natural grain of the

wood workpiece, inferior

cutting surfaces are obtained.

0.02/60

(Fig. 5)

Within

0.1/80

(Fig. 2)

Within 0.1

(Fig. 3)

----

----

Remove surface defects from or

replace Washer (A) [28] and/or

Washer (B ) [29].

Adjust or replace Vise (B) [82].

Replace Vise (B) [82].

Reduce cutting operation speed.

(Appropriate cutting time for a

100 mm (4") workpiece is 10 --- 15

seconds.)

Cut with the natural grain of the

wood workpiece.

Fig. 6

Fig. 7

Workpiece

--- 10 ---

Workpiece

... With Grain (Smooth cutting

surface)

... Against Grain (Cutting surface

inferior to with grain.

Page 11

Item Phenomenon Possible Cause (s) Standard Countermeasure (s)

Cutting operation results in

rough cutting surfaces.

I. The workpiece is not securely fixed in position.

J. The Turn Table is not securely fixed in position with the

Side Handle [116].

K. Excessive looseness or excessive tightening of the turn

connection between the Hinge

[119] and Gear Case [53].

L. Curved or rough surface of

the workpiece causes

workpiece movement during

cutting operation.

M. Excessive vibration during

cutting operation.

----

----

----

----

----

Securely fix the workpiece with

Vise (A) [79].

When performing cutting operations, securely tighten the Side

Handle [116] without fail to fix the

Turn Table in position. (The Ball

Index Settings at 0˚, 15˚, 22.5˚,

30˚ and 45˚ are affected by

vibration, and are not sufficient to

securely fix the Turn Table.)

Repair or adjust affected parts as

described in Item 1. G, above.

Plane the surface of the workpiece to remove defects, and

recheck the cutting.

Check each of Possible Causes

A, B, D, J and K, above.

--- 11 ---

Loading...

Loading...