Page 1

GE

Sensing

DewPro

®

MMR101

High-Temperature Moisture Transmitter

with Two Current Loops

User’s Manual

Page 2

GE

Sensing

DewPro

®

MMR101

High-Temperature Moisture Transmitter

User’s Manual

A40251516B

November 2005

The DewPro® MMR101 Transmitter is a GE General Eastern product. GE General Eastern has joined other GE

high-technology sensing businesses under a new name—GE Sensing.

Page 3

November 2005

Warranty Each instrument manufactured by GE Sensing, Inc. is warranted to be

free from defects in material and workmanship. Liability under this

warranty is limited to restoring the instrument to normal operation or

replacing the instrument, at the sole discretion of GE Sensing, Inc.

Fuses and batteries are specifically excluded from any liability. This

warranty is effective from the date of delivery to the original

purchaser. If GE Sensing, Inc. determines that the equipment was

defective, the warranty period is:

• one year for general electronic failures of the instrument

• one year for mechanical failures of the sensor

If GE Sensing, Inc. determines that the equipment was damaged by

misuse, improper installation, the use of unauthorized replacement

parts, or operating conditions outside the guidelines specified by GE

Sensing, Inc., the repairs are not covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties of merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

Return Policy If a GE Sensing, Inc. instrument malfunctions within the warranty

period, the following procedure must be completed:

1. Notify GE Sensing, Inc., giving full details of the problem, and

provide the model number and serial number of the instrument. If

the nature of the problem indicates the need for factory service,

GE Sensing, Inc. will issue a RETURN AUTHORIZATION number (RA),

and shipping instructions for the return of the instrument to a

service center will be provided.

2. If GE Sensing, Inc. instructs you to send your instrument to a

service center, it must be shipped prepaid to the authorized repair

station indicated in the shipping instructions.

3. Upon receipt, GE Sensing, Inc. will evaluate the instrument to

determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Sensing, Inc. determines that the damage is not covered

under the terms of the warranty, or if the warranty has expired, an

estimate for the cost of the repairs at standard rates will be

provided. Upon receipt of the owner’s approval to proceed, the

instrument will be repaired and returned.

iii

Page 4

November 2005

Table of Contents

Chapter 1: General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Order Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Instrument Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2: Installing the MR101

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Manually Setting the Measurement Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Choosing a Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using a Compression Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Using a Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Making Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

System Configuration with One or Two 24 VDC Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

System Configuration with One 24 VDC Power Supply and Loop Powered Display. . . . . . . . . 2-9

System Configuration with External Power Supply and Display . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

v

Page 5

November 2005

Table of Contents (cont.)

Chapter 3: Operating the MMR101

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Displaying Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Description of Matrix Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

System Administration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Moisture Measurement Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Temperature Measurement Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Error Codes and Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Chapter 4: Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter 5: Maintenance

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter 6: Specifications

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

vi

Page 6

Chapter 1

Page 7

General Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Order Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Instrument Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Page 8

November 2005

Introduction The MMR101 is a moisture and temperature transmitter featuring two

patented isolated 4 to 20-mA current loops. The measuring range lies

between 0 to 100% relative humidity at temperatures of up to 150

o

(300

F). This transmitter has been designed for use in low and hightemperature ranges, such as chemical processes, textile production

and the glass, cement and steel industries. This instrument can be

used in pressurized and not pressurized systems with pressures of up

to 10 bar.

o

C

Unpacking Inspect for any damaged packaging and contents. The post office or

freight carrier must be informed of any damage. Damaged

merchandise must be retained until the matter has been settled.

Check that the delivery is complete and agrees with the shipping

documents of your order (refer to nameplate for type and variant).

The delivery comprises:

• DewPro

®

MMR101

• User’s Manual

• Depending on your order: process connection and display

• Calibration certificate

If you have any questions, consult your supplier or the GE Sensing

sales agency in your area (see back cover of these operating

instructions for addresses).

Safety Notes • You should strictly adhere to the notes and warnings in this

manual.

• Operating this instrument in any way other than as described in

this manual may compromise the safety and function of the

measuring instrument.

• Troubleshooting should only be performed by authorized and

trained personnel.

• To prevent accidental startup, remove the unit from service if you

cannot remedy faults.

• Damaged equipment should be clearly identified as such to preven t

danger.

• Repair work must be performed by authorized GE Sensing Service

Personnel.

General Information 1-1

Page 9

November 2005

Order Code You can identify the various options for your unit by order code on

the nameplate of the instrument.

Figure 1-1:

Moisture Sensor DewPro MMR101

Certification/Approvals

R Standard (not certified)

A FM IS Class I, II, III; Division 1, Groups A-G, T4

B FM XP-IS Class I, Division 1, Groups A-D, T5

C FM NI Class, Division 2, Groups A-D, T4;

DIP Class II, III; Division 1, Groups E-G, T4

F ATEX II 3G EEx nA IIC T4

S Other

Process Connection

3 1/2” NPT-M compression fitting

8

G

½ compression fitting

6 No mounting hardware

2 ¾” NPT-M compression fitting

4 ¾” x 16 “O” ring seal compression fitting

(UNF thread)

S Other

Nameplate

Moisture output units

R % Relative Humidity

o

C

C Dew Point

o

F

F Dew Point

g/m

3

D

X g/kg

V % by volume

o

W

C Wet bulb Temperature

o

T

F Wet bulb Temperature

S Special Version

1-2 General Information

Page 10

November 2005

Display

1 With Display/User Interface

2 w/o Display, current at error: 22 mA

3 w/o Display, current at error: hold

4 w/o Display, current at error: 3,6 mA

S Special Version

Probe Length

A 16” (406 mm) long

B 9” (229 mm) long

S Special Version

MMR101R R 3 C 2 B (example of order code)

Instrument Components The DewPro MMR101 consists of the following components:

• electronics module in industrial IP 67, type 4X enclosure

• 1/2" stainless steel sensor tube

• Compression fitting, G 1/2 or 1/2" NPT thread

• Sensor:- capacitive polymer sensor for moisture measurement- Pt

1000 for temperature measurement

• Protective filter made of sintered stainless steel with a porosity of

40 pm

• Conduit adapter M20 to 1/2 NPT-M

General Information 1-3

Page 11

November 2005

Mode of Operation The MMR101 measures the relative humidity and the temperature of

the process. The sensor tube is designed for direct measurement in the

process (in-line measurement). The relative humidity is measured

using the capacitive measuring principle. The moisture sensor

consists of a capacitor with two electrodes. The dielectric constant of

an organic dielectric located between the electrodes changes with

relative humidity. The capacitance determined is converted to a

frequency by the microprocessor. This moisture signal is compared to

a calibration table permanently stored in the instrument.The relative

humidity in the process is determined based on this signal. A Pt 1000

sensor is used to measure the process temperature. The process

temperature is available to the user via a second 4 to 20 mA output. It

is also used for moisture measurement temperature compensation. All

the moisture units provided by the instrument are determined from

relative humidity and temperature.

1-4 General Information

Page 12

Chapter 2

Page 13

Installing the MR101

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Manually Setting the Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Choosing a Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Mounting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Making Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Page 14

November 2005

Introduction Installing the MR101 consists of finding a suitable installation

location, mounting the unit and then making the necessary wiring

connections. However, if your unit does not have a display, you

should make sure the moisture units have been configured.

Use the following sections to properly install you unit:

• Selecting the Measurement Units, below

• Choosing a Mounting Location on page 2-3

• Mounting the Unit on page 2-4

• Making Electrical Connections on page 2-5

Manually Setting the

Measurement Units

If your MMR101 is not equipped with a display, your unit will

already be configured for the measurement units you specified at the

time of ordering. Use the steps below to select different units or verify

the units is setup as specified.

Note: The sensor measures r elative humidity and temperatur e. Other

moisture units are derived from these live measurements. The

o

temperature loop is 0 to 150

selectable. See Measurement Accuracy on page 3-11 for more

details on accuracy.

Use the steps below to reset the desired measurement units.

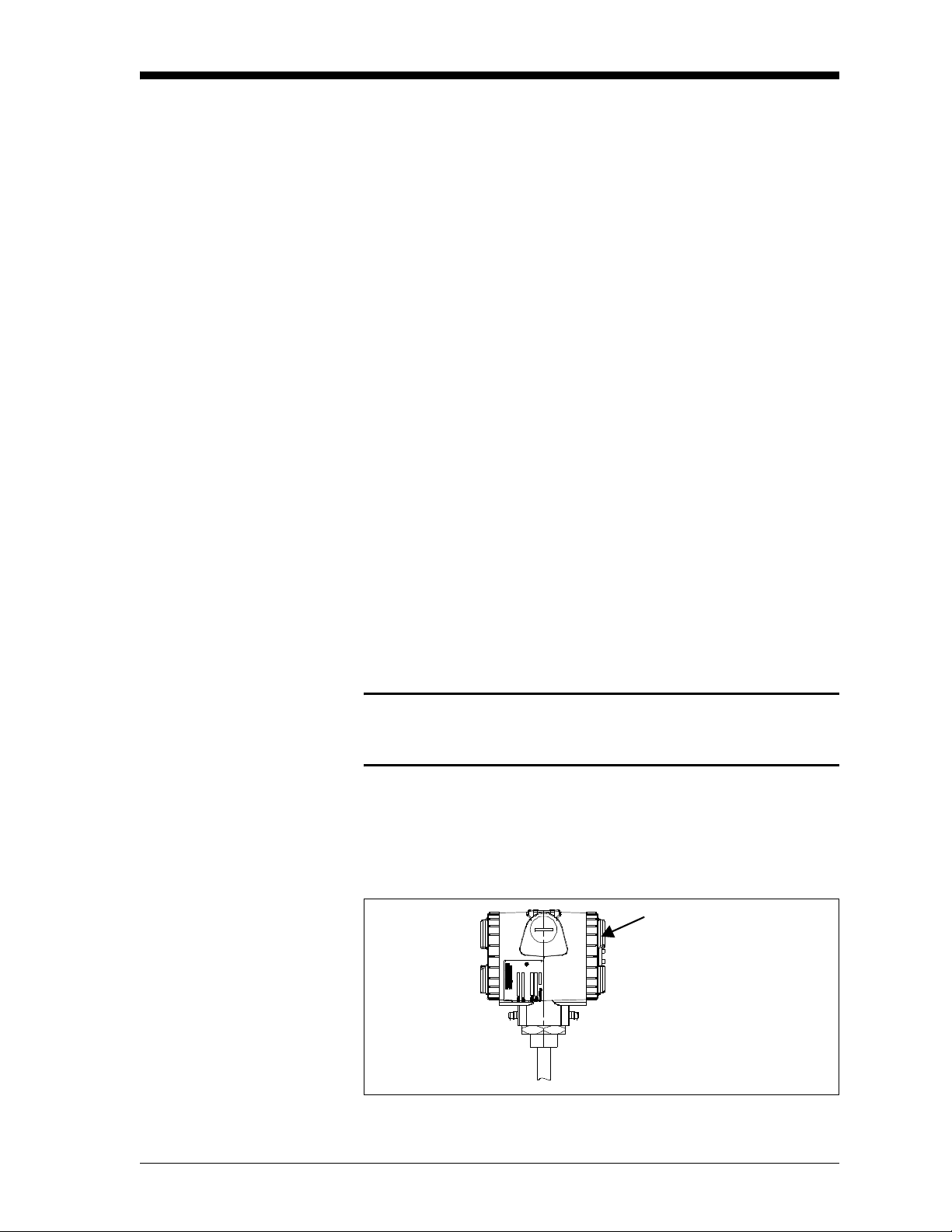

Caution!

If your instrument is connected to power, disconnect it

before performing the following procedure.

1. If your unit is already installed, disconnect it from the power

supply.

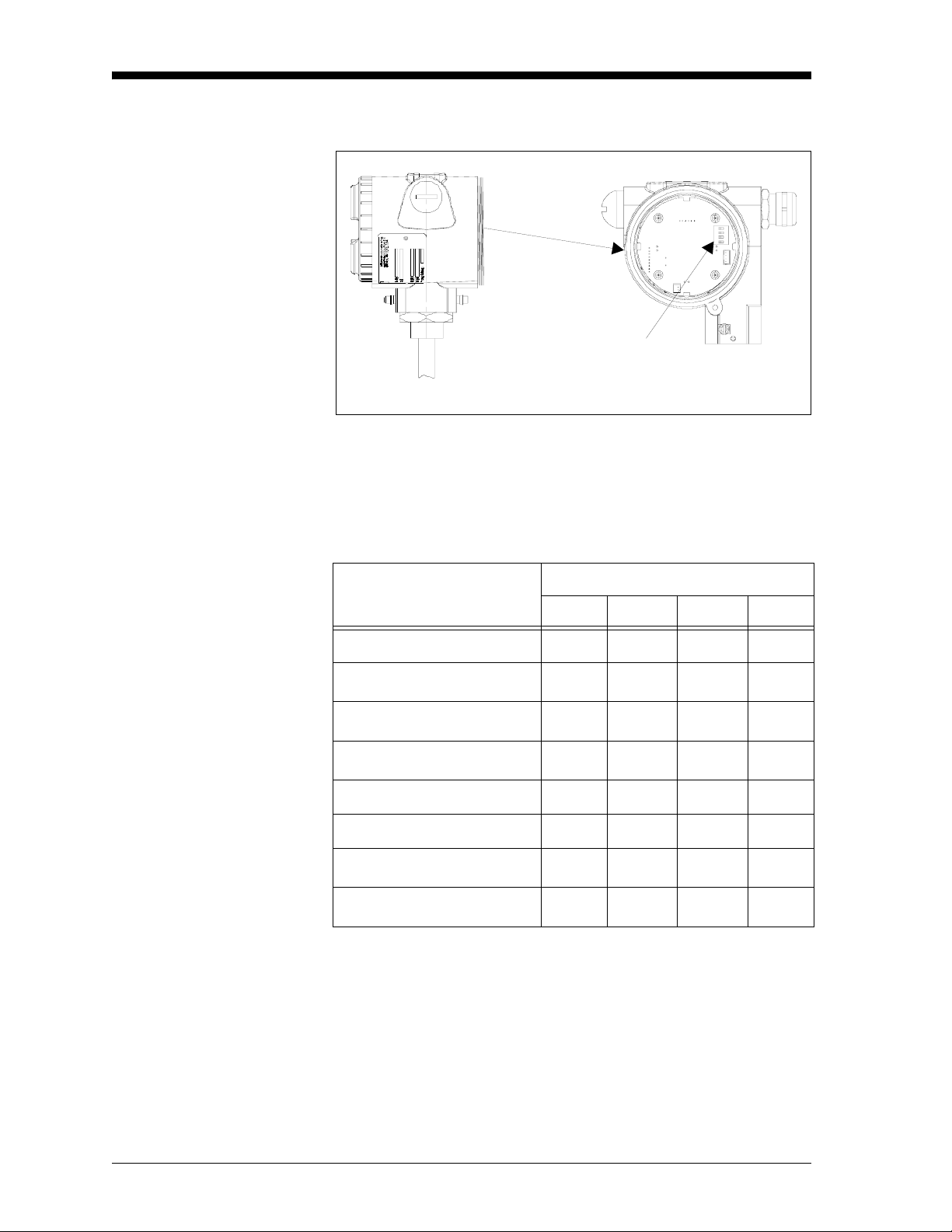

2. Remove the housing cover opposite to the terminal side.

C (32 to 300oF) and is not

Remove

This Cover

Installing the MR101 2-1

Page 15

November 2005

Manually Setting the

Measurement Units

(cont.)

3. Locate the four DIP switches on the printed circuit board.

DIP Switches

(enlarged)

4. Use a pointed object (e.g. a screwdriver) and set switches 1-3

according to the desired output unit (see T able 2-1, below). Switch

No. 4 has no effect.

Table 2-1: DIP Switch Positions for Unit Selection

Switch No.

Unit

1234

Relative Humidity % On On On Dew Point oC

Dew Point oF

Absolute humidity g/m

Off On On -

On Off On -

3

Off Off On -

Mixing ratio g/kg On On Off Volume % Off On Off -

Wet bulb temperature oC

o

Wet bulb temperature

F

On Off Off -

Off Off Off -

2-2 Installing the MR101

Page 16

November 2005

Choosing a Mounting

Location

Choose a mounting location that allows enough clearance for

installation and convenient access during normal operation. Refer to

Figure 2-1, below.

M20 or 1/2“ NPT cable

connections for DC

power supply

5779

129

228

Microprocessor

electronics in IP67

enclosure

129

40m sintered

µ

stainless steel

fliter

Left: MMR101 Assembly 9“ Probe & integrated display/user interface

Right: MMR101 Assembly 16“ Probe, without integrated display/user interface

12.7

12.7

Figure 2-1: Dimension Drawing

412

µ

40m

sintered

stainless

steel

fliter

Installing the MR101 2-3

Page 17

November 2005

Mounting the Unit Caution!

Only trained personnel should install and operate

this unit. Be sure to follow all applicable national

electrical codes and safety codes when installing

this unit, especially for units installed

in hazardous (classified) locations (IS or XP)

You can mount the MMR101 using a:

• Compression Fitting - when installing into a pipe or container.

• Bracket - when measuring trace humidity in ambient air.

Use the appropriate section that follows to select a mounting location

and properly install and mount the MMR101.

Using a Compression

Fitting

Caution!

If you are installing the DewPro into a pressurized

system (up to 10 bar), depressurize the system before

installing or removing the sensor. Pressurized systems

require a stainless steel compression fitting.

1. If you are installing the DewPro into a pressurized system, mount

it after the shut-off valve and then depressurize the pipe/container.

2. The MMR101 is supplied with a stainless steel compression fitting

with a stainless steel ferrule. If you are supplying a fitting, it

should be a stainless steel compression fitting with the following:

• For insertion into pressurized systems, the fitting should

have a 1.471 stainless steel ferrule.

• For un-pressurized systems, the fitting only needs a nylon

ferrule; however, a stainless steel ferrule can be used.

3. Adjust the compression fitting to obtain a minimum sensor

immersion depth of 3 in. (75 mm).

4. Insert the sensor into the pipe/container into the mating connector.

Ideally, the sensor tip should be positioned in the center of the

pipe.

Caution!

When inserting the sensor into the pipe/container,

make sure it does not touch the inside wall

of the pipe/container.

5. Hand-tighten the nut.

6. Using a wrench, tighten the nut 1

properly, the fitting can withstand the specified maximum

pressure.

2-4 Installing the MR101

¼ turns. When tightened

Page 18

November 2005

Using a Bracket When measuring ambient air, the MMR101 can be mounted directly

on a wall, panel or pipe using an optional mounting kit. Mounting kits

can be ordered from the factory. Use Figure 2-2, below to properly

install your unit in the desired configuration.

6.50 in.

(165 mm)

Panel Mounting

2.76 in.

(70 mm)

4.45 in.

(113 mm)

3.23 in.

(82 mm)

4.45 in.

(113 mm)

Vertical Pipe Mounting

0.79 in.

(20 mm)

4.45 in.

(113 mm)

Horizontal Pipe Mounting

2.76 in.

(70 mm)

Horizontal Pipe Mounting

Figure 2-2: Mounting Kit Configurations

Installing the MR101 2-5

Page 19

November 2005

Making Electrical

Connections

The DewPro MMR101 is a loop-powered moisture and temperature

transmitter for two- or four-wire connection being supplied via the

signal line (moisture signal). The first circuit transmits the moisture

unit selected, the second the process temperature. The DewPro can be

optionally supplied from a common or two separate power sources

(1 2 ... 28 V DC). Additional power supply connections are not

required.

Preparation Use the steps below to make electrical connections to the instrument.

Caution!

Make sure that the voltage between the + and -

terminals lies between 12 and 28 V DC.

1. Unscrew the lateral connection cover and remove from the

housing.

2. Loosen the lateral cable gland.

Note: If you are using a cable conduit, remove the cable gland and

replace with the corresponding M20

3. Feed the cable through the cable opening. Use a shielded 4-wire

cable with an outside diameter of 5 mm or greater.

½" NPT adapter.

4. Make connection to the terminal block as shown in Figure 2-3 on

the next page. Connect the cable as follows:

Table: 2-2: Cable Connections

Position Signal

1 Temperature +

2 Temperature 3 Moisture +

4 Moisture 5 External Earth

Ground

6 Internal Earth

Ground

Note: The moisture signal output must always be connected;

connecting the temperature signal output is optional. If the

signal output for temperature is not needed, the corr esponding

terminals should not be used.

2-6 Installing the MR101

Page 20

November 2005

Preparation (cont.) 5. In order to meet EMI/RFI immunity, a 2- or 4-wire shielded cable

with a common foil shield layer is being used to power the

MMR101. Removing the insulation by 3” allows the user to pull

back the foil, clamping it in between the metal cable gland. The

ground wire must be connected to the internal grounding screw.

This way the MMR101 meets EMC requirements according to

IEC 61326, Criterion A (see details under Specifications on page

6-1).

6. Tighten the cable gland to assure protection type IP 67 and to

provide strain relief for the cable.

1 2 3 4 5 6

Figure 2-3: Terminal Block Connections

The DewPro provides various options for making electrical

connections. Use the appropriate section that follows to make

electrical connections.

Installing the MR101 2-7

Page 21

November 2005

System Configuration

with One or Tw o 24 VDC

Power Supplies

Use the figure below to make moisture and temperature connections

using one or two 24 VDC power supplies.

12-28V

12-28V

Temp.

Moisture

Figure 2-4: Connection with One or Two

24 VDC Power Supply

Connection 1 above shows a two wire line with power supply and

moisture signal output (must always be connected).

Connection 2 shows a galvanically separated signal output for

process temperature that can be connected to the same or separate

power source.

2-8 Installing the MR101

Page 22

November 2005

System Configuration

with One 24 VDC Power

Supply and Loop

Powered Display

When making electrical connection for power and the display you

should adhere to the following guidelines:

• The voltage between the + an d - terminals must not drop below

12 V DC.

• Every component connected to the loop causes a voltage drop.

To determine the supply voltage required, add up the voltage

drops of the components connected to the loop and add 12 V.

This sum is the required minimum voltage. A safety margin of

20% should added into the calculated.

• For precision measurement, make sure that both loops are

connected to the power supply at the power supply, do not use

a jumper at the transmitter terminals.

• Adapt the external display to the following measuring ranges

based on the 4 to 20 mA current range:

• 0 to 100% relative humidity

• -40 to 100

• -40 to 212

o

C dew point (up to 150

o

F dew point (up to 300

• 0 to 1000 g/m

3

absolute humidity

o

C for pressurized systems)

o

F for pressurized systems)

• 0 to 1000 g/kg mixing ratio

• 0 to 100% by volume

• -40 to 212

Use the Figure 2-5, below to make moisture and temperature

connections using one or two 24 VDC power supplies.

o

F wet bulb temperature

12...28 VDC

Figure 2-5: Connection with One 24 VDC Power Supply

Installing the MR101 2-9

Page 23

November 2005

System Configuration

with External Power

Supply and Display

Use Figure 2-6, below to make electrical connections for the external

power supply and display.

115/230 VAC

115/230 VAC

Figure 2-6: Connection with External Power Supply and Display

2-10 Installing the MR101

Page 24

Chapter 3

Page 25

Operating the MMR101

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Displaying Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Description of Matrix Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Error Codes and Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Page 26

November 2005

Introduction This section gives a brief description of the MMR101 operation

including powering up and displaying measurements. This section

includes the following:

• Powering Up

• Displaying Measurements

• Measurement Accuracy

Use these instructions to properly operate the MMR101.

Caution!

To ensure the safe operation of this unit, you

must install and operate the MMR101 as described

in this manual. In addition, be sure to follow

all applicable safety codes and regulations

for installing electrical equipment in your area.

Powering Up Caution!

Before powering up make sure that all equipment

in proximity to the unit (e.g. valve, pumps, etc.)

is functioning properly.

The MMR101 has a power supply that accepts 12 to 28 VDC (24

VDC nominal). After making electrical connections, including

grounding, as described in the previous section, Installing the MR101,

connect power. Use the following section to display the desired data.

IMPORTANT: The power line/connection is the main disconnect

device.

Operating the MMR101 3-1

Page 27

November 2005

Displaying

Measurements

If your MR101 is supplied with a display, you can display the desired

measurements using the key located to the left and right of the display

as shown in Figure 3-1, below. Units without the display, must be

manually setup as described in Manually Setting the Measurement

Units on page 2-1.

Figure 3-1: Display and Keys

The available measurements options are arranged in a matrix format.

Each option is assigned coordinates on the 10 by 10 matrix, specified

with V (vertical), H (horizontal) and a number for each. You select

the desired option by entering the matrix position. The matrix, on the

next page, shows all the possible options. See below for an example

of how to program the unit.

Example:

To set the dew point value to 5oC for 4 mA (V1 H3 on matrix):

1. Press the V key until the display shows V1.

2. Press the H key until the display shows H3.

3. Use the + or - key to change the numeric value to 5.

4. Proceed to any part of the matrix.

See Description of Matrix Options on page 3-5 for a description of all

the possible options.

Note: You can return to position V0 H0 from any field by pressing

the V and H keys simultaneously.

3-2 Operating the MMR101

Page 28

November 2005

MMR101 H0 H1 H2 H3 H4 H5 H6 H7 H8 H9

V0

V1

V2

V3

V4

Display

Moisture

Value

%RH

4 mA

Volume %

4 mA

Pressure

Constant in

mmHg

Display

Temp. Value

Select

Display Unit

%RH

20 mA

Volume %

20 mA

Select

Display Unit

o

0 =

C

o

F

1 =

Select

Output Unit

Dew point

o

C 4 mA

o

C Wet bulb

4 mA

Dew point

o

C 4 mA

o

C Wet bulb

20 mA

Dew point

o

F 4 mA

o

F Wet bulb

4 mA

Dew point

o

F 4 mA

o

F Wet bulb

g/m

4 mA

3

20 mA

Temp. 4 mA Temp. 20

mA

Loop # 1 at

Fault

0 = 110%

1 = −10%

2 = Hold

3

g/m

20 mA

Loop # 1 at

Fault

0 = 110%

1 = −10%

2 = Hold

Display

Moisture

Freq.

g/kg

4 mA

Output #1

D/A Cal

4 mA

g/kg

4 mA

Output #1

D/A Cal

20 mA

V5

V6

V7

V8

Display

V9

Matrix Moisture Units: 0=% Relative Humidity 3=g/m

present

Error Code

1=Dew Point

2=Dew Point

o

C4=g/kg7=

o

F5=% by vol.

Software

Version

3

6=oC wet bulb temp.

o

F wet bulb temp.

Output #2

D/A Cal

4 mA

Output #2

D/A Cal

20 mA

Input

Locking

50 = unlock

System

Reset

50 = Reset

Operating the MMR101 3-3

Page 29

November 2005

Description of Matrix

Options

System Administration

Options

The options available can be divided up into the following groups:

• system administration

• moisture measurement

• temperature measurement

• error codes/messages

Use the tables below for a description of each option and the

corresponding matrix coordinates.

Table 3-1: System Administration Options

Location of Matrix Description of Function

Unlock/Lock the Matrix

V8 H9

Unlocks and locks the matrix functions.

When the matrix is locked, the V and H

keys continue to be functional, but the +

and - keys are disabled. This prevents

unauthorized changes to the user

functions. Entering the value, 50 unlocks

the matrix. Entering any other value

locks the matrix.

Default: 0

V9 H9

V9 H3

System Reset

Resets the instrument settings, similar to

switching the instrument off and back on

again. No instrument settings are

changed. Entering a value of 50 in this

position initiates the reset, which is

performed after approx. 5

seconds.Normal operation in matrix

position VH 00 is resumed after the

reset.

Default: 0

Software Version

Displays the software version installed in

the instrument.

Operating the MMR101 3-5

Page 30

November 2005

Moisture Measurement

Options

Table 3-2: Moisture Measurement Options

Location of Matrix Description of Function

Measured Values Display

V0 H0

V0 H1

V0 H2

Displays the measured process humidity

value. The bar graph shows the output

value for the programmed output range

as a percentage.

Selection of the Unit

Unit to be used to display the moisture

value in matrix field V0 H0.

Options available:

0 = % relative humidity

o

C dew point

1 =

o

F dew point

2 =

3 = g/m

3

4 = g/kg

5 = % of volume

o

C wet bulb temperature

6 =

o

F wet bulb temperature

7 =

Default = pre selected based on order

code

Sets the moisture range of the 4 to 20

mA output (circuit 1)

Unit to be used for the 4 to 20 mA

moisture output. The same selections are

available as in position V0 H1. The

display and current output units are

selected independent of each other.

Options available, see V0 H1

Default = pre-selected based on order

code

Loop 1 at fault (circuit 1)

V0 H7

Status of current output 1 according to

error detection by the moisture sensor or

measuring circuit.

Options available:

0 = 110% (22 mA)

1 = -10% (3.6 mA)

2 = hold at previous level

Default: on instruments equipped with

display: 0 on instruments not equipped

with display: selected by order code

3-6 Operating the MMR101

Page 31

November 2005

Moisture Measurement

Options (cont.)

Table 3-2: Moisture Measurement Options (cont.)

Location of Matrix Description of Function

Display of frequency measured (circuit

1)

V0 H8

Displays the current moisture frequency.

Adjustment of moisture range for 4 to

20 mA output (circuit 1)

V1 H0

V1 H1

V1 H2

V1 H3

V1 H4

V1 H5

V1 H6

V1 H7

V1 H8

V1 H9

V2 H0

V2 H1

V2 H2

V2 H3

V2 H4

V2 H5

% RH = 4 mA, default 0

% RH = 20 mA, default 100

o

C dew point = 4 mA, default -40

o

C dew point = 20 mA, default 100

o

F dew point = 4 mA, default -40

o

F dew point = 20 mA, default 212

3

= 4 mA, default 0

g/m

3

= 20 mA, default 1000

g/m

g/kg dry air = 4 mA, default 0

g/kg dry air = 20 mA, default 1000

% by volume = 4 mA, default 0

% by volume = 20 mA, default 100

o

C wet bulb temp. = 4 mA, default -40

o

C wet bulb temp.= 20 mA, default 150

o

F wet bulb temp.= 4 mA, default -40

o

F wet bulb temp.= 20 mA, default 300

V3 H0

V3 H8

V3 H9

Constant pressure adjustment

This function can be used to enter a value

for the process pressure (in mm Hg

column). This value is only needed to

compute the mixing ratio in g/kg.

Default: 760

Adjustment of current output 1

Adjustment of the 4 to 20 mA hardware

settings for the moisture output. This

output is pre adjusted by the factory and

normally does not need readjustment. To

check the setting, connect a current

measuring instrument in series with circuit

1 (see chapter 2). The output signal in

position V3 H8 is automatically switched

to the 4 mA setting, and V3 H9 is

automatically switched to the 20 mA

setting. The + and - keys can be used for

fine adjustment. Move on to any other

matrix field to return the current value

measured.

Operating the MMR101 3-7

Page 32

November 2005

Temperature

Measurement Options

Table 3-3: Temperature Measurement Options

Location of Matrix Description of Function

Current

V4 H0

V4 H1

V4 H5

V4 H6

Displays the temperature measured. The

bar graph shows the output value for the

programmed output range as a percentage.

Selection of unit

Unit of measure to be used to display the

temperature in matrix field V4 H0.

Options available for selection:

o

0 =

C

o

F

1 =

Adjustment of temperature range of 4

to 20 mA output (circuit 2)

Unit value of measure to be used for the 4

to 20 mA temperature output. The value

range for both positions lies between 0

and 150. The output range is always

o

specified in

C independent of the display

unit selected.

Default: 0 (V5 H5) …. 150 (V4 H6)

Loop 2 at fault

V4 H7

Status of current output 2 when an error

has occurred in the temperature measuring

circuit.

Options available for selection:

0 = 110% (22 mA)

1 = - 10% (3.6 mA)

2 = hold at previous level Default: on

instruments equipped with display: 0 on

instruments not equipped with display:

selected by order code.

3-8 Operating the MMR101

Page 33

Temperature

Measurement Options

(cont.)

November 2005

Table 3-3 Temperature Measurement Options (cont.)

Location of Matrix Description of Function

Adjustments of current output 2

V7 H8

V7 H9

Adjustment of 4 to 20 mA hardware

settings for the temperature output. This

output is pre adjusted by the factory and

normally does not need readjustment. To

check the setting, connect a current

measuring instrument in series with

circuit 2. The output signal in position

V7 H8 is automatically switched to the 4

mA setting, and V7 H9 is automatically

switched to the 20 mA setting. The + and

- keys can be used for fine adjustment.

Move on to any other matrix field to

return the output signal to reflect current

measured values.

Default: On instruments not equipped

with display: based on order code

Operating the MMR101 3-9

Page 34

November 2005

Error Codes and

Messages

The MMR101 has a series of error codes and messages that appear on

the display to indicate certain conditions.

Note: Fields that display data cannot be modified. Fields that can be

modified have a flashing digit.

Table 3-4: Error Codes and Messages

Location

of Matrix Description of Function

" - - - - " If this appears in the matrix field, it indicates that the

matrix position is assigned.

V9 H0

Displays the current error code. If no error code is

active, dashes ("- - - ") are displayed in this matrix

position. If several errors exist, the error codes are

displayed using the following priority:

Error Code Error Status

401 Moisture sensor error

201 Relative humidity outside upper

measuring range

202 Relative humidity outside lower

measuring range

203 Temperature outside upper

measuring range

204 Temperature outside lower

measuring range

205 RH loop span too large

206 RH loop span too small

207 Temperature loop span too large

208 Temperature loop span too small

3-10 Operating the MMR101

Page 35

November 2005

Measurement Accuracy The sensor measures relative humidity and temperature. Other

moisture units are derived from these live measurements.

The accuracy of the instrument is specified as a percentage of relative

humidity. Inaccuracy is a result of the temperature dependence of

relative humidity. This dependence is due to physical properties and

is independent of the measuring apparatus. The influence of

temperature fluctuation should be taken into account for relative

humidity, as well as the derived moisture units.

Table 3-5, below shows the influence of temperature fluctuations of

o

± 1

C on relative humidity.

Table 3-5: Change in Relative Humidity

as a Function of the Temperature

Temperature

RH

o

C20

10

o

C30

o

C40

o

C50

10% ± 0,7% ± 0,6% ± 0,5% ± 0,5% ± 0,5%

50% ± 3,5% ± 3,2% ± 3,0% ± 2,6% ± 2,3%

90% ± 6,3% ± 5,7% ± 5,4% ± 4,6% ± 4,1%

o

Note: The temperature loop is 0 to 150

C (32 to 300oF).

o

C

Operating the MMR101 3-11

Page 36

Chapter 4

Page 37

Troubleshooting

Page 38

Troubleshooting

November 2005

Failure Possible Cause Remedy

Current

signal out-

side 4 to

20 mA

range

The sensor circuit has

measured a value which

lies outside the

calibration table range.

This may be caused by

very dry process

conditions (current < 4

mA) or by

condensation effects on

the sensor (current > 20

mA).

Check the display diagram

on instruments equipped

with the optional display

module.

If the signal arrows on

either side are lit or error

code 201 or 202 is

displayed in pos. V9 H0,

this means that the

measuring range has been

exceeded. Remove the

sensor from the process

and expose it to ambient air

or another air source with a

relative humidity between

10 and 90%.

Contact GE Sensing if the

measured value does not

return to the 10 to 90%

range.

The dew point or

another operand is

outside the permissible

range.

All operands are limited by

specific output ranges. The

signal arrows on the

display module only light

up when the relative

humidity lies outside the

calibration range. The

computed quantity , e.g. for

the dew point, may be

outside the operating range

for several combinations of

temperature and relative

humidity

Operation outside these

ranges does not damage the

instrument.

Troubleshooting 4-1

Page 39

November 2005

Failure Possible Cause Remedy

No power Incorrect instrument

connection.

Check the voltage and

polarity at the + and connection terminals. The

voltage should be between

12 and 28 VDC.

Contact GE Sensing if

there is no current flow

even though the voltage

and polarity are correct.

Instru-

ment

response

too slow

The protective filter is

soiled.

Remove the instrument

from the process. Unscrew

the protective filter and

clean it with a solvent (e.g.

hexing, cleaner's naphtha).

If possible, blow clean air

(oil- and dust-free) through

the filter to loosen dirt.

Note: The instrument settings and calibration data are retained in

the event of a power failure thanks to storage in non-volatile

memory.

4-2 Troubleshooting

Page 40

Chapter 5

Page 41

Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Page 42

November 2005

Cleaning Particulate substances in the process gas may clog the protective

filter. This may impair the function of the sensor.

Remove the filter and clean with a strong (halogen-free) solvent or by

flushing with oil- and dust-free, dry air.

In the case of processes with a high concentration of finely distributed

particles, additional filtering may be required to prevent clogging of

the sintered protective filter.

Make sure that the filter does not contain any solvent residue before

screwing it back onto the sensor.

The sensor element must always be handled very carefully. If soiled,

it may be briefly swished in a solvent (pure hexing, toluene or

acetone).

After cleaning the sensor with solvent, allow sufficient time for it to

dry before reinstalling it.

Calibration Factory Calibration

Fifty-five calibration values covering the entire measuring range are

determined at the factory. NIST-certified reference instruments are

used for calibration (NIST = National Institute for Standardization

Technology). The calibration certificate supplied with the sensor

confirms that the sensor matches the reference values.

Recalibrations

Just like moisture measurement, the recalibration cycle greatly

depends on the operating conditions (contamination, aggressive

media, etc.) and sensor stress. Under normal process conditions, the

sensor check / recalibration should be performed after one to two

years.

This cycle may be longer or shorter depending on operating

conditions and accuracy requirements.

Field Validation

The user can perform a sensor check in the field. This validation takes

place at room temperature (approx. 25

solutions. It is intended as a decision aid in determining whether or

not recalibration or sensor replacement is required.

o

C) using saturated salt

This check should be performed using an GE Sensing test unit with

saturated salt solutions of 11.3 and 75.4% relative humidity that can

be ordered from the factory.

Repairs Repairs must be carried out directly by the manufacturer or by the GE

Sensing Service Engineer.

Maintenance 5-1

Page 43

Chapter 6

Page 44

Specifications

Page 45

Specifications

Parameter Specification

Sensing Element Polymer; capacitance

RH Range 0 to 100%

RH Accuracy

± 2% up 65

Temperature Sensor Platinum RTD

Temperature Accuracy

Temperature Resolution

Operating Temperature

Range

Maximum Operating

± 1.1

o

0.05

Process: 0

Electronics: -40

150 psi (10.2 bar)

Pressure

Electronics Microcontroller operated, loop-powered

Loop Power Supply 24 VDC nominal, 12 to 28 VDC range

o

C (150oF) process temperature

o

C (± 2oF)

C (0.09oF)

o

C to +150oC (+32oF to +300oF)

o

C to +85oC (-40oF to 185oF)

November 2005

Outputs Two fully isolated 4 to 20 mA current loops (moisture and tempera-

Hardware Selectable Units

Standard Temperature

Output

Display Four-digit number display with bar graph and matrix position indica-

Protection Type 4X/IP67

Probe Tube 16-in. (406 mm) Probe: 316 stainless steel, 0.5 in diameter. Adjust-

Typical Mounting Adapter

Sensor Guard 40 micron sintered filter, 316 stainless steel cap

Weight 4.4 lbs (2 kg)

ture) patented (U.S. patent #5,677,476)

0% to 100% RH, -40

o

F or 150oC under system pressure), 0 to 1000 g/m3 absolute

300

o

C to 100oC or -40oF to 212oF dew point (up to

humidity, and 0 to 1000 g/kg mixing ratio dry air, 0 to 100% by vol-

o

ume, -40

o

0

C to 150oC (32oF to 300oF) range

C to 100oC or -40oF to 212oF wet bulb temperature.

tion. Four user interface keys for unit selections, output adjustments

and ranging.

able insertion length from 3 in. (76 mm) to 14.25 in. (362 mm)

9-in. (228 mm) Probe: 3 in. (76 mm) to 7.25 in. (184 mm).

1/2 in. tube

x 1/2 in. NP T-M or G1/2 compression fitting; flanges and

other sizes available upon request.

Specifications 6-1

Page 46

November 2005

Parameter Specification

EMI/RFI Protection Meets IEC 61326

Performance Criterion A:

- Conducted Emission Test as per CISPR 11 Class A, 2004

- Radiated Emission Test as per CISPR 11 Class A, 2004

- Radiated Susceptibility Test as per IEC 61000-4-3, 2002

- Electrostatic Discharge Test as per IEC 61000-4-2, 2001

- Electrical Fast Transient Test as per IEC 61000-4-4, 2004

- High Energy Surge Immunity Test as per IEC 61000-4-5,

2001

- Power Frequency Magnetic Field Test as per IEC 61000-4-8,

2001

Optional Certifications/

Approvals

• FM IS Class I, II, III, Division 1, Groups A, B, C, D, E, F & G , T4

• FM XP-IS Class I, Division 1, Groups A, B, C & D, T5

• FM NI Class I, Division 2, Groups A, B, C & D, T4A

DIP Class II, III, Division 1, Groups E, F & G, T4

• ATEX II 3G EEx nA IIC T4

6-2 Specifications

Page 47

GE Industrial

Sensing

We, GE Industrial, Sensing

1100 Technology Park Drive

Billerica, MA 01821

USA

declare under our sole responsibility that the

DewPro® MMR30 Moisture Transmitter Probe

®

DewPro

DewPro

DewPro

to which this declaration relates, are in conformity with the following standards:

• EN 61326:1997+A1+A2

®

MMY30 and MMY31 Dew Point Transmitters

®

MMR101 High-Temperature Moisture Transmitter

MMR31 Moisture Analyzer

DECLARATION

OF

CONFORMITY

following the provisions of the 89/336/EEC EMC Directive.

The units listed above and any sensors and ancillary sample handling systems supplied with them do not bear CE

marking for the Pressure Equipment Directive, as they are supplied in accordance with Article 3, Section 3 (sound

engineering practices and codes of good workmanship) of the Pressure Equipment Directive 97/23/EC for DN<25.

September 16, 2005

Date of Issue Mr. Gary Kozinski

Certification & Standards, Lead Engineer

CERT-DOC-H3 (August 2004)

Page 48

GE Industrial

Sensing

Nous, GE Industrial, Sensing

1100 Technology Park Drive

Billerica, MA 01821

USA

déclarons sous notre propre responsabilité que les

DECLARATION

DE

CONFORMITE

DewPro

DewPro

DewPro

rélatif á cette déclaration, sont en conformité avec les documents suivants:

• EN 61326:1997+A1+A2

suivant les régles de la Directive de Compatibilité Electromagnétique 89/336/EEC.

Les matériels listés ci-dessus, ainsi que les capteurs et les systèmes d'échantillonnages pouvant être livrés avec ne

portent pas le marquage CE de la directive des équipements sous pression, car ils sont fournis en accord avec la

directive 97/23/EC des équipements sous pression pour les DN<25, Article 3, section 3 qui concerne les pratiques et

les codes de bonne fabrication pour l'ingénierie du son.

16 septembre 2005

Date d’émission Mr. Gary Kozinski

®

®

MMR30 Moisture Transmitter Probe

®

DewPro

®

MMY30 and MMY31 Dew Point Transmitters

MMR101 High-Temperature Moisture Transmitter

MMR31 Moisture Analyzer

Certification et normes, ingénieur de fil

CERT-DOC-H3 (August 2004)

Page 49

GE Industrial

Sensing

Wir, GE Industrial, Sensing

1100 Technology Park Drive

Billerica, MA 01821

USA

erklären, in alleiniger Verantwortung, daß die Produkte

KONFORMITÄTS-

ERKLÄRUNG

DewPro

DewPro

DewPro

folgende Normen erfüllen:

• EN 61326:1997+A1+A2

gemäß den Europäischen Richtlinien, EMV-Richtlinie Nr.: 89/336/EG.

Die oben aufgeführten Geräte und zugehörige, mitgelieferte Sensoren und Handhabungssysteme tragen keine

CE-Kennzeichnung gemäß der Druckgeräte-Richtlinie, da sie in Übereinstimmung mit Artikel 3, Absatz 3 (gute

Ingenieurpraxis) der Druckgeräte-Richtlinie 97/23/EG für DN<25 geliefert werden.

16. September 2005

Außtellungsdatum Hr. Gary Kozinski

®

®

MMR30 Moisture Transmitter Probe

®

DewPro

®

MMY30 and MMY31 Dew Point Transmitters

MMR101 High-Temperature Moisture Transmitter

MMR31 Moisture Analyzer

Bescheinigung und Normen, Leitungsingenieur

CERT-DOC-H3 (August 2004)

Page 50

USA

1100 Technology Park Drive

Billerica, MA 01821-4111

Web: www.gesensing.com

Ireland

Shannon Industrial Estate

Shannon, County Clare

Ireland

Loading...

Loading...