Hellwig 7658 User Manual

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

7658 Rear Stabilizer Bar

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET COMPLETELY BEFORE STARTING YOUR INSTALLATION

TORQUE TABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKING BRAKE AND CHOCK TIRES.

NOTE: TO EASE INSTALLATION AND TO PROPERLY ADJUST BAR, THE WEIGHT OF THE VEHICLE MUST BE

ON THE SUSPENSION, AS IF DRIVING DOWN THE ROAD. DO NOT RAISE VEHICLE BY FRAME.

NOTE: THIS UNIT IS DESIGNED TO MOUNT TO THE REAR OF THE AXLE TUBES WITH THE ARMS OF THE BAR

TOWARD THE REAR OF THE VEHICLE. THE HUMP SHOULD TILT SLIGHTLY DOWNWARD.

NOTE: THIS KIT INCLUDES LOCK NUTS WHICH REQUIRE TIGHTENING WITH A WRENCH AFTER BEING STARTED

BY HAND.

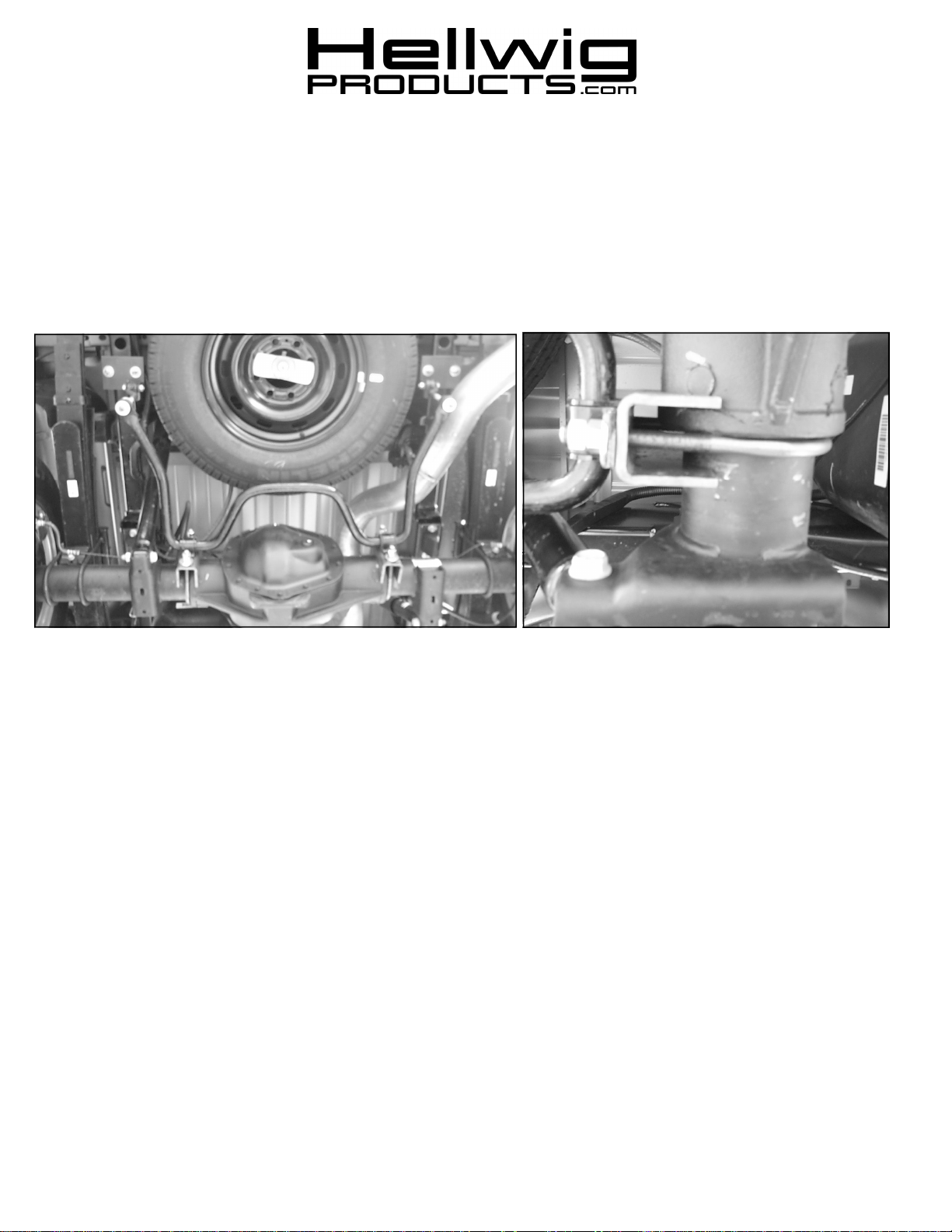

1. As shown in photo one (1), place D-shaped poly-bushings onto straight areas of the bar on each side of center hump. After installing Dbushings onto bar, place U-plates on D-bushings.

2. Place U-bolts on axle tubes next to casting as shown in photo two (2). When installing U-bolts, be sure to put U-bolts under any

brake lines, wires or hoses on the axle to avoid any possible damage.

3. Place saddle brackets on axle by inserting legs of U-bolts into the holes in saddle brackets. Saddle brackets must be installed so that one

leg of the saddle bracket is located on the cast center section with the leg just inside the raised lip on the casting. See photo two (2)

4. Raise bar and place D-bushings on saddle brackets by inserting legs of U-bolts through holes in U-plates. Install flat washers and hex

nuts provided on U-bolts. Do not use locknuts provided in kit on axle U-bolts. LEAVE LOOSE AT THIS TIME to allow for

adjustment later.

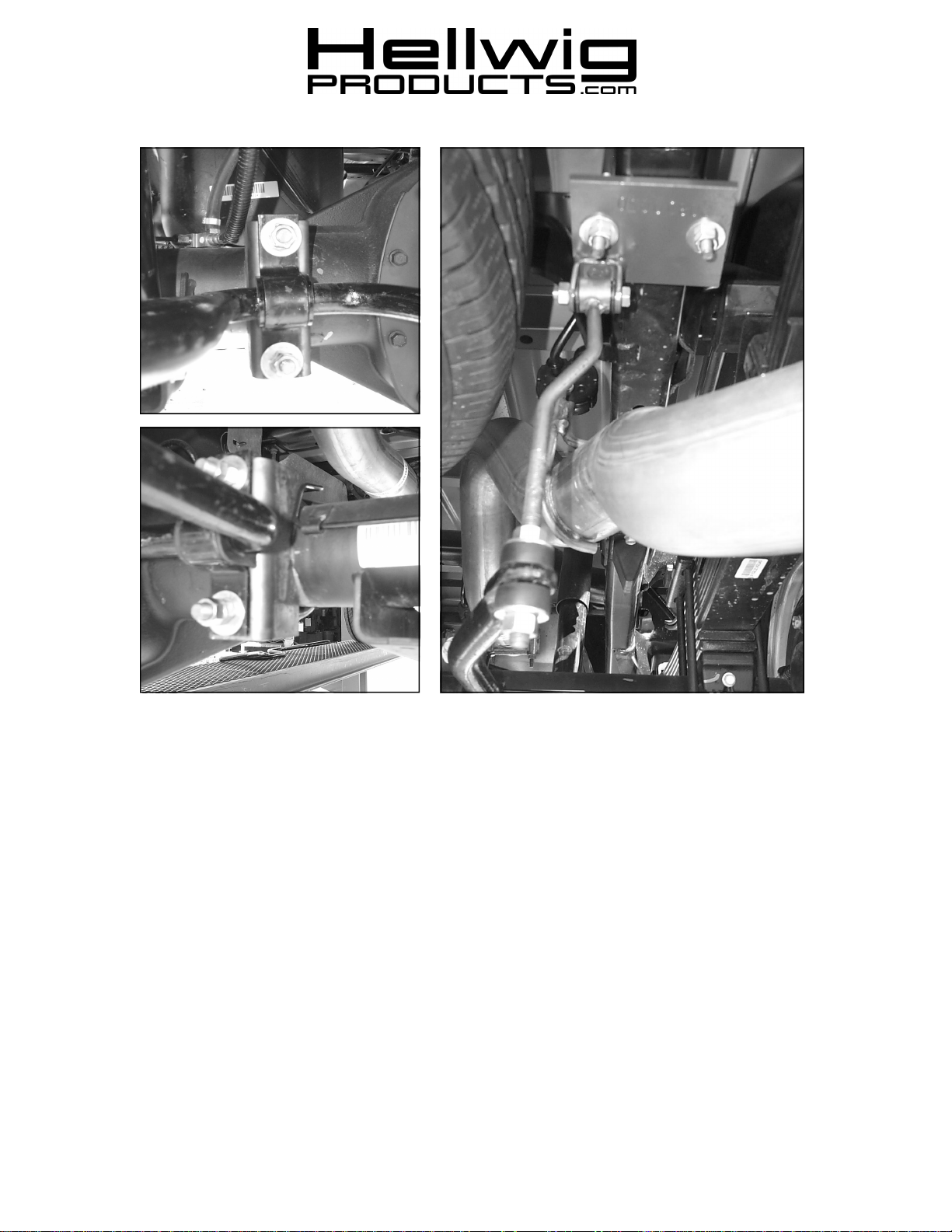

5. Locate existing spare tire crossmember on vehicle frame. Place square U-bolt over frame rail just behind crossmember with legs of Ubolt pointing downward.

6. Insert legs of U-bolt into slotted holes of the hanger brackets. Install hanger brackets with clevis inboard of frame rail and toward front

of vehicle as shown in photo three (3). Attach using 1/2” lock nuts. LEAVE LOOSE for adjustment later.

7. Install bushings and spacer tube into the sleeve in end link. Place end link into clevis with offset inboard. Attach end link with 7/16 X 2

1/4” capscrew. See picture three (3).

ATTENTION INSTALLER: PLEASE MAKE SURE CUSTOMER RECEIVES THIS INSTRUCTION SHEET,

559-734-7451 800-367-5480 FAX 559-734-7460

7. Thread locknut on to threads of end link far enough to mount flat washers and bushings to the end of sway bar as shown in photo three

(3). Attach sway bar to end link using locknuts provided in kit. LEAVE LOOSE AT THIS TIME to allow for adjustment later.

8. With sway bar loosely mounted, work bar back and forth in D-shaped poly bushing to center bar.

9. Tighten frame bracket U-bolts to 50 ft-lb..

10. Tighten end link clevis bolts to specs in torque table.

11. Tighten end link nuts until poly bushings start to bulge slightly. DO NOT OVERTIGHTEN

12. Tighten axle U-bolts to torque spec in torque table. Place second nut on U-bolt and tighten against primary nut to lock in place.

13. Recheck your installation, looking for clearance on any undercarriage components, such as gas lines, exhaust pipes, brake lines, wiring,

differential cover, etc.

14. Drive vehicle for a few miles, then recheck for position and tightness, readjust and retorque as needed. Then recheck periodically

thereafter.

ALL IMPORTANT NOTE CARDS, WARNING CARDS AND THE WARRANTY

FORM

7658(R-7658) 02/17/04

Loading...

Loading...