Page 1

GE

Sensing

Optica

™

Optica is a General Eastern

product. General Eastern has joined

other GE high-technology sensing

businesses under a new name

_

GE Industrial, Sensing.

The Next Generation Humidity

Reference Standard

GE's Optica Series chilled mirror hygrometers offer

National Institute of Standards and Technologies (NIST)

_

traceable humidity, temperature and pressure

measurements for the connected generation. Now data

is accessible from anywhere, any time, from within a

browser over the Internet or from your intranet.

• Temperature

• Relative humidity (% RH)

• Dew/frost point (Td)

• Absolute humidity (m/v)

• Mass mixing ratio (m/m)

• Volume mixing ratio (v/v)

Optica Measures

• Wet bulb (Tw)

• Enthalpy (h)

• Water vapor pressure (e)

• Pressure

• Alarm relays

• Analog outputs

Fundamental dew point measurement is a primary

measurement used as a transfer standard for calibrating

other humidity instruments and sensors. Chilled mirrors

are also the sensors of choice when process and

laboratory measurements call for high precision without

long term drift. Optica may be used with five, fully

interchangeable chilled mirror sensors to provide a

measurement range from -112°F to 185°F (-80°C to 85°C)

dew point with 0.36°F (0.2°C) or better accuracy. Inputs

for a 100 S RTD and silicon-based piezoresistive pressure

transducer ensure precision measurements, which are

used to convert the dew point to any metric, English or

user-defined unit of humidity measure.

g

Page 2

Communications

• Ethernet port

• Java-based applet loads in web browsers

• Data logger 6 megabyte memory

• Recorded data uploads in ASCII format

• Exports to spreadsheets

• Real time "strip chart" graphing

• Color VGA or 4 x 40 matrix display

Software

The Optica software is easy to navigate. Users select

readout display, strip chart, analog output scale, digital

communications, self-diagnostics, cleaning and data

logging with intuitive pull-down menus. Setup values can

be saved in memory and loaded anytime, either locally or

from anywhere via the Ethernet port.

In the Lab or on the Plant Floor

• Calibration labs

• Process control

• Clean rooms

• Environmental test chambers

• Precision HVAC monitoring and control

• Fuel cells

• Heat exchanger and refrigerant coil calorimeters

• Thermal processing/heat treating

• Semiconductor manufacturing

• Storage areas

• Pharmaceutical validation chambers

• Engine test cells and emissions testing

• Aircraft engines and turbines

Functionality

The Optica simultaneously measures dew point,

temperature and pressure. The analyzer is equipped with

programmable math functions to produce custom units.

In, exp +, -, x and / functions enable derived engineering

units to be displayed, recorded and transmitted to data

acquisition systems. The analyzer input channel is a

standard 4 to 20 mA/0 to 5 VDC input, so the Optica can

be connected to any type of process transmitter and be

configured to display engineering units.

Chilled Mirror Sensors Theory of

Operation

GE’s chilled mirror hygrometers are used in standards

and metrology labs as well as in industrial applications

where precise and repeatable humidity measurement

and control is required. The inherent accuracy and long

term stability provides many advantages over other

types of humidity measurement technologies. Chilled

mirrors fundamentally measure the dew or frost point

temperature directly by controlling a reflective surface to

an equilibrium temperature between dew/frost

formation and evaporation, and precisely measuring the

temperature of the mirror at this point.

“Plug and play” setup is easily accomplished with

standard connectors for power, sensor and analog outputs.

GE

Sensing

Page 3

GE's chilled mirrors consist of a small polished hexagonal

rhodium, or platinum mirror attached to thermoelectric

cooling module (TEC). The Optica analyzer's servo

controller applies current to the TEC, which causes the

mirror to cool. The mirror is illuminated with a regulated

Gas emitter, which transmits light in the infrared

spectrum. The light reflected by the mirror is received by

a photodetector. When water vapor condenses on the

mirror as water or frost (ice crystals), the light received

by the photodetector is reduced due to scattering. This

results in the servo controller reducing the power

causing the mirror to slightly warm. The Optica's control

system will modulate the amount of current flowing

though the TEC to maintain a temperature where the

rate of condensation and evaporation of water

molecules and the mass of water on the mirror is

constant. The resulting temperature of the mirror is then,

fundamentally by definition, equal to the dew or frost

point temperature. A precision four-wire platinum RTD

imbedded in the mirror measures the temperature. The

accuracy of the dew point measurement has been

validated to an accuracy of ±0.36°F (±0.2°C) dew/frost

point. The precision can also be enhanced to ±0.27°F

(±0.15°C) dew/frost point.

Dry bulb temperature is measured with a precise

four-wire 100 S platinum RTD and pressure is measured

with a piezoresistive silicon pressure transducer. The

dew/frost point and dry bulb RTD resistance signals are

conditioned and amplified by the Optica monitor to

display and transmit dew/frost point and temperature.

The pressure sensor transmits an amplified 4 to 20 mA

signal that is powered by the Optica. The cardinal

measurements of dew/frost point, dry bulb temperature

and pressure are used to calculate other humidity

parameters such as relative humidity, wet bulb, mass

mixing ratio, volumetric mixing ratio, absolute humidity,

enthalpy and water vapor pressure values using

psychometric equations.

The RTD sensor is imbedded in the chilled mirror and

never comes in contact with the process or test

environment. The wetted parts consist of the platinum or

rhodium mirror, a stainless steel or mylar vapor barrier

and epoxy sealant. The net result is drift-free humidity

measurement designed to maintain accuracy

specifications for many years.

Chilled mirrors require a nominal flow rate across the

mirror to achieve the optimal dew/frost formation and

response time. The sensor should either be installed in a

duct with moving air or be equipped with a sampling

pump. The optimum flow rate is 0.5 to 5 SCFH (0.25 to

2.5 L/min). GE provides sampling systems to temperature

condition, regulate the pressure and filter process air

prior to reaching the chilled mirror. Our application

engineers will discuss your application in detail and

provide a recommendation for the system best suited to

your needs.

Self Cleaning and Digital Control

LED regulation

Thermoelectric

heat pump control

OP

AMP

Light emitting diodes

Photo detectors

Thermoelectric

cooling module

Rhodium or

platinum mirror

Precision four-wire PRTD

Power

Optical balance

Gas flow

For environments where physical contaminants such as

dust, oil mist and pollen are present, the use of a

sampling system with a filter media is recommended.

The filter media must be hydrophobic so as to not

absorb or release water vapor into the test stream. Over

time the mirror can be etched or pitted by particulate,

altering the light scattering characteristics. GE mirrors

are field replaceable. The standard rhodium mirror may

be upgraded to platinum for industrial applications.

GE developed a patented contamination compensation

scheme called PACER®(Program Automatic Error

Reduction). The PACER cycle may be initiated manually or

by programming a timed cycle. The cycle starts by

capturing the data (during the PACER cycle a constant

value is transmitted) and cooling the mirror well below

the dew point such that a thick dew layer forms on the

mirror. The mirror is then rapidly heated. During the

heating a significant amount of soluble and some

non-soluble contamination is flash evaporated. The

contamination left on the mirror tends to aggregate in

dry islands or spots (much like a glass that comes out of

a dishwasher). This process leaves approximately 85% of

the mirror clean. The light signal received by the

photodetector is compared against a reference

LED/photodetector and the two signals are "balanced,"

effectively negating the effect of the residual

contamination left on the mirror. The PACER cycle works

very well, but eventually manual cleaning may be

required. All of GE's chilled mirrors are accessible for

GE

Sensing

Page 4

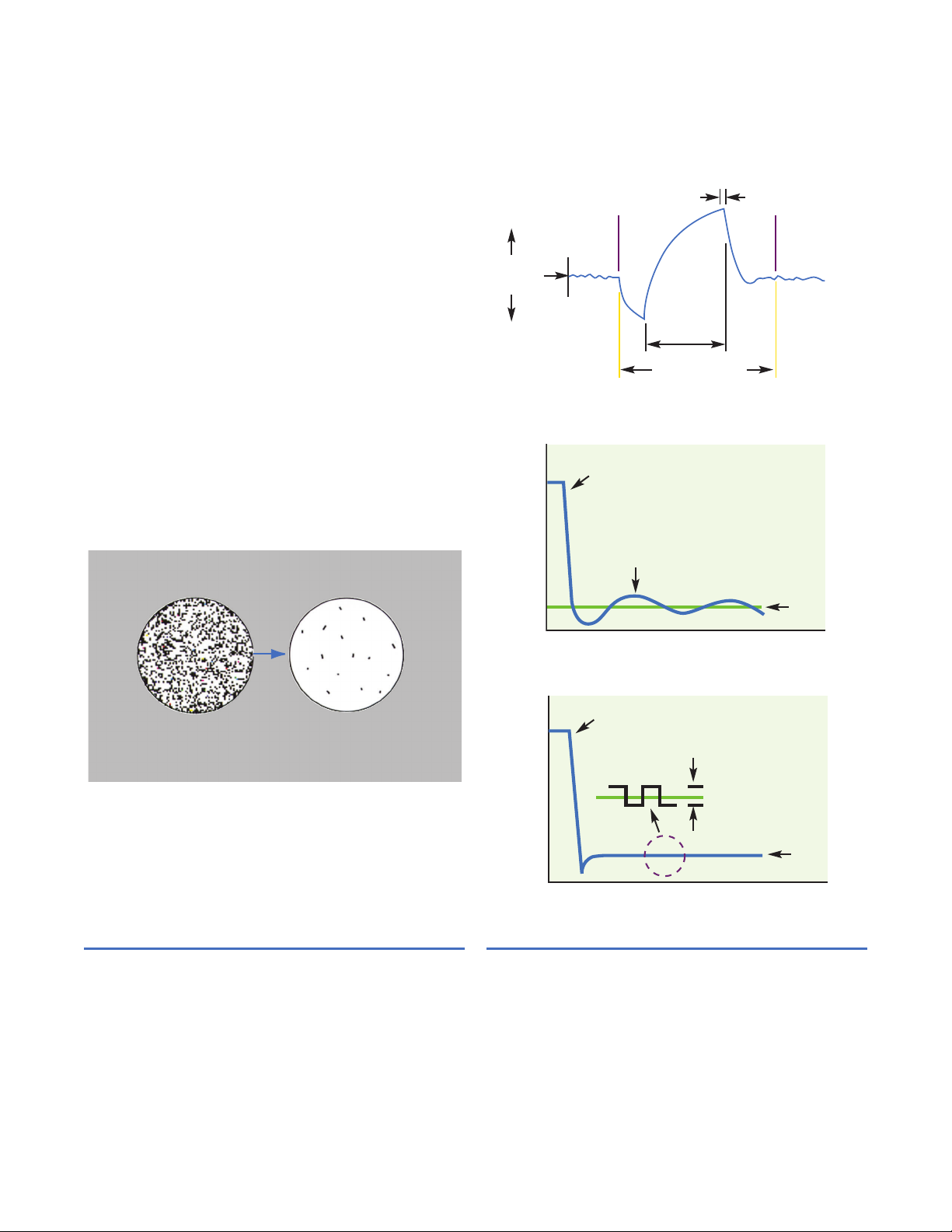

PACER cycle

Before PACER cycle

After PACER cycle

Data is sampled

and held (3 minutes)

Mirror heats

to dry state

(90 seconds)

Mirror returns

to dew point

(60 seconds)

Mirror cools

and coalesces

(30 seconds)

Optical system

automatically adjusts

for correct reflectance

(5 seconds)

Prevailing

dew point

Cooling

Heating

End

of cycle

Start

of cycle

Typical PACER cycle

Slew rate

Dew

point

Oscillation

Time

Temperature

Analog control

Time

Temperature

Digiloop control

Slew rate

Dew

point

0.05°C temperature steps

manual cleaning. Cleaning is a simple process consisting

of wiping the mirror with a cotton swab wetted with

cleaning solution or distilled water. (Distilled water is

recommended as the final cleaning agent .)

GE developed Digiloop™ control to overcome the

limitations of traditional analog PID (Proportional Integral

and Derivative) control. Analog temperature control

produces oscillations particularly at high or trace

humidity levels. It is difficult to apply self-tuning or PID

constants to analog control loops, which are over

damped or under damped. Digiloop utilizes digital

sampling and feed-forward control by taking time-based

samples when the dew point is within a predetermined

proportional band. By recording the oscillations, the

digital control effectively predicts the magnitude of

change and adjusts the current to the thermoelectric

cooling module, which steps the mirror temperature in

0.09°F (0.05°C) increments. This results in a significantly

improved control and dew point precision.

GE

Sensing

Page 5

Models

• Color VGA with data logger and Ethernet

communications available in bench, rack or wall

mount styles

• 4 x 40 dot matrix available in bench, rack or wall

mount styles

Power

95 to 265 VAC, 50/60 Hz, 200 watts

Electrical I/O

IEC-style AC receptacle (bench mount), screw terminal

block (wall mount), multipin chilled mirror and

temperature sensor/cable connectors, screw terminals

for analog outputs, DB-9 for RS232 and 10 base-T for

Ethernet*

Measured Parameters

Dew point, temperature and 4 to 20 mA/0 to 5 VDC

Calculated Parameters

Relative humidity, wet bulb, mass mixing ratio, volumetric

mixing ratio, absolute humidity, water vapor pressure

and enthalpy in English and metric units, as well as userconfigured units

Inputs

1/3 Class A DIN 43760, 100 S RTD and dew/frost point

and dry bulb temperature. Loop powered 4 to 20 mA DC

at 500 S maximum load

Accuracy

System accuracy ±0.36°F (±0.2°C) for dew/frost point,

±0.27°F (±0.15°C) for temperature, 0.5% full scale (FS) for

pressure

Range

Governed by sensor

Hystersis

Negligible

Sensitivity

0.1% FS

A/D

16 bit

Optica

Specifications

Data Logger Memory

6 megabytes*

Display

1/4 color VGA enables up to six parameters to be

displayed or 4 x 40 dot matrix enables three parameters

to be displayed

Operating Temperature

32°F to 122°F (0°C to 50°C)

Cooling Rate

0.27°F (1.5°C )/sec typical above 32°F (0°C)

Digital Interface

RS232 port, Ethernet port*

Digital Output Format

Data ASCII text, Ethernet java applet password

protected*

TCP/IP Address

User programmable*

Analog Outputs

(2) 4 to 20 mA and 0 to 5 VDC, user configurable and

scalable

Analog Outputs

(2) 5 A at 250 V, form C, (SPDT) relays

Enclosure

Benchtop: Type 1

Wall Mount: Type 4

Weight

Benchtop: 8 lb (3.6 kg)

Wall Mount: 10 lb (4.5 kg)

*Feature available with VGA models only

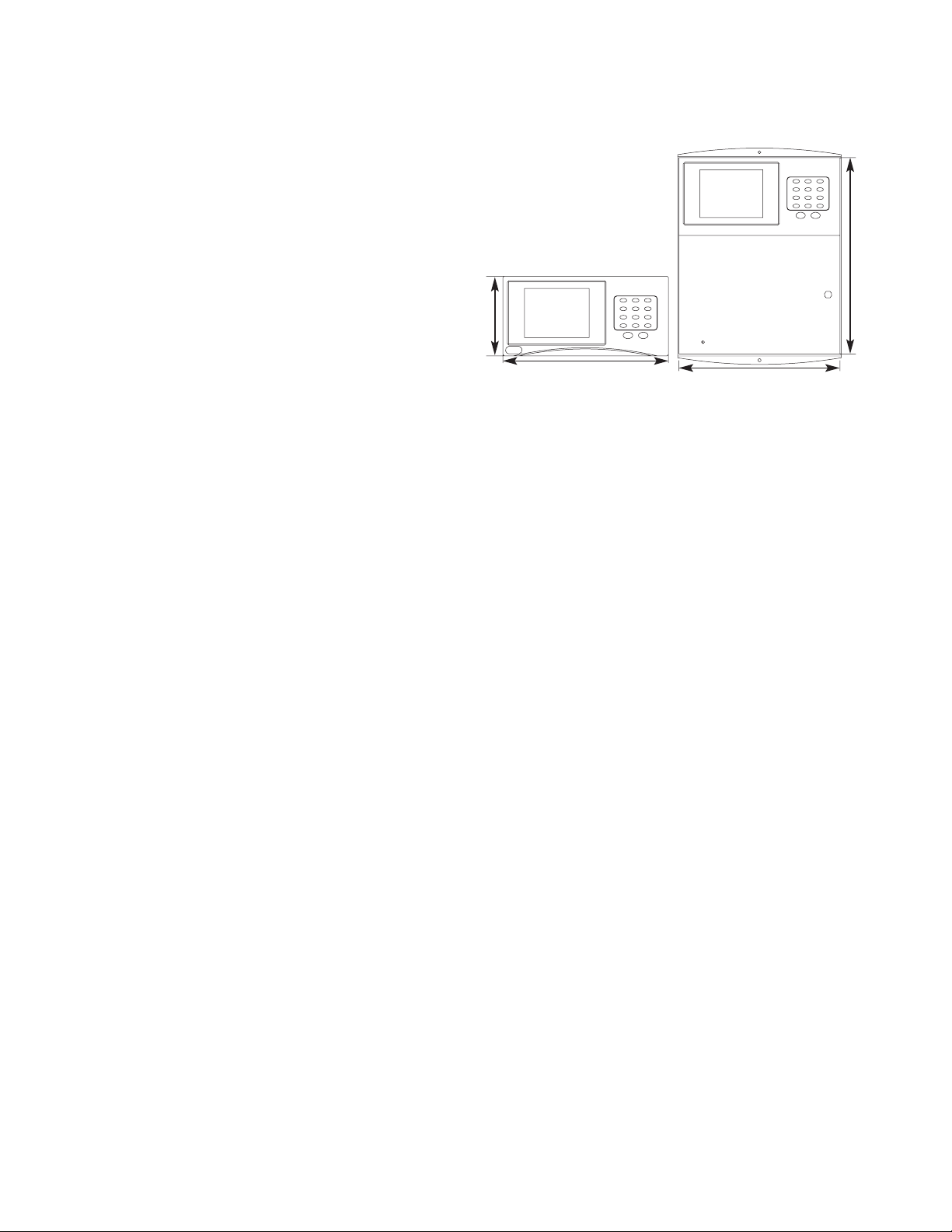

16.5 in (419 mm)

13.5 in (343 mm)

13.5 in (343 mm)

6.5 in

(165 mm)

Bench Top Wall Mount

GE

Sensing

Page 6

Sensing Element

Four-wire 1/3 Class A DIN 43760 RPT, 100 S @ 32°F (0°C)

Dew/Frost Point Accuracy

Standard: ±0.36°F (±0.2°C)

Optional: ±0.27°F (±0.15°C)

Sensitivity

>0.05°F (>0.03°C)

Repeatability

±0.09°F (±0.05°C)

Hysteresis

Negligible

Cooling Stages

Single stage thermoelectric cooling (TEC) module

Auxiliary Cooling

Not applicable

Depression

81°F (45°C) at 77°F (25°C) dry bulb and atmospheric

pressure

Typical Measurement Range

5°F to 77°F (-15°C to 25°C) dew/frost point (Td) in air @

77°F (25°C) and atmospheric pressure. Equivalent to 5%

to 100% RH.

Other humidity parameters based on calculations.

Sample Flow

0.5 to 5.0 SCFH (0.25 to 2.5 L/min)

Operating Temperature

5°F to 176°F (-15°C to 80°C)

Pressure

-3 to 200 psig (0.8 to 15 bar)

1111H

Single-Stage

Chilled Mirror

Specifications

Power

Derived from Optica

Sensor Body

Epoxy-coated aluminum

Filter

Polytetrafluoroethylene (PTFE) filter (standard on

1111H-GE)

Mirror

Standard: Rhodium-plated copper

Optional: Solid platinum

Sensor Wetted Material

Aluminum, copper, mylar, PTFE, rhodium or platinum

Vapor Barrier

Mylar

Electrical Connector

MS-style multipin connector

Weight

1 lb (1.4 kg) net

Accessories

MB-11 Wall mounting bracket

PTFE-GE PTFE filter

P Platinum mirror

X Enhanced accuracy ±0.27°F (±0.15°C) Td

O111D Pressure boss (1111H only)

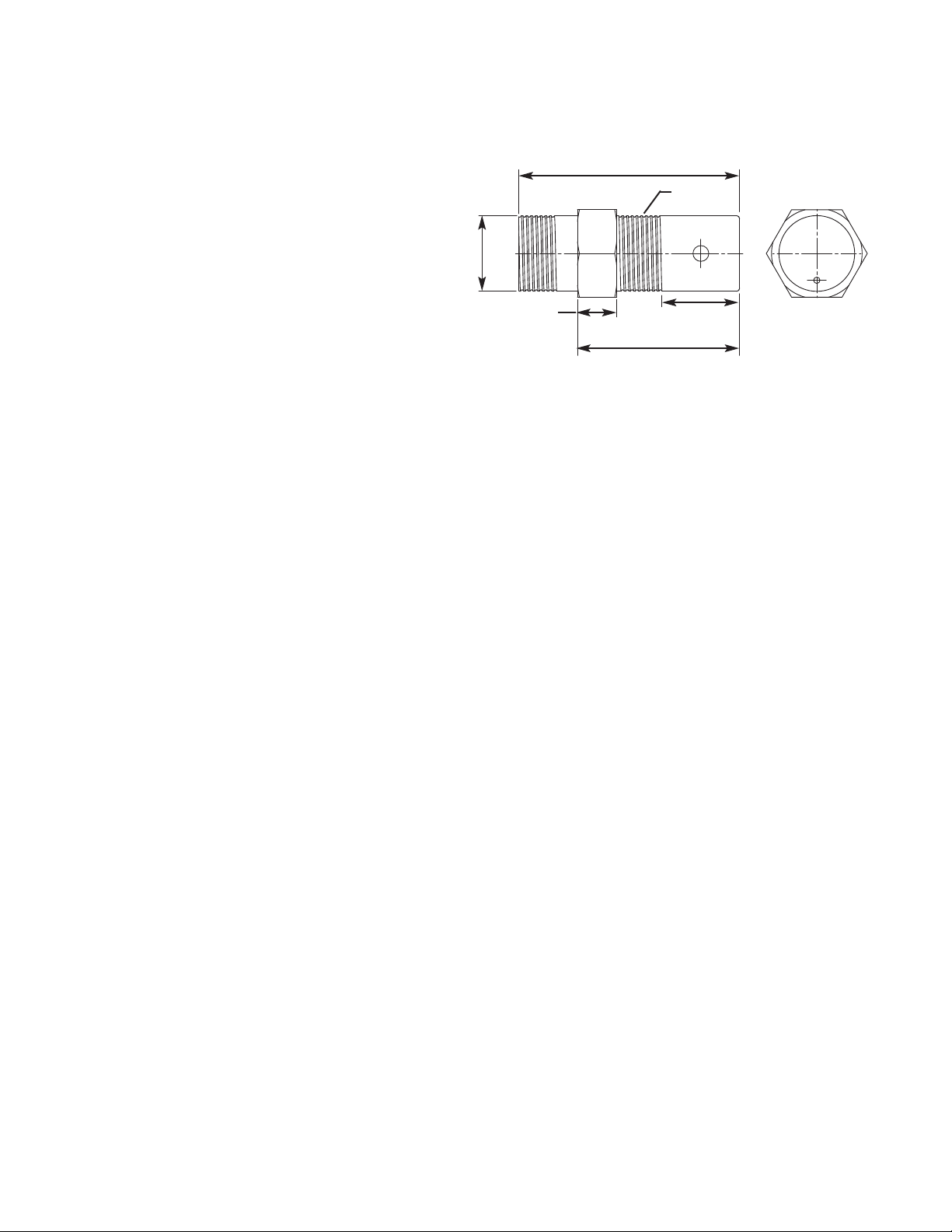

1.23 in

(31 mm)

.62 in

(16 mm)

2.57 in (65 mm)

3.5 in

(89 mm)

Ø 1.2 in

(30 mm)

1 in NPT

GE

Sensing

Page 7

Sensing Element

Four-wire 1/3 Class A DIN 43760 RPT, 100 S @ 32°F (0°C)

Dew/Frost Point Accuracy

Standard: ±0.36°F (±0.2°C)

Optional: ±0.27°F (±0.15°C)

Sensitivity

>0.05°F (>0.03°C)

Repeatability

±0.09°F (±0.05°C)

Hysteresis

Negligible

Cooling Stages

Two-stage TEC module

Auxiliary Cooling

Not applicable

Depression

117°F (65°C) at 77°F (25°C) and atmospheric pressure

Typical Measurement Range

31°F to 77°F (-35°C to 25°C) dew/frost point (Td) in air @

77°F (25°C) and atmospheric pressure. Equivalent to 0.7%

to 100% RH.

Other parameters based on calculations.

Sample Flow

0.5 to 5.0 SCFH (0.25 to 2.5 L/min)

Operating Temperature

-13°F to 185°F (-25°C to 85°C)

Pressure

150 psig (11 bar) maximum

Power

Derived from Optica monitor

D2 Two-Stage

Chilled Mirror

Specifications

Sensor Body

Cast aluminum with 314 stainless steel flow cell

Mirror

Standard: Rhodium-plated copper

Optional: Solid platinum

Sensor Wetted Material

302, 316 stainless steel, silicone o-ring, BK-7 glass,

rhodium or platinum mirror

Vapor Barrier

Stainless steel

Inlet/Outlet

1/4 in OD tubing compression fittings

Electrical Connector

Sub-D 15-pin connector mates with 2130 cable

Weight

4 lb (1.8 kg) net

Accessories

P Platinum mirror

X Enhanced accuracy ±0.27°F (±0.15°C) Td

4.5 in

(114 mm)

square

Ø .107 in (4.75 mm) through 4 places

1/4 in

compression

stainless steel

4 in

(102 mm)

GE

Sensing

Page 8

Sensing Element

Four-wire 1/3 Class A DIN 43760 RPT, 100 S @ 32°F (0°C)

Dew/Frost Point Accuracy

Standard: ±0.36°F (±0.2°C)

Optional: ±0.27°F (±0.15°C)

Sensitivity

>0.05°F (>0.03°C)

Repeatability

±0.09°F (±0.05°C)

Hysteresis

Negligible

Cooling Stages

Two-stage TEC module

Depression

117°F (65°C) at 77°F (25°C) and atmospheric pressure

Typical Measurement Range

31°F to 77°F (-35°C to 25°C) dew/frost point (Td) in air @

77°F (25°C) and atmospheric pressure. Equivalent to 0.7%

to 100% RH.

Other parameters based on calculations.

Sample Flow

0.5 to 5.0 SCFH (0.25 to 2.5 L/min)

Operating Temperature

5°F to 212°F (-15°C to 100°C)

Pressure

300 psig (21 bar) maximum

Power

Derived from Optica

1211H

Two-Stage

Chilled Mirror

Specifications

Sensor Body

Cast aluminum with 314 stainless steel flow cell

Mirror

Standard: Rhodium-plated copper

Optional: Solid platinum

Sensor Wetted Material

302, 316 stainless steel, silicone o-ring, BK-7 glass,

rhodium or platinum mirror

Vapor Barrier

Mylar (upgradeable to stainless steel)

Inlet/Outlet

1/4 in OD tubing compression fittings

Electrical Connector

MS-style multipin connector mates with 2120 cable

Weight

4 lb (1.8 kg) net

Accessories

P Platinum mirror

X Enhanced accuracy ±0.27°F (±0.15°C) Td

S Stainless steel vapor barrier

5 in

(127 mm)

3.6 in

(91.44 mm)

5.7 in

(144.78 mm)

3.1 in

(78.74 mm)

1/4 in

(6.35 mm)

compression

fitting

GE

Sensing

GE Infrastructure

Sensing

1211H

Page 9

Sensing Element

Four-wire 1/3 Class A DIN 43760 RPT, 100 S @ 32°F (0°C)

Dew/Frost Point Accuracy

Standard: ±0.36°F (±0.2°C)

Optional: ±0.27°F (±0.15°C)

Sensitivity

>0.05°F (>0.03°C)

Repeatability

±0.09°F (±0.05°C)

Hysteresis

Negligible

Cooling Stages

Two-stage TEC module

Auxiliary Cooling

Not applicable

Depression

153°F (85°C) at 167°F (75°C) body temperature and

atmospheric pressure

Typical Measurement Range

14°F to 167°F (-10°C to 75°C) dew/frost point (Td) in air @

167°F (75°C) body temperature in 77°F (25°C) ambient

temperature and atmospheric pressure. Equivalent to

0.7% to 100% RH.

Other parameters based on calculations.

Sample Flow

0.5 to 5.0 SCFH (0.25 to 2.5 L/min)

Operating Temperature

5°F to 212°F (-15°C to 100°C)

SIM-12 Heated

Two-Stage

Chilled Mirror

Specifications

Heater Control

Thermostatically controlled. Set point of 77°F (25°C),

104°F (40°C), 131°F (55°C), 158°F (70°C), 185°F (85°C) and

212°F (100°C)

Pressure

50 psig (4.5 bar) maximum

100/115/230 VAC, 50/60 Hz, 75 watts

Sensor Body

Cast aluminum with 314 stainless steel flow cell

Sensor Wetted Material

302, 316 stainless steel, silicone o-ring, BK-7 glass,

rhodium or platinum mirror

Mirror

Standard: Rhodium plated copper

Optional: Solid platinum

Vapor Barrier

Mylar (upgradeable to stainless steel)

Electrical Connector

MS-style multipin connector

IEC receptacle for AC power

Weight

7 lb (3.2 kg) net

Accessories

P Platinum mirror

X Enhanced accuracy ±0.27°F (±0.15°C) Td

S Stainless steel vapor barrier

HSS-12 Heated sampling system. SIM-12 heated

chilled mirror, SIM-HFT heated filter module

and SIM-HFM heated flowmeter mounted

on a plate with SIM-HSL heated sample line.

4 in

(102 mm)

8.64 in (219 mm)

3.5 in

(89 mm)

.25 in compression fitting

GE

Sensing

Inlet

ON

°C

°F

Outlet

25

25

°C

105

77

°F

Max Dewpoint

Ready

Model SIM-12H

Heated Sensor

55

130

70

85

160

185

25

25

Page 10

Sensing Element

Four-wire 1/3 Class A DIN 43760 RPT, 100 S @ 32°F (0°C)

Dew/Frost Point Accuracy

Standard: ±0.36°F (±0.2°C)

Optional: ±0.27°F (±0.15°C)

Sensitivity

>0.05°F (>0.03°C)

Repeatability

±0.09°F (±0.05°C)

Hysteresis

Negligible

Cooling Stages

Four-stage TEC module

Auxiliary Cooling

Liquid cooling jacket

Depression, Air Cooled

171°F (95°C) at 77°F (25°C) and atmospheric pressure

Depression, Liquid Cooled

189°F (105°C) with 59°F (15°C) cooling water

Typical Measurement Range

• -85°F to 77°F (-65°C to 25°C) dew/frost point (Td) in air

@ 77°F (25°C) and atmospheric pressure.

• -103°F to 59°F (-75°C to 15°C) in liquid-cooled mode

with 59°F (15°C) coolant.

Other parameters based on calculations.

Sample Flow

0.5 to 5.0 SCFH (0.25 to 2.5 L/min)

Operating Temperature

32°F to 95°F (0°C to 35°C)

1311-DR

Four-Stage

Chilled Mirror

Specifications

Pressure

300 psig (22 bar) maximum

Power

100/115/230 VAC, 50/60 Hz, 300 watts

Sensor Body

Cast aluminum with 314 stainless steel flow cell

Mirror

Standard: Rhodium-plated copper

Optional: Solid platinum

Sensor Wetted Material

302, 316 stainless steel, silicone o-ring, BK-7 glass,

rhodium or platinum mirror

Vapor Barrier

Mylar (upgradeable to stainless steel)

Inlet/Outlet

1/4 in (6 mm) OD tubing compression fittings

Electrical Connector

MS-style multipin connector mates

IEC receptacle for AC power

Weight

34 lb (16 kg) net

Accessories

P Platinum mirror

X Enhanced accuracy ±0.27°F (±0.15°C) Td

S Stainless steel vapor barrier

8.77 in

(223 mm)

1.8 in

(46 mm)

7.17 in

(182 mm)

Ø 0.31 in

(7.9 mm)

4 places

16.3 in

(414 mm)

GE

Sensing

1311DR

Control

Air Cooling

Liquid Cooling

~ Input Power

Page 11

Sensing Element

Four-wire 1/3 Class A DIN 43760 RPT, 100 S @ 32°F (0°C)

Dew/Frost Point Accuracy

Standard: ±0.27°F (±0.15°C)

Sensitivity

>0.05°F (>0.03°C)

Repeatability

±0.09°F (±0.05°C)

Hysteresis

Negligible

Cooling Stages

Five-stage TEC module

Auxiliary Cooling

Liquid cooling jacket

Depression, Liquid Cooled

202°F (112°C) with 59°F (15°C) cooling water

Typical Measurement Range

-112°F to 59°F (-80°C to 15°C) dew/frost point (Td) in air

@ 77°F (25°C) and atmospheric pressure with 59°F (15°C)

cooling water.

Other parameters based on calculations.

Sample Flow

0.5 to 5.0 SCFH (0.25 to 2.5 L/min)

Operating Temperature

32°F to 95°F (0°C to 35°C)

Pressure

0 to 100 psig (1 to 8 bar)

1311-XR

Five-Stage

Chilled Mirror

Specifications

Power

115/230 VAC, 50/60 Hz, 700 watts

Sensor Body

314 stainless steel

Mirror

Standard: Rhodium-plated copper

Optional: Solid platinum

Sensor Wetted Material

302, 316 stainless steel, silicone o-ring, BK-7 glass,

rhodium or platinum mirror

Vapor Barrier

Mylar (upgradeable to stainless steel)

Inlet/Outlet

1/4 in OD tubing compression fittings

Electrical Connector

MS-style multipin connector

IEC receptacle for AC power

Weight

50 lb (26 kg) net

Accessories

P Platinum mirror

S Stainless steel vapor barrier

6.95 in

(176.5 mm)

5.2 in

(132 mm)

19 in

(483 mm)

5.3 in

(135 mm)

9 in

(129 mm)

GE

Sensing

g

1311XR

1311XR

g

Page 12

Sensing Element

Four-wire 1/3 Class A DIN 43760 RPT, 100 S @32°F ( 0°C)

Accuracy

System at 25°C

Standard: ±0.27°F (±0.15°C)

Optional: ±0.18°F (±0.1°C)

Measurement Range

-148°F to 212°F (-100°C to 100°C)

Response Time

7 seconds for 77°F to 158°F (25°C to 70°C) step change in

fluid

Sensor Body

Stainless steel sheath

T-100

Four-Wire PRTD

Temperature

Mirror

Specifications

Cable

PTFE insulation rated to 302°F ( 150°C). 10 ft (3 m)

standard length.

Fittings

Adjustable 1/4 in NPT stainless steel compression fitting

Strain Relief

Stainless steel spring

Power

Low voltage derived from Optica

Weight

2 lb (0.9 kg) net

Options

Additional cable length

7.5 in (190.5 mm)

Ø .25 in

(6.35 mm)

1/4 in NPT

Connector

PTFE cable, 305°F (150°C), 10 ft (3 m)

standard length

GE

Sensing

Page 13

Sensing Element

Micro-machined silicon strain gauge

Accuracy

System at 77°F (25°C), ±0.5% of full scale

Range PT-30A

0 to 30 psia (0 to 2 bar)

Range PT-300A

0 to 300 psia (0 to 21 bar)

Response Time

1 second for 90% of steady state (10% to 90% change)

Operating Ranges

• -4°F to 176°F (-20°C to 80°C) ambient temperature

• -13°F to 248°F (-25°C to 120°C) process temperature

Temperature Effect

<1% FS on accuracy from 14°F to 122°F (-10°C to 50°C)

for pressure 6 psi (0.4 bar)

PT Series

Pressure

Transducer

Specifications

Power

9 to 30 VDC. Derived from Optica monitor.

Sensor Body Material

316 stainless steel

Sensor Wetted Material

316 stainless steel and Hastelloy diaphragm

Cable

PVC insulation. 10 ft (3 m) standard length process

connection 1/4 in F-NPT.

Weight

4 lb (1.8 kg) net

5.03 in

(1.28 mm)

1.5 in

(38 mm)

10 ft (3 m)

standard

length

GE

Sensing

Page 14

Enclosure

Polycarbonate

Fittings

Brass 1/4 in OD tubing

Compression Internal Tubing

Impolene

Rotameter

0.5 to 5 SCFH (0.2 to 2 L/min)

Maximum Vacuum

-98 in (-250 mm) of Hg

SSM Sampling

System

Specifications

Free Air Displacement

14 SCFH (6.5 L/min)

Maximum Temperature

100°F (38°C)

Power

95 to 265 VAC, 50/60 Hz, 15 watts

3.30 in

(84 mm)

6.70 in (170 mm)

Power

input

module

SSM Sampling System

In Out

2.68 in

(68 mm)

Output gas

fittings

Input gas fittings

GE

Sensing

Page 15

Appendix

1111H Single-Stage Chilled Mirror

Sensor Body Temperature °C

100

75

50

25

0

-25

-50

-75

-100

-50 -25 0 25 50 75 100

Mirror

depression

Sensor Body Temperature °C

Dew Frost Point Temperature °F (°C)

45°C depression

D2 Two-Stage Chilled Mirror

Sensor Body Temperature °C

100

75

50

25

0

-25

-50

-75

-100

-50 -25 0 25 50 75 100

Mirror

depression

Sensor Body Temperature °C

Dew Frost Point Temperature °F (°C)

65°C depression

1211H Two-Stage Chilled Mirror

Sensor Body Temperature °C

100

75

50

25

0

-25

-50

-75

-100

-50 -25 0 25 50 75 100

Mirror

depression

Sensor Body Temperature °C

Dew Frost Point Temperature °F (°C)

65°C depression

SIM-12 Heated

Two-Stage Chilled Mirror

Sensor Body Temperature °C

100

75

50

25

0

-25

-50

-75

-100

-50 -25 0 25 50 75 100

Mirror

depression

Sensor Body Temperature °C

Dew Frost Point Temperature °F (°C)

65°C depression

GE

Sensing

Page 16

Appendix

1311-DR Four-Stage Chilled Mirror

Sensor Body Temperature °C

50

25

0

-25

-50

-75

-100

-50 -25 0 25 50 75 100

Mirror

depression

Ambient Air Temperature °C

Dew Frost Point Temperature °F (°C)

95°C depression

1311-XR Five-Stage Chilled Mirror

Sensor Body Temperature °C

100

75

50

25

0

-25

-50

-75

-100

-50 -25 0 25 50 75 100

Mirror

depression

Sensor Body Temperature °C

Dew FrostPoint Temperature °F (°C)

112°C depression

GE

Sensing

Page 17

Recommended for dew points ≥32°F (≥0°C)

Materials

Anodized aluminum head, nylon bowl, nylon internals,

Buna-N Seals

Fittings

1/4 in compression

Temperature

-150°F to 220°F (-101°C to 104°C)

Filter

Borosilicate glass

Porosity

93% of particles over 0.1 µm

Pressure

150 psig (10 bar) maximum

BF-12SS

Box of 10 replacement filter elements

Accessories

BF-10DX General Purpose Filter

Recommended for dew points ≤32°F (≤0°C)

Materials

316 stainless steel head, bowl and internals. Viton seals

Fittings

1/4 in (6 mm) compression

Temperature

-150°F to 220°F (-101°C to 104°C)

Filter

Borosilicate glass

Porosity

93% of particles over 0.1 µm

Pressure

340 bar (5000 psig) maximum

BF-12SS

Box of ten replacement filter elements

BF-12SS Stainless Steel Filter

Materials

Clear acrylic body, Buna-N Seals, black glass float, brass

valves

Fittings

1/4 in compression

Range

0.5 to 5 SCFH (0.2 to 2 L/min)

Pressure

100 psig (6 bar) maximum

Temperature

150°F (65°C) maximum

FM-1 Rotameter/Needle Valve

5.4 in

(136 mm)

.6 in

(14 mm)

2.7 in

(70 mm)

1/4 in

compression

outlet and

inlet ports

1.75 in (44 mm)

3.53 in

(90 mm)

1.19 in (30 mm)

GE

Sensing

Page 18

Optica Monitor

Color VGA Display With Logger/Ethernet

A Benchtop

B Benchtop with rack mount bracket

C Wall mount

Four-color, 40 Alphanumeric Display

D Benchtop

E Benchtop with rack mount bracket

F Wall mount

Optica Channel One

1 Unit to be sold with new chilled mirror

(see sensor section)

2 Use the existing D2

(conversion cable 2160 required)

3 Use with existing 1111H, 1211H, SIM-12H and

1311DR (conversion cable 2160 required)

4 Use with existing 1311XR

(conversion cable 2140 required)

Default Code

0 Default code

Ordering Code

Guide

Chiller Mirror Cable

Cable Type

0 No cable required

C Adaptor cable for existing sensor/cable

installation 2 ft (.61 m)

A 10 ft (3 m) standard length

X Specify length in ft (m)

O

P A 1 O A C 1 A O

2120 For use with 1111H, 1211H, SIM12,

HSS-12, 1311DR sensors

2130 For use with D2

2140 For use with 1311XR

2150 For use with Optica CCD sensor

2160 Adaptor cable for sensors except 1311XR

2 ft (0.61 mm)

2170 Adaptor cable for 1311XR 2 ft (0.61 mm)

Chilled Mirror Sensor

Sensor

0 No sensor

A 1111H

B 1111H-GE

C D2

D 1211H

SIM-12

E 100 VAC

F 115 VAC

G 230 VAC

HSS-12

H 100 VAC

J 115 VAC

K 230 VAC

1311DR

L 100 VAC

M 115 VAC

N 230 VAC

1311XR

P 100 VAC

Q 115 VAC

R 230 VAC

GE

Sensing

Page 19

Accuracy And Mirror

1 S/R/M standard accuracy, rhodium mirror,

mylar vapor barrier

2 S/P/M standard accuracy, platinum mirror,

mylar vapor barrier

3 S/P/P standard accuracy, platinum mirror,

stainless steel vapor barrier

4 X/R/M enhanced accuracy, rhodium mirror,

mylar vapor barrier

5 X/P/M enhanced accuracy, platinum mirror,

mylar vapor barrier

6 X/P/P enhanced accuracy, platinum mirror,

stainless steel vapor barrier

7 S/R/P standard accuracy, rhodium mirror,

stainless steel vapor barrier (D2)

8 X/R/P enhanced accuracy, rhodium mirror,

stainless steel vapor barrier (D2)

9 S/P/P standard accuracy, platinum mirror,

stainless steel vapor barrier (D2)

Ordering Code

Guide

Temperature Sensor

Sensor

0 No temperature sensor

A T-100 with 10 ft (3 m) cable (standard accuracy)

B T-100 with 10 ft (3 m) cable (enhanced accuracy)

X T-100 with build to fit cable (standard accuracy)

Z T-100 with 10 ft (3 m) cable (enhanced accuracy)

Pressure Sensors

0 No pressure sensor

A PT-30A 10 ft (3 m) cable (standard)

B PT-30A build-to-fit cable

X PT-300A 10 ft (3 m) cable (standard)

Z PT-300A build-to-fit cable

GE

Sensing

Page 20

©2005 GE. All rights reserved.

920-076C

All specifications are subject to change for product improvement without notice.

Optica™ is a trademark of GE. GE®is a registered trademark of General Electric Co.

Other company or product names mentioned in this document may be trademarks or

registered trademarks of their respective companies, which are not affiliated with GE.

g

www.gesensing.com

GE

Sensing

Loading...

Loading...