Page 1

GE Oil & Gas

An Automated High Precision Saturation/Dilution

Calibration System for Trace Moisture Sensors

The paper discusses the physical construction and

operating principles of this saturation/dilution type

calibration system for water vapor in a nitrogen

carrier gas used for the purpose of trace moisture

sensor calibration. The system generates known

moisture standards, allows for settling time, takes

readings from sensors, records sensor readings

and creates data tables. The data tables are either

loaded into “smart” probes with on-board

non-volatile memory and/or printed as data sheets

provided to customers so that calibration data may

be inputted into analyzer electronics. The system

is capable of calibrating 128 aluminum oxide

moisture sensor probes per week, over a range

of –80°C to +10°C dew/frost point temperature.

The system is traceable to the National Institute of

Standard and Technology (NIST). Each aluminum

oxide moisture probe has a dedicated channel for

reading the signal from the probe speeding data

acquisition time. A chilled mirror hygrometer is used

as a traceable transfer standard.

The heritage design, in operation since the early

1980’s, is upgraded with a modern data acquisition,

computer controls, data historian, human-machineinterface, and report generation based around

National Instruments LabView measurement

and automation software. The newly automated

system provides faster system throughput and

more diagnostic information about calibration

performance than the heritage systems. In

addition, the system can provide local and remote

operator alarms should errors in calibration system

operation be detected during the calibration run.

Various aluminum oxide moisture probes that can

be calibrated in the described system

Introduction

One of the major challenges, which every

manufacturer of measurement equipment must

face, is the calibration of the equipment against

a secondary standard on a production line basis

while maintaining strict quality control and quality

assurance. As the number of instruments or

devices, which must be calibrated increases, so

does the challenge. Every eort must be made to

assure consistent accuracy and repeatability of

calibration as throughput increases.

GE manufactures process-oriented hygrometers,

which use aluminum oxide moisture sensors.

The aluminum oxide moisture sensor’s basic

construction is shown in the graphic. The aluminum

oxide moisture sensor is a transducer, which

responds to the vapor pressure of water in the

medium to which it is exposed, either gas phase

or liquid phase. Water molecules diuse through

the porous gold layer of the sensor and into the

aluminum oxide dielectric layer of the sensor.

Because the water molecule is a polar molecule, it

adsorbs to the pore walls of the AlO2 layer, thereby

changing the dielectric of the sensor.

Page 2

The popularity of the aluminum oxide-based

hygrometer among process industries has

increased by several orders of magnitude since its

introduction in the 1960’s. Thus the development

of a sophisticated calibration system capable of

calibrating a large number of moisture probes in

a single run is required to meet customer demand

for new moisture probes and provide capacity for

customer return probes for periodic recalibration.

This transducer must be calibrated against a

secondary standard. The latest system design

upgrades the automation of the system to provide

faster thru-put, more data, better control, and

better data manipulation while keeping the basis

for the moisture generation calibration gas on

the proven double-dilution system. The system is

also scalable as a stand-alone system that can be

replicated easily and provided to global production

and service locations, thus providing customers with

regionally located turn-around for their service needs.

impedance. The volumetric mixing ratio of the gas/water

vapor mixture is then altered and the process is

repeated. The process of calibration consists of two

main sections.

1. Production of the carrier gas/water vapor mixture

2. Data acquisition, storage and reduction

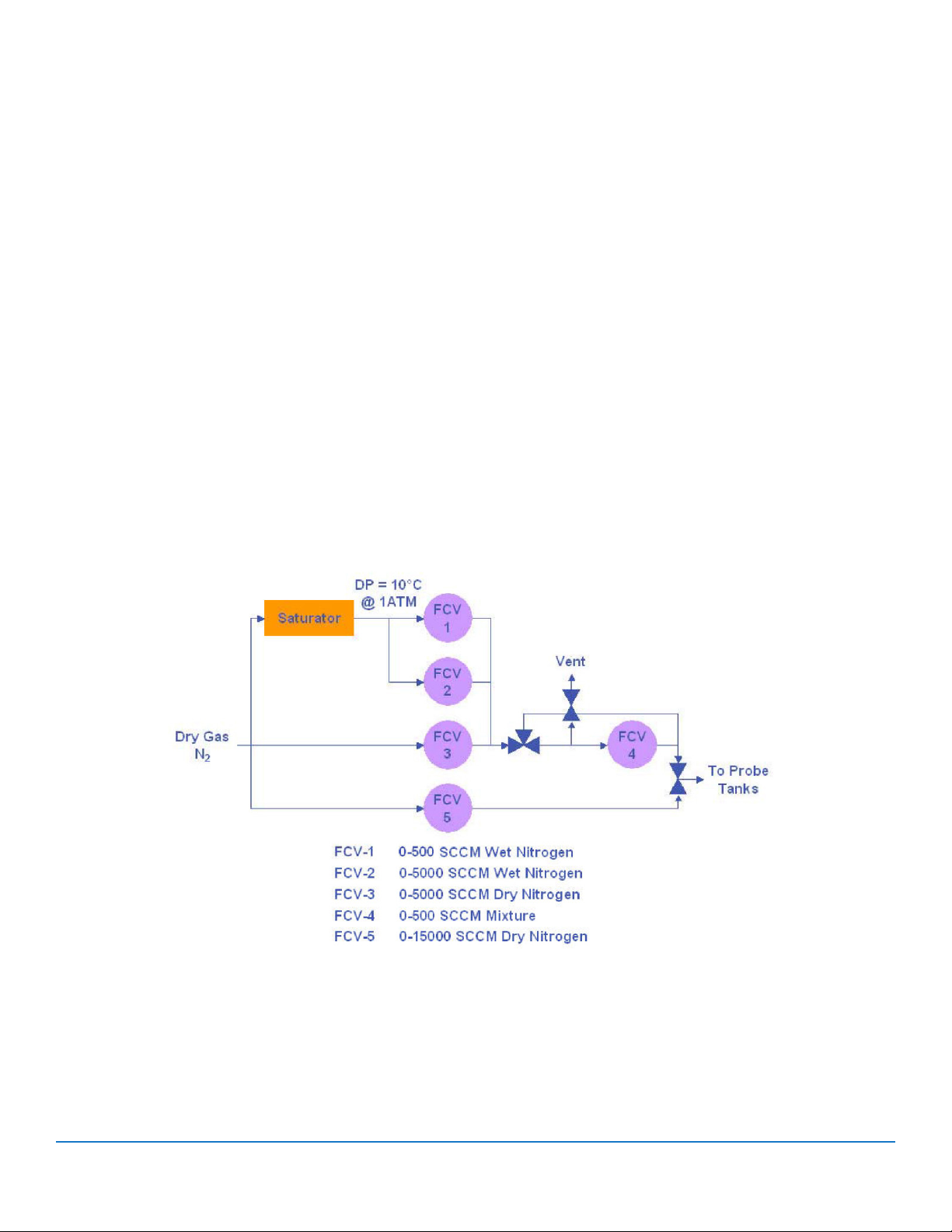

Shown below is a block diagram of the calibration

system. Gaseous nitrogen is withdrawn from a large

tank of liquid nitrogen and transported via a single

section of electro-polished, orbital-welded 316SS

tubing into the calibration laboratory. Although the

theoretical frost point of the nitrogen at this point is

equivalent to the boiling point of nitrogen (-198°C),

due to trace moisture ingress from various sources

(transportation from the gas supplier, tank relling,

etc.), its frost point temperature is actually -85°C

or less at 85 to 95 psig (5.9 to 6.6 bar) pressure.

The pressure of the nitrogen is reduced to ambient

pressure, which further reduces the frost point

to approximately -95°C. The dry nitrogen then

travels through a chamber, which contains several

“standard” aluminum oxide moisture sensor probes.

These standard probes have been previously

calibrated in a laboratory, which is independent

of the facility being described here. They are

used to assure that the nitrogen entering the

calibration system does in fact contain a moisture

concentration, which is insignicant compared to

the nal mixture that is being generated. The dry

gas then enters the moisture generation system.

Aluminum Oxide Moisture

Sensor Construction

The Calibration System

The calibration system, against which GE aluminum

oxide moisture sensor probes are calibrated, operates

on the principal of saturation of a gas with water

vapor, and then dilution of that saturated gas with

dry gas to achieve a nal mixture containing a

known concentration of water vapor. Calibration of

the moisture sensor is accomplished by exposing

the probe to a generated carrier gas/water

vapor mixture and recording the probe’s electrical

2

Aluminum Oxide Moisture Probe

Calibration System

Page 3

Dry gas stream is here split into two parts. One

part remains dry while the other part is saturated

with water vapor by passing it through a large

packed tower containing distilled water. The

tower is maintained at a constant temperature

of 15.2°C and a constant pressure of 20.7 psia

(244Kpa). Temperature of saturation is monitored

by a laboratory thermometer, which has a NIST

traceable calibration and is accurate to within

±0.1°C. Pressure of saturation is monitored

by a pressure transducer regularly calibrated

against a pressure gauge with an NIST traceable

accuracy of ±0.05 psi. This gauge is also used

to calibrate transducers, which monitor the

pressure in the calibration tanks. The saturated

gas mixture will produce a gas mixture with a

dew point of 10°C ±0.1°C when the pressure is

reduced to one atmosphere.

The 10°C dew point gas exits the saturator section of

the calibration system and enters the dilution section.

To produce dew/frost point temperatures above

-50°C, only one dilution stage is necessary. Frost point

generation below -50°C requires two-stage dilution.

Each of the ve ow control valves used in the dilution

stage of the calibration system is of the thermal mass

type and the calibration of each is traceable to NIST.

Their rated accuracy is ± 2% of reading. These ow

control valves consist of two units, a ow sensor and

an automatic controller with control valve. Output

of the ow sensor goes to a comparator, which

automatically adjusts the control valve to deliver the

quantity of dry or wet gas required to produce the

desired nal mixture.

The diagram shows the ow mixing system principal

for the various combinations of “wet” and “dry” gas

owmeters used to generate carrier gas/water

vapor mixtures equivalent to various dew/frost point

temperatures. The table below shows the owrates for

the respective valves to achieve dew/frost set points.

Flow Block Diagram

3

Page 4

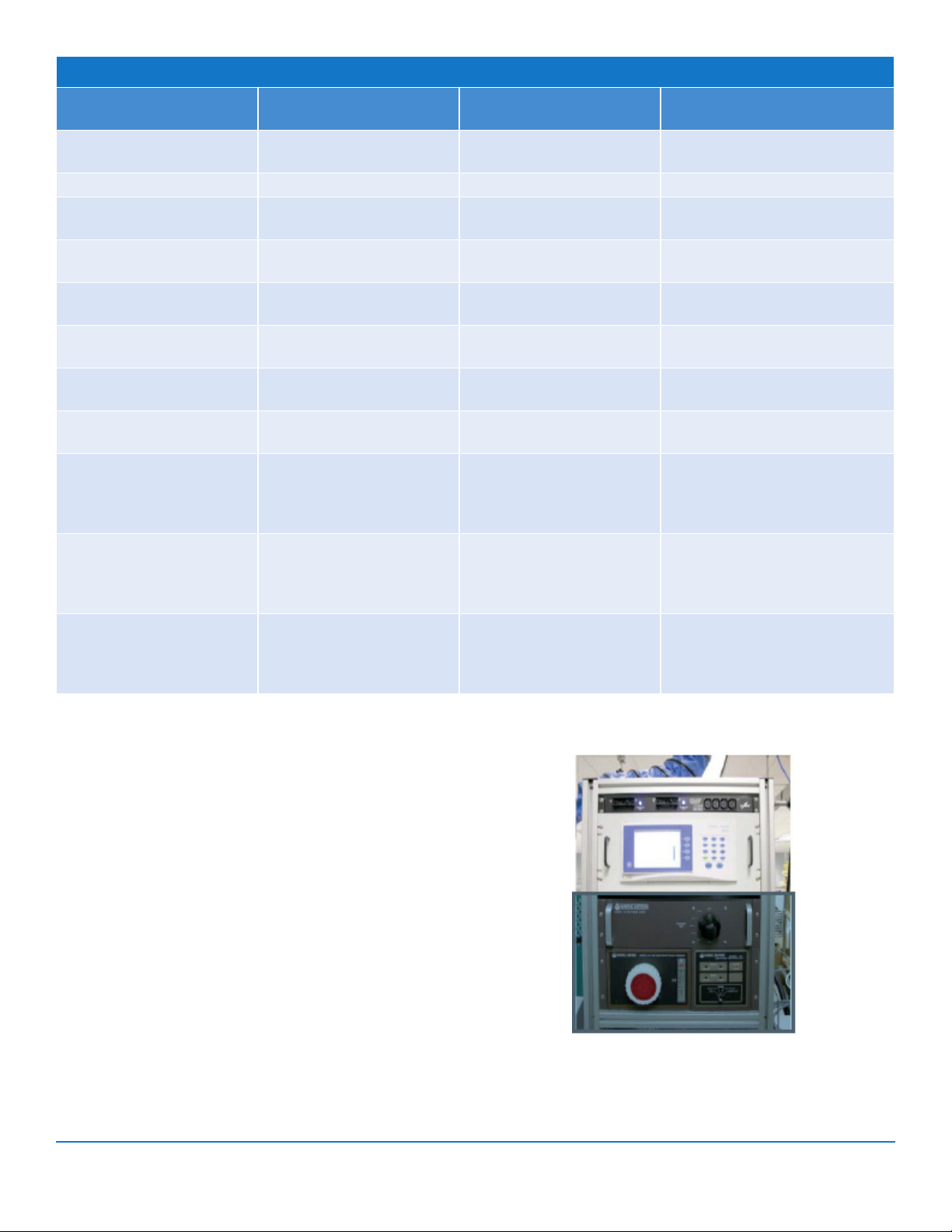

Flowrates & Accuracies for Generation of Dew/Frost Point Temperatures

Dew/Frost Point Flowmeter(s) in Use Flowrate (cc/min)

None

(System Dry-Down)

10°C FCV-2 4854 +/- 0.1

0°C

-10°C

-20°C

-30°C

-40°C

-50°C

-60°C

-70°C

-80°C

FCV-3

FCV-5

FCV-2

FCV-3

FCV-2

FCV-5

FCV-2

FCV-5

FCV-1

FCV-5

FCV-1

FCV-5

FCV-1

FCV-5

FCV-1

FCV-3

FCV-4

FCV-5

FCV-1

FCV-3

FCV-4

FCV-5

FCV-1

FCV-3

FCV-4

FCV-5

4900

15000

4854

4900

4029

15000

1380

15000

480

15000

159

15000

48

15000

159

4900

433

15000

48

4900

337

15000

48

4900

69

15000

Calculated Dew/Frost

Point Accuracy (°C)

-

+/- 0.2

+/- 0.3

+/- 0.3

+/- 0.3

+/- 0.3

+/- 0.4

+/- 0.3

+/- 0.4

+/- 0.4

The accuracy of the calibration system varies with

the generated dew point, as shown in the table.

These accuracy estimates were obtained from an

error analysis of the moisture mixing system, given

in the Appendix of this paper. The overall accuracy

of the calibration system is better than ±0.4°C

dew/frost point.

The outlet of the dilution stage of the calibration

system is routed to the calibration tank capable of

holding 128 probes. Each system can support up

to 3 calibration tanks providing an overall capacity

of 384 probes. Equilibrium conditions in each tank

during calibration are assured by random sampling

of the impedance of probes from each of the three

tanks. These probes are continuously monitored at

each generated dew/frost point temperature until

the change in impedance becomes within the error

of the A-D converter.

4

Chilled Mirror Hygrometer

Page 5

The nal check of the system is a condensation

type hygrometer (also known as a chilled

mirror hygrometer). This hygrometer is a Model

OPTICA/1311-XR manufactured by GE. The

condensation hygrometer is located at the end of

the calibration chain, downstream of the probe

tanks. The condensation hygrometer monitors

the entire system not only to conrm the water

vapor content of the generated mixture, but also

to compensate for the possibility of minute system

leaks, which can bias the generated volume ratio.

The condensation hygrometer has a specied

accuracy of +/- 0.15°C and a range of -80°C

to +20°C dew/frost point temperature. Typical

agreement of the condensation hygrometer with

the generated calibration mixture is shown in the

table below. The variation of these generated dew

points from those shown in the previous table

is within the accuracy tolerance of the specied

accuracy of the condensation hygrometer.

Typical Agreement Between Generated

Dew/Frost Point Temperatures & Chilled

Mirror Hygrometer Readings

D/F PT, Chilled Mirror

Generated D/F PT, °C

9.63 9.61

-0.33 -0.26

-10.31 -10.19

-20.30 -20.08

-30.29 -29.95

-40.28 -40.72

-50.33 -50.70

-60.23 -60.05

-70.21 -70.35

-80.16 -80.04

Hygrometer, °C

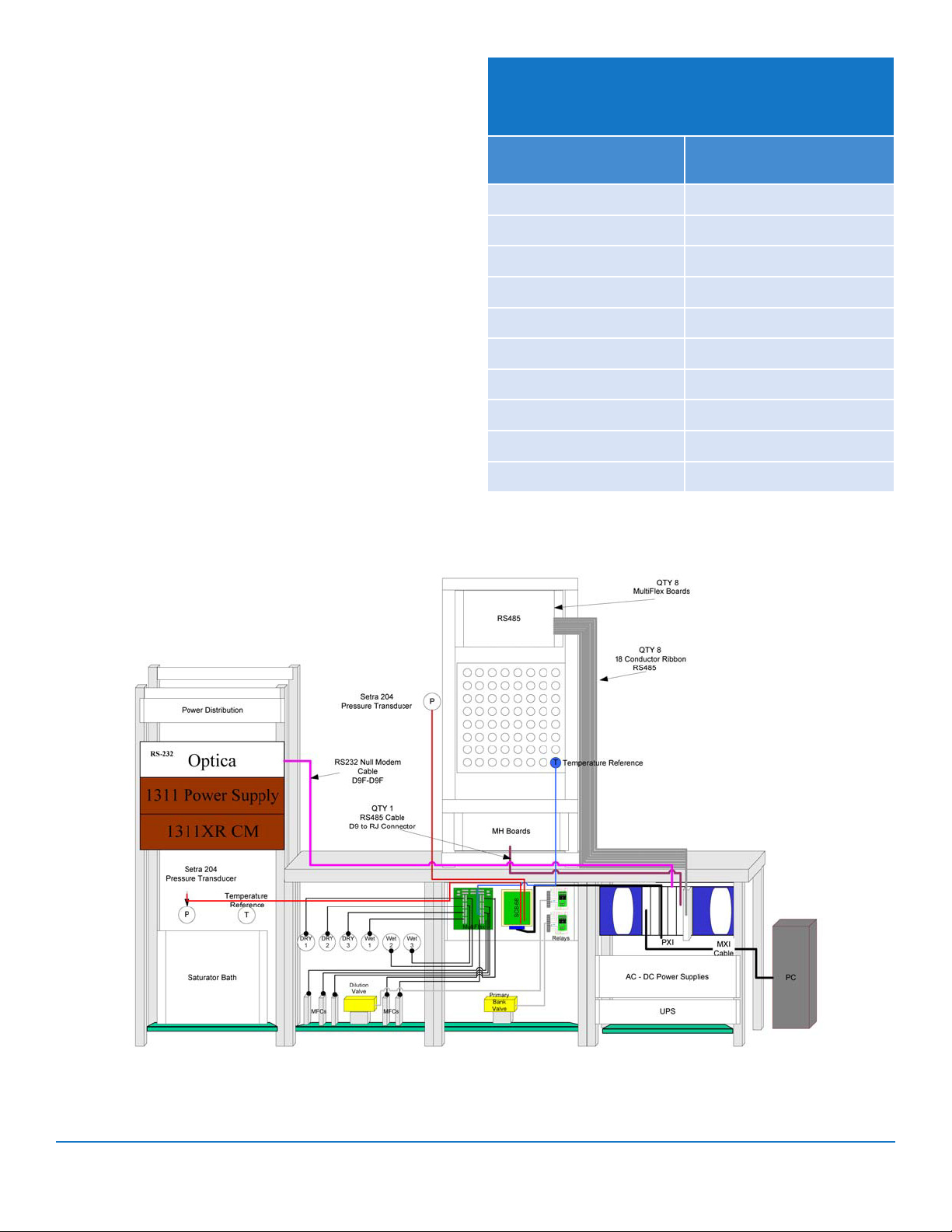

Moisture Calibration System

Singe Manifold

Block Diagram

Calibration system located in a temperature and relative humidity controlled environment

5

Page 6

Data Aquisition, Storage

and Reduction

Data acquisition, storage and reduction is

accomplished by collecting electronic impedance

data for individual moisture sensors through the use

of a direct reading of digital moisture probes, such

as MISP or VeriDri types and by direct reading of

analog moisture probes by means of master circuit

measurement electronics module with an available

channel for each slot in the calibration tank. The

electronics of this module consists of analog signal

processing and analog to digital conversion.

Impedance data for each sensor is accessed by

a dedicated reference hygrometer channel for

each probe on a continuous basis. Providing an

individual analog measurement for each probe is

a signicant improvement over the heritage system

that had limited analog measurement circuits and

required a complex multiplexing system to measure

all the various probes in the calibration bank. The

net benet to the system is faster measurement

processing and reduced overall calibration cycle time.

The analog signal processing segment contains

a unique self-calibration routine which is used to

assure that any drift in the analog section of the

system does not enter into the probe calibration

data. To accomplish self-calibration, the analog

electronics are commanded by the computer to

read several high accuracy impedance standards.

This data is fed back to the computer for testing

against standard data. If the test data is within a

predetermined maximum error band, it is accepted

by the computer, which then generates a calibration

curve. The calibration curve is automatically applied

to the actual probe impedance data. After the

analog data is collected and the calibration curve

applied, it is converted to digital information by the

A-D converter.

At completion of the calibration run, the digitized

impedance data is moved to a long-term storage

le. The data for at least the recent two calibration

data sets is stored in this le. Inventory and probe

suitability data is stored simultaneously.

The two data sets are used to calculate the actual

drift over the last calibration time periods (minimum

two month interval) and projected over the next

six month period. The criteria for drift is that the

calculated normalized drift rate must be less than

± 2°C dew/frost point over a six month period.

In addition, the calibration data is archived to

enable customers to access data about their

sensors from an enterprise server. The historical

data for a given sensor can be accessed and used

to determine the long-term drift characteristics for

a particular application.

Older hygrometer systems dating back into the

1960’s are based on analog electronics. Many of

these platforms are still in operation and moisture

recalibration services are still oered on the

aluminum oxide moisture probes for these units.

Those hygrometers using linear analog circuitry, a

curve is tted to the data points using the following

exponential equation:

Z-1 = AebT + C

where

Z is the sensor impedance

T is the dew point temperature

A, b, and C are constants determined from the t

Oset, span and electronic calibration factors are

calculated for the best curve t and a datasheet

for the instrument of interest is generated by the

calibration computer.

6

Page 7

Typical Calibration Data Sheet for a microprocessor-based hygrometer. For analog probes such as the

common “M-Series” moisture probe, the moisture probe is calibrated and shipped with a calibration

data sheet. The customer enters the 14-point calibration data into their hygrometer.

All current systems utilize microprocessor-based

electronics. For these microprocessor based hygrometers,

the Z-1 (sensor admittance) reading versus the dew/frost

point is tabulated and a data sheet with all the necessary

information for such instruments is generated.

A local pc-based computer is used to control the

calibration system and to collect the calibration data.

A National Instruments LabView interfaces with the

controllers, to view and print sensor data, and to collect

system diagnostics. The system is duplicated at GE

facilities in Boston, MA; Shannon, Ireland; Abu Dhabi,

UAE; Tokyo, Japan; and Changzhou, China.

While this paper is based on the primary

calibration systems designed at GE’s site in

Billerica, MA using NIST traceable calibration

reference standards, systems located in other

geographic locations are traceable to the

applicable ruling metrology authority. For

example, GE’s facility in Shannon, Ireland has their

moisture calibration system use standards that

are calibrated traceable to the National Physics

Laboratory (NPL) in the UK.

7

Page 8

Calibration System LabView Interface oering intuitive graphical control

and monitoring of the calibration run

Replication of this design, data collection, and system control globally makes it possible for the data and

system verication diagnostics to be stored on redundant servers in a global database.

8

Page 9

Conclusion

The GE primary calibration system is capable of

calibrating up to 384 aluminum oxide moisture

sensor probes per calibration run. Each run requires

seven days for completion, including a three and

one-half day dry down period.

The probes are normally calibrated at 10 dew/frost

points over the range from -80°C to +10°C, with an

accuracy of the generated gas/water vapor mixture

of better than +/-0.4°C (see Appendix).

Temperature, pressure and ow measurement devices

used in this system are all traceable to the National

Institute of Standards and Technology. Thus, this

calibration system meets the stated requirement, to

calibrate aluminum oxide moisture probes in quantity

on a production line basis, while maintaining rigorous

quality control and quality assurance criteria.

Overall Aluminum Oxide Moisture Probe Calibration System View

9

Page 10

Appendix

P

KW = Enhancement factor

The error analysis of moisture generator system is

divided into an analysis of gas saturation and an

analysis of gas dilution.

Saturator Section - The vapor pressure of water

generated by the saturator is given by the equation

=

P

ºS

x 6.112exp

K

W

KW = 1.0007 + 3.46 x 10-6 P

17.502 t

240.97+t

t

and the vapor pressure of water delivered to the

calibration banks is given by the equation

PS = P

º

S

x

T

P

º

T

where

PS = Vapor pressure of water in calibration chamber

P°S = Vapor pressure of water generated in saturator

at temperature

t = Temperature within the saturator

The absolute accuracy of the saturator, based on

the accuracy of NIST traceable thermometer

(+/- 0.10°C) and pressure gauge (+/- 0.05 psi), is

+/- 0.7% in PS, or +/- 0.11°C in dew point.

Dilution Section - The error in the dilution section

varies somewhat for dierent dew points, due to

the dierent ow rates and number of owmeters

employed. The vapor pressure of water generated

by dilution, PW, is given by

PW = P

F

W1

S

F

+ F

W1

x

D1

F

W2

F

+ F

W2

D2

where

PS = Vapor pressure output by the saturator

FW1 = Wet gas ow for rst dilution (FCV-1, FCV-2)

FD1 = Dry gas ow for rst dilution (FCV-3)

PT = Total pressure in calibration chamber

P°T = Total pressure in saturator

A complete expression for the error in the above equation can be calculated

Δ

P

W

=

P

W

2 2

P

Δ

S

P

S

+

F

D1

FD1+ F

Δ

W1

2

F

W1

F

W1

F

Δ

+

D1

F

D1

FW2 = Moist gas ow for second dilution (FCV-4)

FD2 = Dry gas ow for second dilution (FCV-5)

(1)

. It is given by

2 2

+

F

D2

FD2+ F

W2

Δ

2

F

W2

F

W2

F

Δ

+

D2

F

D2

1/2

2

The error in PS, +/- 0.7%, has been derived. The owmeter accuracy, specied by an independent calibration

in service, is +/- 2% of ow or +/- 0.5% full-scale ow, whichever is larger. The application of second

equation referenced to the data in Flowrates & Accuracies for Generation of Dew/Frost Point Temperatures

table yields errors for each dew point.

The errors in water vapor pressure vary from +/- 0.7% at the highest dew point up to +/- 6.8% at the lowest

dew point. These errors, converted to a dew point scale, are listed in Flowrates & Accuracies for Generation

of Dew/Frost Point Temperatures table. The dew point errors vary from +/- 0.1°C to +/- 0.40°C.

The systematic error in dew point due to moisture in the dry gas may be neglected at all dew points wetter

than -80°C. For the -80°C point the error is less than +0.4°C in dew point. This is based on a maximum -85°C

dew point at 90 psig in the dry gas supply line.

10

Page 11

Acknowledgments

REFERENCES

The author would like to acknowledge several persons

for their contributions to developing the calibration

system described herein. A partial list of those

people include James Figucia for LabView interface

work; Gene Berkowitz, Joe Ferro and Tony Kowal for

engineering eorts on GE hygrometers and probes;

Dave Spielman for manufacturing engineering eorts

to design, build and test the calibration system; Steve

Rehn for quality and calibration system expertise; and

Sean Donahue for quality leadership eorts.

1. Dietrich. C.F., “Uncertainty, calibration, and

Probability’, John Wiley, New York, 1973, p. 269.

2. Scelzo, Michael; Pierce, Ralph. “A High Precision

Saturation Dilution System for Water Vapor

in a Carrier Gas”. Proceedings of the 1985

International Symposium on Moisture & Humidity.

Instrument Society of America, Research

Triangle Park, NC. 1985. ISBN 0-87664-865-0.

*Trademarks of General Electric Company.

©2016 General Electric Company. All rights reserved.

03/2016

Loading...

Loading...