Page 1

O2.IQ oxygen analyzer

packaged solution

Features

O2.IQ simplifies and standardizes your options for reliable

oxygen measurement in a variety of applications. At the

heart of this package is the oxy.IQ analyzer supported

by a sample conditioning system purposefully designed

to maintain ease of access and functionality in a space

conscious housing. Simply mount the O2.IQ, connect to

the two terminals and the analyzer is ready for its field

calibration. Key highlights include:

• Wall mounted NEMA 4X and IP66 stainless steel package

• Features the oxy.IQ electrochemical analyzer

• Package designed with ease of access including

accessibility to sensor cell replacement

• Sample conditioning system provides isolation, filtration,

pressure regulation, flow and pressure indication along

with a clear window for easy viewing of all readings

Applications

The standard O2.IQ package has been designed with

oxygen measurement in natural gas pipelines in mind;

however, the package is easily transferrable to a wide range

of applications, given its standard sampling conditioning

system. The pressure regulation functionality allows for

inlet pressures of up to 400 psig (27.5 bar) and reduces to

ambient pressure for accurate measurement.

The compact footprint of this stainless-steel package

combined with the loop powered oxy.IQ analyzer make it

perfect for safe and hazardous area locations. Markets and

applications served include:

• Industrial gas production

• Natural gas

• Petrochemical

• Heat treating and annealing

• Inert weld gases

• Gaseous hydrocarbon streams

Page 2

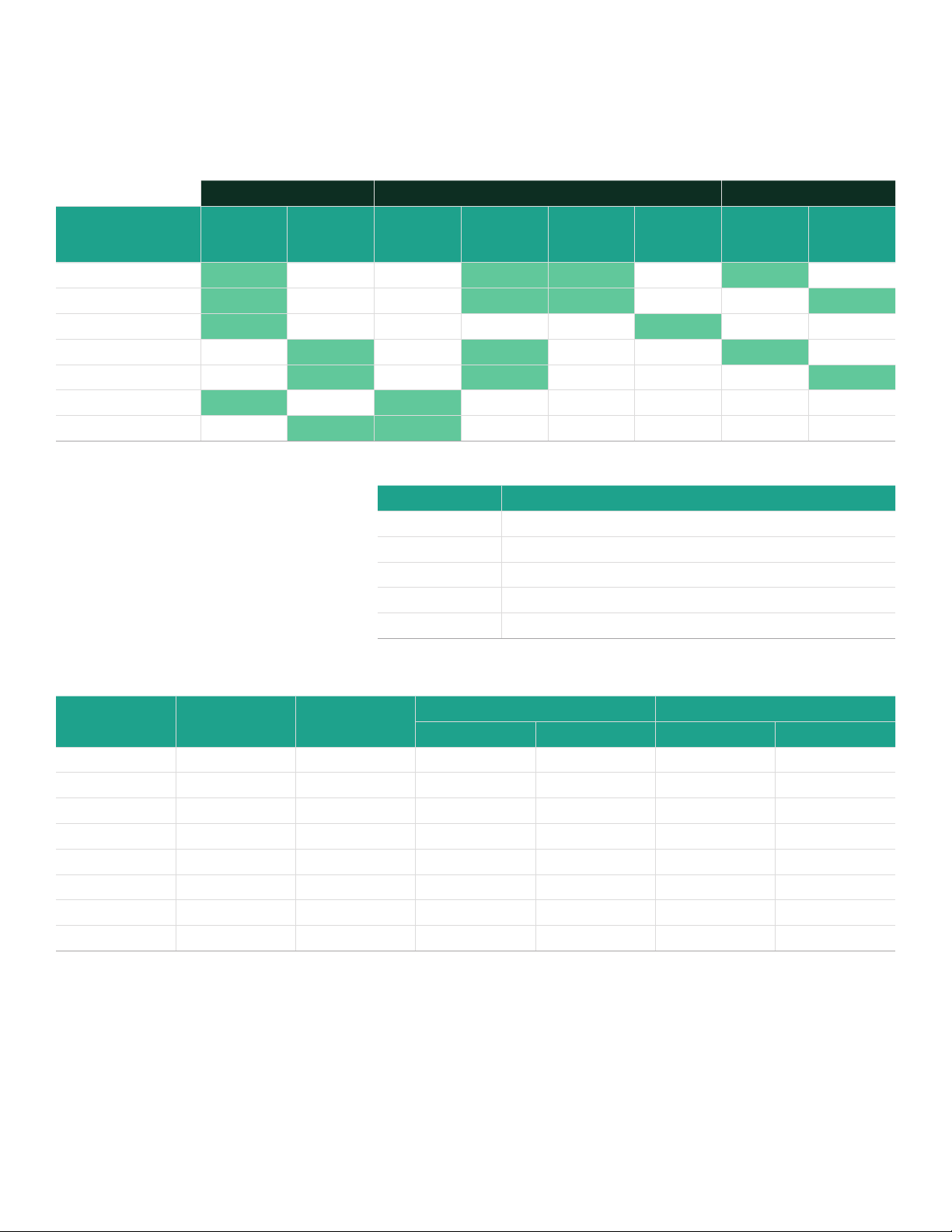

Ordering configuration

The O2.IQ is available in 7 different off-the-shelf configurations covering general purpose to hazardous area requirements,

barrier types and metric or imperial fittings. The selection grid highlights the ordering part number which corresponds to the

features required for your application and relevant area classification.

Fitting selection Area classification Barrier type

Class 1

Div 2 Non

incendive

Zener

barrier

Galvanic

isolator

Ordering Part No. Imperial Metric

O2.IQ-CL1-DIV1-Z

O2.IQ-CL1-DIV1-G

O2.IQ-CL1-DIV2

O2.IQ-IS-Z

O2.IQ-IS-G

O2.IQ-GP-I

O2.IQ-GP-M

✔ ✔ ✔ ✔

✔ ✔ ✔ ✔

✔ ✔

✔ ✔ ✔

✔ ✔ ✔

✔ ✔

✔ ✔

General

purpose

Intrinsically

safe global

Class 1 Div 1

The O2.IQ also requires selection of the

appropriate electrochemical OX sensor

for the oxy.IQ. Ordering configurations

for the OX sensors are as follows and

please refer to the sensor interference

gases for further information.

OX-1 Low range ppm measurement, standard background gases

OX-2 Low range ppm measurement, acid background gases

OX-3 Percent measurement, standard background gases

OX-4 Percent measurement, acid background gases

OX-5 Low/mid-range ppm measurement, standard background gases

Oxygen sensor interference gases

Ordering Part No. Summary

Gas OX-1 and OX-5 OX-2

Continuous Intermittent (1) Continuous Intermittent (1)

H2S <5 ppm <10 ppm 0.0005% 0.01% 0.001% 0.1%

SO

SO

3

2

<10 ppm <10 ppm 0.01% 0.1% 0.01% 0.1%

<10 ppm (3) 0.01% 0.1% (3) (3)

HCl <1000 ppm (3) 0.1% 1.0% (3) (3)

HCN <1000 ppm (3) 0.1% 1.0% (3) (3)

CO

2

NO

2

Cl

2

(1) Recommended maximum exposure 30 minutes, followed by flushing with ambient air for an equal period.

(2) Minimal effect ons ensor performance, but produces signal interference of 1:2 ratio for ppm levels only (e.g., 100 ppm NO2 looks like 200 ppm O2).

(3) Minimal effect on sensor performance.

<1000 ppm (3) 0.1% 20 & (3) (3)

(2) (2) (2) (2) (2) (2)

(2) (2) (2) (2) (2) (2)

OX-3 OX-4

Application parameters

• Sample Gas pressure: 0 - 400 psig (0 - 27.5 Bar)

• Sample gas temperature: 32 to 113°F (0 to 45°C)

• Power requirements: 24 to 28 VDC at 50 mA

Page 3

oxy.IQ specifications

All installations

Accuracy

• ±1% of range at calibration point

• ±2% of range at the calibration point for the 0 to 10 ppmv

range (OX-1 or OX-2 only)

Repeatability

• ±1% of range

• ±2% of range for the 0 to 10 ppmv range (OX-1, OX-2 only)

Resolution

• ±0.1% of range

Linearity

• ±2% of range (OX-1, 2, 3, 5)

• ±5% of range (OX-4)

O2 Sensor operating temperature

32 to 113ºF (0 to 45ºC)

Sample pressure

Vented to atmosphere during operation and calibration

Atmospheric pressure effect

±0.13% of reading per mmHg (directly proportional to

absolute pressure). During calibration, pressure and flow

must be kept constant.

Process connection

1/8 in. NPT inlet and outlet

Dimensions

4.10 x 2.75 x 2.05 in (104.1 x 69.9 x 52.1 mm)

Weight

1.35 lb (612 grams)

Sample flow rate

1.0 SCFH (500 cc/min) recommended for process units

Electrical classification certification

Intrinsically safe

USA/Canada

IS for Class 1, Groups ABCD, T4

AEx ia IIC T4

ATEX and IECEx

Ex ia IIC Ga T4 Tamb -20 to 60ºC

IS package, non-incendive without use of Zener barrier or

galvanic isolator:

• USA/Canada: Class 1, Div 2, Groups A, B, C, D: T4

European compliance

Complies with EMC directive 2004/108/EC

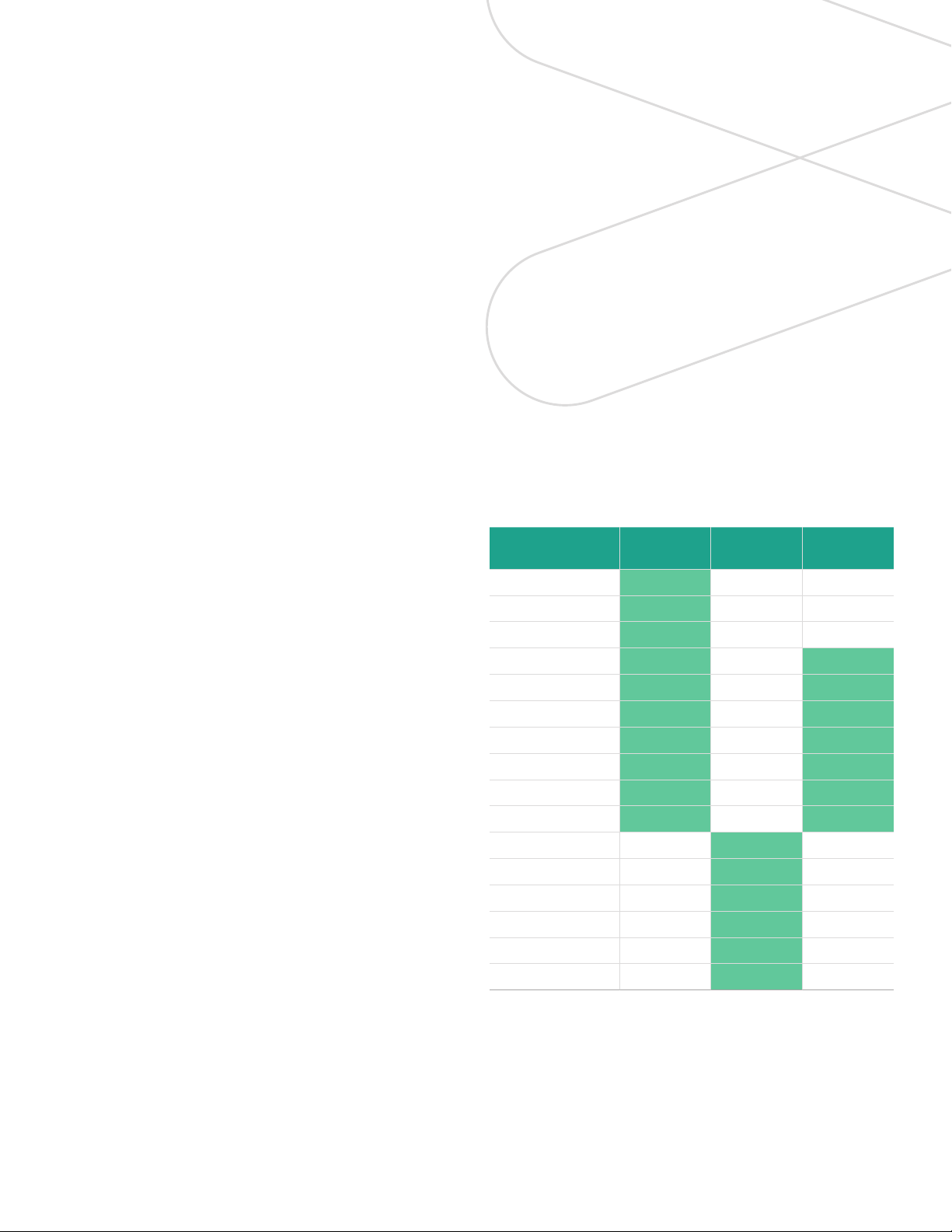

User-selectable measurement range

and corresponding sensor

Oxygen Content

0 to 10 ppmv

0 to 20 ppmv

0 to 50 ppmv

0 to 100 ppmv

0 to 200 ppmv

0 to 500 ppmv

0 to 1,000 ppmv

0 to 2,000 ppmv

0 to 5,000 ppmv

0 to 10,000 ppmv

OX-1 and

OX-2

✔

✔

✔

✔ ✔

✔ ✔

✔ ✔

✔ ✔

✔ ✔

✔ ✔

✔ ✔

OX-3 and

OX-4

0% to 1%

0% to 2%

0% to 5%

0% to 10%

0% to 25%

0% to 50%

OX-5

✔

✔

✔

✔

✔

✔

Page 4

Installation options

Class 1 Div 1/Zone 0 | Global Intrinsically Safe

Hazardous Location Non-Hazardous Location

(1)

ZBB BUS BAR

BROWN

3

4 2

BLUE

MTL7706

1

GREEN

RED

GREEN

BLACK

POWER SUPPLY

+24V

24V RETURN

Class 1 Div 2 - Non incendive

IS Cable

(Blue Jacket)

(1)

1. Equipment connected to barrier

inputs must not use or generate

more than 250V.

2. Total load of R1 + R2 must equal

250 ohms ±5%.

IS GROUND

Non-IS Cable

Hazardous Location Non-Hazardous Location

(1)

BLUE

BROWN

Black Jacket

(1)

Maximum load of analog input device is

dependent on power supply voltage

and cable resistance.

BROWN

4-20MA ANALOG

INPUT DEVICE

R1

BLACK

R2

POWER SUPPLY

+24V

24V RETURN

4-20MA ANALOG

INPUT DEVICE

Non-Hazardous Location POWER SUPPLY

General Purpose

Note: Wiring to integrated terminal strip to be completed at installation site. oxy.IQ connection cable ships separately

(1)

Terminal strip and oxy.IQ connector are internal of the O2.IQ housing. Shown externally for illustration purposes only

(1)

Black Jacket

(1)

BLUE

BROWN

Maximum load of analog input device is

dependent on power supply voltage

and cable resistance.

BROWN

+24V

24V RETURN

4-20MA ANALOG

INPUT DEVICE

Page 5

Start up procedure

Initial setup

• Ensure external wiring is securely connected to the terminal

strip provided in the O2.IQ and that the oxy.IQ cable is

securely fastened at the back of the transmitter and wired

into the terminal blocks provided. Pay special attention to

barrier installation and wiring if in hazardous area. (See

oxy.IQ manual Section 2.2)

• Referring to section 2.3 of the oxy.IQ user manual install the

electrochemical cell into the oxy.IQ

• Follow the procedure set out in Sections 3.3.1 – 3.3.3 to set

up and perform initial air calibration of the unit

• On completion of initial setup, insert the oxy.IQ into its

manifold and ensure it is securely mounted in the O2.IQ

sample handling system

Span calibration

• Check that the needle valve (4) is fully closed and that

the pressure regulator(2) is backed out by rotating anticlockwise

• Slowly open the needle valve to allow any trapped

pressure and gas to vent to the outlet in the event the unit

was in use previously and was shut down for an extended

period

• Switch the 3-way selection valve (1) to point in the direction

of calibration inlet and attach the calibration gas to the

calibration gas inlet port

• Allow calibration gas to flow into the O2.IQ and slowly

turn the pressure regulator clockwise until the pressure

gauge (3) reads 1-2 psig. Crack open the needle valve and

monitor the flow rate on the rotameter (7) and pressure on

the pressure gauge

• Slowly adjust the needle valve until a steady flow rate of 1.0

SCFH (500cc/min) is reached

• Adjust until a steady flow rate of 1.0 SCFH (500cc/min) and

a pressure of 0 psig (14.7 psia) is achieved

• Carry out span calibration as per Section 3.3.4 of the oxy.IQ

manual

• When calibration is complete, switch the 3-way selection

valve to the central block position and fully close in the

needle valve while backing out the pressure regulator by

turning anti-clockwise

Bringing process gas online

• Check that the needle valve is in the closed position and

switch the 3-way selection valve to point in the direction of

the process inlet connection

• With the process gas flowing to the system, slowly turn

the pressure regulator clockwise until the pressure gauge

reads 1-2 psig. Open the needle valve and monitor the flow

rate on the rotameter and pressure on the pressure gauge

• Slowly adjust the needle valve until the flow rate is steady

at 1.0 SCFH (500cc/min)

Shut down procedure

• Slowly shut the needle valve until the flow rate on the

rotameter reads zero flow

• Switch the 3-way selection valve to the block position,

isolating the process gas

• Re-open the needle valve to allow any trapped process

pressure to vent to the outlet

• Close the needle valve back in as added protection

against process gas pass through during shut down or

maintenance periods

Page 6

Figure 2 - O2.IQ Diagram

Page 7

Notes

1. The O2.IQ will ship with a standard oxy.IQ cable in separate

packaging. This offers the end user the capability of wiring

directly to their associated equipment if the terminal

strip is not required. All wiring should be carried out in

accordance with the wiring schematic shown and for

the appropriate area classification. Responsibility for the

quality of workmanship will be with the end user.

2. The O2.IQ is a robust package with many potential

applications. As with all analyzers however, it has certain

limitations beyond which could impact on the relibaility of

measurement and safety. If any question remains around

the suitability of the O2.IQ for a particular application then

Panametrics are happy to assist with our specialist team

of application engineers to support customers in their

selection process.

3. While the O2.IQ is a packaged solution which is ordered

under a single part number, the electrochemical oxygen

sensor must be ordered separately. The selection of

the OX sensor which is most suitable for the application

should be done in accordance with the selection table

included in this datasheet and/or in consultation with

Panametrics sales support. The electrochemical sensors

which are determined by the OX preface will be shipped

as dangerous goods which is standard procedure for all

electrochemical sensors.

Page 8

Copyright 2020 Baker Hughes Company. All rights reserved.

BHCS34789 (06/2020)

panametrics.com

Loading...

Loading...