Henny Penny

Pressure Fryer

Model PFG-691

TECHNICAL MANUAL

Model 691

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the rear shroud cover of the control panel.

Post in a prominent location, instructions to be followed if user smells gas. This information

should be obtained by consulting the local gas supplier .

Do not obstruct the flow of combustion and ventilation air . Adequate clearance must be left all

around appliance for sufficient air to the combustion chamber .

The Model PFG-691 pressure fryer is equipped with a continuous pilot. But fryer cannot be operated

without electric power . Fryer will automatically return to normal operation when power is restored.

Keep appliance area fr ee and clear from combustibles.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. FIRE OR

EXPLOSION COULD RESUL T .

1 10 3 FM06-007 Revised 10-09-08

Model 691

HENNY PENNY

8 HEAD GAS PRESSURE FRYER

SPECIFICATIONS

Height 61" (155 cm)

Width 24" (61 cm)

Depth 41¾" (106 cm)

Floor Space Approximately 7 sq. ft. (0.65 sq. m.)

Pot Capacity 8 Head of chicken (32 lbs.) (14.4 kg.)

130 lbs. shortening (59 kg.)

Electrical 120 VAC, 1 Phase, 50/60 Hz, 10 Amp, 2 W ire + Ground

240 VAC, 1 Phase, 50/60 Hz, 5 Amp, 2 W ire + Ground

Heating Propane or Natural Gas; 100,000 BTU/hr.

Pressure 9 psi operating pressure (621 mbar)

14.5 psi safety relief pressure (999 mbar)

Shipping W eight Approximately 800 lbs. (363 kg.)

Accessories Shipped Eight wire baskets, basket carrier, and standard cleaning

brushes

A data plate, located on the right side panel, gives the information of the type of fryer,

serial number, warranty date, and other information pertaining to fryer .

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING............................................................................................. 1-1

1-1 Introduction .................................................................................................... 1-1

1-2 Safety ............................................................................................................. 1-1

1-3 Troubleshooting ..............................................................................................1-2

1-4 Error Codes .................................................................................................... 1-11

Section 2. MAINTENANCE.......................................................................................................2-1

2-1 Introduction .................................................................................................... 2-1

2-2 Maintenance Hints .........................................................................................2-1

2-3 Preventive Maintenance ................................................................................ 2-1

2-4 High Temperature Limit Control ....................................................................2-1

2-5 Power/Pump Switch ...................................................................................... 2-4

2-6 Temperature Probe Replacement .................................................................. 2-5

2-7 Complete Control Panel - Henny Penny ........................................................ 2-6

2-8 Pressure Regulation .......................................................................................2-6

2-9 Tilting the Lid Upright..................................................................................... 2-7

2-10 Reversing the Lid Gasket ...............................................................................2-8

2- 1 1 Lid Counterweight Cables .............................................................................. 2-9

2-12 Pressure Pads ................................................................................................ 2-11

2-13 Lid Adjustment ............................................................................................... 2-12

2-14 Solenoid V alve ................................................................................................ 2-13

2-15 Deadweight Valve .......................................................................................... 2-15

2-16 Removal of Safety Valve ............................................................................... 2-16

2-17 Pressure Gauge .............................................................................................. 2-17

2-18 Gas Control Valve .......................................................................................... 2-18

2-19 Blower Assembly ........................................................................................... 2-20

2-20 Transformer....................................................................................................2-21

2-21 Airflow Switch ............................................................................................... 2-22

2-22 Drain Microswitch ......................................................................................... 2-23

2-23 Drain Valve and Extension ............................................................................. 2-24

2-24 Air Valve ........................................................................................................ 2-25

2-25 Cleaning the Dilution Box............................................................................... 2-26

2-26 Cleaning the Blower Wheel ........................................................................... 2-26

2-27 Ignition Modules ............................................................................................. 2-27

2-28 Ignitor Assembly ............................................................................................ 2-28

2-29 Flame Sensor Assembly................................................................................. 2-29

2-30 Ignitor and Flame Sensor Adjustment ............................................................ 2-29

2-31 Nylatron Strips Replacement .........................................................................2-30

2-32 Lubricating Lid Rollers ................................................................................... 2-31

120 V olt W iring Diagram ................................................................................ 2-32

208-240 V olt W iring Diagram ......................................................................... 2-33

230 V olt W iring Diagram ................................................................................ 2-34

230 Volt Ladder Diagram ............................................................................... 2-35

Model 691

304 i

TABLE OF CONTENTS

Section Page

Section 3. P AR TS INFORMATION ........................................................................................... 3-1

3-1 Introduction .................................................................................................... 3-1

3-2 Genuine Parts ................................................................................................. 3-1

3-3 When Ordering Parts ..................................................................................... 3-1

3-4 Prices .............................................................................................................3-1

3-5 Delivery .......................................................................................................... 3-1

3-6 Warranty ........................................................................................................ 3-1

3-7 Recommended Spare Parts for Distributors .................................................. 3-1

Model 691

ii 106

Model 691

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION This section provides troubleshooting information in the form

of an easy-to-read table.

If a problem occurs during the first operation of a new fryer,

recheck the installation per the Installation Section of the

Operator’s Manual.

Before troubleshooting, always recheck the Operation Section of

the Operator’s Manual.

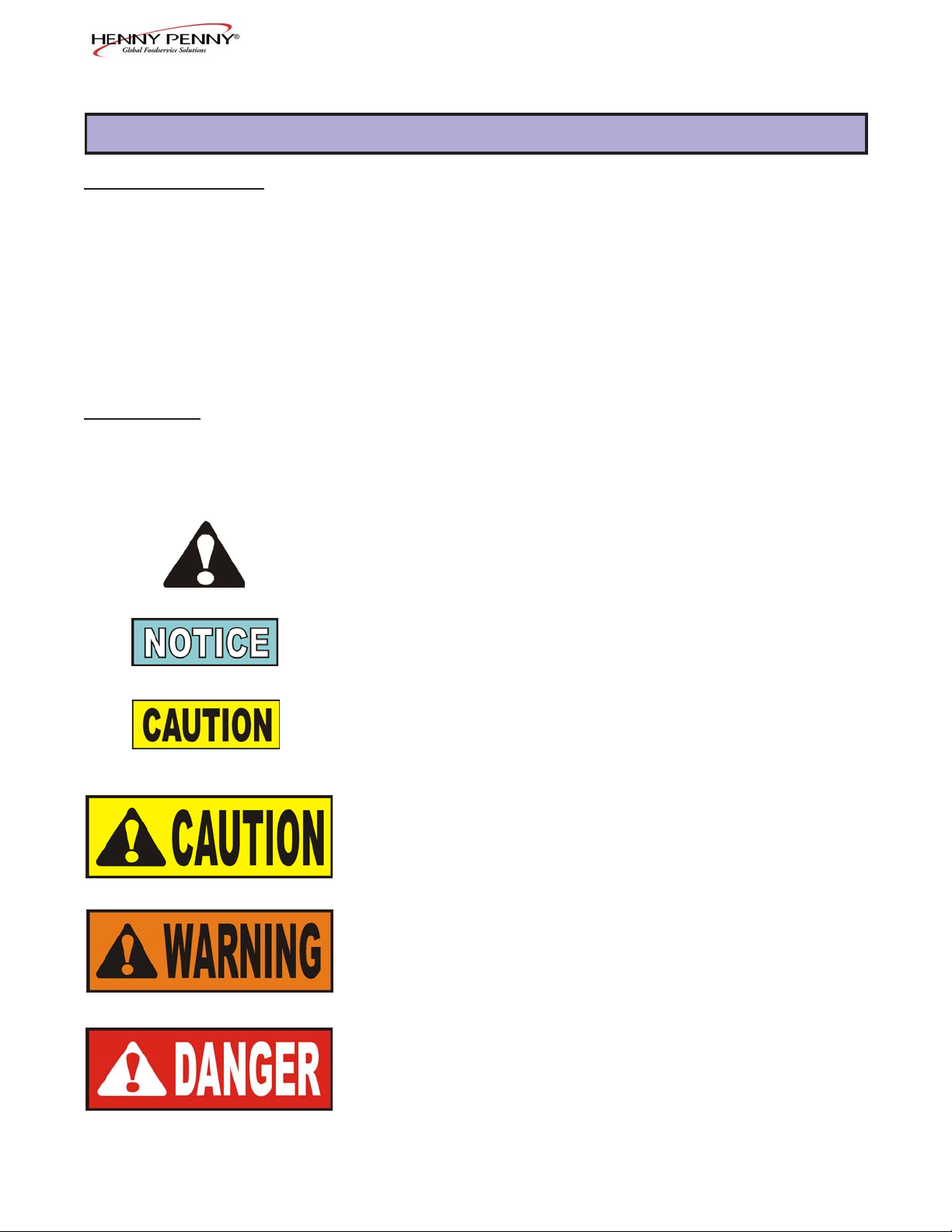

1-2. SAFETY

Where information is of particular importance or safety related,

the words DANGER, WARNING , CAUTION, and NOTICE

are used. Their usage is described below .

SAFETY ALER T SYMBOL is used with DANGER,

W ARNING, or CAUTION which indicates a personal injury

type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICA TES AN IMMINENTL Y

HAZARDOUS SITUA TION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEATH OR SERIOUS

INJURY.

1-1

1-3. TROUBLESHOOTING T o isolate a malfunction, proceed as follows:

1. Clearly define the problem (or symptom) and when it

occurs.

2. Locate the problem in the Troubleshooting table.

3. Review all possible causes. Then, one at a time, work

through the list of corrections until the problem is solved.

4. Refer to the maintenance procedures in the Maintenance

Section to safely and properly make the checkout and repair

needed.

Model 691

If maintenance procedures are not followed corr ectly,

injuries and/or property damage could result.

1-2

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

COOKING SECTION

Product color not correct:

Model 691

A. Too dark

B. T oo light

• Temperature too high • Check temperature setting

in the program mode; see

programming section of

Operator’s Manual

• Faulty temperature probe • Remove and replace tempera-

ture probe

• Shortening too old • Change shortening

• Shortening too dark • Filter shortening

• Change shortening

• Breading product too far • Bread product closer to

in advance actual frying period

• Temperature too low • Check temperature setting.

• Remove and replace tempera-

ture probe

• Fryer incorrect preheat • Allow proper preheat time

C. Product

greasy

• Slow fryer heat-up/recovery • Check gas pressure and blower

airflow

• Wrong cook button • Be sure to select the

pushed correct product to be cooked

• Shortening old • Replace shortening

• Temperature too low • Check temperature setting

• Temperature not recovered

when product was dropped

in frypot

• Faulty temperature probe • Remove and replace defective

temperature probe

• Burner out of adjustment. • Check blower airflow for

restriction

• Frypot overloaded • Reduce cooking load

• Product not removed from • Remove product from

frypot immediately after frypot immediately after

depressurization depressurization

1-3

Model 691

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

COOKING SECTION (Continued)

D. Spotted • Improper separation of the • Load product into basket

product product properly

• Breading not uniform on • Sift breading regularly

the product

• Separate product during

breading

• Burned breading particles • Filter the shortening more

on product frequently

• Product sticking together • Separate product prior to

pressure cooking

E. Dryness of product • Moisture loss prior to • Use fresh products

cooking

• Overcooking the product • Reduce cooking time

• Reduce cooking temperature

• Low operating pressure • Check pressure gauge leaks

reading, check for pressure

• W rong cook button pushed • Be sure to select the correct

product to be cooked

Product flavor (taste):

A. Salty taste • Breading mixture is too salty • Sift breading after each use

• Incorrect breading mixture

• Discard old breading

• Incorrect choice of breading • Use breading designed for

the desired product

B. Burned taste • Burned shortening flavor • Replace shortening

• Cookpot not properly cleaned • Drain and clean frypot

C. Bland taste • Raw product not fresh • Use fresh raw product

1-4

• Breading mixture incorrect • Use breading designed for

for product (spice content desired product

too low)

• Cooking temperature too • Check temperature

high (spice flavors lost)

Model 691

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

COOKING SECTION (Continued)

D. Rancid taste • Shortening too old • Replace shortening and

follow recommended care

and use of shortening

• Infrequent filtering • Replace shortening and

follow recommended care

and use of shortening

• Non-compatible products • Replace shortening

cooked within the same

shortening follow recommended care and

• Use compatible products and

use of shortening

• Raw product not fresh • Use fresh product

General:

A. Meat

Separation procedures

from bone

• Incorrect meat cut • Use correct meat cutting

• Overcooking • Check cooking time

• Product not fresh • Use fresh product

B. Bone color

not proper (black bone)

• Using frozen product • Use fresh product

• Improper processing of • Use proper processing

product (black bone) procedure for product

• Product not thoroughly • Check cooking time

cooked (red bone)

C. Breading falls

off procedure

• Incorrect breading procedures • Use correct breading

• Check cooking temperature

• Product partially frozen • Thoroughly thaw the product

before breading

D. Product • Product breaded too long • Refer to breading and

sticking prior to cooking frying instructions

together

• Improper loading procedure • Properly load product per

loading procedures

• Wrong cook button pushed • Select the correct amount of

product to be cooked

1-5

Model 691

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

POWER SECTION

With switch in • Open circuit • Check to see that unit is

POWER position, plugged in

the fryer is completely

inoperative at supply box

(no power) • Check voltage at wall

• Check the breaker or fuse

receptacle

• Check POWER switch;

replace if defective

• Check cord and plug

PRESSURE SECTION

Pressure will not • Exhaust line from solenoid • T urn unit of f and allow

exhaust at end of valve to exhaust tank fryer to cool to release

cook cycle clogged pressure from frypot;

clean all pressure lines,

exhaust stacks, and exhaust

tank

• Solenoid valve clogged • Check and clean solenoid

valve

Operating

pressure too high fryer to cool to release

• Deadweight clogged • T urn unit of f and allow

pressure from frypot;

remove deadweight and clean

• Exhaust line to stack clogged • Clean exhaust line to stack

DO NOT OPERATE UNIT. IF HIGH PRESSURE CONDITIONS EXIST, SEVERE

INJURIES AND BURNS WILL RESULT. PLACE THE POWER/PUMP SWITCH IN THE

OFF POSITION IMMEDIATELY. RELEASE THE PRESSURE BY ALLOWING UNIT TO

COOL. THE PRESSURE WILL THEN DROP. DO NOT RESUME USE OF UNIT UNTIL

CAUSE OF HIGH PRESSURE HAS BEEN FOUND AND CORRECTED.

1-6

Model 691

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

PRESSURE SECTION (Continued)

Pressure does not • Not enough product in fryer • Place proper quantity of

build or product not fresh fresh product within

frypot to generate steam

• Metal shipping spacer not • Remove shipping spacer;

removed from deadweight see Unpacking section of

Operator’s Manual

• Lid open or not latched • Close and latch lid

• Solenoid valve leaking or • Check or clean solenoid

not closing valve

• Deadweight valve leaking • Repair or replace fittings, or

deadweight body

• Pressure not programmed • Check programming

• Lid gasket leaking • Reverse gasket or lid needs

adjusted

• Safety relief valve leaking • Check and replace, if

necessary

• Pressure plate broken or crushed • Replace pressure plate

1-7

Model 691

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

HEA TING OF SHORTENING SECTION

Shortening will • Blown fuse or tripped • Reset breaker or replace fuse

not heat (“E-20”) circuit breaker at supply

box or control panel

• Blown fuse in PC board • Replace glass fuse in board

• Faulty Power/Pump switch • Check Power/Pump switch

• Faulty cord and plug; • Check cord and plug and

check power at receptacle power at wall receptacle

• Faulty drain switch • Check drain switch

• Faulty PC Board • Remove and replace control

panel

• Faulty high limit control • Check high limit control

switch switch; replace if necessary

• Drain valve open • Close drain valve

• Possible faulty gas control • With power removed from

valve fryer, check across electrical

leads of gas control valve with

multimeter, and with gas valve

knob to ON position

• Possible faulty temperature probe • Replace temperature probe

(“E-6”)

• Bad ignitor • Replace ignitor

• Low air pressure into • Clean or replace blower

burner chamber • Replace air pressure switch

• Faulty ignitor module • Replace module

• Spark ignitor or flame sensor • The spark ignitor needs to be

out of adjustment 1/8 in. (3.18 mm) from the

pilot hood, and the flame

sensor, 1/4 in. (6.35 mm)

1-8

• Gas valve knob turned to the • Make sure the gas valve

OFF position knob is turned to the ON

position

Model 691

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

HEA TING OF SHORTENING SECTION (Continued)

Heating of • Supply line too small; low • Increase supply line size

shortening too gas volume Refer to installation

slow instructions

• Improper ventilation • Refer to installation

system instructions

• Observe burners

• Check gas pressure

• Improper air flow to burners • Check blower for resriction of

airflow

Shortening

overheating in the program mode

• Programming wrong • Check temperature setting

• Faulty PC Board • Remove and replace control

panel

• Faulty temperature probe • Remove and replace tempera-

ture probe

1-9

Model 691

1-3. TROUBLESHOOTING (Continued)

Problem Cause Correction

SHORTENING FOAMING/DRAINING SECTION

Foaming or boiling • Water in shortening • At end of cook cycle,

over of drain shortening and clean

shortening frypo t ; a d d f r e s h

shortening

• Condensation line clogged • Remove and clean conden-

sation line

• Improper or bad shortening • Use recommended

shortening

• Improper filtering • Refer to the procedure

covering filtering the

shortening

• Cold zone full of cracklings • Filter shortening

• Improper rinsing after • Clean and neutralize the

cleaning the fryer frypot; rinse with vinegar

to remove the alkaline, then

rinse with hot water and

dry frypot

Shortening will • Drain valve clogged with • Open valve, push cleaning

not drain from crumbs rod through drain opening

frypot from inside of frypot

• Drain valve will not open by • Replace cotter pins in valve

pulling the handle coupling

Shortening leaking • Obstruction in drain • Remove obstruction

through drain valve

• Faulty drain valve • Replace drain valve

1-10

Model 691

1-4. ERROR CODES In the event of a control system failure, the digital display will show

an error message which are coded: “E-4”, “E-5”, “E-6”, “E-10”,

“E-15”, “E-20A-D”, “E-41”, “E-46”, “E-47”, “E-48”, “E-70B”,

and “E-92”. A constant tone is heard when an error code is

displayed; and to silence this tone, press any of the product buttons.

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-4” Control board Turn switch to OFF position, then turn switch back to ON;

overheating if display still shows “E-4”, the board is getting too hot; check

for signs of overheating behind the control panel; once panel

cools down, the controls should return to normal; if “E-4”

persists, replace the control

“E-5” Shortening Turn switch to OFF position, then back to ON; if display

overheating shows “E-5”, the heating circuits and temperature probe should

be checked; once the unit cools down, the controls should

return to normal; if “E-5” persists, replace the control

“E-6A” Temperature Turn switch to OFF position, then turn switch back to ON;

probe open if display shows “E-6”, have the temperature probe checked

“E-6B” Temperature Turn switch to OFF position, then turn switch back to ON;

probe shorted if display shows “E-6”, have the temperature probe checked

“E-10” High limit Reset the high limit by manually pushing up on the red reset

button; if the high limit does not reset, the high limit must be

replaced; call Henny Penny’s Service Department

“E-15” Drain switch Close the drain using the drain valve handle; if display still

shows “E-15”, call Henny Penny’s Service Department

“E-20A” Air pressure switch Press the timer button to try the ignition process again; and if

failure (stuck closed) “E-20A” persists, call Henny Penny’ s Service Department

“E-20B” Draft fan or Press the Timer button to try the ignition process again; and if

air pressure “E-20B” persists, call Henny Penny’s Service Department

switch failure

(stuck open)

“E-20C” Ignition module Press the Timer button to try the ignition process again; and if

failure “E-20C” persists, call Henny Penny’s Service Department

“E-20D” Modules working Press the Timer button to try the ignition process again; and if

but no ignition “E-20D” persists, call Henny Penny’ s Service Department

1004 1-11

4-2. ERROR CODES (Continued)

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-41” Programming Turn switch to OFF position, then back to ON; if display

failure shows “E-41”, the control should be re-initialized (see Pro-

gramming section); if the error code persists, replace the

control panel

“E-46” Eeprom memory Turn switch to OFF position, then back to ON; if display

write error shows “E-46”, the control should be re-initialized (see Pro

gramming section); if the error code persists, replace the

control panel

Model 691

“E-47” A-to-D failure Turn switch to OFF position, then back to ON; if display

(Analog converter shows “E-47”, the control should be re-initialized (see Prochip) gramming section); if the error code persists, replace the

control panel

“E-48” Input system Turn switch to OFF position, then back to ON; if display

error (CPU can’t shows “E-48”, the control should be re-initialized (see Proread buttons graming section); if the error code persists, replace the control

digital inputs) panel

“E-70B” Faulty power Have power switch checked, along with its wiring; have

switch, or switch Input/Output board replaced if necessary

wiring; faulty

I/O board

“E-92” 24-V AC fuse Have components, in 24-volt circuit (I.E., hi limit, drain switch)

on I/O board open checked for shorts

1-12 1004

Model 691

SECTION 2. MAINTENANCE

2-1. INTRODUCTION This section provides procedures for the checkout and replace-

ment of the various parts used within the fryer. Before

replacing any parts, refer to the Troubleshooting Section. It

will aid you in determining the cause of the malfunction.

2-2. MAINTENANCE HINTS 1. Y ou may want to use a multimeter to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter will read infinity .

Do not move the fryer with hot shortening in the frypot or

filter drain pan. Severe burns can result from splashing

hot shortening.

4. The counterweights can be removed from the frame to easily

access the rear of fryer .

2-3. PREVENTIVE T o ensure a long life of the fryers and their components, regular

MAINTENANCE maintenance should be performed. Refer to the chart below .

Frequency Action

Daily Clean deadweight valve cap, weight and dead-

weight orifice. (See Deadweight V alve Section)

T wice Daily Filter shortening (See Operator’s Manual)

Monthly Check dilution box, Clean as needed

(See Cleaning the Dilution Box Section)

Annually Clean blower wheel (See Cleaning the Blower

Wheel Section)

Annually Lubricate lid rollers in back of fryer.

(See Lubricating Lid Rollers Section)

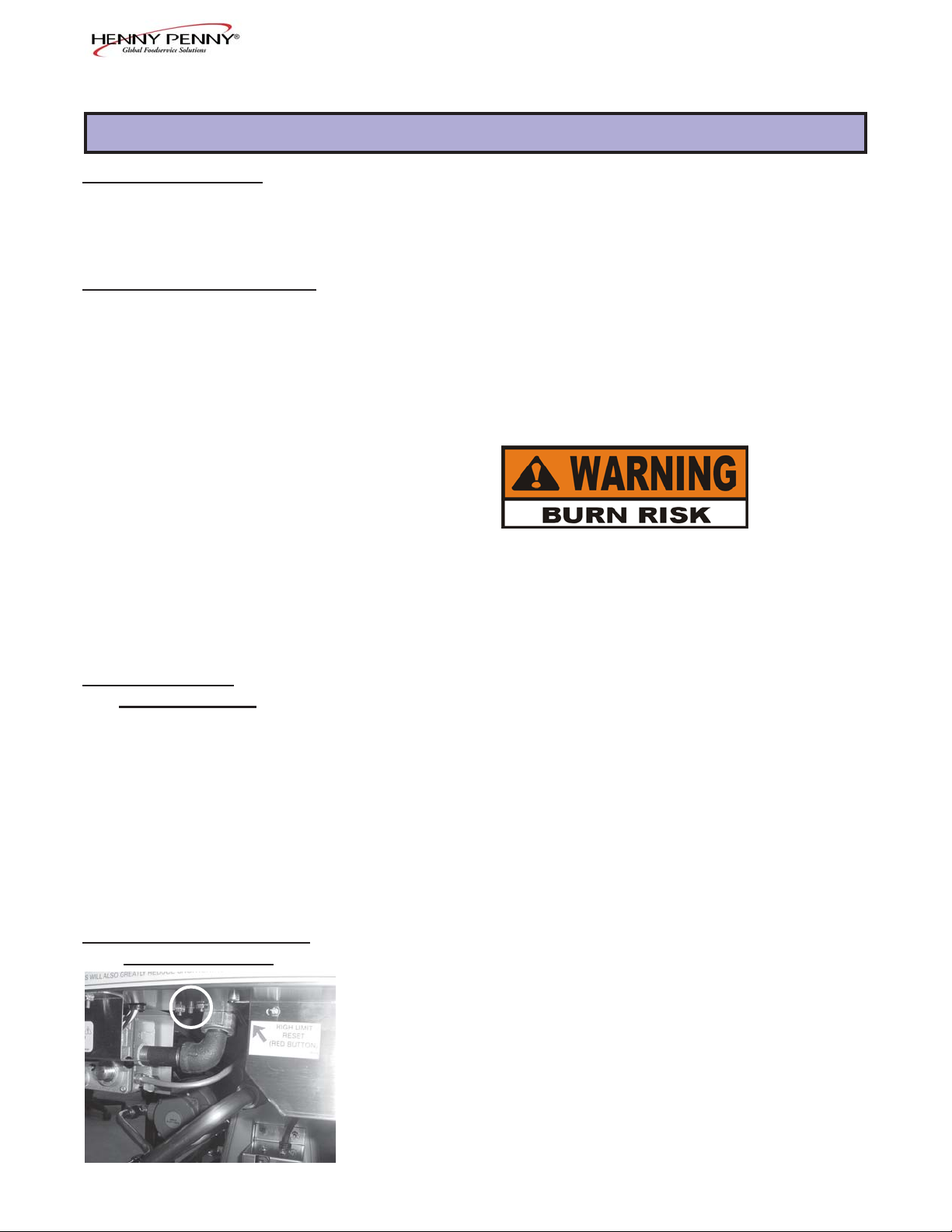

2-4. HIGH TEMPERATURE

LIMIT CONTROL This high temperature control is a safety , manual reset control, which

senses the temperature of the shortening. If the shortening temperature exceeds 425°F (218°C), this switch opens and shuts off the heat

to the frypot. When the temperature of the shortening drops to a

safe operation limit, manually reset by pressing the red reset button.

The red reset button is located under the control panel, in the front of

the fryer. Once reset, the shortening again starts heating.

2-1

Model 691

2-4. HIGH TEMPERATURE

LIMIT CONTROL (Continued)

Checkout Before replacing a high temperature limit control, check to see

that its circuit is closed.

The shortening temperature must be below 380°F (193°C)

to accurately perform this check.

1. Remove electrical power supplied to the fryer.

T o avoid electrical shock or pr operty damage, move the

power switch to OFF and disconnect main circuit

breaker , or unplug cord at wall r eceptacle.

Replacement

2. Remove the control panel.

3. Remove the two nuts securing the high limit bracket to the unit,

and pull the bracket from the unit.

4. Remove the two screws securing the high limit to the bracket,

and remove the high limit from the bracket.

5. Remove the two electrical wires from the high temperature

limit control.

6. Manually reset the control, then check for continuity between

the two terminals after resetting the control. If the circuit is open,

replace the control, then continue with this procedure. (If the cir

cuit is closed, the high limit is not defective. Reconnect the two

electrical wires.)

T o avoid electrical shock or pr operty damage, move the

power switch to OFF and disconnect main circuit

breaker , or unplug cord at wall r eceptacle.

2-2

1. If the tube is broken or cracked, the control will open,

shutting off electrical power . The control cannot be reset.

Model 691

2-4. HIGH TEMPERATURE 2. Drain shortening from the frypot and discard. A substance

LIMIT CONTROL in the tube could contaminate the shortening.

(Continued)

3. Remove control panel.

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holder inside the frypot.

6. Straighten the capillary tube.

7. Remove larger outside nut that threads into pot wall.

8. Remove defective control from control panel area.

9. Insert new control and replace screws.

10. Uncoil capillary line, starting at capillary tube, and insert

through frypot wall.

T o avoid electrical shock or other injury , run the capillary

line under and away from all electrical power wires and

terminals. The tube must NEVER be in a position where it

could accidentally touch the electrical power terminals.

11. Carefully bend the capillary tube as shown in photo and place

into bulb brackets.

12. Pull excess capillary line from pot and tighten nut into frypot

wall.

Be sure capillary bulb of high limit is positioned so it doesn’t

interfere with the carrier or get damaged when cleaning the

frypot.

13. With excess capillary line pulled out, tighten smaller nut.

14. Replace front panel and refill with shortening.

2-3

Model 691

2-5. POWER/PUMP SWITCH The POWER/PUMP switch is a three-way rocker switch with a

center OFF position. W ith the switch in the POWER position,

the fryer will operate. With the switch in the PUMP position ,

the filter pump will operate, but the unit will not heat.

T o avoid electrical shock or pr operty damage, move the

power switch to OFF and disconnect main circuit

breaker , or unplug cord at wall r eceptacle.

Checkout

1. Remove control panel.

2. Label and remove wires from the switch.

3. “OFF” position - should be open circuit anywhere on the

switch.

4. “POWER” position

Check from:

#5 to #6 closed circuit

#l to #2 closed circuit

5. “PUMP” position

Check from:

#4 to #5 closed circuit

#3 to #2 closed circuit

Replacement Check across the jumpers on the wires of the POWER/PUMP

switch. These jumpers have resistors and capacitors which may

be faulty .

1. With control panel removed, and wires off of the switch,

push in on tabs on the switch to remove from the panel.

2. Replace with new switch, and reconnect wires to switch

following the wiring diagram.

3. Replace the control panel.

2-4 1004

Model 691

2-6. TEMPERATURE PROBE The temperature probe relays the actual shortening temperature

REPLACEMENT to the control. If it becomes disabled, “E06” will show in the display .

Also, if the temperature is out of calibration more than 10°F , or 10°C,

the temperature probe should be replaced. An Ohm check can be

performed also. See chart at end of this section.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

3. Remove the control panel.

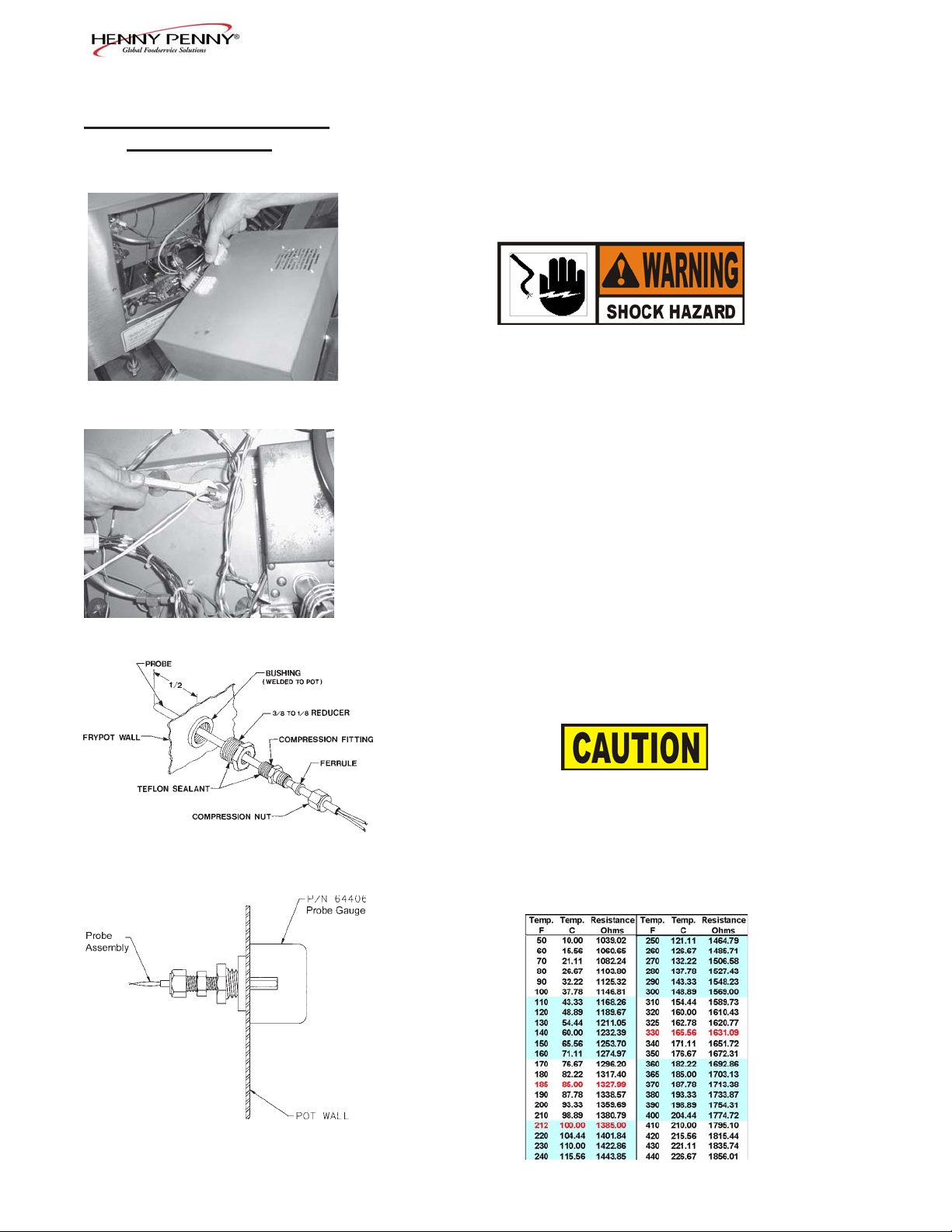

Figure 2-1

4. Using a 1/2" wrench, remove the nut on the compression fitting.

5. Remove the temperature probe from the frypot.

6. Place the nut and new ferrule on the new temperature probe and

insert the temperature probe into the compression fitting until it

extends 1/2 inch (1.3 cm) into the frypot. Use the

temperature probe gauge provided in the temperature probe kit,

to ensure proper placement in frypot. See Figures 2-1 and 2-2.

7. T ighten hand tight and then a half turn with wrench.

Excess force will damage temperature probe.

8. Connect new temperature probe to PC board and replace

control panel.

9. Replace shortening, and then turn power ON and check out

fryer.

Figure 2-2

507 2-5

Model 691

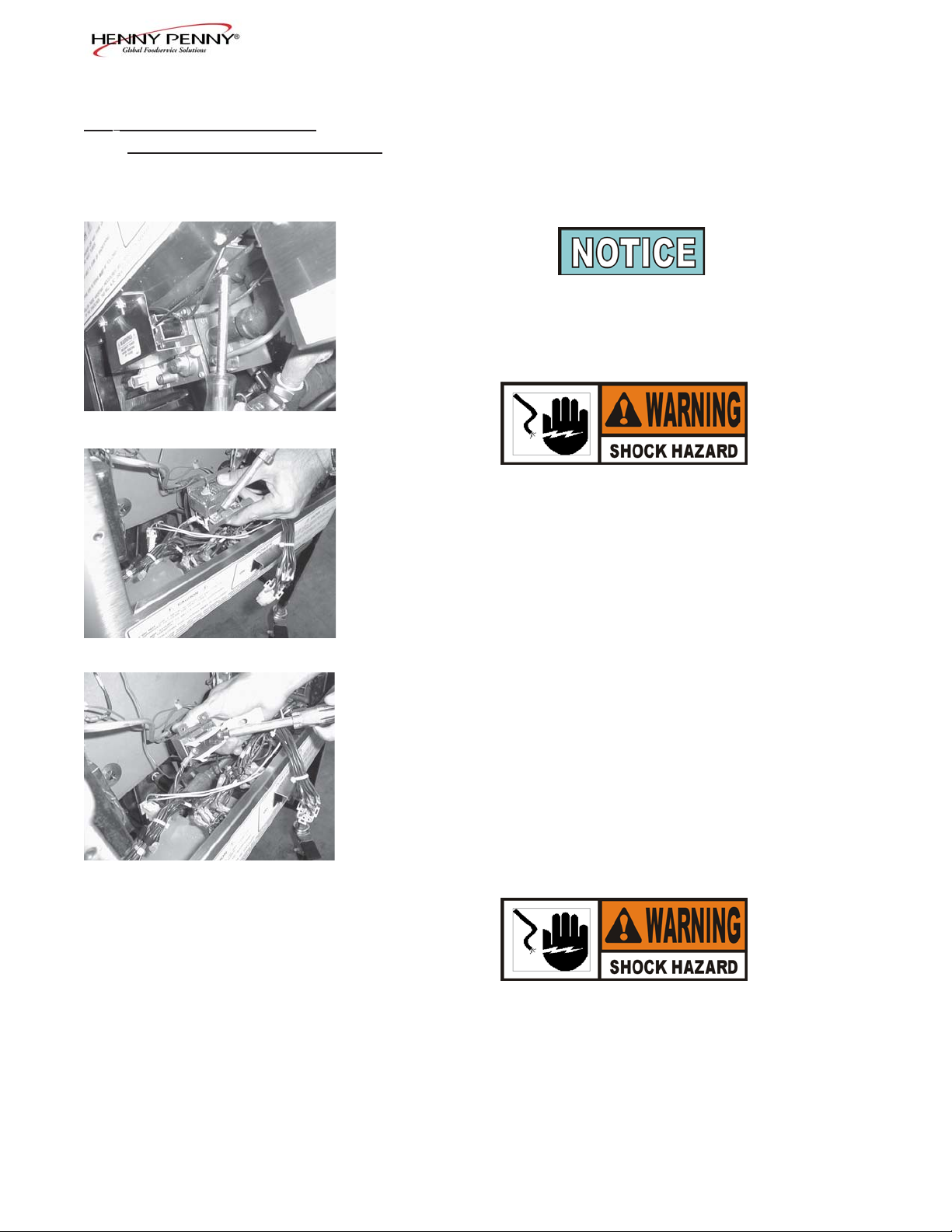

2-7. COMPLETE CONTROL Should the control panel become inoperative, follow these

PANEL - HENNY PENNY instructions for replacing the board.

1. Remove electrical power supplied to the fryer.

T o avoid electrical shock or pr operty damage, move the

power switch to OFF and disconnect main circuit

breaker , or unplug cord at wall r eceptacle.

2. Remove the two screws securing the control panel and lift

panel up and out.

3. Unplug the connectors going to the control board.

4. Install a new control panel.

2-8. PRESSURE REGULA TION The Henny Penny fryer uses pressure as one of the components of

the cooking process. Once the lid is sealed to the frypot and the

solenoid valve closes, a deadweight valve maintains the correct

pressure in the frypot.

The lid has minimal and limited maintenance and repair procedures, which are addressed in the following sections.

The following is a routine maintenance schedule for the lid:

Every 90 days

• Clean and reverse the lid gasket

Y early Inspection

• Check lid gasket for splitting and tears - replace if necessary

• Check pressure pads for wear - rotate if necessary

• Check cam slide guides - replace if worn or broken

• Check lid rollers - replace if cracked or damaged

• Lubricate rear lid rollers

• Cleaning safety relief valve

2-6 1004

Model 691

2-9. TILTING THE LID The lid assembly is easily tilted up for cleaning or servicing.

UPRIGHT

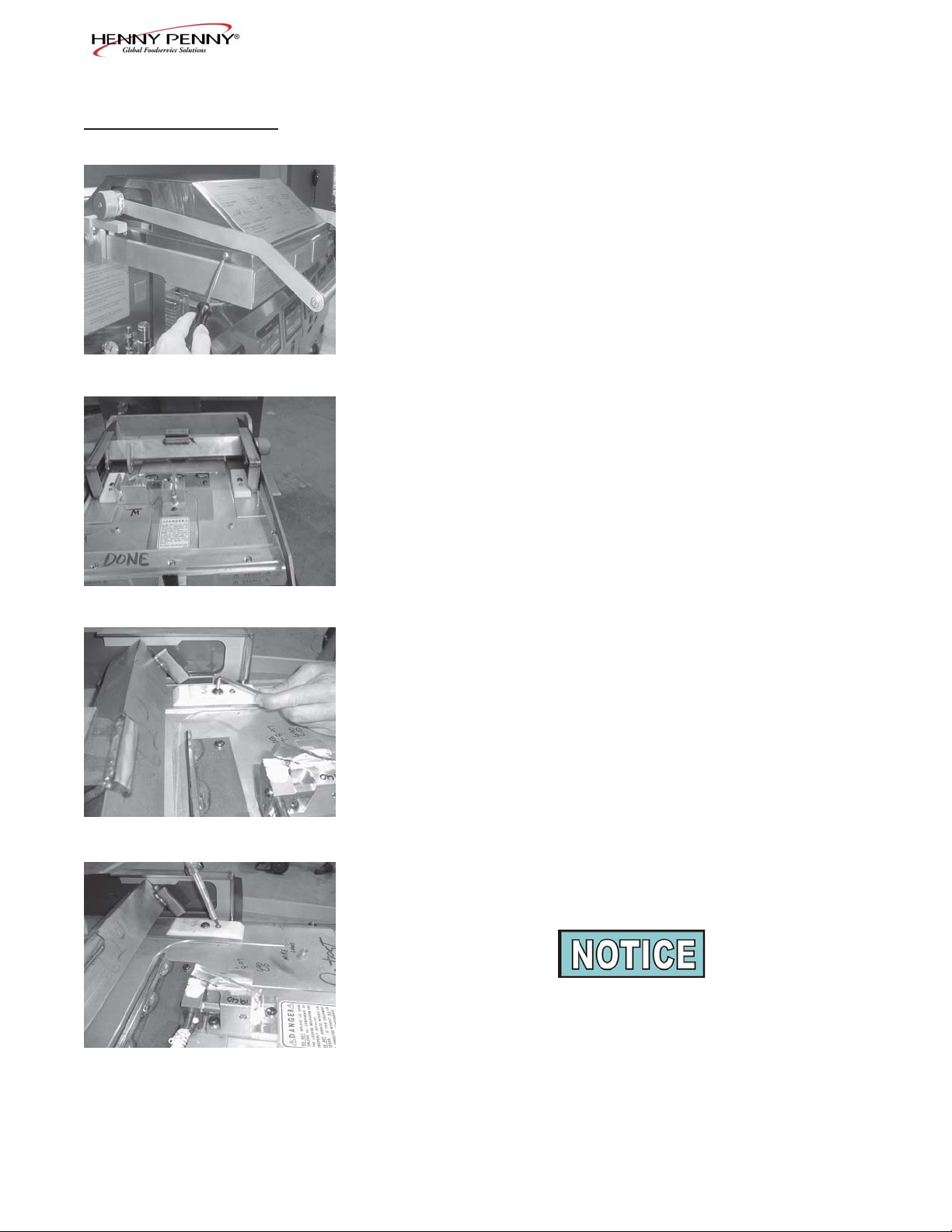

1. Raise the lid and remove racks and carrier.

2. Grasping the lid handle, lift the front of the lid up until it

stops in an upright position.

Be sure the metal arm on the left side of the lid is in the

vertical position holding the lid upright, or severe injuries

could result. (See photo at left.)

904 2-7

Model 691

2-10. REVERSING THE LID The gray rubber gasket surrounding the inside of the lid is

GASKET designed to be reversed.

Because of heat expansion and the pressure used for the cooking

process, the gasket is constantly under extreme stress.

Reversing the lid gasket will help to ensure that the fryer will

not lose pressure through leakage.

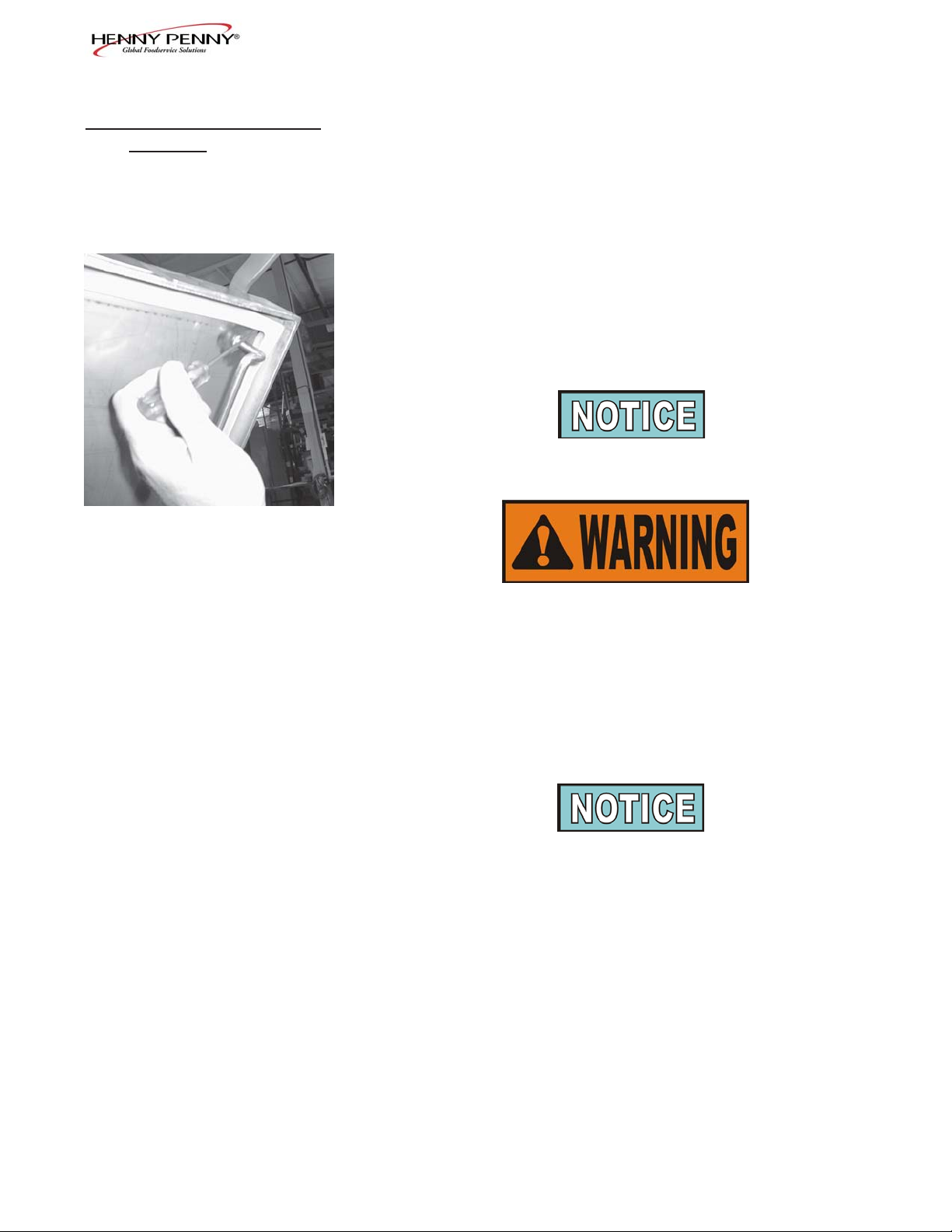

1. Put the lid in the upright position, as previously described.

2. Using a thin blade screwdriver, pry out the gasket at the

corners. Remove the gasket.

Check the gasket for any tears or nicks. If the gasket is

damaged, it needs to be replaced.

Be sure the metal arm on the left side of the lid is in

the vertical position holding the lid upright, or severe

injuries could result. (See photo in Tilting the Lid Upright

Section.)

3. Clean the gasket and gasket seat with hot water.

4. Rotate the gasket with the opposite side facing out.

Install the fourcorners of the lid gasket. Smooth the gasket into

place, working from the corners towards the middle of each

side.

2-8 904

Model 691

2-11. LID COUNTER WEIGHT The lid counterweight in the back of the fryer balances the

CABLES weight of the lid system to allow easier opening and closing of

the lid. The weight has two cables attached to it, and weighs

about 150 lbs. (68.0 Kg).

1. Using a Phillips head screwdriver, remove the screws securing

the back and top shrouds of the fryer and remove the shrouds.

2. Raise the lid.

3. Remove the steam box.

4. Remove the nipples from the deadweight and solenoid that are

attached to the front shroud.

5. Remove the screws securing the shroud to the frame and remove

the shroud.

6. Remove the nut from the nylatron slide and flip loosened end up

over the lid.

7. Remove the four keps nuts from the bracket at top of the shroud.

8. Place support under lid arm (ex: block of wood), and remove the

weights from the frame in the back of the fryer.

2-9 904

Model 691

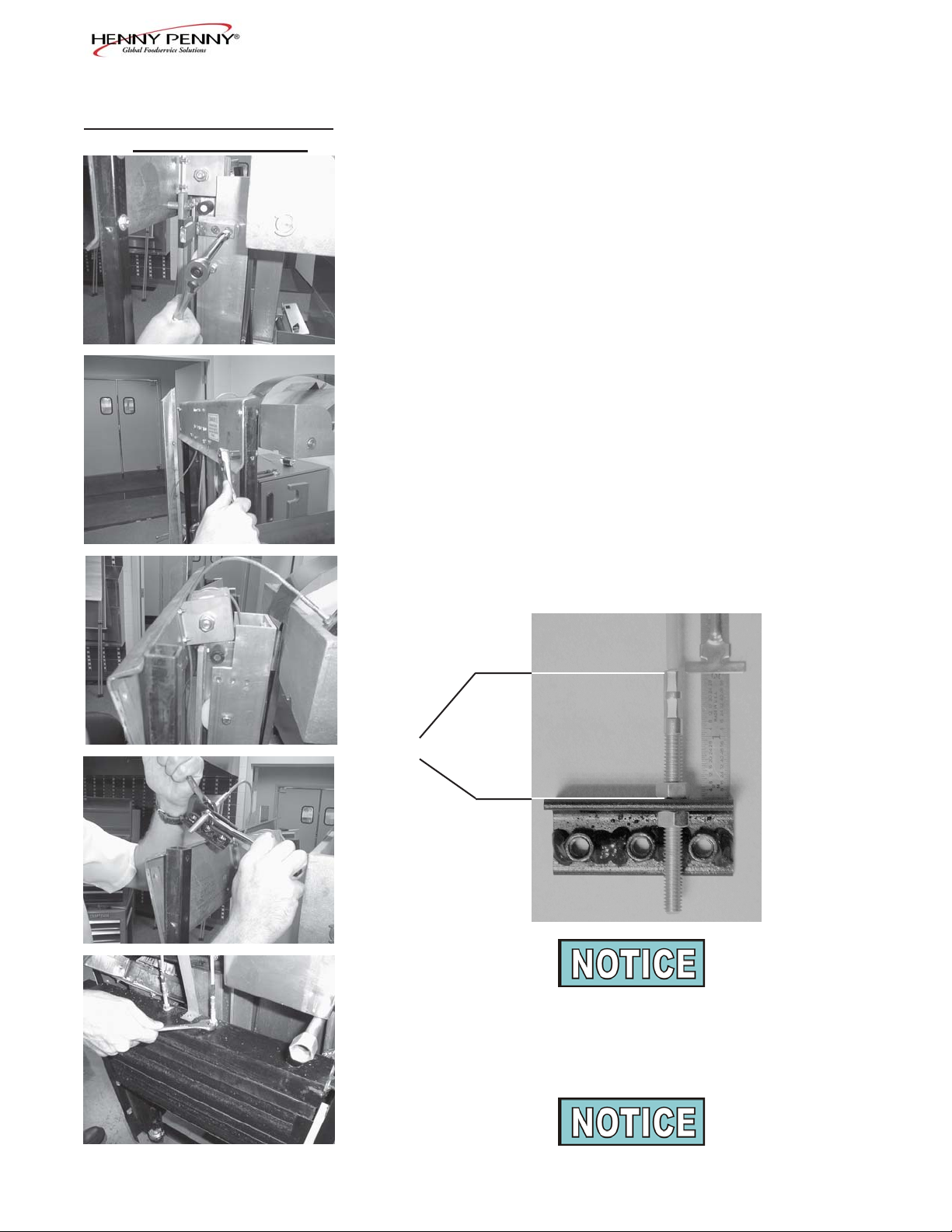

2-11. LID COUNTER WEIGHT 9. Remove the Allen head bolts securing the stabilizer bracket and

CABLES (Continued) remove the bracket.

10. Remove the bolts and spacers securing the pulley bracket, and

pull bracket back, to allow access to cable bracket.

11. Pull cable and bracket from unit and remove cable from bracket.

12. Remove cable from weight frame.

13. Thread new cable through pulley.

14. Thread nut on cable and place cable through weight frame.

15. Thread second nut onto end of cable, but do not tighten.

16. Thread nut on other end of cable and place through the

bracket, then thread a second nut on the end of the cable. Tighten

the nut to the bracket. T wo inches (50.8 mm) of the threaded

end should show above the bracket. See photo below .

2 inches (50.8 mm)

Both cables should have the same amount of threads extending

through the brackets.

17. Tighten cable onto weight frame.

18. Reassemble in reverse order.

Be sure to use pipe sealant on the pipe fittings.

2-10 904

Model 691

2-12. PRESSURE P ADS The pressure pads are plastic strips that the lid cam presses

against to seal the lid. They are located on top of the shims.

1. Raise the lid.

2. Remove the four screws securing the lid cover and remove

cover.

3. Push the lid cam back, off the pressure pads.

4. Using an Allen wrench, remove the large bolt securing the pad.

5. Using a Phillips head screwdriver, remove the small screw

securing the pad securing the pressure plate and remove the

broken pad.

If the pressure pad is worn, but not broken, it can be reversed

180 degrees, and the other end of the pad used.

6. Install new pad in reverse order.

904 2-11

Model 691

2-13. LID ADJUSTMENT If steam leaks out from around the lid gasket, the pressure pads

could be worn or broken. If the pressure pad is worn, but not

broken, it can be reversed 180 degrees, and the other end of the

pad used. See Pressure Pads Section.

If steam leaks, check for:

• Pressure pad wear

• Cracked or worn gasket

• Gasket installed improperly

• Fryer operating above 12 psi (827 mbar)

Fryer should be operating at 12 psi (827 mbar), or serious

burns could result.

2-12 904

Loading...

Loading...