Page 1

GE

Measurement & Control

PANAFLOW Z1G:

TIGHT GAS WELLHEAD FLOWRATE

MEASUREMENT

For over 30 years, Panametrics owmeters from GE have proven to be the most reliable solution

for challenging gas ow measurement applications. With proven reliability in are gas, stack gas

and steam, GE’s robust transducer technology is ideal for shale gas and coal seam gas wellhead

applications. In short, GE oers the most reliable ultrasonic meter available, plus local service when

and where you need it.

Flare Gas Flow Measurement: The Ultimate Reliability Test

As a pioneer in ultrasonic transit-time ow measurement, Panametrics distinguished its owmeters by

providing reliable gas ow measurement solutions in extremely harsh applications for the past three

decades. Joining the GE Measurement & Controls group in 2004, provided Panametrics with greater

technical reach, and improved greater resource access, resulting in even greater improvements in

ultrasonic transducer design.

How can you be sure that your owmeter will operate reliably in something as challenging as a shale

gas or coal seam methane wellhead application? Choose a owmeter with a proven track record

of reliable operation in an even more dicult application! Since the development of the world’s rst

ultrasonic owmeter for are gas applications in 1980, GE has been the market leader with over

7,000 installations in an application with gas compositions from 2 g/mol to over 120 g/mol, ow

velocities from 0.1 ft/s to over 394 ft/s, and process temperatures from -160oC to 280°C. The world’s

best performance and vast experience in this dicult application translates directly to outstanding

performance in shale gas and coal seam gas ow measurement.

Flowmeter Reliability Starts With A Reliable Transducer

Reliable ultrasonic ow measurement starts with transducer sound wave signal amplitude and signal to

noise ratio (SNR). In shale gas or coal seam gas applications, these signals can be weakened from sulfur,

coal ne or other condensate build up on the transducer face.

imagination at work

1

Page 2

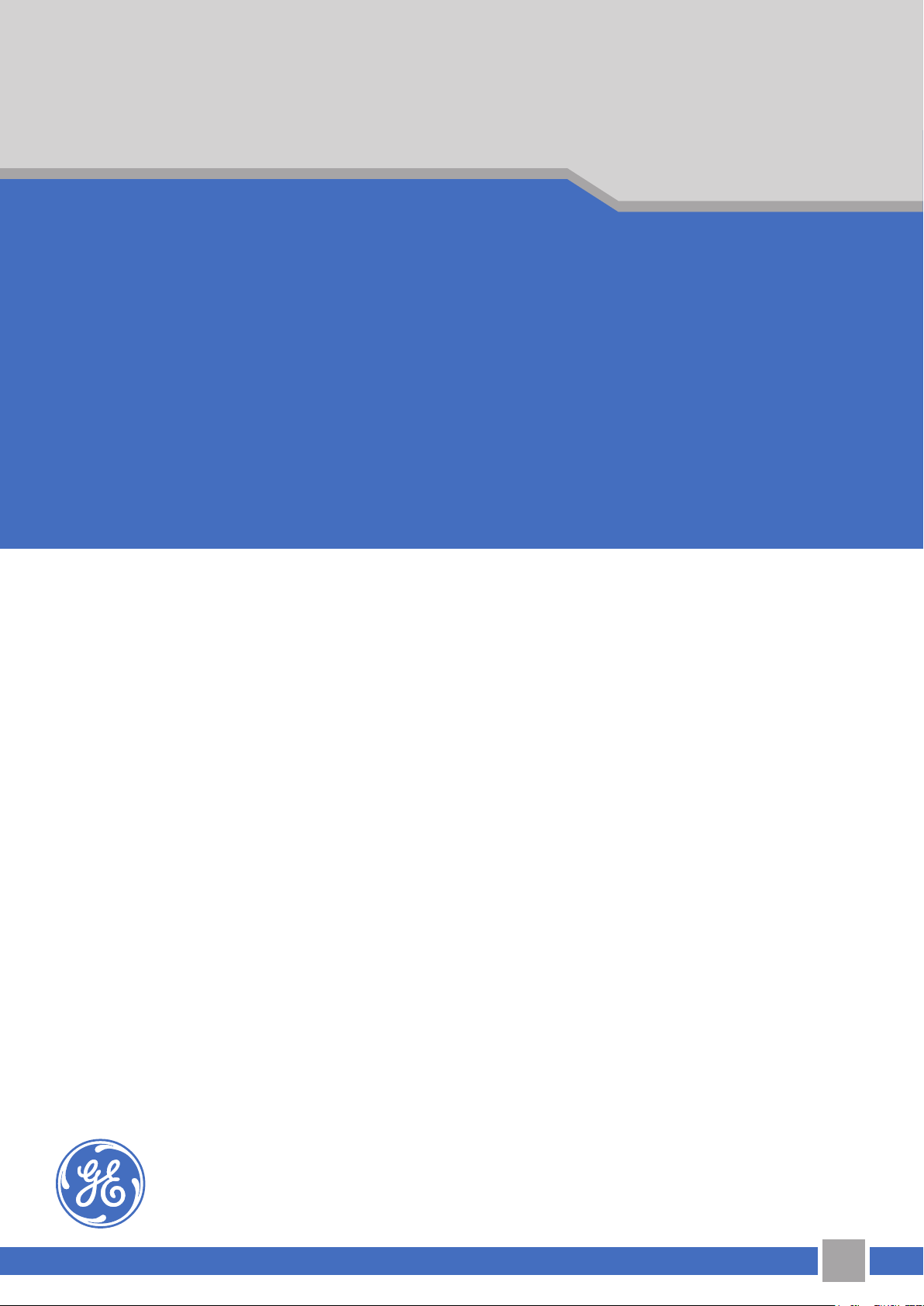

Solids accumulating on the transducer face act like a

muer and attenuate the signal. As this scaling continues

to accumulate, the transmitted and received ultrasonic

signals continue to degrade, which results in reduced signal

amplitude and degraded SNR. The pictures below are

from two dierent locations of working transducers, pulled

for routine maintenance. The better the SNR and signal

amplitude exhibited under ideal conditions, the better the

transducer will be able to hold up under harsh conditions.

GE’s transducers are driven by an industry high 170 volt

pulse, providing very high signal amplitude. This high power

requires an explosion proof enclosure design, (Ex d rating)

to meet hazardous area certication requirements. Other

transducer designs, meet hazardous area certication

requirements by simply being intrinsically safe (Ex ia).

Although intrinsically safe transducers work well in

clean applications, they are not well suited to handle the

challenges presented in shale or coal seam wellhead gas

ow measurement, due to the high level of condensates in

the gas stream

It’s not complicated. Less power means less signal.

Fluctuating Well Head Flow Rates Require

High Turndown Ratio Metering

Throughout the lifecycle of a coal seam well, ow rates

can uctuate considerably as a result of changing well

conditions, therefore it is important to select a meter with

a high turndown ratio to assure a long service life. The

Panaow Z1G has a turndown ratio of 240:1, measuring

ow rates as low as from 0.5 ft/s and as high as 120 ft/s,

and under pressure conditions that are below atmospheric.

Under higher ow conditions, background noise degrades

SNR, however, with the industry highest signal amplitude,

GE transducers overcome this obstacle.

When you have millions of dollars invested in a shale gas

or coal-seam gas well, you need reliable, accurate gas ow

measurement. As the gas moves from the well distribution

network to the gas gathering station for processing,

understanding well production trends is a critical element

in natural gas production eciency. As wells age, gas

production levels are unstable. This information is a critical

part of knowing which wells are producing with maximum

eciency, and which are in need of maintenance.

Despite this signicant amine crystal

build up, these transducers continued to

operate reliably

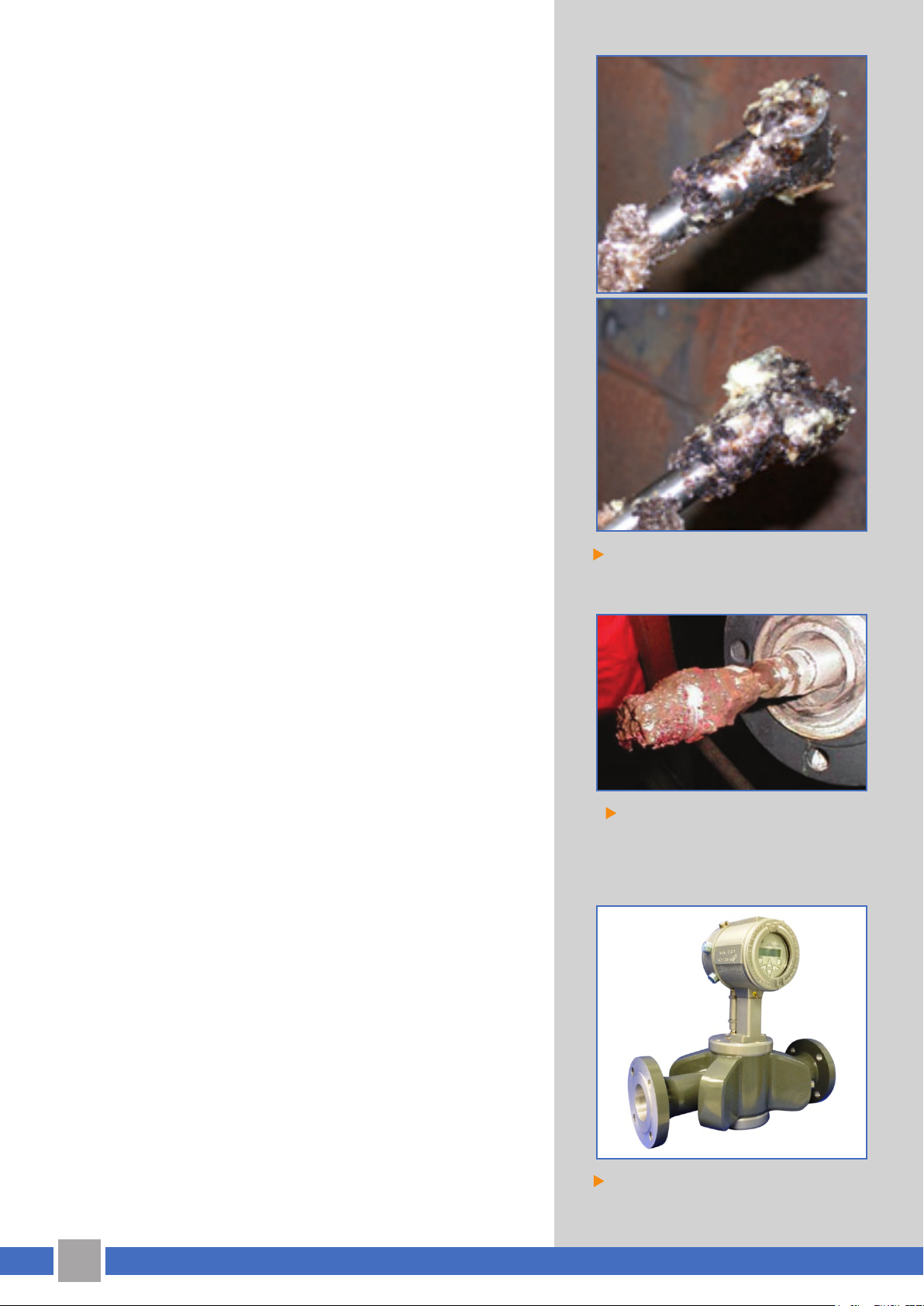

Glycol carry-over and dirt on this

transducer was not enough to stop GE’s

robust transducer technology in this

pipeline gas application

Maintaining a wellhead is a costly proposition. This is

especially true if the well is in a remote location, requires

special land access permitting or both. Visitation to

the wellhead should be limited to well production

2

PanaFlow Z1G Ultrasonic Flowmeter

Page 3

improvements and not be dictated by the reliability of the

ow measurement. Consider that a site-visit to a well may

cost upwards of $10,000, it is easy to understand why

product reliability is so important. Many ow measurement

technologies like orice meters, vortex meters or turbine

meters rely on, or create a pressure change to accurately

measure ow. In a clean gas this is usually acceptable,

however, in wellhead gas ow measurement the raw gas is

simply too wet and dirty, as any change in orice conditions

will directly impact ow measurement. Since Ultrasonic gas

owmeters rely on time dierential sound waves to measure

ow, raw, wet, dirty gas has little or no eect on overall meter

accuracy. While ultrasonic ow measurement technology

tends to be costlier than traditional ow measurement

technologies, advances in system design have greatly

reduced the price gap. Consider that even a single unplanned service visit to a well can cost $10,000 or more, the

added reliability of ultrasonic owmeter technology is well

worth the expense.

Coal Seam well-head with

water separator

Utlizing Advanced Technologies To

Overcome Flow Measurement Challenges

Maintaining accuracy in applications with limited

straight runs remains an industry challenge. In gas ow

measurement ideal conditions require upstream straight

runs as much as 20D. In practice, this may be dicult, costly,

or in some cases impossible to achieve. Recognizing the

challenges associated with limited straight run requirements,

especially when applied to well-head ow measurement,

GE has embarked on a comprehensive year-long study to

quantify pipe bend eects on ow proles under a wide

range of conditions. Leveraging GE’s vast experience in

aircraft engine design and by utilizing Computational Fluid

Dynamics (CFD), GE, has compiled a body of work resulting in

the ability to implement USM ow prole accuracy correction

factors for a variety of piping run conditions that compare

favorably to accuracies normally obtained in straight-runs of

20D or more.

The example to the right is the actual piping ow CFD

dynamic model of a well head skid after the water separator.

With this model GE is able to recommend the optimal meter

position on the skid to maximize accuracy and overall meter

performance as well as dene the Reynolds correction

factors to optimize meter accuracy.

Tight Gas well-head Installation

To the right, one can see the detail of how the ow prole

behaves after the separator (the “in” leg) and after the

u-bend (the “out” leg).

3

Page 4

The optimal ow meter placement would be on the out leg at 8 to 12D from the bend, as shown on the

correction factor curves to the right.

This is a great example of how GE uses CFD to enhance and optimize owmeter performance in dicult

applications. Without this enhanced CFD modeling the meter accuracy would be lost. Consider a meter

placed on the in leg. Depending on meter location, un-corrected meter on the in leg may have an

additional added inaccuracy of 2-5%.

Accuracy Through True Calibration

Wellhead meter accuracy is another key parameter in the

consideration of a ow measurement technology. Z1G

ultrasonic owmeters consistently meet 1.5% accuracy

across the documented ow velocity range, from 1.7 ft/s up

to 60 ft/s, the limit of the calibration lab. As expected, the

owmeter shows even better accuracy at higher ows; for

example, all the meters meet 0.5% accuracy at 60 ft/s and

above. All Z1G meters go through a rigorous calibration,

assuring accuracy across the entire range of ows.

Global In Scope Local In Presence

With a footprint that is global in scope but local in presence,

GE Measurement and Sensing reaches globally in technical

achievement, product performance and product quality; but

acts locally in customer focus, service and support. With

service and applications centers around the globe, staed

with skilled engineers and technicians, GE Measurement

and Sensing is well positioned to provide timely support at

remote locations at a moment’s notice. GE Measurement

and Sensing is your partner in assuring the health and

performance of your critical oil and gas assets.

Contact your Local Account Manager for more information.

Z1G Coal Seam meter calibration results

Global Service Centers

4

Loading...

Loading...