Page 1

GE

Sensing

TF Series

Panametrics Aluminum

Oxide Moisture Probe

TF Series probe is a Panametrics

product. Panametrics has joined

other GE high-technology sensing

businesses under a new name

_

GE Industrial, Sensing.

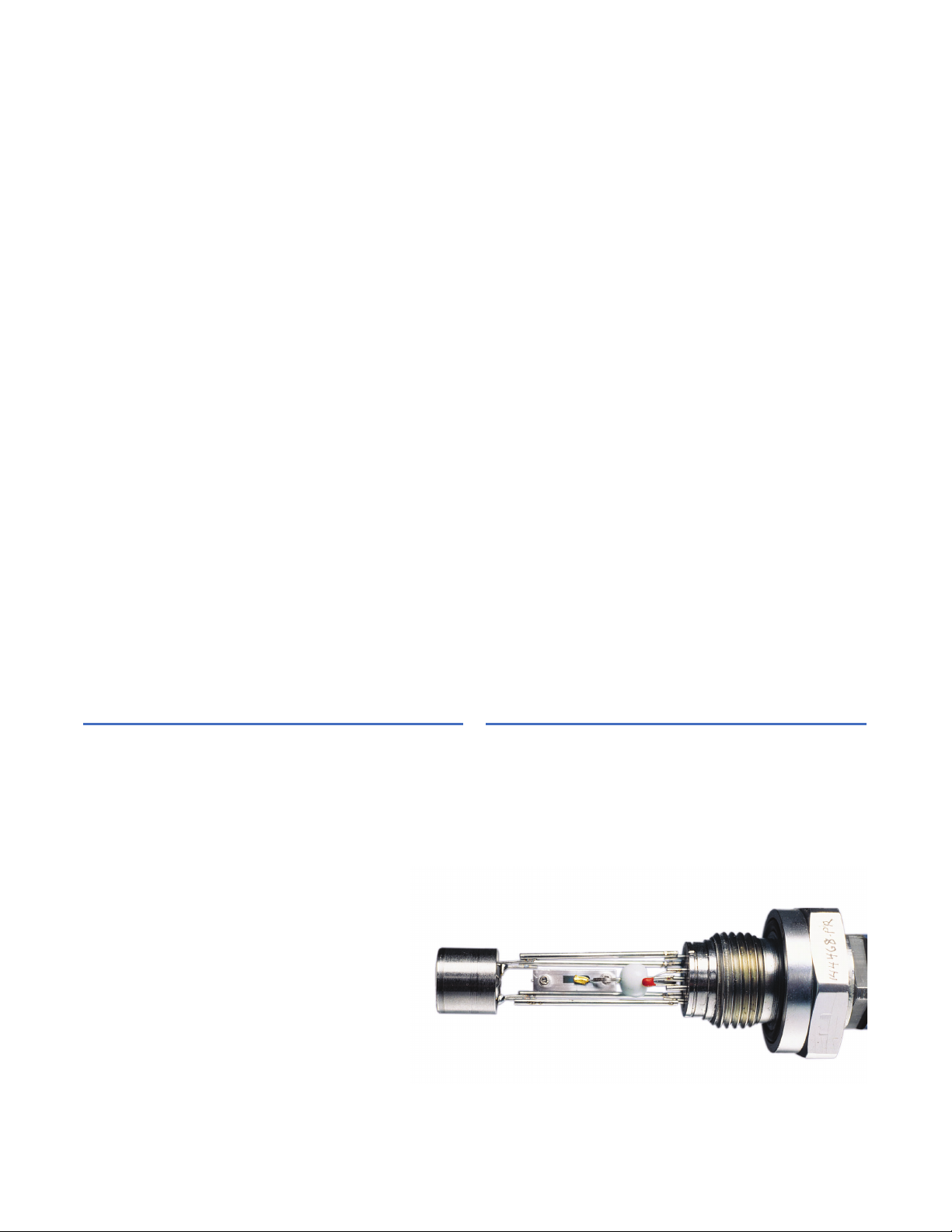

This Panametrics aluminum oxide moisture sensor probe

measures moisture concentration in gases and nonaqueous liquids from trace to ambient levels. It is

designed to be used in conjunction with Moisture

Image®Series 1, Moisture Image Series 2, and Moisture

Monitor™ Series 3 moisture analyzers and PM880

portable hygrometer for industries including:

• Petrochemical

• Natural gas

• Industrial gas

• Semiconductor

• Furnace gas/heat treating

• Power generation

• Air dryer

• Pharmaceutical

• Aerospace

Applications

Features

• Intrinsically safe

• Ambient to ppb moisture measurement

• Built-in temperature and pressure sensors

• Calibrations traceable to National Institute of

Standards and Technology (NIST) or National

Physical Lab U.K. (NPL)

g

Page 2

GE

Sensing

Panametrics Hygrometer

Systems and Moisture Probes

Panametrics aluminum oxide moisture probes have set

the standard of performance and value in industrial

moisture measurement for more than 40 years. In use,

TF Series probes are coupled to Panametrics hygrometer

consoles by an interconnecting cable. Ease of use, wide

measurement range and rigorous calibration standards

make these systems the preferred choice for industrial

moisture measurement worldwide.

Built-In Pressure and

Temperature Measurement

The three-function TF Series probe measures pressure

and temperature, in addition to moisture content . This is

because accurate determination of many moisture

measurement parameters requires knowledge of the

process temperature and pressure. GE eliminated the

inconvenience and limitations associated with installing

and using separate temperature and pressure sensors

by building that capability directly into the TF Series

probe. A nonlinear negative temperature coefficient

(NTC) thermistor to measure temperature from

–22°F to 158°F (–30°C to 70°C) and a choice of five

solid-state piezoresistive transducers are available to

measure pressures up to 5000 psig (345 bar).

Temperature and pressure input data are used by

Moisture Image Series 1 and 2 analyzers, Moisture

Monitor Series 3 analyzer and PM880 portable

hygrometer to determine parameters such as parts per

million (ppm) H2O and relative humidity.

True Absolute Humidity Sensors

Film thickness of the oxide layer is critical to the

performance of this type of sensor. GE manufactures

sensors with an oxide film thickness that causes them to

exhibit true absolute humidity rather than relative

humidity response. This critical film thickness also gives

the TF Series probe quick response and exceptional

calibration stability.

Rigorous Calibration Standards

Traceable to NIST/NPL

The aluminum oxide sensor of each TF Series probe is

individually calibrated in one of the world’s most

advanced moisture calibration facilities. Developed over

several decades, this facility generates precisely known

moisture concentrations, traceable to NIST/NPL, to which

each sensor is exposed during the calibration process.

All data is gathered and stored by a dedicated computer

system. Calibrations are repeated over a period of many

months to ensure the stability of each individual

moisture probe. Only those probes that meet GE’s

demanding specifications for accuracy and stability are

shipped to customers.

Installation Flexibility

TF Series probes are designed to be located at the

process, exactly where the measurement is needed.

Operating temperature is –166° to 158°F

(–110°C to 70°C). The probe can withstand pressures up

to 5000 psig (345 bar). No minimum flow rate is required.

In some cases, TF Series probes can be installed directly

in the process line. More often, to ensure the integrity of

the moisture measurement, a sample conditioning

system is recommended.

GE designs and manufactures a line of reliable,

field-proven conditioning systems to meet the demands

of most applications. If required, a special system will be

designed to meet unique application needs.

Page 3

GE

Sensing

TF Series

Specifications

Moisture Sensor

Intrinsic Safety

Intrinsically safe when connected to

a Panametrics Moisture Series analyzer, PM880 portable

hygrometer or intrinsically safe barriers in accordance

with the user’s manual.

TF Series moisture probe:

BAS01ATEX1096X

II 1 G EEx ia IIC T4 (-20°C to +80°C), and

CSA C US Class I, Division 1, Groups A,B,C&D T4

European Compliance

Complies with EMC Directive 89/336/EEC

and PED 97/23/EC for DN<25

Type

Aluminum oxide moisture sensor probe

Calibration

Each sensor is individually computer calibrated against

known moisture concentrations, traceable to NIST or

NPL.

Dew/Frost Point Calibration Ranges

• Overall: 140°F to -166°F (60°C to –110°C)

• Standard: 68°F to -112°F (20°C to –80°C) with data to

-166°F (–110°C)

• Ultralow: -58°F to -166°F (–50°C to –110°C)

• Extended high: 140°F to -112°F (60° to –80°C) with data

to -166°F (–110°C)

Accuracy

• ±3.6°F (±2°C) from 140°F to -85°F (60°C to –65°C)

• ±5.4°F (±3°C) from -86°F to -166°F (–66°C to –110°C)

Repeatability

• ±0.9°F (±0.5°C) from (60°C to –65°C)

• ±1.8°F (±1.0°C) from (–66°C to –110°C)

Temperature

• Operating: –166°F to 158°F (–110°C to 70°C)

• Storage: 158°F (70°C) maximum

Operating Pressure

5 of Hg to 5000 psig (345 bar), limited by optional

pressure sensor—see pressure sensor ranges

Flow Range

• Gases: Static to 10,000 cm/s linear velocity at 1 atm

• Liquids: Static to 10 cm/s linear velocity at density of

1 g/cc

Response Time

Less than five seconds for 63% step change of moisture

content in either wet-up or dry-down cycle

Probe/Analyzer Separation

• Up to 2000 ft (609 m) for moisture and temperature

• Up to 500 ft (150 m) for pressure

Probe/Analyzer Compatibility

• Moisture Image Series 1 analyzer

• Moisture Image Series 2 analyzer

• Moisture Monitor Series 3 analyzer

• PM880 portable hygrometer

Probe/Analyzer Cable

8-conductor shielded

Input Voltage

1 VAC

Impedance Range

50 kS to 2 MS at 77 Hz, depending on vapor pressure

Limited Warranty

• Calibration: Six months from delivery

• Materials and workmanship: One year from delivery

Built-In Temperature Sensor

Type

Nonlinear NTC thermistor (resultant temperature

linearized by microprocessor)

Operating Range

–22°F to 158°F (–30°C to 70°C)

Accuracy

±0.9°F (±0.5°C) overall

Response Time

1 second in well-stirred oil or 10 seconds in still air for a

63% step change in increasing or decreasing

temperature

Page 4

GE

Sensing

TF Series

Specifications

©2005 GE. All rights reserved.

920-045C

All specifications are subject to change for product improvement without notice.

Moisture Image®and Moisture Monitor™ are registered trademarks and

trademarks of GE. GE®is a registered trademark of General Electric Co. Other

company or product names mentioned in this document may be trademarks or

registered trademarks of their respective companies, which are not affiliated with

GE.

www.gesensing.com

Built-In Pressure Sensor

Type

Solid-state/piezoresistive

Available Ranges

• 30 to 300 psig (3 to 21 bar)

• 50 to 500 psig (4 to 35 bar)

• 100 to 1000 psig (7 to 69 bar)

• 300 to 3000 psig (21 to 207 bar)

• 500 to 5000 psig (35 to 345 bar)

Accuracy

±1% of full scale

Pressure Rating

3 times the span of the available range to a maximum of

7500 psig (518 bar)

g

Loading...

Loading...