HA13609ANT

Three-Phase Brushless Motor Driver

ADE-207-232 (Z)

1st. Edition

May 1997

Description

The HA13609ANT is a 3-phase brushless motor driver IC with digital speed control. It is designed for use

as a PPC or LBP scanner motor driver and provides the functions and features listed below.

Function

• Power MOS and power bipolar transistor driver circuits

• 16-bit serial interface

• Variable-speed digital speed control circuit

• Digital PLL

• Digital ready circuit

• PWM oscillator circuit

• Charge pump circuit

• Integrating amplifier circuit

• Current limit circuit

• Overshoot prevention circuit

• Braking function (with braking compete signal)

• Forward/reverse direction circuit

• Hall open circuit protection

• Watchdog timer (LVI, POR, and RST outputs)

• Stuck rotor protection

Features

• High breakdown voltage (50V/30mA) power transistor drive circuit

• PWM drive

• Variable speed control is possible (varying the servo filter constants is not required)

• Selectable rotation control method (discriminator control, PLL plus discriminator control)

• Selectable feedback type (voltage or current)

• Allows both PWM frequency switching and 100% duty operation

• Selectable current limiting level

• Braking mode selection (reverse braking, regeneration braking)

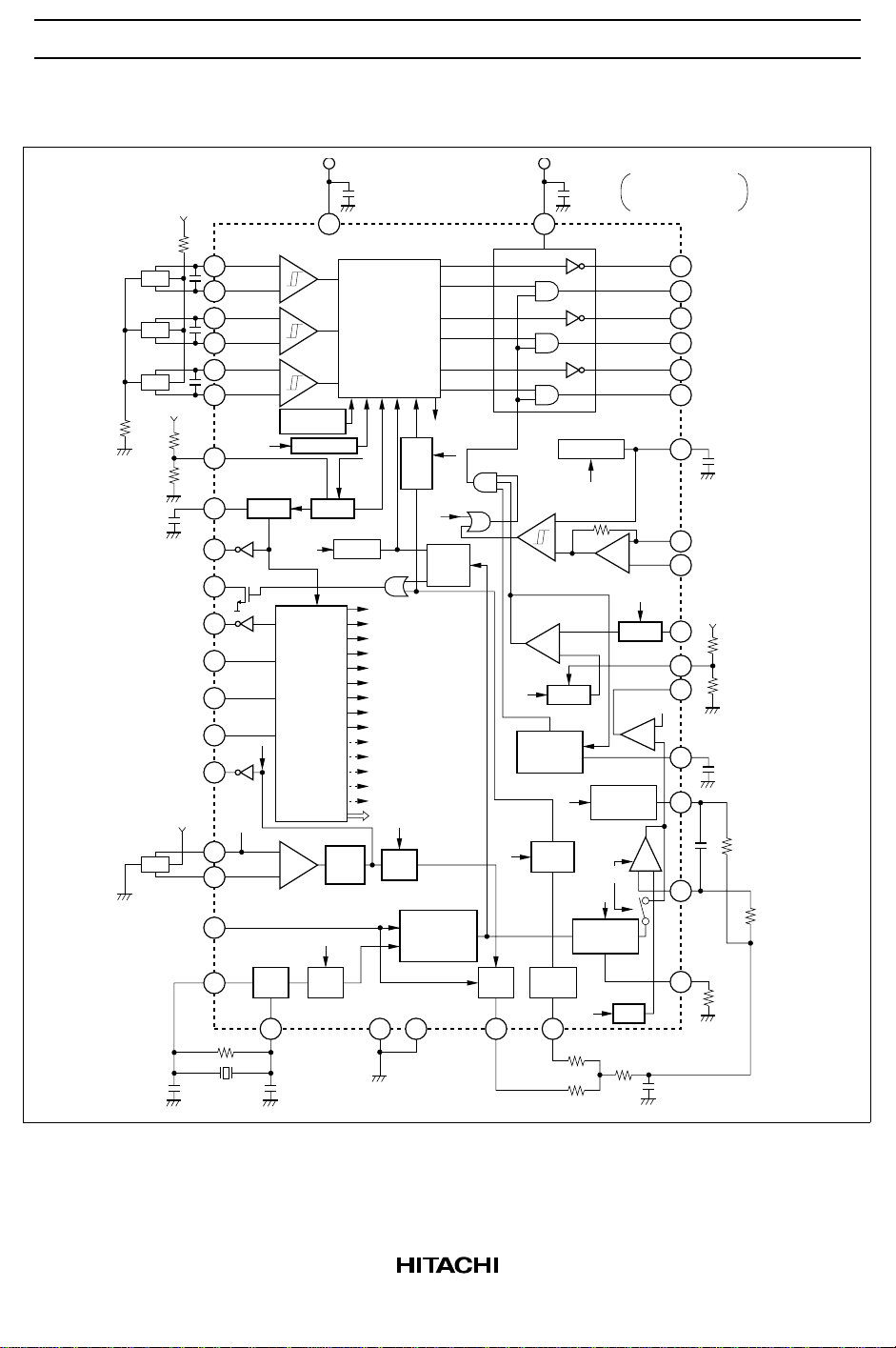

HA13609ANT

Block Diagram

V

SS

R101

Hu

Hv

Hw

V

SS

R102

R126

R127

C108

RST

Monitor output

(Ready: Low)

DATA OUT

CLK

f

= 8 MHz

MAX

ENABLE

DATA

Rotation monitor output

V

SS

MR

SPEED CLK

(0.2 to 5 kHz)

20 p 20 p

42

41

40

39

38

37

20

22

8

7

4

1

2

3

6

29

28

5

9

1 M

8 MHz

MAX

U+

U–

V+

V–

W+

W–

FH × 3

1.4 V

Hall amplifier

+

–

+

–

+

–

Open circuit

protection

R/F

RWD/FWD

P.O.R L.V.I

BRAKE

Serial port

(16 bits)

+

AMP

–

OSC D2

10

21

Wave-

shaping

D2

V

SS

1.25 V

BRAKE

form

(5 V)

C101

Matrix

FH × 3

Overshoot

OSI

preven-

tion

Duty 100

No/8

Counter

MOTOR ON

BRAKE (2 bit)

DUTY 100

READY

O.S.I ON

(2 bit)

V

Ref

MASK

CONTROL

RWD/FWD

D1 (2 bit)

D2 (2 bit)

PLL SEL OR Icp, PC ON

VP (3 bit)

f

(2 bit)

PWM

MODE SEL

D1

D1

Programmable

discriminator

(1024 to 4095)

11 30

Ready

PLL

13

25

PWM

comp.

Current

sense

V

Ref

Stuck rotor

protector

Ready

±4, ±8%

Discrimi-

V

–

+

–

+

V

nator

14

PS

C102

PWM OSC

f

PWM

40 k

Ref

PC

Precharge

Integral

CONT.

Icp × 2

Charge

pump

R4

R5

V

= Bip use

SS

10 to 50 V= MOS use

U

36

U

35

V

34

V

33

W

32

W

31

12

Error

amp

–

27

+

17

MASK

26

MASK

24

18

1.1 V

–

+

Buffer

23

16

–+

15

19

VpVp

R6

C4

(Open collector)

(Push-pull)

C106

Current feedback input

Error amplifier input

V

SS

R106

R107

C105

C3

R3

R7

R1

2

HA13609ANT

Pin Functions

Pin No. Pin Name Function

1 CLK Serial port reference signal input

2 ENABLE Serial port data write/latch signal input

3 DATA Serial port data input

4 DATA OUT Serial port data transfer complete signal output

5 SPEED CLK Speed command signal input

6 TACHO OUT Rotation monitor (MR, Hall ×3) output

7 READY Ready and braking done (no/8) output (open collector output)

8 RST Power supply (VSS) monitor output. High when a reduced power-supply

voltage is detected.

9 OSC IN Oscillator circuit input. Reference signal for all circuits other than the

serial port.

10 OSC OUT Oscillator circuit output

11 S-GND Small-signal ground

12 PWM OSC Connection for the capacitor that sets the oscillator frequency.

13 PLL OUT SPEED CLK vs. speed detection signal speed comparison output

14 DIS OUT SPEED CLK vs. speed detection signal phase comparison output

15 INTEG IN Integrating amplifier input

16 CP OUT Charge pump and integrating amplifier output

17 ERROR AMP IN Error amplifier input

18 BUFFER OUT Buffer amplifier output. Connect to pin 17 when current feedback is

selected.

19 R1 Charge pump output current and PWM oscillator frequency setting

20 LVI Reduced voltage detection level setting

21 V

SS

22 POR Power-on reset delay time setting

23 LOCK PRO Motor rotation constraint mode coil current on/off time setting

24 V

25 V

Ref

PS

26 C Sense Motor coil current detection

27 C F B Current feedback input

28 MR IN – Speed detection input

29 MR IN + Speed detection input

30 P-GND Output driver ground

Small-signal circuit power supply. 5.5V maximum

Current limit setting

Output driver power supply. 50V maximum

3

HA13609ANT

Pin Functions (cont)

Pin No. Pin Name Function

31, 33, 35 U, V, W Lower arm driver push-pull output. Driven by a PWM signal. (Connect

power NMOS or NPN transistors.)

32, 34, 36 U, V, W Upper arm driver open drain output. (Connect a power PMOS or PNP

transistor.)

37 to 42 U+, U–

V+, V–

W+, W–

Hall signal inputs

4

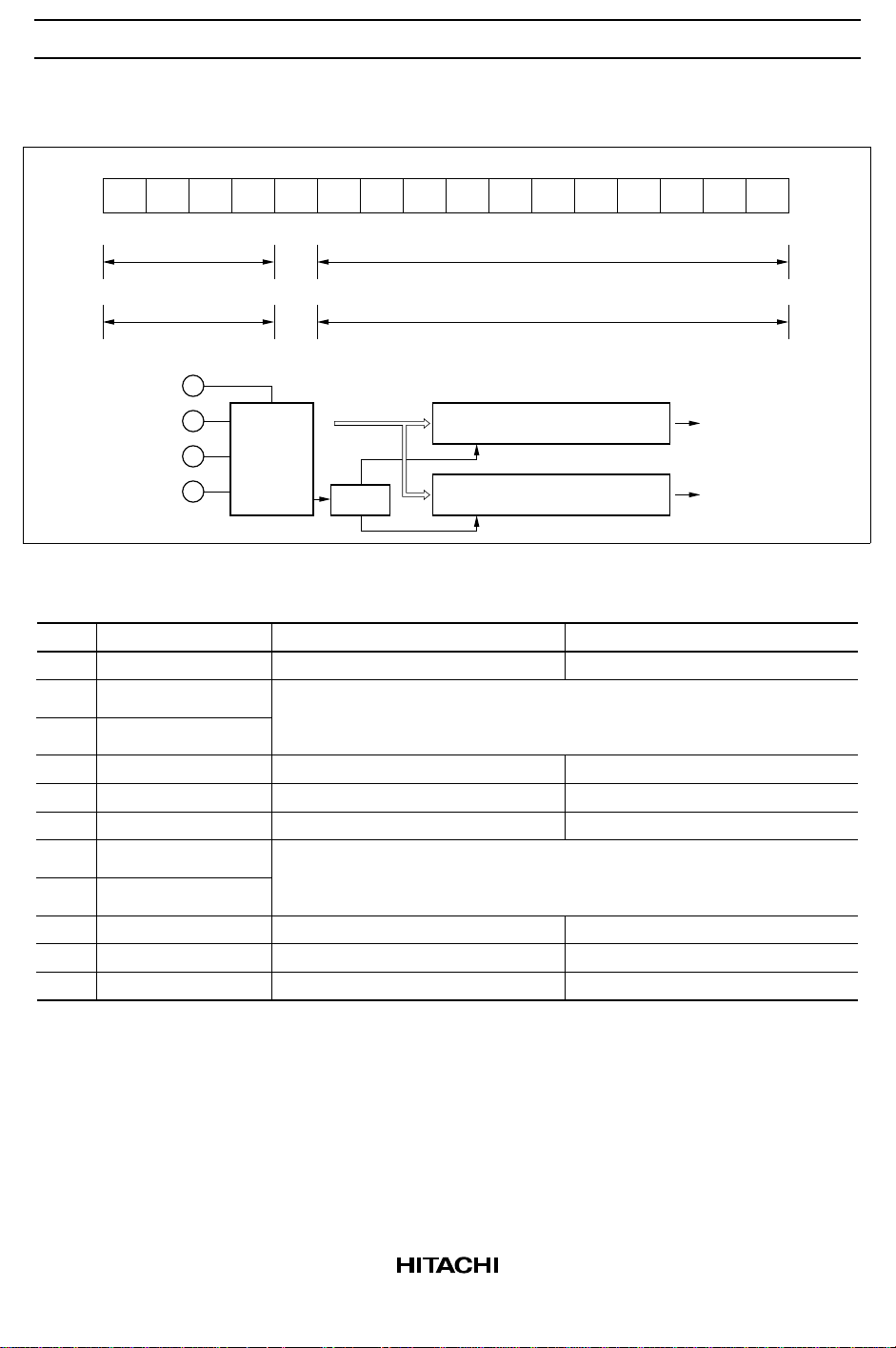

Serial Port Input Data Structure

HA13609ANT

MSB

A4

A3 A2 A1 A0 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Dummy Mode control

Dummy Data control

A0 = 1

A0 = 0

DATA OUT

DATA

CLK

Serial

port

(16 bits)

ENABLE

Mode Control Register (A0 = 1)

Bit

MD0

MD1

MD2

MD3

MD4

MD5

MD6

MD7

MD8

MD9

MD10

Symbol

MOTOR ON

BRAKE 1

BRAKE 2

DUTY 100

READY

O.S.I ON

V

Ref 1

V

Ref 2

MASK

CONTROL

R/F

Decoder

A0

MOTOR ON

MD1

MD2

BRAKE

DUTY 100%

4%

Active

MD6

MD7

V

Ref

×2

Discriminator

Reverse

Mode control register (11 bits)

A0 = 1

Data control register (11 bits)

A0 = 0

1

1

0

OFF

0

0

V

Ref

×2

Brake

←

×1

0

0

1

Brake

1

1

0

Brake

2

0

1

←

×0.75

MOTOR OFF

1

1

3

DUTY

8%

Non Active

1

1

←

×0.5

×1

Discriminator + PLL

Forward

LSB

Mode control

Data control

0

*10

*2

*3

5

HA13609ANT

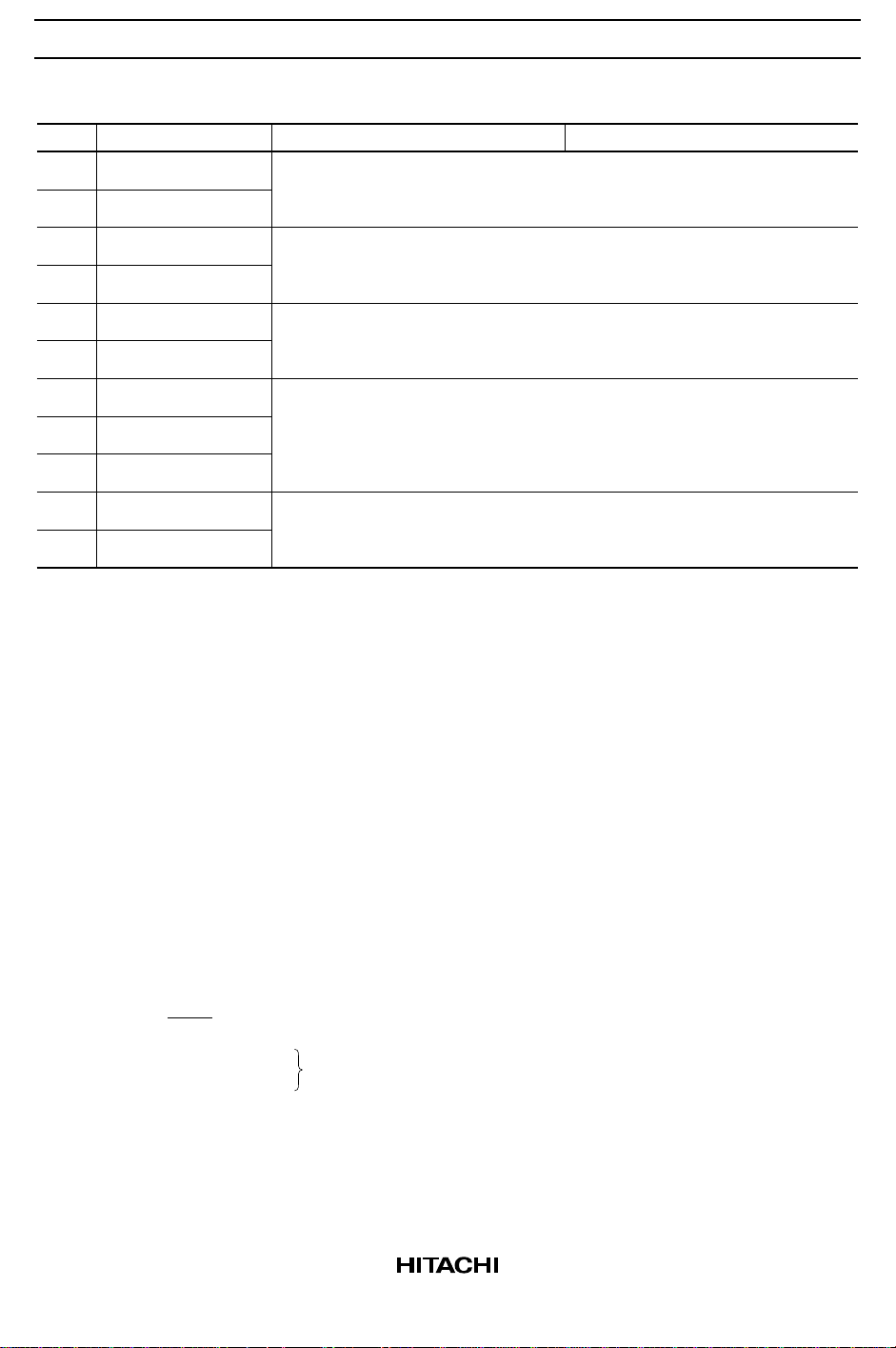

Data Select Register (A0 = 0)

Bit

DD0

DD1

DD2

DD3

DD4

DD5

DD6

DD7

DD8

DD9

DD10

Symbol

D1 A

D1 B

D2 A

D2 B

PLLSEL1 OR Icp

PLLSEL2 OR PC ON

VP1

VP2

VP3

f

PWM1

f

PWM2

DD0

DD1

D1

DD2

DD3

D2

DD4

DD5

PLL OUT(Vp-p)

×100%

DD6

DD7

DD8

VP (V)

DD9

DD10

f

PWM

1/1

1/1

2.2

f

PWM

×1

1

0

0

0

0

0

0

0

0

0

0

Notes: 1. Off: The brake function does not operate.

Brake 1: Braking up to No/8.

Brake 2: Braking up to No/8, and then regenerative braking.

Brake 3: Regenerative braking. The No/8 signal is output.

During a braking operation, when the MR frequency when braking completes cannot be detected

in the circuit (During braking, the speed detection signal for under setting is not output over the

2/D1 occurrence. Thus this occurs more easily for lower settings.), reverse rotation may continue

in some cases. Note that this bit is also used to set the rotation monitor output (FH × 3 or the MR

frequency). FH × 3 is only output from the rotation monitor when motor on (MD0 = 1) and brake 3

are selected.

2. The ready setting range has the following manufacturing variation:

4.3% ±25% (@MD4 = 1)

8.6% ±25% (@MD4 = 0)

3. This function masks the current limiter input (pin 27) (incorrect operation due to the recovery

current). See page 20 for details.

4. The PLL output setting indicates a change relative to 3.5 Vp-p. See the electrical characteristics.

This is valid when MD9 = 0 (PLL control). Note that DD4 also functions as the Icp selection in

discriminator control mode.

V

Icp =

DD4 = 1 . . . . . Icp × 2

DD4 = 0 . . . . . Icp × 1

R1

4 · R1

@MD9 = 1

1

0

1/2

1

0

1/2

1

0

←

×75%

1

0

0

+0.15

1

0

←

×1.4

0

1

1/4

0

1

1/4

0

1

←

×50%

0

1

0

+0.3

0

1

←

×1.9

1

1

1/8

1

1

1/8

1

1

←

×25%

0

0

1

+0.45

1

1

←

×2.8

1

1

0

+0.6

1

0

1

–0.15

0

*4

1

0

1

1

–0.3

*5

1

1

–0.45

*60

6

HA13609ANT

DD5 also controls the PC on function to reduce motor rotation overshoot when MD9 is 1

(discriminator control). This function does not operate when D9 is 0. The precharge voltage (i.e.,

the integrator output voltage initial clamp voltage) can be set by Vp1 to Vp3 (DD6 to DD8). The

figure shows the precharge operation.

MD0 or MD10

Ready lock range

NO

Integrator output Vp

0 V

Precharge

5. The Vp setting indicates the change relative to 2.2V. See the electrical characteristics.

6. Indicates the change relative to f

. See the setting formula.

PWM

(MD4)

7

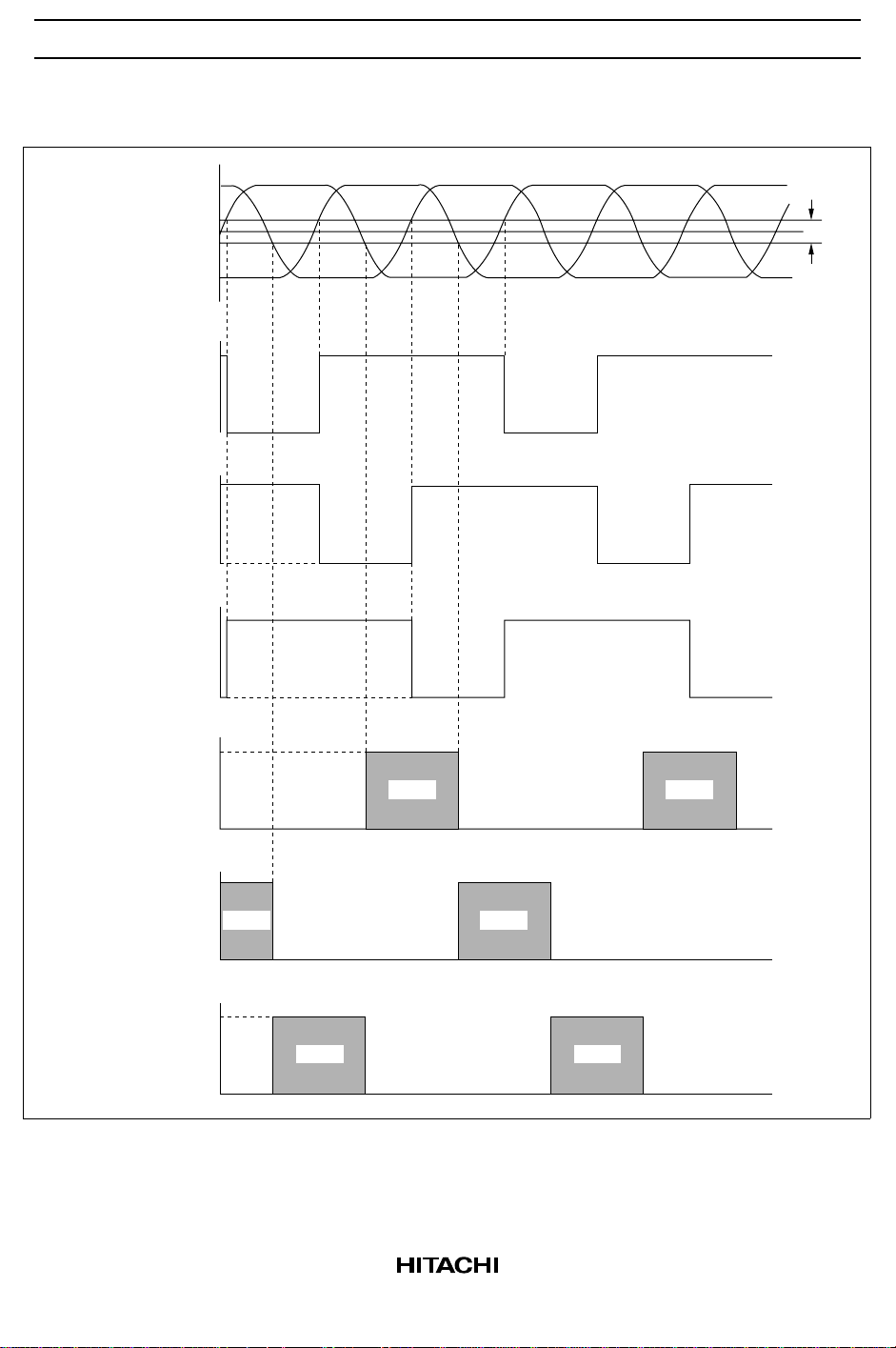

HA13609ANT

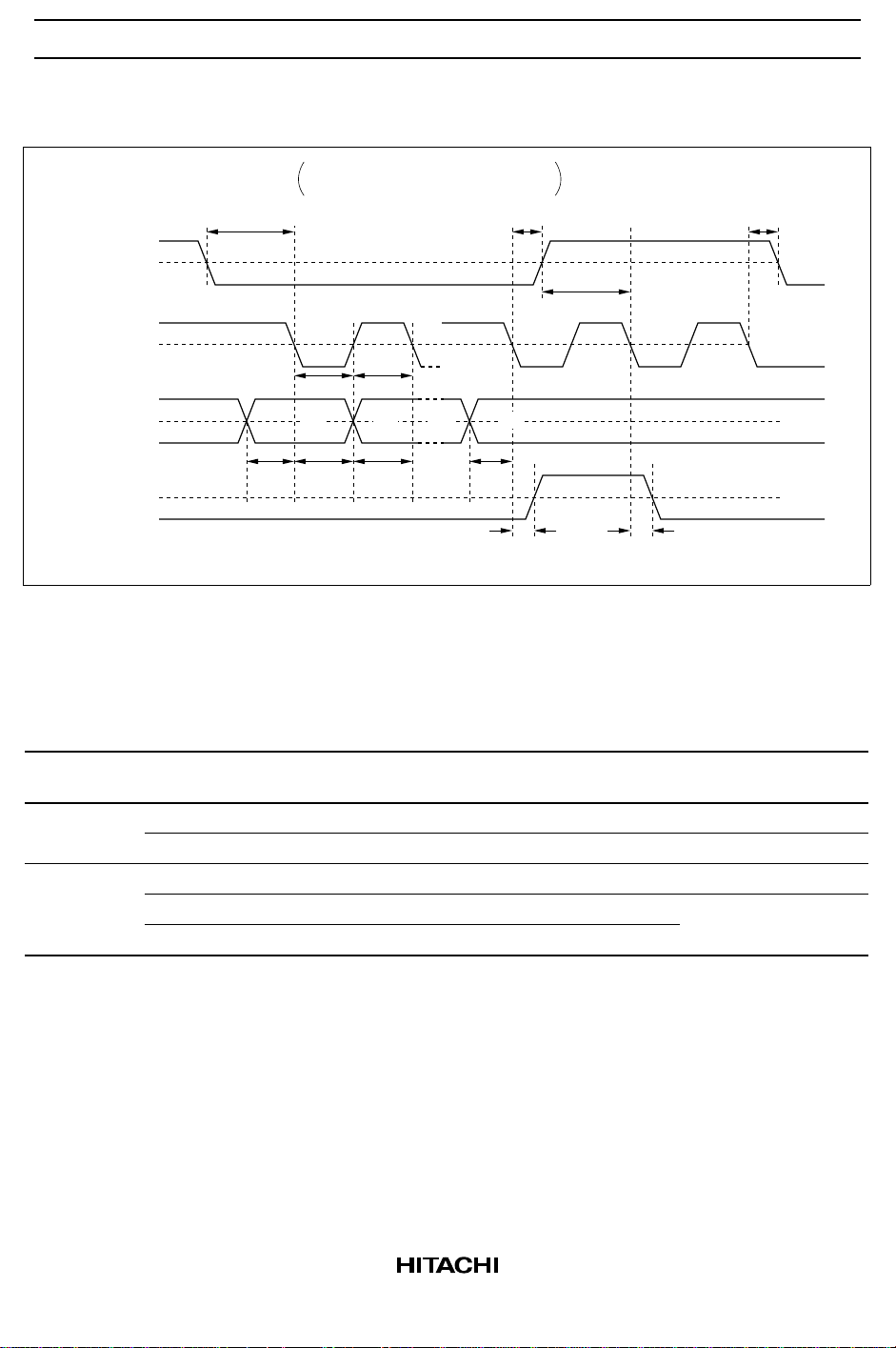

Timing Chart (Forward Mode)

Hall amplifier input

V

U output

V

V output

V

W output

OH1

V

OH1

V

OH1

V

OL

OL

OL

+

Hu Hv Hw

0

Vhys

–

U output

V output

W output

V

OH

PWM PWM

V

OL

V

OH

PWM

V

OL

V

OH

PWM

V

OL

PWM

PWM

8

Serial Port Timing Chart

HA13609ANT

ENABLE

CLK

DATA

DATA OUT

Braking Function

Input and Output Logic

tr, tf < 20 nsec, tsu, th > 20 nsec

tw > 40 nsec

tsu

tw tw

A4 A3 D1 D0

tsu th tsu tsu

The tr and tf times are stipulated

at 10% and 90%, respectively.

th

th

50%

tsu

50%

50%

50%

td1 td2

≤ 50 nsec ≤ 50 nsec

Serial Port Input Output

MOTOR ON

(MD0)

1 * * 0 Forward OFF *1

0 0 0 * — OFF *2

Notes: 1. OFF: The braking function does not operate.

2. The IC goes to standby mode.

3. See the description of mode control for details on the braking operation.

BRAKE 1

(MD1)

* * 1 Reverse OFF

* * 0 Reverse Brake *3

* * 1 Forward

BRAKE 2

(MD2)

R/F

(DD10) Rotation Direction Braking

9

HA13609ANT

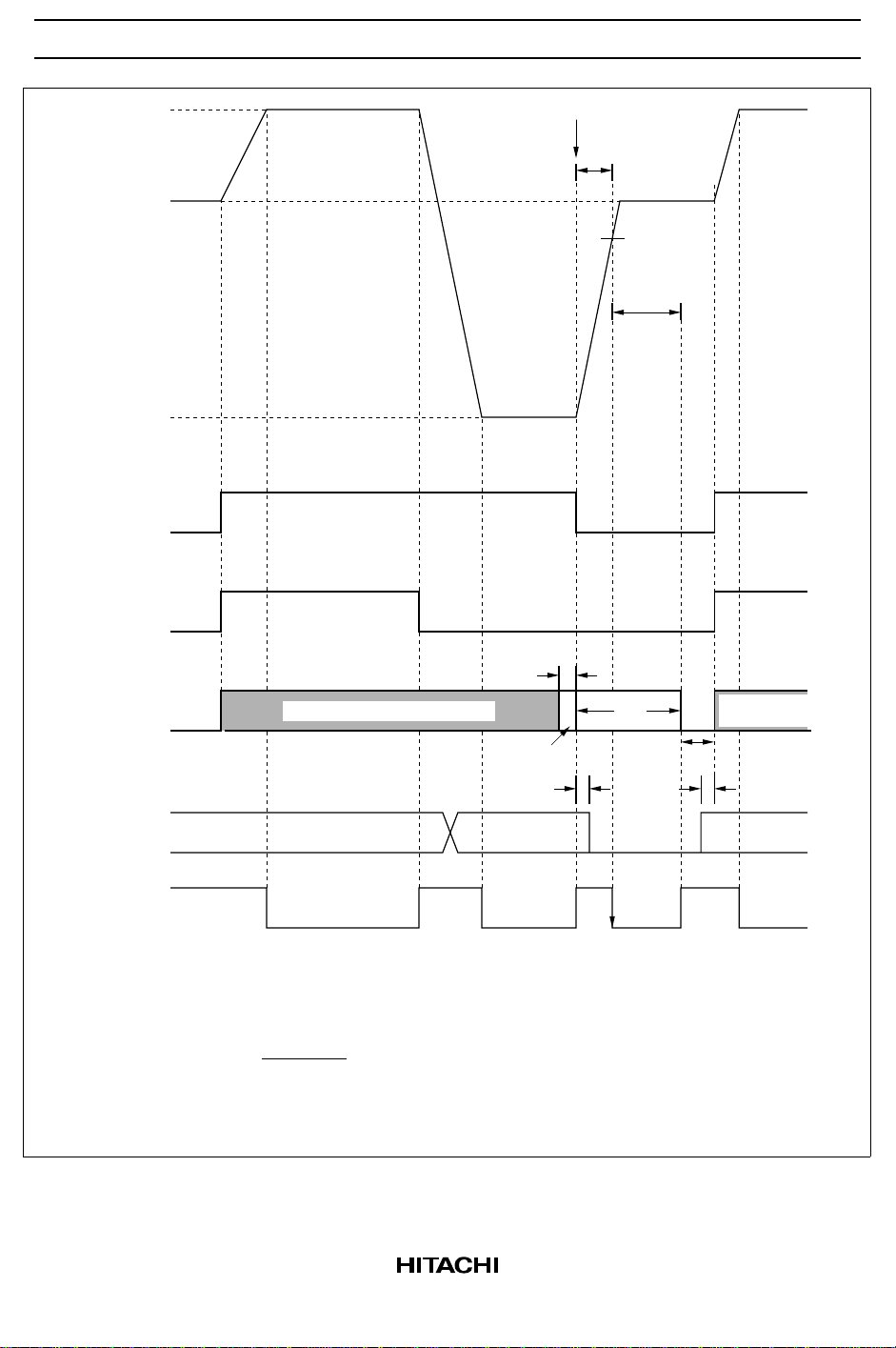

(

N1

Forward

Reverse

N2

MDO

(MOTOR ON)

MD10 (R/F)

MD1 (BRAKE1)

to

MD2 (BRAKE2)

SPEED

CLK input

Braking set

Braking or

regeneration

0

*3

tset up

Rotation monitor output set

Braking set

N2N1 N1

braking

Regeneration

braking

*2

*3

thold

Rotation monitor

output set

*1

*3

tset up

Monitor output

(open drain)

Notes: 1.

10

*4

ReadyReady Ready

The IC goes to standby mode when MOTOR ON, BRAKE1, and BRAKE2 are all 0.

2.

Hold the data values here.

3.

thold, tset up >

4.

The No/8 (braking completion) function does not operate when BRAKE1 and BRAKE2 are 0.

Note that the No/8 detection signal is initialized to the high level in the mode in note 1

standby mode).

1

f

SPEED CLK

× 4

No/8

detection

HA13609ANT

Basic Application Circuit (Bipolar Transistor Circuit, Discriminator + PLL, Voltage

Feedback, and Hall Elements)

MPU

R102

C103

X’tal

C104

R101

Hu

Hv

Hw

MR

V

V

SS

SS

R126

R127

C108

V

SS

R105

21

V

U+

42

U–

41

V+

40

V–

39

W+

38

W–

37

LVI

20

22

P.O.R

RST

8

7

Monitor output

DATA OUT

4

1 CLK

ENABLE

2

DATA

3

SPEED CLK

5

29

MR IN+

MR IN–

28

Rotation monitor

6

output

OSC IN

9

OSC OUT

10

11 30

V

SS

V

PS

C101

25

V

SS

PS

36

U

35

U

R108

R109

R114

Q1

Q2

D1

D2

R117

R115

R110

34

V

R111

33

V

Q3

Q4

D3

D4

R118

R116

R112

32

W

R113

31

W

Q5

Q6

D5

D6

R119

R120

V

input

output

26

C107

C106

12

24

Ref

C105

23

R

NF

V

SS

R106

R107

27

17

18

16

C3

R3

15

19

R7

R1

Current limiter

PWMOSC

Lock protection

Current feedback

Error amplifier input

Buffer amplifier

Integrator output

Integrator input

Discrimi-

PLL

nator

13 14

R4

R6

C4

R5

11

HA13609ANT

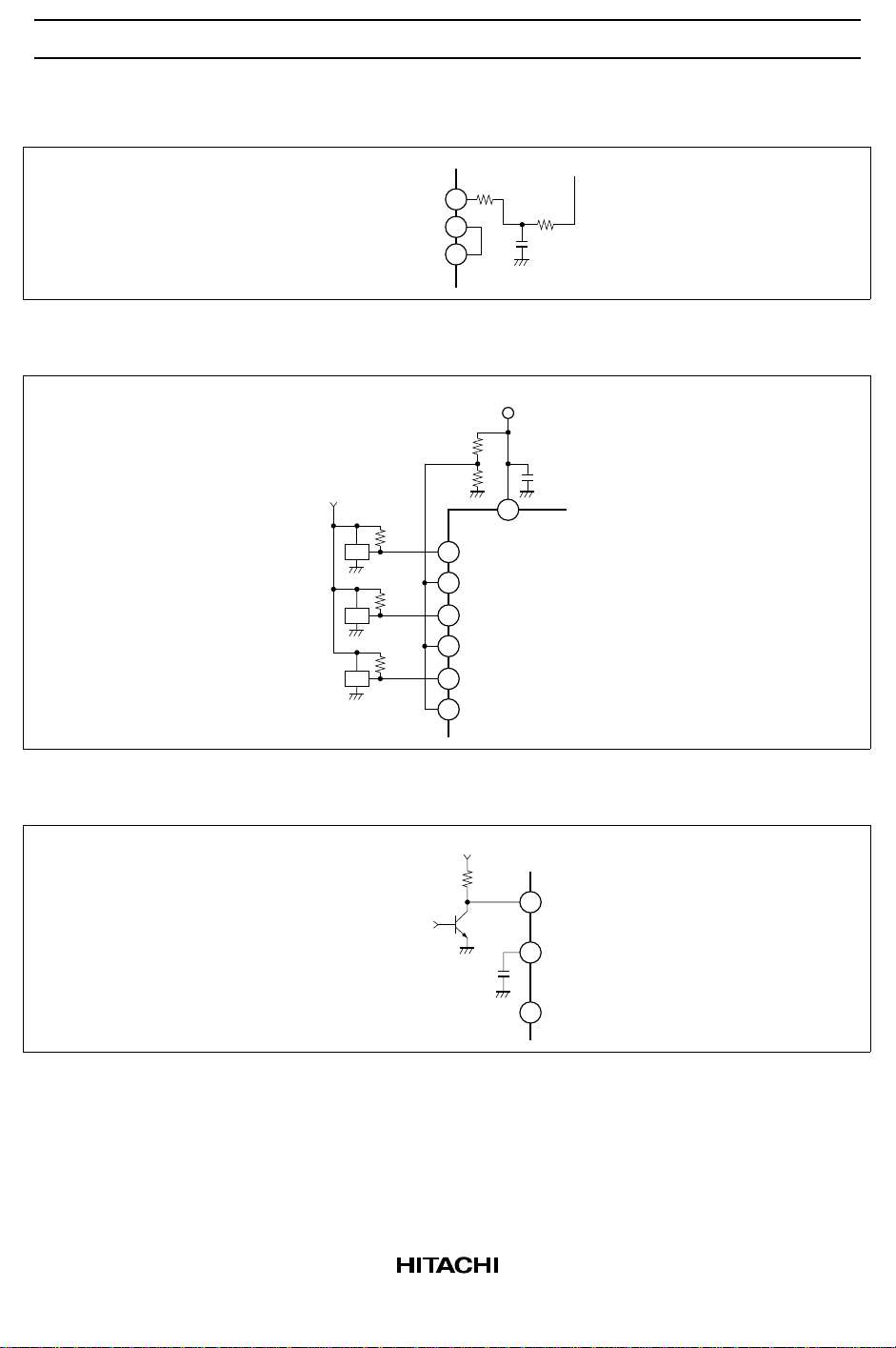

Application Circuits

Application Circuit 1 (Discriminator)

Error amplifier input

Buffer amplifier output

Integrator output

Integrator input

Discrimi-

natorPLL

13 14

Application Circuit 2 (MOS Transistor Circuit)

V

SS

C101

21

V

SS

C102

25

V

PS

U

U

V

V

W

W

17

18

16

C3

M1

M2

M3

M4

M5

M6

R2

R1

NF

C1

V

PS

D1

D2

D3

D4

D5

D6

15

19

ZD1

R114

R108

36

R109

35

R117

ZD2

R115

R110

34

R111

33

R118

ZD3

R116

R112

32

R113

31

R119

R

12

Application Circuit 3 (Current Feedback)

Current feedback input

Error amplifier input

Buffer amplifier output

Application Circuit 4 (Hall IC input)

V

SS

HA13609ANT

R

R125

27

17

18

V

SS

R103

R104

21

V

R122

IC

IC

IC

R123

R124

42

41

40

39

38

37

SS

U+

U–

V+

V–

W+

W–

NF

R121

C110

C101

Application Circuit 5 (External Reset Input)

External reset input

H: standby

V

SS

C108

R126

LVI

20

22

P.O.R

RST

8

13

HA13609ANT

External Components

Recommended

Part No.

R101, R102 — Hall element bias current 12

R103, R104 — Hall IC applications, Hall input voltage 14

R105 1MΩ Oscillator stabilization

R106, R107 — Current limiter reference voltage 15

R108 to R113 — Power transistor base current limiter 16

R114 to R119 — Power transistor base-emitter resistors (gate-source resistors) 16

R120 ≥ 4.7kΩ Current limiter filter 13

R121 — Current feedback input filter 9

R122 to R124 — Hall IC output current 14

R125 — Current feedback input gain adjustment 10

R126, R127 — LVI operating voltage, external reset input pull up 11

R

NF

R1 ≥ 1.5kΩ Integration constant, PWM carrier frequency 2, 3, 5

R2 — Integration constant 2

R3 to R7 — Integration constant 3

C101, C102 ≥ 0.1µF Power supply stabilization

C103, C104 10p to 50pF Oscillator stabilization 7

C105 — Lock protection operation time 4

C106 — PWM carrier frequency 5

C107 — Current limiter filter 13

C108 — Power-on reset delay time 11

C110 — Current feedback input filter 9

C111 to C113 — Hall output stabilization 8

C1 — Integration constant 2

C2 — Integration constant 2

C3, C4 — Integrator filter 3

ZD1 to ZD3 ≈ 20V MOS power transistor gate destruction protection 8

D1 to D6 — Fly wheel diodes 8

X’tal 4 to 8MHz Oscillator 6, 7

Notes: 1. Current limiter operates according to the following formula:

Value Purpose Note

— Current detection 1

V

Ref

Iop =

Here, V

[A]

R

NF

is the value according to the V

Ref

select function.

Ref

14

HA13609ANT

2. Use the following formulas as a guideline for setting the integration constant (@MD9 = 1). To

minimize rotation deviation, set R1 to a relatively small value.

2π

ωo ≤

R1

However, R1 must be in the range 1.5kΩ ≤ R1 ≤ 15kΩ.

20

9.55 · V

=

4 · J · ωo · No

· fMR · D1

· KT · R2

R1

· A

[rad/s]

[Ω]

C1 = 1 / (√10 · ωo · R2)

C2 = 10 · C1

Here, No : Rotation speed [min

f

: MR frequency [Hz]

MR

[F]

[F]

–1

]

D1 : Divider determined by D1 select

V

: Charge pump bias voltage 1.16 [V]

R1

K

: Motor torque constant [N·m/A]

T

J : Motor moment of inertia [kg·m

2

]

A : PWM comparator current gain [A/V]

Voltage feedback method: A =

Current feedback method: A =

V

: Power system power-supply voltage [V]

PS

V

: Motor back EMF [V

E

2Vps – 0.83V

R

G

B

NF

Rm · Vosc

– Vsat

E

P-P

/T·T]

Vsat : External transistor saturation voltage [V] (See the electrical characteristics)

Rm : Motor coil resistance [Ω/T·T]

Vosc : PWM amplitude voltage [V

G

: Buffer amplifier gain [V/V] (See the electrical characteristics)

B

] (See the electrical characteristics)

P-P

3. Use the following formulas as guidelines for setting the integrator filter:

First determine the angular frequency of ω

= 2π · fMR · D1 [rad/s]

ω

P

Determine the angular frequency of ω

9.55

1

No

·

J

≈

ω

M

KT ·

Vref

R

NF

– T

L

[rad/s]

for DIS OUT and PLL OUT.

P

for Motor.

M

Determine the ωo.

ωo = √ω

Determine the integrator’s DC gain G

(E)

· ωM [rad/s]

P

J · ωo

=

9.55 · KT · A

(E)

·G

Z

· D1 · 2π · Kø · PLL SEL

60

1

ωo

.

Here, Kø : PLL gain = 0.28 [V/rad/s]

T

: Rated load torque [N·m]

L

PLL SEL : PLL output ratio

Vref : Current limiter reference voltage [V]

Z : MR pulse per round [P/R]

15

HA13609ANT

Set C3 and derive the integration constants from following formulas.

R6 = 0 Ω

R3 =

ωP · C3

R3

R5 =

G

(E)

C4 =

2 · R5 · ωo

R7 = R5

Next, determine R4 to match the phase of PLL OUT.

R4

=

(V

Here, V

When log ω

required. Use the following formula to set the phase advance;

C5 · R8 >

DIS

PLL

4. The following formulas determine the stuck rotor protect detection time t

limiter operating time), the output off time t

operating waveforms.

t

t

t

See the electrical characteristics for the definitions of ∆V1, ∆V2, Isink, Isource, and Is.

(MD0k to 2 = Low)

LP

OFF

set

=

=

∆V1

Isink

=

Isource

V

P

1

1

(3.46 – V

– 1.2) – (1.9 – VP) · R3 / R5

P

P

) R3

: See the electrical characteristics.

is greater than 2, a phase advance to compensate for this phenomenon is

P/ωM

20 · 2

ω

P

R4

R6 R7

R8

R5

C4

C5

· C105 ≈ 0.09 × 106 · C105

∆V2

· C105 ≈ 0.32 × 106 · C105

LH2

· C105 ≈ 0.0005 × 106 · C105

Is

Standby

Enable

, and the setup time t

OFF

[sec]

[sec]

[sec]

(detects the current

LP

. The figures show the

set

Current limiter

operation

16

I

RNF

0

V

Lock

protect

pin

LH1

V

LH2

V

LL

0

t

set

t

LP

t

OFF

Output off

t

LP

∆V1

∆V2

Note that a capacitor with a leakage current sufficiently smaller that Isource must be used for

C105.

HA13609ANT

5. The PWM carrier frequency f

f

PWM

= 0.0489

1

C106 · R1

6. The relationships between the crystal oscillator frequency f

f

, the speed detection signal fMR, and the discriminator resolution (number of counts) C are

CLK

is determined by the following formula:

PWM

[Hz]

OSC

and the speed command clock

shown below.

= fMR·D1

f

CLK

f

= f

OSC

·1 / D2·C [Hz]

CLK

However, C must be in the range 1024 ≤ C ≤ 4095

Here, D1 : The MR signal divisor determined by D1 select

D2 : The crystal oscillator frequency divisor determined by D2 select.

Configuration of the speed control and phase control blocks when @MD9 = 0

Buffer amplifier

f

Speed signal

f

MR

SPEED CLK

f

CLK

D1

MR’

–+

CLK counter

Discriminator

counter setting

16

C3

R3

X’tal

f

OSC

D2

Discriminator

(1024 to 4095)

Charge

pump

15

R7

19

R1

4Icp

PLL

Discrimi-

nator

Vp

Discriminator

PLL SEL

4% pulse

output

14

PLL output

R4

R6

C4

13

R5

Note: If possible, Tr and Tf for the SPEED CLK signal should be under 20 ns when using this circuit.

17

HA13609ANT

g

Timing in phase control mode

f

MR'

≈ 3.6 V

Discriminator output

≈ 0 V

A A

ACC ACC

A × 4% A × 4%

ACCACC

PLL output

≈ 3.6 V

≈ 1.85 V

≈ 0 V

ACCACC

∆Vo

Integrator output

Configuration of the speed control block when @MD9 = 1

f

Speed signal

f

MR

SPEED CLK

f

CLK

D1

MR’

CLK counter

Discriminator

counter setting

X’tal

f

OSC

D2

Discriminator

(1024 to 4095)

Charge

pump

DEC DEC

Buffer

amplifier

16

C2

R2

R1

19

R1

4Icp

C1

Note: If possible, Tr and Tf for the SPEED CLK si

18

nal should be under 20 ns when using this circuit.

HA13609ANT

7. The table below lists reference values for the stabilization capacitors C103 and C104 for the

crystal oscillator element according to the frequency used.

X’tal (MHz) C103, C104 (pF)

4 to 6 ≈ 20 to 40

6 to 8 ≈ 10 to 20

Use a resonance resistance of under 50Ω as a criterion for selecting the crystal element used.

8. Include these components if required.

9. The cutoff frequency of the filter formed by C110 and R121 should be between 3 and 10 times

the PWM oscillator frequency.

10.The gain, G

= 1 +

G

CTL

11.The formulas below determine the relationship between capacitor C108, which sets the power on

reset (POR) delay time, and the resistors R126 and R127, which set LVI.

V

= V

LVI

However, V

V

= R126 · I

HYS

However, V

t

= 0.052 × 106 · C108 [sec]

POR

The time t

longer.

, from the error amplifier input to RNF is given be the following formula:

CTL

Rif

R125

SD

V

R127

> 3V

LVI

HYS

– V

LVI

POR

LVI

> 2.5V

HYS

is the time required for the oscillator to reach stability. This time should be 20ms or

V

HYS

R126

1 +

[V]

[V]

VSD, I

: See the electrical characteristics.

HYS

V

SS

< 2.0 V

0 V

2.0 V

0 V

0 V

1.3 V

t

POR

t

POR

POR

RST

When using an external reset input to set the IC to the standby state, pin 20 must be set to a low

level that is under 0.4V.

12. When the Hall inputs are common mode input, the open circuit protection circuit makes the

output transistors non-operational. When all the Hall input phases are open, the lower side

output transistors become non-operational.

The output transistors will be disabled if one or two phases are disconnected (become open) only

when the Hall inputs are common mode.

19

HA13609ANT

13.When setting up the current limiter filter consisting of R120 and C107, R120 should be 4.7k Ω or

larger, and C107 and R120 should function as a filter for the recovery current. This filter masks

the recovery current due to internal circuits for the current limiter input (pin 26) and the C107

discharge operation determines the PWM off time (by making the current limiter input a low

impedance). See the figures.

Output (U to W)

V

RNF

1/f

PWM

ON ON

C107 discharge

t

MASK

t

MASK

Current limiter input

voltage (pin 26)

≈ 0 V

For recovery current masking:

t

MASK

48

= [SEC]

fosc

64

to

fosc

@MD8 = 1

t

MASK

24

= [SEC]

fosc

32

to

fosc

@MD8 = 0

14. Use the formula below as a guideline for determining the values of R103, R104, and R122 to

R124 when a Hall IC is used.

R103 // R104 = R122 to R124 < 20kΩ

15.Take the current limiter input current (see the electrical characteristics) into consideration when

determining the values for R106 and R107.

16.Determine the values of R108 to R119 based on the characteristics of the output power

transistors used and the output driver characteristics (see the electrical characteristics).

17. Design the wiring in applications so that the potential of the pin 11 ground (the small-signal

ground) does not become higher than that of the pin 30 ground (the output stage ground) as

shown in the figure.

V

SS

11 30

20

HA13609ANT

Absolute Maximum Ratings

Item Symbol Rated Value Unit Note

Power-supply voltage V

Input voltage V

SS

V

PS

IN

Output voltage Vout 50 V 4

Output current Iout 30 mA 5

Allowable power dissipation P

T

Operating temperature Topr –20 to 70 °C

Storage temperature Tstg –55 to +125 °C

Notes: 1. A surge voltage of 6.0V is allowed for up to 10ms. Note that the operating range is as follows:

V

= 4.25 to 5.5V

SS

2. The maximum is VSS if bipolar transistors are used as the output transistors.

The maximum is 50 V if bipolar transistors are used as the output transistors.

3. Applies to the logic input pins 1, 2, 3, 5, and 9, and to the analog input pins 17, 20, 24, 26 to 29,

and 37 to 42.

4. Applies to the output pins 32, 34, and 36, and to pin 7, the monitor output pin.

5. Applies to the output pins 31 to 36. The maximum value for the monitor output pin is 10mA.

5.5 V 1

VSS to 50 V 2

V

SS

V3

0.8 W

21

HA13609ANT

O

O

O

Electrical Characteristics

Item Symbol Min Typ Max Unit

Current drain I

Logic

inputs

Input lowlevel current

Input high-

I

I

I

I

I

SSO

SS

PSO

PS

IL

IH

— 3.0 6.5 mA MD0 to 2 = 0,

— 15 25 mA MD0 to 2 = 1,

— 0.13 0.5 mA MD0 to 2 = 0,

— 2.5 3.5 mA MD0 to 2 = 1,

— –50 –100 µA 1 to 3, 5, 9

—0 ±10 µA

level current

Input low-

V

IL

— — 1.5 V

level voltage

Input high-

V

IH

3.5 — — V

level voltage

Clock

f

CLK

4 — 20 MHz 9

frequency

Logic

outputs

Output highlevel voltage

Output low-

V

OH1

V

OL1

3.5 4.6 — V IOH = 0.5mA 4, 6, 8, 10

— 0.25 0.4 V IOL= 0.5mA

level voltage

Hall

amplifier

Input

resistance

Common-

Rh — 10 ±25% kΩ 37 to 42

Vh 1.5 — VSS–1.5 V

mode input

voltage range

Differential-

Vd 70 — VSS/2 mV

mode input

voltage range

Output

drivers

Hysteresis V

Output high-

level voltage

HYS

V

OH2

V

OH2

V

OH2

— 40 — mV Rh = 400Ω 1, 2

VPS–1.8 VPS–1.6 — V I

10 12.5 15 V I

5.5 9.0 — V I

Test

Condition

VSS = 5.5V

VSS = 5.5V

VPS = 50V

no load,

VPS = 50V

= 20mA,

H

VPS = V

SS

= 1mA,

H

VPS = 24V

= 1mA,

H

VPS = 12V

Applicable

Pins Notes

21 6

25 6

31, 33, 35

22

Electrical Characteristics (cont)

SS

HA13609ANT

Item Symbol Min Typ Max Unit

Output

drivers

Output leakage

current

Output low-

I

LEAK

V

OL2

——±100 µAV

— 0.15 0.3 V IOL = 20mA 31 to 36

level voltage

Output

T

PHI

— — 1.0 µsIO = 10mA 3

response time

PWM

oscillator

Oscillator lowlevel voltage

T

PLH

V

L

— — 1.0 µs

— 1.1 ±10% V 12

and

PWM

com-

Oscillator highlevel voltage

V

H

— 2.8 ±10% V

parator

Oscillator

f

PWM

2 — 30 kHz 2

frequency

range

Oscillator

ferr1 — 7.7 ±10% kHz f

frequency

precision

Comparator

V

PHYS

— 50 — mV 2

hysteresis

Current

Input current I

IN1

——±10 µA Vi = 0 to 2V 24, 26

limiter

Speed

detection

amplifier

Offset voltage V

Common-mode

input voltage

range

Differential-

OFF

V

CM

V

DIFF

–15 –25 –40 mV Vi = 0.5 to 2V 26

1.5 — V

V 28, 29

–1.5

60 — V

SS

mV

mode input

voltage range

Gain Gain — 32 — dB f = 1kHz 2

Input current I

Input current

IN2

I

28

I

29

Iratio 1.45 — 2.25 — I28 / I

——±20 µA Vi = 1.4V

–146 –95 –62 µA Vi = 0V

–67 –53 –39 µA Vi = 0V

ratio

Input sensitivity V

S

15——mV 6 2

P-P

Test

Condition

= 50V 32, 34, 36

OH1

× 1,

PWM

R1 = 6.2kΩ,

C106 =

1000pF

29

Applicable

Pins Notes

23

HA13609ANT

Electrical Characteristics (cont)

Item Symbol Min Typ Max Unit

Clock

oscillator

Oscillator

frequency range

Oscillator

fosc 4 — — MHz X’tal 9, 10

ferr2 — — ±0.01 % X’tal = 8MHz 2

frequency

precision

Program

Count range N 1024 — 4095 Count 14, 16

-mable

discrimi-

nator

Operating

frequency

fdis — — 20 MHz 4

Count error DC 0 — 1LSB —

Charge

R1 voltage V

R1

— 1.16 ±10% V R1 = 1.5kΩ 19

pump

Charge current I

Discharge

I

CP+

CP–

— 190 ±10% µA R1 = 1.5kΩ,16

— 190 ±10% µA Vo = 2.0V

current

Current ratio I

CP+/ICP–

0.8 1.0 1.2 —

Leakage current Ioff1 — — ±100 nA Vi = 1.5V

Clamp voltage Vclamp 2.8 3.0 — V

Digital

ready

Lock range

manufacturing

∆N——±25 % 7

variation

Precharge

Buffer

amplifier

Clamp

voltage (1)

Internal

reference

Vcp(1) — Vp ±10% V 16

Vref — 1.15 ±10% V 16

voltage

Output

Ro 9.8 14 18.2 kΩ 18

resistance

Maximum output

V

B(MAX)

— 0.7 ±10% V

voltage

Error

Voltage gain G

Input current I

B

IN3

–8 –6 –4 dB

——±150 nA Vi = 1.5V 17, 27

amplifier

Offset voltage Voff — –25 –50 mV

Voltage gain Ge — 60 — dB Vi = 2.5V 2

Gain-bandwidth

Be — 0.1 — MHz 2

product

Feedback

Rif — 40 ±25% kΩ VSS = 5V

resistance

Test

Condition

Applicable

Pins Notes

24

Electrical Characteristics (cont)

HA13609ANT

Item Symbol Min Typ Max Unit

Integrating

amplifier

Internal

reference

voltage

Internal

Vp — 2.2 ±10% V DD6 to 8 = 0 15, 16

∆Vp — 2.2+∆Vp ±10% V

reference

voltage

difference

Input current I

Output voltage V

Voltage gain G

Gain-

IN4

OH3

V

OL3

I

B

I

—— ±250 nA Vi = 1.5V

2.75 3.0 — V Io = 0.5mA

— — 0.9 V Io = 0.5mA

— 60 — dB Vi = 2.5V 2

— 0.3 — MHz 2

bandwidth

product

PLL and

offset

discriminator

Output highlevel voltage

Output lowlevel voltage

V

OH4

V

OL4

— 3.6 ±10% V Io = 0.1mA 13, 14

— 0.1 0.2 V

output

Monitor

output

Output leakage

current

Output low-

I

LEAK2

V

OL5

—— 50µAVOH = 50V 7

— 0.2 0.4 V IOL = 10mA

level voltage

Stuck

rotor

Minimum

detection time

t

LP

—40 ±25% ms C105 = 0.47µF23 2

protector

Output off time t

High-level V

voltage V

Low-level

OFF

LH1

LH2

V

LL

— 165 ±25% ms

3.0 3.2 — V

2.5 2.7 — V

— 1.4 1.6 V

voltage

Potential ∆V1 — 1.9 ±10% V V

difference ∆V2 — 1.35 ±10% V V

Detection-time

I

SINK

—25 ±30% µA Pin 23 voltage

sink current

Output off

I

Source

— 5.0 ±30% µA Pin 23 voltage

source current

Standby-mode

I

S

— 4.7 ±35% mA Pin 23 voltage

source current

Test

Condition

LH1–VLL

LH2–VLL

= 2.5V

= 2.5V

= V

LH

Applicable

Pins Notes

2

25

HA13609ANT

Electrical Characteristics (cont)

Item Symbol Min Typ Max Unit

LVI Internal reference

voltage

Hysteresis

current

Output voltage

maintained range

P.O.R Delay time t

Vsd 1.13 1.21 1.29 V Turn on 20

I

V

HYS

LV

POR

—50±25% µA

2.0 — — V 21

— 24.5 ±25% ms C108 = 0.47µF 8, 22

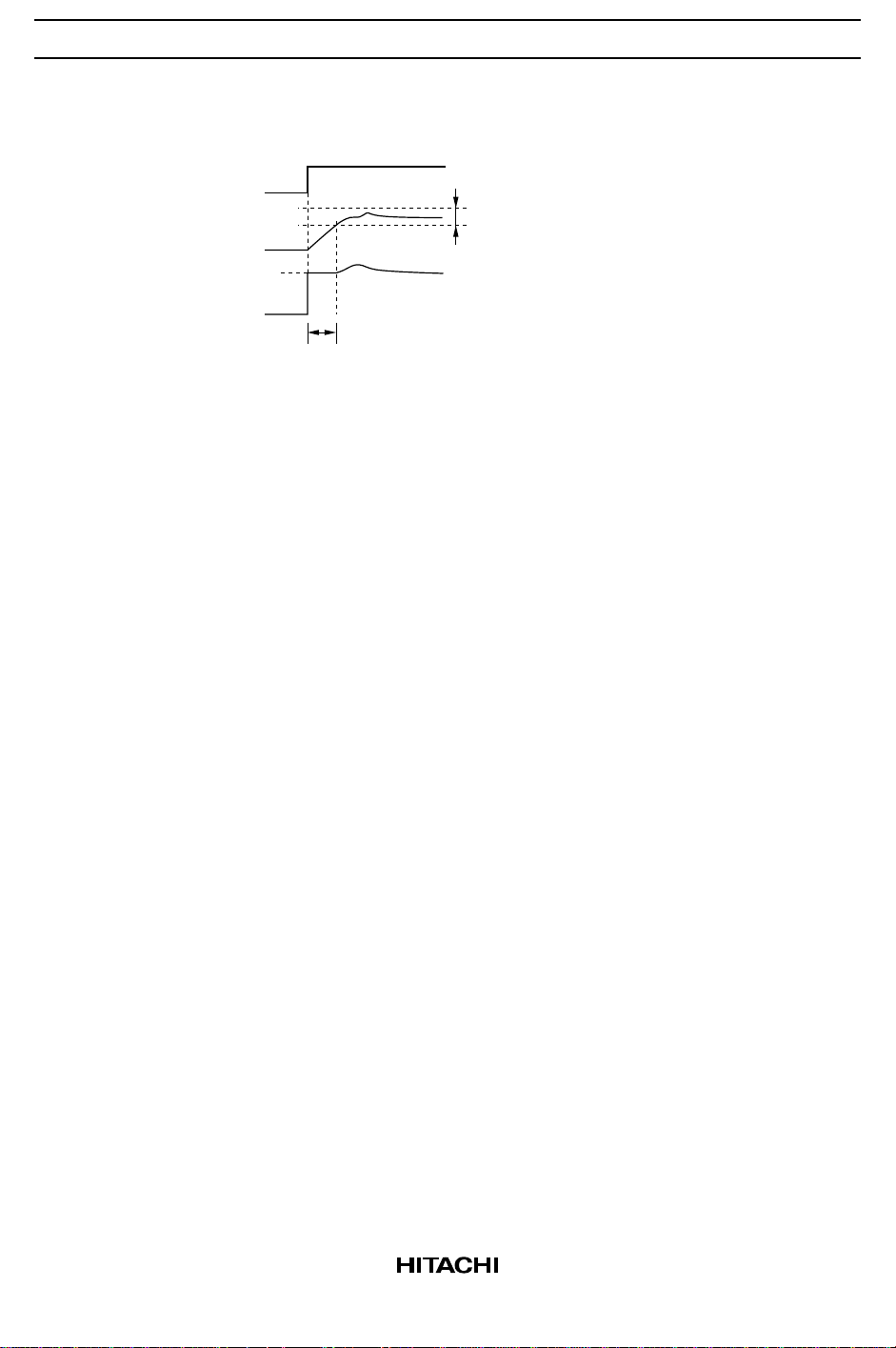

Notes: 1. Timing chart

2. Design target values. These are not tested at delivery time.

3. The figure below stipulates the output response time. This is not tested at delivery time.

90%

10%

T

PLH

T

PHL

4. Stipulated at the discriminator input frequency.

5. See the timing charts.

6. Stipulated at conditions in which the OSC input is fixed.

Test

Condition

Applicable

Pins Notes

26

Reference Data

Current Drain vs. Supply Voltage Current Drain vs. Supply Voltage

30

Tj = 25°C

HA13609ANT

4

Tj = 25°C

(mA)

20

SSO

, I

SS

10

Current Drain I

0

1.5 4.5

0

2.5 3.5 5.5

Supply Voltage V

Output Driver Low-Level Voltage vs.

Output Current

0.4

(V)

OL

0.3

SS

(V)

I

SS

I

SSO

Tj = 125°C

3

(mA)

PSO

, I

PS

2

1

Current Drain I

0

0

20 30 50

Supply Voltage V

Output Driver High-Level Voltage vs.

Output Current

15

(V)

OH

10

Tj = 125°C Tj = 25°C

V

= 50 V

PS

PS

(V)

I

PS

I

PSO

4010

Tj = –20°C

0.2

0.1

Output Driver Low-Level Voltage V

0

0

10 20 30

Output Current I

O

(mA)

Tj = 25°C

Tj = –20°C

5

Output Driver High-Level Voltage V

0

0

Output Current I

Tj = 125°C Tj = 25°C

V

= 50 V

PS

10 20 30

(mA)

O

Tj = –20°C

27

HA13609ANT

PWM Frequency vs.

Junction Temperature

10.0

9.0

(kHz)

PWM

C106 = 1000 pF

R1 = 6.2 kΩ

× 1

f

PWM

8.0

7.0

PWM Frequency f

–20 40 70 125

10 100

Junction Temperature Tj (°C)

Error Amplifier Rif vs.

Junction Temperature

70

R1 Voltage vs.

Junction Temperature

1.4

1.3

(V)

R1

1.2

R1 Voltage V

1.1

–20 40 70 12510 100

Junction Temperature Tj (°C)

Integrator vs.

Junction Temperature

2.4

R1 = 6.2 kΩ

(V)

60

50

40

Error Amplifier Rif (kΩ)

30

P

2.3

2.2

2.1

2.0

Integrator Reference Voltage V

–20 40 70 12510 100–20 40 70 12510 100

Junction Temperature Tj (°C)

Junction Temperature Tj (°C)

28

HA13609ANT

Monitor Output vs.

Output Current

0.4

0.3

(V)

OL

Tj = 125°C

0.2

Tj = 25°C

0.1

Monitor Output V

0

0 46 1028

Tj = –20°C

Output Current IO (mA)

LVI Reference Voltage vs.

Junction Temperature

1.4

Lock Protector vs.

Junction Temperature

300

(ms)

200

OFF

, t

LP

t

OFF

100

Lock Protector t

t

LP

0

–20 40 70 12510 100

Junction Temperature Tj (°C)

POR Delay Time vs.

Junction Temperature

30

C105 = 0.47 µ

C108 = 0.47 µ

(V)

1.3

SD

1.2

1.1

LVI Reference Voltage V

Junction Temperature Tj (°C)

25

(ms)

POR

20

15

POR Delay Time t

–20 40 70 12510 100–20 40 70 12510 100

Junction Temperature Tj (°C)

29

HA13609ANT

Package Dimensions

42

1

37.34

38.0 Max

0.89

1.27 Max

1.0

Unit: mm

22

13.4

14.6 Max

21

15.24

5.10 Max

+ 0.10

0.25

0.48 ± 0.101.78 ± 0.25

0.51 Min

1° – 13°

2.54 Min

– 0.05

Hitachi Code

JEDEC Code

EIAJ Code

Weight

DP-42SA

—

SC-551-42

4.42 g

30

Cautions

1. Hitachi neither warrants nor grants licenses of any rights of Hitachi’s or any third party’s patent,

copyright, trademark, or other intellectual property rights for information contained in this document.

Hitachi bears no responsibility for problems that may arise with third party’s rights, including

intellectual property rights, in connection with use of the information contained in this document.

2. Products and product specifications may be subject to change without notice. Confirm that you have

received the latest product standards or specifications before final design, purchase or use.

3. Hitachi makes every attempt to ensure that its products are of high quality and reliability. However,

contact Hitachi’s sales office before using the product in an application that demands especially high

quality and reliability or where its failure or malfunction may directly threaten human life or cause risk

of bodily injury, such as aerospace, aeronautics, nuclear power, combustion control, transportation,

traffic, safety equipment or medical equipment for life support.

4. Design your application so that the product is used within the ranges guaranteed by Hitachi particularly

for maximum rating, operating supply voltage range, heat radiation characteristics, installation

conditions and other characteristics. Hitachi bears no responsibility for failure or damage when used

beyond the guaranteed ranges. Even within the guaranteed ranges, consider normally foreseeable

failure rates or failure modes in semiconductor devices and employ systemic measures such as failsafes, so that the equipment incorporating Hitachi product does not cause bodily injury, fire or other

consequential damage due to operation of the Hitachi product.

5. This product is not designed to be radiation resistant.

6. No one is permitted to reproduce or duplicate, in any form, the whole or part of this document without

written approval from Hitachi.

7. Contact Hitachi’s sales office for any questions regarding this document or Hitachi semiconductor

products.

Hitachi, Ltd.

Semiconductor & Integrated Circuits.

Nippon Bldg., 2-6-2, Ohte-machi, Chiyoda-ku, Tokyo 100-0004, Japan

Tel: Tokyo (03) 3270-2111 Fax: (03) 3270-5109

URL NorthAmerica : http:semiconductor.hitachi.com/

For further information write to:

Hitachi Semiconductor

(America) Inc.

179 East Tasman Drive,

San Jose,CA 95134

Tel: <1> (408) 433-1990

Fax: <1>(408) 433-0223

Europe : http://www.hitachi-eu.com/hel/ecg

Asia (Singapore) : http://www.has.hitachi.com.sg/grp3/sicd/index.htm

Asia (Taiwan) : http://www.hitachi.com.tw/E/Product/SICD_Frame.htm

Asia (HongKong) : http://www.hitachi.com.hk/eng/bo/grp3/index.htm

Japan : http://www.hitachi.co.jp/Sicd/indx.htm

Hitachi Europe GmbH

Electronic components Group

Dornacher Stra§e 3

D-85622 Feldkirchen, Munich

Germany

Tel: <49> (89) 9 9180-0

Fax: <49> (89) 9 29 30 00

Hitachi Europe Ltd.

Electronic Components Group.

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire SL6 8YA, United Kingdom

Tel: <44> (1628) 585000

Fax: <44> (1628) 778322

Hitachi Asia Pte. Ltd.

16 Collyer Quay #20-00

Hitachi Tower

Singapore 049318

Tel: 535-2100

Fax: 535-1533

Hitachi Asia Ltd.

Taipei Branch Office

3F, Hung Kuo Building. No.167,

Tun-Hwa North Road, Taipei (105)

Tel: <886> (2) 2718-3666

Fax: <886> (2) 2718-8180

Copyright ' Hitachi, Ltd., 1999. All rights reserved. Printed in Japan.

Hitachi Asia (Hong Kong) Ltd.

Group III (Electronic Components)

7/F., North Tower, World Finance Centre,

Harbour City, Canton Road, Tsim Sha Tsui,

Kowloon, Hong Kong

Tel: <852> (2) 735 9218

Fax: <852> (2) 730 0281

Telex: 40815 HITEC HX

Loading...

Loading...