Page 1

GE

Measurement & Control Solutions Flow

Model T9

Ultrasonic Flow Transducer

Installation Guide

916-080 Rev. B

July 2010

Page 2

Page 3

Model T9

Ultrasonic Flow Transducer

Installation Guide

916-080 Rev. B

July 2010

GESensingInspection.com

©2010 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Contents

Chapter 1. Information

1.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Transducer Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Chapter 2. Installing Pipe Nozzles

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Identifying and Checking the Nozzle Installation Kit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.3 Selecting and Marking the First Nozzle Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Determining and Marking the Second Nozzle Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.5 Installing the First Welding Boss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.6 Installing the First Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.7 Installing the Second Welding Boss and Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.8 Hot Tapping the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Chapter 3. Inserting T9 Transducers into the Pipe

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2 Inserting Transducers with the Simple Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3 Inserting Transducers with the Barrel Holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4 Inserting Transducers with the Flanged Holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.4.1 Securing the Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Chapter 4. Maintenance

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.2 Removing Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Chapter 5. T9 Specifications

5.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Model T9 Ultrasonic Flow Transducer Installation Guide iii

Page 6

Contents

[no content intended for this page]

iv Model T9 Ultrasonic Flow Transducer Installation Guide

Page 7

Preface

Information Paragraphs

Note paragraphs provide information that provides a deeper understanding of the situation, but is not essential to

•

the proper completion of the instructions.

• Important paragraphs provide information that emphasizes instructions that are essential to proper setup of the

equipment. Failure to follow these instructions carefully may cause unreliable performance.

• Caution! paragraphs provide information that alerts the operator to a hazardous situation that can cause damage to

property or equipment.

• Warning! paragraphs provide information that alerts the operator to a hazardous situation that can cause injury to

personnel. Cautionary information is also included, when applicable.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national codes,

regulations, rules and laws related to safety and safe operating conditions are met for each

installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As equipment

can move suddenly and without warning, do not enter the work cell of this equipment during

automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before you

perform maintenance procedures on the equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Model T9 Ultrasonic Flow Transducer Installation Guide v

Page 8

Preface

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control Solutions is an active participant in Europe’s Waste Electrical and Electronic Equipment

(WEEE) take-back initiative, directive 2002/96/EC.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Visit http://www.gesensing.com/environment/weee.htm

this initiative.

for take-back instructions and more information about

vi Model T9 Ultrasonic Flow Transducer Installation Guide

Page 9

Chapter 1. Information

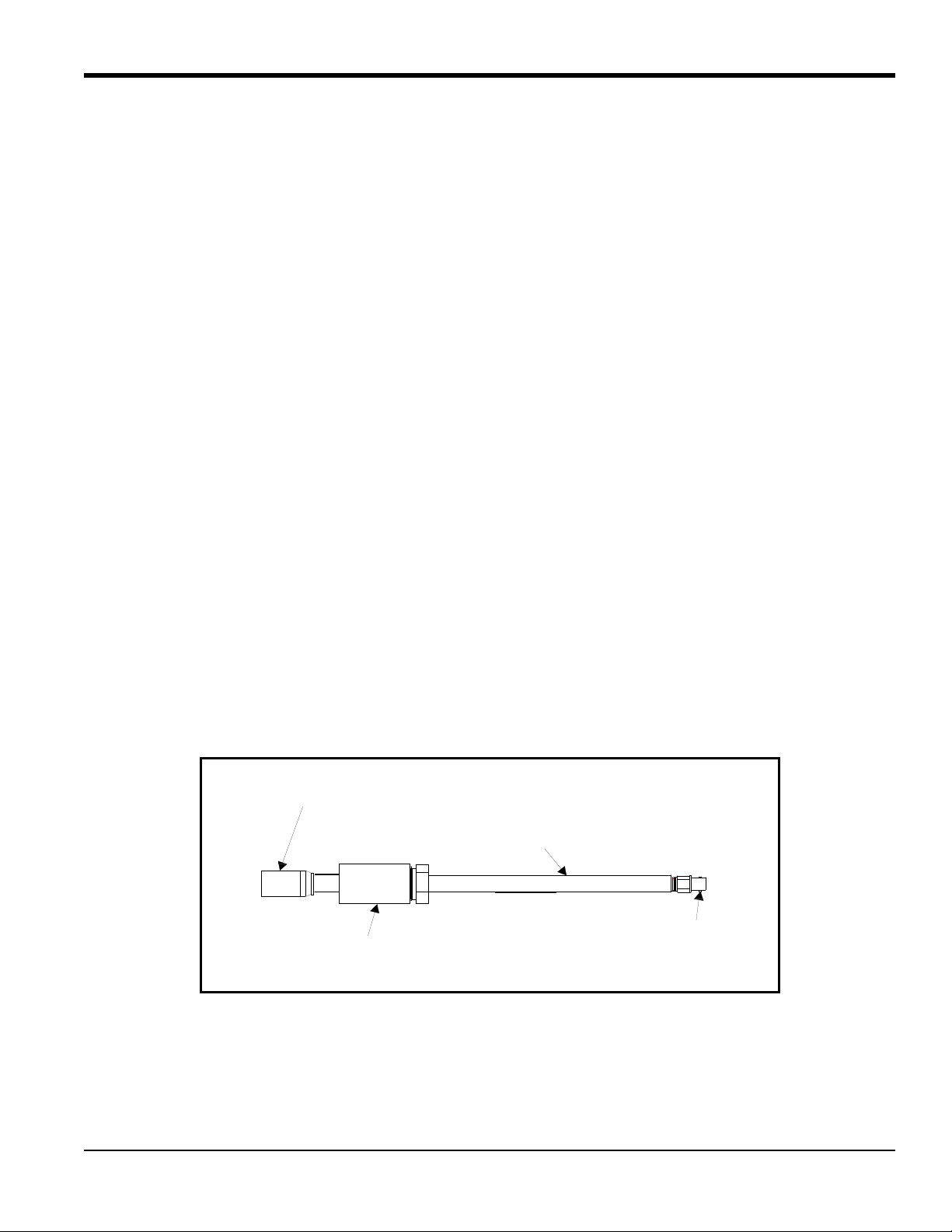

Metallic Body

Transducer Head

BNC Connector

Optional Noise Dampening Fitting

Chapter 1. Information

1.1 Overview

The T9 ultrasonic flow transducer is used exclusively with the GE line of ultrasonic flowmeters. These transducers

measure the flow rate of saturated steam and most gases through pipes having diameters between 2 in. (50 mm) and 48

in. (1200 mm). Such measurements are independent of the pipe material. This document provides details on the

following topics:

• Transducer Construction

• Nozzle Installation

• Transducer Installation

• Maintenance

• Specifications

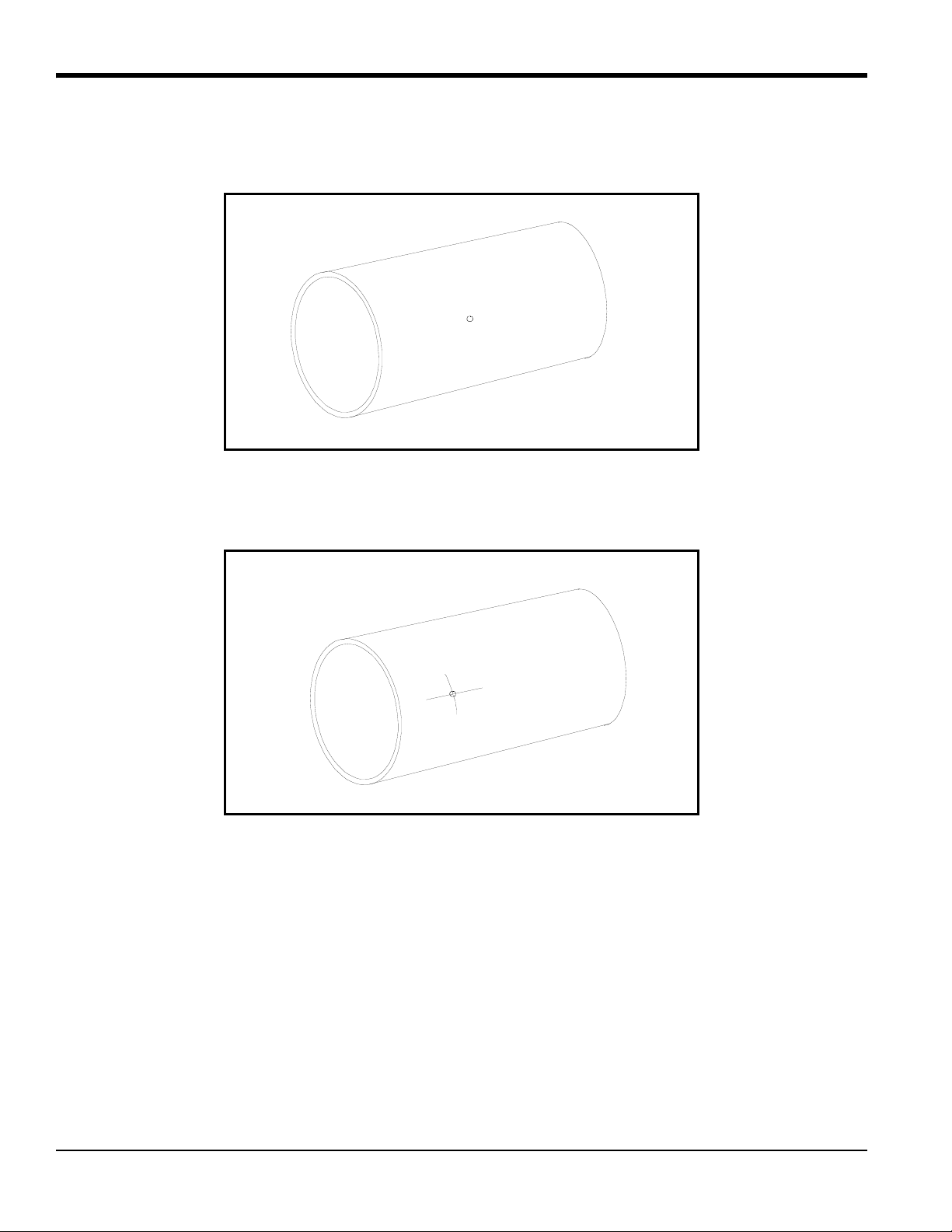

1.2 Transducer Construction

Each T9 transducer assembly (see Figure 1) consists of the following components:

• a metallic body

• a transducer head that consists of a piezoelectric element wired to the BNC connector

• a BNC style connector for use in connecting the transducer to the flowmeter

• an optional noise dampening fitting improves transducer signal transmission.

o

The T9 transducer has a 180

(40 cm).

head and is available in the following lengths: 11 in. (28 cm), 13 in. (33 cm) and 16 in.

Figure 1: General T9 Transducer

Model T9 Ultrasonic Flow Transducer Installation Guide 1

Page 10

Chapter 1. Information

[no content intended for this page]

2 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 11

Chapter 2. Installing Pipe Nozzles

Chapter 2. Installing Pipe Nozzles

2.1 Introduction

Before the T9 transducers can be installed into the pipe, you will need to install pipe nozzles. Nozzles can be installed

on a hot or cold pipe using a GE Nozzle Installation Kit. Nozzles are installed in a Tilted 45

IMPORTANT: This procedure only applies if you ar e usin g a Nozzle Installation Kit. If you are tapping the pipe without

using a Nozzle Installation Kit, refer to the supplied drawings in your shipment. This procedure is written

and illustrated for installations on horizontal pipes; however, the procedure is the same for vertical pipe

installations.

This procedure contains the following instructions:

• Identifying and Checking the Nozzle Installation Kit Components

• Selecting and Marking the First Nozzle Location

• Determining and Marking the Second Nozzle Location

o

configuration.

• Installing the First Welding Boss

• Installing the First Nozzle

• Installing the Second Welding Boss and Nozzle

• Hot Tapping the Pipe

Model T9 Ultrasonic Flow Transducer Installation Guide 3

Page 12

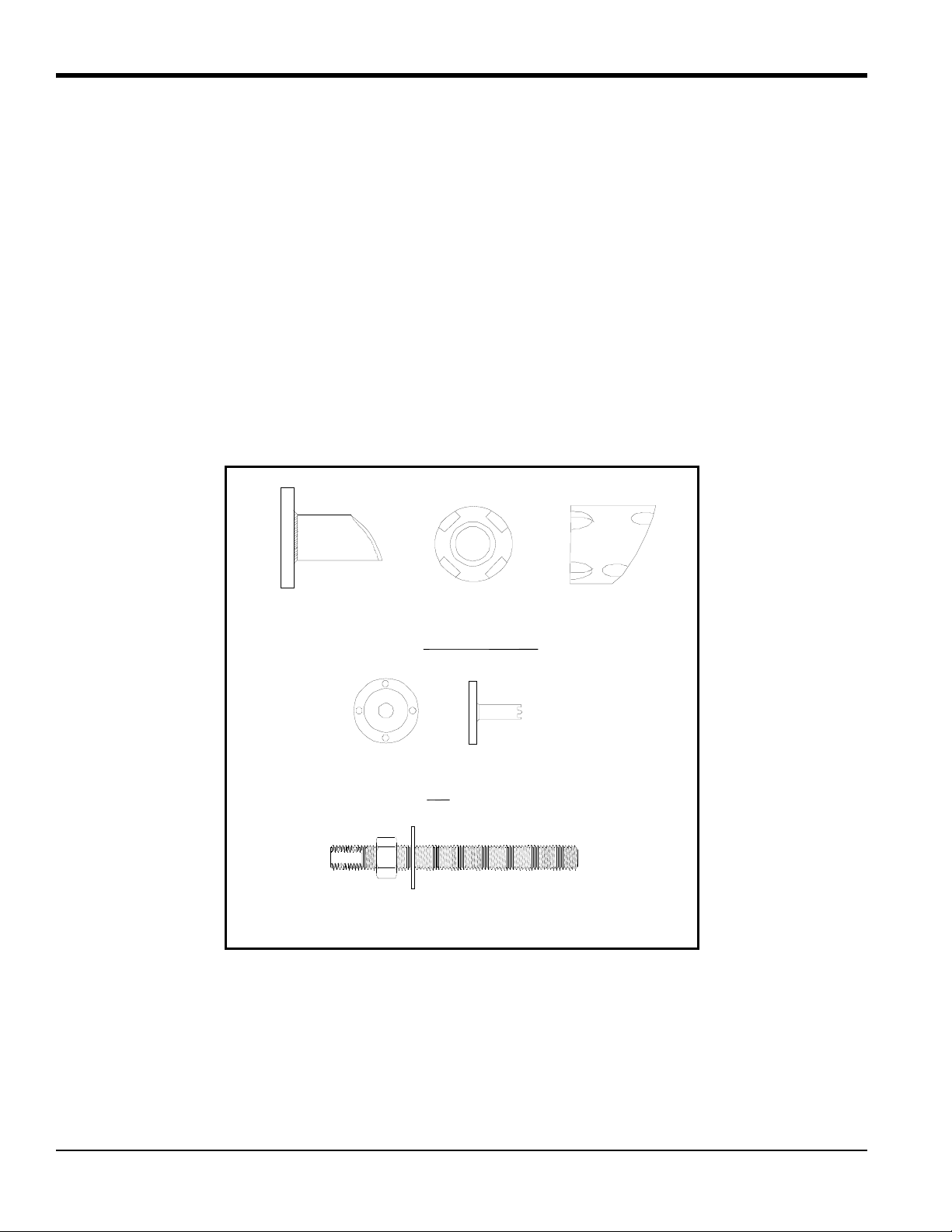

Chapter 2. Installing Pipe Nozzles

Nozzle

Top

Welding Boss

Side

Top

Jig

Side

Threaded Rod with Washer and Nut

2.2 Identifying and Checking the Nozzle Installation Kit Components

The nozzle kit consists of various components which you must identify and check as described in the following

sub-sections.

The Nozzle Installation Kit contains the materials listed below. Use Figure 2 to help identify each component.

• 2 Nozzles

• 2 Welding Bosses

• 1 Jig

• 1 Threaded Rod (1 in. diameter), washer and nut

IMPORTANT: You will need to supply eight

5

/8 in. 4.25 in. studs with two nuts each.

Figure 2: Components for Nozzle Installation Kit

4 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 13

Chapter 2. Installing Pipe Nozzles

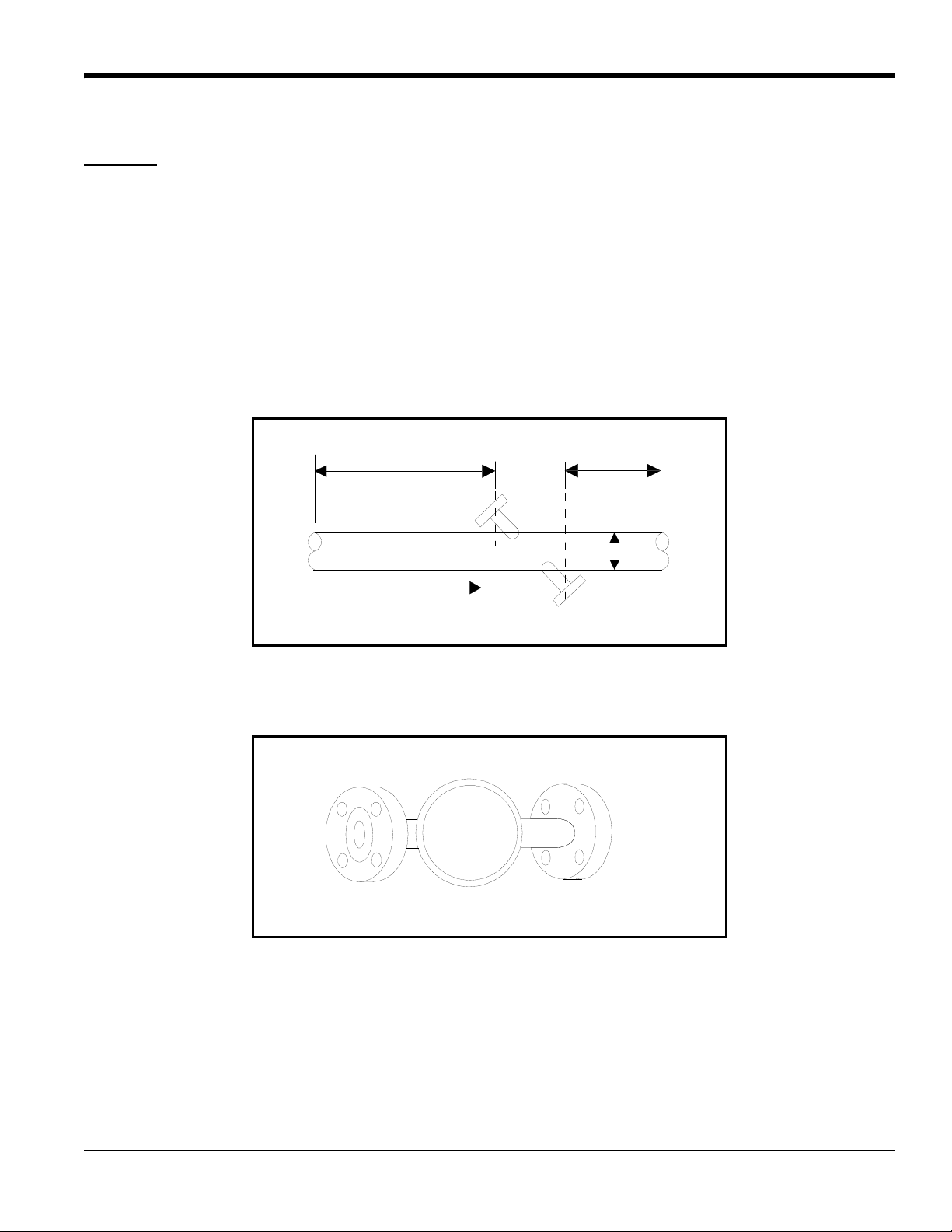

10D

5D

D

Flow

End View

2.3 Selecting and Marking the First Nozzle Location

CAUTION! Correct nozzle alignment is critical to the successful operation of the flowmeter; therefore, all

marking, positioning and welding operations must be carried out with the utmost attention to

accuracy. Unless otherwise stated, dimensional positioning of the nozzles must be held to a

tolerance of 1/16 in. (1.6 mm) relative to each other and with respect to the pipe centerline. the

angular tolerance must be held to 1

All hole cutting in process piping must be performed using hot tapping equipment.

1. For optimum performance, you should select a location that has undisturbed straight run pipeline at least 10 pipe

diameters upstream and 5 pipe diameters downstream from the point of measurement. Undisturbed pipe means

avoiding sources of turbulence such as valves, flanges, elbows; avoiding swirl; and avoiding disturbed flow

profiles.

O

.

2. We recommend that you install the nozzles on a diameter as near as possible to the horizontal plane (i.e., 3 o’clock

and 9 o’clock) as shown below.

Model T9 Ultrasonic Flow Transducer Installation Guide 5

Page 14

Chapter 2. Installing Pipe Nozzles

Side View

Side View

2.3 Selecting and Marking the First Nozzle Location (cont.)

3. At the 3 o’clock position, center punch the pipe to mark the position for the center of the first nozzle.

4. Spray this area with a marking dye product. Using a metal edge, scribe a vertical and a horizontal line (6 in. long)

that intersect at the center punch mark.

6 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 15

Chapter 2. Installing Pipe Nozzles

D1

D2

D3

D4

Side View

Average

O.D.

4 X O.D.

2.4 Determining and Marking the Second Nozzle Location

1. The position for the second nozzle is a distance equal to one pipe diameter along the pipe and loc ated on the

opposite side of the pipe (i.e., 180

2. Due to the possible variation in outside diameter of the pipe, measure the outside diameter of the pipe at four

locations between the nozzle centers. Calculate the average outside diameter based on these measurements.

°

around). Spray this area with a marking dye product.

3. Using a roll of polyester film (or equivalent), cut a strip of film at the width and length as follows:

IMPORTANT: Ensure that the sides of the film are cut parallel to each other.

• Width - equal to the average outside diameter calculated in Step 1 above.

• Length - equal to 4 times the outside diameter of the pipe.

Model T9 Ultrasonic Flow Transducer Installation Guide 7

Page 16

Chapter 2. Installing Pipe Nozzles

Side View

Overlap Mark

Overlap Mark Fold to Here

Mark the Edge

2.4 Determining and Marking the Second Nozzle Location (cont.)

4. Wrap the strip of film around the pipe with one edge running along the vertical scribe line at the first nozzle

location. Make sure the strip overlaps squarely

equals the circumference of the pipe.

around the pipe and mark the overlap position of the strip. This

5. Remove the strip of film and fold it as shown below to determine the position which is diametrically opposite the

overlap position when the film is reapplied to the pipe.

6. Mark the outside of the fold for reference.

8 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 17

Chapter 2. Installing Pipe Nozzles

Fold Mark

Side View

Punch Here

Side View

Scribe Lines

Side View

2.4 Determining and Marking the Second Nozzle Location (cont.)

7. Place the strip of film on the pipe again; this time, line up the overlap mark with the horizontal and vertical scribe

lines. Again, make sure you wrap the strip of film squarely around the pipe.

8. The new position of the center of the second nozzle is now identified as the intersection of the fold line and the

second edge of the strip of film. Center punch this location prior to removing the strip of film.

9. Remove the film.

10. Scribe vertical and horizontal lines (each 6 in. long) to intersect at the center-punch mark.

Model T9 Ultrasonic Flow Transducer Installation Guide 9

Page 18

Chapter 2. Installing Pipe Nozzles

XD2

d2

sin1–dDtan

-------------------------------------------–=

True Center Line

Oblique Center Line

Side View

2.5 Installing the First Welding Boss

1. Before welding the first boss, you must add another scribe line known as the oblique center line. The oblique center

line compensates for the slope or oblique of the boss. The oblique center line is offset from the true center (vertical)

scribe line marked earlier by a distance of “X,” which is dependent on the pipe outside diameter as follows:

where:

D = pipe outside diameter

d = welding boss outside diameter, 1.660 in. (4 cm)

Table 1 below shows values of X for various pipe sizes.

Table 1: X Values for Various Pipe Sizes

Pipe

X DimensionsNPS (DN) O.D.

6 in. (150 mm) 6.625 in. (17 cm) 0.106 in. (2.69 mm)

8 in. (200 mm) 8.625 in. (22 cm) 0.081 in. (2.06 mm)

10 in. (250 mm) 10.75 in. (27 cm) 0.064 in. (1.62 mm)

12 in. (300 mm) 12.75 in. (32 cm) 0.054 in. (1.37 mm)

14 in. (350 mm) 14.00 in. (35.5 cm) 0.049 in. (1.24 mm)

2. Scribe the oblique center line on the pipe at the prescribed distance from the true center line. The oblique center

line should be marked on the side of the true center line that is closer to the second nozzle location.

10 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 19

Chapter 2. Installing Pipe Nozzles

Oblique Center Line

Top View

Side View

Scribe Mark

2.5 Installing the First Welding Boss (cont.)

3. Position the welding boss such that the four scribe lines on the welding boss are lined up with the horizontal scribe

mark and the oblique center line on the pipe. Make sure you orient the boss as shown below.

4. Clamp the boss in place using a pipe strap or equivalent so that it cannot move during tack welding.

5. Check the boss alignment, then tack weld the carbon steel boss to the pipe in each of the four grooves between the

boss scribe marks.

6. Remove the clamp and check the alignment again. If the boss is misaligned by 0.02 in. (0.5 mm) or more, remove

the boss, grind off the welds and reinstall.

Model T9 Ultrasonic Flow Transducer Installation Guide 11

Page 20

Chapter 2. Installing Pipe Nozzles

Threaded Rod

Welded Boss

Jig

Nozzle

Studs &

Sets of Nuts

2.6 Installing the First Nozzle

IMPORTANT: It is essential that the nozzle is set up and fixed in position using the jig and 1-in. threaded rod provided,

prior to welding the nozzle.

1. Screw the threaded rod into boss that is welded onto the pipe. If necessary, remove the washer and nut from the

threaded rod.

2. Insert the pipe section of the jig into the pipe section of the nozzle and fasten using four studs and eight nuts (not

supplied).

12 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 21

Chapter 2. Installing Pipe Nozzles

Jig/Nozzle Assembly

Threaded Rod

Welded Boss

Washer and Nut

2.6 Installing the First Nozzle (cont.)

3. Slide the jig/nozzle assembly over the threaded rod, fitting the jig into the welding boss while aligning the

contoured end of the nozzle so it matches the pipe arc.

4. Align the nozzle scribe marks with the pipe scribe marks and tighten the assembly in place, using the washer and

nut.

Model T9 Ultrasonic Flow Transducer Installation Guide 13

Page 22

Chapter 2. Installing Pipe Nozzles

Flow

2.6 Installing the First Nozzle (cont.)

5. The jig, boss, and nozzle combination is designed to provide a 0.094 in. (2.4 mm) root gap between the beveled

edge of the nozzle and the outside diameter of the pipe. If the 0.094 in.

(2.4 mm) clearance does not exist all around, the nozzle must be removed and ground appropriately to provide the

required clearance. If the root gap is larger than the 0.094 in. (2.4 mm) dimension, then suitably sized wa shers ma y

be inserted between the jig and the nozzle in order to reduce the root gap dimension.

WARNING!

6. Tack weld the nozzle to the pipe at four diametrically opposed points, each tack being approximately 0.6 in. (15

mm) in length. Allow to cool for 30 seconds between tacks.

7. Proceed to complete the root pass and subsequent filler passes as required.

8. Allow to cool, then remove the threaded rod, washer, nut, and jig.

ONLY QUALIFIED PERSONNEL SHOULD WELD BOSSES AND NOZZLES, USING A SUITABLE ASME IX

QUALIFIED WELDING PROCEDURE.

2.7 Installing the Second Welding Boss and Nozzle

Install the second welding boss and nozzle at the required position as described in Installing the First Welding Boss and

Installing the First Nozzle beginning on page 10. The completed installation should appear as shown below.

2.8 Hot Tapping the Pipe

WARNING! HOT TAPPING SHOULD BE PERFORMED ONLY BY QUALIFIED PERSONNEL. FOLLOW ALL

APPLICABLE CODE AND SAFETY PRACTICES DURING THESE PROCEDURES.

1. Install 3 in. ANSI flanged full-bore isolation valves on both nozzles (8 in. face-to-face for 150#RF or 11.125 in. for

300#RF) with gasket and 5/8-in. diameter studs and nuts. Orient valve ha ndles to minimize interference.

2. Hot tap holes in the pipe using hot tap machine equipped with a 3/4 in. (19 mm) drill bit. Then use a coupon

retaining hole saw to cut a hole a minimum diameter of 2.36 in. (60 mm).

14 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 23

Chapter 3. Inserting T9 Transducers into the Pipe

Z Dimension

Chapter 3. Inserting T9 Transducers into the Pipe

3.1 Introduction

The T9 transducer is typically installed into a meter body. The meter body is a section of pipe that contains the ports

where the transducers will be mounted. The meter body may be prefabricated or created by installing ports on the

existing pipe. The T9 can be inserted into the pipes using a number of methods:

• Simple Holder

• Barrel Holder

• Flanged Holder

3.2 Inserting Transducers with the Simple Holder

The simple holder consists of a flange with a compression fitting tapped or welded in the middle of the flange.

o

Transducers are usually installed in a diagonal 45

The procedure below applies to a diagonal 45

not exceed the pipe inside diameter. Consult GE for other configurations.

configuration, although other configurations are available.

o

single-traverse configuration when the transducer insertion depth does

IMPORTANT: If you do not know the transducer insertion depth, measure the length of the nozzle (from the top of the

nozzle to the pipe) and then add the pipe ID to that measurement. If this measurement equals the Z

dimension, then the transducer insertion depth does not exceed the pipe ID.

Use the steps below to insert the simple holder.

1. Measure the Z dimension as shown below. The Z dimension is set at the factory and should be verified.

Model T9 Ultrasonic Flow Transducer Installation Guide 15

Page 24

Chapter 3. Inserting T9 Transducers into the Pipe

Transducer Head

Nozzle

Gasket

Pipe

Pipe

Nut

Washer

Nozzle

Washer

Bolt

3.2 Inserting Transducers with the Simple Holder (cont.)

2. Insert the holder into the pipe nozzle. Place a spiral-wound gasket between the nozzle and the holder. The nozzle

length determines the transducer face position.

3. Bolt the holder flange onto the nozzle flange as shown below.

16 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 25

Chapter 3. Inserting T9 Transducers into the Pipe

Junction Box

Compression Fitting

45°

C

L

3.2 Inserting Transducers with the Simple Holder (cont.)

4. Install the junction box on the end of the transducer using the compression fitting.

5. Repeat the above steps for the other transducer. The figure below shows a completed installation.

Model T9 Ultrasonic Flow Transducer Installation Guide 17

Page 26

Chapter 3. Inserting T9 Transducers into the Pipe

L

P

3.2 Inserting Transducers with the Simple Holder (cont.)

6. Use the equation below to calculate the path length (P) based on the pipe inside diameter and transducer face angle:

P = ID/cos (A)

where: ID = pipe inside diameter and

A = nozzle angle

7. Record the axial dimension (L). The L dimension is equal to the pipe inside diameter.

8. Refer to your flowmeter Startup Guide or User’s Manual to make transducer electrical connections.

You have completed transducer installation.

18 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 27

Chapter 3. Inserting T9 Transducers into the Pipe

Stainless Steel Pipe

180 Transducer Head

o

Compression Fitting

(with PTFE)

Carbon Steel Blind Flange

Insertion Depth

(from end of transducer to raised face on flange)

180° Head Transducer

3.3 Inserting Transducers with the Barrel Holder

A barrel holder is a flange with a pipe welded through its center (the flange and pipe size are dependent upon the

application.) The pipe provides support for the transducer. Compression fittings on the top and bottom of the barrel

holder keep the transducer in place. See Figure 3.

Figure 3: Barrel Holder with 180

o

Head Transducer

1. All equipment comes pre-assembled. Measure the insertion depth as shown below. The insertion depth is set at the

factory and should be verified.

Model T9 Ultrasonic Flow Transducer Installation Guide 19

Page 28

Chapter 3. Inserting T9 Transducers into the Pipe

Barrel Holder

Nozzle

Pipe

Gasket

Nozzle

Washer

Nut

Pipe

Bolt

Inserting Transducers with the Barrel Holder (cont.)

Procedure for Inserting Transducers with the Barrel Holder (cont.)

2. Insert the holder into the pipe nozzle. Place a spiral-wound gasket between the nozzle and the holder. The nozzle

length determines the transducer face position.

3. Bolt the holder flange onto the nozzle flange as shown below.

20 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 29

Chapter 3. Inserting T9 Transducers into the Pipe

Compression Fitting

Junction Box

L

P

45°

C

L

3.3 Inserting Transducers with the Barrel Holder (cont.)

4. Install the junction box on the end of the transducer using the compression fitting.

5. Repeat the above steps for the other transducer.

6. Use the equation below to calculate the path length (P) based on the pipe inside diameter and transducer face

angle:

P = ID/cos (A)

where: ID = pipe inside diameter

A = nozzle angle

7. Record the axial dimension (L).

8. Refer to your flowmeter Startup Guide or User’s Manual to make transducer electrical connections.

You have completed transducer installation.

Model T9 Ultrasonic Flow Transducer Installation Guide 21

Page 30

Chapter 3. Inserting T9 Transducers into the Pipe

T9 Transducer

1.5-in. Flange with Hub

Compression

Fitting

PipeWallThickness

Acos

--------------------------------------------------- -

T9 Transducer

Loosen

Compression

Fitting

Transducer Insert ion Depth (TID)

3.4 Inserting Transducers with the Flanged Holder

The flanged holder is constructed of a 1½ in.-300 or 1½ in.-600# flange. The flange has a large hub that supports the

T9 transducer and also provides acoustic isolation. The transducer is inserted through the flange and is held in place by

a 1/2 in. tube compression fitting. See Figure 4.

Use the procedure below to install transducers.

Figure 4: Flanged Holder with T9 Transducer

1. Calculate the transducer insertion depth (TID). To do this measure from the inside diameter of the pipe to the raised

face of the nozzle flange via the centerline. Then add 0.125 in. (3.2 mm) to the measurement. This equals the TID.

If you are not able to measure from the inside of the nozzle, use the following equation:

Transducer Insertion Depth = Nozzle Length + + 0.125 in. (3.2 m) (where A = Nozzle Angle)

2. Set the transducer to the desired depth by loosening the compression fitting and moving the transducer to the

calculated insertion depth.

22 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 31

Chapter 3. Inserting T9 Transducers into the Pipe

Gasket

Gasket

3.4 Inserting Transducers with the Flanged Holder (cont.)

3. Tighten the compression fitting to hold the transducer in place.

4. Place a spiral-wound gasket over the end of the transducer.

Note: You must use a gasket in order to provide the proper acoustic isolation.

5. Inspect the pipe nozzle. Make sure it is free from dirt/rust. Use the steel wool to clean the pipe nozzle if necessary.

6. Insert the transducer into the nozzle.

Model T9 Ultrasonic Flow Transducer Installation Guide 23

Page 32

Chapter 3. Inserting T9 Transducers into the Pipe

Top View

Top View

3.4 Inserting Transducers with the Flanged Holder (cont.)

3.4.1 Securing the Transducers

1. Secure the flanges together by placing the studs, washers and nuts as shown below. Hand-tighten each stud. The

factory recommends using ASTM A193 Grade B7 (or equivalent) studs and ASTM A19 Grade 2H (or equivalent)

nuts.

24 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 33

Chapter 3. Inserting T9 Transducers into the Pipe

1

1

2

2

3

3

4

4

5

6

7

8

Begin Here

4-Hole Flange

8-Hole Flange

1

1

2

2

3

3

4

4

5

6

7

8

Begin Here

4-Hole Flange

8-Hole Flange

3.4.1 Securing the Transducers (cont.)

2. Once all the studs are inserted and hand-tightened, the studs must be torqued to 80 ft-lb (108 N-m) in three stages.

Set the torque wrench to 30 ft-lb (40 N-m) and torque the studs in the order shown below.

3. Set the torque wrench to 60 ft-lb (81 N-m) and torque in the order shown below.

4. Set the torque wrench to 80 ft-lb (108 N-m) and tighten in the order shown above.

5. Repeat steps 1 through 4 for the other nozzle.

Model T9 Ultrasonic Flow Transducer Installation Guide 25

Page 34

Chapter 3. Inserting T9 Transducers into the Pipe

Top View

Compression Fitting

3.4.1 Securing the Transducers (cont.)

6. Install the junction boxes on the end of the transducers using the compression fittings.

7. Refer to your flowmeter Startup Guide or User’s Manual to make transducer electrical connections.

26 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 35

Chapter 4. Maintenance

Chapter 4. Maintenance

4.1 Introduction

Once the transducers are properly installed into the pipe nozzles as described in the previous section, the T9 transducers

require no additional adjustments.

Periodic inspection of the installation to verify the torque on the mounting bolts may be required, if erratic flow rate

measurements are observed.

If you suspect something is wrong with a transducer or need to replace a transducer, use the appropriate removal

procedure that follows.

4.2 Removing Transducers

Use the steps below to remove transducers that have been installed with a simple, barrel or flange holder.

Note: The illustrations in the steps below use a simple holder.

WARNING!

1. Disconnect power from the flowmeter.

WARNING!

2. Shut down or isolate the process line where you will be removing the transducers.

WARNING!

FOLLOW ALL APPLICABLE SAFETY CODES WHILE PERFORMING THE FOLLOWING PROCEDURES.

MAKE SURE POWER IS DISCONNECTED BEFORE PERFORMING THE FOLLOWING STEPS.

SHUT DOWN THE PROCESS LINE BEFORE REMOVING TRANSDUCERS. SERIOUS INJURY MAY

OCCUR IF TRANSDUCERS ARE REMOVED FROM A LIVE PROCESS LINE.

Model T9 Ultrasonic Flow Transducer Installation Guide 27

Page 36

Chapter 4. Maintenance

Junction Box

4.2 Removing Transducers (cont.)

3. Disconnect the transducer cables at the junction box.

28 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 37

Chapter 4. Maintenance

Compression Fitting

4.2 Removing Transducers (cont.)

4. Remove the junction box from the end of the transducer by loosening the compression fitting and unscrewing the

junction box.

Model T9 Ultrasonic Flow Transducer Installation Guide 29

Page 38

Chapter 4. Maintenance

Bolts

Bolts

Gasket

Blind Flange

4.2 Removing Transducer (cont.)

5. Remove the bolts that fasten the simple/barrel/flange holder to the nozzle flange, and remove it from the pipe

nozzle.

[no content intended for this page]

6. Install a new flange gasket on the pipe nozzle. Then, fasten the “blind” flange to the pipe nozzle with the bolts

removed in the previous step.

7. Repeat steps 3 through 6 for the other transducer if necessary.

You have completed the removal procedure, it is now safe to reopen the process line.

30 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 39

Chapter 5. T9 Specifications

5.1 Specifications

Table 2: T9 Transducer Specifications

Transducer T9 Specification

Designation Hazardous area applications; flare gas, hydrocarbon gases, saturated steam.

Installation Type Wetted

Material

Field Mounting Flowcell, hot or cold tap

Process Connection 1.5 in. (40 mm) flanged

Holder Type Simple, barrel or flanged holder

Holder Ratings 150#, 300#, 600#

Operating Frequency 100 kHz

Pressure Range 0 to 2700 psig

Electrical Rating 200 V peak-to-peak, 5 mA

Ambient Temperature Range

Process Temperature Range

Standard: Titanium

Optional: 316SS, Monel

Europe: -40 to +158°F (-40 to +70°C)

North America: -4 to +140°F (-20 to +60°C)

Normal Temperature: -58 to +302°F (-50 to +150°C)

High Temperature: -58 to +500°F (-50 to +260°C)

or Hastelloy

Chapter 5. T9 Specifications

Model T9 Ultrasonic Flow Transducer Installation Guide 31

Page 40

Chapter 5. T9 Specifications

[no content intended for this page]

32 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 41

Warranty

Warranty

Each instrument manufactured by GE Sensing is warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to normal operation or replacing the instrument, at

the sole discretion of GE Sensing. Fuses and batteries are specifically excluded from any liability. This warranty is

effective from the date of delivery to the original purchaser. If GE Sensing determines that the equipment was

defective, the warranty period is:

• one year from delivery for electronic or mechanical failures

• one year from delivery for sensor shelf life

If GE Sensing determines that the equipment was damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines specified by GE Sensing, the repairs are not covered

under this warranty.

The warranties set forth herein are exclusive and are in lieu of all other warranties whether

statutory, express or implied (including warranties or merchantability and fitness for a

particular purpose, and warranties arising from course of dealing or usage or trade).

Return Policy

If a GE Sensing instrument malfunctions within the warranty period, the following procedure must be completed:

1. Notify GE Sensing, giving full details of the problem, and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for factory service, GE Sensing will issue a RETURN

AUTHORIZATION NUMBER (RAN), and shipping instructions for the return of the instrument to a service

center will be provided.

2. If GE Sensing instructs you to send your instrument to a service center, it must be shipped prepaid to the authorized

repair station indicated in the shipping instructions.

3. Upon receipt, GE Sensing will evaluate the instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty , the i nstrument will be repaired at no cost to the owner and

returned.

• If GE Sensing determines that the damage is not covered under the terms of the warranty, or if the warranty has

expired, an estimate for the cost of the repairs at standard rates will be provided. Upon receipt of the owner’s

approval to proceed, the instrument will be repaired and returned.

Model T9 Ultrasonic Flow Transducer Installation Guide 33

Page 42

Warranty

[no content intended for this page]

34 Model T9 Ultrasonic Flow Transducer Installation Guide

Page 43

Page 44

Customer Support Centers

U.S.A.

The Boston Center

1100 Technology Park Drive

Billerica, MA 01821

U.S.A.

Tel: 800 833 9438 (toll-free)

978 437 1000

E-mail: sensing@ge.com

Ireland

Sensing House

Shannon Free Zone East

Shannon, County Clare

Ireland

Tel: +353 (0)61 470291

E-mail: gesensingsnnservices@ge.com

916-080 Rev. B

An ISO 9001:2000 Certified Company

www.gesensinginspection.com/en/about_us/quality.html

www.gesensinginspection.com

©2010 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Loading...

Loading...