Page 1

GE

Measurement & Control

™

DigitalFlow

Panametrics Liquid Flow Ultrasonic

Transmitter

The DigitalFlow XMT868i liquid fl ow transmitter is

a complete ultrasonic fl ow metering system for

measurement of:

Applications

• Hydrocarbon liquids

XMT868i

• Liquefi ed natural gas (LNG)

• Crude oil

• Lubricating oils

• Diesel fuel oils

• Solvents

• Water and wastewater

• Hot/chilled water

• Chemicals

• Beverages

• Other liquids

Features

• Economical non-intrusive fl ow measurement

• Hazardous (classifi ed) location certifi cations

• Simple set-up and installation

• Suitable for wide range of pipe sizes and materials

• Two-channel/two-path version available

Page 2

Panametrics Liquid Flow Ultrasonic

Transmitter

The DigitalFlow XMT868i ultrasonic fl ow transmitter

combines state-of-the-art fl ow measurement capability

with a low-cost transmitter package that can be installed

right at the process measurement point. The XMT868i

carries appropriate certifi cation for for installation in

hazardous (classifi ed) locations commonly found in

petrochemical and chemical processing environments.

The all-digital XMT868i has no moving parts, requires

minimal maintenance and provides long-term, drift-free

operation. An onboard microprocessor provides exclusive

digital signal coding and correlation detection routines,

automatic adjustment to changing fl uid properties, and

dynamically-confi gured operating software to simplify

programming.

Improved Programming Capability

The DigitalFlow XMT868i introduces an infrared

six-button keypad to allow safe programming and

diagnostics verifi cation in your hazardous (classifi ed)

location. There is no need to open the case to use a PC

to program and no need for an additional handheld

programmer. Just touch the glass of the XMT868i and

the IR buttons will sense your touch. If you prefer your

PC interface, the DigitalFlow XMT868i maintains its RS232

capability, providing full access to the meter’s diagnostics

and programming using PanaView™ software. PanaView

also provides continuous logging capability.

Wetted or Clamp-On Transducers

Ultrasonic fl ow transducers are classifi ed as either wetted

or non-wetted (clamp-on). Clamp-on transducers are

clamped onto the outside of the pipe and never come

into contact with the process fl uid. Wetted transducers

are mounted into the pipe or fl owcell in direct contact

with the process fl uid.

Clamp-on transducers offer maximum convenience,

fl exibility and a low installation cost compared to

traditional fl ow metering technologies. With proper

installation, wetted transducers provide maximum

accuracy (better than 0.5 percent of reading) in most

applications.

The DigitalFlow XMT868i can be used with a variety of

wetted solutions including the PanaFlow™ system. The

PanaFlow meter system relies on the XMT868i as an

integral component to simplify installation. A DigitalFlow

XMT868i is easily mounted to the top of a PanaFlow

system and is shipped ready to install.

Dual-Channel Version Reduces Costs

and Improves Performance

The optional dual-channel/dual-path model can be userconfi gured for a variety of applications. It can be set up

to measure fl ow in two separate pipes with one meter to

reduce the cost-per-measurement point.

To minimize the effects of fl ow profi le distortions, fl ow

swirl and cross fl ow, and for maximum accuracy, you

can install the two sets of transducers on the same pipe.

DigitalFlow XMT868i shown with clamp-on transducers

Page 3

DigitalFlow XMT868i Flow Transmitter

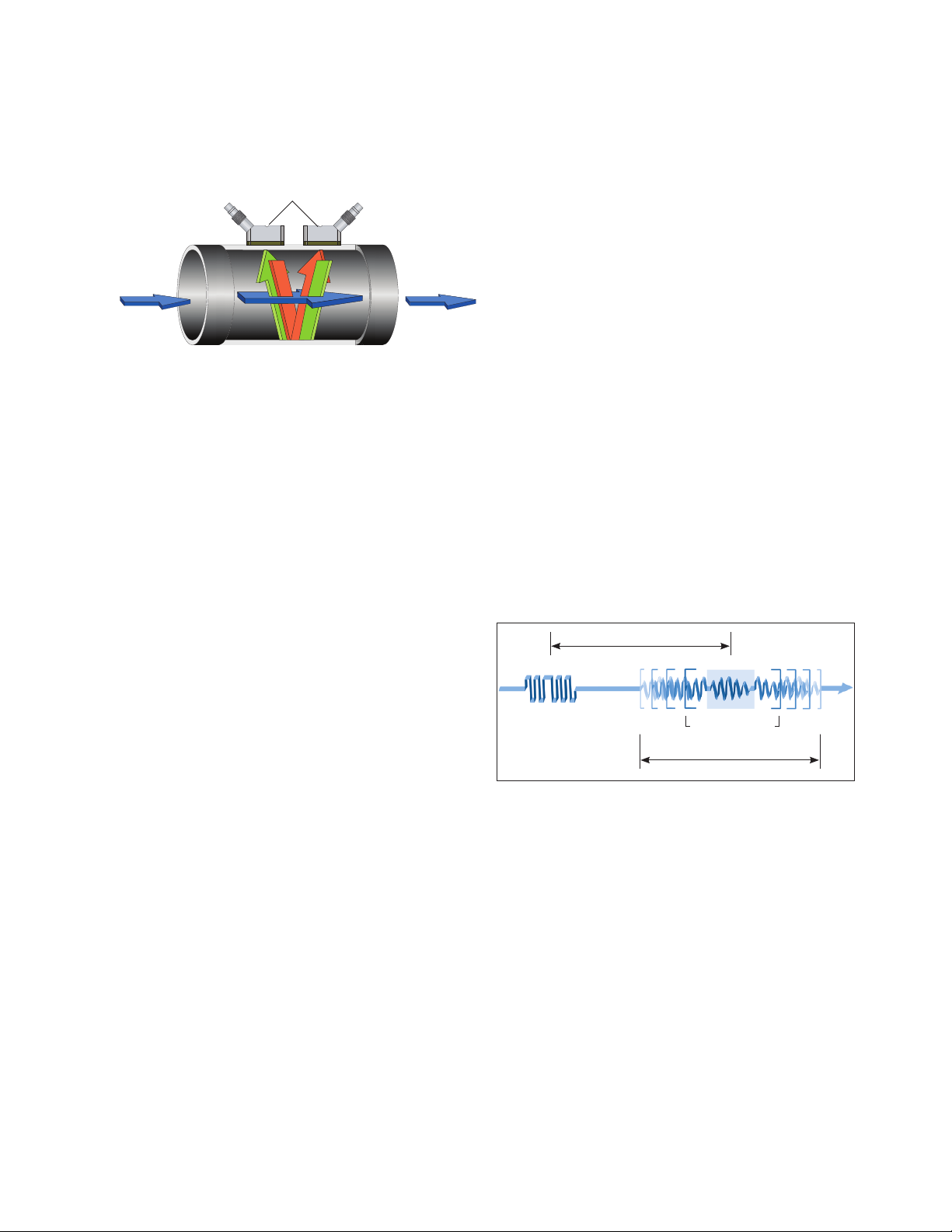

Uses Transit-Time Flow Measurement

Technique

Flowmeter transducers

Fluid

fl ow

Automatically Adjusts to Changing

Fluid Properties

Standard in all DigitalFlow XMT868i transmit ters, our

unique Automatic Tracking Window™ (ATW™) feature

ensures accurate fl ow measurements even when fl uid

properties are unknown or changing. Like the seek mode

on your car stereo, ATW dynamically sweeps the receiver

window whenever the sound speed of the fl uid changes.

This powerful feature lets you measure fl ow when the

fl uid sound speed is unknown, is changing due to large

temperature shifts, or when a new liquid starts to fl ow in

a multiproduct pipeline.

Ultrasonic signal path

Transit-time fl ow measurement technique

In this method, two transducers serve as both ultrasonic

signal generators and receivers. When mounted on a

pipe, they are in acoustic communication with each other,

meaning the second transducer can receive ultrasonic

signals transmitted by the fi rst transducer and vice versa.

In operation, each transducer functions as a transmitter,

generating a certain number of acoustic pulses, and

then as a receiver for an identical number of pulses.

The time interval between transmission and reception

of the ultrasonic signals is measured in both directions.

When the liquid in the pipe is not fl owing, the transit-time

downstream equals the transit-time upstream. When the

liquid is fl owing, the transit-time downstream is less than

the transit-time upstream.

The difference between the downstream and upstream

transit times is proportional to the velocity of the fl owing

liquid, and its sign indicates the direction of fl ow.

ATW works for both clamp-on and wetted transducer

applications by searching for a reliable ultrasonic

receive signal. It does this by varying the time between

the transmit signal and the receive signal window until

the receive signal is found. The tracking window automatically sweeps through a range of time intervals based

on the minimum and maximum expected sound speeds

programmed by the user.

The window moves (tracks) in response to changes in the

fl uid sound speed. Once the optimal signal is found, ATW

locks onto it until another large change in sound speed

occurs. When this happens, ATW returns to the seek

mode until the optimal signal is found again.

Variable time interval

Receive signalTransmit signal

Tracking window

locked onto

receive signal

Range of tracking window

ATW ensures accuracy when fl uid conditions change

Time

Page 4

XMT868i Specifi cations

Electronics

Operation and Performance

Fluid Types

Acoustically conductive fl uids, including most clean

liquids, and many liquids with entrained solids or gas

bubbles. Maximum void fraction depends on transducer,

interrogation carrier frequency, path length and pipe

confi guration.

Pipe Sizes

• Clamp-on transducers: 0.5 in to 300 in (12.7 mm to 7.6

m) and larger

• Wetted transducers: 1 in to 200 in (25.4 mm to 5 m)

and larger

Pipe Wall Thickness

Up to 3 in (76.2 mm)

Pipe Materials

All metals and most plastics. Consult GE for concrete,

composite materials, and highly corroded or lined pipes.

Flow Accuracy (Velocity)

±0.5% of reading (achievable with process calibration)

Typical Clamp-On Flow Accuracy (Velocity)

• Pipe ID>6 in (150 mm): ±1% to 2% of reading

• Pipe ID<6 in (150 mm): ±2% to 5% of reading

Typical Wetted Flow Accuracy (Velocity)

±1% of reading

Accuracy depends on pipe size, installation and whether

measurement is one-path or two-path.

Repeatability

±0.1% to 0.3% of reading

Range (Bidirectional)

–40 to 40 ft/s (–12.2 to 12.2 m/s)

Rangeability (Overall)

400:1

Flow Measurement

Patented Correlation Transit-Time™ mode

Enclosures

• Standard: Epoxy-coated aluminum weatherproof

Type 4X/IP66 Class I, Divison 1, Groups B, C & D; Class

II, Groups E, F & G; Class III Flameproof II 2 GD EEx d IIC

T5/T6

• Optional: Stainless steel

Dimensions

Standard: Weight 10 lb (4.5 kg), size (h x d) 8.2 in x 6.6 in

(208 mm x 168 mm)

Channels

• Standard: One channel

• Optional: Two channels (for two pipes or two-path

averaging)

Display

Optional: two-line x 16-character backlit LCD display,

confi gurable to display up to four measurement

parameters in sequence

Keypad

Built-in infrared, six-button keypad, for full functionality

operation

Power Supplies

• Standard: 100-240 VAC ±10%

• Optional: 12 to 28 VDC, ± 5%

Note: For DC-powered meters, Class 2 rated supplies must

be used for the line power

Power Consumption

20W maximum

Operating Temperature

-40°F to 140°F (-40°C to +60°C)

Storage Temperature

–67°F to 167°F (–55°C to 75°C)

Specifi cations assume a fully developed fl ow profi le

(typically 10 diameters upstream and 5 diameters

downstream of straight pipe run) and fl ow velocity

greater than 1 ft/s (0.3 m/s).

Measurement Parameters

Volumetric fl ow, totalized fl ow and fl ow velocity

Page 5

Standard Inputs/Outputs

Two 0/4 to 20 mA isolated outputs, 600 S maximum load

Namur NE043 compliant

Optional Inputs/Outputs

All analog and digital I/O are available in specifi c

combinations. Consult GE for available option cards.

• Two additional 0/4 to 20 mA isolated outputs, 1000

maximum load

• Two 4 to 20 mA isolated inputs, 24-VDC loop power

• Two or four isolated, three-wire RTD (temperature)

inputs, –148°F to 662°F (–100°C to 350°C), 100 S

platinum

• Two or four pulse or frequency outputs, optically

isolated, 3A maximum, 100 VDC maximum, 1W

maximum, from DC to 10 kHz maximum

• Alarm relays

Digital Interfaces

• Standard: RS232

• Optional: RS485 (multiuser)

• Optional: HART

• Optional: Modbus

• Optional: Foundation Fieldbus

• Optional: OPC server

• Optional: Ethernet

®

protocol

®

protocol

®

Data Logging

• Standard: None

• Optional: Memory capacity (linear and/or circular type)

to log up to 150,000 fl ow data points

Wetted Ultrasonic Flow Transducers

Temperature Ranges

• Standard: –40°F to 212°F (–40°C to 100°C)

• Optional (overall range): –310°F to 1112°F (–190°C to

600°C)

Pressure Ranges

• Standard: 0 to 3000 psig (1 to 207 bar)

• Optional: Higher pressures on request

Materials

• Standard: Stainless steel

• Optional (for Pan-Adapta

Titanium, Hastelloy

PVDF and others

Pan-Adapta plugs allow installation and removal of

wetted transducers without interrupting the process or

emptying the pipe.

Temperature Ranges

• Standard: –40°F to 212°F (–40°C to 100°C)

• Optional (overall range): –310°F to 1112°F (-190°C to

600°C)

Pressure Ranges

• Standard: 0 psig to 3000 psig (1 bar to 207 bar)

• Optional: Higher pressures on request

®

Plugs):

®

alloy, Monel® alloy, duplex, CPVC,

European Compliance

System complies with EMC Directive 89/336/EEC, 73/23/

EEC LVD (Installation Category II, Pollution Degree 2) and

transducers comply with PED 97/23/EC for DN<25

Clamp-On Ultrasonic Flow Transducers

Temperature Ranges

• Standard: -40°F to 302°F (-40°C to 150°C)

• Optional: -328°F to 752°F (-200°C to 400°C)

See specifi c transducer for exact temperature range.

Mountings

Stainless steel chain or strap, welded or magnetic

clamping fi xtures

Area Classifi cations

• Standard: General purpose

• Optional: Weatherproof Type 4X/IP66

• Optional: Explosion Proof, Class I, Division 1, Groups B, C

& D; Class II, Groups E, F & G; Class III

• Optional: Flameproof II 2 G EEx md IIC T6–T3

• Optional: Submersible

Materials

• Standard: Stainless steel

• Optional (for Pan-Adapta

Titanium, Hastelloy

PVDF and others

Pan-Adapta plugs allow installation and removal of

wetted transducers without interrupting the process or

emptying the pipe.

®

Plugs):

®

alloy, Monel® alloy, duplex, CPVC,

Process Connections

• Standard: 1 in or 3/8 in NPTM

• Optional: RF fl anged, socket weld, fuse bond and others

Mountings

Flanged fl owcell, hot tap or cold tap

Area Classifi cations

• Standard: General purpose

• Optional: Weatherproof Type 4/IP65

• Optional: Class I, Division 1, Groups B, C & D; Class II,

Groups E, F & G; Class III

• Optional: Flameproof II 2 G EEx d IIC T6

• Optional: Submersible

Page 6

Transducer Cables

• Standard: One pair of coaxial cables, type RG62 AU, or

as specifi ed for transducer type

• Optional: Lengths up to 1000 ft (330 m) maximum

High-Temperature and High-Pressure

Ultrasonic Flow Transducers

Bundle Waveguide Technology™ System transducer and

holder (see BWT™ System specifi cations)

Clamp-on extended temperature (C-ET) range transducer

system

Energy Measurement

Calculates energy fl ow rate and totalized energy.

Requires optional RTD or analog I/O board.

Temperature Transducers

Loop-powered, three-wire, platinum RTDs; clamp-on and

wetted (thermo-well) types are available

Accuracy

±0.15°C with wetted RTDs (matched pairs)

Range

-4°F to 500°F (-20C° to 260°C)

The accuracy of the energy measurement is a

combination of the accuracy of the associated fl ow

and temperature measurements. 1% to 2% of reading

is typical for calibrated systems. Not all extremes of

parameters can be achieved simultaneously.

Additional Options

PanaView™ PC Interface Software

The DigitalFlow XMT868i communicates with a PC

through a serial interface and Windows

systems. Consult the manual for details on sites, logs and

other operations with a PC.

®

operating

Page 7

XMT868i Application Notes

Additional Options

in Brief

Ultrasonic Flowmeter Saves Money Over Mag

Meter

A sewerage/wastewater facility found that installing a

GE clamp-on ultrasonic fl owmeter offered excellent

performance and accuracy and was far less expensive

than installing a new mag meter. When comparing cost

of a new 30 in (750 mm) mag meter to be installed on

their cast iron line to that of a two-path GE meter, the

water treatment plant decided that the ultrasonic meter

was a bargain. The 30 in (750 mm) mag required the line

to be shut down for installation and major piping work

needed to be done. It was estimated that it would take

several days to get the meter running. The GE meter was

easily installed to existing piping without ever shutting

down the pipe and installation was complete within a

day.

PanaView™ PC Interface Software

The DigitalFlow XMT868i communicates with a PC

through a serial interface and Windows

systems. Consult the manual for details on sites, logs and

other operations with a PC.

®

operating

710°F (376°C) Resid Line? No Problem.

With the DigitalFlow XMT868i combined with the Bundle

Wafeguide Technology System from GE, you can

measure cryogenic fl uids like LNG or the demanding

temperatures of coker resid lines that can run hotter

than 700°F (371°C). Ultrasonic fl owmeters will not cause

pressure drop and have no impulse lines to plug, making

them a great solution for diffi cult fl uids.

Even though most ultrasonic manufacturers’ fl owmeters

can only handle up to 500°F (260°C), GE’s BWT systems

have been able to reach up to 1000°F (537°C). The unique

design removes the piezoelectric element from the

extreme temperatures by using wave guide technology.

The transducer can even be swapped out under

operating conditions. One customer has installed 16

units, replacing their wedge meters, and has had them

operating maintenance free for more than fi ve years.

Accuracy

±0.15°C with wetted RTDs (matched pairs)

Range

–4°F to 500°F (–20C° to 260°C)

The accuracy of the energy measurement is a

combination of the accuracy of the associated fl ow

and temperature measurements. 1% to 2% of reading

is typical for calibrated systems. Not all extremes of

parameters can be achieved simultaneously.

Bundle Waveguide Technology System

Page 8

www.gemeasurement.com

920-170E

© 2016 General Electric Company. All Rights Reserved. Specifi cations are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product

names mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affi liated with GE.

Loading...

Loading...