Page 1

GE

Sensing

Applications

OxyTrak™ 411

Panametrics In Situ Flue

Gas Oxygen Analyzer

OxyTrak 411 is a Panametrics

product. Panametrics has joined

other GE high-technology sensing

businesses under a new name

_

GE Industrial, Sensing.

An in situ oxygen analyzer for

• Utility boilers; natural gas or oil fired

• Process heaters; natural gas or oil fired

Features

• Self calibrating

• Sealed internal reference sensor_no reference gas

required

• IR through-the-glass keypad for Zone 1/Division 1

areas

• Probe lengths of 19, 39 or 60 inches (0.5, 1 or 1.5 m)

• One-step, one-gas, calibration verification

• Drop-down menu user program

• RS485 or RS232 communications port

• Isolated current loop or voltage output

• Fail-safe fault alarm

• Onboard system diagnostics

g

Page 2

GE

Sensing

Self Calibrating with No Reference Gas

The OxyTrak 411 uses a patented miniaturized zirconia

sensor with a sealed internal-reference chamber to

accurately determine flue gas oxygen content and

rapidly respond to process changes. This new sensor’s

unique design is self calibrating. The internal electrical

calibration of the sensor is performed automatically

without the need for calibration gases.

User-Friendly

The OxyTrak 411 is a modular design that maximizes

serviceability. A separate port is provided for access to

the sensor core.

Why Monitor Flue Gas?

Ideally, every burner should mix a precise ratio of air and

fuel, and the fuel should burn stoichiometrically to yield

only heat, water vapor and carbon dioxide. In reality, this

rarely happens. Burners age, mixing is imperfect,

colorific value of fuel varies, firing rates change, and the

weather changes from day to day. Any of these factors

can change the amount of air required for safe and

efficient combustion of fuel. Accurate flue gas analysis

minimizes fuel costs and reduces pollution in all

combustion processes.

Accurate and reliable oxygen measurement has always

been dependent upon tedious sensor calibration and

costly reference gases_until now.

Too little O

2

Increase air

supply

Typical

zone of

control

Too much O

2

Decrease air supply

Low High

Combustibles

losses

O2&

combustibles

optimum

control

point

O2only

operating

set point

Excess

air losses

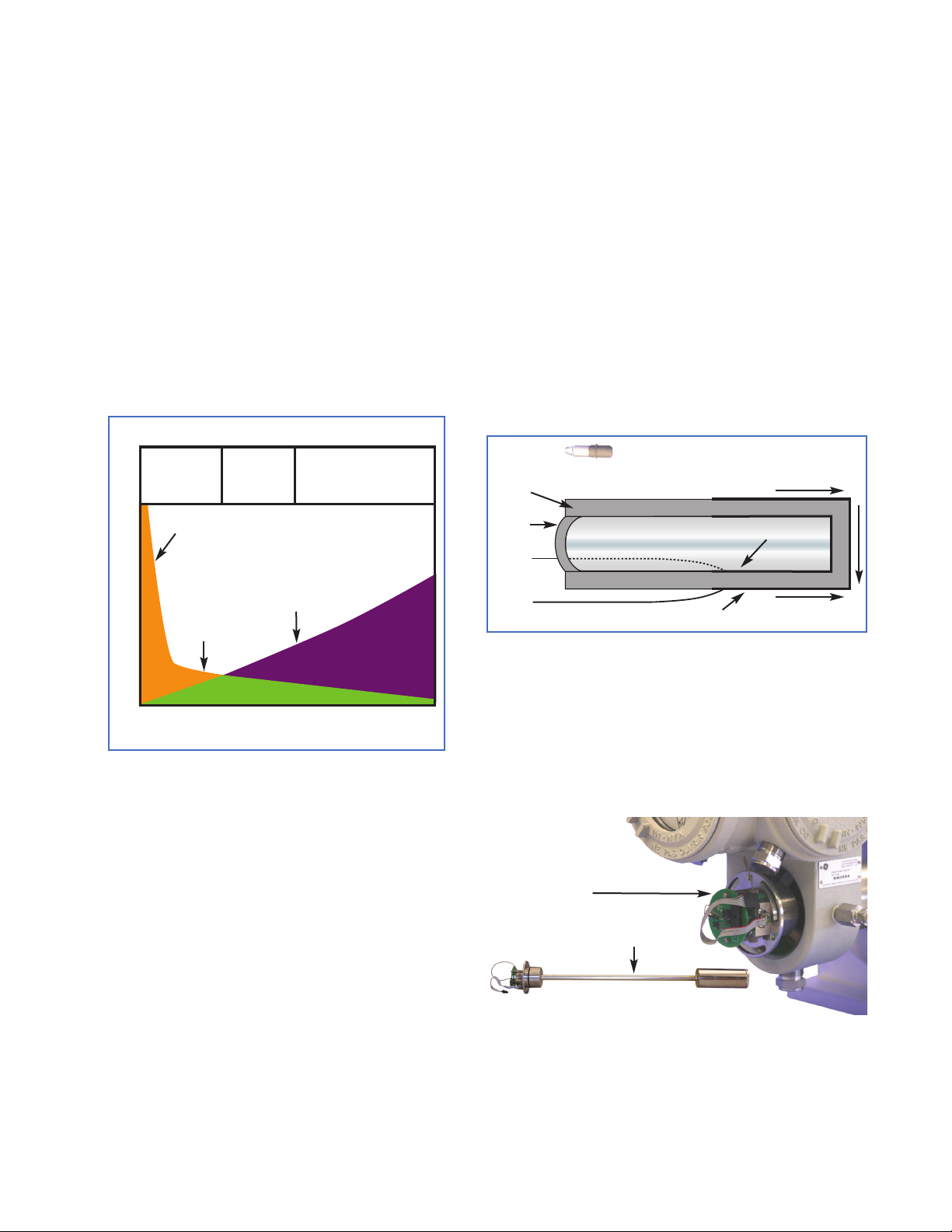

Typical Combustion Control Scenario

% Excess O

2

PPM Combustibles

Combustion applications typically trim burner air supply to run

excess oxygen at an optimal level to ensure complete

combustion.

The system works by pumping oxygen out of sealed

reference chamber to establish a baseline and then

measuring the electrical charge as oxygen ions

re-equalibrate back into the chamber equal to oxygen

partial pressure in the flue gas. The electrical charge

measured is directly proportional to oxygen

concentration.

In addition, the sensor’s sealed internal-reference

chamber eliminates the need for a reference gas. If

manual calibration verification is desired, a gas port is

provided for a simple, one-gas, one-step procedure,

using air or other gases and remote or local user

interfaces.

Sensor assembly access port and probe assembly

Glass

seal

Sensor

Diffused process gas flow

ZrO

2

Inner reference chamber

Inner

electrode

Outer electrode

Sealed-reference zirconia oxygen sensor and sensor technology

Sensor assembly access

port with sensor assembly

partially removed

Sensor assembly

(not to scale)

Page 3

GE

Sensing

OxyTrak 411

Specifications

Accuracy

±0.1% O2or 1% of reading whichever is greater

Repeatability

±0.05% O

2

Output Resolution

±0.01% O

2

Measurement Range

0% to 25% O

2

Ambient Temperature Effect

±0.02% oxygen/°F (°C)

Process Pressure Effect

Less than ±0.05% O2per psi pressure compensation

Process Pressure Range

450 to 1000 mm Hg

Supply Voltage Effect

Less than ±0.05% O

2

Alarm Output

• One fail-safe, Form C fault alarm

• Two Form C, general purpose,

assignable alarm outputs

• Two Form C autocal alarms

Performance

Functional

Analog Output

Linearized, isolated, 0/4 to 20 mA or 0 to 2 V output, user

selectable, field programmable for any range from 0 to

25% O2(e.g., 0 to 5% O2)

8.19 in

(208 mm)

5.06 in

(129 mm)

10.54 in

(268 mm)

L

6.12 in

(156 mm)

8.40 in

(213 mm)

4.62 in

(117 mm)

8.64 in

(219 mm)

1.56 in

(40 mm)

2.00 in

(51 mm)

5.60 in

(142 mm)

L = probe length

Digital Output

RS485 or RS232, user selectable

Output Load

600 Ω at 20 mA output

Power

100, 115, 230 or 240 VAC

Ambient Temperature Range

-4°F to 140°F (–20°C to 60°C)

Sensor Temperature

Self-heated and controlled 1382°F (750°C)

Flue Gas Temperature Range

302°F to 1202°F (150°C to 650°C)

Calibration Verification

Gas flow rate (optional) 100 ±10 cc/min

ESC ENTER

Page 4

GE

Sensing

OxyTrak 411

Specifications

Physical

Sensor Type

Patented, sealed, internal-reference, zirconium oxide

sensor

Wetted Materials

316 stainless steel, ceramic

Probe Lengths

• Standard: 19 in (0.5 m)

• Optional: 39 in (1 m) or 60 in (1.5 m)

Electronics Dimensions (w x h x d)

9 in x 10 in x 9 in (229 mm x 254 mm x 229 mm)

Total Length (19 inch probe)

31 in (787 mm)

Total Weight (19 inch probe)

31 lb (14 kg)

Mounting

• Standard: 2 1/2 in MNPT

• Optional: 2, 2 1/2 in, 3 in or 4 in flange

Housing

Weatherproof: Type 4X, IP66

Hazardous Area Certifications

• Explosion-proof design: Suitable for Class I, Division 1,

Groups C&D Type 4X (approval pending)

• Flameproof design: EEx d IIC T5 (approval pending)

European Compliance

Complies with EMC Directive 89/336/EEC, 73/23/EEC LVD

(Installation Category II, Pollution Degree 2) and PED

97/23/EC for DN<25

©2004 GE. All rights reserved.

920-049C

All specifications are subject to change for product improvement without notice.

OxyTrak™ trademark of GE. GE®is a registered trademark of General Electric Co. Other

company or product names mentioned in this document may be trademarks or

registered trademarks of their respective companies, which are not affiliated with GE.

Flue gas

flow

OxyTrak 411

probe and

probe sleeve

Mating flange

(customer supplied)

OxyTrak 411

mating flange,

bolts, nuts

Nozzle

(customer supplied)

Flue wall

Typical horizontal flue gas analyzer installation

Order Information

Record selected option in blank indicated at bottom of form.

OxyTrak 411 In Situ Flue Gas Analyzer

Package

1 Weatherproof

2 Explosionproof

Power

1 100 VAC

2 115 VAC

3 230 VAC

4 240 VAC

Probe Length

1 19 in (0.5 m)

2 39 in (1 m)

3 60 in (1.5 m)

OxyTrak 411___ __ __ Use this number to order product

g

www.gesensing.com

Loading...

Loading...