Page 1

Trace moisture Transmitter for

pressure or atmospheric dewpoint

®

DewPro

MMY30

Installation and Operation Manual

GE Measurement & Sensing Technologies

GE General Eastern

Page 2

DewPro MMY30

Caution!

Safety

General Notes

Caution!

Before installation please read all instructions.

Safety

- The DewPro is designed to be mounted to pressurized systems. Take necessary

precautions when mounting or removing the DewPro.

General Eastern reserves the right to change or modify our product appearance and

specifications at any time and without notice. Therefore, information in this document is

subject to change without notice and does not represent a commitment on the part of

General Eastern.

No part of this manual may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying and recording, for any

purpose without the express written permission of General Eastern.

DewPro is a Registered Trademark of General Eastern.

If you should have questions regarding the product described in this document, or need

further assistance, please contact your local GE General Eastern Sales Centre

Installation and Operation Manual

GE General Eastern

2

Page 3

DewPro MMY30

Installation and Operation Manual

Contents

General Notes 2

1.0 General System Information …………………………. 5

1.1 Unpacking and Inspection 5

1.2 Introduction 6

1.3 Theory of Operation 6

1.4 Dimensions 7

2.0 Installation Guidelines …………………..……………. 7

2.1 General Hints 7

2.2 Method 1 - Orifice at Outlet 8

2.3 Method 11 - Orifice at Inlet 9

2.4 Method Ill - No Flow Restriction 9

2.5 Method IV - Bypass Installation 10

3.0 Wiring Instructions …………………………………... 11

3.1 Wiring, General Guidelines 11

3.2 System Configuration 11

3.3 Mounting in Normal Environments 12

3.4 Mounting in Environments with Severe Electrical Noise 12

3.5 Electrical Connection 12

3 6 General Wiring Instructions 13

4.0 Optional Display/User Interface……………………… 14

4.1 Installation 14

4.2 Description of the DewPro MMY 30 Programming Matrix 15

4.3 Special Functions of the Pushbuttons 16

4.4 Functions of the Matrix (Refer to Figure 20 or appendix) 16

GE General Eastern

3

Page 4

DewPro MMY30

Installation and Operation Manual

5.0 Troubleshooting 21

5.1 General Recommendations 21

5.2 Removing the Filter 21

6.0 Technical Specifications 23

6.1 Optional Onboard Display with User Interface 23

7.0 Accessories 24

7.1 Available Accessories 24

7.2 Example of Power Supplies and Displays23 24

Appendix

GE General Eastern

4

Page 5

DewPro MMY30

Installation and Operation Manual

1.0 General System Information

1. 1 Unpacking and Inspection

Upon receipt of the DewPro MMY 30, examine the shipping carton for broken or

open packing, distortion, or any other evidence of mishandling. If inspection

indicates damage to the unit or any of its components, notify the carrier (within 15

days of delivery) and request an inspection.

Move the carton to a clean work area and unpack. The carton you receive should

contain:

• DewPro MMY 30

• Installation and Operation Manual

• Calibration Certificate

Compare the model number (on the product label) with product structure (see

below) to ensure you have received everything you ordered.

GENERAL EASTERN

MODEL:

SERIAL NO:

SUPPLY:

RANGE:

P max: 500 PSIG

Product Structure

MMY30 -

Certification/Approvals:

R Standard (not certified)

Other

Y

Process Connection:

2

1 ½” MNPT (1/4” tube fitting if B, C or D is selected below)

G ½ (6 mm tube fitting if B, C or D is selected below)

9 Other

Orifice Configuration:

A

D

Inlet: None; Outlet: Orifice, with ¼” FNPT

B Inlet: None; Outlet: Orifice, with (6 mm) ¼ " tube fitting

C Inlet: None; Outlet: None, with (6 mm) ¼ " tube fitting

Inlet: Orifice; Outlet: None, with (6 mm) ¼ " tube fitting

Y Other

Enclosure Conduit:

1

½ " FNPT

2 PG 16

9 Other

Output Configuration/Dewpoint Range:

A Td -90 oC to +10 oC (-130 oF to +50 oF), no display, error

22 mA

B

Td -90 oC to +10 oC (-130 oF to +50 oF), no display, error

Hold

C Td -90 oC to +10 oC (- 130 oF to +50 oF), no display,

error 3.6 mA

F

D 0-100 ppmv 1 bar, no display, error 22 mA

E 0-100 ppmv 1 bar, no display, error Hold

0-100 ppmv 1 bar, no display, error 3.6 mA

G With integral display/user interface

Y Other

R 2 A 2 A

The Humidity Experts

MMY30-R-2-A-2-A

10124

9...32 VDC

Unpacking

Check Model

Number

Fig. 1

GE General Eastern

5

Page 6

DewPro MMY30

Installation and Operation Manual

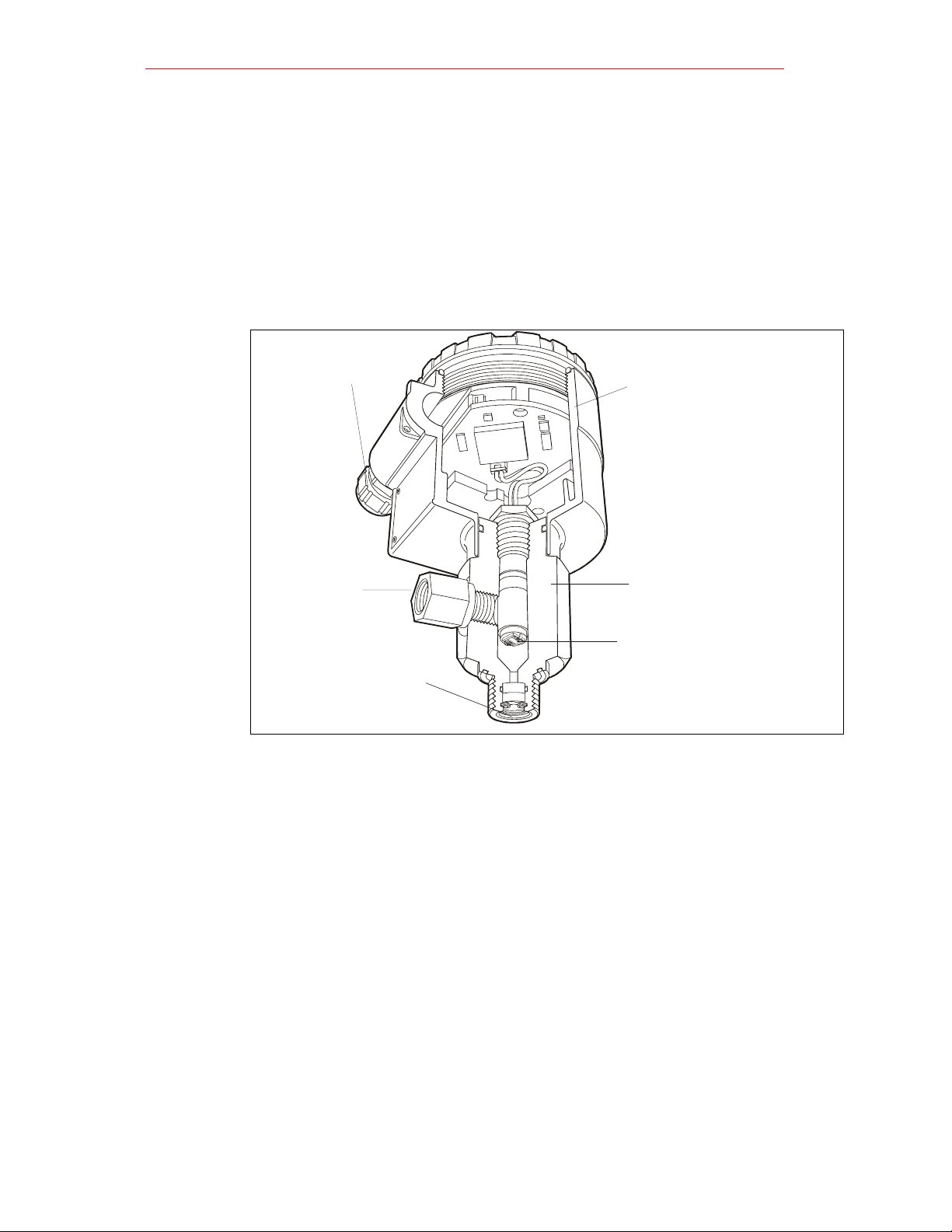

1.2 Introduction

Unit description

The DewPro MMY 30 trace moisture transmitter is a loop-powered dewpoint

measuring device. The transmitter includes a sensor element, a flow chamber, a

weather-proof enclosure, microprocessor electronics, and assorted fittings all in a

compact assembly In most cases, either the inlet or outlet port includes an orifice to

regulate the flow. The placement of this orifice determines whether the dewpoint

measurement is done at process (line) pressure (outlet orifice), or at atmospheric

pressure (inlet orifice). A 2 micron sintered inlet filter prevents particles from entering

the device.

Optional

Display/User

The optional display/user interface feature allows the DewPro to be configured to the

user's specifications. See Chapter 4.0, pages 14-20 for more information.

Interface

Power Signal

Cable Entry

Electronics Housing

Outlet

(Exhaust)

Fitting

Flow Cell

SensorElement

Fig. 2

Sinterfilter

Inlet (Process

Connection)

1.3 Theory of Operation

4 to 20 mA

Loop

By-pass In dryer applications, the moisture sensor performs best when mounted in a bypass. The

Planar Sensor

Calibration Each DewPro is factory calibrated against precise NIST certified moisture references

The DewPro MMY 30 microprocessor controlled electronics operate with a DC voltage

supply from 12 to 32 V DC. At the nominal 24 V DC supply, the maximum loop resistance

is 600 Ohm. The signal is represented by the 4 to 20 mA loop current and is

directly proportional to the dewpoint range in oC or oF In the standard range, 4 mA

corresponds to -90 oC (-130 oF) and 20 mA to +10 oC (+50 oF) dewpoint temperature.

The optional unit of measure is ppmv in the standard range 0 - 100 ppm-v.

built-in bypass of the DewPro eliminates costly hardware associated with traditional

sampling methods. The DewPro installs simply into the process with its G ½ or ½ "

MNPT threaded connection.

The heart of the MMY 30 is the new planar sensor element. It incorporates a new,

superior aluminum oxide sensor that provides longer calibration stability, excellent

corrosion resistance, and improved speed of response. The sensor, mounted on a

ceramic substrate, also has a reduced temperature coefficient.

and has an accuracy of ñ2 OC dewpoint. For field recalibration, GE General Eastern is

offering a unique calibration device. The MMY145 field calibrator connects to the DewPro

on site and corrects the calibration data automatically.

GE General Eastern

6

Page 7

DewPro MMY30

Installation and Operation Manual

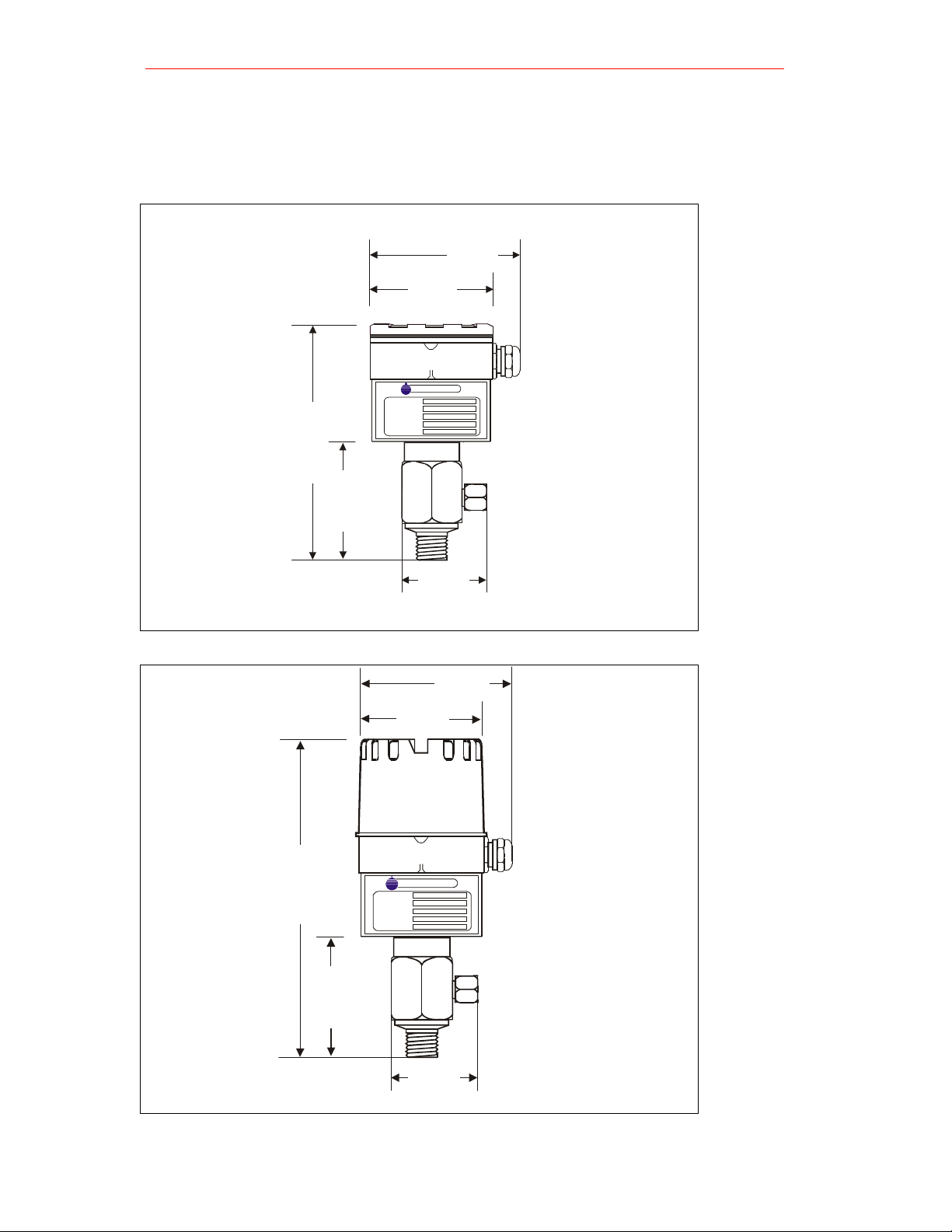

1.4 Dimensions

Choose a mounting location which allows enough clearance for the use of tools and

for connection of the field calibrator.

116

86

GENE RAL EAS TERN

The Humidity Experts

MMY30

MODEL:

SERIAL NO:

12...32 VDC

SUPPLY:

DEWPOINT RANGE:

P max:

168

83

PSIG

65

1 mm = 0,04 in

.

Standard DewPro

Fig. 3

116

76

220

MODEL:

SERIAL NO:

SUPPLY:

DEWPOINT RANGE:

P max:

GENERAL EASTERN

The Humidit y Expe rts

MMY30

12...32 VD C

PSIG

83

65

1 mm = 0,04 in

.

DewPro with

Optional

Display/User

Interface

Fig. 4

GE General Eastern

7

Page 8

DewPro MMY30

2.0 Installation Guidelines

2.1 General Hints

• Mount the DewPro vertically whenever possible to prevent particles or

condensation from entering the bypass.

• Mount the DewPro after a shut-off valve to depressurize the DewPro when

removing it from the process pipe in case of maintenance or field calibration.

Caution!

Do Not OverTighten

Caution!

The outlet fitting is connected to the bypass block with a G 114 straight thread

(with gasket) which will seal if the fitting is simply hand-tightened. When

connecting an external device, counter the fitting with a second wrench when

tightening.

If the inlet is equipped with a G 112 straight thread and gasket, the seal is obtained

by simply hand-tightening the DewPro.

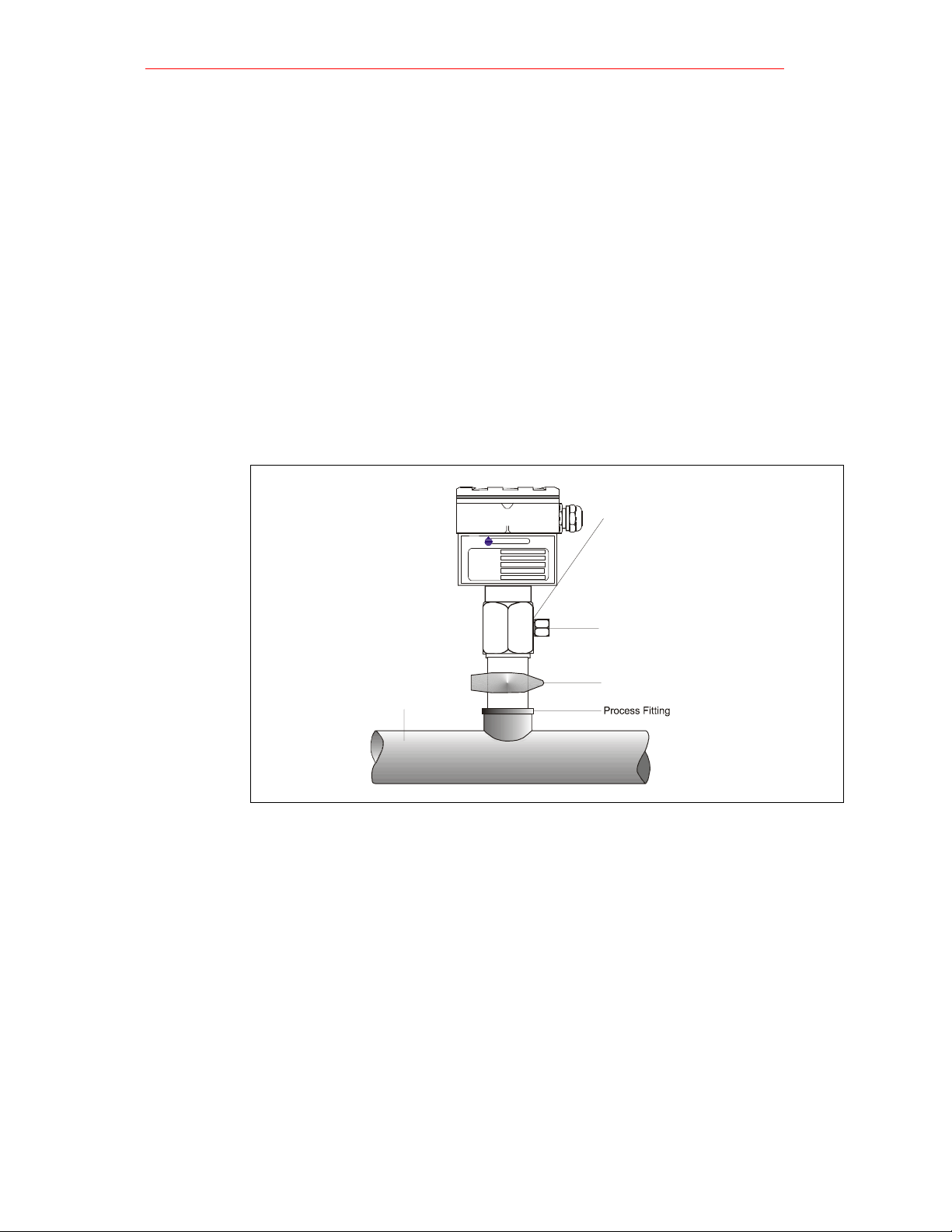

2.2 Method I – Orifice at Outlet

Fig. 5

Pressure

Dewpoint

Air Flow

Air dryers producing general instrument air are typically specified with a pressure

dewpoint rating. The majority of dryers operate in a dewpoint range between -40 oC to

-75 oC (-40 oF to -100 oF). A pressure of 7 to 8 bar (= 100 psig) is very common.

The DewPro is designed to measure the pressure dewpoint. By restricting the flow at

the outlet of the integral bypass with an orifice, the sensor monitors the dewpoint at

process pressure. The bleed-off air to the atmosphere at 7 to 8 bar (100 psig),is

approximately 70 cc/min. (=4 [/h or =0. 14 cfh). For smaller sized dryers of 3m'/min.

(=100 cfm) the air loss is only 0.002% of the air production and is negligible.

Despite the very low flow rate through the bypass as shown, the air sample in the

DewPro bypass chamber is refreshed every second due to the small volume design.

As a result, the sensor sees changes in moisture instantaneously.

Due to the low flow rate, the flow velocity is also very low at < 0.01 m/sec. (=34m/h).

The low flow velocity prevents the inlet filter from clogging since there is not enough

kinetic energy to draw dust particles into the filter.

Process Pipe

GENERAL EASTERN

MODEL: MMY30

SERIAL NO:

SUPPLY:

DEWPOINT R ANGE:

P max:

Installation and Operation Manual

G ¼" Straight Thread

The Humidity Experts

12...32 VDC

PSIG

Outlet connection with orifice

Shut-off valve

GE General Eastern

8

Page 9

DewPro MMY30

Installation and Operation Manual

2.3 Method II – Orifice at Inlet

G ¼" Straight Thread

GENERAL EAS TERN

MODEL:

SERIAL NO:

SUPPLY:

DEWPOINT RANGE:

P max:

MMY30

9...32 VDC

PSIG

The Humidity Expe rts

6 mm compression fitting

Diffusion Coil

Shut-Off valve

2.4 Method III – No flow restriction

GENERAL EASTERN

MODEL:

SERIAL NO:

SUPPLY:

DEWPOINT RANGE:

P max:

MMY30

12...32 VDC

PSIG

The Humidity Experts

G ¼ " Straight Tread

6 mm compression fitting

Pressure drop

Closed loop drying systems, which are very common with hopper dryers in the Low

Pressure Closed Loop plastics industry, operate at very low pressures of a few

inches of water. The air passing through the DewPro bypass is fed back to the main

stream after a pressure drop in the main line.

In this configuration, the DewPro bypass has no flow restriction at the inlet and

outlet.

The outlet is equipped with a 6 mm (l/4") tube fitting to allow simple connection of

the loop tubing.

Fig. 6

Low pressure

closed loop

Fig. 7

GE General Eastern

9

Page 10

DewPro MMY30

Installation and Operation Manual

Method IV – Bypass Installation

Fig. 8

Remote

installation

Fig. 9

Wall Mounting

G ¼ " Straight Tread

GENERAL EASTERN

The Hu mi dity E xpe r ts

MMY30

MODEL:

SERIAL NO:

SUPPLY:

DEWPOINT RANGE:

P max:

12...32 VDC

PSIG

6 mm compression fi tting

6 mm (1/4") Tubing from

Process

In some cases there may not be enough room to install the DewPro directly to the

process pipe. The tube connection at the inlet allows mounting the DewPro at a remote

location. The functions of Methods 1-III can be selected.

G ¼" Straight Thread

GENERAL EASTERN

The Humidity Experts

MODEL: MMY30

SERIAL NO:

SUPPLY:

12...32 VDC

DEWPOINT RA NGE:

P max:

PSIG

Mounting

bracket

The DewPro can be mounted on a wall or a plate using a bracket available from GE

General Eastern.

6 mm tubbing fitting

6 mm (1/4") Tubing from

Process

GE General Eastern

10

Page 11

DewPro MMY30

2

Installation and Operation Manual

3.0 Wiring Instructions

3.1 Wiring, General Guidelines

Note: If the DewPro is equipped with an optional display/user interface, please refer

to section 4.0, page 14 prior to wiring

Caution!

The DewPro system contains electronic components that are susceptible to damage

by electric electricity. Proper handling procedures must be observed during the

removal, installation, or other handling of internal boards or devices.

3.2 System Configuration

8888

GENERAL EASTERN

The Humid i ty Expe r ts

Note regarding customer's power supply: The voltage at the +/- terminal of the

Designing the Loop DewPro should not fall below 12 V DC. The maximum loop resistance

is an important measure for selection of the supply voltage. Each device connected to the

loop causes a voltage drop. For instance, using a loop-powered display with an input

impedance of 50 fl will cause a voltage drop of 1 V DC at 20 mA using Ohm's law.

Connecting the loop to a PLC will cause a voltage drop across the input.

When designing your loop, add up all voltage losses across the devices connected to the

loop and add 12 V The sum will be the minimum supply voltage required from the power

supply Calculate with a 20% safety factor.

Optional loop powered

display available from

General Eastern, such as Md102

Customer s power supply

24 V DC ( 9...32 V DC )

-

Power suppl y

available from General Eastern

~

8888

-

Power supply with display

and optional relay availabl e

from General Eastern such as Md10

~

115 /2 30 V

AC

115/230 V

AC

Caution!

Various Power

Supplies /

Displays

Fig.10

Designing the

Loop

GE General Eastern

11

Page 12

DewPro MMY30

3.3 Mounting in Normal Environments

Standard

Fig.11

• A standard four-wire, stranded cable can be used to interconnect the DewPro

with the power source.

Two -W ire

Cable

External

Earth

Ground

3.4 Mounting in Environments with Severe Electrical Noise

EMI/RFI

Fig.12

• In areas where EMI/RFI interference is likely a shielded signal cable is to be used

for full protection. The DewPro MMR31 meets requirements of IEC 801-1

through 6 (EN 50081-1, 50082-2) when shielded cable is used.

Shielded Two-Wire

Cable

Fasten Shield under Cable

Clamp for Maximum

RFI Protection

3.5 Electrical Connection

Fig. 13

G

E

N

E

R

A

L

E

T

h

A

e

H

S

u

m

T

i

d

i

E

t

y

E

R

x

p

e

N

r

t

s

External

Earth Ground

Installation and Operation Manual

Capped

Off

Capped

Off

+

24 V DC Nominal (9-32V)

-

+

24 V DC Nominal (9-32V)

-

GE General Eastern

12

Page 13

DewPro MMY30

Installation and Operation Manual

3.5 General Instructions

1. Unscrew the cap on top of the unit.

2. Loosen the grey cable gland located on the side of the unit

3. Feed the cable through the conduit opening.

Use a standard signal cable size.

NOTE:

4. Retighten the grey cable gland to meet IP 67 and to relieve any stress on the

wire.

5. Verify that 12 to 32 V DC is across the terminals marked + and -.

NOTE: This is the voltage that appears across the DewPro terminals,

not necessarily the power supply voltage due to voltage loss in wire length, displays,

indicators, etc.

6. Connect shield to internal grounding for maximum EMI / RFI protection

GE General Eastern

13

Page 14

DewPro MMY30

Installation and Operation Manual

4.0 Optional Display/User Interface

4.1 Installation

If the DewPro is equipped with an optional display / user interface follow the procedure

below to access the terminals prior to applying power. Please use Figure 18 below as a

reference when removing any parts from the DewPro.

Dewpro with

Display

assembly

Fig. 14

1. Unscrew and remove the protective lid from the top of the DewPro, exposing the

display module below

2. Unplug the display from the lower terminal board.

3. Carefully grasp the display bracket and pull straight up.

4. Follow the procedure outlined in Section 3.0, pages 8-10.

5. To replace the display module, locate the six holes on the underside of the

display bracket. The MMR 31 uses the holes with the additional markings next to

them.

6. Align the display bracket with the standoffs and snap the display bracket onto the

three standoffs.

7. Carefully rotate the display module on the display bracket until properly aligned

for readability.

8. Reconnect the display to the lower terminal board observing the key on the plug

and socket.

N

R

s

t

r

E

e

p

x

T

E

S

y

t

i

d

i

A

m

u

E

H

e

h

L

T

A

R

E

N

E

G

GE General Eastern

14

Page 15

DewPro MMY30

Installation and Operation Manual

4.2 Description of the DewPro MMY30, Programming Matrix

In the DewPro trace moisture transmitter with display option, a matrix-style input is

used for programming the unit of measure, measuring range, error status of output,

and output adjustment. For users of other General Eastern equipment, this 'GEI

matrix" format is familiar. The following describes the features and usage of the

various matrix location as they apply to the MMY30.

8888

ppm

mA

Unit ID

v

Software

Version

----------

-

Numeric

Display

Bar Graph

The display of the DewPro MMY30 continuously shows the current matrix location

using the vertical (V) and horizontal (H) coordinates to designate the row and

column, respectively. The bar graph represents the output current in an analogue

fashion (refer to Figure 15). See the Appendix for an enlarged overview of the

matrix.

MMY 30/31 H0 H1 H2 H3 H4 H5 H6 H7 H8 H9

Select

Display

Moisture Unit

Moisture Unit

Loop Range

Constant;

Loop

Hardware

Calibration

Access Key

Misc. Setup

Moisture

V0

Dewpoint °C

V1

V2

Constant for

V3

ppmv comp.

V4

V5

V6

V7

V8

V9

Present Error

Value

4 mA

Pressure

(bar)

Display

see table

below

Dewpoint °C

20 mA

Display

Previous Error

Movement through the matrix is accomplished by using the "V" and "H" buttons to

move to another row or column. For example, beginning at VH 00 and successively

pressing "V", leads the user to VH 10, VH 20, VH 30, VH 40, VH 50, VH 60, VH 70,

VH 80, VH 90 and back to VH 00. At any location where a value may be changed

by the user, the desired value is programmed using the "+" and “-“ buttons.

88

Reset To

Defaults

50 = Reset

VH

VH Position

Indicators

User Interface

Keys

Loop 1 at Fault

Loop 1 Raw

0= -10%,

1=110%,

Reading

2=Hold

Loop 1 D/A

Calibration

Low

Loop 1 D/A

Calibration

High

Input Locking

50 = Unlock

System Reset

50 = Reset

Fig. 15

Fig. 16

GE General Eastern

15

Page 16

DewPro MMY30

Installation and Operation Manual

1. Reset to "Normal" Display: Pressing the 'V' and “H” buttons simultaneously

3. Default Values

This section describes the functions available to the user through the matrix. grouped by

DISPLAY AND OUTPUT MODE

1. Dewpoint display

2. Selecting the Device Unit

4.3 Special Functions of the Push buttons

returns the user to VH 00 (normal display).

2. Display Only: Note that eight (6) matrix locations me for display only and may not

be changed by the user (refer to Figure 20 or Appendix). The 'display only' fields

are as follows:

• VH 00 = normal display (in dewpoint oC)

• VH 08 = indicates digitized moisture signal

• VH 90 = during a system alarm, displays the error code for the fault

encountered

• VH 91 = during normal operation, the previous error code is displayed for

reference

• VH 92 = displays the factory issued identification number

• VH 93 = displays the factory issued reference number designating the

device type and software version

A default value is assigned to each programmable matrix field. The values are

present after a reset to factory programmed data has been executed (see VH 95).

4.4 Functions of the Matrix (Refer to Figure 16 or Appendix

common function areas. The function is accessed by positioning to the specified location

within the matrix

Location in Matrix Description of Function

VH 00

Location in Matrix Description of Function

VH 01

This is the normal display of the transmitter when in operation.

The dewpoint is shown in oC or oF, or ppm-v as selected

under VH 01.

Selects units to be displayed. Changing from oC to oF does not

change the current loop. Changing from dewpoint to ppmv

does change the current loop.

NOTE: When switching to ppmv, the display may indicate an

error " 3" if the dewpoint reading is above -20 oC. (For

example, the DewPro is exposed to ambient air.)

GE General Eastern

16

Page 17

DewPro MMY30

3. Loop at Fault

Location in Matrix Description of Function

VH 07

4. Selecting the Analogue Output Offset (4 mA)

Location in Matrix Description of Function

VH 10

5. Selecting the Analogue Output Span (20 mA)

Location in Matrix Description of Function

VH 11

6. Setting the Span Value for the ppm-v Range

Location in Matrix Description of Function

VH 12

If any fault malfunction occurs, the loop can be set to either "10%" (=3.6 mA), to "110%" (=22 mA) or "Hold" (stays at last

valid value).

The dewpoint value corresponding to the analogue output

offset (4 mA) is entered here.

Caution! Ensure this is always at least 20 OC below the value

assigned to 20 mA.

Default: -90 oC

The dewpoint value corresponding to the analogue output span

(20 mA) is entered here.

Caution! Ensure this is always at least 20 oC above the value

assigned to 4 mA.

Default: + 10 oC

Selection of this field sets the span value for the ppm-v range.

NOTE: The offset is always 0 ppm-v. Do not exceed 1000

ppm-v

Default: 100

Installation and Operation Manual

GE General Eastern

17

Page 18

DewPro MMY30

SPECIAL CALIBRATION

7. Adjusting the pressure constant

Location in Matrix Description of Function

VH 30

8. Adjusting the Current Loop at 4 mA

Location in Matrix Description of Function

VH 38

9. Adjusting the Current Loop at 20 mA

Location in Matrix Description of Function

VH 39

The process pressure constant is entered in bar (absolute), which

is used to calculate ppmv. The moisture unit ppmv is the ratio of

water vapor pressure to the total process pressure and is,

therefore, independent of the process pressure. The reason is

that when compressing a gas (process pressure) all partial

pressures increase by the same factor (Daiton's Law).

The gold/aluminum oxide sensor is selective to water vapour

pressure monitoring a higher vapor pressure when the total

pressure (process pressure) increases. The formula utilized by

the analyser refers to the total pressure of 1 bar. An elevated

pressure of the process has to be corrected by programming the

actual process pressure to the matrix field VH 30.

The system should be designed to maintain a constant pressure,

for instance, by using a pressure regulator in a bypass system.

Default: 1 bar (absolute)

By connecting a mA-meter in the loop, the correct current (4 mA)

can be adjusted by increasing or decreasing the displayed digits.

NOTE: If the matrix input is locked (VH89), the calibration values

are displayed but the current output is unaffected. To enable

adjustments, VH89 has to be unlocked by entering "50" into this

field.

Selection of this field assists during calibration generating a

nominal 20 mA signal, but the actual value must be 21,92 mA, an

over range to a dewpoint of 22 oC.

By connecting a ma-meter in the loop, the correct current (21.92

mA) can be adjusted by increasing or decreasing the displayed

digits.

NOTE: If the matrix input is locked (VH89), the calibration values

are displayed but the current output is unaffected. To enable

adjustments, VH89 has to be unlocked by entering "50" into this

field.

Installation and Operation Manual

GE General Eastern

18

Page 19

DewPro MMY30

Installation and Operation Manual

MODE OF OPERATION

10. Input locking

Location in Matrix Description of Function

VH 89

11. Displaying the present Error Code

Location in Matrix Description of Function

VH 90

12. Displaying the previous Error Code

Location in Matrix Description of Function

VH 91

Any number other than "50" will lock the instrument settings

from inadvertent or unauthorized changes. (The instrument is

only unlocked at "50".)

In the event of a system fault, this field displays the diagnostic

error code for the fault encountered.

Error Code

0

1

2

3

4

5

7

When a system fault condition is cleared, the value of the error

code is stored in this location. That is, during normal operation,

the most recent error code is displayed for reference.

Description

No error

Dewpoint underrange. The current

output has fallen below the 4.00 mA

point.

Dewpoint overrange. The current

output has exceeded the 21.92 mA

level.

The instrument is no longer reading

between -90 and -20 'C dewpoint while

in ppm-v mode and has fallen off of the

internal vapor pressure table.

ppm-v overrange. The current output

has exceeded the 20 mA level. Rerange the ppm-v upper scaling limit to

keep this error from occurring.

Sensor is shorted.

Sensor is open.

GE General Eastern

19

Page 20

DewPro MMY30

13. Instrumentation Identification number

Location in Matrix Description of Function

VH 92

14. Identification Field

Location in Matrix Description of Function

VH 93

15. Set to Default Values

Location in Matrix Description of Function

VH 94

16. Resetting the Device

Location in Matrix Description of Function

VH 94

The instrumentation identification number should always read

“100”.

This field indicates the software version (ie. version 2.02 or

higher).

This field sets all factory defaults

NOTE: Anything that has been calibrated will not be reset.

The device is reset in this field.

Note: Reset the device only after field calibration using

the DewComp MCY 40 calibrator.

Installation and Operation Manual

GE General Eastern

20

Page 21

DewPro MMY30

Installation and Operation Manual

5.0 Troubleshooting

5.1 General Recommendations

5.1 General Recommendations

1. The loop current is outside the range of 4-20 mA, as shown on display or

current meter

• The process dewpoint is out of range. If the dewpoint is above + 10

oC (+50 oF), the current will go to 22 mA. Apply dry air for 20

minutes. If the dewpoint doesn't decrease, consult the factory.

• It the dewpoint is below -90 oC (-130 oF), the current will go below 4

mA. Expose the DewPro to ambient air for several minutes. If the

error remains, the cause may be a defective sensor assembly or an

electronics malfunction. Consult the factory.

2. There is no current.

• Check the voltage and polarity across +/- terminals with a DC

voltmeter. If the voltage is within 12-32 V DC, consult the factory.

3. The response time is very slow.

• Verify the flow with an air flow meter. If the orifice is at the outlet of

a 7 to 8 bar (=100 psig) process, the air flow should indicate 20 to

30 1/h (500 cc/min., 1 cfh). If the flow is dramatically lower, the inlet

filter may be clogged. Remove the 2 micron filter and clean it with a

solvent or replace it.

5.2 Removing the Filter

Orifice / Spacer

Sintered Filter

Spring Washer

Retaining Ring

Fig. 17

GE General Eastern

21

Page 22

DewPro MMY30

6.0 Technical Specifications

Sensing element: Planar sensor, aluminum oxide capacitance principle

Measurement range: - 90 oC to + 10 oC (-130 oF to +50 oF) dewpoint temperature.

Optional 0 to 100 ppm-v standard range or up to 1000 ppm-v if specified.

Recommended recalibration cycle: 6 to 12 months, depending on the application and

required accuracy

Calibration accuracy: + /- 2 oC ( +/- 4 oF) dewpoint

Repeatability: +/- 1 oC

Maximum relative humidity: 50% at dewpoint temperatures >0 oC (32 oF)

Temperature coefficient: ∆Td/∆T <0.2 oC / oC (<0.4 oF / oF)

Operating and storage temperature: -40 oC to +60 oC(-40 oF to +140oF)

Air bleed off at 7 to 8 bar (100 psig): approximately 28 l/h (1 cfh) (volume related to

atmospheric pressure)

Maximum operating pressure: 30 bar (450 psig)

Helium leak-rate: <10

Output: 4 to 20 mA; 16 uA resolution

Flow block: 316 stainless steel 1.440/1.4436 with G ½ thread (DIN ISO 228) and VITON

0-ring seal or ½ " MNPT

Filter at inlet: 2 micron

Wrench width for flow block: 42 mm (1 5/8 “)

Electronics: Microprocessor controlled

Moisture unit.. Dewpoint temperature in oC or 0F, ppm-v

Supply power: 24 V DC nominal, tolerance 12 to 32 V DC

Protection: IP 66

Weight: 2 kg (4.4 Ibs)

6.1 Optional Onboard Display with User Interface

The optional onboard display with user interface uses the General Eastem matrix

configurator for:

• range changes

• unit of measure selection

• current loop adjustment

• error diagnostics

• current value selection for fault conditions,

• and entering a pressure constant for ppm-v.

-6

mbar l/s

Installation and Operation Manual

GE General Eastern

22

Page 23

DewPro MMY30

_

E

R

N

Installation and Operation Manual

7.0 Accessories

7.1 Available Accessories

Accessory Description

Single power supply

Panel mount display, power supply, no relays

Panel mount display, power supply, two alarms

Panel mount display, power supply, two alarms. 4 to 20 repeating output

Consult GE General Eastern for further information!

7.2 Example of Power Supplies and Displays

GENE

RAL EAST

T

h

e

H

u

m

i

d

i

t

y

E

x

p

e

r

t

s

Optional loop powered

display available

from General Eastern

Optional loop-powered

display available from

General Eastern

+

Customer’s 24 V (9...32V DC)

or power supply available

from General Eastern

Example

Fig. 18

GE General Eastern

23

Page 24

DewPro MMY30

Installation and Operation Manual

APPENDIX

MMY 30/31 H0H1H2H3H4H5H6H7H8H9

Moisture Unit

V0

Display

Moisture

Value

Select

Moisture Unit

see table

below

Loop 1 at Fault

0= -10%,

1=110%,

2=Hold

Loop 1 Raw

Reading

Loop Range

Constant;

Loop

Hardware

Calibration

Access Key

V1

V2

V3

V4

V5

V6

V7

V8

Dewpoint °C

4 mA

Pressure

Constant for

ppmv comp.

(bar)

Dewpoint °C

20 mA

ppm

mA

v

Loop 1 D/A

Calibration

Low

Loop 1 D/A

Calibration

High

Input Locking

50 = Unlock

Misc. Setup

V9

Display

Present Error

Display

Previous Error

Unit ID

Software

Version

Reset To

Defaults

50 = Reset

GE General Eastern

System Reset

50 = Reset

24

Loading...

Loading...