Page 1

GE

Measurement & Control Oxygen Analysis

XMO2-IDM

User’s Manual

910-141 Rev. F

October 2013

Page 2

Page 3

XMO2-IDM

Oxygen Analyzer

User’s Manual

910-141 Rev. F

October 2013

ATTENTION! This manual should be used only for XMO2 units with the IDM User Program (Option D = 3 or 4).

For XMO2 units with the Terminal User Program (Option D = 1 or 2), manual number 910-141A

must be used.

www.ge-mcs.com

©2013 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Preface

Information Paragraphs

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper setup of

the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe

damage to the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these

instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national

codes, regulations, rules and laws related to safety and safe operating conditions are met for

each installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during

manual operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out

before you perform maintenance procedures on the equipment.

XMO2 User’s Manual iii

Page 6

Preface

Auxiliary Equipment (cont.)

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control Solutions is an active participant in Europe’s Waste Electrical and Electronic Equipment

(WEEE) take-back initiative, directive 2002/96/EC.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Visit http://www.ge-mcs.com/en/about-us/environmental-health-and-safety/1741-weee-req.html

take-back instructions and more information about this initiative.

iv XMO2 User’s Manual

for

Page 7

Contents

Chapter 1. Features and Capabilities

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Basic Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1 The XMO2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4.2 The Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.4.3 Long Cables (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.4.4 Power Supply (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.4.5 The TMO2D Display/Controller (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Chapter 2. Installation

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2 Installing the XMO2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.3 Installing the Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3.1 A Basic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3.1 Wiring the XMO2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.2 CE Mark Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.3 Grounding the XMO2 Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.4 Cable Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.3.5 Accessing Terminal Blocks TB1 and TB2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.3.6 Wiring the Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.4 Establishing the RS232 Communication Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.5 Connecting to Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.5.1 The PS5R-C24 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.5.2 TMO2D Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.5.3 LDP Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.5.4 XDP Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.5.5 Moisture Image/Monitor Series Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.5.6 System 1 Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Chapter 3. Startup & Operation

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.2 Powering Up the XMO2 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.3 Establishing a Sample Gas Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4 Analog Output Calibration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.5 Factory Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.6 Enhancing the Factory Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.7 Required Calibration Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.8 Preparing for Field Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.9 One-Gas Pushbutton Field Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

XMO2 User’s Manual v

Page 8

Contents

3.10 Two-Gas Pushbutton Field Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.10.1 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.10.2 Zero Gas Pushbutton Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.10.3 Span Gas Pushbutton Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.11 IDM Digital Communication Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.12 The Edit Functions Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.13 The Field Cal Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.13.1 Perform Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.13.2 Configure Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.13.3 Calibration Drifts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.13.4 Clear Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.13.5 Hold Last Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.14 Changing the 4-20 mA Analog Output Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.14.1 4-20mA Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.14.2 4mA Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.14.3 20 mA Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.14.4 4-20mA Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.14.5 %O2 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Chapter 4. Programming with Instrument Data Manager

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.2 The Edit Functions Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2.1 The Error Handler Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.2.2 Total Drift Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4.2.3 All Other Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.3 The Factory Cal Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.3.1 Background Gas Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.3.2 Pressure Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

4.4 The Advanced Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.1 Fast Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.4.2 Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.4.3 Meter ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Chapter 5. Specifications

5.1 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

5.2 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

5.3 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

5.4 Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

5.5 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

5.6 Calibration Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

5.7 A Calibration Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

vi XMO2 User’s Manual

Page 9

Contents

Appendix A. Two Typical Applications

A.1 Blanketing Gases in Hydrocarbon Liquid Storage Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

A.1.1 The Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

A.1.2 Equipment Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

A.1.3 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

A.1.4 Previous Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

A.2 Reactor Feed Gases in Formaldehyde Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

A.2.1 The Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

A.2.2 Equipment Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

A.2.3 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

A.2.4 Previous Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

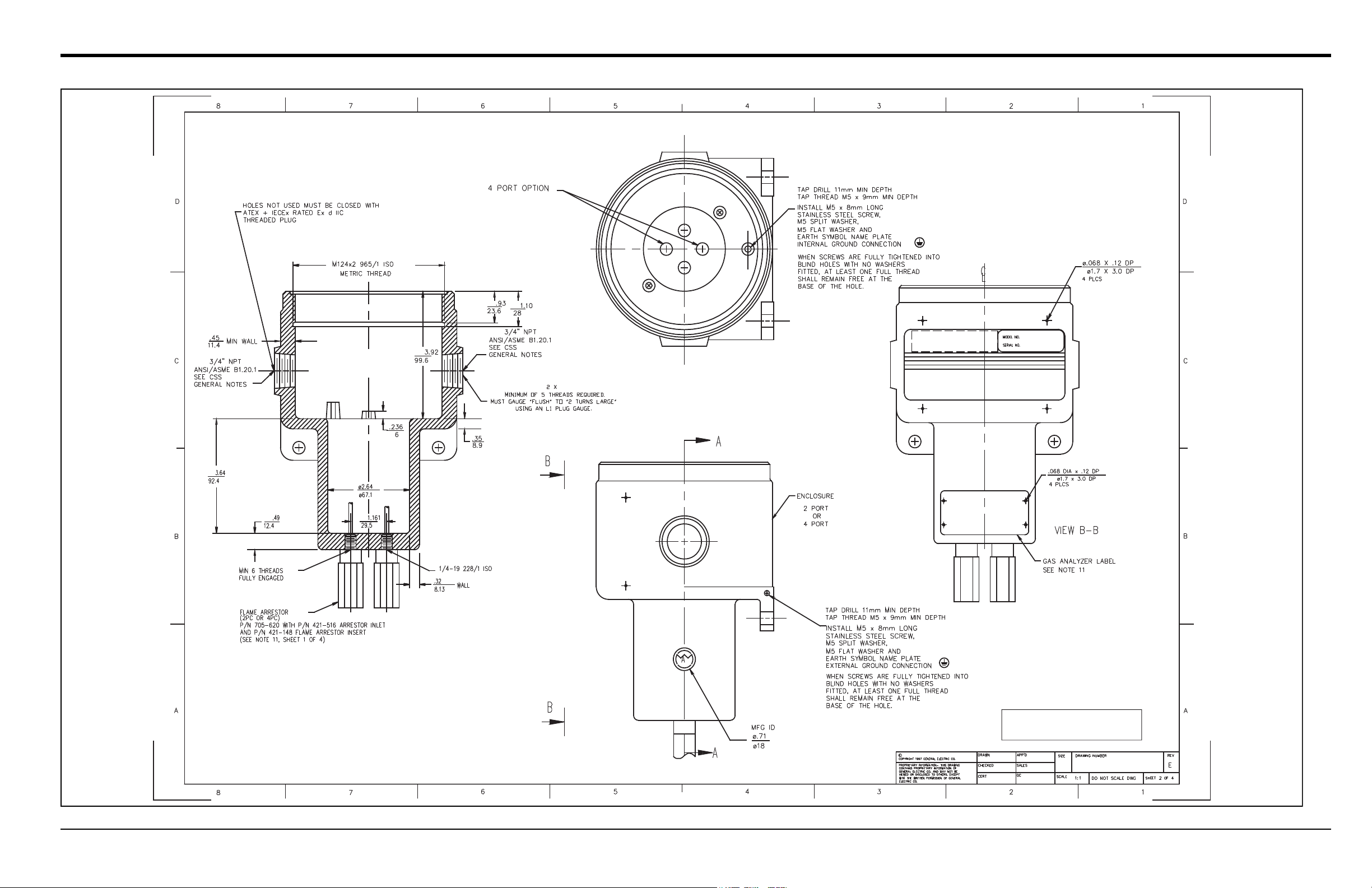

Appendix B. Outline and Installation Drawings

Appendix C. IDM Menu Maps

Appendix D. Programming with PanaView

D.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

D.2 Wiring the RS232 Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

D.3 Setting Up the Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

D.4 Adding the XMO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

D.5 Changing Meter Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Appendix E. CE Mark Compliance

E.1 CE Mark Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

E.2 EMI Filter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

E.3 Wiring the Signal Connections for the Weatherproof Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

E.4 Wiring the Signal Connections for the Explosion/Flameproof Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Appendix F. Certifications

F.1 EC-Type Examination Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

F.2 IECEx Certificate of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

XMO2 User’s Manual vii

Page 10

Contents

[no content intended for this page]

viii XMO2 User’s Manual

Page 11

Chapter 1. Features and Capabilities

Chapter 1. Features and Capabilities

1.1 Introduction

This chapter introduces you to the features and capabilities of the GE XMO2 Thermoparamagnetic Oxygen

Transmitter. The following specific topics are discussed:

• Basic Features - a brief discussion of the XMO2 Transmitter’s basic features and capabilities

• Theory of Operation - details on the sensor’s construction and how the measurements are made

• System Components - a description of the available XMO2 options and the required sample system

Note: The XMO2 technical specifications and ordering information can be found in Chapter 5, Specifications.

1.2 Basic Features

The XMO2 Transmitter measures the concentration of oxygen in the 0-100% range in a variety of gas mixtures, and it

provides a 4-20 mA analog output signal that is proportional to the oxygen concentration. In performing these

measurements, the microprocessor-based XMO2 provides automatic oxygen signal compensation for background gas

composition and/or pressure variations. In addition, the XMO2 is equipped with Fast-Response software, real-time

error detection, and push-button field calibration.

The XMO2 Transmitter offers several unique design features:

• Ultra-stable thermistors and a measuring cell that is temperature-controlled at 45°C (113°F) provide excellent

zero and span stability, as well as a high tolerance to ambient temperature variations. Optional measurement

cell operating temperatures of 60°C (140°F) and 70°C (158°F) are available for special applications.

• The measurement cell design is resistant to contamination and relatively tolerant of sample gas flow rate

variations. As it has no moving parts, the XMO2 performs reliably under the shock and vibration found in

many industrial applications.

• The XMO2’s unique “bridge-within-a-bridge” measurement circuit and microprocessor-based operation

automatically compensate the oxygen signal for variations in the magnetic and thermal properties of the

background gas that would otherwise cause measurement errors.

XMO2 User’s Manual 1

Page 12

Chapter 1. Features and Capabilities

1.2 Basic Features (cont.)

At high oxygen concentrations, changes in atmospheric pressure have significant effects on the measured

•

oxygen level. However, the XMO2 provides automatic microprocessor-based atmospheric pressure

compensation of the oxygen signal for these applications.

• The XMO2 modular construction means that the unit can be field-calibrated quickly and easily. Also, the

plug-in measuring cell can be replaced with a pre-calibrated spare in just minutes.

• The XMO2 transmitter, which is available in weatherproof or explosion-proof packaging, is designed to be

installed as close as possible to the process sample point. It can be located up to 450 ft (150 m) from the control

system, display, or recorder using standard GE cables.

• An RS232 serial communications interface and a multi-level, menu-driven User Pr ogram provide a convenient

means for calibrating and programming the XMO2

• Internal software algorithms along with user-programmed calibration data provide compensation of the oxygen

signal for background gas composition, atmospheric pressure, or both background gas composition and

atmospheric pressure.

• GE proprietary Fast-Response software provides enhanced response times to track rapidly changing processes.

• Sophisticated error-checking software with user-programmable defaults and error limits detects abnormal

measurement conditions.

• Pushbutton adjustment of the 4-20 mA analog output zero and span values is a standard feature with the

XMO2.

• A drift calibration routine provides automatic drift compensation for minor changes in the sensor calibration

setting.

• Programmable recalibration is accomplished in the field via a computer interface, with no potentiometers to

adjust.

2 XMO2 User’s Manual

Page 13

Chapter 1. Features and Capabilities

Induced Gas

Flow

Magnetic

Field

Upper

Measurement

Chamber

Lower

Flow-Through

Chamber

Sample

Inlet

Sample

Outlet

Wind

Receiving

(Warmed)

Thermistor

Wind

Generating

(Cooled)

Thermistor

1.3 Theory of Operation

The XMO2 measures the concentration of oxygen in a gas mixture by utilizing the unique paramagnetic properties of

oxygen.

As its magnetic susceptibility is approximately 100 times greater than that of most other common gases, oxygen can be

easily distinguished from these gases based on its behavior in a magnetic field. Also, oxygen’s magnetic susceptibility

varies inversely with temperature. Therefore, by carefully combining a magnetic field gradient and a temperature

gradient within the XMO2 measuring cell, an oxygen-containing gas mixture can be made to flow along these

gradients. This induced gas flow is known as a magnetic wind. The intensity of this magnetic wind depends on the

concentration of oxygen in the gas mixture.

Figure 1 below shows a flow schematic for the XMO2 measuring cell. Permanent magnets within the cell create a

magnetic field, while the cell temperature is controlled at 45°C (113°F) to maintain thermal equilibrium. In addition,

the cell contains two pairs of highly-stable, glass-coated thermistors. One thermistor of each pair located inside the

magnetic field and the other thermistor of each pair located outside the field. Because the thermistors are electrically

heated, a temperature gradient is thus created within the magnetic field.

XMO2 User’s Manual 3

Figure 1: Measuring Cell Flow Schematic

Page 14

Chapter 1. Features and Capabilities

Induced Gas Flow Induced Gas Flow

Wind Receiving

(Warmed)

Thermisters

Wind Generating

(Cooled)

Thermisters

Magnetic Field

1.3 Theory of Operation (cont.)

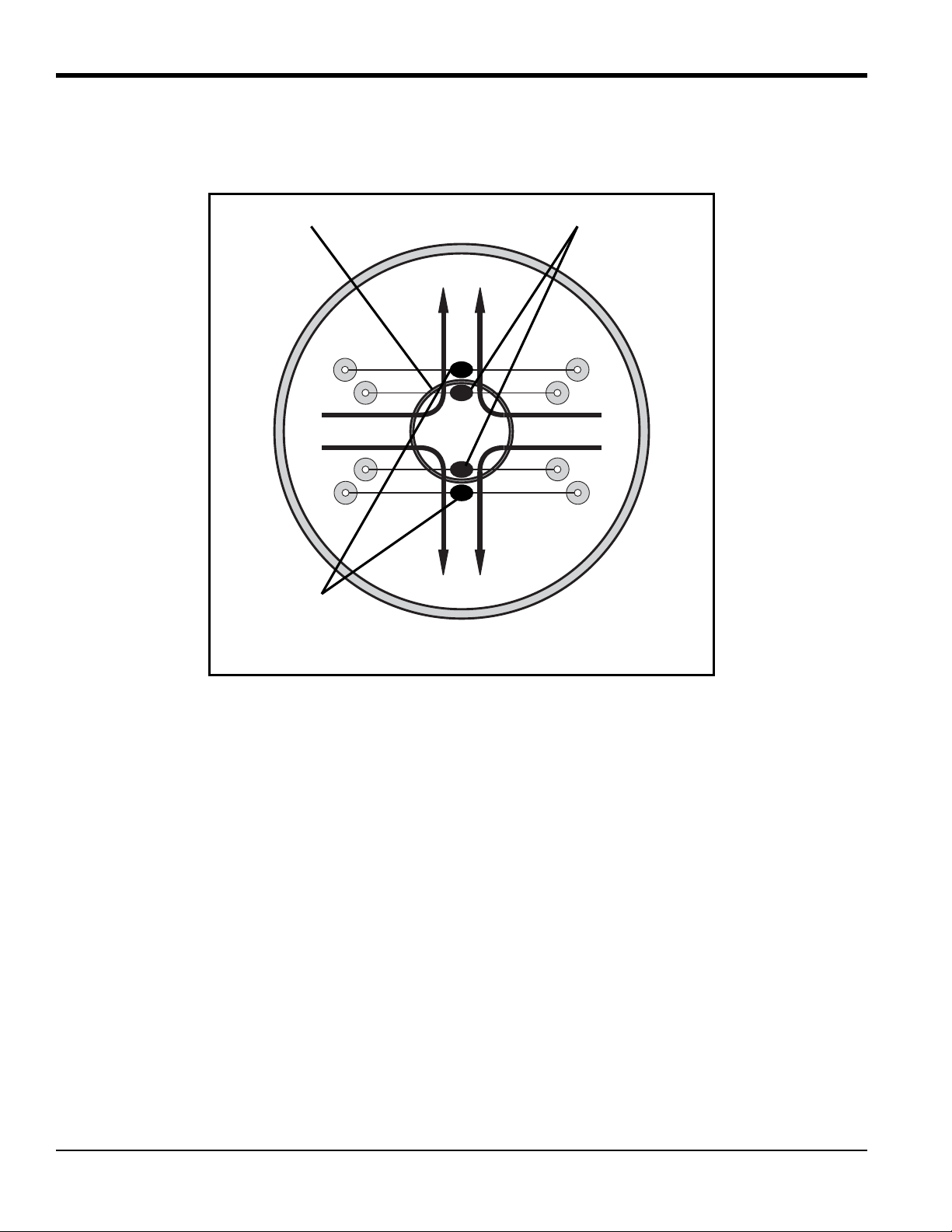

Figure 2 below shows the arrangement of the two thermistor pairs.

Figure 2: Arrangement of the Thermistor Pairs

A small portion of the sample gas flow is allowed to diffuse from the lower chamber into the upper chamber of the

measurement cell. If the sample gas contains a paramagnetic gas such as oxygen, it is attracted to the magnetic field,

causing the sample gas pressure to become locally higher in the center of the chamber. At the same time, the sample gas

pressure is slightly lower near the thermistors because the high thermistor temperature causes the paramagnetic

properties of oxygen to decrease. This slight gradient in sample gas pressure causes the sample gas to flow outward

from the center of the magnetic field and over the thermistors. As a result, the inner, wind-generating thermistors

decrease in temperature as they lose heat to the magnetic wind. This causes a temperature gradient between the cooler

inner thermistors and the warmer outer thermistors.

4 XMO2 User’s Manual

Page 15

Chapter 1. Features and Capabilities

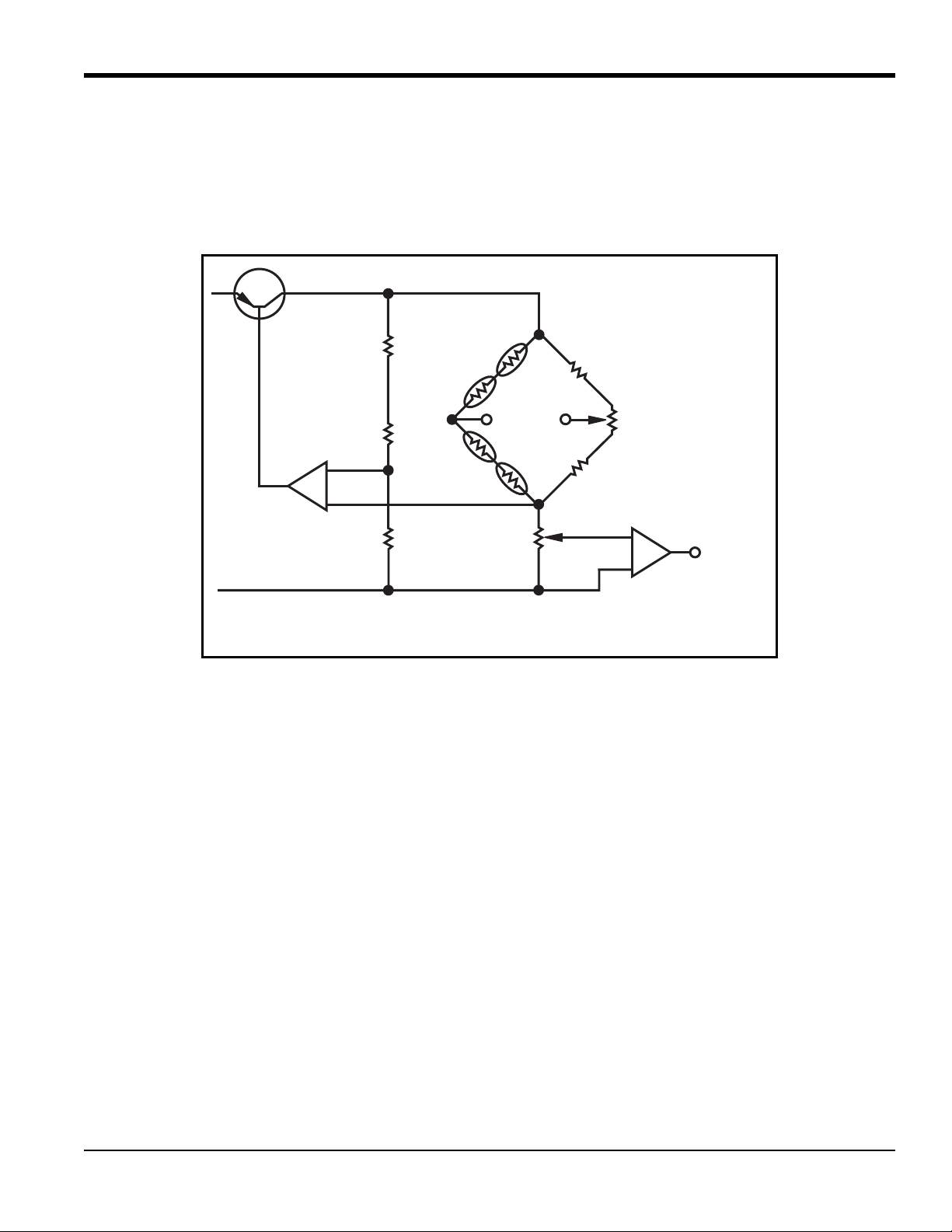

R1

W1

W2

R2

V02

Vcomp

W1, W2 = Wind Generating (Cooled) Thermistors

R1, R2 = Wind Receiving (Warmed) Thermistors

1.3 Theory of Operation (cont.)

Figure 3 below shows how the two thermistor pairs are connected in series in an electronic bridge circuit. The bridge

circuit becomes unbalanced as the electrical resistance of the thermistors changes with temperature. This circuit

imbalance causes a voltage drop, which is proportional to the oxygen concentration in the gas being measured, to

appear across the bridge circuit.

Figure 3: Thermistor Bridge Circuit

As the background gases that comprise the balance of an oxygen-containing gas mixture change, the magnetic and

thermal properties of the gas mixture also change. This affects the accuracy and response of any paramagnetic oxygen

analyzer. To compensate for such variations, the XMO2 has a unique “bridge-within-a-bridge” design.

The oxygen measuring bridge circuit described on the previous page is itself one arm of another compensation bridge

circuit that maintains the oxygen bridge at a constant temperature as background gas composition changes. The

electrical power change necessary to keep the oxygen bridge at constant temperature is a function of the thermal

properties of the background gas. Therefore, this power fluctuation provides a signal that is related to the thermal

conductivity of the background gas. That signal is then used to reduce the effects of the background gas variation on the

oxygen span point measurement.

In addition to maintaining a constant oxygen bridge temperature, the XMO2 microprocessor compensates for any zero

point shift in the oxygen bridge circuit output caused by background gas changes.

Finally, the bridge circuit voltage is further adjusted for variations in background gas composition and/or atmospheric

pressure by internal, microprocessor-based compensation algorithms. The compensated signal is then amplified and

converted to a 4-20 mA analog output that is proportional to the concentration of oxygen in the gas mixture.

XMO2 User’s Manual 5

Page 16

Chapter 1. Features and Capabilities

1.4 System Components

The basic XMO2 measurement system consists of an XMO2 Transmitter mounted in a Sample System. The sample

system is mandatory, and can either be provided by GE or constructed according to our recommendations.

1.4.1 The XMO2 Transmitter

The XMO2 transmitter is self-contained, consisting of the oxygen sensor and associated electronics. It requires a 24

VDC power input @1.2 A maximum at power-up, and it provides a 4-20 mA analog output signal that is proportional

to the oxygen concentration of the sample gas and has fully programmable zero and span points. Also provided is an

RS232 digital output for oxygen concentration, background gas, and atmospheric pressure signals. Programming, and

calibration of the unit may also be performed via this interface.

All XMO2 transmitters include a 10 ft (3 m), 4-conductor cable for connecting the power input and the 4-20 mA analog

output. Optional XMO2 accessories available from GE include:

• Power/analog output cable lengths of up to 450 ft (150 m)

• 24 VDC power supply (Model PS5R-C24)

• 3-conductor cable with a DB9 (male or female) or DB25 (male or female) connector for connecting the XMO2

RS232 digital output to external devices

The XMO2 is designed to be installed in a sample system as close as possible to the process sample point. It is

available in two environmental packages:

• Weatherproof

• Explosion-proof/Flameproof (with gas inlet and outlet flame arrestors)

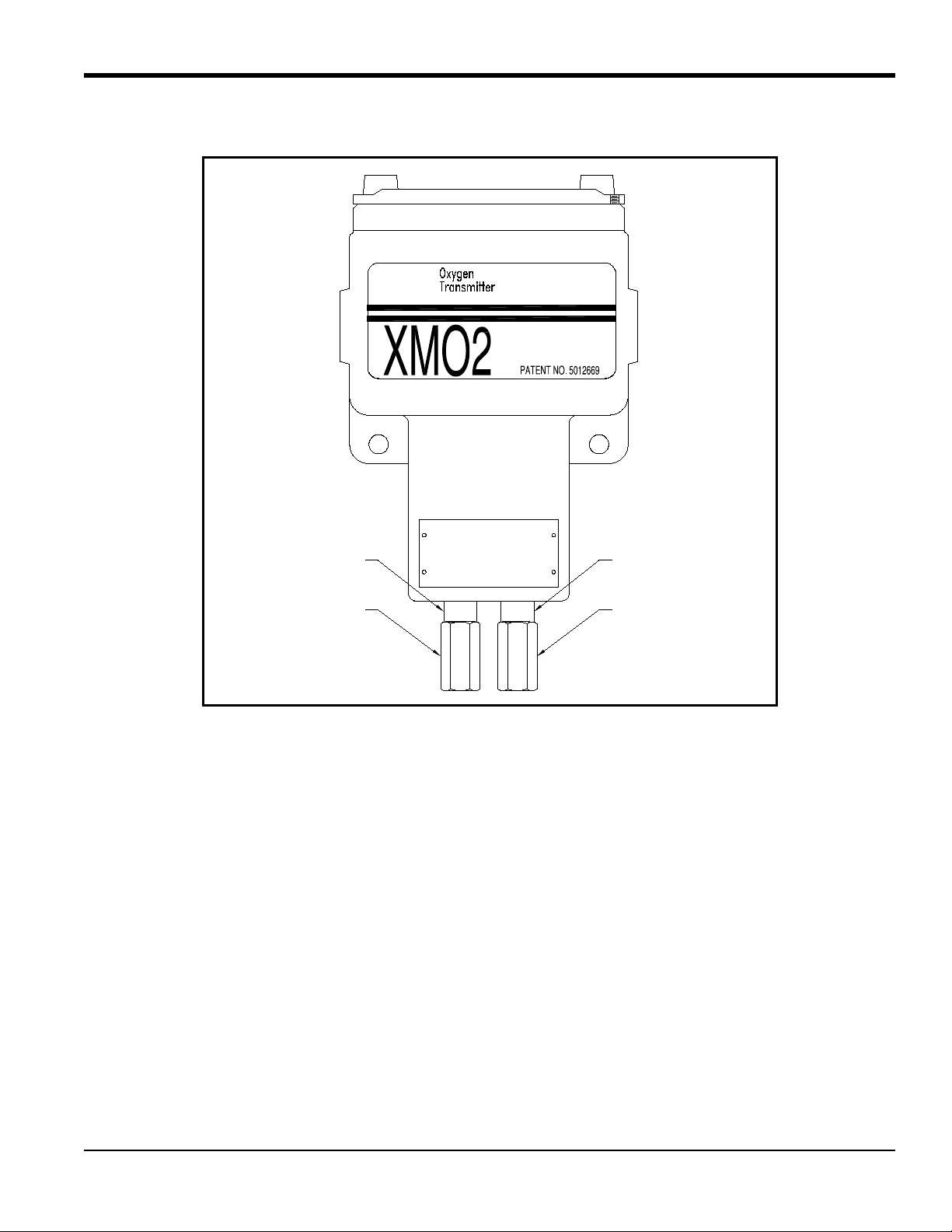

The XMO2 transmitter, which is shown in Figure 4 on page 7, can be configured for the following standard oxygen

ranges:

0 to 1% 0 to 25%

0 to 2% 0 to 50%

0 to 5% 0 to 100%

0 to 10% 80 to 100%

0 to 21% 90 to 100%

*Pressure compensation is required

*

*

*

*

6 XMO2 User’s Manual

Page 17

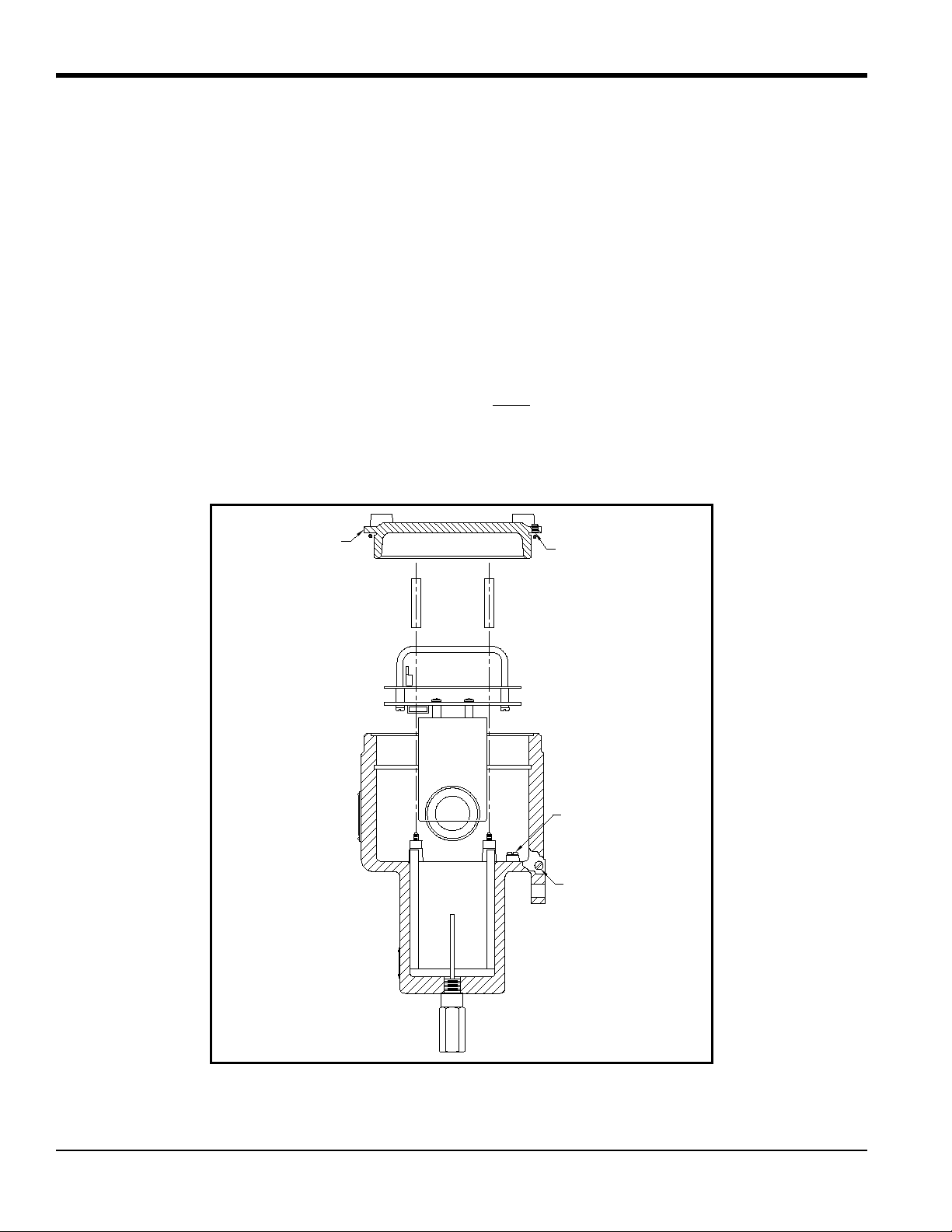

1.4.1 The XMO2 Transmitter (cont.)

Inlet

Flame Arrestor

Outlet

Flame Arrestor

Chapter 1. Features and Capabilities

The standard XMO2 transmitter maintains the measurement cell at an operating temperature of 45°C (113°F). An

optional 60° (140°F) or 70°C (158°F) cell operating temperature is available upon request.

Note: The 60° (140°F) or 70°C (158°F) cell operating temperatures should be selected only when necessary, as the

higher cell operating temperature results in reduced sensitivity.

XMO2 User’s Manual 7

Figure 4: The XMO2 Transmitter

Page 18

Chapter 1. Features and Capabilities

1.4.2 The Sample System

A sample system is mandatory for use with the XMO2 transmitter. The specific design of the sample system depends

on the conditions of the sample gas and the requirements of the application. At a minimum, the sample system should

include a sample gas flowmeter and a gas flow regulator valve.

In general, the sample system must deliver a clean, representative sample of the gas mixture to the XMO2 transmitter at

a temperature, pressure, and flow rate that are within acceptable limits. The standard XMO2 transmitter sample gas

conditions are as follows:

• -20° to +40°C (-4° to +104°F), at the standard measurement cell operating temperature of 45°C (113°F)

• Atmospheric pressure

• 1.0 SCFH (500 cc/min) flow rate

GE offers sample systems for a wide variety of applications. A typical sample system for use with the XMO2

transmitter is shown in Chapter 2, Installation. For assistance in designing your own sample system, please consult the

factory.

IMPORTANT: ATEX compliance requires both:

• Fast Response calibration of the XMO2 transmitter

• Pressure Compensation of the XMO2 or constant control of the sample system pressure.

1.4.3 Long Cables (optional)

GE provides a standard 10 ft (3 m), 4-conductor, col or -coded cable with each XMO2 to connect to the power input and

the analog output. Optional cables are available in lengths up to 450 ft (150 m) as P/N X4(*), where * specifies the

length in feet. For longer cables or to use your own cable, refer to Chapter 2, Installation, for recommendations.

1.4.4 Power Supply (optional)

The XMO2 requires 24 VDC input power at a maximum start-up current of 1.2 A. The GE PS5R-C24 power supply

may be used to convert 100-240 VAC to the required 24 VDC.

1.4.5 The TMO2D Display/Controller (optional)

The GE TMO2D Display/Controller provides a two-line x 24-character back-lit LCD display for the XMO2’ s 4-20 mA

analog output signal. It also permits display and option programming via its keyboard. Additional features include:

recorder outputs, a real time clock, alarm relays, and relays for driving sample system solenoids for automatic zero and

span calibration. For more information on the TMO2D, please contact GE.

8 XMO2 User’s Manual

Page 19

Chapter 2. Installation

Chapter 2. Installation

2.1 Introduction

This chapter describes how to install the XMO2 transmitter and its sample system. It also contains information on

connecting optional system components. Installation of the XMO2 system consists of three basic steps:

1. Installing the XMO2 transmit ter in the sample system (if you purchased your sample system from GE, this step

has already been done for you)

2. Mounting, plumbing, and wiring the sample system

3. Making wiring connections for power input, 4-20 mA analog output, RS232 digital output, and optional

external devices

2.2 Installing the XMO2 Transmitter

Note: This section applies only if the XMO2 transmitter has not already been installed in the sample system by GE.

The sample system must deliver a clean, representative gas sample to the XMO2 at the proper temperature, pressure

and flow rate. This usually means a clean, dry gas sample that is free of solid and liquid particulates and is delivered at

atmospheric pressure, a temperature no greater than 40°C (104°F), and a flow rate of approximately 1.0 SCFH

(500 cc/min). A typical sample system fo r the XMO2 might include an inlet gas flow regulating needle valve, a sample

gas flow meter, and a pressure gauge.

Note: Because factory calibration of the XMO2 is done at atmospheric pressure and at a flow rate of 1.0 SCFH,

operation of the XMO2 at other pressures and/or flow rates requires a field recalibration to ensure optimum

accuracy.

To install the XMO2 transmitter in the sample system, complete the following steps:

1. Select a location in the sample system that provides at least 9 in. (230 mm) of clearance above the top cover of

the XMO2 for access to the interior of the transmitter enclosure.

2. Mount the XMO2 transmitter in the sample system via its two mounting holes. Be sure that the transmitter is

upright and is level to within ±15°.

3. Use 1/4” stainless steel tubing to connect the sample system Inlet and Outlet fittings to the corresponding

XMO2 ports.

WARNING! For explosion-proof units, be sure to conform to all safety and electrical code

requirements.

XMO2 User’s Manual 9

Page 20

Chapter 2. Installation

0.875 (22.2)

(685.8)

27.00

25.25

(641.3)

4 places

Ø1/2"

SPAN GAS

INLET

ZERO GAS

INLET

INLET

SAMPLE

OUTLET

SAMPLE

19.25 (488.9)

21.00 (533.4)

9.00

(229.5)

(MIN)

TRANSMITTER

XMO2

0.875 (22.2)

2.3 Installing the Sample System

You can order a complete sample system from GE that is mounted on a steel panel and includes the XMO2 transmitter

and all necessary components and plumbing. Several standard sample systems are available, and custom-designed

sample systems can be built to your exact specifications.

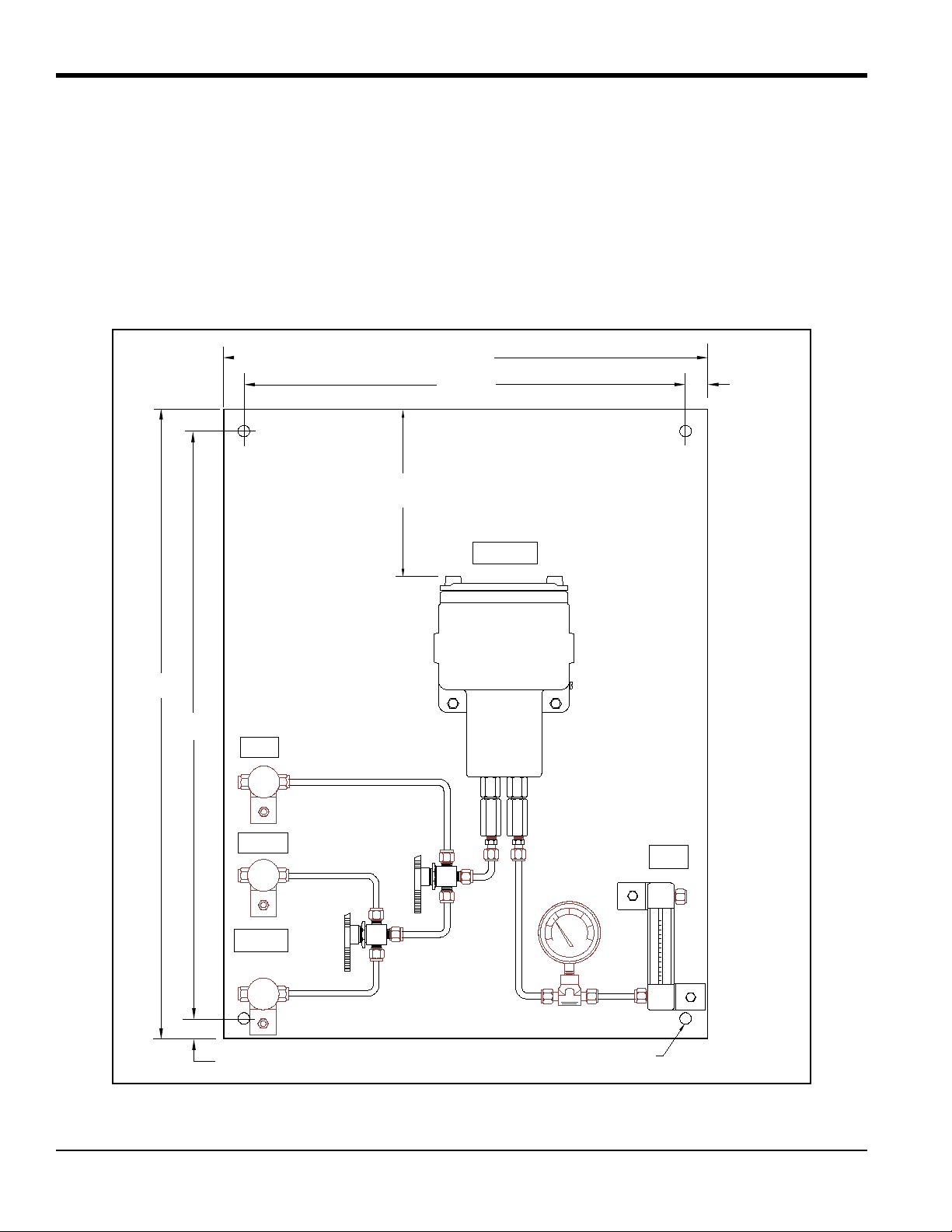

2.3.1 A Basic System

Figure 5 below shows a basic sample system (dwg #732-164) that has been designed for use with the XMO2

transmitter.

Figure 5: Basic XMO2 Sample System (ref. dwg #732-164)

10 XMO2 User’s Manual

Page 21

Chapter 2. Installation

2.3 A Basic System (cont.)

The sample system shown in Figure 5 on page 10 consists of a painted steel plate with the following components

mounted on it:

• Inlet needle valves for sample, zero, and span gas flow regulation

• Ball valves for flow selection

• An XMO2 transmitter

• A sample gas outlet pressure gauge

• A sample gas flowmeter

Other components, such as a pump, a filter/coalescer, or a pressure regulator could be added to the system if needed.

2.3.0a Mounting the Sample System

To mount the sample system, complete the following steps:

1. Select a location that is as close as possible to the process sampling point. The ambient temperature at this

location should be in the range of -20° to +40°C (-4° to +104°F).

IMPORTANT: For locations where the ambient temperature falls below -20°C (-4°F), install the sample system in a

heated enclosure.

2. Using the mounting holes provided, fasten the sample system to a convenient vertical surface. The system must

be installed in an orientation that keeps the XMO2 transmitter upright and level to within ±15°.

3. After the sample system has been mounted, use 1/4” stainless steel tubing to connect all inlet and outlet lines to

the 1/4” tube fittings on the sample system. The sample line leading from the process to the sample system

should be as short as possible in order to decrease system lag time and to prevent condensation in the line.

Proceed to the next section to begin wiring the system.

CAUTION! Always apply power to the XMO2 transmitter immediately after installation,

especially if it is mounted outdoors or in a humid area.

XMO2 User’s Manual 11

Page 22

Chapter 2. Installation

Cover

Set Screw

Internal

Ground

Screw

Screw

External

Ground

2.3.1 Wiring the XMO2 Transmitter

This section describes how to make all necessary electrical connections to the XMO2 system.

2.3.2 CE Mark Requirements

CAUTION! To meet CE Mark requirements, all electrical cables must be grounded and shielde d

as described in Appendix E.

2.3.3 Grounding the XMO2 Enclosure

WARNING! The XMO2 transmitter enclosure must be properly grounded.

Connect the external ground screw on the XMO2 enclosure (see Figure 6 below) to a suitable earth ground.

Figure 6: XMO2 Ground Screw Locations

12 XMO2 User’s Manual

Page 23

Chapter 2. Installation

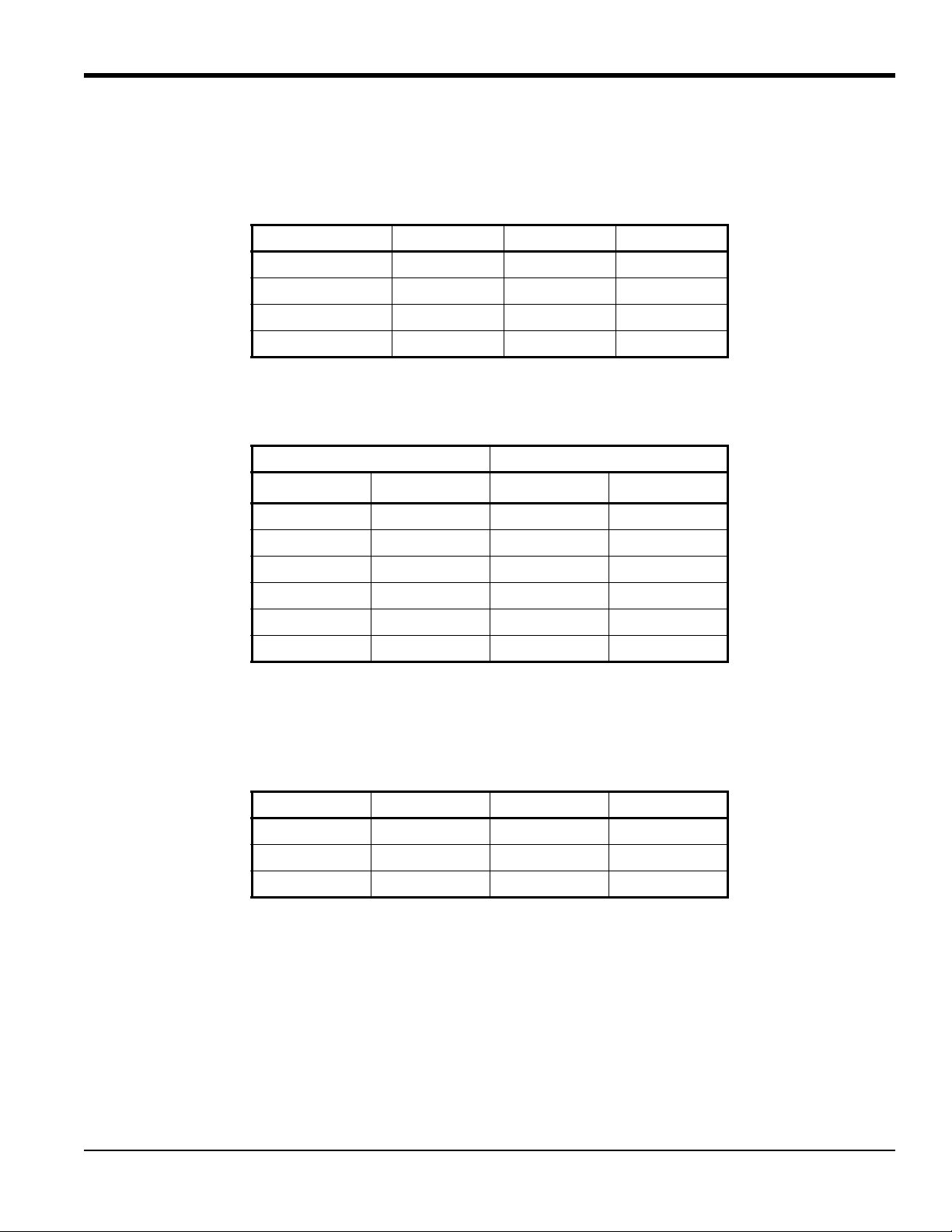

2.3.4 Cable Specifications

Table 1 below shows the transmitter wiring connections using the standard GE XMO2 4-wire cable [P/N X4(L), where

L = length in ft]. This cable can be used for distances up to 450 ft (150 m).

Table 1: GE 4-Wire XMO2 Cable

Lead Color AWG Terminal

+24 VDC Line Red 22 TB1-1

24 VDC Return Black 22 TB1-2

4-20 mA (+) White 22 TB1-3

4-20 mA (-) Green 22 TB1-4

If you are using your own cable to wire the XMO2, refer to Table 2 below for cable requirements.

Table 2: Non-GE Cable Requirements

MAX. CABLE LENGTH WIRE SIZE

ft m AWG mm

2

450 130 22 0.35

700 200 20 0.60

1,050 320 18 1.00

1,700 500 16 1.20

2,800 850 14 2.00

4,000 1,200 12 3.00

Table 3 below shows the connections for the GE standard 3-wire RS232 cable (P/N 704-667, -668, -669, or -670-L,

where L = length in ft), which is available with a DB-9 or a DB-25 connector (male or female). This cable is available

in standard lengths of 6 ft and 12 ft.

Table 3: GE 3-Wire RS232 Cable

Lead Color AWG Terminal

RX Red 22 TB2-1

TX White 22 TB2-2

GND Green 22 TB2-3

See EIA-RS Serial Communications (GE document #916-054) for a more detailed discussion of RS232 wiring.

Note: See Figure 64 on page 74 for detailed drawings of the standard GE cables described above.

XMO2 User’s Manual 13

Page 24

Chapter 2. Installation

1

+24VDC Line (red)

1

2

3

4

2

3

–24VDC Return (black)

+4 to 20mA (white)

–4 to 20 mA (green)

RS232 TX (white)

RS232 GND (green)

2

3

4

1

3

External Ground Screw

Cover

Internal Ground Screw

Set Screw

RS232 RX (red)

1

2

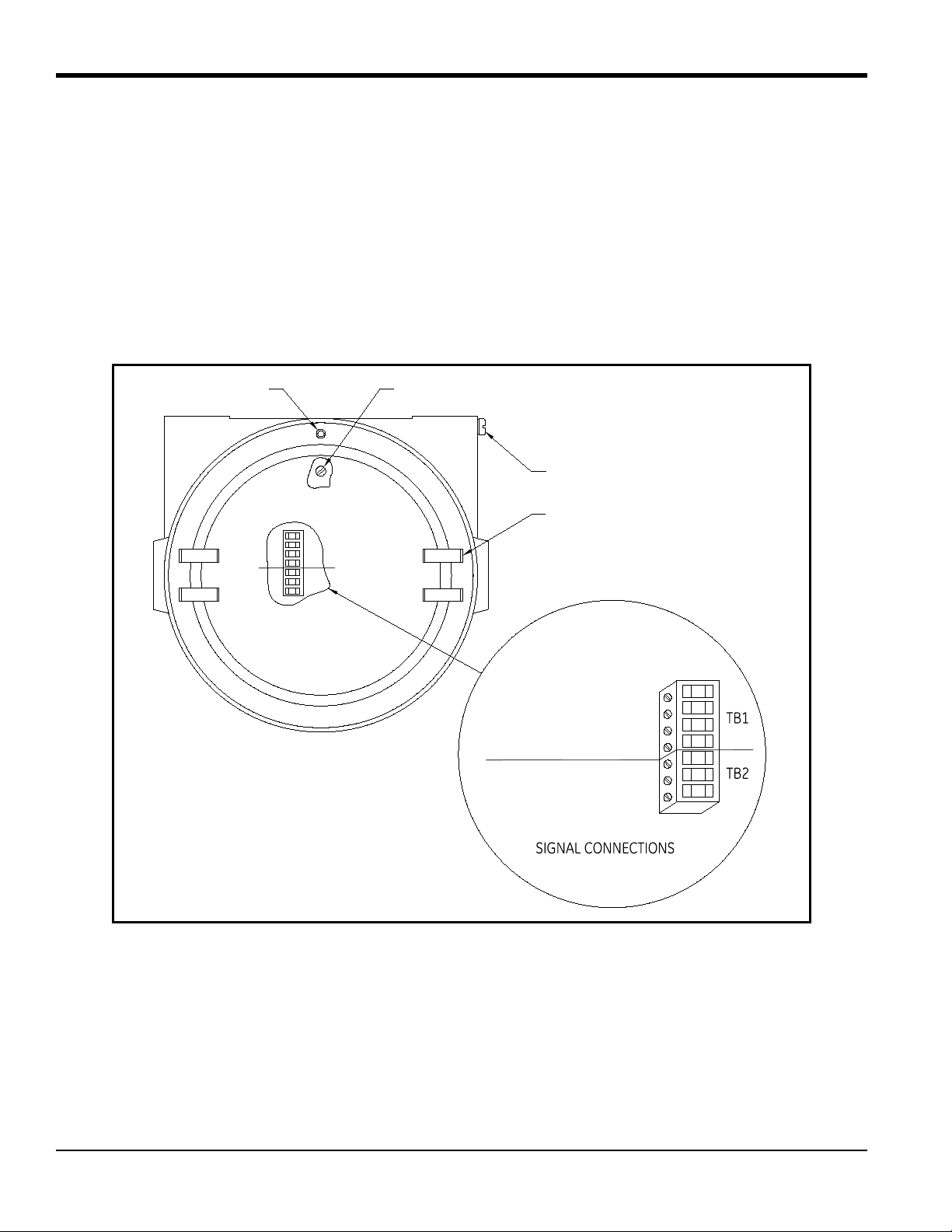

2.3.5 Accessing Terminal Blocks TB1 and TB2

The 24 VDC power input, 4-20 mA analog output, and RS232 digital output wiring connections are made to terminal

blocks TB1 and TB2 inside the XMO2 enclosure (see Figure 7 below). To access this terminal block, loosen the

locking set screw and remove the cover from the transmitter. Then, refer to Figure 7 below for the location and pin

designations of terminal blocks TB1 and TB2.

CAUTION! Do not make any connections to any unused pins on terminal blocks TB1 or TB2.

Figure 7: TB1 and TB2 Terminal Block Connections

Proceed to the next section to begin making connections to terminal blocks TB1 and TB2.

14 XMO2 User’s Manual

Page 25

Chapter 2. Installation

2.3.6 Wiring the Signal Connections

Complete the following steps to make the signal connections to terminal blocks TB1 and TB2:

1. Install a cable clamp or gland in one of the 3/4” conduit holes.

CAUTION! Be sure to plug the unused conduit hole to maintain the designated weatherproof or

explosion-proof rating.

2. Route the 4-wire and 3-wire (if used) cables through the cable clamp. Then, tighten the clamp to secure the

cable(s).

3. Unplug the TB1 and TB2 connectors by pulling them straight off the printed circuit board, and loosen the

screws on the side of the connectors.

4. Connect the 24 VDC input power leads as follows:

CAUTION! Connecting the +24 VDC (red) lead to any terminal except TB1-1 will damage the

XMO2.

a. Insert the 4-wire cable +24 VDC line (red) lead into pin TB1-1 and tighten the screw.

b. Insert the 4-wire cable 24 VDC return (black) lead into pin TB1-2 and tighten the screw.

5. Connect the 4-20 mA analog output leads as follows:

a. Insert the 4-wire cable + 4-20 mA (white) lead into pin TB1-3 and tighten the screw.

b. Insert the 4-wire cable – 4-20 mA (green) lead into pin TB1-4 and tighten the screw.

6. Connect the option al RS 232 digital output leads as follows:

a. Insert the 3-wire cable RX (red) lead into pin TB2-1 and tighten the screw.

b. Insert the 3-wire cable TX (white) lead into pin TB2-2 and tighten the screw.

c. Insert the 3-wire cable GND (green) lead into pin TB2-3 and tighten the screw.

7. Carefully plug the TB1 and TB2 connectors back onto the printed circuit board, and reinstall the cover on the

XMO2.

8. Connect the other ends of the cables to the 24 VDC power supply, the 4-20 mA input of the display/control

device, and the serial port of the computer or terminal (see the instruction manuals for those devices for

details).

XMO2 User’s Manual 15

Page 26

Chapter 2. Installation

2.4 Establishing the RS232 Communication Link

Before the XMO2 can be programmed, a link between the built-in RS232 digital output and a computer terminal must

be established. To accomplish this, proceed as follows:

Note: See GE document EIA-RS Serial Communications (916-054) for a details of the RS232 standard.

1. Verify that either Com 1 or Com 2 on the computer is unused.

IMPORTANT: Do not use a virtual Com port, such as Com 3 or Com 4, for communicating with the XMO2.

2. With both the XMO2 and the computer turned OFF, connect a serial cable from the XMO2 to the PC. See

Chapter 2, Installation, for detailed instructions.

CAUTION! Never make any connections to a computer while it is powered up. Damage to the

system may result.

3. Power up the PC and launch the IDM software.

Note: See the IDM User’s Manual (910-185) for information on installing and launching your program.

4. In the Global menu of IDM, select the Preferences option to specify the com port to which your XMO2 has

been connected.

5. For proper communications with the XMO2, the following com port settings must be specified:

• Baud Rate = 9600

• Data Bits = 8

• Parity = None

• Stop Bits = 1

• Flow Control = Xon/Xoff

6. Select the Connect to a New Instrument option, enter the XMO2 ID number (1 to 254), and select OK.

16 XMO2 User’s Manual

Page 27

Chapter 2. Installation

2.5 Connecting to Other Devices

This section discusses interconnection of the XMO2 transmitter with other GE devices. The following devices are

included:

• PS5R-C24 power supply

• TMO2D display

• LDP display

• XDP display

• Moisture Image/Monitor Series analyzers

• System 1 moisture analyzer

2.5.1 The PS5R-C24 Power Supply

The GE PS5R-C24 power supply converts a 100-240 VAC input to the required 24 VDC output. Figure 8 below shows

the PS5R-C24 connections. As indicated, the AC input Line, Neutral and Ground connections are made to the

terminals along the bottom of the panel, while the DC output +24V line and 24V return connections are made to the

terminals along the top of the panel. See the instructions provided with the power supply for more details.

Figure 8: PS5R-C24 Power Supply Connections

XMO2 User’s Manual 17

Page 28

Chapter 2. Installation

2.5.2 TMO2D Display

The GE TMO2D Display provides a two-line x 24 character back-lit LCD. It features display and option programming

via the keyboard and it offers recorder outputs, alarm relays, and optional relays for driving sample system solenoids

for automatic zero and span calibration of the XMO2. See Figure 74 on page 84 for an interconnection diagram, and

refer to the TMO2D User’s Manual (910-084) for details on its operation.

2.5.3 LDP Display

The LDP Display provides an integral, regulated 24 VDC power supply, an adjustable 3-digit display to program the

4-20 mA analog input range, two programmable SPDT alarm relays rated for 1A @250 VAC, and an isolated,

independently-adjustable 4-20 mA analog output. The LDP is supplied in an explo sion-proof enclosure t hat is rated for

Cenelec EEx d IIC T6 and IP66 (with an optional gasket). See Figure 74 on page 84 for an interconnection diagram,

and refer to the LDP User’s Manual (910-225) for details on its operation.

2.5.4 XDP Display

The XDP Explosion-proof Display Package provides an integral, regulated 24 VDC power supply, a 3-digit display

with an adjustable 4-20 mA analog input range, two SPDT alarm relays rated for 1A @250 VAC, and an isolated,

independently-adjustable 4-20 mA analog output. See Figure 74 on page 84 for an interconnection diagram, and refer

to the XDP User’s Manual (910-204) for details on its operation and specifications.

2.5.5 Moisture Image/Monitor Series Analyzers

These GE instruments include the Moisture Image Series 1 and Moisture Monitor Series 3 analyzers. These analyzers

accept inputs from a variety of sensors (including the XMO2) and offer graphical and digital interfaces. See Figure 74

on page 84 for interconnection diagrams, and refer to the User’s Manual (910-108 or 110) for details on its operation.

Note: An external 24 VDC power supply (such as the PS5R-C24) is required to use the XMO2 with these analyzers.

2.5.6 System 1 Analyzer

The GE System 1 is a versatile multi-channel analyzer which accepts inputs from any combination of GE moisture,

temperature, oxygen, and thermal conductivity transmitters. See Figure 74 on page 84 for an interconnection diagram,

and refer to the System 1 User’s Manual (900-019) for details on its operation.

Note: An external 24 VDC power supply (such as the PS5R-C24) is required to use the XMO2 with the System 1

analyzer.

18 XMO2 User’s Manual

Page 29

Chapter 3. Startup & Operation

Chapter 3. Startup & Operation

3.1 Introduction

This chapter provides instructions for starting up and operating the XMO2 system. The following specific topics

discussed:

• Powering up the XMO2 transmitter

• Establishing a sample gas flow

• Calibration of the analog output signal

If you have not already done so, read Chapter 2, Installation, for details on mounting and wiring the XMO2 transmitter ,

the sample system, and any other optional equipment.

3.2 Powering Up the XMO2 Transmitter

The XMO2 transmitter does not have a power switch. It begins taking measurements and generating an analog output

signal in the 0-25 mA range as soon as it is connected to a 24 VDC power source. To power up the system, simply

energize the 24 VDC power supply.

Because the standard XMO2 measurement cell is controlled at a constant 45°C (113°F) operating temperature, allow at

least 30 minutes for the unit to warm up and reach temperature stability before taking any measurements. During this

time, you can establish a sample gas flow through the system, as described in the next section.

3.3 Establishing a Sample Gas Flow

Usually, the XMO2 transmitter is factory-calibrated at a sample gas flow rate of 1.0 SCFH (500 cc/min) and at

atmospheric pressure. Unless otherwise specified on your XMO2 calibration sheet, optional sample system tagging, or

optional sample system instructions, your XMO2 should be operated at atmospheric pressure and at the flow rate listed

in Table 4 below.

Table 4: Recommended Sample Gas Flow Rates

XMO2 Type Flow Rate in SCFH (cc/min)

Weatherproof 1.0 ± 0.5 (500 ± 250)

Explosion-proof 1.0 ± 0.2 (500 ± 100)

Pressure-compensated 0.5 ± 0.5 (250 ± 50)

Note: For optimum performance, operating the XMO2 at conditions other than those used for the factory calibration

requires that the unit be recalibrated at the actual field conditions.

XMO2 User’s Manual 19

Page 30

Chapter 3. Startup & Operation

3.3 Establishing a Sample Gas Flow (cont.)

To establish a flow of sample gas through the system, complete the following steps (see Figure 5 on page 10 as an

example):

1. Set the sample system ball valves to direct only the sample inlet stream to the inlet port of the XMO2

transmitter.

2. Use the sample inlet needle valve to regulate the flow of sample gas until the flowmeter reads the same flow

rate listed for your unit in Ta ble 4 on page 19.

3. Read the resulting system pressure on the pressure gauge. Make sure that there are no unnecessary flow

restrictions downstream of the sample system.

IMPORTANT: For atmospheric pressure-compensated units, the XMO2 outlet port must be vented directly to

atmosphere with no restrictions, by installing all sample system components and tubing upstream of the

XMO2 transmitter.

4. Take a reading of the XMO2 4-20 mA analog output.

In some applications, pressure changes due to flow rate changes can cause noticeable errors in the oxygen

measurement. In such cases, consider the following corrective measures:

• Reducing the flow rate to the minimum recommended value minimizes flow rate sensitivity. A bypass flow

type sample system (speed loop) allows minimum flow through the XMO2 yet maintains a fast transport of the

sample gas to the XMO2.

• For the fastest transport, minimize the sample line length from the process.

• If you cannot shorten the sample line length, reduce the sample line pressure to les s than 5 psig.

Proceed to the next section to complete the initial XMO2 startup.

20 XMO2 User’s Manual

Page 31

Chapter 3. Startup & Operation

3.4 Analog Output Calibration Options

The XMO2 4-20 mA analog output has been calibrated at the factory for the oxygen range indicated on the XMO2

Calibration Sheet shipped with the unit. (Figure 9 on page 22 shows a typical calibration sheet.) Upon initial startup,

field verification and/or calibration of the 4-20 mA analog output is required. To perform this task, either of the

following procedures may be used:

• Pushbutton calibration (offset gas method)

• IDM digital communication calibration (zero/span gas method)

This section provides information on calibrating the XMO2 in the field using either a one-gas (offset gas) method or a

two-gas (zero gas and span gas) method. The following specific topics are discussed:

• Factory calibration procedures

• Updating the factory calibration

• Required calibration materials

• Getting the XMO2 ready and locating the calibration switches

• How to perform a one-gas (Offset Gas) or two-gas (Zero and Span Gas) Pushbutton calibration

• How to perform an IDM digital communication calibration

After the XMO2 is in operation, field calibration is recommended at intervals of about 1-3 months, depending on the

application.

3.5 Factory Calibration Procedures

Prior to shipment, your XMO2 was calibrated at the factory for the %O2 range specified at the time of purchase. The

following standard %O

• 0 to 1% • 0 to 5% • 0 to 21% • 0 to 50%* • 80 to 100%*

• 0 to 2% • 0 to 10% • 0 to 25% • 0 to 100%* • 90 to 100%*

In addition, your XMO2 was calibrated at the factory for the compensation signal specified at the time of purchase. The

following standard compensation signals are provided:

• Background Gas Compensation - the standard factory calibration uses N

ranges are available:

2

* Pressure compensation is required

and CO2 as the background gases.

2

• Pressure Compensation - the standard factory calibration is for atmospheric pressure (700-800 mm of Hg).

Note: Compensation signals are available for special background gases and/or special pressure ranges. For

availability, pricing, and delivery, please contact GE.

XMO2 User’s Manual 21

Page 32

Chapter 3. Startup & Operation

3.5 Factory Calibration Procedures (cont.)

Figure 9: Sample Calibration Sheet

22 XMO2 User’s Manual

Page 33

Chapter 3. Startup & Operation

3.6 Enhancing the Factory Calibration

When your XMO2 transmitter was calibrated at the factory, the actual factory calibration data points were entered into

the XMO2 software. If requested on the original order, calibration data points for expected field background gas

composition and/or measurement cell pressure variations may also have been entered. To supplement this factory

calibration data, calibration data points generated in the field for these parameters can be added into the XMO2

software.

The factory calibration can be further enhanced by performing periodic recalibrations in the field. The XMO2 then uses

the new calibration data to create offset and drift curves that compensate the original factory calibration data for

variations that occur in the field.

When making a measurement, the XMO2 uses the Offset Curve or Drift Curve, along with any background gas and/or

cell pressure compensation data, entered at the factory or in the field, to update the factory calibration data.

To maintain the integrity of this process, the XMO2 should be recalibrated periodically. This is typically done every

1-3 months with a single (offset) calibration gas, depending on the application. The optimum recalibration interval

depends on such factors as %O

gas, etc. In addition, the XMO2 should be recalibrated with the two-gas (zero gas and span gas) method at least once

per year. Again, the optimum calibration interval depends on the specific application.

range, required accuracy, components of the gas mixture, the cleanliness of the sample

2

Using the calibration procedures in this chapter, the XMO2 can be recalibrated for the same %O

range, background

2

gas mixture, and compensation signals used for the factory calibration. However, if it has been some time since the

original factory calibration, or if you want to calibrate the XMO2 for a different %O

range, gas mixture, or

2

compensation signal, contact the factory for instructions.

CAUTION! The calibration procedures described in this chapter require the use of specialized

apparatus and should be performed only by properly trained service personnel, following all

applicable safety practices.

XMO2 User’s Manual 23

Page 34

Chapter 3. Startup & Operation

3.7 Required Calibration Materials

To perform a field calibration, the following materials are required:

• Offset gas - for a one-gas %O

• Zero gas - for a two-gas %O

• Span gas - for a two-gas %O

Note: Suggestions for suitable calibration gases are listed on the XMO2 Calibration Sheet provided with your unit.

Also, the accuracy of the calibration will only be as good as the accuracy of the calibration gas(es) used.

calibration

2

calibration and/or a 4-20 mA analog output calibration

2

calibration and/or a 4-20 mA analog output calibration

2

• GE XMO2 Calibration Sheet

• A sample system or individual components (e.g., flowmeter, needle valve, pressure gauge, etc.) for introducing

the calibration gas(es) to the XMO2 transmitter at the required pressure and flow rate. See Chapter 2,

Installation, for specific recommendations.

• A multimeter or ammeter (for a 4-20 mA analog output calibration)

WARNING! Avoid using explosive gas mixtures as your XMO2 calibration gases.

3.8 Preparing for Field Calibration

To prepare the XMO2 for a field calibration, refer to Figur e 10 on page 25 and perform the following preliminary

steps:

1. Turn the power on and allow at least 30 minutes for the XMO2 to reach temperature stability.

2. Loosen the set screw that locks the XMO2 cover in place, and unscrew the cover.

IMPORTANT: Remember to replace the cover after the field calibration has been completed.

3. Refer to Figure 11 on page 25, and locate the following items:

• Calibration pushbutton (Switch S3)

• Zero/span selector (Switch S1)

• Terminal block TB1

Note: If you plan to perform the field calibration at a computer terminal via the XMO2 RS232 digital output, you do

not need to access the above items because you will skip steps 1-2 above.

24 XMO2 User’s Manual

Page 35

3.8 Preparing for Field Calibration (cont.)

Set Screw

Circuit Board

Cover

Switch S1

Switch S3

TB2

TB1

Chapter 3. Startup & Operation

Figure 10: XMO2 Cover, Set Screw, and PCB

Note: The XMO2 digital PCB (see Figure 11 below) is located directly below the cover (see Figure 10 above).

Figure 11: PCB Calibration Switches

CAUTION! Switch S2, jumper P6, potentiometer R24, and potentiometer R25 are also located

on the XMO2 circuit boards. However, these items are not

used for normal field calibration.

Never touch these items unless specifically instructed to do so by GE.

XMO2 User’s Manual 25

Page 36

Chapter 3. Startup & Operation

3.9 One-Gas Pushbutton Field Calibration

This simplified field calibration procedure uses a single (offset) gas to recalibrate the XMO2. Then, the XMO2

compares the data from this field recalibration to the original factory calibration data, and stores the difference as an

Offset Curve.

The XMO2 is usually factory-programmed for the offset gas pushbutton calibration method. The Calibration Sheet

shipped with your unit specifies the recommended oxygen level (in %O

offset gas oxygen level that was used for the factory calibration. If no offset gas %O

Calibration Sheet, the factory calibration was done with 100% N

2

same offset gas.

To perform a pushbutton offset gas field calibration, complete the following steps:

1. Verify that your XMO2 is configured for a one-gas calibration. This is the factory default configuration for all

units.

2. Using the sample system controls, stop the flow of sample gas to the XMO2 inlet port and initiate a flow of the

same offset gas specified on the XMO2 Calibration Sheet. Establish the same flow rate and pressure conditions

used for the sample gas, and allow the offset gas to flow through the XMO2 for at least three minutes.

) for the offset gas to be used. This is the same

2

is specified on the XMO2

2

(0.00 %O2) and the field calibration should use the

3. Using Figure 11 on page 25 as a guide, locate the Calibration Pushbutton (Switch S3). Depress the

Calibration Pushbutton and hold it down for 20 seconds. During this time, the green light below the

Calibration Pushbutton will go out.

4. When the Calibration Push Button is released, the green light will come back on and the XMO2 has been

recalibrated.

You may now return the XMO2 to normal operation by using the sample system controls to stop the offset gas flow and

restart the flow of sample gas.

26 XMO2 User’s Manual

Page 37

Chapter 3. Startup & Operation

3.10 Two-Gas Pushbutton Field Calibration

This simplified field calibration procedure uses two (zero and span) gases to recalibrate the XMO2. Then, the XMO2

compares the data from this field recalibration to the original factory calibration data, and stores the difference as a

Drift Curve.

Note: If the range of your XMO2 is 0 to 21% O

, you can use air as the span gas.

2

3.10.1 Setup

Before proceeding, you must be sure that your XMO2 is configured for a two-gas calibration. The required

reprogramming must be done via the IDM communication link, as follows:

1. Launch IDM.

2. From the Instrument window, pu ll down the Edit Functions menu, as shown in Figure 12 on page 30.

3. Click on the Field Cal option. In the Field Cal window (shown in Figure 13 on page 31), click on the

Configure Cal button.

4. In the Configure Cal window (shown in Figure 17 on page 33), click on the Field Cal Type button.

5. In the Field Cal Type window (shown in Figure 18 on page 33), click on either the 1-Point or 2-Point button.

Then, click on any button on the right to return to the Configure Cal window.

Note: The zero and span calibrations can be performed in either order. For zero-based calibration ranges

(e.g., 0-25%), we recommend performing the span calibration first. For non-zero-based calibration ranges

(e.g., 90-100%), we recommend performing the zero calibration first.

Proceed to the appropriate section to begin the field calibration.

XMO2 User’s Manual 27

Page 38

Chapter 3. Startup & Operation

3.10.2 Zero Gas Pushbutton Calibration

To perform a zero gas pushbutton field calibration, complete the following steps:

1. Using the sample system controls, stop the flow of sample gas to the XMO2 inlet port and initiate a flow of the

same zero gas specified on the XMO2 Calibration Sheet. Establish the same flow rate and pressure conditions

used for the sample gas, and allow the zero gas to flow through the XMO2 for at least three minutes.

2. Using Figure 11 on page 25 as a guide, locate the Zero/Span Selector (Switch S1). Set the Zero/Span Selecto r

(Switch S1) to position “1” (“Zero”).

3. Using Figure 11 on page 25 as a guide, locate the Calibration Pushbutton (Switch S3). Depress the

Calibration Pushbutton and hold it down for 20 seconds. During this time, the green light below the

Calibration Pushbutton will go out.

4. When the Calibration Pushbutton is released, the green light will come back on and the XMO2 has been

recalibrated. Verify that the mA reading on the ammeter is now equal to the expected value.

IMPORTANT: If the XMO2 fails to recalibrate to the correct analog output value, contact GE for assistance.

3.10.3 Span Gas Pushbutton Calibration

To perform a span gas pushbutton field calibration, complete the following steps:

1. Using the sample system controls, stop the flow of sample gas to the XMO2 inlet port and initiate a flow of the

same span gas specified on the XMO2 Calibration Sheet. Establish the same flow rate and pressure conditions

used for the sample gas, and allow the span gas to flow through the XMO2 for at least three minutes.

2. Using Figure 11 on page 25 as a guide, locate the Zero/Span Selector (Switch S1). Set the Zero/Span Selecto r

(Switch S1) to position “3” (“Span”).

3. Using Figure 11 on page 25 as a guide, locate the Calibration Pushbutton (Switch S3). Depress the

Calibration Pushbutton and hold it down for 20 seconds. During this time, the green light below the

Calibration Pushbutton will go out.

4. When the Calibration Pushbutton is released, the green light will come back on and the XMO2 has been

recalibrated.

You may now return the XMO2 to normal operation by using the sample system controls to stop the span gas flow and

restart the flow of sample gas.

28 XMO2 User’s Manual

Page 39

Chapter 3. Startup & Operation

3.11 IDM Digital Communication Calibration

At the initial startup of the XMO2, IDM Digital Communication Calibration is the second method available for field

verification/calibration of the 4-20 mA analog output.

Note: IDM can also be used to change the 4-20 mA analog output range. See the next section for details.

To prepare for this calibration method, refer to Figure 10 on page 25 and perform the following preliminary steps:

1. Make sure that the RS232 digital output of the XMO2 has been connected to a computer or terminal in

accordance with the instructions given in Chapter 2, Installation.

2. Loosen the set screw that locks the XMO2 cover in place, and unscrew the cover.

IMPORTANT: Remember to replace the cover after the calibration has been completed.

3. Turn the computer or terminal on and launch IDM.

Note: Be sure you have properly installed Instrument Data Manager on your PC before attempting to program the

XMO2.

XMO2 User’s Manual 29

Page 40

Chapter 3. Startup & Operation

3.12 The Edit Functions Menu

T o access the XMO2 calibration, pull down the Edit Functions menu from the Instrument window. This menu consists

of the five commands displayed in Figure 12 below. To access any of the commands, simply select it from the menu.

Note: As a programming aid, the relevant portions of the Edit Functions menu have been mapped in Figure 75 on

page 87 and Figure 76 on page 88.

Figure 12: Edit Functions Menu

The following three buttons appear at the right of all menu windows (see Figure 13 on page 31):

• Previous Item - returns you to the previous window (either the command menu or the previous parameter

entered).

• Next Item/Enter - confirms the selection or data entered, and either opens the next window or returns you to

the command menu (depending on your position in the program).

• Exit Page - returns you to the command menu.

30 XMO2 User’s Manual

Page 41

Chapter 3. Startup & Operation

3.13 The Field Cal Menu

When you select the Field Cal option, a window similar to the one in Figure 13 below opens.

IMPORTANT: The instructions in this section assume that the factory-programmed 2-Gas calibration method is still

selected. If you have previously changed this to the 1-Gas calibration method, any windows that show

Zero and Span calibration gas buttons are replaced with a window that shows just the single Offset

calibration gas button.

Figure 13: Field Cal Window

The Field Cal option offers the following five choices:

• Perform Cal - calibrates the XMO2

• Configure Cal - sets the calibration type and parameters

• Calibration Drifts - lists drift percentages for zero and span gases

• Clear Calibration - clears the last calibration

• Hold Last Value - holds the last value calibrated

Note: Clicking on the Next Item/Enter button selects the option listed on the status line above the option buttons

(Perform Cal in Figure 13 above). The option listed on the status line in any window is the option that was

chosen the last time that menu was used.

Clicking on any of the above choices opens a new window that allows you to perform that function. Proceed to the

appropriate section for a detailed description of each option.

XMO2 User’s Manual 31

Page 42

Chapter 3. Startup & Operation

3.13.1 Perform Cal

Clicking on the Perform Cal button opens a window similar to Figure 14 below.

Figure 14: Perform Cal Window

Click on the Zero Field Cal button to calibrate the zero point or on the Span Field Cal button to calibrate the span point.

In either case, a window similar to Figure 15 below opens.

Figure 15: Zero Cal Window

Click Yes to perform the calibration, or Abort Field Cal to stop the calibration and return to the previous menu. The

result of a completed calibration is shown in Figure 16 below.

Figure 16: Zero Cal Results

Click on Previous Item or on Next Item/Enter to return to the previous window, or on Exit Page to return to the

Instrument Menu.

32 XMO2 User’s Manual

Page 43

Chapter 3. Startup & Operation

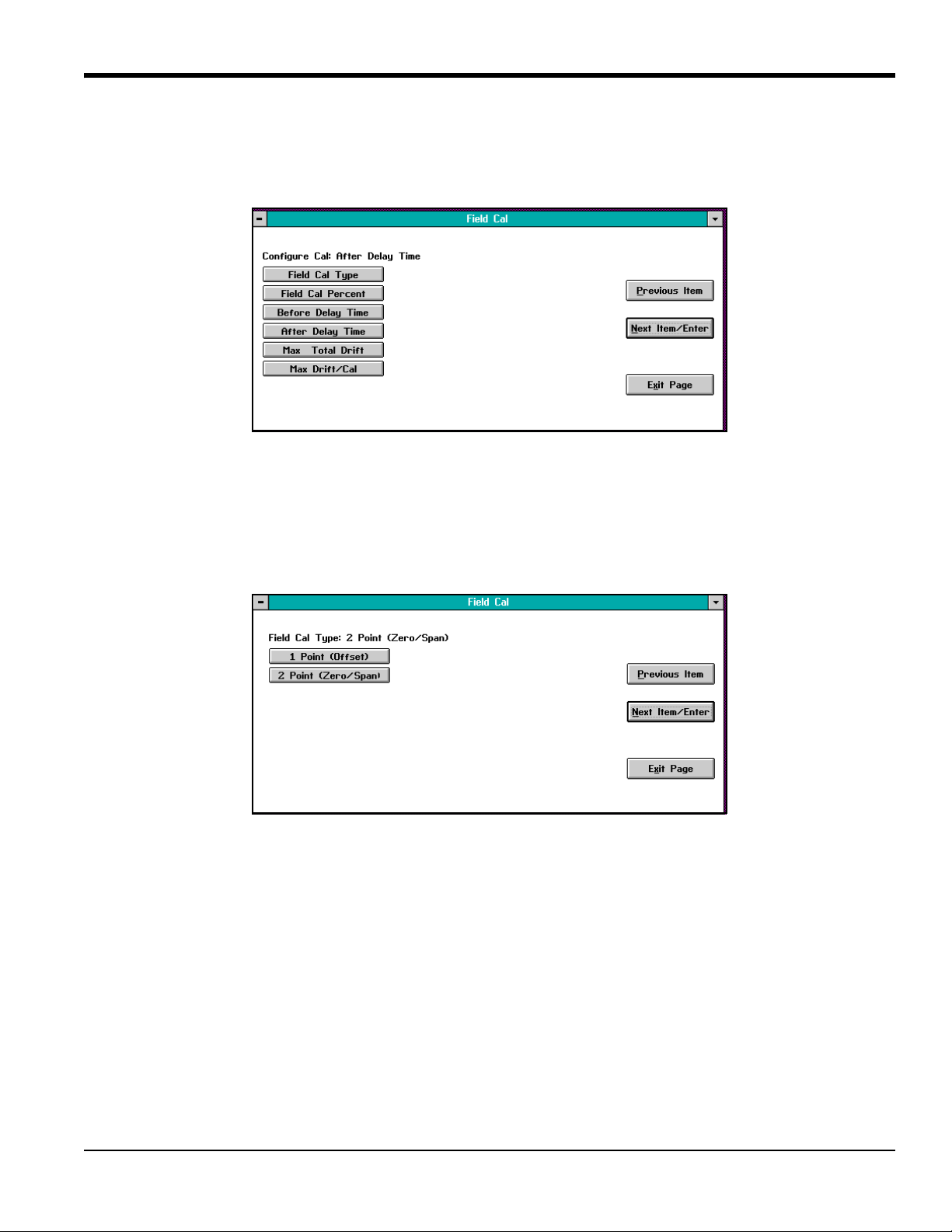

3.13.2 Configure Cal

The Configure Cal option enables you to change the field calibration type and various calibration parameters. Clickin g

on the Configure Cal button opens a window like that shown in Figure 17 below.

Figure 17: Configure Cal Window

Click on the desired option button and proceed to the appropriate section for a discussion of that option.

3.13.2a Field Cal Type

A typical Field Cal Type window is shown in Figure 18 below.

Figure 18: Field Cal Type Window

IMPORTANT: The factory setting is the 2 Point (Zero/Span) calibration type.

Click on the appropriate button to select the desired calibration type. Then, click on any button on the right to return to

the Configure Cal window.

XMO2 User’s Manual 33

Page 44

Chapter 3. Startup & Operation

3.13.2b Field Cal Percent

A typical Field Cal Percent window is shown in Figure 19 below.

Figure 19: Field Cal Percent Window

The above menu is used to specify the oxygen percentages of the zero and span calibration gases that will be used. The

recommended gases are listed on the XMO2 Calibration Data Sheet.

Click on the Zero Field Cal button to enter the percentage of oxygen in your zero gas. A window similar to Figure 20

below opens.

Figure 20: %O2 Entry Window

Type the zero gas oxygen percentage in the text box, and click the Next Item/Enter button to confirm the entry (click

Previous Item or Exit Page button to leave the window without changing the existing percentage).

IMPORTANT: The factory setting is for a 0.00% zero gas and a 20.93% span gas (air).

Repeat the above procedure to enter your span calibration gas oxygen percentage. Then, click on any button on the

right to return to the Configure Cal window.

34 XMO2 User’s Manual

Page 45

Chapter 3. Startup & Operation

3.13.2c Before Delay Time

Clicking on the Before Delay Time button opens a window similar to Figure 21 below.

Figure 21: Before Delay Time Window

In the above window, click on the Zero Field Cal button to enter the before delay time for the zero calibration point. A

window similar to Figure 22 below opens.

Figure 22: Zero Point Delay Time Window

Enter the desired zero point before delay time, in minutes and seconds, in the text box. Then, click on the Next

Item/Enter button to confirm the entry (click the Previous Item or Exit Page button to exit the window without

changing the existing value).

Repeat the above procedure to enter the before delay time for the span point.

3.13.2d After Delay Time

Repeat the procedure in the above section to set the after delay time for both the zero and span points.

XMO2 User’s Manual 35

Page 46

Chapter 3. Startup & Operation

3.13.2e Max Total Drift

Max Total Drift is the maximum total calibration drift allowable, expressed as a percentage of the full-scale reading.

Selecting this option opens a window similar to Figure 23 below.

Figure 23: Max Total Drift Entry Window

Enter the desired percentage of the full-scale reading in the text box, and click the Next Item/Enter button to confirm

the entry (click the Previous Item or Exit Page button to leave the window without changing the existing percentage).

3.13.2f Max Drift/Cal

Max Drift/Cal is the maximum calibration drift allowable per calibration, expressed as a percentage of the full-scale

reading. To enter a value, repeat the procedures in the above section.

3.13.3 Calibration Drifts

The Calibration Drifts option enables you to view the current calibration drift at both the zero and span points since the

last calibration was performed. Clicking on this button opens a window similar to Figure 24 below.

Figure 24: Calibration Drifts Window

Click on any button to return to the main Field Cal window.

36 XMO2 User’s Manual

Page 47

Chapter 3. Startup & Operation

3.13.4 Clear Calibration

The window for the Clear Calibration option is similar to Figure 25 below.

Figure 25: Clear Calibration Window

Click on the Yes button to clear the most recent calibration, or click on the No, Previous Item or Exit Page button to

close the window without clearing the most recent calibration. If you click on the Yes button, a confirmation screen

similar to Figure 26 below opens.

Figure 26: A Typical Cleared Calibration

Click on the Previous Item button to return to the Clear Calibration window, or click on the Next Item/Enter or Exit

Page button to return to the main Field Cal window.

3.13.5 Hold Last Value