Page 1

10/2/00

TMO2D with Fault Alarm and Event Log

Your TMO2D oxygen analyzer has been modified to provide a Fault

Alarm relay contact and an Event Log. However, before you can

access these features, the TMO2D must be installed and programmed

as instructed in your basic User’s Manual.

Depending on the specific software version installed in your unit, the

details for using the Fault Alarm and Event Log differ somewhat.

After verifying your software version, proceed directly to one of the

following sections:

• Software Version 4B or earlier - go to the section below

• Software Version 4C or later - go to the section on page 7

Software Version 4B (or Earlier)

Using the Fault Alarm The Fault Alarm relay is energized during normal operation. If a fault

If the software installed in your analyzer is Version 4B or earlier,

proceed with this section. However, if software Version 4C or later is

installed in your analyzer, skip this section and proceed directly to the

section on page 7.

or a power failure occurs, the relay is de-energized. This is known as

failsafe operation. The relay has Form-C contacts, so that a fault can

be indicated with either an open contact or a closed contact.

The failsafe Fault Alarm trips when one or more of the following

fault events occurs:

• power failure

• RAM checksum failure (memory corruption)

• transmitter under range

• transmitter over range

• no calibration curve

The TMO2D indicates a fault event by de-energizing the relay. If

multiple faults occur simultaneously, the TMO2D indicates the fault

from highest precedence (power failure) to lowest (no calibration

curve), in the order listed above. When all fault conditions have been

removed, the fault relay is re-energized.

Faults are detected only when the TMO2D is in Operate Mode

(displaying data). When in Menu Mode (during programming), the

detection and signaling of faults is suspended. In this case, the Fault

Alarm holds its last state (energized or de-energized) until the unit has

been returned to Operate Mode.

913-220B 1

Page 2

10/2/00

Using the Fault Alarm

(cont.)

To provide power-failure detection, the Fault Alarm relay is

energized (ON) during normal operation and de-energized (OFF)

during a fault condition. Therefore, when testing the alarm relay,

select “ON” to indicate a normal operating condition and “OFF” to

indicate a fault condition (see Table 1 below).

Table 1: Fault Alarm Relay Conditions

Condition Alarm State Alarm Test Selection

normal operation energized ON

fault de-energized OFF

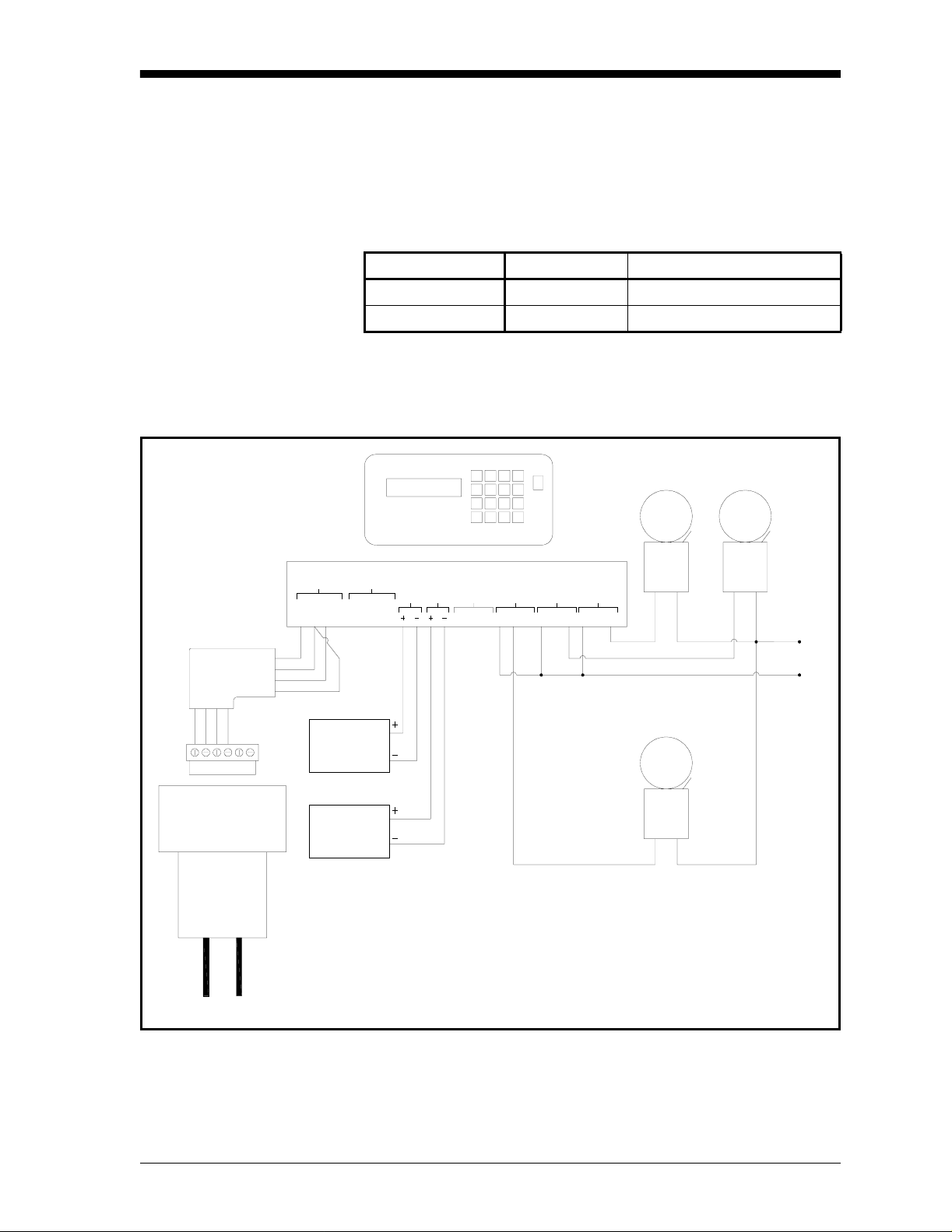

Wiring the Fault Alarm Your TMO2D uses the relay labeled “CAL” for the Fault Alarm.

Wire the Fault Alarm as shown in Figure 1 below.

LOWHIGH

ALARM

ALARM

TMO2D

T-CABLE

237-047

OR EQUAL

E

K

T

E

C

I

D

U

A

H

L

E

L

W

B

B

R

4321

TRANSMITTER

OUTLET

INLET

RED

BLACK

WHITE

BLUE

+

2

4

V

SPAREOXYGEN

CELL

INPUTS

C

+

O

R

2

M

D

T

4

X

V

N

P

RECORDER

A

OPTIONAL

RECORDER

B

R

T

N

RECORDERS

I

I

N

N

2

1

0/4-20MA

RECBRECA

NOTES:

AUTOCAL

CALPROCESS

NO NO NO NONC NC NC NCCCCC

ALARMS

HIGHLOW

ALARM

POWER

FAULT

ALARM

1. Standard relays are rated for 2 Amps, 120 VAC.

2. User must ensure ag a i nst explosive gas mixtures

when using auto-calibration.

3. Fault alarm is wired normally-closed to common

at the CAL relay.

Figure 1: Wiring the TMO2D with Fault Alarm (Software Version 4B or Earlier)

913-220B 2

Page 3

10/2/00

Testing the Fault Alarm The Fault Alarm is tested in the same way as the other alarms (refer

to Table 1 on page 2 for a summary of the Fault Alarm relay

conditions). Follow the instructions in Chapter 4 of your User’s

Manual under Alarms Test to enter the

that the display below now shows

[Alarms Test] menu. Notice

[fault] as an additional choice.

Select alarm to test:

[HIGH] low fault done

Select alarm to test:

high low [FAULT] done

Turn Fault Alarm:

[ON] off done

Note: When

[YES] is pressed above, the alarm relay turns ON (non-

fault condition), and the selection brackets move to

Turn Fault Alarm:

on [OFF] done

Note: When

[YES] is pressed above, the alarm r elay turns OFF (fault

condition), and the selection brackets move to

Use the [NO] or arrow keys to

select

[FAULT].

Press [YES] to confirm your

selection.

Use the [NO] or arrow keys to

select

[ON]. Then press [YES]

to turn the Fault Alarm ON

(non-fault condition).

[OFF].

Press [YES] to turn the Fault

Alarm OFF (fault condition).

[ON].

Turn Fault Alarm:

on off [DONE]

When you finish testing the

Fault Alarm, use the

arrow keys to select

Then, press

[YES] to exit the

[NO] or

[DONE].

Fault Alarm test menu.

Exit the

913-220B 3

[Alarms Test] menu as described in your User’s Manual.

Page 4

10/2/00

Using the Event Log Your modified TMO2D maintains an Event Log in battery-backed

memory . Among other things, this log indicates the nature of any fault

signaled by the Fault Alarm relay by recording the type, date, and

time of the relevant events.

The Event Log can record up to 25 events of the following types:

• factory initialization

• system power on

• system RESET

• RAM checksum failure (memory corruption)

• transmitter under range

• transmitter over range

• no calibration curve

• return to normal operation

Note: Testing the Fault Alarm does not appear in the Event L o g .

The TMO2D stores only the 25 most recent events in its memory.

When additional events occur, the TMO2D discards the oldest event

from the log to make room for the new event.

913-220B 4

Page 5

10/2/00

Viewing the Event Log The Event Log may be viewed on the TMO2D display or transmitted

to a computer, printer or other data acquisition system via the RS232

serial port. T o view the Event Log on the TMO2D display , press

and the following prompt appears:

[NO],

Enter Code: ***

50.0% Alarm:

MAIN MENU

Setup?

MAIN MENU

System Log?

SYSTEM LOG MENU

Display System Log?

03: Normal Operation:

04/04/1997 10:21:58

Using the keypad, enter the

system passcode (123). An

asterisk is displayed as each

digit is entered.

Press [NO] until the System

Log? prompt appears.

Press [YES].

Press [NO] until the Display

System Log? prompt appears.

Then, press

[YES].

The most recent event in the

Event Log is displayed.

At the above prompt, use the arrow keys to scroll through the logged

events ([←] for the previous event, [→] for the next event). When

done, press

[NO] to exit the Event Log. See Figure 2 below for a

description of the components of the event log screen.

Event Number (0-24)

Type of Event

03: Normal Operation:

10/02/2000 10:21:58

Date of Event

Time of Event

Figure 2: The Event Log Display Screen

913-220B 5

Page 6

10/2/00

Printing the Event Log To print the Event Log, enter the [System Log] menu, as described in

the previous section. The following display appears:

SYSTEM LOG MENU

Display System Log?

SYSTEM LOG MENU

Print System Log?

Press [NO].

Press [YES] and the entire log

is transmitted via the RS232

serial port.

The Event Log printout looks similar to the example shown in Figure

3 below.

Event Number

Event Date

00: Factory Init at: 10/02/2000 09:34:32

01: Cell Under Range at: 10/02/2000 09:34:33

02: No Calibration at: 10/05/2000 10:14:44

03: Normal Operation: 10/05/2000 10:21:58

Exiting the [System Log] Menu

Event Type

Event Time

Figure 3: A Typical Event Log Printout

To exit the [System Log] menu, proceed as follows:

SYSTEM LOG MENU

Print System Log?

SYSTEM LOG MENU

Done?

Press [NO] until the Done?

prompt appears

Press [YES] to return to the

Main Menu.

913-220B 6

Page 7

10/2/00

Software Version 4C (or Later)

If the software installed in your analyzer is Version 4C or later,

proceed with this section. However, if software Version 4B or earlier

is installed in your analyzer, skip this section and proceed directly to

the section on page 1.

Using the Fault Alarm The Fault Alarm relay is energized during normal operation. If a fault

or a power failure occurs, the relay is de-energized. This is known as

failsafe operation. The relay has Form-C contacts, so that a fault can

be indicated with either an open contact or a closed contact.

The failsafe Fault Alarm trips when one or more of the following

fault events occurs:

• power failure

• RAM checksum failure (memory corruption)

• transmitter under range

• transmitter over range

• no calibration curve

• AutoCal T otal drift

• AutoCal Drift/Cal

The TMO2D indicates a fault event by de-energizing the relay. If

multiple faults occur simultaneously, the TMO2D indicates the fault

from highest precedence (power failure) to lowest (no calibration

curve), in the order listed above. When all fault conditions have been

removed, the fault relay is re-energized.

Faults are detected only when the TMO2D is in Operate Mode

(displaying data). When in Menu Mode (during programming), the

detection and signaling of faults is suspended. In this case, the Fault

Alarm holds its last state (energized or de-energized) until the unit has

been returned to Operate Mode.

To provide power-failure detection, the Fault Alarm relay is

energized (ON) during normal operation and de-energized (OFF)

during a fault condition. Therefore, when testing the alarm relay,

select “ON” to indicate a normal operating condition and “OFF” to

indicate a fault condition (see Table 2 below).

Table 2: Fault Alarm Relay Conditions

Condition Alarm State Alarm Test Selection

normal operation energized ON

fault de-energized OFF

913-220B 7

Page 8

10/2/00

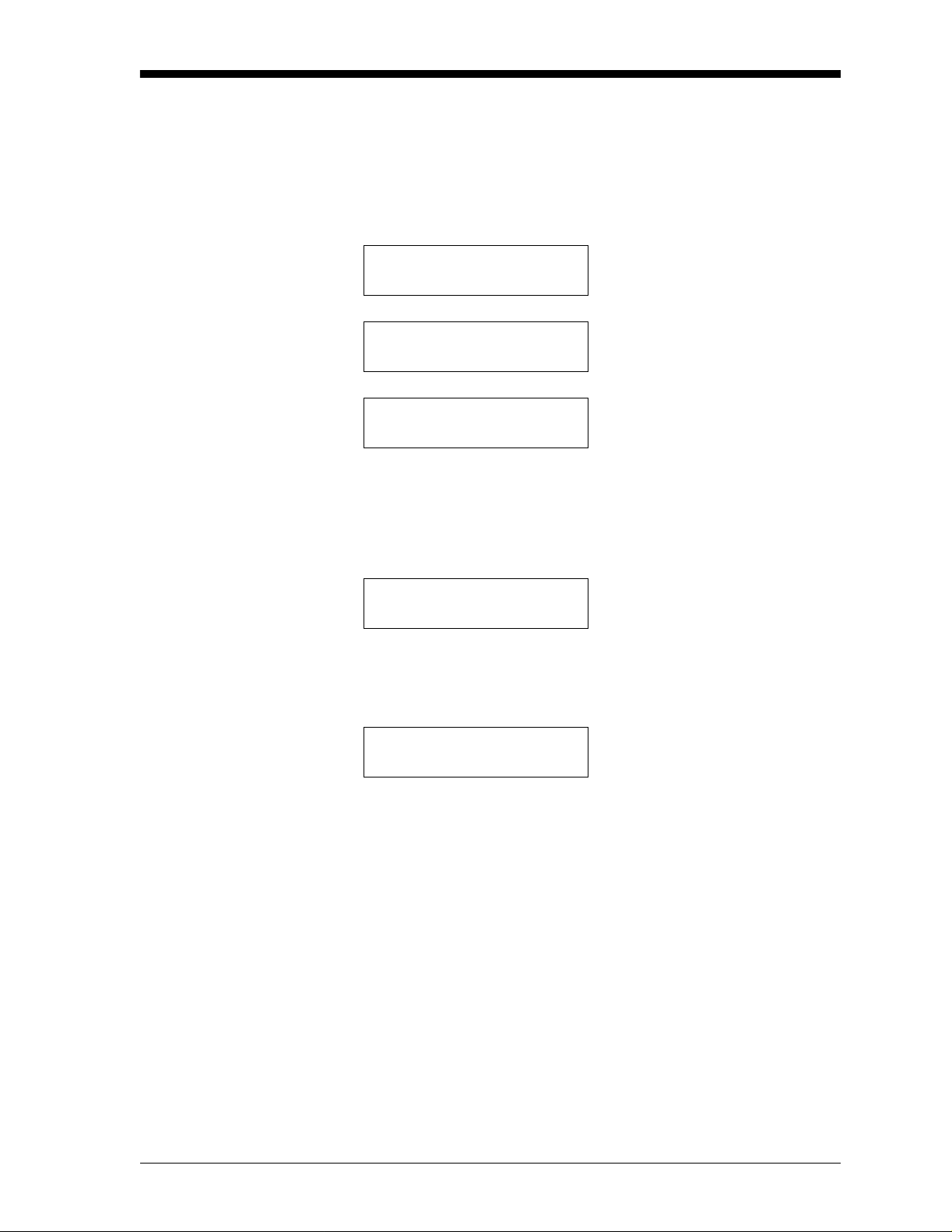

Wiring the Fault Alarm Your TMO2D uses the relay labeled “HIGH” for the Fault Alarm.

Wire the Fault Alarm as shown in Figure 4 below.

Note: With this software version, the “LOW” alarm relay handles

both the low alarm trip point and the high alarm trip point.

HI-LOWFAULT

ALARM

ALARM

TMO2D

RECORDERS

SPAREOXYGEN

CELL

+

2

4

V

INPUTS

C

+

O

R

2

M

D

T

4

X

V

N

P

0/4-20MA

R

I

T

N

N

1

RECBRECA

I

N

2

AUTOCAL

CALPROCESS

NO NO NO NONC NC NC NCCCCC

ALARMS

HIGHLOW

T-CABLE

237-047

OR EQUAL

E

K

T

E

C

I

D

U

A

H

L

E

L

W

B

B

R

4321

TRANSMITTER

RED

BLACK

WHITE

BLUE

RECORDER

A

OPTIONAL

RECORDER

B

NOTES:

1. Standard relays are rated for 2 Amps, 120 VAC.

2. User must ensure ag a i nst explosive gas mixtures

when using auto-calibration.

3. Fault alarm is wired normally-closed to common

at the HIGH relay.

OUTLET

INLET

Figure 4: Wiring the TMO2D with Fault Alarm (Software Version 4C or Later)

ALARM

POWER

913-220B 8

Page 9

10/2/00

Testing the Fault Alarm The Fault Alarm is tested in the same way as the other alarms (refer

to Table 2 on page 7 for a summary of the Fault Alarm relay

conditions). Follow the instructions in Chapter 4 of your User’s

Manual under Alarms Test to enter the

that the display below now shows

[Alarms Test] menu. Notice

[fault] as an additional choice.

Select alarm to test:

[HI-LOW] fault done

Select alarm to test:

hi-low [FAULT] done

Turn Fault Alarm:

[ON] off done

Note: When

[YES] is pressed above, the alarm relay turns ON (non-

fault condition), and the selection brackets move to

Turn Fault Alarm:

on [OFF] done

Note: When

[YES] is pressed above, the alarm r elay turns OFF (fault

condition), and the selection brackets move to

Use the [NO] or arrow keys to

select

[FAULT].

Press [YES] to confirm your

selection.

Use the [NO] or arrow keys to

select

[ON]. Then press [YES]

to turn the Fault Alarm ON

(non-fault condition).

[OFF].

Press [YES] to turn the Fault

Alarm OFF (fault condition).

[ON].

Turn Fault Alarm:

on off [DONE]

When you finish testing the

Fault Alarm, use the

arrow keys to select

Then, press

[YES] to exit the

[NO] or

[DONE].

Fault Alarm test menu.

Exit the

913-220B 9

[Alarms Test] menu as described in your User’s Manual.

Page 10

10/2/00

Using the Event Log Your modified TMO2D maintains an Event Log in battery-backed

memory . Among other things, this log indicates the nature of any fault

signaled by the Fault Alarm relay by recording the type, date, and

time of the relevant events.

The Event Log can record up to 25 events of the following types:

• factory initialization

• system power on

• system RESET

• RAM checksum failure (memory corruption)

• transmitter under range

• transmitter over range

• no calibration curve

• return to normal operation

• AutoCal T otal drift

• AutoCal Drift/Cal

Note: Testing the Fault Alarm does not appear in the Event L o g .

The TMO2D stores only the 25 most recent events in its memory.

When additional events occur, the TMO2D discards the oldest event

from the log to make room for the new event.

913-220B 10

Page 11

10/2/00

Viewing the Event Log The Event Log may be viewed on the TMO2D display or transmitted

to a computer, printer or other data acquisition system via the RS232

serial port. T o view the Event Log on the TMO2D display , press

and the following prompt appears:

[NO],

Enter Code: ***

50.0% Alarm:

MAIN MENU

Setup?

MAIN MENU

System Log?

SYSTEM LOG MENU

Display System Log?

03: Normal Operation:

04/04/1997 10:21:58

Using the keypad, enter the

system passcode (123). An

asterisk is displayed as each

digit is entered.

Press [NO] until the System

Log? prompt appears.

Press [YES].

Press [NO] until the Display

System Log? prompt appears.

Then, press

[YES].

The most recent event in the

Event Log is displayed.

At the above prompt, use the arrow keys to scroll through the logged

events ([←] for the previous event, [→] for the next event). When

done, press

[NO] to exit the Event Log. See Figure 5 below for a

description of the components of the event log screen.

Event Number (0-24)

Type of Event

03: Normal Operation:

10/02/2000 10:21:58

Date of Event

Time of Event

Figure 5: The Event Log Display Screen

913-220B 11

Page 12

10/2/00

Printing the Event Log To print the Event Log, enter the [System Log] menu, as described in

the previous section. The following display appears:

SYSTEM LOG MENU

Display System Log?

SYSTEM LOG MENU

Print System Log?

Press [NO].

Press [YES] and the entire log

is transmitted via the RS232

serial port.

The Event Log printout looks similar to the example shown in Figure

6 below.

Event Number

Event Date

00: Factory Init at: 10/02/2000 09:34:32

01: Cell Under Range at: 10/02/2000 09:34:33

02: No Calibration at: 10/05/2000 10:14:44

03: Normal Operation: 10/05/2000 10:21:58

Exiting the [System Log] Menu

Event Type

Event Time

Figure 6: A Typical Event Log Printout

To exit the [System Log] menu, proceed as follows:

SYSTEM LOG MENU

Print System Log?

SYSTEM LOG MENU

Done?

Press [NO] until the Done?

prompt appears

Press [YES] to return to the

Main Menu.

913-220B 12

Loading...

Loading...