Page 1

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Page 2

IMPORTANT — READ FIRST — IMPORTANT

The Groen food service equipment you have purchased has been handcrafted from the finest

mat-erials, meticulously inspected, and tested to ensure you receive the best possible product.

With reasonable care and periodic-maintenance, your Groen unit should provide years of faithful

service.

PLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING OR OPERATING YOUR

GROEN EQUIPMENT. It contains information you will need to install, operate, and maintain the

equipment properly.

It is recommended that you establish a timetable for periodic maintenance as outlined in the

operator manual. Space has been provided in the manual for a maintenance and service log.

Keep the log up to date and on file with the warranty information.

CONDITIONS AND TERMS OF LIMITED WARRANTY

The warranty does not extend to:

1. Installation and start-up.

2. Malfunction as a result of improper service.

3. Repairs made by anyone other than qualified service personnel as recommended by Groen.

4. Damage caused in shipment or damage as a result of improper use.

5. Normal maintenance as outlined in this manual.

6. Damage caused by tampering with, removal of, or change of any preset control or safety

device.

7. Lubrication of gears or pivot points. Lubrication points must be checked regularly as a part of

routine service.

8. Damage to any part of the unit as a result of cleaning with high pressure water or steam. DO

NOT SPRAY THIS EQUIPMENT WITH WATER OR STEAM.

9. Damage caused by overloading the mixer with high viscosity materials. SOME PRODUCTS

REQUIRE HEAVY INDUSTRIAL MOTORS AND DRIVE ASSEMBLIES.

10. Normal wear on scraper fingers.

11. Labor involved in moving other equipment to gain access to the unit. The user must maintain

the accessibility of the unit for service under the warranty.

CAUTION: Use of any replacement parts other than those supplied by Groen or

their authorized distributor VOIDS ALL WARRANTIES. Service

performed by other than factory authorized personnel WILL VOID

ALL WARRANTIES.

If you have any questions about warranty coverage, operating procedures, or maintenance,

contact your area Groen representative or an authorized Groen Service Agency.

Page 3

Table of Contents

I. OWNER INFORMATION

EQUIPMENT DESCRIPTION ......................................................2

INSTALLATION & START-UP ..................................................3,4

II. OPERATOR INSTRUCTIONS

OPERATION ..........................................................................3, 4

CLEANING ................................................................................ 5

OPERATOR'S TROUBLESHOOTING LIST ..................................6

III. SERVICE INFORMATION

SERVICE ...................................................................................7

SERVICE TROUBLESHOOTING ..............................................7,8

PARTS LIST ...............................................................................9

REFERENCES ...........................................................................9

DIAGRAMS & SCHEMATICS ...............................................10,11

SERVICE LOG .........................................................................12

WARRANTY INFORMATION ....................................................13

For operator information on the kettle portion of your cooker/ mixer, see the separate kettle

manual.

1

Page 4

Equipment Description

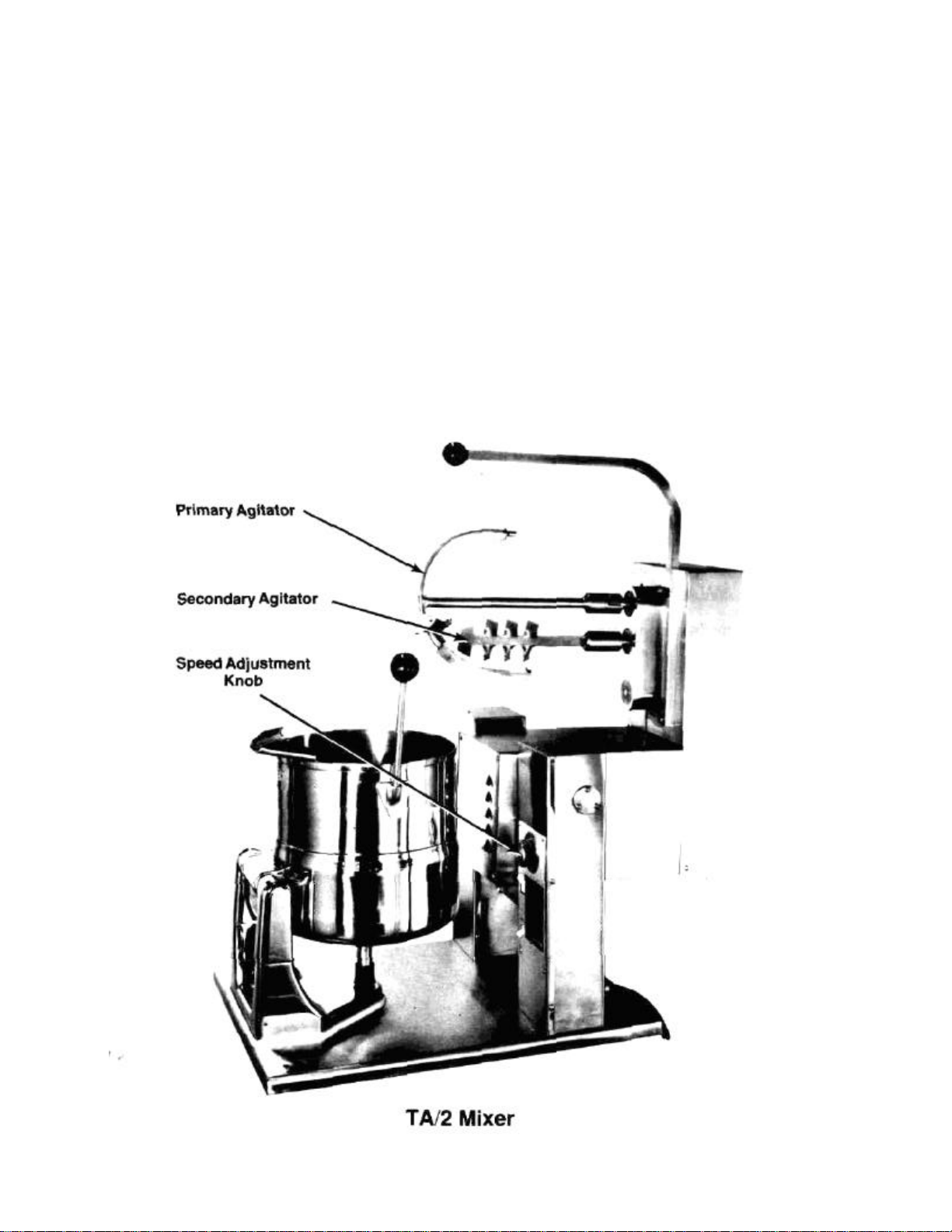

Groen TA/2 is an electrically powered, twin shaft mixer, which is mounted on Groen kettles with

capacities of 20 to 40 quarts. The mixer is mounted with a kettle on a common base. To permit easy

cleaning of the equipment and emptying of the kettle, a hinge in the pedestal allows the mixer to be

tilted back out of the kettle.

Model TA/2 has a motor (1/2 HP or optional 3/4 HP) that drives removable agitators through a combination of belt and gears. Th»stainless steel agitators consist of a primary agitator, which continuously scrapes the bottom and side of the kettle with nylon fingers, and a faster, counter rotating,

secondary agitator, which operates between the center line and the wall of the kettle.

Controls for the mixer are an on/off power switch and a variable speed adjustment knob. For safety,

the mixer is also equipped with an automatic tilt cutoff switch. All controls and drive components are

enclosed in a stainless steel console with a No. 4 finish.

Installation of the TA/2 requires connection to a 120 or 240 V, 1 PH, 50 or 60 HZ electrical service.

If the mixer is employed with an electrically heated kettle, a separate electrical connection is

required for the kettle heating elements.

For a description of the kettle component of your cooker/mixer, see the separate kettle manual.

2

Page 5

Installation & Start-Up

A. INSTALLATION

Your Groen mixer has been test operated at the factory and furnished with all internal wiring, complete

and ready for final connection. A wiring diagram is furnished on the inside of the service panel.

WARNING: INSTALLATION OF THE COOKER/MIXER MUST BE DONE BY PERSONNEL

QUALIFIED TO WORK WITH ELECTRICITY. IMPROPER INSTALLATION CAN

RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

WARNING: ANY MECHANICAL OR ELECTRICAL CHANGE MUST BE APPROVED BY

THE GROEN FOOD SERVICE ENGINEERING DEPARTMENT.

1. Set the cooker/mixer in place and level it. Confirm that there is enough rear wall and overhead

clearance to tilt the mixer safely through its entire tilting range. Provide enough clearance to permit

access for service. Fasten the unit base to the work surface to eliminate any chance that the unit

could tip over.

2. Provide the proper electric power supply as specified on the electrical information plate attached to the

equipment. Observe local codes and/or The National Electrical Code in accordance with ANSI/NFPA

70 - latest edition. The installation should conform to the code that has the more strict requirements.

A standard mixer requires 1 PH, 60 HZ service that provides 8 AMP at 120 V. (See the table of

electrical requirements.) Any electrical service for the kettle requires a separate connection.

ELECTRICAL REQUIREMENTS

120 Volts 240 Volts

1/2 HP motor 7.9 Amps 4.0 Amps

3/4 HP motor 11.5 Amps 5.8 Amps

3. Bring electrical service through the entrance in the back of the control console. Use

waterproof conduit and waterproof connectors.

WARNING: TO PREVENT POSSIBLE ELECTRIC SHOCK, GROUND THE UNIT AT

THE TERMINAL PROVIDED.

4. The following check list may be used to confirm the correctness of the installation.

— Unit level

— Adequate clearance for tilting

— Access for service

— Unit fastened down

— Mixer power supply conforms to information plate and code

— Electrical conduit and connections are waterproof

— Mixer grounded

For instructions on installing the kettle component of your cooker/mixer, see the separate

kettle manual.

B. START-UP

After the mixer is installed, the installer should confirm that the equipment is operating correctly.

1. At the circuit breaker or fuse box, turn on the electric power supply to the mixer.

2. Tilt the mixer to confirm that it can swing back far enough, so there is no interference when

the kettle is tilted.

3. Make sure that each agitator is properly seated on its drive shaft and that the drive pin is

fully engaged with the coupling.

3

Page 6

Installation & Start-Up (con't)

4. Carefully examine the primary agitator to make sure that every nylon finger is positioned so

the flat side will be against the kettle wall and the beveled side will face the center of the

kettle. An inverted finger will not sweep the surface of the kettle and may be damaged or

knocked off the agitator.

5. When the mixer is in operating position, the primary agitator should be centered in the kettle,

and all the nylon fingers should touch the inside of the kettle.

6. Press the power switch to turn on the drive. Rotate the speed adjustment knob to confirm that

the mixer operates smoothly throughout its speed range.

7. Make sure the primary agitator turns in the correct direction, so it pushes the fingers ahead of

the agitator bar.

If the mixer functions as described above, it is ready for use. If it does not, contact your

authorized Groen Service Agency.

For instructions on initial start-up of the kettle component of your cooker/mixer, see the separate

kettle manual.

Operation

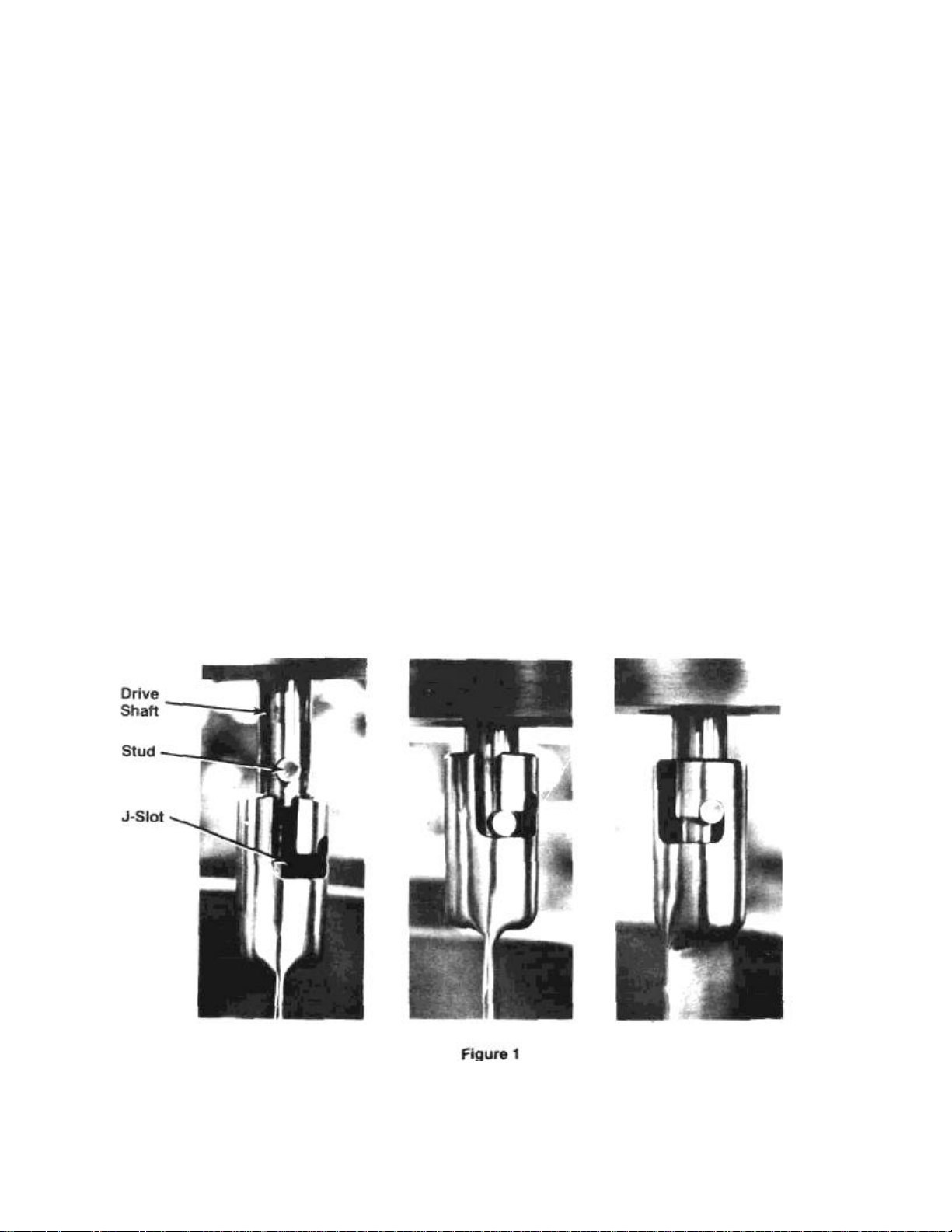

1. Mount the larger (primary) agitator on the drive shaft that operates over the center of the kettle

and the smaller (secondary) agitator on the other shaft. Slide the agitator up onto the shaft as

far as it will go, then turn the agitator and pull it down, so the stud on the shaft becomes firmly

seated against the end of the the J-slot. (See Figure 1)

2. Before you operate the mixer, confirm that each agitator is properly connected with its shaft. This

precaution will prevent damage to the unit.

4

Page 7

3. Turn the speed adjustment knob to the lowest setting. (See Figure 2) *

CAUTION: Starting with the mixer set at HIGH

SPEED MAY CAUSE material to

SPILL out of the kettle.

4. To start the mixer, press the power switch to "ON".

WARNING: IF POWER IS ON WHEN A TILTED

MIXER IS LOWERED INTO OPERATING POSITION, THE MIXER WILL

START AUTOMATICALLY, BECAUSE THE UNIT HAS AN

AUTOMATIC TILT CUTOFF SWITCH.

5. Set the desired mixing speed by turning the speed

adjustment knob. To avoid damaging the speed

control, do not run the mixer continuously under

heavy load at speeds less than 5% of full speed.

6. To stop the mixer, press the power switch to

"OFF".

7. Before you tilt the mixer, switch it off. As you begin

to tilt the mixer, tilt the kettle forward slightly, so

the agitators will clear the wall of the kettle. Scrape

excess product off the agitators, so it will not drip

onto the exterior of the kettle and surroundings.

8. When the cooker/mixer is to be cleaned or

serviced, or when it will not be used for a week or

longer, shut off all supplies of electric power to the

unit.

For instructions on operating the kettle component of

your cooker/mixer, see the separate kettle manual.

5

Page 8

Cleaning

A. SUGGESTED TOOLS & MATERIALS

1. Cleaner, like HC-10 or HC-32 from ECOLAB, Inc.

2. Stiff brush

3. Sanitizer, like Klenzade XY-12 B. PRECAUTIONS

WARNING: BEFORE CLEANING ANY PART OF THE MIXER, OTHER THAN THE

AGITATORS, SHUT OFF ALL ELECTRIC POWER TO THE COOKER/MIXER

AT THE CIRCUIT BREAKER OR FUSE BOX, TO AVOID POSSIBLE ELECTRIC SHOCK.

WARNING: KEEP WATER AND SOLUTIONS OUT OF THE CONTROLS, ELECTRICAL

WIRING, AND DRIVE MECHANISM. NEVER SPRAY OR HOSE THE MIXER.

C. PROCEDURE

1. Wash the agitators as soon as possible after use. If the unit is in continuous use, thoroughly clean all

parts of the mixer at least once every 12 hours.

2. Take each agitator off its drive shaft by pushing the agitator up toward the drive housing, then turning

the agitator and pulling it down, to slip the J-slot off the stud on the shaft. Remove the nylon fingers

from the primary agitator by sliding them to the end of the agitator bar and turning them until they can

slip off the end.

WARNING: AVOID CONTACT WITH THE CLEANER, AS RECOMMENDED BY THE

SUPPLIER. CAREFULLY READ THE WARNINGS AND FOLLOW THE

DIRECTIONS ON THE LABEL OF THE CLEANER. MANY CLEANERS ARE

HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES, AND CLOTHING.

3. Prepare a hot solution of the cleaning compound as instructed by the supplier. Wash the agitator parts

and rinse them well.

NOTE: To obtain the sweeping action and avoid damage, make sure each nylon finger is replaced on

Use a cloth moistened with the cleaning solution to clean other parts of the mixer.

4. To remove materials stuck to the agitators, use a brush, sponge, cloth, plastic or rubber scraper, or

plastic wool along with the cleaning solution. To make washing easier, let the cleaning solution soak

into the residue. When you clean the stainless steel parts, do not use any abrasive material (like

metal sponges or scouring powder) or metal implement (like a spoon, scraper, or wire brush) that

might scratch the surface. Scratches make the surface hard to clean and provide places for bacteria

to grow. Do not use steel wool, which may leave particles imbedded in the surface and cause

eventual corrosion and pitting.

5. As part of the daily cleaning program, clean all surfaces that may have been soiled. Remember to

check such parts as the back and underside of the drive housing, back of the control console, etc.

6. When the agitators need to be sanitized, use a sanitizing solution equivalent to one that supplies 100

parts per million available chlorine. Obtain advice on the best sanitizing agent from your supplier of

sanitation products. Following the supplier's directions, apply the sanitizer after the agitators have

been washed, then rinse off the sanitizer completely. It is recommended that the agitators be sanitized

just before use.

CAUTION: NEVER LEAVE A SANITIZER in contact with the surface of stainless steel

7. The exterior of the unit may be polished with a recognized stainless steel cleaner like "Zepper" from

Zep Manufacturing Company.

Cleaning procedures for the kettle component of your cooker/mixer are described in the separate kettle

manual.

the agitator with the flat side against the kettle wall and the beveled side toward the center of

the kettle.

LONGER THAN 30 MINUTES. Longer contact can cause corrosion.

6

Page 9

OPERATOR'S

Troubleshooting List

The mixer is designed to operate smoothly and efficiently if properly maintained. However, the following is a

list of checks to make in the event of a problem.

If following the directions in this list does not correct the problem, call an authorized Groen Service Agency.

SYMPTOM

Motor will not run. a. That power is turned on at the circuit breaker or

Motor runs at low speed only. a. For a mechanical overload.

Motor speed varies rapidly. a. For an oscillating load, by disconnecting the mixer

Motor overheats and/or sparks excessively. a. For an overload.

Fuse blows frequently. a. For an overload.

Troubleshooting guidance for the kettle component of your cooker/mixer is contained in the separate kettle

manual.

WHAT TO CHECK

fuse box.

b. That power is being supplied to the building.

c. Fuse in the control console.

d. For a mechanical overload, that is, too much

material in the kettle or material that is too thick or

hard to mix.

drive from the agitators and checking motor

speed.

7

Page 10

Service

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR

A. PERIODIC SERVICE

1. The interior of control and drive housings should be kept clean and dry.

2. Electrical wiring should be kept securely connected and in good condition.

3. Regular service of the mixer should include cleaning the motor, checking the motor brushes and

commutator, lubricating the gears and pivot points, and checking the belt for tightness and wear.

B.COMPONENT REPLACEMENT

WARNING: BEFORE REPLACING ANY PARTS, SHUT OFF ALL ELECTRIC POWER SUPPLIES TO

All internal wiring is marked as shown on the schematic drawings. Be sure that new components are wired

in the same manner as the old components.

C. SERVICE RECORDS

A Service Log is provided with the warranty information. Each time service is performed on this Groen

equipment, enter the date on which the work was done, what was done, and who did it. The owner

should file the log with the warranty.

Service procedures for the kettle component of the cooker/mixer are described in the separate kettle

manual.

THEIR AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN CAUSE

BODILY INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT.

SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL WILL

VOID ALL WARRANTIES.

THE COOKER/MIXER.

Service Troubleshooting

If an item in the "WHAT TO CHECK" column is followed by an asterisk (*), the work should be

done only by an authorized Groen Service Representative.

SYMPTOM WHAT TO CHECK

Motor will not run. a. Power supply to the unit.

Motor runs at high speed only a. Speed adjustment pot or wiring.*

without control. b. Power module.*

b.

Fuse in the control console.

c. For a mechanical overload.

d. That the tilt switch is closed.*

e. For a ground or short in the motor.*

f. For a defect in the power module. Check SCRs

and diodes.*

g.

Regulator.*

h. For loss of reference voltage. Check speed ad-

justment pot and wiring. Check maximum speed

pot.*

i. Motor brushes for wear or sticking.*

c. Regulator.*

8

Page 11

SYMPTOM

Motor runs at low speed only

a.

For a mechanical overload.

c. I.R. drop compensation, and adjust if set

too high.*

Motor overheats and/or

a.

For an overload.

Fuse blows frequently.

a.

For an overload.

cessive starting load.*

WHAT TO CHECK

Motor speed varies rapidly. a. For an oscillating load, by disconnecting the mixer

sparks excessively. b. Motor brushes for wear or improper seating.*

SCRs or diodes have short lives. a. For constant overload, peak overload, or ex-

b. Speed adjustment pot or wiring.*

c. Motor brushes for wear or improper seating.*

d. Regulator.*

e. For open motor field circuit, by checking field

current.*

drive from the agitators and checking motor speed.

b. Motor brushes for wear, improper seating, or

sticking in holders.*

d. SCRs.*

e. I.R. drop compensation pot.*

f. Dirty or defective regulator.*

g. Control panel and motor for a ground.*

c. Grade of brushes used.*

b. For incorrect jumper horsepower.*

c. Power module.*

d. Regulator.*

e. Whether line voltage is too high.*

f. Motor armature and wiring for ground or short.*

g. For open motor field circuit, by checking field

current.*

Troubleshooting guidance for the kettle component of your cooker/mixer is contained in the separate kettle

manual.

b. Panel for overheating, because ambient

temperature is too high or ventilation is

obstructed.*

c. Line voltage.*

d. Motor or wiring for a ground.*

9

Page 12

Parts List

NO.

To order parts, contact your authorized Groen Service Agency. Supply the model designation, part description, part

number, quantity, and where applicable, voltage and phase.

WARNING: USE ONLY GROEN SUPPLIED PARTS. SUBSTITUTION OF UNAUTHORIZED PARTS OR GENERIC

PARTS CAN CAUSE BODILY INJURY TO THE OPERATOR AND DAMAGE TO THE EQUIPMENT.

PAR

ITEM

T

NO.

1 12692

2 12691

3 13355

4 13382

5 9442

6 9199

7 6495

8 6455

9 13972

10 13491

11 12337

12 13357

13 13358

14 13378

15 13366

DESCRIPTION

TOLERANCE RING (PART OF ITEM 2)

PLASTIC KNOB (FRICTION)

GASKET (BUNA N RUBBER)

SHAFT

BRONZE BEARING

CORD GRIP

3-WIRE POWER CORD, 8' LONG

3-PRONG ELECTRIC CORD PLUG

CONTROL. DC ADJUSTABLE SPEED

MOTOR

SCRAPER, HALF FINGER

GEAR CARRIER

BEARING

PRIMARY SHAFT

SEAL

ITEM

NO.

PART

NO.

16 13383

17 13359

18 13386

19

20 13379

21 13360

22 13361

23 13384

24 13362

25 13363

26 13364

27 13380

28 13381

29 13385

30

DESCRIPTION

SPACER

GEAR, 48-TOOTH. 4.000 P. DIA.

KEY

1538

SNAPPING

SECONDARY SHAFT

GEAR, 18-TOOTH, 1.5000 P. DIA

GEAR, 72-TOOTH, 6.000 P. DIA,

SPACER

PULLEY, 7" O.D.

V-BELT

PULLEY, 2 3/4" O.D.

PULLEY SHAFT

PLUG

SPACER

9253

COUPLING PIN

A list of parts for the kettle component of your cooker/mixer is contained in the separate kettle manual.

References

KLENZADE SALES CENTER — ECOLAB, INC.

370 Wabasha

St. Paul, Minnesota 55102

800/328-3663 or 612/293-2233

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/70 The National Electrical Code

NATIONAL SANITATION FOUNDATION

3475 Plymouth Rd.

Ann Arbor, Michigan 48106

ZEP MANUFACTURING CO.

1390 Lunt Avenue

Elk Grove Village, Illinois 60007

KLENZADE SALES CENTER — ECOLAB, INC.

370 Wabasha

St. Paul, Minnesota 55102

800/328-3663 or 612/293-2233

10

Page 13

11

Page 14

Schematic

12

Page 15

LIMITED WARRANTY TO

OM

-

TA/2 (Revised

2/88)

COMMERCIAL PURCHASERS

(Continental U.S., Hawaii & Canadian Sales Only)

Groen Foodservice Equipment ("Groen Equipment") has been skillfully manufactured, carefully inspected and

packaged to meet rigid standards of excellence. Groen warrants its Equipment to be free from defects in

material and workmanship for (12) twelve months, with the following conditions and subject to the following

limitations.

I. This parts and labor warranty is limited to Groen Equipment sold to the original commercial

purchaser/users (but not original equipment manufacturers), at its original place of installation, in the

continental United States, Hawaii and Canada,

II. Damage during shipment is to be reported to the carrier, is not covered under this warranty, and is the

sole responsibility of purchaser/user.

III. Groen, or an authorized service representative, will repair or replace, at Groen's sole election, any

Groen Equipment, including but not limited to, draw-off valves, safety valves, gas and electric

components, found to be defective during the warranty period. As to warranty service in the territory

described above, Groen will absorb labor and portal to portal transportation costs (time & mileage) for

the first twelve (12) months from date of installation or fifteen (15) months from date of shipment from

Groen.

IV. This warranty does not cover boiler maintenance, calibration, periodic adjustments as specified in

V. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

VI. Groen Equipment is for commercial use only. If sold as a component of another (O.E.M.)

operating instructions or manuals, and consumable parts such as scraper blades, gaskets, packing,

etc., or labor costs incurred for removal of adjacent equipment or objects to gain access to Groen

Equipment. This warranty does not cover defects caused by improper installation, abuse, careless

operation, or improper maintenance of equipment. This warranty does not cover damage caused by

poor water quality or improper boiler maintenance.

OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANT ABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE

REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL GROEN BE

LIABLE FOR SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR

DELAY IN PERFORMANCE OF THIS WARRANTY.

manufacturer's equipment, or if used as a consumer product, such Equipment is sold AS IS and

without any warranty.

•(Covers All Foodservice Equipment Ordered after October 1, 1995)

GROEN, A Dover Industries

Company

1900 Pratt Boulevard Elk Grove

Village, Illinois 60007

Telephone: (312) 439-2400

TELEX 28 7413

Loading...

Loading...