Page 1

GE Infrastructure

Sensing

Moisture Monitor™ Series 3

Panametrics Hygrometer

Programming Manual

Page 2

GE Infrastructure

Sensing

Moisture Monitor™ Series 3

Panametrics Hygrometer

Programming Manual

910-110PB

February 2005

Moisture Monitor™ is a GE Panametrics product. GE Panametrics has joined other GE high-technology

sensing businesses under a new name—GE Infrastructure Sensing.

Page 3

February 2005

Warranty Each instrument manufactured by GE Infrastructure Sensing, Inc. is

warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to

normal operation or replacing the instrument, at the sole discretion of

GE Infrastructure Sensing, Inc. Fuses and batteries are specifically

excluded from any liability. This warranty is effective from the date of

delivery to the original purchaser. If GE Infrastructure Sensing, Inc.

determines that the equipment was defective, the warranty period is:

• one year for general electronic failures of the instrument

• one year for mechanical failures of the sensor

If GE Infrastructure Sensing, Inc. determines that the equipment was

damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines

specified by GE Infrastructure Sensing, Inc., the repairs are not

covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties of merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

Return Policy If a GE Infrastructure Sensing, Inc. instrument malfunctions within the

warranty period, the following procedure must be completed:

1. Notify GE Infrastructure Sensing, Inc., giving full details of the

problem, and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for

factory service, GE Infrastructure Sensing, Inc. will issue a RETURN

AUTHORIZATION number (RA), and shipping instructions for the

return of the instrument to a service center will be provided.

2. If GE Infrastructure Sensing, Inc. instructs you to send your

instrument to a service center, it must be shipped prepaid to the

authorized repair station indicated in the shipping instructions.

3. Upon receipt, GE Infrastructure Sensing, Inc. will evaluate the

instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Infrastructure Sensing, Inc. determines that the damage is not

covered under the terms of the warranty, or if the warranty has

expired, an estimate for the cost of the repairs at standard rates

will be provided. Upon receipt of the owner’s approval to proceed,

the instrument will be repaired and returned.

iii

Page 4

February 2005

Table of Contents

Chapter 1: Features and Capabilities

Introduction to the Moisture Monitor Series 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Electronics Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

M Series and TF Moisture Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Pressure Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Delta F Oxygen Cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

M Series and TF Series Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Delta F Oxygen Cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Pressure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

RS232 Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2: Basic Programming

Startup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Using the Keypad and Passcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Displaying Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Setting the Backlight Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Viewing or Setting the Clock and Calendar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Accessing System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

v

Page 5

February 2005

Table of Contents (cont.)

Chapter 3: Advanced Programming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Up the Communications Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Using Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Checking the Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Setting Up the Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Storing Logged Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Setting up a Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Viewing Logged Data and Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Description of a Sample Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Entering System Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Entering a Saturation Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Using Computer Enhanced Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Setting Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Reconfiguring a Channel for a New Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Multiple Input Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Entering Calibration Data for New Probes/Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Entering Moisture Curve Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Entering Oxygen Curve Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Entering Pressure Curve Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Entering Auxiliary Input Curve Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Loading New Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Chapter 4: Programming with PanaView

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Changing Measurement Modes and Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Changing Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Changing Recorder Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Setting Recorder Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Testing Recorder Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Programming Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Programming User Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Entering User Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Entering Saturation Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Checking the Battery and Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

vi

Page 6

Chapter 1

Page 7

Features and Capabilities

Introduction to the Moisture Monitor Series 3 . . . . . . . . . . . . . . . . . . . . . 1-1

Electronics Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Page 8

February 2005

Introduction to the Moisture Monitor Series 3

The GE Panametrics Moisture Monitor Series 3 is a one- or twochannel analyzer designed to measure dissolved moisture

concentration in gases and non-aqueous liquids, and dissolved

oxygen concentration in gases.

A microprocessor-based instrument, the Series 3 combines hardware

and software to make various measurements. The user connects the

needed inputs (moisture probes, pressure transmitters, oxygen cells,

etc.) to the back panel of the electronics unit using the appropriate

cables. Typically, the user installs moisture probes and oxygen cells

into the process using a sample system that is specifically designed

for the application. The sample system delivers a sample of the

process gas or liquid to the probes. The probes then send signals to

the Series 3 electronics unit, which interprets the signals and converts

them into measurements.

The complete analyzer, including electronics, cab l es and

measurement probes, forms a “system” that is designed to monitor the

process accurately and reliably. The following sections discuss each

part of this “system.”

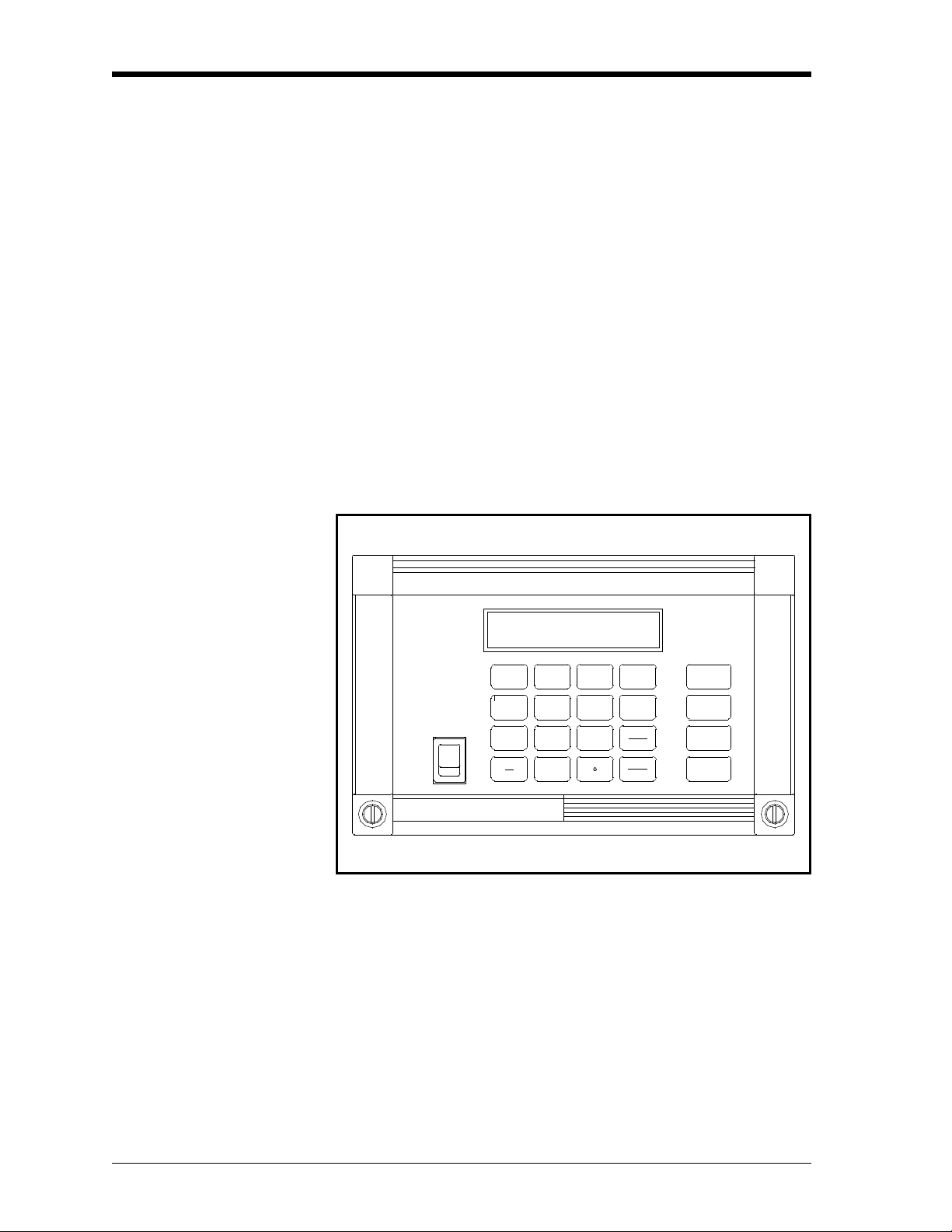

Electronics Unit The center of the “system” is the electronics unit. The electronics unit

has many components, including the terminal blocks for all

connections, an RS232 port, a Liquid Crystal Display (LCD), a

keypad, and menu keys (see Figure 1-1 on page 1-2). The Series 3 is

also available with an optional battery pack.

The back panel of the electronics unit consists of the terminal blocks

for connecting moisture probes, oxygen cells, recorders and optional

alarms (standard or hermetically sealed). The Series 3 also provides

connections for two isolated outputs per channel. Input connections

for the M and TF Series moisture probes, as well as the Delta F

oxygen sensors, are intrinsically safe.

As an optional feature, the Series 3 provides connections for two

auxiliary inputs (not intrinsically safe) for each channel. The auxiliary

inputs can accept signals from any 0/4 to 20-mA or 0 to 2-VDC

device, including other GE Panametrics analyzers.

The RS232 port enables the user to connect a remote terminal, printer,

or computer to the Series 3. Using an optional PanaView™ software

package, the user can also set up and operate one or more analyzers

from a remote location, program user functions, transfer data, and

create data logs.

Features and Capabilities 1-1

Page 9

February 2005

Electronics Unit (cont.) The front panel of the electronics unit contains a 2-line x 20 character

Liquid Crystal Display (LCD) to show measurements, a 4 x 4 matrix

keypad for entering data and operating the Series 3, and four function

keys.

The Series 3 is also available with an optional rechargeable battery

pack that makes it ideal for survey applications. The user can move

the Series 3 from location to location to takes spot samples and store

measurements. When fully charged, the battery pack provides eight

hours of continuous operation.

The BASEEFA-approved electronics unit is available in rack mount,

portable bench mount, and panel mount versions. The electronics unit

is also available in NEMA-4X weatherproof and NEMA-7 explosionproof housings, but these packages are not BASEEFA approved.

IMPORTANT: Only the Series 3’s that have serial numbers 2001

and above are intrinsically sa fe.

MOISTURE MONITOR

SERIES 3

POWER

1

5

4

8

7

0

YES

32

NO

6

9

Figure 1-1: Moisture Monitor Series 3

MODE

CHAN

PROG

RUN

1-2 Features and Capabilities

Page 10

February 2005

Probes Probes are the part of the system that come into contact with the

process flow. The Series 3 uses various types of probes to fit the

needs of different applications.

The term “probe” includes devices such as moisture sensors, pressure

transducers, and oxygen cells. Although users can supply their own

probes for certain measurements, GE Infrastructure Sensing provides

the following standard probes to make moisture, temperature,

pressure, and oxygen measurements:

• Moisture (M) Series - moisture and temperature (in gases and

liquids)

• Three Function (TF) Series - moisture, temperature, and pressure

(in gases and liquids)

• Delta-F Cells - oxygen measurement (in gases).

The most commonly used probes are discussed in more detail below.

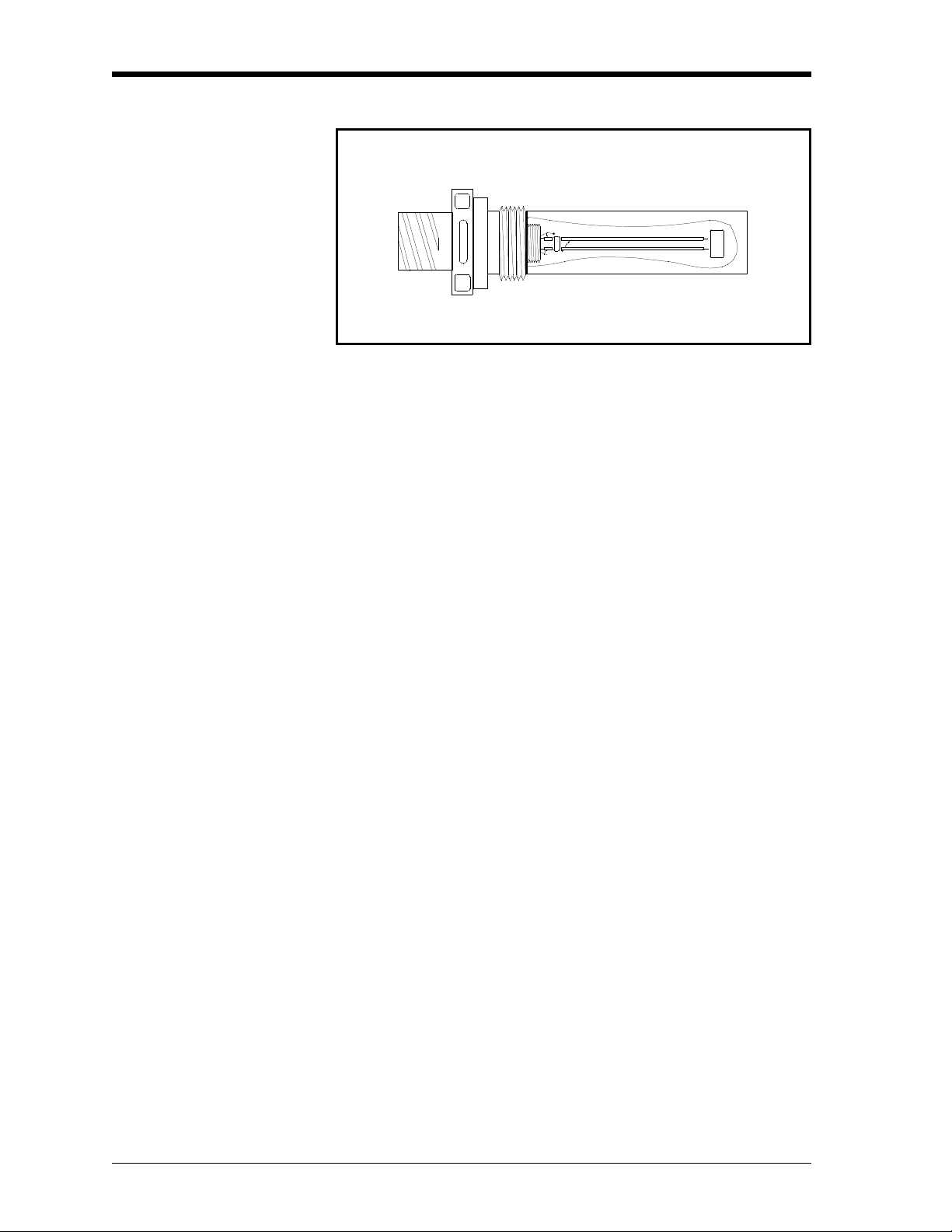

M Series and TF Moisture Probes

The M Series and TF Series probes are very similar. Both probes use

GE aluminum oxide sensors to measure moisture, and thermistors to

measure temperature (the thermistor is optional). The TF Series,

however, has an optional built-in strain-gage-type pressure

transducer. The sensor assemblies are secured to a probe mount and

are usually protected with a sintered stainless-steel shield (TF-9

probes typically do not have a shield). Other types of shields are

available. See Figure 1-2 below and Figure 1-3 on page 1-4.

When using an M Series probe, a separate pressure transmitter is

required if in-line pressure measurement is needed. The Series 3 can

use any pressure transmitter with a 0/4 to 20-mA and/or a 0 to 2-V

output. Alternatively, the user can enter fixed values for temperature

and pressure into the Series 3 memory if the process conditions are

constant.

Figure 1-2: M Series Probe

Features and Capabilities 1-3

Page 11

February 2005

M Series and TF Moisture

Probes (cont.)

Figure 1-3: TF Series Probe

Although the M and TF Series probes may be installed directly into

the process line, they are usually inserted into a sample system. The

sample system protects the probes and enables the user to easily

remove the probes for calibrating, servicing, and cleaning. Sample

systems also control the flow of the process stream so that it is within

the specifications of the measurement probe or cell.

The M and TF Series probes, when operated with a BASEEFAapproved Series 3, are intrinsically safe (see Chapter 3 of the Startup

Guide, Specifications, for BASEEFA certification numbers) and are

designed to meet requirements of IEC/CENELEC zone 0 areas.

The M and TF Series probes measure moisture content in a standard

range from -110°C to 20°C (-166°F to 68°F) dew/frost point

temperature, and optionally from -110°C to 60°C (-166°F to 140° F).

Both probes optionally measure temperature in a range of -30°C to

70°C (-22°F to 158°F).The TF probe optionally measures pressure

from 30-300/50-500/100-1000/300-3000/500-5000 psig.

Pressure Transmitter In addition to the M Series probe, a separate pressure transmitter may

be needed for on-line pressure measurement. Pressure measurement

is a necessary input for conversion to certain moisture parameters,

such as parts per million by volume water vapor in a gas. The Series 3

can use any pressure transmitter with a 0/4 to 20 mA or 0 to 2-V

output. Additionally, constant temperature and pressure can be

programmed into the Series 3 if these process conditions are constant.

Temperature measurement is a necessary input for conversion to

certain moisture parameters, such as parts per million by weight water

vapor dissolved in a liquid. It is also necessary so maximum

temperature/pressure conditions are not exceeded.

1-4 Features and Capabilities

Page 12

February 2005

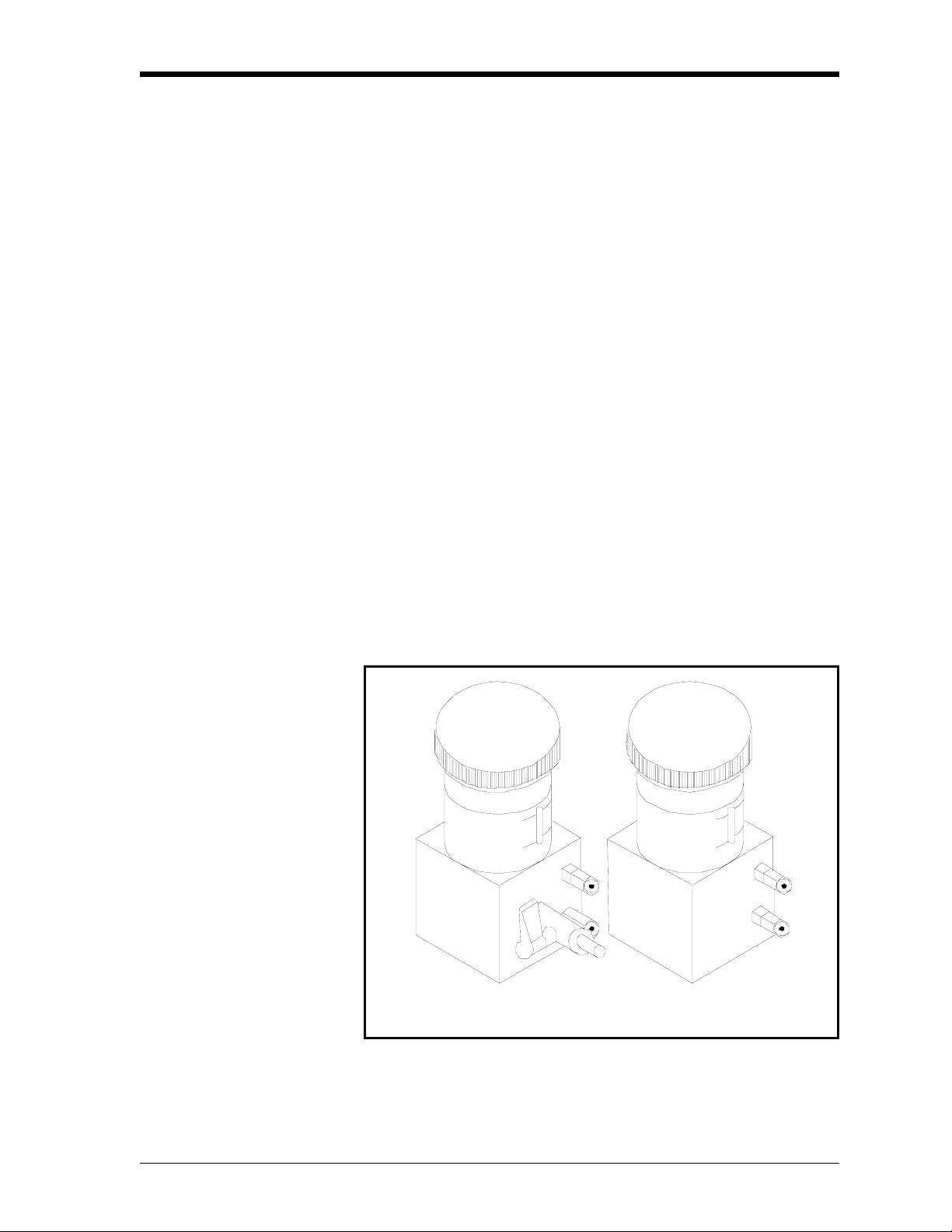

Delta F Oxygen Cell The Series 3 standard oxygen measurement probe is the Delta-F Cell.

Overall oxygen content range measured using this cell is from 0 to

25%. You may choose from seven standard oxygen ranges. The

lowest standard range is 0 to 1/10/100 ppm; the highest standard

range is 0 to 25% oxygen. An ultra-low-range sensor that covers 0500 ppb

Series 3 can also accept oxygen inputs from other GE Panametrics

oxygen sensors using the auxiliary inputs.

If your application has a high concentration of acid-forming

components, GE Infrastructure Sensing supplies a STAB-EL option

for the Delta F Cell. The STAB-EL option is specially designed to

effectively neutralize these components from the sample gas stream.

The Delta F Cell is available in a general purpose model with both a

top and bottom drain, or only a top drain as shown in Figure 1-4

below . The Delta F Cell is usually installed in its own sample system.

The Delta F Cell is optionally available with VCR

in a NEMA-4X enclosure for weatherproof corrosion resistant

applications, or mounted in a NEMA-7 enclosure for hazardous areas.

and is sensitive to less than 5 ppb is also available. The

v

®

fittings, mounted

The Delta F Cell is BASEEFA-approved, and when connected to a

BASEEFA-approved Series 3, provides certified intrinsic safety. See

Chapter 3 of the Startup Guide, Specifications, for certification

numbers.

Bottom Drain

Top Drain

Figure 1-4: Bottom and Top Drain Delta F Oxygen Cells

Features and Capabilities 1-5

Page 13

February 2005

Cabling Each probe requires an interconnecting cable. Cables differ

depending on the probe. The various cables are discussed belo w

under the appropriate probe type. All of the cable assemblies can be

ordered from GE Infrastructure Sensing.

IMPORTANT: See the Calibration Data Sheets, shipped with the

probes, to connect the probes to their corresponding

channels. If a probe is connected to the wrong

channel, the meter will display incorrect data.

IMPORTANT: To maintain good contact at each terminal bl ock and

to avoid damaging the pins on the connector, pull the

connector straight off (not at an angle), make cable

connections while the connector is away from the

unit, and push the connector straight on (not at an

angle) when the wiring is complete.

M Series and TF Series Probes

The M and TF Series Probes are connected to the analyzer with a

special GE Panametrics shielded cable. Probes can be located up to

600 m (2000 ft) from the Series 3 (consult GE Infrastructure Sensing

for distances up to 1,200 m). To measure pressure with a TF Probe,

the maximum cable length is approximately 152 m (500 ft). Small

electrical offsets, especially with longer cables, are possible and

should be corrected as described in Performing a Calibration Test/

Adjustment, on page 1-22 of the Service Manual.

Delta F Oxygen Cell The standard Delta F Oxygen Cells are connected to the analyzer with

a four-wire shielded cable (22 A WG). Oxygen cells with a range from

0 to 1/10/100 ppm

(50 ft) away from the analyzer. All other oxygen cells can be located

up to 91 m (300 ft) away. Consult GE Infrastructure Sensing for

longer cable lengths.

or 0 to 0.5/5/50 ppmv can be located up to 15 m

v

Pressure Sensors The Series 3 accepts either pressure transducers or pressure

transmitters. Most pressure transducers can be connected with a

standard four-wire shielded cable. Most pressure transmitters are

connected using either a two or four-wire non-shielded cable and can

be either loop- or self-powered.

RS232 Communications Port

1-6 Features and Capabilities

A personal computer or serial printer can be connected to the Series 3

RS232 communications port using a standard serial cable. The

Series 3 has a special switch that enables you to configure the unit as

a Data Terminal Equipment (DTE) or a Data Communications

Equipment (DCE) device (see Chapter 1 in the Service Manual for

details on DTE/DCE configuration).

Page 14

February 2005

User Program The Series 3 has a user program that is accessed and controlled by its

keypad and the four function keys. The user program enables the user

to enter the necessary probe data, set up the LCD screen, and control

the operational features of the Series 3. The Series 3 stores this in

battery-backed RAM for up to five years, even when power is off.

The Series 3 user program consists of the following 12 main menus:

• SYSTEM - This menu enables the user to enter calibration and

configurations data.

• AUTOCAL - To compensate for any drift in the electronics, the

user can program the Series 3 to calibrate itself automatically at

pre-selected intervals.

• USER - This menu is used to enter a saturation constant which the

Series 3 requires to measure ppm

menu is also used to select the Enhanced Response option.

in liquids. If applicable, this

w

• LOGGER - In this menu the user can (1) program the Series 3 to

log data at pre-selected time intervals, and (2) access the logged

data for viewing.

• TEST - This menu allows the user to test the alarm relays and the

recorder outputs.

• CONTRAST - In this menu the user can adjust the contrast of the

display screen to adapt to lighting conditions.

• BACKLIGHT - T o maintain the life of the LCD backlight, the user

can program the electronics unit to turn the backlight off

automatically after a predetermined time period.

• CLOCK - This menu enables the user to set and/or view the clock

and calendar.

• PORT - In this menu, the user can select the baud rate, report

format and interval for transmitting measurements and logged data

over the RS232 communications port.

• ALARMS - The Series 3 can be equipped with two optional alarm

relays (high and low) for each channel. The user can set up both

alarms for any of the available measurement modes and units.

• RECORDERS - The Series 3 has two recorder outputs (A and B)

for each channel. The user must set up the output ranges for each

recorder and each channel.

• SysInfo - This menu supplies basic information on the serial

number, program, run time and boot device for a user’s particular

Series 3.

Features and Capabilities 1-7

Page 15

Chapter 2

Page 16

Basic Programming

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Displaying Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Setting the Backlight Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Viewing or Setting the Clock and Calendar . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Page 17

February 2005

Startup Procedure Sensor configuration and system calibration data for your Series 3 are

entered at the factory . After you un pack the unit, use the sections that

follow to verify that your system is working properly and set up the

screen to display the desired measurements.

Powering Up The Series 3 has a universal power supply that automatically adjusts

to line voltages from 95 to 260 VAC, and a portable battery pack

(optional). After making electrical connections as described in

Chapter 1 of the Startup Guide, press the

Series 3.

IMPORTANT: For compliance with the EU’s Low V oltage Directive

(IEC 1010), this unit requires an external power

disconnect device such as a switch or circuit br eaker.

The disconnect device must be marked as such,

clearly visible, directly accessible, and located

within 1.8 m (6 ft) of the Series 3. The power line is

the main disconnect device.

[ON] switch to power up the

Caution!

Do not operate the Delta F Oxygen Cell for extended

periods of time at oxygen concentrations that are over

range. Trace and low percent range sensors may be

damaged if exposed to high levels of oxygen, such as air,

for long periods (>1 hour) while the Series 3 is on.

If exposure is unavoidable, either disconnect the oxygen

cell from the Series 3 or equip the sample system with a

valve that allows the cell to be switched to purge gas.

The Series 3 normally shows a series of messages that indicate it is

functioning normally, and then begins displaying data.

Basic Programming 2-1

Page 18

February 2005

Using the Keypad and Passcode

Use the following sections to become familiar with the key functions

and discover the passcode number you will need to access the user

program.

Key Functions The function keys to the right of the keypad are used in the following

manner:

• [MODE] - modifies or selects the measurement mode to display.

• [CHAN] - toggles between channels (only works with units that have

two channels installed).

• [PROG] - accesses the user program.

• [RUN] - exits the Modify Display Mode or the user program (except

during numeric entry) and returns to displaying measurements.

The keypad below the Series 3 screen consists of 16 keys (including

the [.] and [–] symbols), two arrow keys, and two response keys,

[YES] and [NO]). The numeric keys are for numeric entry only;

(

however, the arrow and response keys have more than one function.

The arrow keys perform three functions:

• arrow keys - scroll through the screen selections by moving the

brackets forward or backward to the desired location.

• left arrow key - moves backward and erases during numeric entry.

• right arrow key - moves the cursor to the desired location during

numeric entry and accepts a change at the present location.

The response keys perform three functions:

• [YES] or [NO] - respond to questions and/or exit a screen.

• [YES] - confirms an entry or retrieves a previous number after you

erase it.

• [NO] - moves backward through the menu.

IMPORTANT: After pressing a key, wait for the unit to perform the

desired function before executing another key

function.

Passcode To enter the user program you must enter a passcode. The passcode

prevents unauthorized users from changing data. When entering the

user program, the Series 3 prompts for the passcode. Refer to the end

of this chapter for your default passcode.

2-2 Basic Programming

Page 19

February 2005

Displaying Measurements

The Series 3 begins displaying measurements immediately after

power-up. It provides two lines in order to display measurements.

You may select the measurement mode for each line as described in

the procedure below.

Since the display has a limited amount of space, the Series 3 uses

abbreviations to represent the displayed measurement mode and units

as shown in Table 2-3 on page 2-5.

Press the

Display Page: 1

Press YES to Edit

[MODE] key to enter the Modify DSP Mode.

The Series 3 can display six

pages of measurements, each

showing two different

parameters. Use the numeric

keys to enter the desired page

[YES].

[YES].

Modify DSP Mode P1

LINE1 [LINE2]

and press

Use the arrow keys to move the

brackets to the desired line you

want to edit and press

Line 2 DSP Mode P1

[CH 1] CH 2

Select DSP Mode P1

_[H] T P Aux1`

Use the arrow keys to move the

brackets to the desired channel

you want to display and press

[YES].

Use the arrow key to move the

brackets to the measurement

mode and press

[YES]. See

Table 2-1 on page 2-4 for a list

of the available measurement

modes.

Basic Programming 2-3

Page 20

February 2005

Displaying

Measurements (cont.)

Table 2-1: Measurement Modes

Display Abbreviation Measurement Mode

O Oxygen

HHygrometry

T Temperature

PPressure

AUX1 Auxiliary 1

AUX2 Auxiliary 2

USER* User Function

VREF Volt Reference

GND Signal Ground

*User functions are only available through PanaView software.

For more information, refer to Chapter 4.

When selecting a measurement mode, please remember that some

measurement modes require multiple inputs. For example, to display

, you need a moisture and pressure input. Table 2-2 below shows

ppm

v

a list of measurement modes that require multiple inputs and what

you need to display them. If the Series 3 displays “No Data,” you may

have to reconfigure the channel. Refer to Reconfiguring a Channel

for a New Sensor on page 3-31.

Table 2-2: Measurement Modes and Required Inputs

To measure: You need the following inputs:

RH Temperature and moisture

PPM

v

PPM

w

MCF/IG Moisture and pressure

MCF/NG Moisture and pressure

PPM

/NG Moisture and pressure

v

.

Select HYGRO Unit L1

[DP/°C] DP/ °F `

Moisture and pressure

Moisture, temperature and

saturation constant data

Use the arrow keys to move the

brackets to the measurement

units and press

[YES].

Repeat this procedure to set up the other line. When you are done,

[RUN].

press

2-4 Basic Programming

Page 21

February 2005

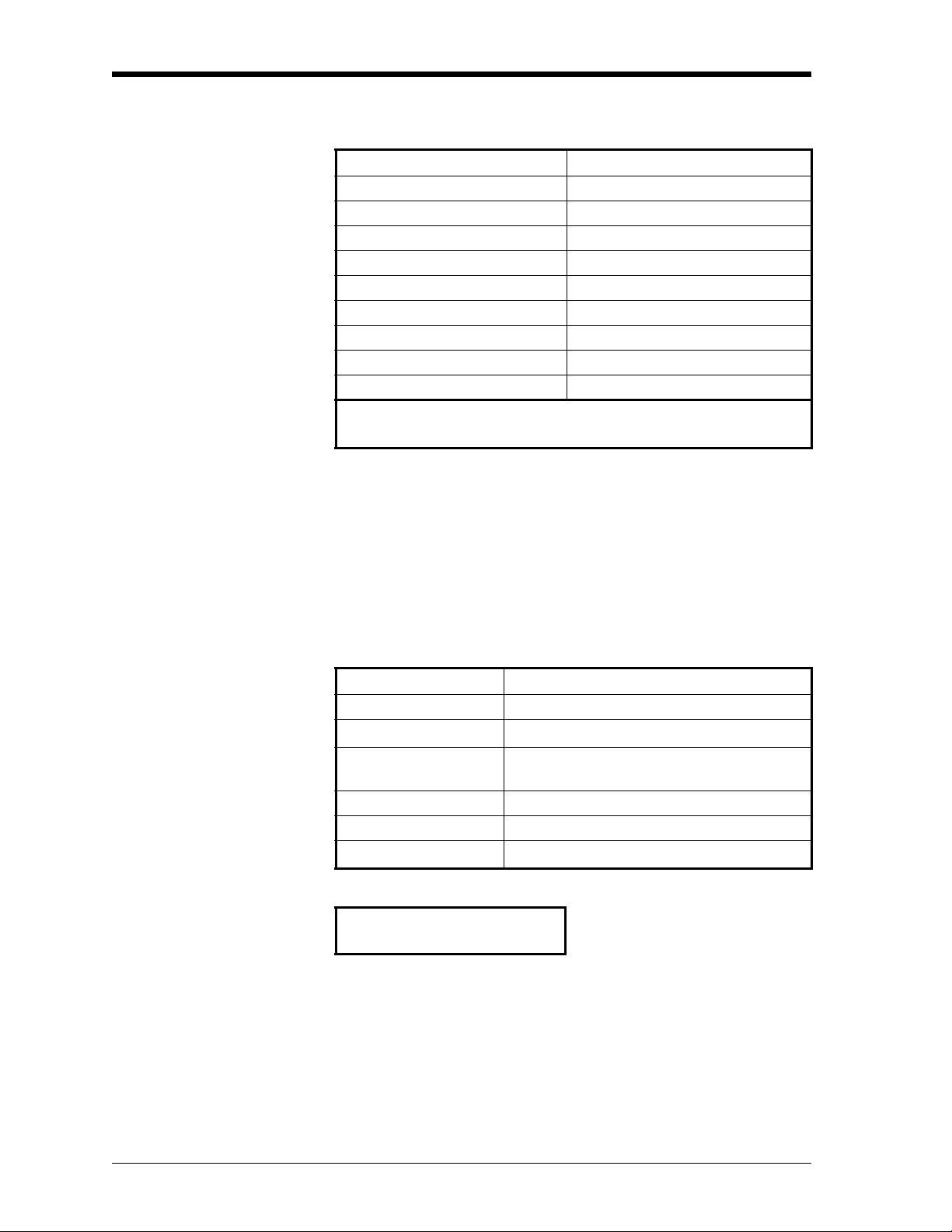

Table 2-3: Measurement Modes and Units for the Series 3

Selected Meas.

Mode Description of Units

%= Percent Oxygen default O%

ppm

= Parts Per Million by volume O PPMv

Oxygen

Hygrometry

Temperature

Pressure

Auxiliary 1

Auxiliary 2

Volt Reference VREF = Volts default (Diagnostic Mode)

Signal Ground GND = Volts default (Diagnostic Mode)

v

µA = Microamps (Diagnostic Mode) O µA

DVM = Digital Voltmeter (Diagnostic Mode) O VDC

°C = Dew/Frost Point default DP °C

°F = Dew/Frost Point °F DP °F

K = Dew/Frost Point K (Kelvin) DP K

R.H. = Relative Humidity H %

H/ppMv = Parts per Million of Water by Volume H HPMv

H/ppMw = Parts per Million of Water by Weight (for liquids only) H ppMw

MCF/IG = Pounds of Water per Million Std. Cubic Feet in Ideal Gas H Ilbs

MCF/NG = Pounds of Water per Million Std. Cubic Feet in Natural Gas H Nlbs

ppMv/NG = Parts Per Million by Volume in Natural Gas H NPMv

Pw/mmHg = Vapor Pressure of Water in mmHg H mmHg

Pw/Pa = Vapor Pressure of Water in Pascals H Pa

MH = MH* (Diagnostic Mode) H MH

DVM = Digital Voltmeter (Diagnostic Mode) H VDC

°C = Degrees Celsius default T°C

°F = Degrees Fahrenheit T °F

K = Kelvin TK

DVM = Digital Voltmeter (Diagnostic Mode) T VDC

PSIg = Pounds per Square Inch Gauge default PPSIg

Bars = Bars P Bars

mbs = Millibars P mbs

mm/Hg = Millimeters of Mercury P mmHg

Pas = Pascal P Pg

kPas = KiloPascal P KPg

pMV = Pressure in millivolts P mV

DVM = Digital Voltmeter (Diagnostic Mode) P VDC

VDC X1 VDC

mA X1 mA

Func X1 none

VDC X2 mV

mA X2 mA

Func X2 none

*The MH value is the moisture sensor’s response value and is the value which is recorded during calibration.

Displayed

Meas. Mode

VR

Displayed

Units

VDC

Basic Programming 2-5

Page 22

February 2005

Setting the Backlight Timer

The Series 3 has a backlight timer which is provided with batterypowered units to preserve battery power and prolong the life of the

LCD.

Press the

Enter Passcode: XXXX

[PROG] key to enter the user program.

Enter the passcode.

Note: If you have already entered the user program, refer to the

menu maps at the end of Chapter 3 to navigate to the

Backlight Menu.

Programming Menu 1

_[BACKLIGHT]`

Backlight On Time 1

00:05 (HH:MM)

Use the arrow keys to move the

brackets to BACKLIGHT and

[YES].

press

Enter the desired time interval

and press

[YES]. If you do not

want to use the backlight, enter 0

(zero).

You may now do one of the following:

• Refer to another section and perform a different procedure. Refer

to the menu maps at the end of Chapter 3 to navigate through the

user program.

• Exit by pressing the [RUN] key.

2-6 Basic Programming

Page 23

February 2005

Viewing or Setting the Clock and Calendar

Use the steps below to view or set the clock and calendar.

Press the

Enter Passcode: XXXX

[PROG] key to enter the user program.

Enter the passcode.

Note: If you have already entered the user program, refer to the

menu maps at the end of Chapter 3 to navigate to the Clock

Menu.

Programming Menu 1

_ BACKLIGHT [CLK]`

Use the arrow keys to move the

brackets to CLOCK and press

[YES].

Clock Menu 1

[SHOW] SET

Use the arrow keys to move the

brackets to the desired selection

and press [YES].

If you select SHOW:

Clock Menu 1

12:14 06/01/1997

The time and date appear. Press

[YES] to return to the

Programming Menu.

If you select SET:

Use the arrow keys to move the cursor, and then enter the correct

information. The cursor automatically jumps to the next position.

When you are done making changes, press [YES] to confirm your

entry. Then press [NO] to leave the Clock Menu and return to the

Programming Menu.

You may now do one of the following:

• Refer to another section and perform a different procedure. Refer

to the menu maps at the end of Chapter 3 to navigate through the

user program.

• Exit by pressing the [RUN] key.

Basic Programming 2-7

Page 24

February 2005

Accessing System Information

If you need to confirm the system information on your particular

Series 3 unit, the user program includes a menu, SysInfo, that

supplies the serial number, run time and boot device for your meter.

Press the [PROG] key to enter the user program.

Enter Passcode: XXXX

Enter the passcode.

Note: If you have already entered the user program, refer to the

menu maps at the end of Chapter 3 to navigate to the SysInfo

Menu.

Programming Menu 1

_ [SysInfo]

Use the arrow keys to move the

brackets to SysInfo and press

[YES].

System Information

[PROGRAM] UpTime`

Use the arrow keys to move the

brackets to the desired selection

and press

[YES].

If you select PROGRAM:

Code:MMS3.STD.003C

Mfg. 9/21/00

If you select UpTime:

Up Time; 0 Days

5 Hrs 36 Min

If you select BootDevice:

Boot device is

Flash

The program code and

manufacturing date appear,

followed by the serial number

and PCI number. The program

then returns to the SysInfo menu.

The screen briefly displays the

time the Series 3 has run since it

was turned on, and then returns

to the SysInfo menu.

The screen briefly displays the

type of boot device installed, and

then returns to the SysInfo menu.

2-8 Basic Programming

Page 25

February 2005

Accessing System

Information (cont.)

You may now do one of the following:

• Refer to another section and perform a different procedure. Refer

to the menu maps at the end of Chapter 3 to navigate through the

user program.

• Exit by pressing the [RUN] key.

Basic Programming 2-9

Page 26

Your passcode is 2719.

Please remove this page and put it in a safe place for future reference.

Page 27

Chapter 3

Page 28

Advanced Programming

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Up the Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Using Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Checking the Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Setting Up the Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Description of a Sample Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Entering System Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Entering a Saturation Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Using Computer Enhanced Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Setting Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Reconfiguring a Channel for a New Sensor . . . . . . . . . . . . . . . . . . . . . . . 3-31

Entering Calibration Data for New Probes/Sensors. . . . . . . . . . . . . . . . 3-35

Loading New Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

Page 29

February 2005

Introduction Now that the Series 3 is running and the screen is set up, you may

want to use the other operational features included in this chapter (see

the previous page for the list and locations of those features).

Setting Up the Alarms The Series 3 can be equipped with an optional high and low alarm

relay for each channel.

Press the [PROG] key to enter the user program.

Enter Passcode: XXXX

Enter the passcode.

Note: If you have already entered the user program, see Figure 3-3

on page 3-45 to navigate to the Alarms Menu.

Programming Menu 1

_ [ALARMS] `

Use the arrow keys to move the

brackets to ALARMS and press

[YES].

Be sure the number displayed in the upper right-hand corner of the

screen is the channel you want to program. If not, press the [CHAN]

key to select the desired channel.

Select Alarm 1

[A] B

Use the arrow keys to move the

brackets to the desired alarm

(A or B) and press

[YES].

The Series 3 briefly flashes a message, “Relay Status -- Reset,” and

then displays the next prompt.

Select Mode 1

O [H] T P Aux1`

Use the arrow keys to move to

the desired measurement mode

and press

[YES]. See T able 3-1 on

page 3-2 for a list of available

measurement modes.

Advanced Programming 3-1

Page 30

February 2005

Setting Up the Alarms

(cont.)

Table 3-1: Measurement Modes

Display Abbreviation Measurement Mode

O Oxygen

HHygrometry

T Temperature

P Pressure

Aux 1 Auxiliary 1

Aux 2 Auxiliary 2

User* User Function

Vref Volt Reference

Gnd Signal Ground

*User functions are available only through PanaView software

(refer to Programming User Functions in Chapter 4).

Select Unit 1

[DP/°C] DP/ °F `

Use arrow keys to move the

brackets to the desired units and

press [YES].

Note: The number of measurement choices and the units of

measurement vary depending on the measurement mode

selected.

Select Trip Type 1

[Above] Below

Use the arrow keys to move the

brackets to the desired trip type

(whether you want the alarm to

trip above or below the

programmed value) and press

[YES].

A Setpoint DeadBD 1

+0.0 +0.0

Use the numeric keys to enter the

setpoint (the value above or

below which you want the alarm

to trip) and press [YES] to

confirm the entry. If you wish to

enter a deadband value

(explained on the next page),

press the right arrow key to reach

the value, use the numeric keys

to enter the value, and press

[YES].

3-2 Advanced Programming

Page 31

February 2005

Setting Up the Alarms

(cont.)

The deadband allows users to set a programmable range of (normally

small) values beyond the setpoint, so that the Series 3 will not trigger

an alarm unless the measured value goes outside the deadband range.

On a High (Above) alarm, the alarm will trip if the measurement is

greater than or equal to the setpoint. It will not RESET until the

measurement is less than the setpoint minus the deadband. However,

on a Low (Below) alarm, the alarm will trip if the measurement is less

than or equal to the setpoint. It will not RESET until the measurement

is greater than the setpoint plus the deadband.

You may now do one of the following:

• Set up the alarms for the other channel (page 3-1). Begin by

checking the channel number.

• Refer to another section and perform a different procedure. Refer

to the menu maps at the end of this chapter to navigate through the

user program.

• Exit by pressing the [RUN] key.

Advanced Programming 3-3

Page 32

February 2005

Setting Up the Recorders The Series 3 has two recorder outputs (A and B) for each channel.

IMPORTANT: Switch Blocks must be set to the appropriate

positions for output ranges (see Setting the Switch

Blocks in Chapter 1 of the Service Manual).

Press the

Enter Passcode: XXXX

[PROG] key to enter the user program.

Enter the passcode.

Note: If you have already entered the user program, see Figure 3-3

on page 3-45 to navigate to the Recorder Menu.

Programming Menu 1

_[RECORDERS]`

Use the arrow keys to move the

brackets to RECORDER and

press [YES].

Be sure the number displayed in the upper right-hand corner of the

screen is the channel you want to program. If not, press the

[CHAN]

key to select the desired channel.

Select Recorders 1

[A] B

Use the arrow keys to move the

brackets to the desired recorder

and press [YES].

Select RCD Range 1

[0-20mA] 4-20mA `

Use the arrow keys to move the

brackets to the desired recorder

range and press [YES].

Select Mode 1

O [H] T P Aux1`

Use the arrow keys to move to

the desired measurement mode

and press [YES]. See T able 3-2 on

page 3-5 for a list of available

measurement modes.

3-4 Advanced Programming

Page 33

February 2005

Setting Up Recorders

(cont.)

Table 3-2: Measurement Modes

Display Abbreviation Measurement Mode

O Oxygen

HHygrometry

T Temperature

PPressure

Aux 1 Auxiliary 1

Aux 2 Auxiliary 2

User* User Function

Vref Volt Reference

Gnd Signal Ground

*User functions are available only through PanaView software

(refer to Programming User Functions in Chapter 4).

Select Units 1

[DP/°C] DP/°F`

Use arrow keys to move the

brackets to the desired units and

[YES].

press

Note: The number of measurement choices and the units of

measurement vary depending on the measurement mode

selected.

Set RCD-A OUTPUT 1

[ZERO] SPAN

RCD-A Zero Setup 1

20.0

Use the arrow keys to move the

brackets to ZERO and press

[YES].

Enter the zero value and press

[YES]. Then press [NO] to

return to the previous screen.

Repeat the two final steps to enter the span value.

You may now do one of the following:

• Set up another recorder by pressing [NO] until you return to the

Select Recorder step, and then begin with the recorder selection

step (refer to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45

for a menu map of the user program).

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [RUN] key.

Advanced Programming 3-5

Page 34

February 2005

Setting Up the Communications Port

The Series 3 can transmit measurements and logged data to a serial

printer or personal computer using the RS232 communications port.

You can select the baud rate, report format and interval as described

below. Other serial port settings are set and cannot be changed:

• 8 bit word length

• no parity

• 1 stop bit

• flow control is not supported.

IMPORTANT: For proper operation, make sure the RS232 switch is

set correctly (see Connecting a P ersonal Computer or

Printer in Chapter 1 of the Service Manual).

Press the

Note: If you have already entered the user program, see Figure 3-3

[PROG] key to enter the user program.

on page 3-45 to navigate to the Port Menu.

Enter Passcode: XXXX

Programming Menu 1

_ [PORT] ALARMS `

Enter the passcode.

Use the arrow keys to move the

brackets to PORT and press

[YES].

Port Menu 1

[BAUD] FORMAT

Use the arrow keys to move the

brackets to one of the selections

and press

[YES].

IMPORTANT: T o ensur e the communications port is set up pr operly ,

you should check all the selections in the Printer

Port Menu.

If you selected BAUD:

Select Baud Rate 1

_19200 [9600] `

Use the arrow keys to select the

desired baud rate and press

[YES].

Note: If you are using PanaView™ software, set the baud rate to

19,200.

3-6 Advanced Programming

Page 35

February 2005

Setting Up the

Communications Port

(cont.)

If you selected FORMAT:

Refer to page 3-19 for a sample output and description of report data.

Format Menu

[PRINTER]`

Use the arrow keys to select the

desired report format (either

printer or PanaView) and press

[YES].

If you selected PRINTER:

Enter Interval 1

90:00 (MM:SS.)

Enter the interval (0 to 90

minutes) at which you want the

Series 3 to transmit data and

[YES].

press

Note: Enter 0 (zero) as the interval to print at the unit’s update rate.

If you selected PANAVIEW:

Enter Node ID 1

16

Unless you are instructed to

change the Node ID number by

the factory, please leave the

number at the default ID of 16.

You may now do one of the following:

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [RUN] key.

Advanced Programming 3-7

Page 36

February 2005

Using Automatic Calibration

The Series 3 automatically calibrates itself (Auto-Cal) at userselectable intervals. Auto-Cal compensates for any drift in the

electronics. GE Infrastructure Sensing recommends setting the AutoCal interval to eight hours (480 minutes). Set a smaller interval to

Auto-Cal more frequently if the Series 3 is exposed to extreme

temperatures or weather conditions.

Press the

Enter Passcode: XXXX

[PROG] key to enter the user program.

Enter the passcode.

Note: If you have already entered the user program, see Figure 3-2

on page 3-44 to navigate to the Autocal Menu.

Programming Menu 1

SYSTEM [AUTOCAL]`

Use the arrow keys to move the

brackets to AUTOCAL and

press [YES].

Be sure the number displayed in the upper right-hand corner of the

screen is the channel you want to program. If not, press the

[CHAN]

key to select the desired channel.

Autocal Interval 1

01:00 (HH:MM)

Enter an Auto-Cal interval

between 0 and 24 hours and

[YES].

press

After you exit the user program, the Series 3 immediately performs

Auto-Cal. The next time Auto-Cal occurs will depend on the length of

the time interval set, as shown in the example below.

Example:

The Series 3 establishes a fixed schedule, beginning at Midnight,

using the interval specified to determine the times of subsequent

Auto-Cals. For example, if you enter a 90 minute time interval,

Auto-Cal will occur 16 times per day:

(1 day =1440 minutes ÷ 90 minutes = 16).

The fixed schedule will be as follows:

1. 1:30 a.m. 9. 1:30 p.m.

2. 3:00 a.m. 10. 3:00 p.m.

3. 4:30 a.m. 11. 4:30 p.m.

4. 6:00 a.m. 12. 6:00 p.m.

5. 7:30 a.m. 13. 7:30 p.m.

6. 9:00 a.m. 14. 9:00 p.m.

7. 10:30 a.m. 15. 10:30 p.m.

8. 12:00 p.m. (Noon) 16. 12:00 a.m. (Midnight)

3-8 Advanced Programming

Page 37

February 2005

Using Automatic

Calibration (cont.)

If you set the 90 minute Auto-Cal interval at 6:10 p.m., the next

Auto-Cal will occur at 7:30 p.m. (excluding the Auto-Cal performed

when first leaving the Autocal Menu).

If you enter a time interval that is not evenly divisible into 1440

minutes (1 day), the Series 3 rounds up to the next acceptable

interval.

You may now do one of the following:

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [RUN] key.

Advanced Programming 3-9

Page 38

February 2005

Checking the Battery Status

If your Series 3 has the battery pack, you should periodically monitor

the amount of charge the battery has left, as described below.

Disconnect the AC power. Press the

[PROG] key to enter the user

program.

Enter Passcode: XXXX

Enter the passcode.

Note: If you have already entered the user program, see Figure 3-3

on page 3-45 to navigate to the Test Menu.

Programming Menu 1

_[TEST] CONTRAST`

Test Menu 1

_[BATTERY]

Use the arrow keys to move the

brackets to TEST and press

[YES].

Use the arrow keys to move the

brackets to BATTERY and press

[YES].

Battery Test

[STATUS] RdChgTime

Battery Status (v)

XX.XX Press [YES]

Run Time Left (min)

XXX

Use the arrow keys to move the

brackets to STATUS and press

[YES].

The Series 3 alternates two

displays showing the battery

voltage and how much longer the

battery will operate (in minutes).

3-10 Advanced Programming

Page 39

February 2005

Checking the Battery

Status (cont.)

When the battery voltage reads:

• 12.0 Volts - the battery is fully charged and will supply

approximately 480 minutes (8 hours) of power.

• 11.4 Volts - the Series 3 displays the low battery message (refer to

Recharging the Battery Pack in Chapter 2 of the Service Manual).

• 10.9 Volts - the Series 3 will shut down (refer to Recharging the

Battery Pack in Chapter 2 of the Service Manual).

Note: Continuous use of the backlight and alarms shortens the

battery life by 1-2 hours from the estimated battery life

displayed on the screen.

[YES] to proceed.

Press

You may now do one of the following:

• Recharge the battery as described in Recharging the Battery Pack

in Chapter 2 of the Service Manual.

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [RUN] key.

Advanced Programming 3-11

Page 40

February 2005

Setting Up the Data Logger

The Series 3 has a data logging feature that enables you to internally

store and view data. Data is logged at user-selected time intervals and

is stored in the unit’ s SRAM memory or in an optional PCMCIA card.

You may choose up to twelve (12) para meters to log at a time. Since a

fixed amount of memory is assigned to data logging, the more

parameters you select and the more frequent the time interval, the

sooner the available memory will be filled. The Series 3 has a status

screen that lists the number of records, bytes free, bytes used, and the

remaining hours and minutes the log will run before running out of

memory.

Press the

Enter Passcode: XXXX

Note: If you have already entered the user program, see Figure 3-2

Programming Menu 1

_USER [LOGGER]`

[PROG] key to enter the user program.

Enter the passcode.

on page 3-44 to navigate to the Logger Menu.

Use the arrow keys to move the

brackets to LOGGER and press

[YES].

You can do one of the following:

• Indicate how to store logged data, as described in Storing Logged

Data on page 3-13.

• Select measurements you want to log as described in Setting Up a

Log on page 3-14.

• View logged data or the status of the log as described in Viewing

Logged Data and Status on page 3-17.

• Exit by pressing the [RUN] key.

3-12 Advanced Programming

Page 41

February 2005

Storing Logged Data

Data Logging 1

[STORAGE] SETUP`

Select Storage 1

[A] B

# Bytes Free: 65269

# Bytes Used: 839

Records: 78

Rem: 23:46:44

You may now do one of the following:

Use the arrow keys to select

STORAGE and press

[YES].

Use the arrow keys to select A

(for internal storage) or B (for a

PCMCIA card) and press

[YES].

Two displays briefly appear

before the program returns to the

Data Logging menu.

• Set up a log as described in Setting up a Log on page 3-14.

• View logged data or the status of the log as described in Viewing

Logged Data and Status on page 3-17.

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [RUN] key.

Advanced Programming 3-13

Page 42

February 2005

Setting up a Log

Data Logging 1

_ [SETUP] VIEW

Use the arrow keys to select

SETUP and press

[YES].

Create New Log? 1

Press YES or NO

Be sure the number displayed in the upper right-hand corner of the

screen is the channel you want to log. If not, press the

select the desired channel.

Press [YES] to create a new log, or

[NO] to return to the previous

screen.

[CHAN] key to

Cyclic: 1

[NO] YES

Error Log: 1

[NO] YES

Start: 1

10/03/2000 12:01:14

End: 1

10/03/2000 12:01:14

Use the arrow keys to indicate

whether or not you want a cyclic

(circular) log. Press

[YES] to

confirm your entry.

Use the arrow keys to indicate

whether or not you want to

record errors. Press

[YES] to

confirm your entry.

Use the arrow keys to move from

one digit of the starting date and

time to another, and use the

numeric keys to change an entry.

Press [YES] to confirm your

entry.

Use the arrow keys to move from

one digit of the end date and time

to another, and use the numeric

keys to change an entry. Press

[YES] to confirm your entry.

Interval: 1

00:05

Use the numeric keys to enter the

desired log interval in minutes

and seconds (down to 5 sec).

[YES] to confirm the entry.

Press

Enter Log#: (1-12) 1

1

3-14 Advanced Programming

Enter the log item number and

[YES].

press

Page 43

Setting up a Log (cont.)

February 2005

Sel. DATA LOG Mode 1

[O] H T P Aux1`

Use the arrow keys to move to

the desired measurement mode

and press

[YES]. See Table 3-3

below for a list of available

measurement modes

.

Table 3-3: Measurement Modes

Display Abbreviation Measurement Mode

OOxygen

HHygrometry

TTemperature

P Pressure

Aux 1 Auxiliary 1

Aux 2 Auxiliary 2

User* User Function

VREF Volt Reference

GND Signal Ground

*User functions are available only through PanaView software

(see Programming User Functions in Chapter 4).

Datalog HYGRO Unit 1

[DP/°C] DP°F`

Use arrow keys to move the

brackets to the desired units and

[YES].

press

Note: The number of measurement choices and the units of

measurement vary depending on the measurement mode

selected.

Finished (YES/NO)?

If you press [NO], the menu

returns to the “Enter Log#”

prompt. Repeat the preceding

steps to select the remaining

measurements you want to log

(up to 12). When you have

finished entering items and

[YES].

Start Logging?

Press [YES] or [NO]

parameters, press

Press [YES] to begin logging, or

[NO] to leave the menu without

logging.

Advanced Programming 3-15

Page 44

February 2005

Setting up a Log (cont.) You may now do one of the following:

• Indicate how to store logged data, as described in Storing Logged

Data on page 3-13.

• View logged data or the status of the log as described in Viewing

Logged Data and Status on page 3-17.

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [RUN] key.

3-16 Advanced Programming

Page 45

February 2005

Viewing Logged Data and Status

Data Logging 1

SETUP [VIEW]

View Data Log 1

[STATUS] DATA

Use the arrow keys to select

VIEW and press

[YES].

Use the arrow keys to move the

brackets to one of the selections

and press

[YES].

If you selected STATUS:

Storage: Internal

The log status will display each

of the following screens for two

seconds before returning to the

# Bytes Free: 65269

# Bytes Used: 839

Records: 78

Rem: 23:46:44

Data Logging menu.

To view data, refer back to the “View Data Log” option above in the

Data Logging menu. If you are done, skip to page 3-18.

If you selected DATA:

Searching . . .

Log Started at:

10/3/00 14:33

TIME CH1:02%:

14:36:55 ERR01

The Series 3 displays data

similar to the following:

Use the following keys to view data:

• Use the arrow keys to scroll to the desired measurement parameter

to view (e.g., temperature, oxygen).

• Use the [1] key to view the next measurement taken at the specified

interval (e.g., move from the measurement logged at 17:35 to the

measurement logged at 17:36).

• Use the [3] key to scroll to the previous measurement recorded at

the specified interval (e.g., move from measurement logged at 4:01

to the measurement logged at 4:00).

• Press [NO] to end viewing data. To view the status, refer back to

Step 2. If you are done, proceed to page 3 - 18.

Advanced Programming 3-17

Page 46

February 2005

Viewing Logged Data and

Status (cont.)

You may now do one of the following:

• Indicate how to store logged data, as described in Storing Logged

Data on page 3-13.

• Set up another log as described in Setting up a Log on page 3-14.

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [RUN] key.

3-18 Advanced Programming

Page 47

February 2005

Description of a Sample Output

Figure 3-1 below shows a typical data record. Each record displays:

message ID, date, time, channel, mode/unit, data, and carriage return.

Time

Channel

Mode/Unit

Data

Carriage

Return

Figure 3-1: Record Sample

Message ID

Date

*D 06/1/97 11:50:07 1:DP/C=18.0 1:T/C=35.9<CR/LF>

Note: The length of the line depends on how many characters your

screen has per line, or the width of the page.

Message ID Every record begins with the Message ID that consists of an asterisk

(*) and the report type. *D denotes a Display (Matrix) report and *L

denotes a Log Report. The Message ID is always followed by one

ASCII space.

Date The date of the report is shown in MM/DD/YY format. The Series 3

uses a zero as a column place holder, so the date will always be eight

characters long. The date is always followed by one ASCII space.

Time The time of the report is shown in HH:MM:SS format. Time is in 24-

hour format. The Series 3 uses a zero as a column place holder, so the

time will always be eight characters long. The time is always

followed by one ASCII space.

Channel The channel is a single digit from 1 to 6, and is the channel from

which the displayed measurement was read. The channel is always

followed by a colon (:).

Mode/Unit The modes or units are represented by an abbreviation. Refer to

Table 3-4 on page 3-20 for abbreviatio ns. The Mode/Unit is always

followed by an equals sign (=).

Data Data is the actual measurement. The number of digits and the position

of the decimal point, if any, will vary with the magnitude and type of

data (see Table 3-4 on page 3-20 for mod e/units number formats).

Signed values will contain a leading plus (+) or minus (–). Unsigned

values (percent oxygen, for example) have no sign. The data is

always followed by two ASCII spaces.

Advanced Programming 3-19

Page 48

February 2005

<CR/LF> Every record is terminated with a carriage return/line feed pair

(ASCII 13 and 10 decimal, 0D and 0A hexadecimal).

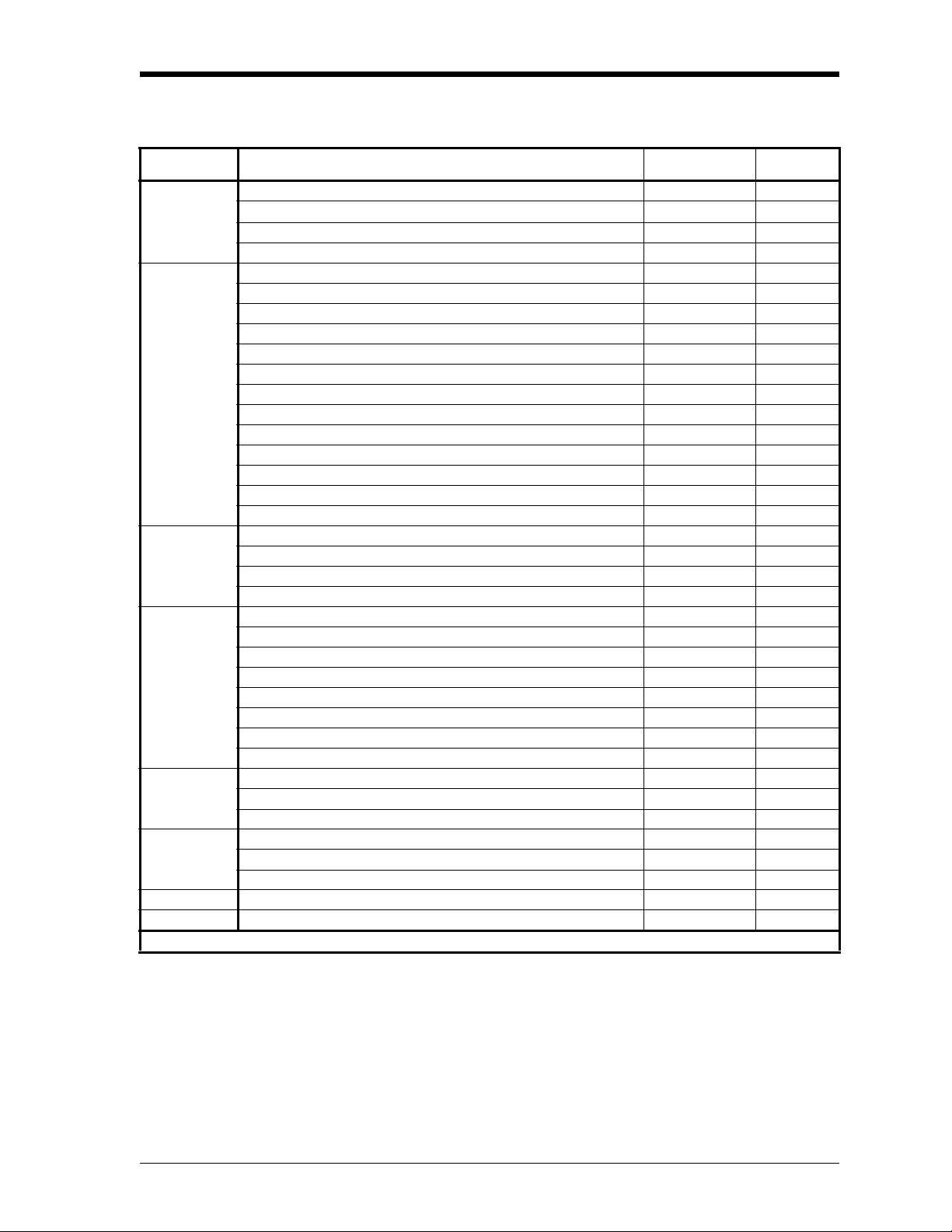

Table 3-4: Print-Out Symbols and Abbreviations

Number

Mode/Unit

Oxygen

O/% XXX.X Oxygen concentration in percent.

O/PPMv XXXX.XX Oxygen concentration in parts per million.

O/uA ±XXX.XXX Oxygen cell current in micro amperes.

O/VDC ±X.XXXX Oxygen circuit voltage in volts DC

Moisture

DP/C ±XXX.X Dew point in degrees Celsius.

DP/F ±XXX.X Dew point in degrees Fahrenheit.

DP/K ±XXX.X Dew point in Kelvin.

H/% XXX.X Relative humidity in percent.

H/HPMv XXX.XXX Parts per million of water by volume.

H/ppMw XXX.XXX Parts per million of water by weight.

H/Ilbs X.XXXX Pounds of water per million standard cubic feet of an ideal gas.

H/Nlbs X.XXXX Pounds of water per million standard cubic feet of natural gas.

H/NPMv XXX.XXX Parts per million of water by volume in natural gas.

H/MH X.XXXX GE Panametrics moisture calibration unit for M and TF Series probes.

H/VDC ±X.XXXX Moisture circuit voltage in volts DC.

Temperature

T/C ±XXX.X Temperature in degrees Celsius.

T/F ±XXX.X Temperature in degrees Fahrenheit.

T/K ±XXX.X Temperature in Kelvin.

T/VDC ±X.XXXX Temperature circuit voltage in volts DC.

Pressure

P/PSIg ±X.XXX Pressure in pounds per square inch gage.

P/Bars X.XXXX Pressure in bars absolute.

P/mbs XXXX.X Pressure in millibars.

P/mmHg XXX.XXX Pressure in millimeters of mercury absolute.

P/Pg XXXXX Pressure in Pascals absolute.

P/kPg XXX.XX Pressure in kiloPascals absolute.

P/mV XXX.XX Pressure in millivolts.

P/VDC ±X.XXXX Pressure circuit voltage in volts DC.

Format Measurement Mode

3-20 Advanced Programming

Page 49

Table 3-4: Print-Out Symbols and Abbreviations (cont.)

Number

Mode/Unit

Format Measurement Mode

Auxiliary Inputs

X1/VDC ±X.XXXX Auxiliary input #1 in volts.

X1/mA ±XX.XXX Auxiliary input #1 in milliamperes.

X1/ ±XX.XXXX Auxiliary input #1 in user-defined units.

X2/VDC ±X.XXXX Auxiliary input #2 in volts.

X2/mA ±XX.XXX Auxiliary input #2 in milliamperes.

X2/ ±XX.XXXX Auxiliary input #2 in user-defined units.

Other

VR/VDC ±X.XXXX Channel card reference voltage.

GD/VDC ±X.XXXX Channel card ground voltage.

Note: In the formats presented above, the plus/minus (±) symbol

indicates that the data is signed and will be preceded by a plus

(+) or minus (–) sign. The number of decimal places indicated

is for nominal values. The instrument will maintain the

number of digits by “floating” the decimal point to the right

as the magnitude of the number increases. DO NOT “hardcode” the decimal points when using data acquisition

software.

February 2005

Advanced Programming 3-21

Page 50

February 2005

Entering System Constants

A system constant is a fixed value for moisture (Kh), temperature

(Kt), or pressure (Kp) entered into the Series 3 instead of using a

“live” input. For example, if the process runs at a steady pressure, that

pressure is entered into the Series 3 memory rather than using a

pressure transmitter.

In addition, you can multiply the ppm

value by a constant for special

v

purposes. The default multiplier is 1.000.

Note: To enter a constant multiplier for the oxygen cell, see

Background Gas Correction Factors in Chapter 2 of the

Service Manual. You must use a current multiplier for oxygen

if you are using a different background gas than the one for

which the cell was calibrated.

IMPORTANT: In order for the constant to work properly, you must

make sure you also configured the channel for a

constant (Kh, Kt or Kp) as described in

Reconfiguring a Channel for a New Sensor on

page 3-31.

Press the

[PROG] key to enter the user program.

Enter Passcode: XXXX

Enter the passcode.

Note: If you have already entered the user program, see Figure 3-2

on page 3-44 to navigate to the System Menu.

Be sure the number displayed in the upper right-hand corner of the

screen is the channel you want to program. If not, press the

[CHAN]

key to select the desired channel.

Programming Menu 1

[SYSTEM] AUTOCAL`

.

Measurement Mode 1

O [H] T P AUX1`

Use the arrow keys to move the

brackets to SYSTEM and press

[YES].

You must now select the type of

measurement the probe is

capable of taking. Use the arrow

keys to move to the desired

measurement mode and press

[YES]. See Table 3-5 on page 3-23

for a list of available

measurement modes.

3-22 Advanced Programming

Page 51

February 2005

Entering System

Constants (cont.)

Table 3-5: Measurement Modes

Display Abbreviation Measurement Mode

O* Oxygen

H Hygrometry

T Temperature

PPressure

AUX1* Auxiliary 1

AUX2* Auxiliary 2

CNST-PPMV PPMv Multiplication Factor

*System constants are not available for these measurement

modes.

System Menu 1

CURVES [CONSTANT]`

Use the arrow keys to move the

brackets to CONSTANT and

press [YES].

Const. Dew Point °C 1

+20.0

Enter the constant value and

press [YES].

Note: The screen display varies, depending on the measurement

mode selected.

When the Series 3 displays measurements that are using a constant, it

will insert or replace the first letter of the mode on the display with

“K.” For example, the Series 3 will display DP as KP (dew point) or

H as KH.

You may now do one of the following:

• To enter a constant for the other channel, press [NO] until you

return to the Programming Menu (as shown on page 3-22).

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [NO] key followed by the [RUN] key.

Advanced Programming 3-23

Page 52

February 2005

Entering a Saturation Constant

The Series 3 requires a saturation constant in order to calculate parts

per million by weight (ppm

) in non-aqueous liquids. If the

w

saturation constant of the process is unknown, contact GE

Infrastructure Sensing. (Saturation constants are necessary for ppm

w

in Henry’s Law type liquids only. See Appendix A of the Service

Manual.)

T o enter a saturation constant, the user must enter 1 to 6 data points to

represent a curve of Cs (saturation constant) versus temperature.

Enter curves for each channel separately.

Press the

Enter Passcode: XXXX

[PROG] key to enter the user program.

Enter the passcode.

Note: If you have already entered the user program, see Figure 3-2

on page 3-44 to navigate to the User Menu.

Be sure the number displayed in the upper right-hand corner of the

screen is the channel you want to program. If not, press the

[CHAN]

key to select the desired channel.

Programming Menu 1

_[USER] LOGGER`

User Menu 1

[SAT-CONST] `

# T(°C) Cs 1

1 +56 0

# T(°C) Cs 1

1 +56 33

Use the arrow keys to move the

brackets to USER and press

[YES].

Use the arrow keys to move the

brackets to SAT-CONST and

[YES].

press

If you want to begin entering

data at the data point displayed,

press the right arrow key to

move the bracket to T/°C.

Otherwise, enter the desired data

point number. Press [YES] to

confirm the entry. Then press the

right arrow key.

Enter the desired temperature.

[YES] to confirm the entry,

Press

and press the right arrow key.

# T(°C) Cs 1

1 +56 33

Enter the corresponding

saturation constant. Press

[YES] to

confirm the entry.

3-24 Advanced Programming

Page 53

February 2005

Entering a Saturation

Constant (cont.)

Repeat the last three steps to enter all the information for each data

point (maximum of six points). Enter the next data point number yo u

want to enter over the present data point number and press the right

arrow key. When you do this, the T/°C and Cs values will display

values of the current saturation constant curve. This indicates you are

ready to begin entering information for the selected data point.

You may now do one of the following:

• T o enter a saturation constant for the other channel, press [NO] until

you return to the Programming Menu on page 3-24.

• Refer to another section and perform a different procedure. Refer

to Figure 3-2 on page 3-44 and Figure 3-3 on page 3-45 to navigate

through the user program.

• Exit by pressing the [NO] key followed by the [RUN] key.

Advanced Programming 3-25

Page 54

February 2005

Using Computer Enhanced Response

Computer Enhanced Response uses a dynamic moisture calibration

technique to extrapolate the moisture level to the end point when

making measurements in abrupt “dry down” conditions. The system

response time depends on the relative change in dew point. For a

change from ambient moisture levels to trace levels, the unit can

respond in three to five minutes.

The accuracy of Computer Enhanced Response is ±2°C of the reading

the sensor would have read if it were allowed to reach equilibrium

with the gas. To ensure that Computer Enhanced Response is as

accurate as possible, your applications should:

• have a reasonably constant flow rate and final dew point.

• have a minimum flow rate of one standard cubic foot per hour

(SCFH).

• operate at atmospheric pressure (0 psig).

• have an actual moisture content dew/frost point or wetter of -85°C.

Allow the sensor to reach equilibrium at ambient moisture levels

before being exposed to the dry gas. Exposing the sensor to dew

points of 5° to 10°C for ten minutes will enable the sensor to reach

equilibrium.

Press the [PROG] key to enter the user program.

Enter Passcode: XXXX

Note: If you have already entered the user program, refer to Figure

3-2 on page 3-44 to navigate to the User Menu.

Be sure the number displayed in the upper right-hand corner of the

screen is the channel you want to program. If not, press the

key to select the desired channel.

Programming Menu 1

_[USER] LOGGER`

User Menu 1

_ [ENHANCED]

Enter the passcode.

[CHAN]