Harbor Freight Tools 40939 Product manual

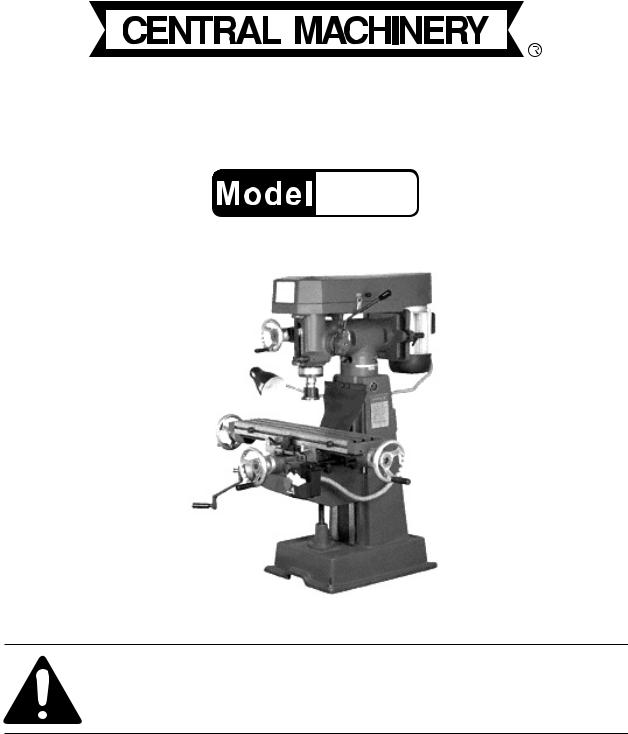

Vertical Bench

Milling Machine

40939

Set up and Operating Instructions

Visit our website at: http://www.harborfreight.com

Read this material before using this product. Failure to do so can result in serious injury. Save this manual.

Copyright© 2007 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork contained herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing improvements, actual product may differ slightly from the product described herein. Tools required for assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual revised 08l, 09l

SPECIFICATIONS

Electrical |

220 V~ / 60Hz / 10 A |

Requirements |

|

Table Size |

6-1/2” x 26” |

Long. Travel |

15-1/2” Max. |

Cross Travel |

6” Max. |

Vertical Travel |

7.68” Max. |

T-Slot |

1/2” (3) |

Spindle Travel |

2-3/4” |

Lead Screw |

1” x 8tpi |

Spindle Taper |

R8 |

Swing |

13” |

Head Tilt |

45o L and R |

Motor |

2 HP, 1720 RPM |

Speeds |

9 Speeds: |

|

240, 355, 545, 735, 1342, |

|

1425, 1650, 2350, 2885 RPM |

Base Dimensions |

22” x 16” |

Features

•This model is a compact vertical milling machine. It is easy to set up. The controls are designed for operator convenience, including dual table hand wheels.

•This machine is practical for technical schools, small parts production, toolrooms, R&D work, maintenance shops, and hobby use.

•This machine is ideally suited for many operations, including conventional milling, compound angle milling, engraving, and jig boring.

•All the Ways are hand finished for perfect bearing alignment. The table is ground for accurate squareness. Castings are high strength material. They are aged for several months, before normalizing and tempering, to minimize deformation.

Save this manual

You will need the manual for the safety warnings and cautions, assembly instructions, operating procedures, maintenance procedures, trouble shooting, parts list, and diagram. Keep your invoice with this manual. Write the invoice number on the inside of the front cover. Keep both this manual and your invoice in a safe, dry place for future reference.

SAFETY WARNING & CAUTIONS

WARNING!

The Warnings, Cautions, and Instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL!

1.KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

REV 09l

SKU 40939 |

For technical questions, please call 1-800-444-3353. |

Page 2 |

2.OBSERVE WORK AREA CONDITIONS. Do not use tools in damp, wet, or poorly lit locations. Don’t expose to rain. Keep work area well lit. Do not use electrically powered equipment in the presence of flammable gases or liquids.

3.KEEP CHILDREN AWAY. Children must never be allowed in the work area. Do not let them handle machines, tools, or equipment.

4.STORE IDLE EQUIPMENT. When not in use, tools must be locked up in a dry location to inhibit rust. Always lock up tools and keep out of reach of children.

5.DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for which it was intended. Do not use inappropriate attachments in an attempt to exceed the tool’s capacities.

6.USE THE RIGHT TOOL FOR THE JOB. Do not use a tool for a purpose for which it was not intended.

7.Dress Properly Do not wear loose clothing or jewelry, as they can be caught in moving parts. Non-skid footwear is recommended. Wear restrictive hair covering to contain long hair. Always wear appropriate work clothing.

8.USE EYE, EAR and breathing PROTECTION. Always wear ANSI approved impact safety goggles if you are producing metal filings or wood chips. Wear an

ANSI approved dust mask or respirator when working around metal, wood, and chemical dusts and mists. Use ANSI approved ear protection when working in a loud or noisy environment.

9.DO NOT ABUSE THE POWER CORD. Protect the power cord from damage, either from impacts, pulling or corrosive materials. Do not yank machine’s cord to disconnect it from the receptacle.

10.DO NOT OVERREACH. Keep proper footing and balance at all times. Do not reach over or across running machines.

11.MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and changing accessories. Inspect power cord periodically and, if damaged, have it repaired by an authorized technician. Inspect all hydraulic seals for leaks prior to use. Control handle and power switch must be kept clean, dry, and free from oil and grease at all times.

12.REMOVE ADJUSTING KEYS AND WRENCHES. Be sure that keys and adjusting wrenches are removed from the tool or machine work surface before operation.

13.AVOID UNINTENTIONAL STARTING. Be sure that you are prepared to begin work before turning the start switch on.

14.STAY ALERT. Watch what you are doing. Do not operate this machine when you are tired.

SKU 40939 |

For technical questions, please call 1-800-444-3353. |

Page 3 |

15.Do Not operate this machine while under the influence of alcohol, drugs, or prescription medicines.

16.CHECK FOR DAMAGED PARTS. Before using any tool, any part that appears damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment and binding of moving parts, any broken parts or mounting fixtures, and any other condition that may affect proper operation. Any part that is damaged should be properly repaired or replaced by a qualified technician. Do not use the tool if any switch does not turn on and off properly.

17.REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical replacement parts intended for use with this tool. Replacement parts are available from Harbor Freight Tools. Use of any other parts will void the warranty.

Special Warnings when using this Vertical Mill

Using this Vertical Mill may create special hazards.

Take particular care to safeguard yourself and those around you.

1.Electrical Safety. Never operate any tool if there is an electrical hazard. Never operate an electrical tool in wet conditions. Never operate a tool with an improper electrical cord or extension cord. Never operate an electrical tool unless you are plugged into a properly grounded outlet, which supplies 220 Volts at 60 Hz. We recommend you use a circuit which is protected by an appropriate circuit breaker.

2.Ejected Material. Use safe practices to avoid injury from ejected material. Because the Milling tools and workpieces turn at high speed, there is a danger of being injured by materials that may be ejected. Always wear ANSI-certified eye protection. Never attempt to machine any item if it is not adequately held. Always stand to one side of the plane in which the materials are spinning, to avoid being hit if an item is ejected. Never allow bystanders to be in the proximity of the Vertical

Mill while in operation.

3.Entanglement. Use extreme caution to prevent loose materials from being caught in the machine. Never operate this mill with loose clothing, long hair, jewelry, or other items which may become caught in the tools or workpieces. In case of entanglement, press the OFF switch immediately.

NOTICE: No list of warnings can be all inclusive. The operator must supply common sense, and operate this tool in a safe manner.

SKU 40939 |

For technical questions, please call 1-800-444-3353. |

Page 4 |

Loading...

Loading...