Page 1

GE

Sensing

DewPro® MMR30

General Eastern Mid-Range Moisture Transmitter

User’s Manual

Page 2

GE

Sensing

DewPro® MMR30

General Eastern Mid-Range Moisture Transmitter

User’s Manual

A40251524A

November 2005

DewPro® is a GE General Eastern product. GE General Eastern has joined other GE high-technology sensing

businesses under a new name—GE Sensing.

Page 3

November 2005

Warranty Each instrument manufactured by GE Infrastructure Sensing, Inc. is

warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to

normal operation or replacing the instrument, at the sole discretion of

GE Infrastructure Sensing, Inc. Fuses and batteries are specifically

excluded from any liability. This warranty is effective from the date of

delivery to the original purchaser. If GE Infrastructure Sensing, Inc.

determines that the equipment was defective, the warranty period is:

• one year for general electronic failures of the instrument

• one year for mechanical failures of the sensor

If GE Infrastructure Sensing, Inc. determines that the equipment was

damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines

specified by GE Infrastructure Sensing, Inc., the repairs are not

covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties of merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

Return Policy If a GE Infrastructure Sensing, Inc. instrument malfunctions within the

warranty period, the following procedure must be completed:

1. Notify GE Infrastructure Sensing, Inc., giving full details of the

problem, and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for

factory service, GE Infrastructure Sensing, Inc. will issue a RETURN

AUTHORIZATION number (RA), and shipping instructions for the

return of the instrument to a service center will be provided.

2. If GE Infrastructure Sensing, Inc. instructs you to send your

instrument to a service center, it must be shipped prepaid to the

authorized repair station indicated in the shipping instructions.

3. Upon receipt, GE Infrastructure Sensing, Inc. will evaluate the

instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Infrastructure Sensing, Inc. determines that the damage is not

covered under the terms of the warranty, or if the warranty has

expired, an estimate for the cost of the repairs at standard rates

will be provided. Upon receipt of the owner’s approval to proceed,

the instrument will be repaired and returned.

iii

Page 4

November 2005

Table of Contents

Chapter 1: General System Information

Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Checking the Model Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Optional Display/User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

4 to 20 mA Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Polymer Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

v

Page 5

November 2005

Table of Contents (cont.)

Chapter 2: Installation Guidelines

General Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Method I - Orifice at Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pressure Dewpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Method II - Orifice at Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Method III - No Flow Restriction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Low Pressure Closed Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Method IV - Remote Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Mounting Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Chapter 3: Wiring Instructions

Wiring, General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Designing the Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mounting in Normal Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting in Environments with Severe Electrical Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

vi

Page 6

November 2005

Table of Contents (cont.)

Chapter 4: Optional Display/User Interface

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

DewPro with Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Replacing the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Description of the DewPro MMR30 Programming Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Special Functions of the Push Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Functions of the Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

System Administration Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Moisture Measurement Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Setting the Output Range for the Humidity 4-20 mA Output . . . . . . . . . . . . . . . . . . . 4-6

Temperature Measurement Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Directions for Detecting the Correct Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Chapter 5: Troubleshooting

Problems and Recommended Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Removing the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

vii

Page 7

November 2005

Table of Contents (cont.)

Chapter 6: Technical Specifications

MMR30 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Sensing Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Measurement Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Dew Point Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Standard Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Air Bleedoff at 7 to 8 bar (100 psig). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maximum Operating Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Flow Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Wrench Width for Flow Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Moisture Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Supply Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

European Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Optional Onboard Display with User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

EMI/RFI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

EMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

viii

Page 8

November 2005

Table of Contents (cont.)

Chapter 7: Accessories

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Appendix A: Matrix Table for Programming

ix

Page 9

Chapter 1

Page 10

General System Information

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Page 11

November 2005

Unpacking and Inspection

Upon receipt of the DewPro MMR30, examine the shipping carton

for broken or open packing, distortion, or any other evidence of

mishandling. If inspection indicates damage to the unit or any of its

components, notify the carrier (within 15 days of delivery) and

request an inspection.

Unpacking Move the carton to a clean work area and unpack. The carton you

receive should contain:

• DewPro MMR30

• Installation and Operation Manual

• Calibration certificate

Checking the Model Number

Compare the model number (on the product label) with the product

structure (see Figure 1-1 below) to ensure you have received

everything you ordered.

Figure 1-1: Sample MMR30 Product Label with Model Number

Product S tructure MMR30

Certification/Approvals:

R Standard (not certified)

S Other

Process Connection:

1 ½” MNPT (1/4” tube fitting if B, C or D is selected below)

2 G ½ (6 mm tube fitting if B, C or D is selected below)

S Other

Orifice Configuration:

A Inlet: None; Outlet: Orifice, with ¼” FNPT connection

B Inlet: None; Outlet: Orifice, with (6 mm) ¼” tube fitting installed

C Inlet: None; Outlet: None, with (6 mm) ¼” tube fitting installed

D Inlet: Orifice; Outlet: None, with (6 mm) ¼” tube fitting installed

S Other

General System Information 1-1

Page 12

November 2005

Checking the Model

Number (cont.)

Introduction

Unit Description

Enclosure Conduit:

1 Enclosure conduit M20X 1.5-F with cable gland and plug

2 Enclosure conduit M20X 1.5-F with 1/2” NPT-F adapter and plug

S Other

Output Configuration/Dewpoint Range:

A Td -15°C to +10°C (+5°F to +185°F), no display, error 22 mA

C As A, fault status: hold

D As A, fault status: 3.6 mA

G As A, with integral display, user interface

S Other

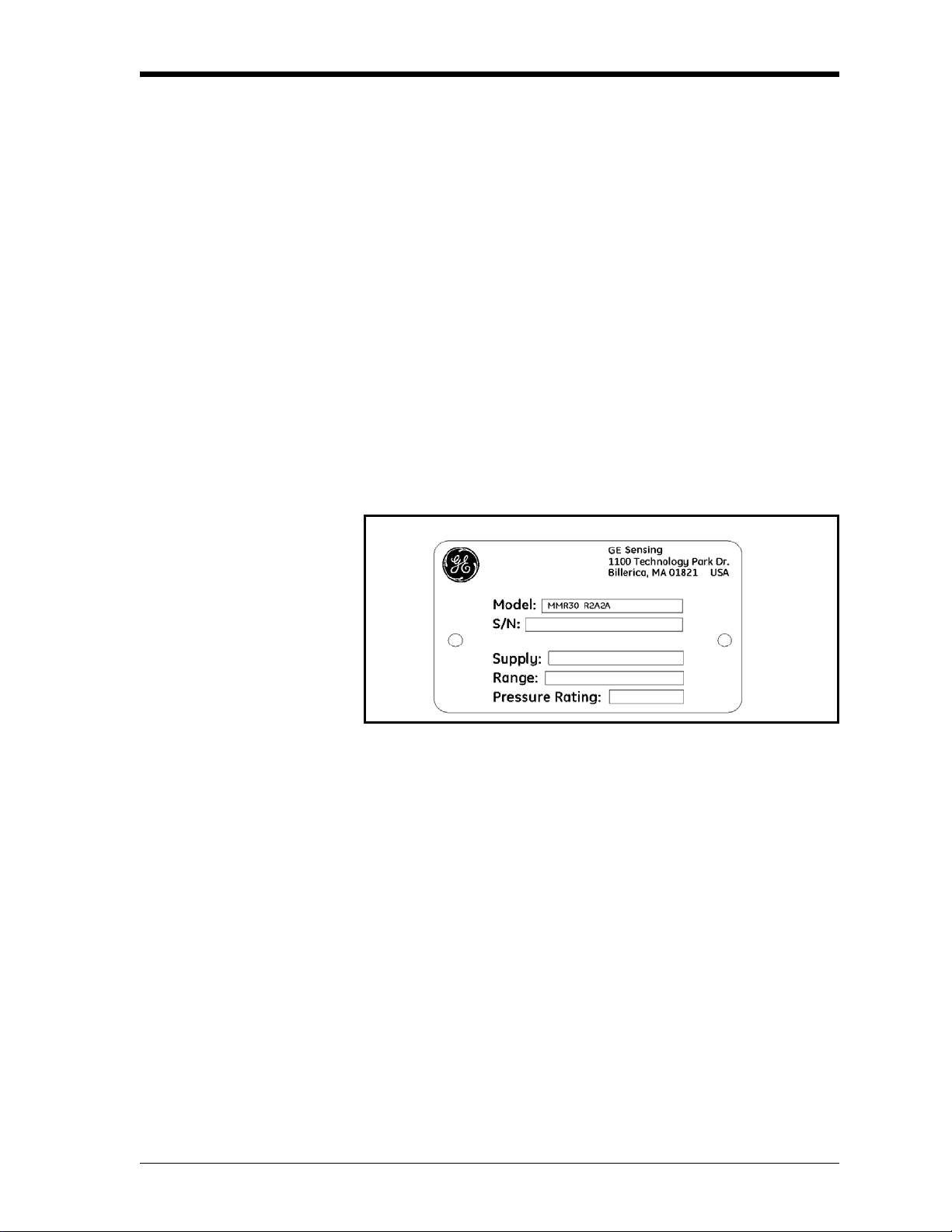

The DewPro MMR30 (shown in Figure 1-2 below) is a loop powered

mid-range moisture transmitter. The transmitter includes a sensor

element, a flow chamber, a weatherproof enclosure, microprocessor

electronics, and assorted fittings, all in a compact assembly. In most

cases, either the inlet or outlet port includes an orifice to regulate the

flow . The placement of this ori fice determines whether the dew point

measurement is done at process (line) pressure (outlet orifice), or at

atmospheric pressure (inlet orifice).

Optional Display/User Interface

The optional display/user interface feature allows the DewPro to be

configured to the user's specifications. See Chapter 4 for more

information.

Figure 1-2: The DewPro MMR30

1-2 General System Information

Page 13

November 2005

Theory of Operation

4 to 20 mA Loop The DewPro MMR30 microprocessor controlled electronics operate

with a DC voltage supply from 12 to 28 VDC. At the nominal 24

VDC supply , the maximum loop resistance is 600 Ohm. The signal is

represented by the 4 to 20 mA loop current and is directly

proportional to the dewpoint range in °C or °F. In the standard range,

4 mA corresponds to -15°C (+ 5°F) and 20 mA to +85°C (+185°F)

dew point temperature.

Bypass In dryer applications, the moisture sensor performs best when

mounted in a bypass. The built-in bypass of the DewPro eliminates

costly hardware associated with traditional sampling methods. The

DewPro installs easily into the process with its G ½ or ½” NPT-M

threaded connection.

Polymer Sensor The sensing element in the MMR30 is a silicon-based polymer that

uses the capacitance principle for the moisture measurement. The IC

chip includes the moisture sensor and appropriate integrated circuitry.

A platinum RTD temperature sensor is built in to provide temperature

compensation for maximum accuracy. The sensor element is

protected from condensation using a hydrophobic sintered filter.

Calibration Each DewPro is factory calibrated against precise NIST certified

moisture references and has an accuracy of ±1°C dew point for dew

points above 0°C. Field calibration is possible with the use of a

moisture generator. Consult the factory for details.

General System Information 1-3

Page 14

November 2005

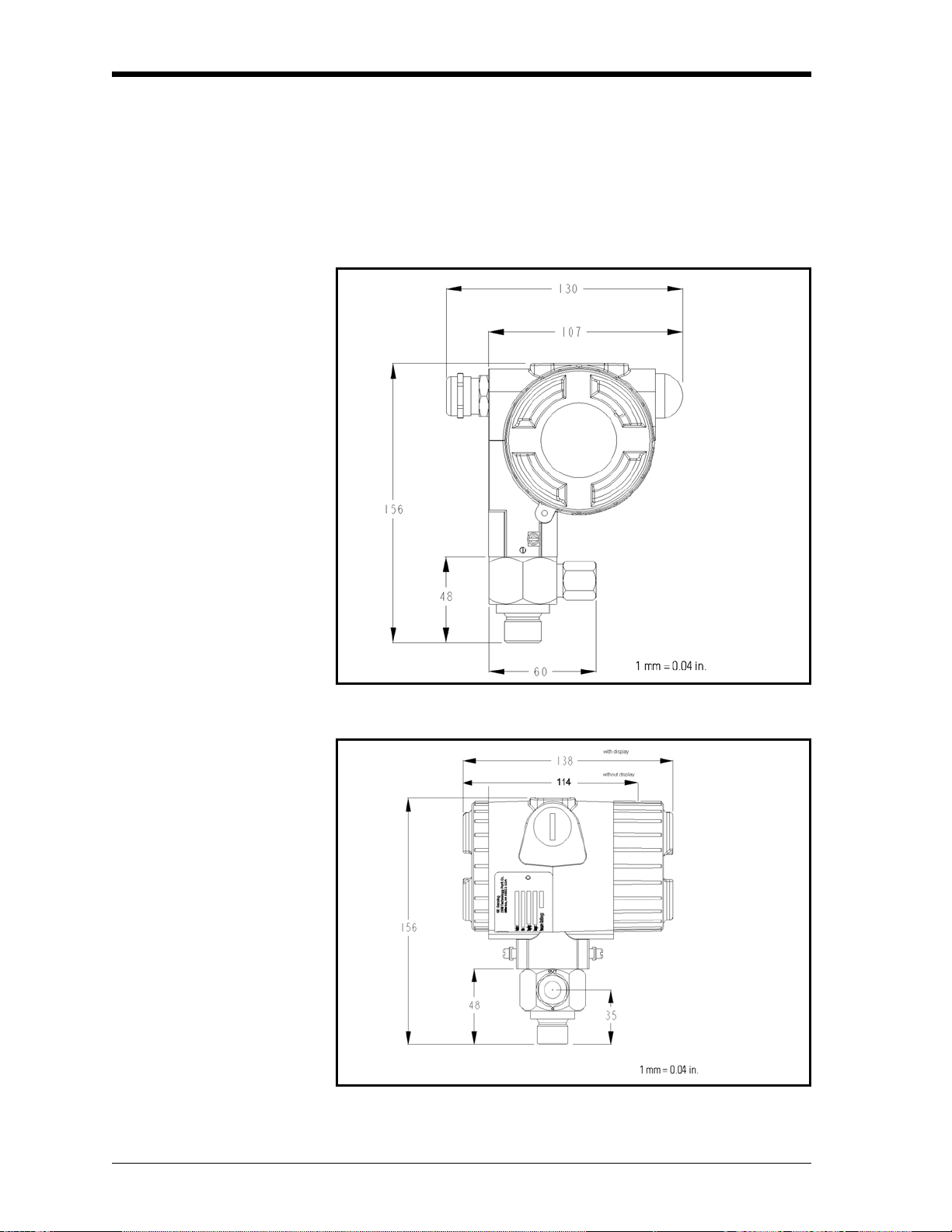

Dimensions Choose a mounting location which allows enough clearance for the

use of tools.

Fig 1-3 below shows installation dimensions for a standard DewPro,

while Figure 1-4 below shows the dimensions for a DewPro with the

optional display/user interface.

Figure 1-3: Standard DewPro Dimensions

Figure 1-4: DewPro with Optional Display/User Interface

1-4 General System Information

Page 15

Chapter 2

Page 16

Installation Guidelines

General Hints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Method I - Orifice at Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Method II - Orifice at Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Method III - No Flow Restriction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Method IV - Remote Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Page 17

General Hints Caution!

B e f o r e i n s t a l l a t i o n , p l e a s e r e a d a l l i n s t r u c t i o n s .

The DewPro is designed to be mounted to pressurized

systems. Take necessary precautions when mounting or

removing the DewPro.

November 2005

• Mount the DewPro

particles or condensation from entering the bypass.

• Mount the DewPro

DewPro when removing it from the process pipe in case of

maintenance.

Do not over-tighten! The outlet fitting is connected to the

bypass block with a G 1/4 straight thread (with gasket)

which will seal if the fitting is simply hand-tightened. When

connecting an external device, counter the fitting with a

second wrench when tightening. If the inlet is equipped

with a G 1/2 straight thread and gasket, the seal is

obtained by simply hand-tightening the DewPro®.

If you are installing the DewPro into a pressurized system

(up to 10 bar), depressurize the system before installing or

removing the sensor. Pressurized systems require a

stainless steel compression fitting.

®

vertically whenever possible to prevent

®

after a shutoff valve to depressurize the

Caution!

Caution!

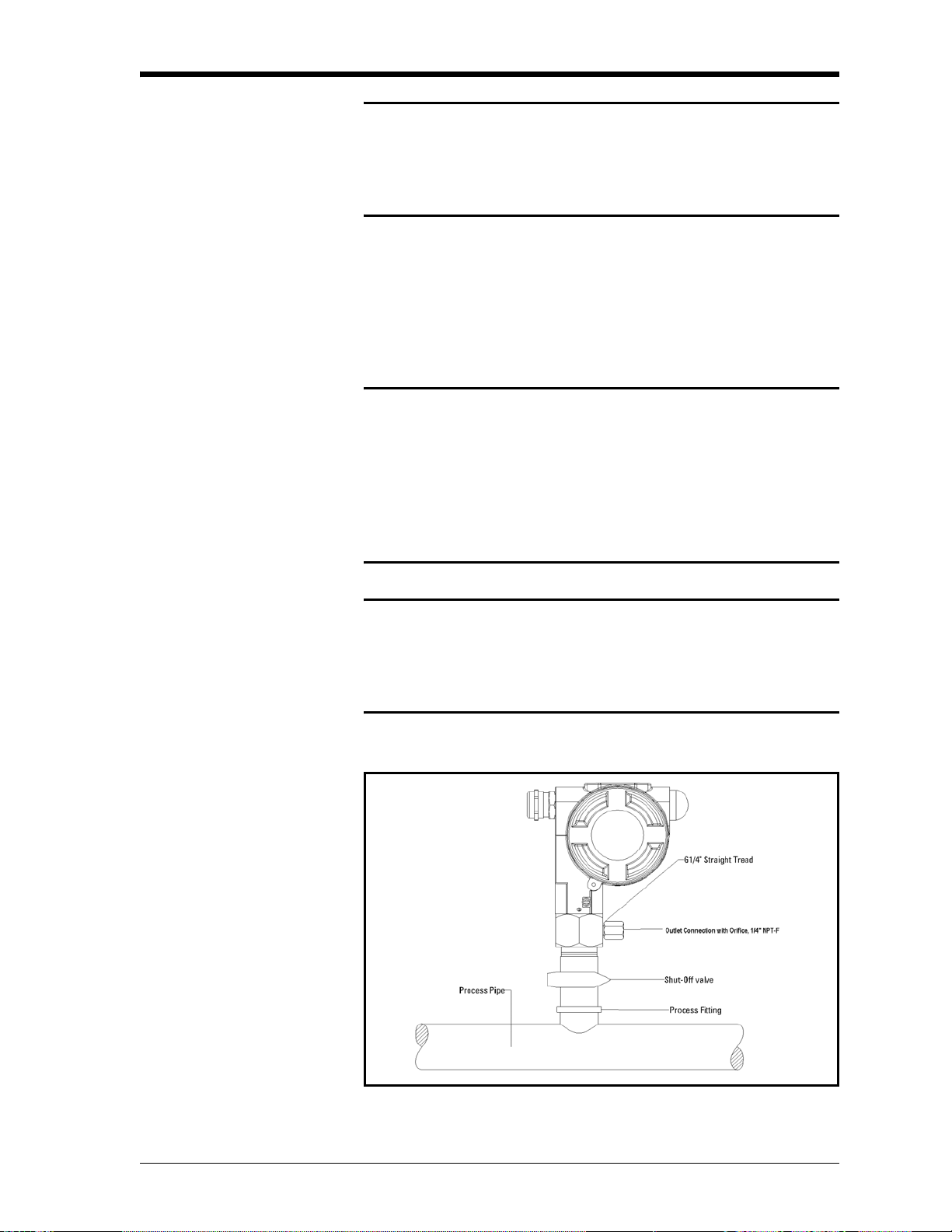

Method I - Orifice at Outlet

Figure 2-1: DewPro Installation with Orifice at the Outlet

Installation Guidelines 2-1

Page 18

November 2005

Pressure Dewpoint Refrigeration air dryers producing general instrument air are typically

specified with a pressure dewpoint rating. The majority of dryers

operate in a dewpoint range between +2°C to +10°C (+35°F to

+50°F). A pressure of 7 to 8 bar (= 100 psig) is very common.

Air Flow The DewPro is designed to measure the pressure dew point. By

restricting the flow at the outlet of the integral bypass with an orifice,

the sensor monitors the dewpoint at process pressure. The bleedoff air

to the atmosphere at 7 to 8 bar (100 psig), is approximately 70 cc/min.

(=4 l/h or =0.14 cfh). For smaller sized dryers of 3m

the air loss is only 0.002% of the air production and is negligible.

Despite the very low flow rate through the bypass as shown in Figure

2-1 on the previous page, the air sample in the DewPro bypass

chamber is refreshed every second due to the small volume design.

As a result, the sensor sees changes in moisture instantaneously.

Due to the low flow rate, the flow velocity is also very low at <0.01

m/sec. (=34m/h).The low flow velocity prevents the inlet filter from

clogging, since there is not enough kinetic energy to push dust

particles into the filter.

3

/min.(=100 cfm)

2-2 Installation Guidelines

Page 19

Method II - Orifice at Inlet

November 2005

Figure 2-2: DewPro with Orifice Restriction at Inlet

In case the application requires the dew point measurement under

atmospheric pressure, the orifice flow restriction is to be mounted at

the inlet of the DewPro

®

bypass.This may not be typical for dryer

applications. The dew point reading will be lower since the water

vapor pressure is reduced by the factor of the pressure drop across the

inlet orifice.

®

In this configuration, the outlet of the DewPro

bypass is not flow

restricted and will be equipped with a 6 mm (1/4”) tube fitting. In

order to prevent back diffusion of water vapor from the ambient air,

five feet of exhaust tubing should be mounted to the tube fitting, or,

better, a diffusion coil from GE Sensing can be used.

Installation Guidelines 2-3

Page 20

November 2005

Method III - No Flow Restriction

Low Pressure Closed Loop

Figure 2-3: DewPro with No Flow Restriction

Closed loop systems, with dew points >-15 °C, may operate at a low

pressure. The air passing through the DewPro bypass is fed back to

the main stream after a pressure drop in the main line.

In this configuration, the DewPro bypass has no flow restriction at the

inlet and outlet. The outlet is equipped with a 6 mm (1/4”) tube fitting

to allow simple connection of the loop tubing.

2-4 Installation Guidelines

Page 21

November 2005

Method IV - Remote Installation

In some cases there may not be enough room to install the DewPro

directly to the process pipe. The tube connection at the inlet allows

mounting the DewPro at a remote location, as shown in Figure 2-4

below. The functions of Methods I-III can be selected.

Figure 2-4: DewPro in Remote Installation

Mounting Brackets The DewPro can be mo unted on a wall, a plate or a pipe using a

bracket available from GE Sensing, as shown in Figure 2-5 below.

Panel Mounting

6.50 in.

(165 mm)

2.76 in.

(70 mm)

Horizontal Pipe Mounti ng

3.23 in.

(82 mm)

4.45 in.

(113 mm)

4.45 in.

(113 mm)

2.76 in.

(70 mm)

4.45 in.

(113 mm)

0.79 in.

(20 mm)

Vertical Pipe Mounting

Horizontal Pipe Mounting

Figure 2-5: DewPro with Various Mounting Brackets

Installation Guidelines 2-5

Page 22

Chapter 3

Page 23

Wiring Instructions

Wiring, General Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mounting in Normal Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting in Environments with Severe Electrical Noise. . . . . . . . . . . . . 3-2

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Page 24

November 2005

Wiring, General Guidelines

Note: If the DewPro is equipped with an optional display/user

interface, please refer to Chapter 4.

Caution!

The DewPro system contains electronic components that

are susceptible to damage by static electricity. Proper

handling procedures must be observed during the

removal, installation, or other handling of internal boards

or devices.

System Configuration Figure 3-1 below shows various power supplies and displays for use

with the DewPro.

Figure 3-1: Power Supplies and Displays for DewPro

Designing the Loop If users provide their own power supply, the voltage at the +/-

terminal of the DewPro should not fall below 12 VDC. The maximum

loop resistance is an important measure for selection of the supply

voltage. Each device connected to the loop causes a voltage drop. For

instance, using a loop-powered display with an input impedance of 50

Ohm will cause a voltage drop of 1 VDC at 20 mA using Ohm's law.

Connecting the loop to a PLC will cause a voltage drop across the

input.

When designing your loop, add up all voltage losses across the

devices connected to the loop and add 12 V. The sum will be the

minimum supply voltage required from the power supply. Calculate

with a 20% safety factor.

Wiring Instructions 3-1

Page 25

November 2005

Mounting in Normal Environments

Mounting in Environments with Severe Electrical Noise

A standard two-wire, stranded cable (shown in Figure 3-2 below) can

be used to interconnect the DewPro with the power source.

Figure 3-2: Standard Cable for Use with DewPro

The DewPro MMR30 meets the EMC requirements of IEC 61326 for

equipment used in industrial locations. The MMR30 passed all tests

to the standards IEC 61000-4- to the performance criterion A. Test

details appear in Chapter 6, Specifications.

Figure 3-3: DewPro with Shielded Signal Cable

3-2 Wiring Instructions

Page 26

November 2005

Electrical Connection Figure 3-4 below shows the DewPro wiring connections.

Figure 3-4: DewPro Wiring Connections

General Instructions 1. Unscrew the cap on the unit.

2. Loosen the cable gland located on the side of the unit.

3. Feed the cable through the conduit opening.

Note: Use a standard signal cable size.

4. Retighten the metal cable gland to meet IP67 and to relieve any

stress on the wire.

5. Verify that a voltage between 12 and 28 V DC is across the

terminals marked + and -.

Note: This is the voltage that appears across the DewPro terminals,

not necessarily the power supply voltage due to voltage loss in

wire length, displays, and indicators.

6. In order to meet EMI/RFI immunity, a two-wire shielded cable

with a common foil shield layer is being used to power the

MMR30. Removing the insulation by 3” allows users to pull back

the foil, clamping it in between the metal cable gland. You must

connect the ground wire to the internal grounding screw.

Wiring Instructions 3-3

Page 27

Chapter 4

Page 28

Optional Display/User Interface

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Description of the DewPro MMR30 Programming Matrix . . . . . . . . . . . . 4-2

Special Functions of the Push Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Functions of the Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Page 29

November 2005

Installation If the DewPro is equipped with an optional display/user interface,

follow the procedure below to access the buttons.

Figure 4-1: DewPro with Display Assembly

DewPro with Display Assembly

1. Unscrew and remove the protective window lid from the top of the

DewPro (as shown in Figure 4-1 above), exposing the display

module below. The buttons V, H, + and - are now accessible.

Replacing the Display 2. The display unit snaps onto the printed circuit board, resting on

four posts. When removing the display, push one post to the

outside, using a small screwdriver, and pull the display out.

3. Then unplug the display cable.

Optional Display/User Interface 4-1

Page 30

November 2005

Description of the DewPro MMR30 Programming Matrix

In the DewPro MMR30 transmitter with display option, a matrixstyle input is used for programming the unit of measure, measuring

range, error status of output, and output adjustment. Each option is

assigned coordinates on the 10 by 10 matrix, specified with V

(vertical), H (horizontal) and a number for each.The following

sections describe the features and usage of the various matrix

locations as they apply to the MMR30.

Figure 4-2: The MMR30 Optional Display

The display of the DewPro MMR30 continuously shows the current

matrix location using the vertical (V) and horizontal (H) coordinates

to designate the row and column, respectively.The bar graph

represents the output current in an analog fashion (refer to Figure 4-2

above). See Appendix A for an enlarged overview of the matrix.

Table 4-1: Matrix Input for Programming

MMR30 H0 H1 H2 H3 H4 H5 H6 H7 H8 H9

Moisture Unit

Loop Range

V0

V1

Display

Moisture

Value

Select

Moisture

Unit

1 = °C

2 = °F

Dewpoint

°C 4 mA

Dewpoint

°C 20

mA

Dewpoint

°F 4 mA

Dewpoint

°F 20 mA

Loop

at Fault

1=110%

2=Hold

0=-10%

Loop Raw

Reading

V2

Constant:

Loop

Hardware

Calibration

Temperature

Unit: Loop 1

Hardware

Calibration

V3

V4

Pressure Constant in

mmHg

Display

Temperature

Value

Select Unit

of Temperature:

0 =°C

1 =°F

Loop D/A

Calibration Low

Loop D/A

Calibration

High

V5

V6

Loop 2

Hardware

Calibration

Access Key

Misc. Setup

V7

V8

V9

Display

Present Error

Previous

Error

Unit ID Software

Versi o n

Reset to

Defaults

50=Reset

Input Locking

50 =

Unlock

System

Reset

50 = Reset

4-2 Optional Display/User Interface

Page 31

November 2005

Description of the

DewPro MMR30

Programming Matrix

(cont.)

You select the desired option by entering the matrix position.

Movement through the matrix is accomplished by using the “V” and

“H” buttons to move to another row or column, as shown in the

example below . At any location where a value may be changed by the

user, the desired value is programmed using the “+” and “-” buttons.

Table 4-2: Matrix Number and Moisture Units

Matrix Moisture Unit

1Td °C

2Td °F

Example To set the dew point value to -10°C for 4 mA (V1 H2 on matrix):

1. Press the V key until the display shows V1.

2. Press the H key until the display shows H2.

3. Use the + o r - ke y to ch ange the num eric value to -10. The digit to

be changed is flashing.

4. Proceed to any part of the matrix.

Special Functions of the Push Buttons

1. Reset to “Normal” Display: Pressing the “V” and “H” buttons

simultaneously returns the user to VH 00 (normal display).

2. Display Only: Note that seven (7) matrix locations are for display

only and may not be changed by the user (refer to Table 4-1 or

Appendix). The “display only” fields are as follows:

• VH 00 = normal display (in dewpoint)

• VH 08 = indicates digitized moisture signal

• VH 40 = temperature display

• VH 90 = during a system alarm, displays the error code for the

fault encountered

• VH 91 = during normal operation, the previous error code is

displayed for reference

• VH 92 = displays the factory issued identification number

• VH 93 = displays the factory issued reference number

designating the device type and software version

3. Default Values

A default value is assigned to each programmable matrix field.

The values are present after a reset to factory programmed data

has been executed (see VH 95).

Optional Display/User Interface 4-3

Page 32

November 2005

Functions of the Matrix This section describes the functions available to the user through the

matrix grouped by common function areas. The function is accessed

by positioning to the specified location within the matrix.

System Administration Functions

1. Unlocking/Locking the Matrix

Location in

Matrix Description of Function

VH

89

This location allows the user to lock and unlock the

matrix input functions. When the matrix is locked,

“V” and “H” keys are still functional but the “+” and

“-” keys are disabled. This prevents unauthorized

modification of any of the user input functions, such

as output ranging or unit selection. Entering the

value “50” in this location unlocks the matrix. Any

other value locks the matrix.

Default: 0

2. System Reset

Location in

Matrix Description of Function

VH

99

This location allows the user to a reset of the system

electronics, similar to removing and re-applying

power to the instrument. No system parameter settings are modified. Entering the value “50” in this

location initiates the reset, and after approximately

five (5) seconds the reset is executed. After the reset,

normal operation is resumed at location VH 00.

3. Transmitter Identification

l

Location in

Matrix Description of Function

VH

92

This location displays the identification number of

the transmitter. The display should read “200.”

4. Software Version

Location in

Matrix Description of Function

VH

93

4-4 Optional Display/User Interface

This location displays the version number (3.00) of

the instrument software.

Page 33

November 2005

Moisture Measurement Functions

5. Display Present Process Value

Location in

Matrix Description of Function

VH

00

6. Select Unit of Measure for Display

Location in

Matrix Description of Function

VH

01

This location displays the present process humidity

value measured by the instrument. The unit of measure for the displayed value (i.e., dewpoint or unit

selected under VH 01) is selected in position VH 01.

The bar graph beneath the numeric display represents the position of the present value within the

range programmed for the selected unit of measure.

This location selects the unit of measure to be used

for the humidity value display. The possible selections are as follows:

1 =°C dewpoint

2 = °F dewpoint

Default: 1

7. Loop #1 at Fault

Location in

Matrix Description of Function

VH

07

This location specifies the state of current output

corresponding to the detection of a fault with either

the humidity sensor or the measurement circuitry.

The possible selections are:

0 = -10% (3.6 mA)

1 = 110% (22 mA)

2 = Hold at previous level

Default: 1

Optional Display/User Interface 4-5

Page 34

November 2005

Moisture Measurement

Functions (cont.)

Setting the Output Range for the Humidity 4-20 mA Output

8. Displaying the Moisture Frequency

Location in

Matrix Description of Function

VH

08

9. Range of Humidity Values

Assign any value to 4 and 20 mA to establish desired output range.

Location in

Matrix Description of Function Default Values

VH

12

VH

13

VH

14

When this location is selected, the A/D counts from

the moisture measurement circuit are displayed.

°C dewpoint 4 mA -15

°C dewpoint 20 mA +85

°F dewpoint 4 mA 5

VH

15

10. Pressure Constant Adjustment

Location in

Matrix Description of Function

VH

30

°F dewpoint 20 mA 185

This location allows the user to enter a value for the

process pressure. The value is entered in mmHg.

This value is only used for the calculation of the unit

grams/kg dry air.

Default: 760

4-6 Optional Display/User Interface

Page 35

November 2005

Setting the Output Range

for the Humidity 4-20 mA

Output (cont.)

11. Calibrating the Current Output

Location in

Matrix Description of Function

VH

38

VH

39

These locations are used to calibrate the 4 mA and

20 mA settings of the humidity output current loop.

This output comes calibrated from the factory and

should not normally need adjustment. To check the

setting, connect a current meter in series with the

power terminals for loop (see Chapter 3). Move to

matrix location VH 38. The output will automatically change to the 4 mA setting. Adjust as necessary using the “+” and “-” keys. Move to location

VH 39. The output will automatically change to the

20 mA setting. Again, adjust as necessary. Move to

any other matrix location to return the output to normal operation.

Note: If the matrix input is locked (VH 89), the calibration values are displayed but the current output

is unaffected.

Temperature Measurement Functions

Attention!

The standard MMR30 does not offer a temperature

measurement output. The second analog output is only

available at special request. These functions only apply to

this special version.

12. Displaying the Measured Temperature

Location in

Matrix Description of Function

VH

40

13. Selecting the Temperature Unit

Location in

Matrix Description of Function

VH

41

Selecting this location displays the present process

temperature. The unit of measure (°C/°F) is the unit

selected in location VH 41 (see Table 4-1 on page 4-

2). The bar graph displays the percentage of output

for the programmed output range.

This location allows the user to select either °C or °F

as the temperature measurement unit to be displayed

in location VH 40. Setting this location to “0”

selects °C, and setting to “1” selects °F.

Default: 0

Optional Display/User Interface 4-7

Page 36

November 2005

Error Codes 14. Display the Present Error Code

Location in

Matrix Description of Function

VH

90

This field displays a number associated with an error

code. If no error condition exists, the location displays “0.” During normal operation, it is possible for

the humidity channel to be in error, yet have a temperature channel read correctly . It is also possible for

the temperature to be in error, but have the humidity

read correctly. If a moisture unit is selected that

needs both humidity and temperature (such as dewpoint) in order to be properly calculated, the error

conditions for Td<-15°C and Td >+85°C will be set.

Follow the instructions on the next page to properly

detect the correct error code.

4-8 Optional Display/User Interface

Page 37

November 2005

Directions for Detecting the Correct Error Code

1. Take the error code display ed at the matrix location VH 90 and

divide it by 16. The digit(s) before the decimal point represent the

error code associated with the temperature channel.

Temperature Error

Bit: 0010

xxxx

Temperature <-15°C

Temperature >+40°C

Output on CH.2 less than 4 mA.

Output on CH.2 greater than 20 mA.

2. To calculate the moisture error code, take the remainder of the

previous division (the digit(s) after the decimal point) and

multiply it by 16.

Moisture Error

Bit: 0111

xxxx

RH <0%

RH >100%

Output on CH.1 less than 4 mA.

Output on CH.1 greater than 20 mA.

3. Use Table 4-3 on the next page to convert both numbers into their

respective bit codes.

Note: Every “1” corresponds to an error. See the example below

T able 4-3 for help when calculating. Please r efer to Chapter 5,

Troubleshooting, for further information.

Optional Display/User Interface 4-9

Page 38

November 2005

Directions for Detecting

the Correct Error Code

(cont.)

Table 4-3: Error Code Conversion Chart

0 0000

1 0001

2 0010

3 0011

4 0100

5 0101

6 0110

7 0111

8 1000

9 1001

10 1010

11 1011

12 1100

13 1101

14 1110

15 1111

Example 1:

Error Code: 1

1. 1/16 = 0.0625 No temperature error

2. 0.0625 x 16 = 1 Moisture error code = 1

3. Error Code Bit Map (0) (1)

0000 0001

+ >> RH < 0% (gas too dry)

Example 2:

Error Code: 39

1. 39/16 = 2.4375 Temperature error code = 2

2. 0.4375 x 16 = 7 Moisture error code = 7

3. Error Code Bit Map (2) (7)

0010 0111

++ >> Moisture Unit Selected

Depends on Temperature

+ >> Output 1 < 4mA

+ >>Temperature > + 85°C

4-10 Optional Display/User Interface

Page 39

Chapter 5

Page 40

Troubleshooting

Problems and Recommended Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Removing the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Page 41

November 2005

Problems and Recommended Solutions

Problem: The loop current is outside the range of 4-20 mA, as

shown on display or current meter. (In some cases, 22

mA can be ordered as the fault current.)

Solution: The process dewpoint is out of range. If the dewpoint is

above +85°C (+185°F), the current will go to 22 mA.

Apply dry air for 20 minutes. If the dewpoint doesn't

decrease, consult the factory.

If the dewpoint is below -15°C (+5°F), the current will go

below 4 mA and then to 22 mA as the fault current.

Expose the DewPro to wetter for several minutes. If the

error remains, the cause may be a defective sensor

assembly or an electronics malfunction. Consult the

factory.

Problem: There is no current.

Solution: Check the voltage and polarity across +/- terminals with a

DC voltmeter. If the voltage is within 12-28 V DC,

consult the factory.

Problem: The response time is very slow.

Solution: Verify the flow with an air flowmeter. If the orifice is at

the outlet of a 7 to 8 bar (=100 psig) process pressure, the

air flow should indicate 20 to 30 1/h (500 cc/min., 1 cfh).

If the flow is dramatically lower, the inlet filter may be

clogged. Remove the 2 micron filter and clean it with a

solvent or replace it.

Removing the Filter Figure 5-1 below illustrates filter parts for removal.

Figure 5-1: Filter Parts

Troubleshooting 5-1

Page 42

Chapter 6

Page 43

Technical Specifications

MMR30 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Optional Onboard Display with User Interface. . . . . . . . . . . . . . . . . . . . . 6-2

Page 44

November 2005

MMR30 Specifications

Sensing Element Silicon-based polymer, capacitance principle, IC electronics

Measurement Range -15°C to +85°C (+5°F to +185°F)

Dew Point Accuracy ±1°C (±1.8°F) for dew points above 0°C (+32°F)

Repeatability ±1°C (±1.8°F)

Standard Operating and

-15°C to +85°C (+5°F to + 185°F)

Storage Temperature

Air Bleedoff at 7 to 8 bar (100 psig)

Maximum Operating

Approximately 28 l/h (1 cfh) (volume related to atmospheric

pressure)

17 bar, 1.7 MPa (250 psia)

Pressure

Output Loop current 4 to 20 mA; 16 µA resolution

Flow Block 316 stainless steel (1.440/1.4436) with ½” (12.7 mm) MNPT or G ½

thread (DIN ISO 228) and gasket seal

Wrench Width for Flow

42 mm (1 5/8”)

Block

Electronics Microcontroller operated

Moisture Unit Dew point temperature in °C or °F (hardware selectable)

Supply Power 24 VDC nominal, tolerance 12 to 28 VDC

Protection Type 4X (IP67)

Weight 2 kg (4.4 lbs)

European Compliance Complies with EMC Directive 89/336/EEC and PED 97/23/EC for

DN <25

Technical Specifications 6-1

Page 45

November 2005

Optional Onboard

Display with User

The optional onboard display with user interface uses a matrix

configurator for:

Interface

• range changes

• unit of measure selection

• current loop adjustment

• error diagnostics

• current value selection for fault conditions

• and entering a pressure constant for ppm

EMI/RFI Performance Criterion A:

1. Conducted Emission Test as per CISPR 11 Class A, 2004

2. Radiated Emission Test as per CISPR 11 Class A, 2004

3. Radiated Susceptibility Test as per IEC 61000-4-3, 2002

4. Electrostatic Discharge Test as per IEC 61000-4-2, 2001

.

v

5. Electrical Fast Transient Test as per IEC 61000-4-4, 2004

6. High Energy Surge Immunity Test as per IEC 61000-4-5, 2001

7. Power Frequency Magnetic Field Test as per IEC 61000-4-8, 2001

EMC IEC 61326, Industrial Locations

6-2 Technical Specifications

Page 46

Chapter 7

Page 47

Accessories

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Page 48

Accessories Single power supply

Panel mount display, power supply, no relays

Panel mount display , power supply, two alarms

Panel mount display , power supply, two alarms.

4 to 20 repeating output

Consult GE Sensing for further information.

November 2005

Accessories 7-1

Page 49

Appendix A

Page 50

Matrix Table for Programming

Page 51

November 2005

Table A-1: Matrix Input for Programming

MMR30 H0 H1 H2 H3 H4 H5 H6 H7 H8 H9

Moisture

Unit

Loop Range V1 Dewpoint

V0 Display

Moisture

Value

V2

Select Moisture Unit

1 = °C

2 = °F

°C 4 mA

Dewpoint

°C 20 mA

Dewpoint

°F 4 mA

Dewpoint

°F 20 mA

Loop

at Fault

1=110%

2=Hold

0=-10%

Loop Raw

Reading

Constant:

Loop

Hardware

Calibration

Temperature

Unit: Loop 1

Hardware

Calibration

Loop 2

Hardware

Calibration

Access Key V8 Input

V3 Pressure

Constant in

mmHg

V4 Display

Temperature

Value

V5

V6

V7

Select Unit of

Temperature:

0=°C

1=°F

Loop

D/A

Calibration

Low

Loop

D/A

Calibration

High

Locking

50 = Unlock

Misc. Setup V9 Display

Present Error

Matrix Table for Programming A-1

Previous

Error

Unit ID Software

Version

Reset to

Defaults

50=Reset

System Reset

50 = Reset

Page 52

GE Industrial

Sensing

We, GE Industrial, Sensing

1100 Technology Park Drive

Billerica, MA 01821

USA

declare under our sole responsibility that the

DewPro® MMR30 Moisture Transmitter Probe

®

DewPro

DewPro

DewPro

to which this declaration relates, are in conformity with the following standards:

• EN 61326:1997+A1+A2

®

MMY30 and MMY31 Dew Point Transmitters

®

MMR101 High-Temperature Moisture Transmitter

MMR31 Moisture Analyzer

DECLARATION

OF

CONFORMITY

following the provisions of the 89/336/EEC EMC Directive.

The units listed above and any sensors and ancillary sample handling systems supplied with them do not bear CE

marking for the Pressure Equipment Directive, as they are supplied in accordance with Article 3, Section 3 (sound

engineering practices and codes of good workmanship) of the Pressure Equipment Directive 97/23/EC for DN<25.

September 16, 2005

Date of Issue Mr. Gary Kozinski

Certification & Standards, Lead Engineer

CERT-DOC-H3 (August 2004)

Page 53

GE Industrial

Sensing

Nous, GE Industrial, Sensing

1100 Technology Park Drive

Billerica, MA 01821

USA

déclarons sous notre propre responsabilité que les

DECLARATION

DE

CONFORMITE

DewPro

DewPro

DewPro

rélatif á cette déclaration, sont en conformité avec les documents suivants:

• EN 61326:1997+A1+A2

suivant les régles de la Directive de Compatibilité Electromagnétique 89/336/EEC.

Les matériels listés ci-dessus, ainsi que les capteurs et les systèmes d'échantillonnages pouvant être livrés avec ne

portent pas le marquage CE de la directive des équipements sous pression, car ils sont fournis en accord avec la

directive 97/23/EC des équipements sous pression pour les DN<25, Article 3, section 3 qui concerne les pratiques et

les codes de bonne fabrication pour l'ingénierie du son.

16 septembre 2005

Date d’émission Mr. Gary Kozinski

®

®

MMR30 Moisture Transmitter Probe

®

DewPro

®

MMY30 and MMY31 Dew Point Transmitters

MMR101 High-Temperature Moisture Transmitter

MMR31 Moisture Analyzer

Certification et normes, ingénieur de fil

CERT-DOC-H3 (August 2004)

Page 54

GE Industrial

Sensing

Wir, GE Industrial, Sensing

1100 Technology Park Drive

Billerica, MA 01821

USA

erklären, in alleiniger Verantwortung, daß die Produkte

KONFORMITÄTS-

ERKLÄRUNG

DewPro

DewPro

DewPro

folgende Normen erfüllen:

• EN 61326:1997+A1+A2

gemäß den Europäischen Richtlinien, EMV-Richtlinie Nr.: 89/336/EG.

Die oben aufgeführten Geräte und zugehörige, mitgelieferte Sensoren und Handhabungssysteme tragen keine

CE-Kennzeichnung gemäß der Druckgeräte-Richtlinie, da sie in Übereinstimmung mit Artikel 3, Absatz 3 (gute

Ingenieurpraxis) der Druckgeräte-Richtlinie 97/23/EG für DN<25 geliefert werden.

16. September 2005

Außtellungsdatum Hr. Gary Kozinski

®

®

MMR30 Moisture Transmitter Probe

®

DewPro

®

MMY30 and MMY31 Dew Point Transmitters

MMR101 High-Temperature Moisture Transmitter

MMR31 Moisture Analyzer

Bescheinigung und Normen, Leitungsingenieur

CERT-DOC-H3 (August 2004)

Page 55

USA

1100 Technology Park Drive

Billerica, MA 01821-4111

Web: www.gesensing.com

Ireland

Shannon Industrial Estate

Shannon, County Clare

Ireland

Loading...

Loading...