Hellwig 7662 User Manual

BE SURE THE CUSTOMER RECEIVES THIS INSTRUCTION SHEET, ALL WARNING

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLA TION INSTRUCTIONS

FRONT STABILIZER BAR

Ford F150, Expedition

Thank you for purchasing a quality Hellwig Product.

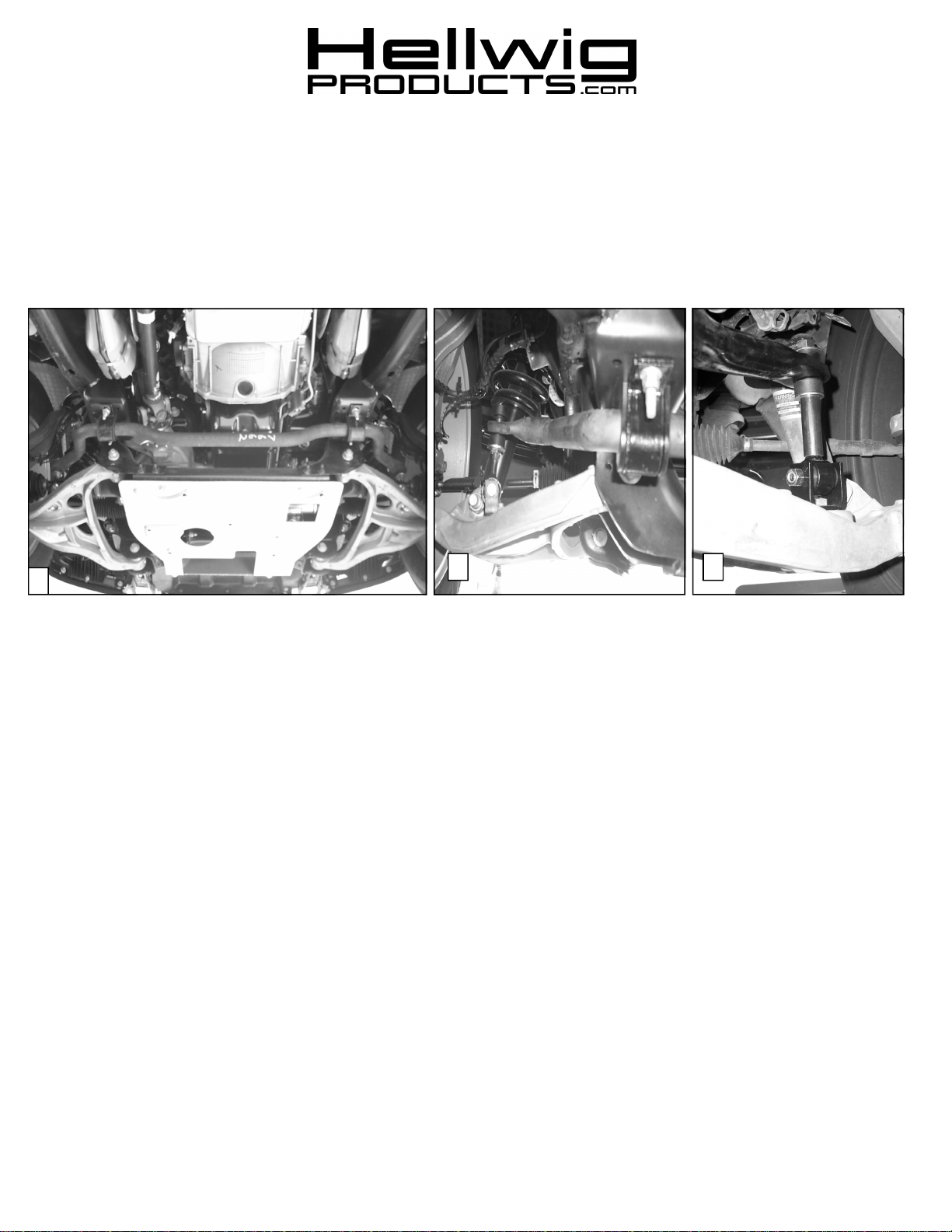

2

3

1

TORQUE TABLE

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKING BRAKE AND CHOCK THE WHEELS.

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.

NOTE: TO EASE INSTALLATION AND TO PROPERLY ADJUST BAR, THE WEIGHT OF THE VEHICLE MUST BE ON THE SUSPEN-

SION, AS IF DRIVING DOWN THE ROAD. DO NOT RAISE THE VEHICLE BY FRAME.

NOTE: THIS UNIT IS DESIGNED TO REPLACE THE FACTORY INSTALLED FRONT ANTI SWAY BAR USING THE FACTORY U-

PLATE MOUNTING BOLTS.

1. Remove the factory installed front anti-sway and all the mounting hardware. Do not discard the factory U-plate mounting bolts as they

will be needed to install the new front sway bar. If vehicle is 2006 or newer, see page 2 to re-use factory end links. If re-using factory

end links is not desired, go to step 2.

2. Locate and remove the factory sway bar end links from the vehicles lower control arms ( both left and right hand side ).

3. Install the D-shaped poly bushings on the new sway bar in as close a possible location as the factory sway bar. ( see photo one ( 1 ).

4. Install the hour glass shaped poly bushings and insert them into the sleeved ends of the end links. Insert the steel sleeve through the poly

bushings. Slightly grease the poly bushings and the steel sleeves to ease installation ( taking care as to not damage the bushings ). Install

the remainder of the round poly bushings on the end links as in photo three ( 3 ).

5. Install the clevis brackets on the vehicles lower control arms where the factory end links were mounted. Use the 1/2” x 1-1/2” cap screws

and tighten slightly. Install the sleeved end of the end links to the clevis brackets using mounting hardware provided. Leave loose at this

time to allow for adjustment later. ( Orient the clevis brackets as shown in photo ( 3 ) for best fit ).

6. Position the sway bar up on the vehicles frame, using the U-plate brackets and the factory mounting bolts that were removed in step (1).

Leave loose at this time to allow for adjustment later. Lift the arms of the sway bar over the installed end links and finish the installation as in photo. ( See photos one ( 1 ) and three ( 3 ).

7. With the sway bar properly aligned and the end links straight up and down as possible. Torque the U-plate mounting bolts on the frame to

factory specifications. Torque the clevis bracket on the lower control arms to the specified rate. Tighten the end link just slightly that the

poly bushings start to bulge. Do not over tighten or damage can occur to the poly bushings.

8. Test drive your vehicle and recheck your installation. Re-adjust and torque as necessary. Recheck your installation on a regular basis

thereafter.

ATTENTION INSTALLER:

AND NOTE CARDS AND THE WARRANTY FORM.

7662 ( R-7662 ) 12/06/04

559-734-7451 800-367-5480 FAX 559-734-7460

4

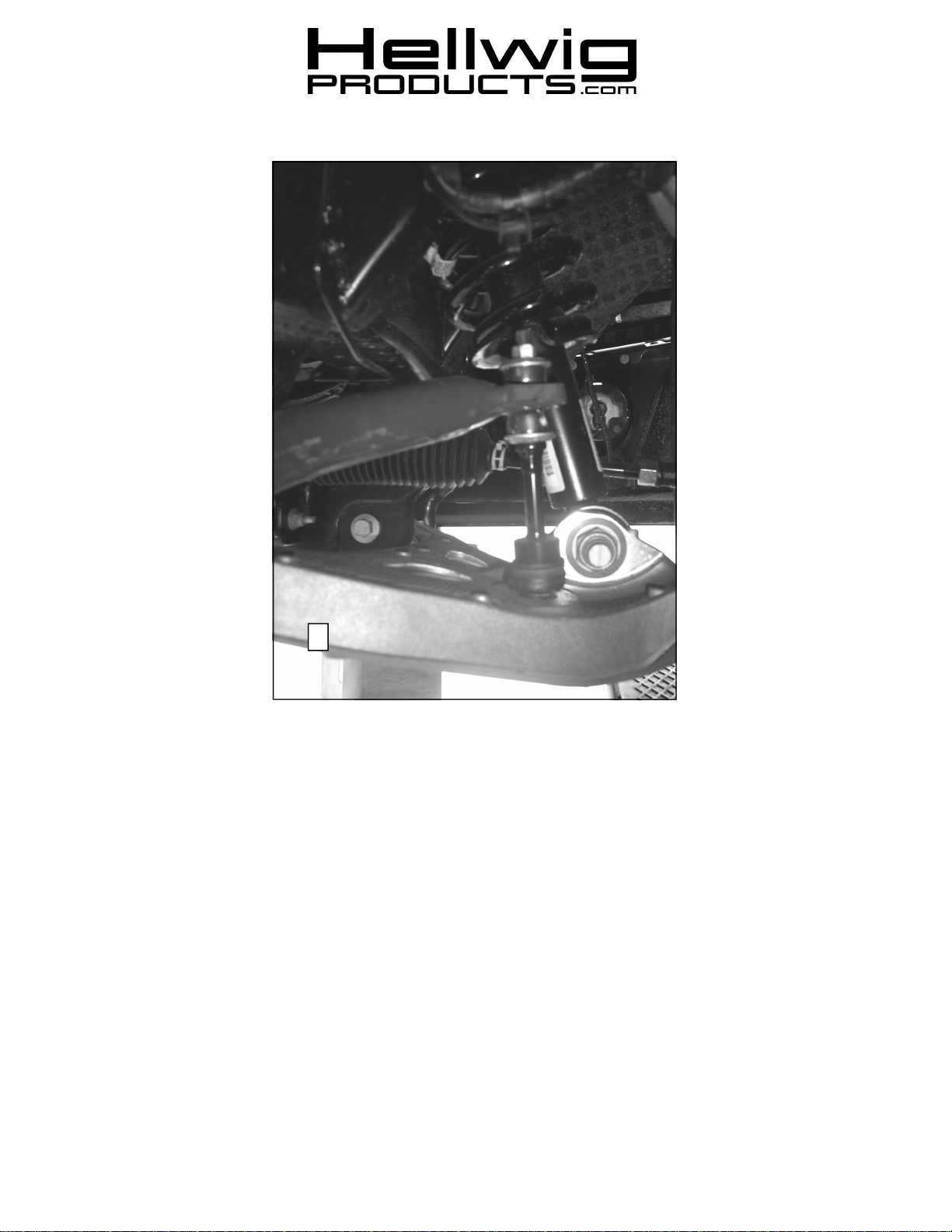

Special Instructions for re-use of factory end links on 2006 and newer models.

1. 2006 and newer vehicles may re-use the factory end links if desired as the Hellwig sway bar is a direct replacement for the factory sway

bar on these vehicles. See photo (4). If the end links on your vehicle look like photo (4) the factory end links can be re-used if they are in

good condition.

2. Install the D-shaped poly bushings on the new sway bar in as close a possible location as the factory sway bar. See photo one ( 1 ).

3. Position the sway bar up on the vehicles frame, using the U-plate brackets and the factory mounting bolts that were removed in step (1).

Leave loose at this time to allow for adjustment later. Lift the arms of the sway bar over the installed end links and finish the installation as in photo. See photos one ( 1 ) and four( 4).

4. With the sway bar properly aligned and the end links straight up and down as possible. Torque the U-plate mounting bolts on the frame

and end link bolts to factory specifications.

5. Test drive your vehicle and recheck your installation. Re-adjust and torque as necessary. Recheck your installation on a regular basis

thereafter.

7662 ( R-7662 ) 12/06/04

Loading...

Loading...