Page 1

GE

Measurement & Control Moisture

®

DewPro

Installation & Operation Manual

MMR31

A40251532 Rev. B

May 2015

Page 2

Page 3

®

DewPro

Moisture Transmitter

(Mid-Range, 1 or 2 Current Loops)

Installation & Operation Manual

A40251532 Rev. B

May 2015

MMR31

gemeasurement.com

©2015 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Preface

Information Paragraphs

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT:These paragraphs pr ovide information that emphasizes instructions that ar e essential to pr oper setup of

the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these

instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national

codes, regulations, rules and laws related to safety and safe operating conditions are met for each

installation. The safety of any system incorporating the equipment is the responsibility of the

assembler of the system.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures on the equipment.

WARNING! It is the responsibility of the user to make sure the PWR, Hart, Modbus and I/O cable

can meet the cable specification, which is described in Appendix A.

DewPro® MMR31 Installation & Operation Manual iii

Page 6

Preface

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE)

take-back initiative, directive 2012/19/EU.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Visit https://www.gemeasurement.com/environmental-health-safety-ehs

information about this initiative.

for take-back instructions and more

iv DewPro® MMR31 Installation & Operation Manual

Page 7

Contents

Chapter 1. General Information

1.1 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Version Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4 Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4.1 First 4-20 mA Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4.2 Second 4–20 mA Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4.3 Polymer Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.4 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Chapter 2. Installation

2.1 Mounting the MMR31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.1 Using a Compression Fitting or a Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1.2 Using a Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Wiring Configurations with One Current Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2.1 General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.2 Normal Environments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.3 Environments with Severe Electrical Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.4 General Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3 Wiring Configurations with Two Current Loops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.3.1 General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Normal Environments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.3 Environments with Severe Electrical Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.4 General Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4 Selecting the Units of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Chapter 3. Calibration and Troubleshooting

3.1 Calibration Using Two Saturated Salt Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2 Calibration Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.1 Calibrating the Low RH Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.2.2 Calibrating the High RH Reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.1 Loop Current is Out of Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.2 No Loop Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.3 Slow Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.4 Frozen Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

DewPro® MMR31 Installation & Operation Manual v

Page 8

Contents

Chapter 4. Optional Display/User Interface

4.1 Accessing the Programming Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.1.1 Removing the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.2 Programming the Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3 Matrix Buttons - Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.1 Reset to “Normal” Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.2 Display Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.3 Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.4 Matrix Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.4.1 System Administration Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.4.2 Moisture Measurement Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.4.3 4-20 mA Output Range Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.4.4 Temperature Measurement Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.4.5 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Chapter 5. Specifications

5.1 Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.2 Optional Onboard Display with User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.3 EMI/RFI Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.4 EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.5 Available Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

vi DewPro® MMR31 Installation & Operation Manual

Page 9

Chapter 1. General Information

GE Sensing

1100 Technology Park Dr.

Billerica, MA 01821 USA

Model:

S/N:

Supply:

Range:

Pressure Rating:

MMR31 - R8A2A

Chapter 1. General Information

1.1 Unpacking and Inspection

Upon receipt of the DewPro MMR31, examine the shipping carton for broken or open packing, distortion, or any other

evidence of mishandling. If your inspection indicates damage to the unit or any of its components may have occurred,

notify the carrier within 15 days of delivery and request an inspection.

If no shipping damage is suspected, move the carton to a clean work area and unpack the contents. The carton you

received should contain:

• DewPro MMR31 Instrument

• Installation and Operation Manual

• Calibration Certificate

1.2 Model Number

Locate the product label on your MMR31, and compare the last five characters of the model number with the product

numbering structure shown on the next page. This will confirm that your MMR31 has been configured to your

specifications. In the example shown in Figure 1 below, the characters R8A2A indicate: standar d certification (not

certified), G1/2 compression fitting (male thread) with gasket and SS ferrule, protective cap with standard

100 micron sintered filter, encl osure conduit M20 x 1.5-F with 1/2” NPT-F adapter and plug, and one selectable

4-20 mA output (RH 0-100% or dew point –15°C to +85°C, absolute humidity, mixing ratio, no display,

fault status 22 mA).

Figure 1: DewPro MMR31 Product Label

DewPro® MMR31 Installation & Operation Manual 1

Page 10

Chapter 1. General Information

1.2 Model Number (cont.)

MMR31 –

1 - Certification

R. Standard Certification (not certified)

S. Other

2 - Process Connection

1. 3” diameter galvanized floor flange with 12.7 mm (½” NPT-M) compression fitting

2. 3/4” NPT-M compression fitting

3. 1/2” NPT-M compression fitting

4. 3/4” x 16 “O” ring compression fitting (UNF thread)

6. No mounting hardware

8. G1/2 compression fitting (Male thread), gasket, SS ferrule

S. Other

12345

3 - Protective Cap

A. Standard, with 100 micron sintered filter

S. Other

4 - Enclosure Conduit

1. Enclosure Conduit M20 x 1.5-F with cable gland and plug

2. Enclosure Conduit M20 x 1.5-F with 1/2” FNPT adapter and plug

S. Other

5 - Output Configuration/Dewpoint Range

A. One output 4-20 mA selectable: RH 0-100% or dewpoi nt 15 to +85°C (5 to 185°F), absolute humidity,

mixing ratio, no display, fault status 22 mA

B. Two 4-20 mA DC output loops: 1st loop Moisture, 2nd loop temperature –15 to +85°C (5 to 185°F),

no display, fault status 22 mA

C. As A, fault status hold

D. As A, fault status 3.6 mA

E. As B, fault status hold

F. As B, fault status 3.6 mA

G. As A, with integral display, user interface

H. As B, with integral display, user interface

S. Other

2 DewPro® MMR31 Installation & Operation Manual

Page 11

Chapter 1. General Information

1.3 Version Descriptions

The DewPro MMR31 mid-range moisture transmitter is available in two versions:

• One isolated 4-20 mA current loop: The loop current represents the selected moisture unit (see “Selecting the

Units of Measure” on page 14).

• T wo isolat ed 4-20 mA loops: The second loop current represents temperature. A unique patented feature of this

version is that both loops can be powered by a single supply.

The MMR31 transmitter includes:

• Sensor element

• Stainless steel probe

• Weather-proof enclosure

• Microprocessor electronics

It is designed to be inserted directly into the process. Various mounting hardware, such as flange and compression

fittings are available for mounting into a duct, process chamber, wall, etc. The DewPro MMR31 measures relative

humidity in %, dew point temperature in °F or °C, absolute humidity in g/m

display with user interface allows the user to configure the MMR31 (see Chapter 4, “Optional Display/User Interface”

on page 19).

3

, or mixing ratio in g/kg. An optional

DewPro® MMR31 Installation & Operation Manual 3

Page 12

Chapter 1. General Information

1.4 Theory of Operation

1.4.1 First 4-20 mA Loop

The MMR31 microcontroller-operated electronics operates with a voltage supply of 12 to 28 VDC. At the nominal

24 VDC supply, the maximum loop resistance is 600 ohms. The signal is represented by the 4 to 20 mA loop current

and is directly proportional to 0 to 100% relative humidity, or, if selected, the dew point temperature range of

5 to 185°F (-15 to +85°C), the absolute humidity in a range of 1 to 350 g/m

1 to 830 g/kg.

1.4.2 Second 4–20 mA Loop

The specifications for the first loop current are also valid for the second loop current, except that the 4 to 20mA signal

always corresponds to the temperature range of 5 to 185°F (-15 to +85°C).

1.4.3 Polymer Sensor

The sensing element in the MMR31 is a silicon-based polymer that uses the capacitance principle for the moisture

measurement. The IC chip includes the moisture sensor and appropriate integrated circuitry. A platinum RTD

temperature sensor is built in to provide temperature compensation for maximum accuracy. The sensor element is

protected from condensation using a hydrophobic sintered filter. An additional removable filter cap serves as a

pre-filter.

3

, or the mixing ratio in a range of

1.4.4 Calibration

Each MMR31 is factory-calibrated against precise NIST certified moisture references. Field calibration is possible with

the use of saturated salt solutions (refer to Chapter 3, “Calibration and Troubleshooting” on page 15).

4 DewPro® MMR31 Installation & Operation Manual

Page 13

Chapter 2. Installation

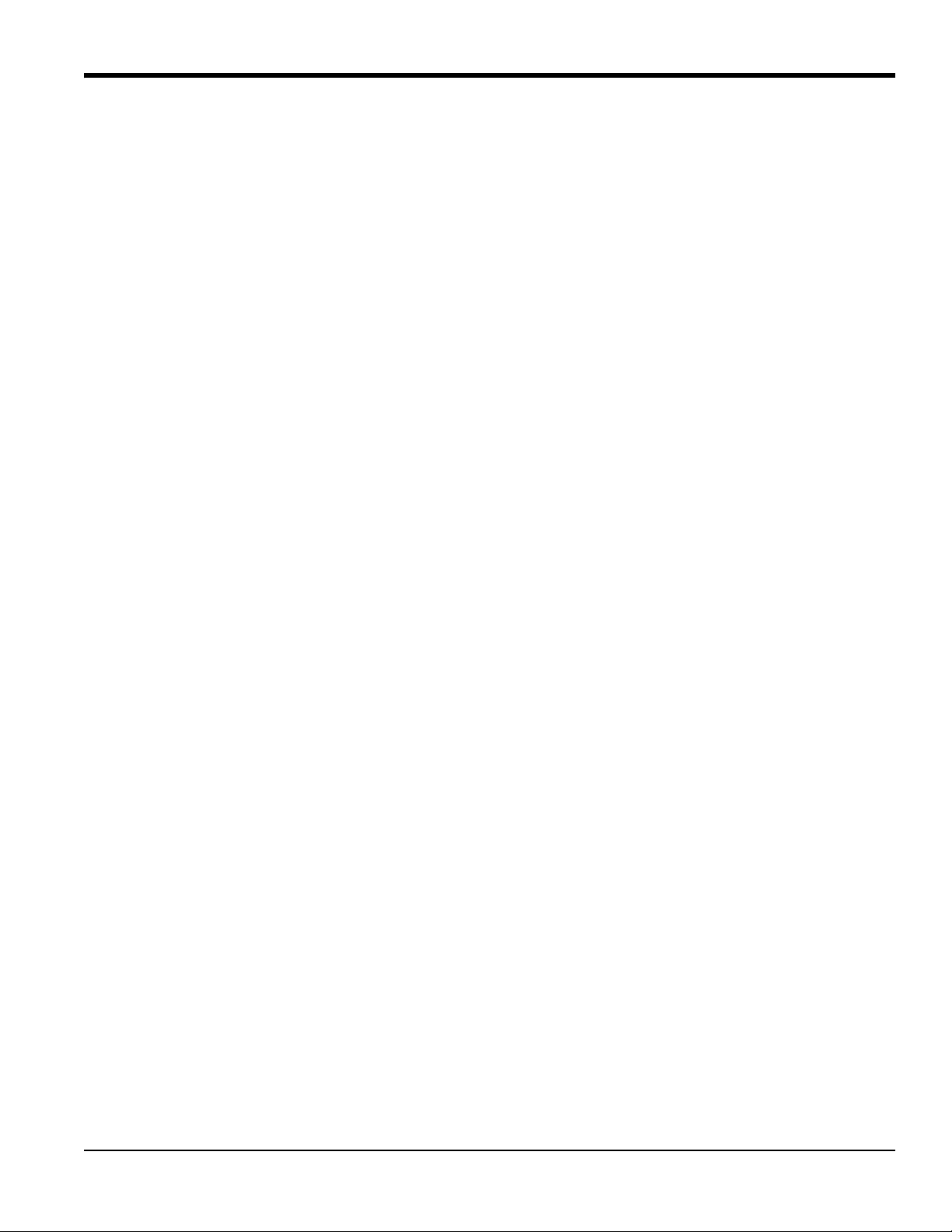

11.50 [292]

4.25 [108]

0.79 [20]

0.50 [12.7]

5.43 [138] (w/display)

4.49 [114] (wo/display)

NOTE: Dimensions are inches [mm]

Compression Fitting

2.00 [50.8]

Ø3.00 [76.2]

Thread

(G1/2, 1/2" NPT-M, etc.)

To properly install your MMR31, carefully follow the instructions in this chapter.

2.1 Mounting the MMR31

To select a suitable mounting location, refer to the dimensions shown in Figure 2 below.

Chapter 2. Installation

Figure 2: MMR31 and Compression Fitting Dimensions

DewPro® MMR31 Installation & Operation Manual 5

Page 14

Chapter 2. Installation

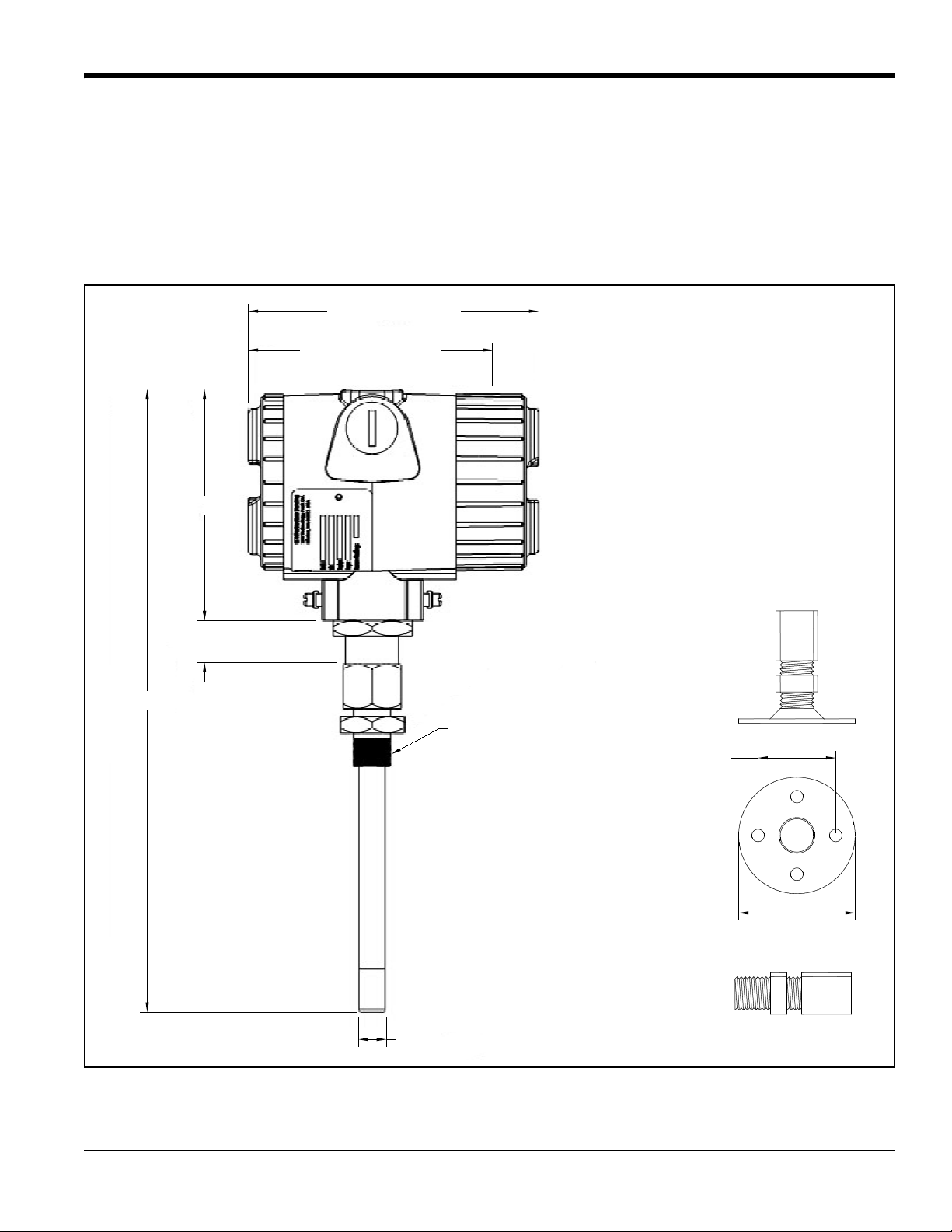

Min. 1 in. (25 mm)

2.1.1 Using a Compression Fitting or a Flange

IMPORTANT: Be certain that the tip of the probe does not touch the inside wall of the pipe or container.

IMPORTANT: A 1.4571 stainless steel ferrule is required for use in pressurized systems. Ensure that your probe has

the appropriate fitting for your application.

T o monitor moisture inside a pipe or container, mount the probe using a compression fitting connection or a flange (see

Figure 3 below). Adjust the ferrule for a probe insertion length of at least 1 in. (25 mm) and tighten the compression

fitting as follows:

1. Hand-tighten the nut.

2. Use a wrench to tighten the nut 1-1/2 turns. When tightened in this manner, the fitting with a stainless steel

ferrule can withstand pressures up to 17 bar (250 psi).

Figure 3: Mounting the Probe in a Pipe

6 DewPro® MMR31 Installation & Operation Manual

Page 15

Chapter 2. Installation

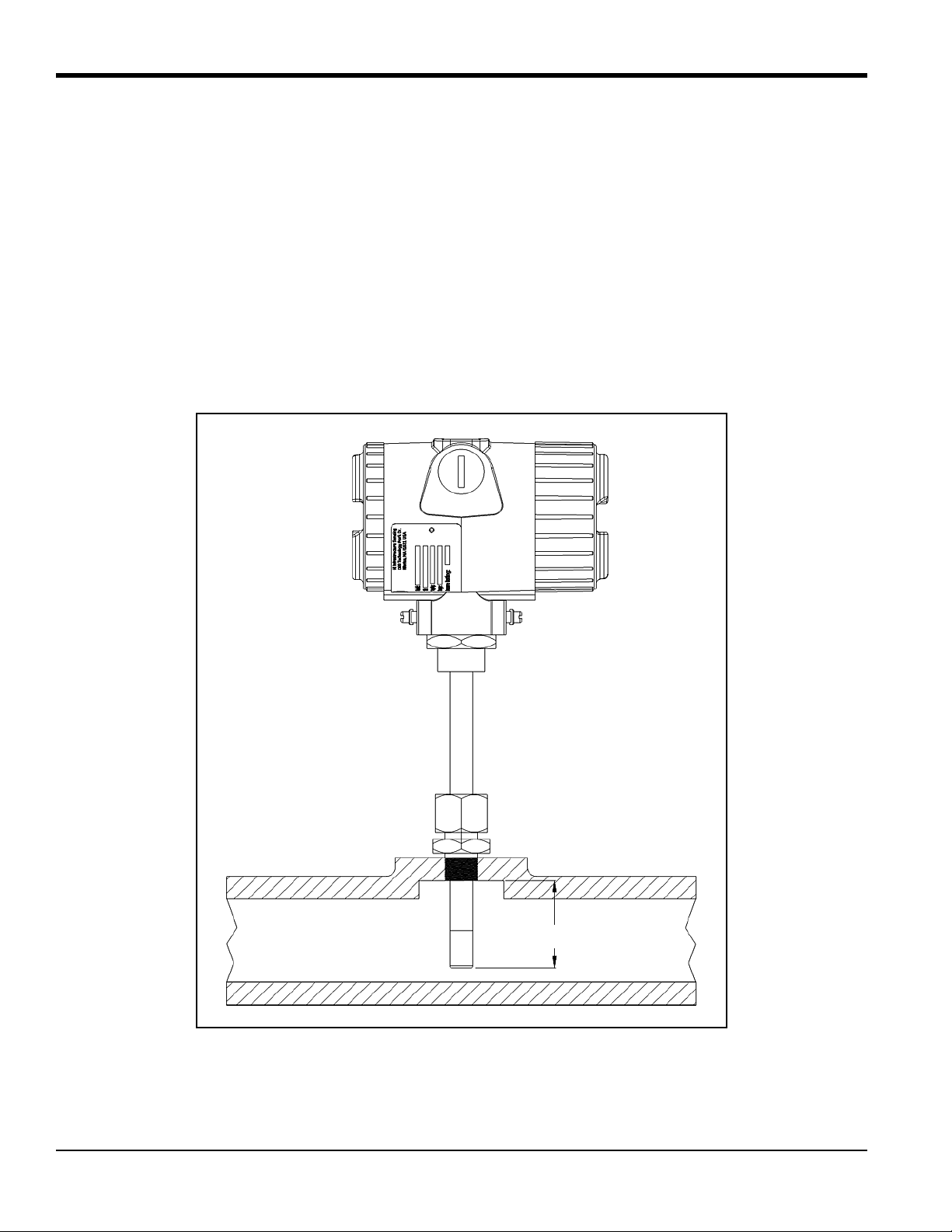

6.50 in.

(165 mm)

2.76 in.

(70 mm)

4.45 in.

(113 mm)

3.23 in.

(82 mm)

4.45 in.

(113 mm)

2.76 in.

(70 mm)

0.79 in.

(20 mm)

4.45 in.

(113 mm)

Panel Mounting

Vertical Pipe Mounting

Horizontal Pipe Mounting

Horizontal Pipe Mounting

2.1.2 Using a Bracket

The MMR31 can be used to monitor the air in a room or other such area, by using the available mounting kits shown in

Figure 4 below.

Figure 4: Mounting Kit Configurations

DewPro® MMR31 Installation & Operation Manual 7

Page 16

Chapter 2. Installation

Customer’s Power Supply

24 VDC (12-28 VDC)

Power Supply

(available from GE)

Power Supply with Display and Optional Relay

(available from GE)

115/230 VAC

115/230 VAC

2.2 Wiring Configurations with One Current Loop

CAUTION! The MMR31 system contains electronic components that are susceptible to damage by

static electricity. Proper handling procedures must be observed during the removal, installation, or

other handling of internal circuit boards.

2.2.1 General Guidelines

The maximum loop resistance is an important parameter for selection of the supply voltage, because each device

connected to the loop causes a voltage drop. For instance, using a loop-powered display with an input impedance of

50 ohms will cause a voltage drop of 1 VDC at 20 mA, per Ohm's law (V = R x I = 50 x 0.020 = 1). Similarly,

connecting the loop to a Programmable Logic Controller (PLC) will cause a voltage drop across its input.

When designing your loop, add up all voltage drops across the devices connected to the loop and then add 12 V. This

sum is the minimum supply voltage required for the circuit. T o ensure reliable operation, it is recommended that a 20%

safety factor be added to the calculated voltage requirement.

IMPORTANT: The voltage across the + and - terminals of the MMR31 should not fall below 12 VDC.

If an external display is used, configure it to the proper range: 0-100 % RH, 5 to 185°F (–15 to +85°C) dew point,

1 to 350 g/m

3

absolute humidity, 1 to 830 g/kg mixing ratio, or custom range corresponding to 4–20 mA. Figure 5

below illustrates some common system configuration options.

Figure 5: System Configuration Options

8 DewPro® MMR31 Installation & Operation Manual

Page 17

Chapter 2. Installation

External Earth Ground

Connect the cable shield

Shielded Two-Wire

Cap

Cable

to the ground terminal

for maximum RFI protection

2.2.2 Normal Environments

A standard two-wire, stranded cable can be used in a normal environment to interconnect the MMR31 with its loop

power source.

2.2.3 Environments with Severe Electrical Noise

When the MMR31 is installed in environments with severe electrical noise, wiring must be done with shielded and

grounded cable, as shown in Figure 6 below. Details of the MMR31 testing and certifications in such environments can

be found in Chapter 5, “Specifications” on page 29, and the CE Declaration of Conformity at the end of this manual.

Figure 6: Shielded Cable Wiring Diagram

DewPro® MMR31 Installation & Operation Manual 9

Page 18

Chapter 2. Installation

GND

LOOP 1

–+

+

–

24 VDC Nominal (12–28V)

External GND/SHIELD Connection

Internal GND Connection

2.2.4 General Wiring Instructions

To wire the MMR31, refer to Figure 7 below and complete the following steps:

1. Unscrew the cap on the terminal side of the unit.

2. Loosen the cable gland located on the side of the unit.

3. Feed the cable through the conduit opening.

Note: Use a standard signal cable size.

4. Retighten the metal cable gland to meet IP 67 and to relieve any stress on the wire.

5. Connect the wires to the MMR31 terminals as shown in Figure 7 below.

6. Verify that a voltage between 12 and 28 VDC is present across the terminals marked + and –.

Note: This is the voltage that is actually measured acr oss the MMR31 terminals. It is not necessarily exactly the same

as the power supply voltage, due to voltage loss in the wires, displays, indicators, etc.

7. To meet EMI/RFI immunity requirements, a two-wire shielded cable with a common foil shield layer is used to

power the MMR31. To clamp the shield foil in the metal cable gland, remove 3 in. (75 mm) of the insulation

and fold back the foil. The ground wire must be connected to the internal grounding screw.

Figure 7: Electrical Connections - One Current Loop

10 DewPro® MMR31 Installation & Operation Manual

Page 19

Chapter 2. Installation

115/230 VAC

115/230 VAC

2.3 Wiring Configurations with Two Current Loops

CAUTION! The MMR31 system contains electronic components that are susceptible to damage by

static electricity. Proper handling procedures must be observed during the removal, installation, or

other handling of internal circuit boards.

2.3.1 General Guidelines

The maximum loop resistance is an important parameter for selection of the supply voltage, because each device

connected to the loop causes a voltage drop. For instance, using a loop-powered display with an input impedance of

50 ohms will cause a voltage drop of 1 VDC at 20 mA, per Ohm's law (V = R x I = 50 x 0.020 = 1). Similarly,

connecting the loop to a Programmable Logic Controller (PLC) will cause a voltage drop across its input.

When designing your loop, add up all voltage drops across the devices connected to the loop and then add 12 V. This

sum is the minimum supply voltage required for the circuit. T o ensure reliable operation, it is recommended that a 20%

safety factor be added to the calculated voltage requirement.

IMPORTANT: The voltage across the + and - terminals of the MMR31 should not fall below 12 VDC.

If an external display is used, configure it to the proper range: 0-100 % RH, 5 to 185°F (–15 to +85°C) dew point,

1 to 350 g/m

3

absolute humidity, 1 to 830 g/kg mixing ratio, or custom range corresponding to 4–20 mA. Figure 8

below illustrates a typical configuration.

The same general specifications apply to the second current loop. However, the range for the second current loop is

always 5 to 185°F (–15 to +85°C), corresponding to temperature, unless an optional display/user interface is used for a

custom range.

IMPORTANT: Be sure that the two current loops are connected independently. DO NOT install a jumper at the

MMR31 + and - terminals to power both current loops from a single power supply.

Figure 8: System Configuration with Display and Power Supply

DewPro® MMR31 Installation & Operation Manual 11

Page 20

Chapter 2. Installation

External Earth Ground

Connect the cable shield

Shielded Four-Wire

Cap

Cable

to the ground terminal

for maximum RFI protection

2.3.2 Normal Environments

A standard two-wire, stranded cable can be used in a normal environment to interconnect the MMR31 with its loop

power sources.

2.3.3 Environments with Severe Electrical Noise

When the MMR31 is installed in environments with severe electrical noise, wiring must be done with shielded and

grounded cable, as shown in Figure 9 below. Details of the MMR31 testing and certifications in such environments can

be found in Chapter 5, “Specifications” on page 29, and the CE Declaration of Conformity at the end of this manual.

Figure 9: Shielded Cable Wiring Diagram

12 DewPro® MMR31 Installation & Operation Manual

Page 21

Chapter 2. Installation

GND

LOOP 1

–+

+

–

+

–

24 VDC Nominal (12–28V)

24 VDC Nominal (12–28V)

External GND/SHIELD Connection

Internal GND Connection

LOOP 2

+–

2.3.4 General Wiring Instructions

To wire the MMR31, refer to Figure 10 below and complete the following steps:

1. Unscrew the cap on the terminal side of the unit.

2. Loosen the cable gland located on the side of the unit.

3. Feed the cable through the conduit opening.

Note: Use a standard signal cable size.

4. Retighten the metal cable gland to meet IP 67 and to relieve any stress on the wire.

5. Connect the wires to the MMR31 terminals as shown in Figure 10 below.

6. Verify that a voltage between 12 and 28 VDC is present across the terminals marked + and –.

Note: This is the voltage that is actually measured acr oss the MMR31 terminals. It is not necessarily exactly the same

as the power supply voltage, due to voltage loss in the wires, displays, indicators, etc.

7. To meet EMI/RFI immunity requirements, a four-wire shielded cable with a common foil shield layer is used

to power the MMR31. T o clamp the shield foil in the metal cable gl and, remove 3 in. (75 mm) of the insulat ion

and fold back the foil. The ground wire must be connected to the internal grounding screw.

Figure 10: Electrical Connections - Two Current Loops

DewPro® MMR31 Installation & Operation Manual 13

Page 22

Chapter 2. Installation

0

5

1

2

3

4

6

7

8

9

S3

2.4 Selecting the Units of Measure

Unless otherwise specified, the MMR31 is shipped with a standard range of 0-100% relative humidity. To select other

units of measure, complete the following steps:

1. Remove the cover opposite to the wiring compartment to access Switch S3 (see Figure 11 below).

Figure 11: Switch S3 Location

2. Using a 2-mm screwdriver, turn Switch S3 to the position corresponding to your desired units of measure. The

available options are listed in Table 1 below:

Table 1: Units of Measure Options

Switch S3 Position Mode Range

0 % RH 0 to 100%

1 Dew point 5 to 185°F

(–15 to +85°C)

2 Mixing Ratio 1 to 830 g/kg

3 Absolute Humidity

1 to 350 g/m

3

8 Dew point Custom

9

with Salt Bottles (75.4 and 11.3%)

% RH Calibration

0 to 100%

For example, if Switch S3 is set to position 1 to select dew point mode, the current output represents a 5 to 185°F

(–15 to +85°C) dew point temperature range. Any attached indicators need to be rescaled from their original

RH (0–100%) range to the new dew point range.

14 DewPro® MMR31 Installation & Operation Manual

Page 23

Chapter 3. Calibration and Troubleshooting

Chapter 3. Calibration and Troubleshooting

3.1 Calibration Using Two Saturated Salt Solutions

CAUTION! Be certain that the system is depressurized. The MMR31 must be removed from the

process prior to calibration.

Utilizing saturated salt solutions is one of many methods available to calibrate a relative humidity sensor. Depending

on the salt used (lithium chloride and sodium chloride are recommended), a defined relative humidity will occur above

the solution at a given temperature. The accuracy of this method is dependent on the stability of the temperature during

the calibration. It is important that the temperature of the salt solution and the temperature of the enclosed atmosphere

above the solution are the same.

Note: To achieve optimum results, it is recommended that calibration be performed at 77.5°F (25.3°C) because the

temperature compensation correction is zero at this temperature. Deviating from this value by ±9°F (±5°C)

will introduce an error of approximately 1%.

To complete the following procedure, you will need:

• Two salt calibration bottles (11.3% and 75.4%) of the type available from GE for RH field calibration

• Screwdriver, 2-mm wide

• An ammeter or current display with a range of 0-100 mA

DewPro® MMR31 Installation & Operation Manual 15

Page 24

Chapter 3. Calibration and Troubleshooting

0

5

1

2

3

4

6

7

8

9

S3

3.2 Calibration Steps

Note: The following steps describe the use of an ammeter for calibration. If the current loop already contains a

current display to indicate the moisture values, an additional ammeter is unnecessary.

1. Remove both covers from the MMR31 enclosure.

2. Disconnect the negative (–) lead of moisture loop 1.

3. Connect the ammeter into the loop as shown in Figure 12 below.

4. Choose the 20 mA range on the ammeter.

Figure 12: Ammeter Connections

T wo buttons (S1 an d S2) and one rotary switch (S3) are located on the circuit board. Button S1 is used to calibrate the

11.3% RH value with a lithium chloride salt solution, while button S2 is used to calibrate the 75.4% RH value with a

sodium chloride salt solution. Switch S3 is set to position 9 for calibration mode (see Figure 13 below).

Note: If the unit is equipped with a display, the buttons on the display are used instead (see Chapter 4, “Optional

Display/User Interface” on page 19 for detailed instructions).

5. Use a 2-mm screwdriver to turn Switch 3 to position 9.

16 DewPro® MMR31 Installation & Operation Manual

Figure 13: Setting Switch S3

Page 25

Chapter 3. Calibration and Troubleshooting

3.2.1 Calibrating the Low RH Reading

Note: For the low RH reading, a saturated salt solution of lithium chloride is used to provide an 11.3% relative

humidity reference.

1. Insert the probe into the calibration bottle, almost to the bottom.

2. Observe the ammeter. The reading will change toward 5.8 mA (or 11.3% on a display) after insertion of the

probe.

Note: For successful calibration, it is important that the temperature in the salt solution and in the enclosed

atmosphere above the solution r each equilibrium at the same value. After waiting for appr oximately two hours,

the ammeter reading should stabilize.

3. If the meter reading is stable at 5.80 mA (or 11.3% on a display), press Sl for at least one second. This assigns

the 11.3% RH value. If only the low RH calibration will be performed, return Switch S3 to position 0 (see

Figure 13 on page 16). Otherwise, continue to the next section to calibrate the high RH reading.

3.2.2 Calibrating the High RH Reading

Note: For the high RH reading, a saturated salt solution of sodium chloride is used to provide an 75.4% relative

humidity reference.

1. Insert the probe into the calibration bottle, almost to the bottom.

2. Observe the ammeter. The reading will change toward 16 mA (or 75.4% on a display) after insertion of the

probe.

Note: For successful calibration, it is important that the temperature in the salt solution and in the enclosed

atmosphere above the solution r each equilibrium at the same value. After waiting for appr oximately two hours,

the ammeter reading should stabilize.

3. If the meter reading is stable at 16 mA (or 75.4% on a display), press S2 for at least one second. This assigns

the 75.4% RH value. Return Switch S3 to position 0 (see Figure 13 on page 16).

4. After successful calibration, remove the ammeter, reconnect the negative (-) lead and reinstall the cover.

Note: During calibration, if the wrong key is pressed, the value will not be accepted due to a plausibility check

DewPro® MMR31 Installation & Operation Manual 17

Page 26

Chapter 3. Calibration and Troubleshooting

3.3 Troubleshooting

3.3.1 Loop Current is Out of Range

3.3.1a Unit of Measure is RH

Note: 0% and 100% relative humidity are absolute limits. However , a defective sensor or a malf unction of th e sensor

electronics could generate sensor signal values which are outside the 0-100% range. If the sensor signal value

is above 100% or below 0%, the current will go to the fault current specified on the order or in the matrix field

VH 07.

Solution: Expose the sensor to ambient air which normally has a relative humidity between 10% and 90%. If the

current returns the 4–20 mA range, check the sensor calibration (see “Calibration St eps” on page 16). However, if the

current remains in error mode contact GE for assistance.

3.3.1b Unit of Measure is Dew Point

Solution 1: The process dew point is out of range. If the dew point is above 185°F (85°C), the current will go to the

fault current specified on the order or in the matrix field VH 07. Apply dry air for a few minutes. If the current remains

in error mode contact GE for assistance.

Solution 2: If the dew point is below 5°F (–15°C), the current will go to the fault current specified on the order or in the

matrix field VH 07. Move the sensor into a wetter environment for a few minutes. If the dew point doesn't increase, the

cause may be a defective sensor assembly or an electronics malfunction. Contact GE for assistance.

Note: The same approach is valid for the other available units of measure and for the second loop (temperature).

3.3.2 No Loop Current

Solution: Check the voltage and polarity across the positive (+) and negative (-) terminals of the MMR31 with a DC

voltmeter. If the voltage is within the 12-28 VDC range, contact GE for assistance.

3.3.3 Slow Response Time

Solution: Remove the protective filter cap by turning it counter -clockwise, and clean it with air flow or a solvent. If the

sensor filter is contaminated, clean it with hot water using a brush.

3.3.4 Frozen Output Current

Solution: Check Switch S3, which should be in position 0, 1, 2, 3, 8 or 9.

18 DewPro® MMR31 Installation & Operation Manual

Page 27

Chapter 4. Optional Display/User Interface

S

e

n

si

n

g

Chapter 4. Optional Display/User Interface

4.1 Accessing the Programming Buttons

If your MMR31 is equipped with an optional display/user interface, follow the procedure below to access the

programming buttons.

4.1.1 Removing the Display

To remove the display/user interface, refer to Figure 14 below and complete the following steps:

1. Unscrew and remove th e pro t ectiv e co ver from th e t op of the MMR31, exposing the display module. The four

buttons V, H, + and – are now accessible.

2. The display un it snaps on to the prin ted circu it bo ard an d rests on fou r posts. When removing th e d i sp lay, push

one post to the outside, using a small screwdriver, and pull the display out.

3. Then, unplug the display cable.

Figure 14: MMR31 with Display

DewPro® MMR31 Installation & Operation Manual 19

Page 28

Chapter 4. Optional Display/User Interface

H

V

+

–

DewPro

4.2 Programming the Matrix

In the MMR31 with the display option, a matrix-style input is used for programming the units of measure, measuring

range, error status of output, and output adjustment.

Note: For users of other GE Sensing equipment, this matrix format may be familiar. However, this section describes

the features and usage of the various matrix locations only as they apply to the MMR31.

The MMR31 display (see Figure 15 below) continuously shows the current matrix location using the vertical (V) and

horizontal (H) coordinates to designate the row and column, respectively. The bar graph represents the output current in

an analog fashion.

Figure 15: MMR31 Display

The V and H buttons are used to move to another row or column in the matrix (see Table 3 on page 21). For example, to

select location VH 45 from a starting location of VH 00, press V four times and then press H five times to arrive at

VH 45 (i.e., row 4 and column 5).

At any matrix location where the matrix value may be changed by the user, the digit to be changed is flashing, and the

desired value is programmed using the + and – buttons. For example, at matrix location VH 01, the desired moisture

units are selected by choosing from the matrix values listed in Table 2 below.

Table 2: Moisture Unit Options

Matrix Moisture Unit

0% RH

1 Td °C

2Td °F

3

20 DewPro® MMR31 Installation & Operation Manual

4g/kg

g/m

3

Page 29

Chapter 4. Optional Display/User Interface

Table 3: Matrix Options

MMR31RowH0H1H2H3H4H5H6H7H8H9

Moisture

Unit

V0

Display

Moisture

Value

Select

Moisture

Unit (see

Table 2)

Loop 1

at Fault

0 = –10%

1 = 110%

2 = Hold

Loop 1 Raw

Reading

Loop Range

V1

% RH

4 mA

% RH

20 mA

Dewpoint

°C

4 mA

Dewpoint

°C

20 mA

Dewpoint

°F

4 mA

Dewpoint

°F

20 mA

g/m

3

4 mA

g/m

3

20 mA

g/kg

4 mA

g/kg

20 mA

V2

Constant;

Loop

Hardware

Calibration

V3

Pressure

Constant in

mmHg

Loop 1 D/A

Calibration

Low

Loop 1 D/A

Calibration

High

T emp. Unit;

Loop 1

Hardware

Calibration

V4

Display

Temp. Value

Select Unit

of Temp.

0 = °C;

1 = °F

Temp.

4 mA

Temp.

20 mA

Loop 2

at Fault

0 = –10%

1 =110%

2 = Hold

Loop 2 Raw

Reading

V5

RH

Calibration

V6

Enable

Calibration;

enter digit

other than 0

Enter Low

RH (%)

Enter High

RH (%)

Loop 2

Hardware

Calibration

V7

Loop 2 D/A

Calibration

Low

Loop 2 D/A

Calibration

High

Access Key

V8

Input

Locking

50 = Unlock

Misc. Setup

V9

Display

Present

Error

Previous

Error

Unit ID Software

Version

Reset to

Defaults

50 =Reset

System

Reset

50 = Reset

DewPro® MMR31 Installation & Operation Manual 21

Page 30

Chapter 4. Optional Display/User Interface

4.3 Matrix Buttons - Special Functions

4.3.1 Reset to “Normal” Display

Pressing the V and H buttons simultaneously returns the user to VH 00 (normal display).

4.3.2 Display Only

Eight (8) matrix locations are for display only and may not be changed by the user (see Table 3 on page 21). The

“display only” fields are as follows:

Table 4: “Display Only” Matrix Locations

Location Display Description

VH 00 Normal display (in dewpoint, % RH, mixing ratio or absolute humidity

as selected in VH 01)

VH 08 Indicates digitized moisture signal

VH 40 Displays temperature

VH 48 Indicates digitized temperature signal

VH 90 During a system alarm, displays the error code for the fault encountered

VH 91 During normal operation, displays the previous error code for reference

VH 92 Displays the factory issued identification number

VH 93 Displays the factory-issued reference number designating the device type

and software version

4.3.3 Default Values

A default value is assigned to each programmable matrix field. These values are loaded after a reset to factory

programmed data has been executed (see VH 95).

4.4 Matrix Functions

This section describes the functions available to the user through the matrix, grouped by common function areas (see

Table 3 on page 21). Each function is accessed by moving to its specified location within the matrix.

22 DewPro® MMR31 Installation & Operation Manual

Page 31

Chapter 4. Optional Display/User Interface

4.4.1 System Administration Functions

Table 5: System Administration Functions

Function Location Description

Locking/

Unlocking

the Matrix

System Reset VH 99 This location allows the user to reset the system electronics in a manner similar to

VH 89 This location allows the user to lock and unlock the matrix input functions. When the

matrix is locked, the V and H keys are still functional but the + and – keys are disabled.

This prevents unauthorized modification of any of the user input functions, such as output

ranging or units selection. Entering the value 50 in this location unlocks the matrix. Any

other value locks the matrix. (Default: 0)

removing and re-applying power. No system parameter settings are modified. Entering

the value 50 in this location initiates the reset, and after approximately five (5) seconds

the reset is executed. After the reset, normal operation is resumed at location VH 00.

Transmitter

Identification

Software

Version

Two-Point

Calibration

Using Any

Low and High

RH Value

Low RH Point

Calibration

High RH Point

Calibration

VH 92 This location displays the identification number of the transmitter. The display should

read 200.

VH93 This location displays the version number of the instrument software.

VH67 In this location, the calibration using VH 68 and VH 69 is enabled by entering any digit

other than 0. Follow the steps described in “Calibration Steps” on page 16. Enter 11.3 in

VH 68 and 75.4 in VH 69.

If a different moisture source is being used (e.g., a variable moisture generator or other

saturated salt solutions), any low value can be entered in VH 68 and any high value in VH

69. Be sure the high and low values differ by at least 20%.

The hardware buttons on the printed circuit board are still active, performing an 11.3 and

75.4 calibration. As described in “Calibration Steps” on page 16, location VH 68 would

reset to 11.3 and location VH 69 to 75.4.

VH68 Enter the low RH value in % when the reading is stable. VH 67 has

to have a value other

than 0. Be sure the high and low values differ by at least 20%.

VH 69 Enter the high RH value in % when reading is stable. VH 67 has to have a value other

than 0. Be sure the high and low values differ by at least 20%.

DewPro® MMR31 Installation & Operation Manual 23

Page 32

Chapter 4. Optional Display/User Interface

4.4.2 Moisture Measurement Functions

Table 6: Moisture Measurement Functions

Function Location Description

Display

Current

Process Value

Select Units of

Measure for

Display

VH 00 This location displays the current process humidity value measured by the instrument.

The units of measure for the displayed value (i.e., % RH, dew point or units selected

under VH 01) is selected in position VH 01. The bar graph beneath the numeric display

represents the position of the current value within the range programmed for the selected

units of measure.

VH 01 This location selects the units of measure to be used for the humidity value display. The

available options are :

0 = % relative humidity (Default)

1 = °C dew point

2 = °F dew point

3 = grams/m

3

4 = grams/kg dry air.

Loop #1

at Fault

Display the

Moisture

Frequency

VH 07 This location specifies the state of current output #1, corresponding to the detection of a

fault with either the humidity sensor or the measurement circuitry. The available options

are:

0 = –10% (3.6 mA)

1 = 110% (22 mA) (Default)

2 = Hold at previous level

VH 08 When this location is selected, the A/D counts from the moisture measurement circuit are

displayed.

24 DewPro® MMR31 Installation & Operation Manual

Page 33

4.4.3 4-20 mA Output Range Functions

Table 7: Setting Output Ranges for Humidity 4-20mA Output

Function Location Description

Range of

Humidity

Values

Pressure

Constant

Adjustment

VH 10 % RH 4mA (Default: 0)

VH 11 % RH 20mA (Default: 100)

VH 12 °C dew point 4mA (Default: –15)

VH13 °C dew point 20mA (Default: +85)

VH 14 °F dew point 4mA (Default: 5)

VH 15 °F dew point 20mA (Default: 185)

VH 16

VH 17

grams/m

grams/m

3

4mA (Default: 1)

3

20mA (Default: 350)

VH 18 grams/kg dry air 4mA (Default: 1)

VH 19 grams/kg dry air 20mA (Default: 830)

VH 30 This location allows the user to enter a value for the process pressure. The value is

entered in mmHg. This value is used only for the calculation of the unit grams/kg dry air.

(Default: 760)

Chapter 4. Optional Display/User Interface

Calibrating the

Current Output

VH 38

VH 39

These locations are used to calibrate the 4 mA and 20 mA hardware settings of the

humidity output current loop. This output comes calibrated from the factory and should

not normally need adjustment. To check the setting, connect an ammeter in series with

the negative (–) power terminal for loop #1 (see “Wiring Configurations with One

Current Loop” on p age 8). Move to matrix location VH 38. The output will automatically

change to the 4 mA setting. Adjust as necessary using the + and – keys. Move to location

VH 39. The output will automatically change to the 20 mA setting. Adjust as necessary.

Move to any other matrix location to return the output to normal operation.

If the matrix input is locked (VH 89), the calibration values are displayed, but the current

output is unaffected.

DewPro® MMR31 Installation & Operation Manual 25

Page 34

Chapter 4. Optional Display/User Interface

4.4.4 Temperature Measurement Functions

Table 8: Temperature Measurement Functions

Function Location Description

Displaying the

Measured

Temperature

Selecting the

Temperature

Unit

VH 40 Selecting this location displays the present process temperature. The unit of measure

(°F/°C) is the unit selected in location VH41 (see below).

VH 41 This allows the user to select either °F or °C as the temperature measurement unit to be

displayed in location VH 40. Setting this location to 0 selects °C, and setting to 1

selects °F. (Default: 0)

Setting the

Temperature

Output Range

Loop #2

at Fault

Calibrating the

Current Output

VH 45

VH 46

These locations specify the range of temperatures corresponding to the 4–20 mA range of

current output #2. The range of values for both locations is from –15 and +85. The output

range is always specified in °C, regardless of the display units selected.

VH 47 This location specifies the condition for current output #2 when a fault is detected in the

temperature measurement circuitry. The available options are:

0 = –10% (3.6 mA)

1 = 110% (22 mA) (Default)

2 = Hold at previous level

VH 78

VH 79

These locations are used to calibrate the 4 mA and 20 mA hardware settings of the

temperature output current loop. This output comes calibrated from the factory and

should not normally need adjustment. To check the setting, connect an ammeter in series

with the negative (–) power terminal for loop #2. Move to matrix location VH 78. The

output will automatically change to the 4 mA setting. Adjust as necessary using the + and

– keys. Move to location VH 79. The output will automatically change to the 20 mA

setting. Again, adjust as necessary. Move to any other matrix location to return the output

to normal operation.

If the matrix input is locked (VH 89), the calibration values are displayed, but the current

output is unaffected.

26 DewPro® MMR31 Installation & Operation Manual

Page 35

Chapter 4. Optional Display/User Interface

4.4.5 Error Codes

During normal MMR31 operation, it is possible for the temperature channel to be in error, while the RH channel still

reads correctly. It is also possible for the RH channel to be in error, while the temperature channel still reads correctly.

If a moisture unit that depends on both the RH and temperature values (e.g., dewpoint) is selected, the error conditions

for both RH < 0% and RH > 100% will be set. MMR31 errors are indicated in the matrix (see Table 3 on page 21), as

shown in Table 9 below.

Table 9: Error Code Display

Function Location Description

Display the

Present

Error Code

The procedure for interpreting the VH 90 error codes involves the conversion of numbers from decimal format into

binary format. To perform these conversions, refer to Table 10 below.

VH 90 This location displays a number associated with an error code. If no error condition

exists, the location displays 0. Use the instructions in this section to properly interpret the

error code.

Table 10: Decimal to Binary Conversions

Decimal Value Binary Equivalent

0 0000

1 0001

2 0010

30011

4 0100

5 0101

60110

7 0111

8 1000

9 1001

10 1010

11 1011

12 1100

13 1101

14 1110

15 1111

DewPro® MMR31 Installation & Operation Manual 27

Page 36

Chapter 4. Optional Display/User Interface

4.4.5 Error Codes (cont.)

When a value other than 0 is displayed in matrix location VH 90, complete the following steps to determine the cause of

the error (a value of 39 is used as an example in the steps below):

1. Divide the error code displayed in matrix location VH 90 by 16.

[Example: 39/16 = 2.4375]

2. Determine the temperature channel error code by converting the integer portion of the result in step 1 to binary

format (see Table 10 on page 27).

[Example: integer portion of 2.4375 = 2 = 0010 binary]

3. Determine the moisture channel error code by multiplying the decimal portion of the result in step 1 by 16 and

then converting the result to binary format (see Table 10 on page 27).

[Example: 16 x decimal portion of 2.4375 = 16 x 0.4375 = 7 = 0111 binary]

4. Each “1” in the binary values calculated in steps 2 and 3 above corresponds to a particular MMR31 error.

Identify these errors by referring to Table 11 below.

[Example: The “1” in the third position of the temperatur e channel error code (see step 2 above) means that the

temperature reading is > 85°C. The “1” in the second, third and fourth positions of the moisture channel error

code (see step 3 above) means that Output 1 is < 4 mA and that the moisture unit selected depends on the

temperature.

Table 11: Error Code Identifications

Temperature Channel 4-Digit Code Moisture Channel 4-Digit Code

XXXX XXX*X*

CH2 Output

> 20 mA

CH2 Output

< 4 mA

Temp.

> +85°C

Temp.

< -15°C

CH1 Output

> 20 mA

CH1 Output

< 4

mA

RH

> 100%

RH

< 0%

* If both of these positions are set to “1”, the selected moisture unit depends on the temperature.

To further illustrate the process, let’s try one more example. If the VH 90 matrix location displays an error code of 1:

Step 1: 1/16 = 0.0625

Step 2: temperature channel error code = integer portion of 0.0625 = 0 = 0000 binary

Step 3: moisture channel error code = 16 x decimal portion of 0.0625 = 16 x 0.0625 = 1 = 0001 binary

Step 4: There are no temperature errors. The moisture error indicates that RH < 0%

28 DewPro® MMR31 Installation & Operation Manual

Page 37

Chapter 5. Specifications

5.1 Technical Specifications

Sensing Element:

Silicon-based polymer, capacitance principle, IC electronics

RH Range:

0 to 100%

RH Accuracy:

±2% in the range of 0% to 90% at 25°C

±3% in the range of 90% to 100% at 25°C

Dew Point Range:

5 to 185°F (–15 to +85°C)

Chapter 5. Specifications

Dew Point Accuracy:

±1.8°F (±1°C) above 32°F (0°C), T <86°F (<30°C) and RH >30%

Operating Temperature Range:

5 to 185°F (–15 to +85°C); temperature signal available with second loop

Operating Temperature of Electronics:

–40 to +185°F (–40 to +85°C)

Temperature Accuracy:

±0.9°F (±0.5°C)

Absolute Humidity Range:

1 to 350 g/m

Mixing Ratio Range:

1 to 830 g/kg

3

Maximum Operating Pressure:

250 psig (17 bar)

Outputs:

Loop current 4 to 20 mA, 16 µA resolution, optional output for temperature

DewPro® MMR31 Installation & Operation Manual 29

Page 38

Chapter 5. Specifications

5.1 Technical Specifications (cont.)

Electronics:

Microcontroller operation

EM I/RFI Protection:

See “EMI/RFI Protection” on page 31

Moisture Units:

% RH, dew point temperature in °F or °C, absolute humidity in g/m

Power Supply:

24 VDC nominal, 12 to 28 VDC range

Protection:

Type 4X (IP67)

3

, or mixing ratio in g/kg, hardware selectable

Probe Tube:

316 stainless steel, 1/2 in. (12.7 mm) diameter, insertion length 3.0 in. (75 mm) to 5.9 in. (150 mm), adjustable

Typical Probe Mounting:

1/2 in. (12.7 mm) tube x 1/2 in. (12.7 mm) NPT-M or

1/2 in. (12.7 mm) tube x G 1/2 compression fitting.

Weight:

3.3 lb (1.5 kg)

5.2 Optional Onboard Display with User Interface

The optional onboard display with user interface uses a matrix configurator for:

• Range changes

• Unit of measure selection

• Current loop adjustment

• Error diagnostics

• Current value selection for fault conditions

• Entering a pressure constant for ppm

30 DewPro® MMR31 Installation & Operation Manual

v

Page 39

Chapter 5. Specifications

5.3 EMI/RFI Protection

IEC 61000-4, Performance Criterion A test results for the MMR31 were as follows:

• Conducted Emission Test as per CISPR 11 Class A, 2004

• Radiated Emission Test as per CISPR 11 Class A, 2004

• Radiated Susceptibility Test as per IEC 61000-4-3, 2002

• Electrostatic Discharge Test as per IEC 61000-4-2, 2001

• Electrical Fast Transient Test as per IEC 61000-4-4, 2004

• High Energy Surge Immunity Test as per IEC 61000-4-5, 2001

• Power Frequency Magnetic Field Test as per IEC 61000-4-8, 2001

5.4 EMC Compliance

The MMR31 meets the EMC requirements of IEC 61326 for equipment used in industrial locations

5.5 Available Accessories

The following optional accessories are available for the MMR31:

• Single power supply

• Panel mount display, power supply, no relays

• Panel mount display, power supply, two alarms

• Panel mount display, power supply, two alarms, 4-20 mA repeating output

Note: For other requirements, contact GE for assistance.

DewPro® MMR31 Installation & Operation Manual 31

Page 40

Chapter 5. Specifications

[no content intended for this page]

32 DewPro® MMR31 Installation & Operation Manual

Page 41

Index

A

Accessories, Available . . . . . . . . . . . . . . . . . . . . . . . 31

Ammeter, Calibration . . . . . . . . . . . . . . . . . . . . . . . 15

B

Binary Conversion Table . . . . . . . . . . . . . . . . . . . . . 27

Bracket, Mounting with . . . . . . . . . . . . . . . . . . . . . . . 7

Buttons

Calibration

Matrix Programming . . . . . . . . . . . . . . . . . . . . . . 20

Programming, Accessing . . . . . . . . . . . . . . . . . . . 19

Special Functions. . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

C

Cable, Shielded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibration

Ammeter

Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

High RH Reading . . . . . . . . . . . . . . . . . . . . . . . . 17

Low RH Reading. . . . . . . . . . . . . . . . . . . . . . . . . 17

NIST Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Steps Required. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Using Saturated Salt Solutions . . . . . . . . . . . . . . . 15

Components, Transmitter. . . . . . . . . . . . . . . . . . . . . . 3

Compression Fitting, Mounting with. . . . . . . . . . . . . . 6

Conversion, Decimal to Binary Table . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

D

Date of Publication . . . . . . . . . . . . . . . . . . . . . . . . . . i

Default Values, Matrix. . . . . . . . . . . . . . . . . . . . . . . 22

Dimensions, Mounting. . . . . . . . . . . . . . . . . . . . . . . . 5

Display

Matrix Locations

Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Display/User Interface

Programming Buttons

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Document Number . . . . . . . . . . . . . . . . . . . . . . . . . . i

. . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . 20

E

Electrical Connections

One Current Loop

Two Current Loops . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Noise. . . . . . . . . . . . . . . . . . . . . . . . . . 9, 12

EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . 31

EMI/RFI Protection. . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . 10

Environmental Compliance . . . . . . . . . . . . . . . . . . . iv

Error Codes

Examples

Interpreting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Matrix Location. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Examples, Error Codes . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

F

Flange, Mounting with. . . . . . . . . . . . . . . . . . . . . . . . 6

Functions

4-20 mA Output Range

Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Moisture Measurement. . . . . . . . . . . . . . . . . . . . . 24

System Administration. . . . . . . . . . . . . . . . . . . . . 23

Temperature Measurement . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . 25

G

Guidelines, Wiring . . . . . . . . . . . . . . . . . . . . . . . 8, 11

I

Information Paragraphs . . . . . . . . . . . . . . . . . . . . . . iii

Installation

Compression Fitting

Flange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

In Pipe or Container. . . . . . . . . . . . . . . . . . . . . . . . 6

In Room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . 5

With Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . 6

L

Label, Product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Loop

Current Out of Range

First, Description . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Frozen Output Current . . . . . . . . . . . . . . . . . . . . . 18

No Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

One, Electrical Connections . . . . . . . . . . . . . . . . . 10

Second, Description. . . . . . . . . . . . . . . . . . . . . . . . 4

Two, Electrical Connections . . . . . . . . . . . . . . . . . 13

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8, 11

. . . . . . . . . . . . . . . . . . . . . . 18

DewPro® MMR31 Installation & Operation Manual 33

Page 42

Index

M

Matrix

"Display Only" Locations

4-20 mA Output Range Functions. . . . . . . . . . . . . 25

Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Moisture Measurement Functions . . . . . . . . . . . . . 24

Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

System Administration Functions . . . . . . . . . . . . . 23

Table of Options . . . . . . . . . . . . . . . . . . . . . . . . . 21

Temperature Measurement Functions . . . . . . . . . . 26

Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 1, 2

Moisture Units, List of Options . . . . . . . . . . . . . . . . 20

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . 22

N

NIST, Calibration Reference. . . . . . . . . . . . . . . . . . . . 4

Noise, Electrical . . . . . . . . . . . . . . . . . . . . . . . . . 9, 12

Normal Environments, Wiring . . . . . . . . . . . . . . . 9, 12

O

Operation, Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Options, Available. . . . . . . . . . . . . . . . . . . . . . . . . . 31

P

Pipe, Mounting in . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Supply, Specifications . . . . . . . . . . . . . . . . . . 30

Product Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Programming

Buttons

Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Programming Buttons, Accessing . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

R

Removing the Display . . . . . . . . . . . . . . . . . . . . . . . 19

Response Time, Slow. . . . . . . . . . . . . . . . . . . . . . . . 18

Return Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

RH

Calibrating High Reading

Calibrating Low Reading . . . . . . . . . . . . . . . . . . . 17

Room, Mounting in . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . 17

S

Safety

Auxiliary Equipment

General Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Personal Equipment . . . . . . . . . . . . . . . . . . . . . . . iv

Salt Solutions, Saturated for Calibration . . . . . . . . . . 15

Sensor, Description . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shielded Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Shipping Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Special Functions, Buttons. . . . . . . . . . . . . . . . . . . . 22

Specifications

Display/User Interface

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Technical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Switch, Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . iii

. . . . . . . . . . . . . . . . . . . . . 30

T

Technical Specifications. . . . . . . . . . . . . . . . . . . . . . 29

Terminals, Wiring . . . . . . . . . . . . . . . . . . . . . . . 10, 13

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Frozen Output Current . . . . . . . . . . . . . . . . . . . . . 18

Loop Current Out of Range . . . . . . . . . . . . . . . . . 18

No Loop Current . . . . . . . . . . . . . . . . . . . . . . . . . 18

Slow Response Time . . . . . . . . . . . . . . . . . . . . . . 18

U

Units of Measure

Selecting

Table of Values . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V

Version Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 3

W

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

WEEE Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Weight, Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring

Electrical Noise

General Guidelines . . . . . . . . . . . . . . . . . . . . . 8, 11

General Instructions. . . . . . . . . . . . . . . . . . . . 10, 13

Normal Environments . . . . . . . . . . . . . . . . . . . 9, 12

One Current Loop . . . . . . . . . . . . . . . . . . . . . . . . . 8

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . 10, 13

Two Current Loops . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . 9, 12

34 DewPro® MMR31 Installation & Operation Manual

Page 43

Warranty

Warranty

Each instrument manufactured by GE Sensing is warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to normal operation or replacing the instrument, at

the sole discretion of GE Sensing. Fuses and batteries are specifically excluded from any liability. This warranty is

effective from the date of delivery to the original purchaser. If GE Sensing determines that the equipment was

defective, the warranty period is:

• One year from delivery for electronic or mechanical failures

• One year from delivery for sensor shelf life

If GE Sensing determines that the equipment was damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines specified by GE Sensing, the repairs are not covered

under this warranty.

The warranties set forth herein are exclusive and are in lieu of all other warranties whether

statutory, express or implied (including warranties or merchantability and fitness for a

particular purpose, and warranties arising from course of dealing or usage or trade).

Return Policy

If a GE Sensing instrument malfunctions within the warranty period, the following procedure must be completed:

1. Notify GE Se n sin g , giv ing full details of the prob lem, and p rovi de the model number and serial number of th e

instrument. If the nature of the problem indicates the need for factory service, GE Sensing will issue a

RETURN AUTHORIZATION NUMBER (RAN), and shipping instructions for the return of the instrument to

a service center will be provided.

2. If GE Sensing instructs you to send your instrument to a service center, it must be shipped prepaid to the

authorized repair station indicated in the shipping instructions.

3. Upon receipt, GE Sensing will evaluate the instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty , the instrument will be repai red at no cost to the owner

and returned.

• If GE Sensing determines that the damage is not covered under the terms of the warranty , or if the warranty has

expired, an estimate for the cost of the repairs at standard rates will be provided. Upon receipt of the owner’s

approval to proceed, the instrument will be repaired and returned.

DewPro® MMR31 Installation & Operation Manual 35

Page 44

Warranty

[no content intended for this page]

36 DewPro® MMR31 Installation & Operation Manual

Page 45

GE

Sensing

We, GE Sensing

1100 Technology Park Drive

Billerica, MA 01821

USA

declare under our sole responsibility that the

DewPro® MMR30 Moisture Transmitter Probe

DewPro

®

DewPro

DewPro

to which this declaration relates, are in conformity with the following standards:

MMY30 and MMY31 Dew Point Transmitters

®

MMR101 High-Temperature Moisture Transmitter

®

MMR31 Moisture Analyzer

EC DECLARATION

OF

CONFORMITY

DOC-0017, Rev. B

• EN 61326-1: 2006, Class A, Group 1, Table 2, Industrial Locations

• EN 61326-2-3: 2006

following the provisions of the 2004/108/EC EMC Directive.

The unit listed above and any ancillary equipment supplied with them do not bear CE marking for the Pressure

Equipment Directive, as they are supplied in accordance with Article 3, Section 3 (sound engineering practices and

codes of good workmanship) of the Pressure Equipment Directive 97/23/EC for DN<25.

Billerica - November 21, 2014

Issued Mr. Gary Kozinski

Certification & Standards, Lead Engineer

Page 46

[no content intended for this page]

Page 47

Page 48

Customer Support Centers

U.S.A .

The Boston Center

1100 Technology Park Drive

Billerica, MA 01821

U.S.A.

Tel: 800 833 9438 (toll-free)

978 437 1000

E-mail: sensing@ge.com

Ireland

Sensing House

Shannon Free Zone East

Shannon, County Clare

Ireland

Tel: +353 (0)61 470200

E-mail: gesensingsnnservices@ge.com

A40251532 Rev. B

An ISO 9001:2008 Certified Company

www.gemeasurement.com/quality-certifications

www.gemeasurement.com

©2015 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Loading...

Loading...