Page 1

pro.IQ moisture transmitter

packaged solution

Features

pro.IQ simplifies the selection and installation of your

moisture transmitter for a complete moisture measurement

solution. Only a few simple steps; install the moisture

transmitter, connect your loop power and sample gas to the

inlet fitting and you are ready to measure. Includes:

• IP66 & NEMA 4X package

• The moisture transmitter, sample system and Zener barrier

(if hazardous area option selected)

• Features the HygroPro moisture transmitter

• Sample system to provide isolation, filtration, pressure

and flow indication, with a clear door for easy viewing of

all readings

Applications

The standard pro.IQ package is designed for moisture

measurements in any hydrocarbon gas or inert gas

application. It may be used in environments classified as

safe or hazardous areas, where the process gas pressure

is up to 200 psig (14 bar) in safe area and 400 psig (27 bar)

in hazardous area. The system combines the Panametrics

HygroPro with 50 years of sample system design experience ,

to deliver the moisture measurement you have come to trust.

Markets and applications served include:

• Natural gas

• Hydrocarbon gases

• Petrochemical

• Metal heat treatment

• Industrial gas

• Power generation

Page 2

Ordering configuration

pro.IQ is comprised of the following items:

• HygroPro moisture transmitter

• Sample system 733-2500 or 733-2501 or 733-2502

or 733-2503 dependent on version selected

• Zener Barrier (Hazardous area option only)

Available versions

• pro.IQ-H-I : Hazardous Area, ¼” Tube Fittings

• pro.IQ-H-M : Hazardous Area, 6mm Tube Fittings

• pro.IQ-GP-I : General Purpose Area, ¼” Tube Fittings

• pro.IQ-GP-M : General Purpose Area, 6mm Tube Fittings

Application parameters

General purpose configuration

• Sample Gas Pressure: 0 to 200 psig (14 bar)

• Recommended Operating Temperature Range: 32°F

to 122°F (0 to +50°C)

Hazardous area configuration

• Sample Gas Pressure: 0 to 400 psig (27 bar)

• Recommended Operating Temperature Range: 32°F

to 122°F (0 to +50°C)

Common

• Moisture Content: 68°F to -166°F (20°C to -110°C)

dew/frost point, non-condensing

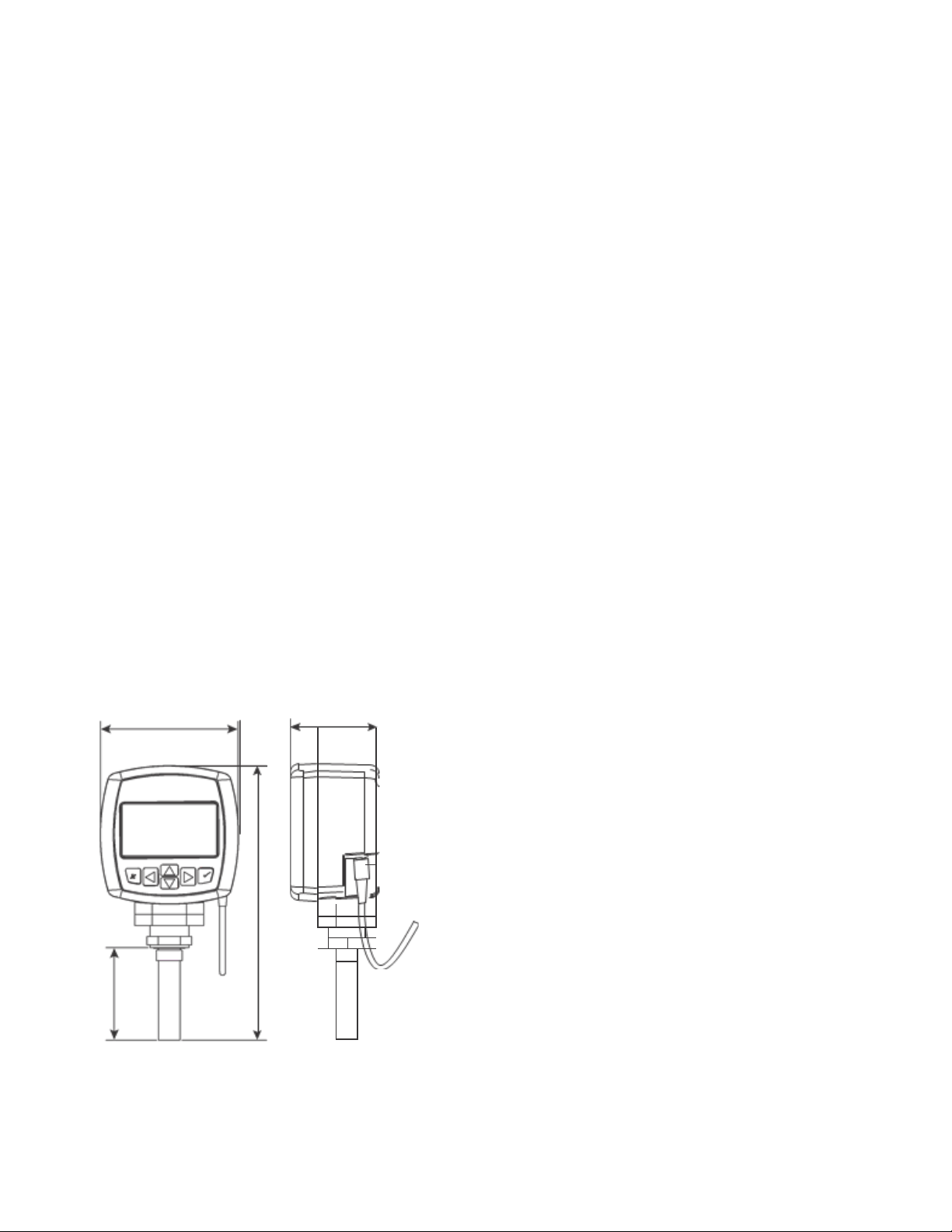

4 in. (102 mm)

2.6 in. (65 mm)

6 in. (65

mm)

HygroPro specifications

Dew point/frost point calibration ranges

• Overall: 68°F to -166°F (20°C to -110°C)

• Standard: 68°F to -112°F (20°C to –80°C)

Operating temperature

–4°F to 140°F (–20°C to 60°C*)

*Refer to pro.IQ specifications for overall system limits

Storage temperature

158°F (70°C) maximum

Warm-up time

Meets specified accuracy in three minutes

Calibrated accuracy @ 77°F (25°C)

• ±3.6°F (±2°C) above -148°F (-100°C)

• ±5.4°F (±3°C) below -148°F (-100°C)

Repeatability

• ±0.4°F (±0.2°C) above -148°F (-100°C)

• ±0.9°F (±0.5°C) below -148°F (-100°C)

Electrical

Power

• Voltage: 12 to 30 VDC (loop-powered, customer supplied)

• Output: 4 to 20 mA analog, RS485 digital

• Output Resolution: 0.01 mA/12 bits

• Load: Max R = (PSV x 33.33) - 300

Example: (24 x 33.33) - 300 = 500 W

• Cable: 1.5 ft (0.5m), standard includes molded M8

connector with flying leads to connect transmitter to

sample system terminal block

Display

• 128 x 64 LED backlit LCD

• Display from one to three parameters and diagnostics

2.7 in. (68 mm)

HygroPro dimensions

8 in. (201 mm)

Mechanical

Sample connection

• 3/4-16 in. (19 mm) straight male thread with O-ring

Operating pressure

5 mHg to 5000 psig (345 bar*)

*Refer to pro.IQ specifications for overall system limits

Enclosure

Type 4X/IP67

Dimensions

• H x W x D: 7.88 x 3.99 x 2.56 in. (200 x 101 x 65 mm)

• Weight: 1.2 lb (550 g)

Page 3

European compliance

Complies with EMC Directive 2004/108/EC

and PED 97/23/EC for DN<25

Hazardous area certification

• C-US Class I, Division 1, Groups A,B,C&D, Type 4X

• II 1 G Ex ia IIC T4 (ATEX)

• Ex ia IIC T4 (IEC Ex)

Moisture sensor

Sensor type

Thin-film aluminum oxide moisture sensor

Calibration

Each sensor is individually computer-calibrated against

known moisture concentrations, traceable to International

Standards.

Calibration interval

Sensor recalibration by Panametrics is recommended every

six to twelve months depending on application.

Flow rate

Gases: Static to 100 m/s linear velocity at 1 atm

Built-in temperature sensor

Type

NTC thermistor

Operating range

-22°F to 158°F (-30°C to 70°C)

Accuracy

±0.9°F (±0.5°C) overall

Response time (maximum)

One second in well stirred oil or 10 seconds in still air for

a 63% step change in increasing or decreasing temperature

Built-in pressure sensor

Type

Solid state/piezoresistive

Available ranges for pro.IQ

• 30 to 300 psig (3 to 21 bar)

• 50 to 500 psig (4 to 35 bar)

Accuracy

±1% of full scale (FS)

Pressure rating

Three times the span of the specified range

to a maximum of 7500 psig (518 bar*)

*Refer to pro.IQ specifications for overall system limits

Page 4

Page 5

Start-up procedure

• Insert moisture transmitter into the sample cell and

connect earth to ground connection of the transmitter

• Follow HygroPro manual wiring instructions to connect

power, and zener barrier installation and wiring if in

hazardous area

• Two filter elements are provided. Sintered steel for clean

gases and liquids. Fiber for gases with entrained liquids or

aerosols. Install the filter element most appropriate for the

application

• Start with the inlet valve NV1, the drain valve NV3 and the

sample outlet valve NV2 fully closed

• For measurement at process pressure, slowly turn the inlet

valve NV1 until fully open; then crack the sample outlet

valve NV2 to get flow on mid range of the flowmeter scale

• For measurement at atmospheric pressure, fully open

the sample outlet valve NV2; then crack the inlet needle

valve NV1 to get flow on scale

• For applications with potential light liquid contaminant

crack the drain needle valve NV3 to ensure continuous

removal of any liquid mists from the sample gas

Shut-down procedure

• Slowly close the inlet needle valve NV1

• Close outlet needle valve NV2 fully

• Slowly open the drain needle valve NV3 until

the pressure on the pressure gauge is 0 psig

• Remove the moisture transmitter

Copyright 2020 Baker Hughes Company. All rights reserved.

BHCS34790 (05/2020)

panametrics.com

Loading...

Loading...