Page 1

Moisture Image Series 1

Hygrometer

Programming Manual

Page 2

April 2004

Process Control Instruments

Moisture Image Series 1

Hygrometer

Programming Manual 910-108PB2

!ATTENTION!

This manual contains inst ructions for Serie s 1 unit s

equipped with controller card p/n 703-1250. This

controller card supports the PanaCom/PanaView

user interface software.

Page 3

June 2003

Warranty Each instrument manufactured by GE Panametrics is warranted to be

free from defects in material and workmanship. Liability under this

warranty is limited to restoring the instr ument to normal operation or

replacing the instrument, at the sole discretion of GE Panametrics. Fuses

and batteries are specif ically exclu ded from any liability. This warranty

is effective from the date of de livery to the original purch as er. If GE

Panametrics determines that the equipment was defective, the warranty

period is:

• one year for general electronic failures of the instrument

• one year f or mechanical failures o f the transducers

If GE Panametrics determines that the equipment was damaged by

misuse, improper installation, the use of unauthorized replacement parts,

or operating conditions outside the guidelines specified by GE

Panametrics, the repairs are not covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties or merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

Return Policy If a GE Panametrics instrument malfunctions within the warranty period,

the following procedure must be completed:

1. Notify GE Panametrics, giving full details of the problem, and

provide the model numbe r and s eri al numbe r of t he instr umen t. I f the

nature of the problem indicates the need for factory service, GE

Panametrics will issue a RETURN AUTHORIZATION NUMBER

(RAN), and shipping in str uc tions for the return of the i nst rume nt to a

service center will be p ro vided.

2. If GE Panametrics instructs you to send your instrument to a service

center, it must be shipped prepaid to the authorized repair station

indicated in the shipping instructions.

3. Upon receipt, GE Panametrics will evaluate the instrument to

determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Panametrics determines that the damag e is not covered under

the terms of the warranty, or if the warra nty has expired , an es timate

for the cost of the repairs at standard rates will be provided. Upon

receipt of the owner’s approval to proceed, the instrument will be

repaired and returned.

iii

Page 4

April 2004

Table of Contents

Chapter 1: Features and Capabilities

Introduction to the Moisture Image

Series 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Electronics Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

BASEEFA Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

CSA Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1- 3

Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

M Series and TF Series Moisture Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Moisture Image Series Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Delta F Oxygen Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

M Series and TF Series Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Moisture Image Series Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Delta F Oxygen Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Pressure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

RS232 Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

User Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Chapter 2: Basic Programming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1

Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Enter i n g Da t a in t o the U s er P ro g ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Screen and Key Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Entering the Passcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Getting On-Line Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Verifying and Entering Setup Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Activating and Changing Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Entering Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Entering High and Low Reference Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Displaying Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Setting Up the Matrix Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Setting Up the Line Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Tagging the Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Adjusting the Contrast of the Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Setting the Clock and Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

v

Page 5

April 2004

Table of Contents (cont.)

Chapter 3: A d vanced Prog r amming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Selecting Measurement Mode and Units for Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Setting the Range for Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting Up the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Selec t ing th e Measur ement Mo d e , Un i t s an d H ig h / L o w Va lu es fo r A la rm s . . . . . . . . . . . . 3-5

Entering the Setpoint and Deadband Values for Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Using Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Entering Constants and User Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Entering User Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Specifying User Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Entering User-Defined Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Entering Saturation Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Using Computer Enhanced Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting Up the Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 7

Viewing the Data Logger Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Viewing Logged Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Removing Logged Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Entering Data Logger Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Setting Up the RS232 Communications Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Configuring the Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Description of a Sample Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Setting Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Procedure for Setting Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Loading New Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 3 0

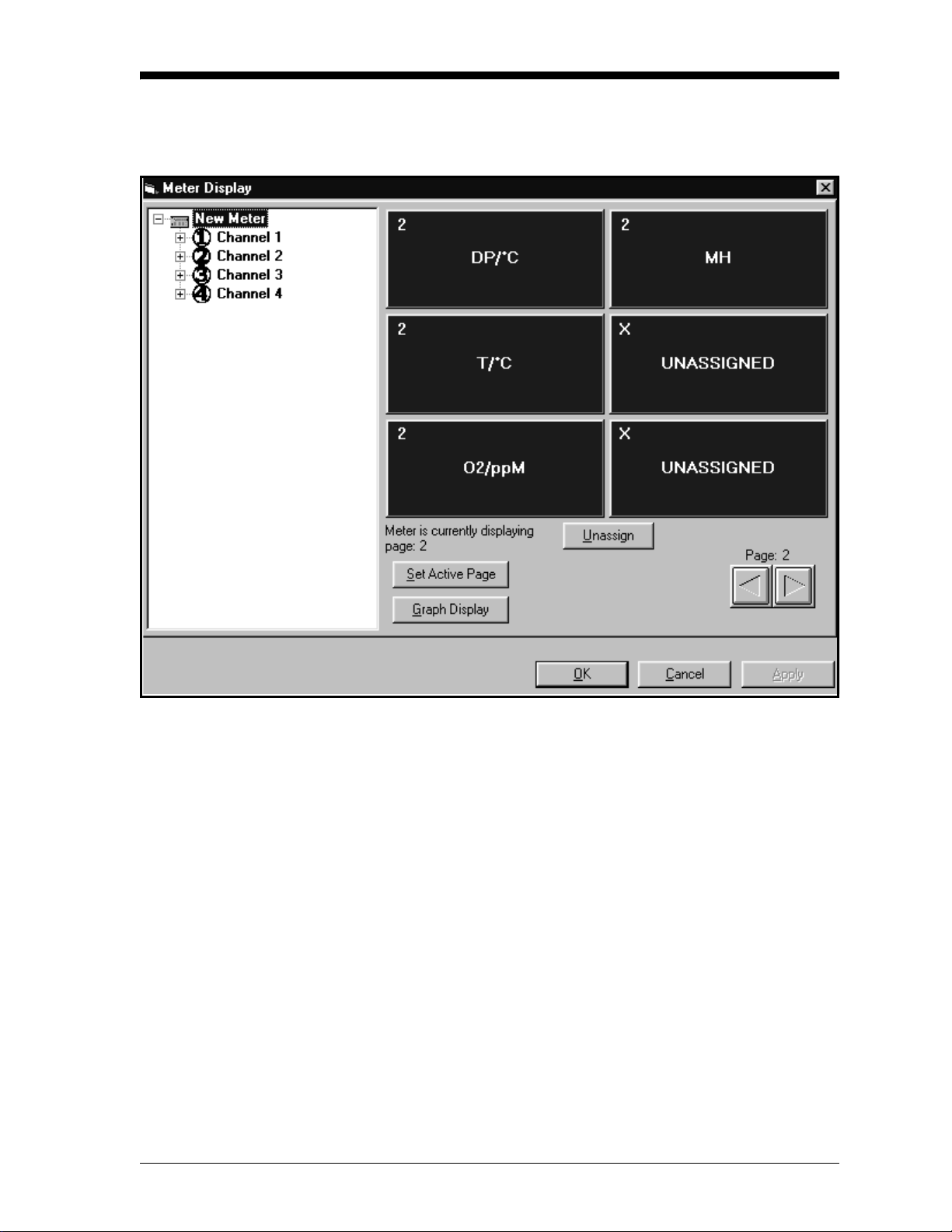

Chapter 4: Programming with PanaView

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Changing Measurement Modes and Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Open the Meter Display Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Change Meter Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Changing a Matrix Display to a Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Changing Alarm Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Changing Recorder Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 9

Setting Recorder Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Testing Recorder Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Programming Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Programming User Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Entering User Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -1 4

Entering Saturation Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

vi

Page 6

Chapter 1

Page 7

Features and Capabilities

Introduction to the Moisture Image Series 1 . . . . . . . . . . . . . . . . .1-1

Electronics Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Page 8

June 2003

Introduction to the Moisture Image Series 1

The GE Panametrics Moisture Image Seri es 1 is a microproc essor

based multi-cha nnel ana lyze r designe d to mea sure dissolve d moistur e

concentration in gas es and non-aqueous liquids, and dissolved

oxygen concentration in gases. It is a highly advanced industrial

analyzer whi ch is ve rs ati le and ad ap tab l e to ma ny ap pl ic ation s.

The Series 1 combines the use of hardware and software to make

various measur ements. The user conne cts the need ed input s (moi sture

probes, oxygen cells, pressure transducers, etc.) to the back panel of

the electronics unit using several types of cables. Typically , the user

installs moisture probes and oxygen cells into the process using a

sample system that is specifically designed for the application. The

sample system delivers a sa mple of the process to the probes. The

probes then se nd a signal to the Series 1 electronics unit, which

interprets the signa l and converts it into a measurement.

The complete analyzer, including electronics, cables, and

measurement probes, forms a “syste m” which is designed to monitor

the process accurately and reliably. The following sections discuss

each part of this “system.”

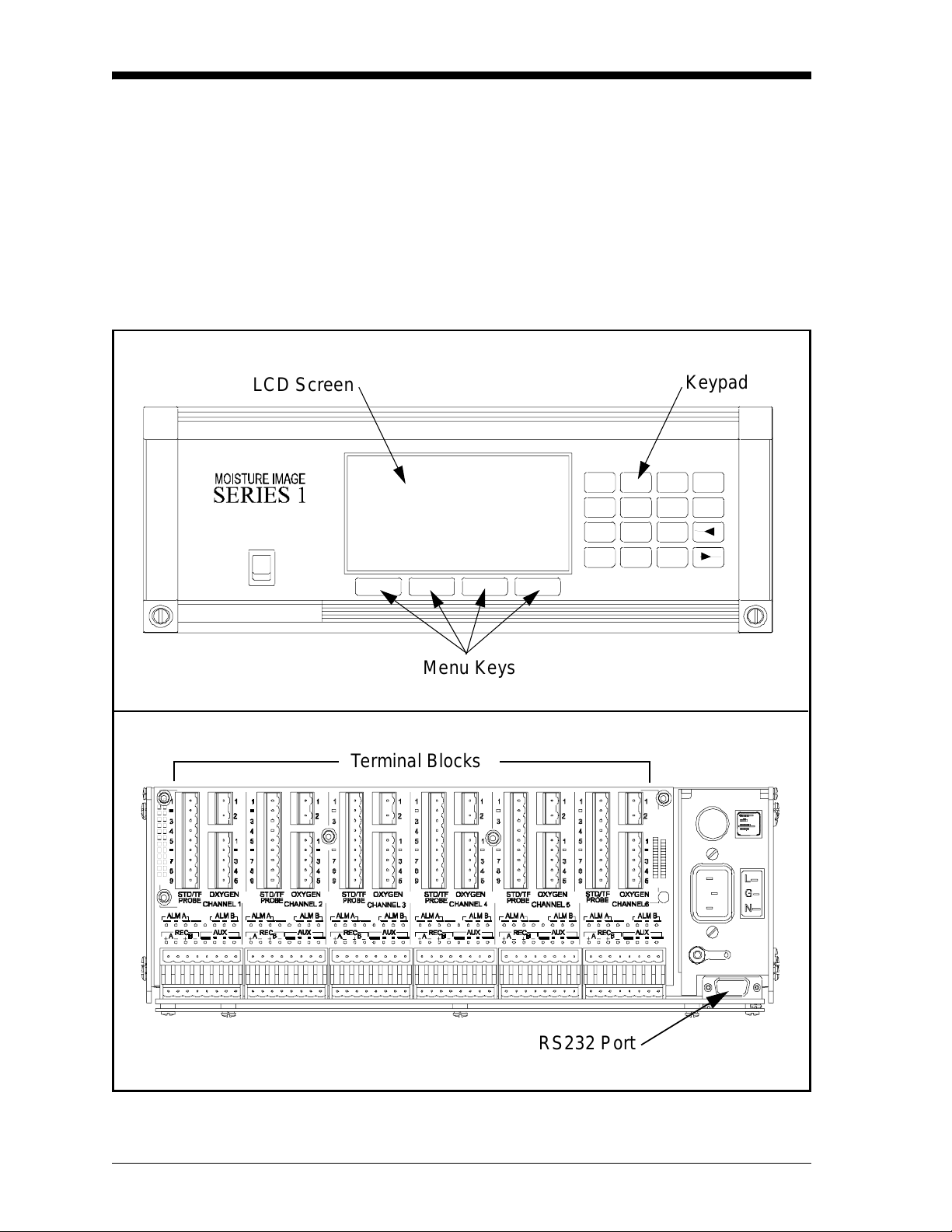

Electronics Unit The center of the “sys tem” is the el ectroni cs unit. The elect ronics unit

has many components, including terminal blocks for all connections,

an RS232 port, a Liquid Crystal Display (LCD), a keypad, and menu

keys. See Figure 1-1.

The back panel of the e lectro nics unit cont ai ns the ter minal bl ocks for

connecting moisture probes, oxygen cells, recorders, and optional

alarms (standard or hermetically sealed) for up to six channels. The

Series 1 also provides connections for two isolated outputs per

channel. Input connections for the M Series, TF Series, Moisture

Image Series and Delta F oxygen sensors are intrinsically safe.

As an optional feature, the Series 1 provides connections for two

auxiliary inputs ( not intr insi cally safe ) on each channe l. The auxil iary

inputs can accept signals f rom any 0/4 to 20-mA or 0 to 2-VDC

device, including other GE Panametrics analyzers.

The RS232 port enables the user to connect a remote terminal,

printer, or computer to the S eries 1. Using an optional Personal

Compute r (PC ) int erfa ce s oft ware p ack a g e, the user ca n als o set up

and operate one or more analyzers from a remote location, transfer

data for further analysis, and create data logs.

The front panel of the electronics unit has a Liquid Crystal Display

(LCD) to show da ta.The LCD is capable of displaying data in a line

graph, or a text matrix format.

Features and Capabilities 1-1

Page 9

April 2004

123

YES

12

2

3

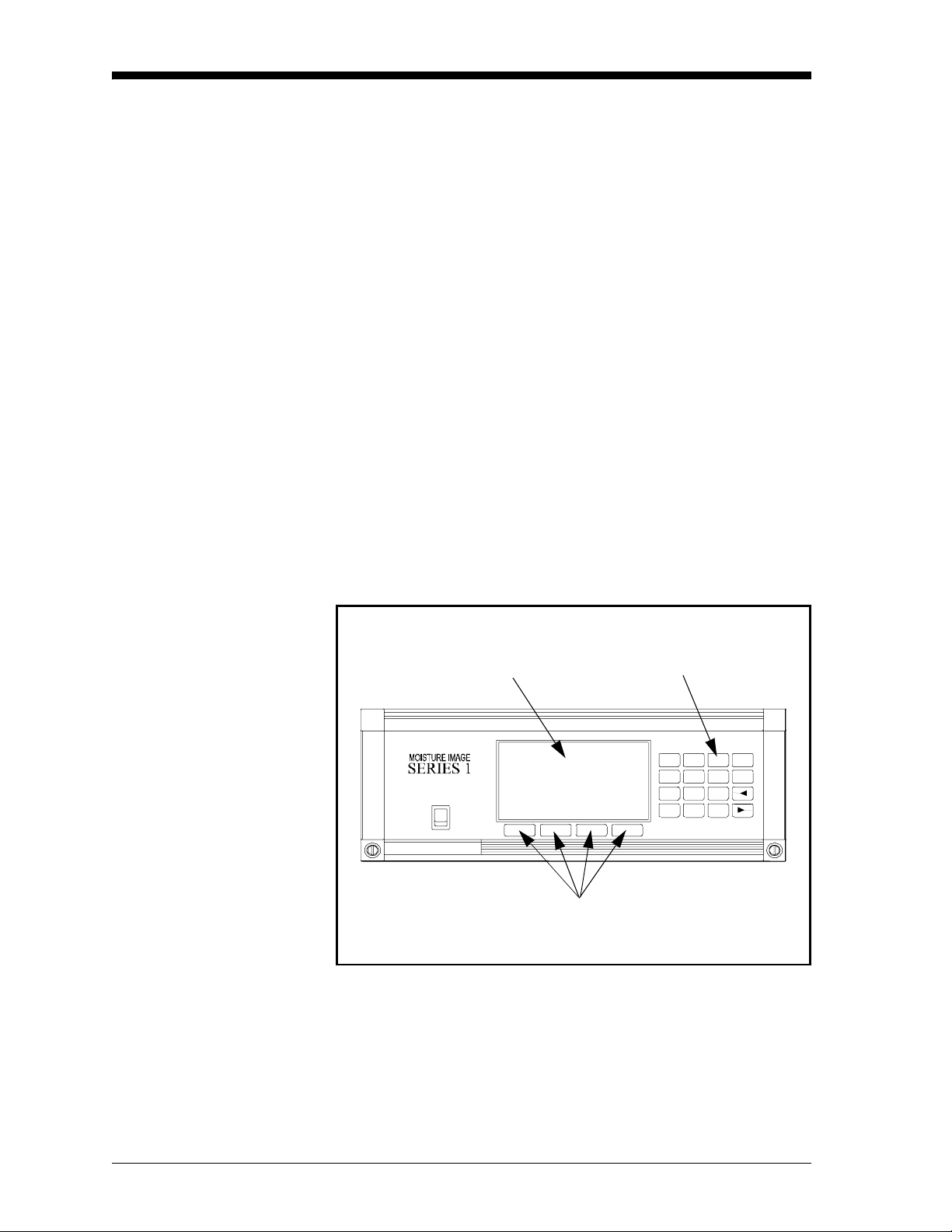

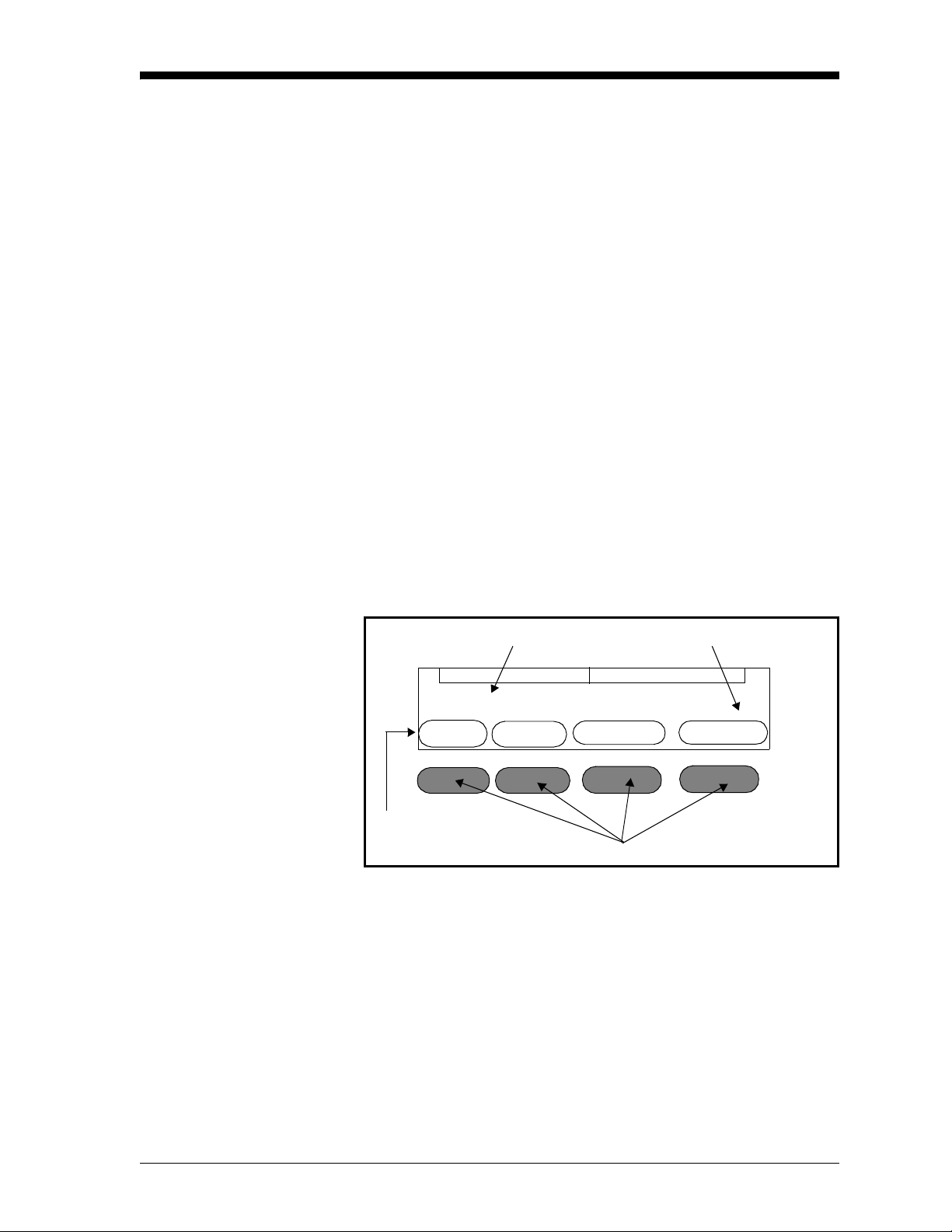

Electronics Unit (cont.) The front panel a lso has a 16-key keypa d th at is used t o en ter data a nd

operate the S eries 1. There are four menu keys below the LCD, as

shown in Figure 1-1 below. The function of a menu key is indicated

directly above it on the LCD. The menu key functions chan ge as the

user makes menu selections.

The electron ics unit wi th al l thes e featu re s is avai l abl e in a rack

mount, bench mount, panel mount, weatherproof, or explosion-proof

versions.

LCD Screen

POWER

Menu Keys

Terminal Blocks

Keypad

4

7

5

8

0-

6NO

9

.

50

RS232 Port

Figure 1-1: The Serie s 1 Electronics Unit Features

1-2 Features and Capabilities

Page 10

June 2003

BASEEFA Certification Rack, bench, panel Series 1s s/n 2000 and above and WPF Series 1s

s/n 2300 and a bove are BASEEFA certified to supply intrinsically

safe levels. Installation requires that the Series 1 be mounted in a

general purpose area only. M Series, TF Series, and Moisture Image

Series probes and Delta F oxygen cells a re intrinsically safe when

connected to the Series 1, allowing f or sensor installation in IE C/

CENELEC zone 0 areas.

CSA Certification Newer versions of rack, bench, panel and WPF Series 1’s are

CSA-NR TL certified intrinsically safe. Install ation requires the

Series 1 be mounted in either a NEC CL.1, Div. 2, Group B, C or D

hazardous area or a general purpose area. M Series, TF Series, and

Moisture Image Series probes and Delta F oxygen cells are

intrinsically sa fe when connected to the Series 1, allowing for sensor

installati on in NEC CL.1, Div. 1, Groups A, B, C and D hazardous

areas.

Note: Refer to certification labels on your instrument and

installation drawing #752-138 to determine the applicable

level of certificat i on that yo ur meter ca r rie s.

Features and Capabilities 1-3

Page 11

June 2003

Probes Probe s are the part of the system that come into contact with the

process flow. The Series 1 uses various types of probes to fit the

needs of a wide range of applications.

The term “probe” includes devices such as moisture se nsors, pressure

transducers, and oxygen cells. Although you can supply your own

probes for certain measurements, GE Panametrics provides the

following standar d probes to make moisture, temperature, pressur e

and oxygen measurements:

• Moisture (M) Series - moisture and temperature (in gases and

liquids)

• Three Function (TF) Series and Moisture Image Series Probes -

moisture, temperature, and pressure (in gases and liqui ds)

• Delta-F Cells - oxygen measurement (in gases)

The most commonly used probes are discussed in more detail below.

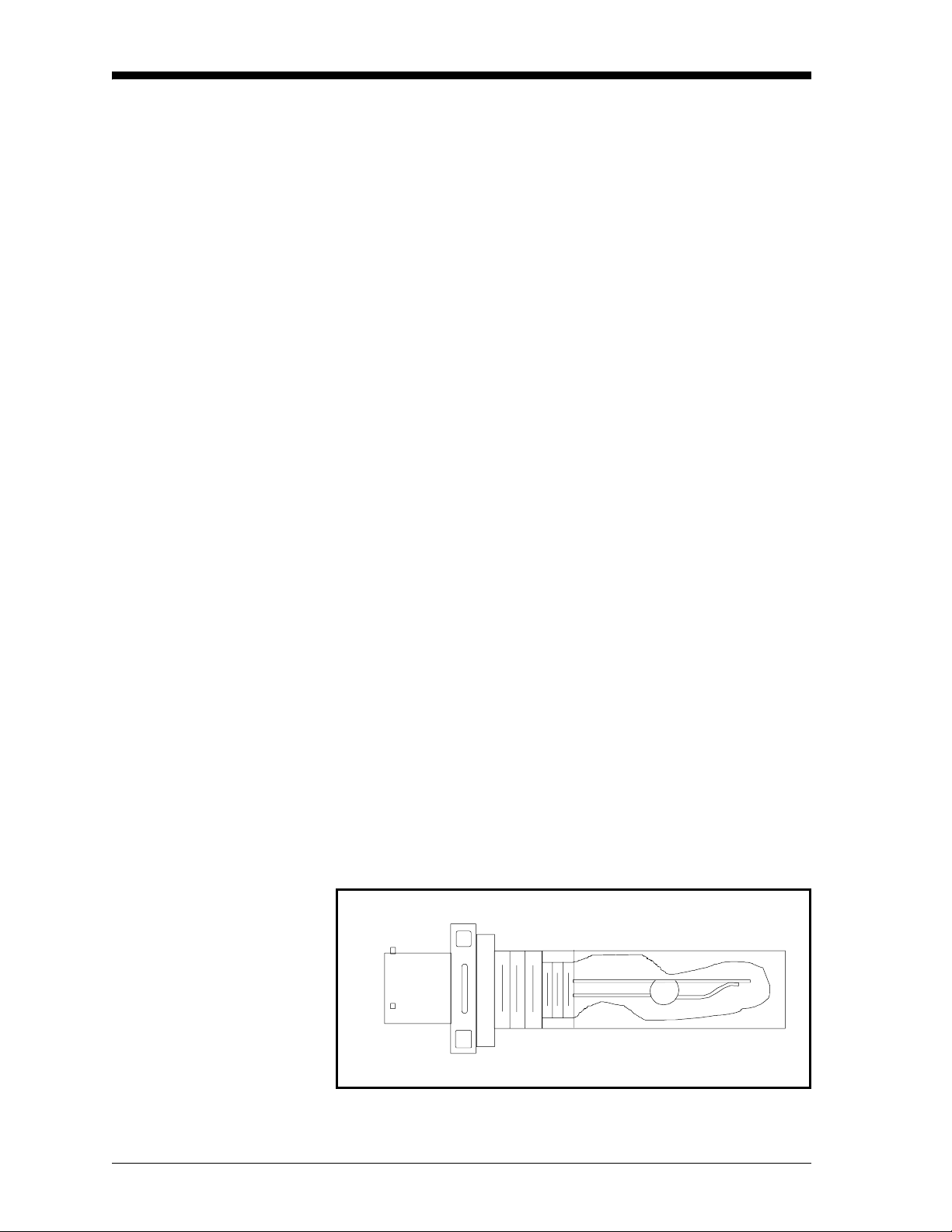

M Series and TF Series Moisture Probes

The M Series and the TF Series probes are very similar. Both probes

use GE Panametrics aluminum oxide sensor s to measure moisture,

and thermistor beads to measure temperature (the thermistor is

optional). The TF Series, howe ver, also has an optional built-in

strain-gag e-ty p e pres su re tr ans d ucer. The sensor ass em b lies are

secured to a probe mount and are usually protected with a sintered

stainless-ste el shield (TF-9 probes do not have a shield). Othe r types

of shields are availabl e (refer to Figure 1-2 below and Figure 1-3 on

page 1-5).

When using an M Series probe, a separate pressure transmitter is

required if in-li ne pressure measurement is needed. The Series 1 can

use any pressure transmitte r with a 0/4 to 20 mA or 0 to 2-V output.

Alternativel y, the user can enter fixed values for temperature and

pressure into the Series 1 memory if the process conditions are

constant.

Figure 1-2: The M Serie s Probe

1-4 Features and Capabilities

Page 12

M Series and TF Series

Moisture Probes (cont.)

June 2003

Figure 1-3: The TF Series Probe

Although the M and the TF S eries probes may be installed directly in

the process line, more often these probes are inserted into a sample

system. The sample system protects the probes and enables the user to

easily remove the probes for calibrating, servicing and cle aning.

Sample systems also control the flow of the process stream so that it

is within the specifications of the measurement probe or cell.

The M and TF Series probes, when used with a BASEEFA-approved

Series 1, are intrinsically safe (see Chapter 3, Specifications, of the

Start up Guide for BASEEFA certification numbers) and designed to

meet the requirements of IEC/CENELEC zone 0 areas.

When operated with a CSA-NRTL approved Series 1, the M and TF

Series probes are intrinsically safe (see Chapter 3, Specifications, of

the Series 1 Startup Guide for CSA-NRTL certification numbers) and

designed to meet the requirements of NEC C1.1, Di v. 1, Groups A, B,

C and D hazardous areas.

The M and TF Series probes measure moisture conten t in a standa rd

range from –110°C to 20°C (–166°F to 68°F) dew/frost point

temperature and option ally from –110°C to 60°C (–166° F to 140°F).

Both probes optionally measure temperature in a range of –30°C to

70°C (–22°F to 158°F). The TF probe optionally measures pressure

from 30 to 300, 50 to 500, 100 to 1000, 300 to 3000, or 500 to 5000

PSIG.

Features and Capabilities 1-5

Page 13

June 2003

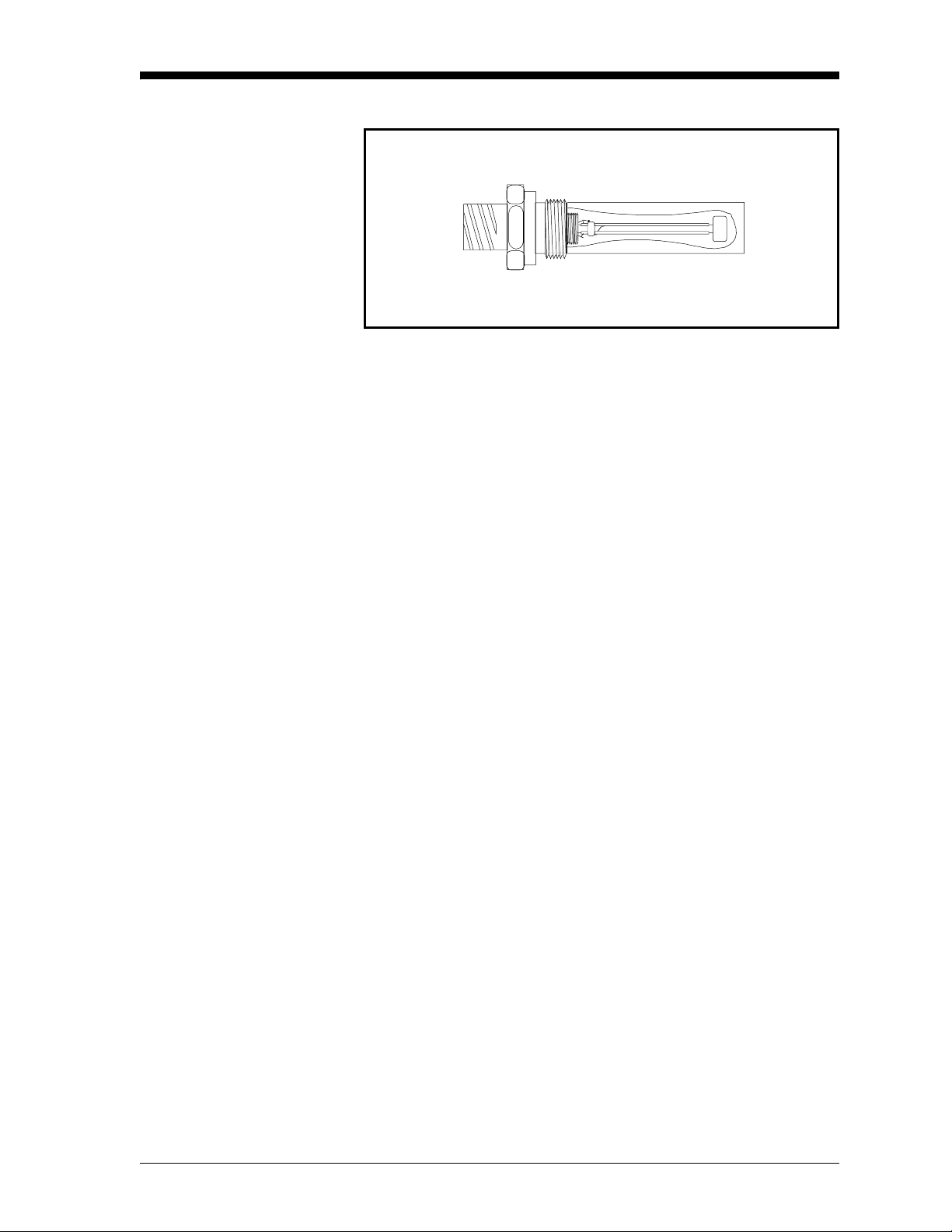

Moisture Image Series Probe

The Moisture Image Series Probe measures moisture, temperature

(optional), and pressure (optional). The Moistu re Image Ser ies Probe

has its own electronics module that consists of a built-in

microcontroller with 16-bit resolution (see Figure 1-4 below).

The electronics module stores the probe cali bration and refere nce data

in non-volatile memory; the refore, the user never needs to enter the

data by hand. The Moisture Image Series Probe also features

continuous compensation of its own analog circuitry to assure longterm electronic stability.

The Moisture Image Series Probe, when operated with a BASEEFAapproved Series 1, is intrinsically safe (see Cha pter 3, Specifications,

of the Startup Guide for BASEEFA certification numbers) and

designed to meet the require ments of IEC/CENELEC zone 0 areas.

The Moisture Image Series Probe, when operated with a CSA-NRTL

certified Series 1, is intrinsically safe (see Chapter 3, Specifications,

of the Series 1 St artup Guide for CSA-NRTL certification numbers)

and designed to meet the requirements of NEC C1.1, Div. 1, Groups

A, B, C and D hazardous areas.

The Moisture Image Series Probe measures moisture content in a

standard range from –110°C to 20°C (–166°F to 68°F) dew/frost

point temperature and optionally from –110°C to 60°C (–166°F to

140°F). Additionally, the Moisture Image Series Probe can be used to

measure temperature in a range of –30°C to 70°C (–22°F to 158°F)

and pressure from 30 to 300, 50 to 500, 100 to 1000, 300 to 3000, or

500-5000 PSIG.

Electronics Module

Figure 1-4: The Moisture Image Series Probe

1-6 Features and Capabilities

Page 14

June 2003

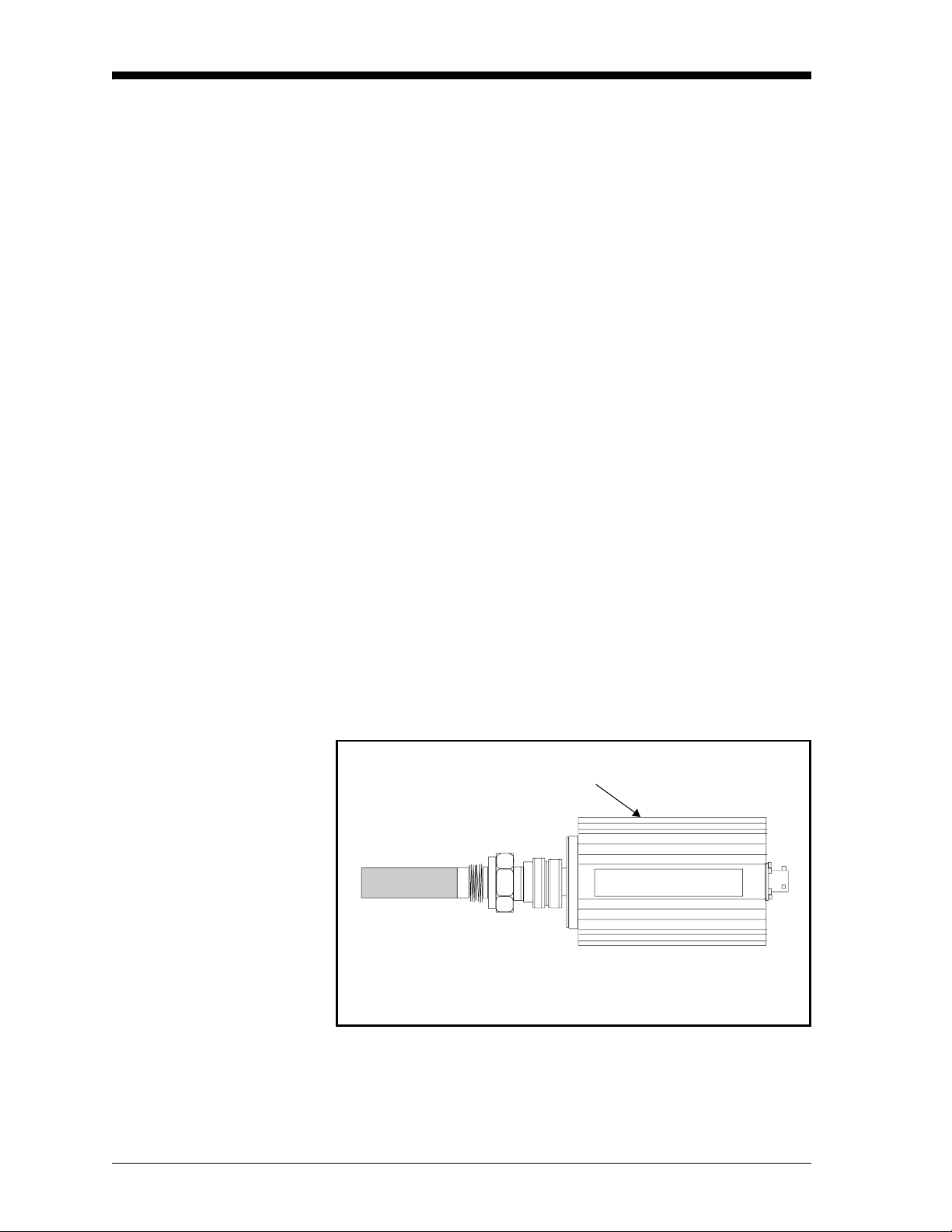

Delta F Oxygen Cell The Series 1 stand ard oxygen measurement probe is the Delta F Cell.

Overall oxygen content range is from 0 to 25%. You may choose

from seven standard oxygen r anges.The lowest standard ra nge is 0 to

1/10/100 ppm, and the highest st andar d range is 0 to 25% oxygen. An

ultra-low range sensor that covers 0-500 ppb

than 5 ppb is also available. The Series 1 also accepts oxygen inputs

from other GE Panametrics oxygen sens ors.

If your application has a high conc entration of acid-forming

components, GE P anametrics can supply a STAB-EL option for the

Delta F Cell. The STAB-EL option is specially designed to

effective ly neutralize these components from the sample gas stream.

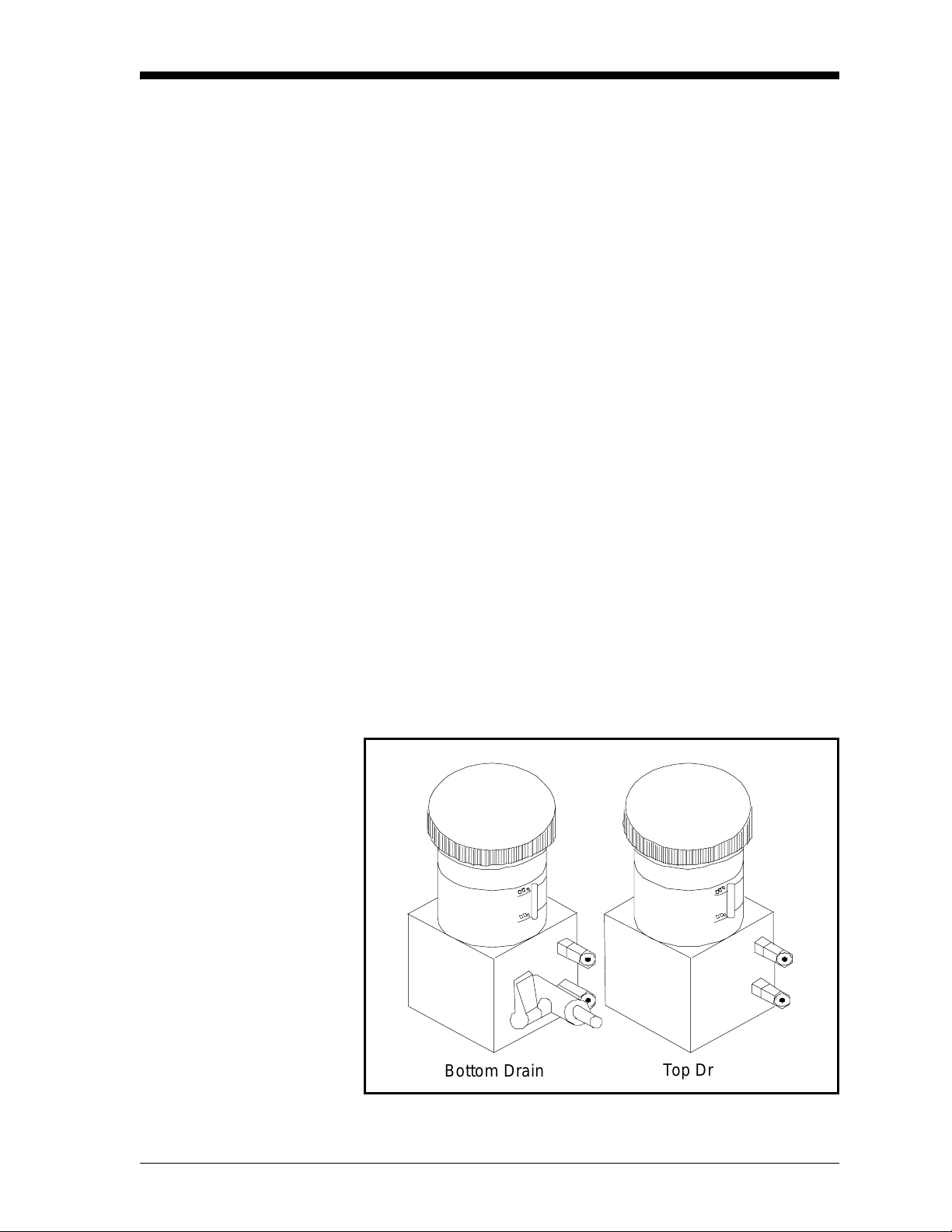

The Delta F Cell is available in a general purpose model with both a

top and bottom drain or only a top drain (see Figure 1-5 below) . The

Delta F Cell is usually inst alled in its own sample system.The Delta F

Cell is available with VCR® fittings, mounted in a NEMA-4X

enclosure for weatherproof/cor rosion resistant applications, or

mounted in a NEMA-7 enclosure for hazardous areas.

and is sensitive to le ss

v

The Delta F Cel l, when ope rat ed w i th a BASE E FA-approved

Series 1, is intrinsically safe (see Chapter 3, Specifications, of the

Start up Guide for BASEEFA certification numbers) and designed to

meet the requirements of IEC/CENELEC zone 0 areas.

The Delta F Cell, when used with a CSA-NRTL certified Series 1, is

intrinsically sa fe (see Chapter 3, Specifications, of the Series 1

Start up Guide for CSA-NRTL certification numbers) a nd designed to

meet the requirements of NEC C1.1, Div. 1, Groups A, B, C and D

hazardous areas.

Bottom Drain

Top Drain

Figure 1-5: Delta F Oxygen Cells - Bottom and Top Drain

Features and Capabilities 1-7

Page 15

April 2004

Cabling Each probe requires an interc onne cting cable. Cables differ

depending on the probe. The various cables are discussed below

under the appropr iate pr obe type . All of these cable assembl ies c an be

ordered from GE Panametrics.

M Series and TF Series Probes

Moisture Image Series Probe

The M and the TF Series probes are connected to the analyzer with a

special GE Panametrics shielded cable. Probes can be located up to

600 meters (2000 feet) from t he Series 1 (consult GE Panametrics for

distances up to 1200 meters). To measure pressure with a TF probe,

the maximum cable length is approximately 152 meters (500 feet).

Small electronic offsets, especially with longer cables, are possibl e

and should be corrected as described in Performing a MH C alibrati on

Test/Adjustment on page 1-20 of the Service Manual.

The Moisture Image Series Probe can be connected to the Series 1

with an unshie lded, twisted-pair cable. The probe may be located up

to 915 meters (3000 feet) from the analyz er using 22 AWG twisted

pair cable. (Consult GE Panametrics for longer cable lengths.)

Delta F Oxygen Cells The standard Delta F Cell is connected to the analyzer with a four-

wire shielded cable (22 AW G). With 22-AWG cable, oxygen cells

with a range from 0 to 1/10/100 ppm

located up to 90 meters (300 feet) away from the analyz er. All other

oxygen cells can be located up to 15 meters (50 feet) away. For

greater cable lengths, 20, 18 or 16 AWG wir e is required. Consult a

factory engineer when a longer length is required.

or 0 to 0.5/5/50 ppmv can be

v

Pressure Sensors The Series 1 accep ts either p res su re t rans du cer s or pr es sur e

transmitters. Most pressure transducers can be connect ed with a

standard four-wire shielded cable. Most pressure tr ansmitters are

connected using either a two or four-wire non-shielded cable and can

be either loop or self-power ed.

RS232 Communications Port

A personal computer or serial printer can be connected to the Series 1

RS232 communications port using a standard serial cable. A special

switch enabl es the u ser to co n fig u re the un it as Da ta Terminal

Equipment (DTE) or Data Communications Equipment (DCE). (See

Connecting a PC or Printer in Chapte r 1 of the Service Manual for

details on DTE/DCE configuration.)

1-8 Features and Capabilities

Page 16

June 2003

User Program The Series 1 has a user program that is accessed and controlled by the

keypad (to the right of the LCD screen) and the four menu keys

(located under the LCD screen).The user program enables the user to

enter the necessary pr obe data, set up the LCD screen, and control the

other operational features. The meter stores this data in bat terybacked RAM for up to five years, even if power is off.

The user program consists of the following four main menus:

• HELP - provides on-li ne he lp for t he various m enus wit hin the use r

program.

• SELECT - lets the user selec t the type of measur ement and units to

display.

• SETTINGS - enables the user to enter probe data and set up basic

functions suc h as recor de rs an d alarm s .

• OPTIONS - enables the user to set up the Series 1 screen to display

measurements in matrix or graphic format and perform advanced

functions.

The Settings Menu pro mpts the user to e nter a passcod e (see Entering

the Passcode in Chapter 2) .

All the functions and f eature s of the S eries 1 progr am are dis cussed in

Chapters 2 and 3, Basic Programming and Advanced Programming.

Features and Capabilities 1-9

Page 17

Chapter 2

Page 18

Basic Programming

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Ver ifying and Entering Setup Data . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Displaying Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Adjusting the Contrast of the Screen. . . . . . . . . . . . . . . . . . . . . .2-40

Setting the Clock and Calendar . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Page 19

June 2003

Introduction The Moisture Image Series 1 is a highly advanced and versatile

instrument. Because of this, operation ranges from basic to advanced

functions. This section is designed to provide a step-by-step guide to

basic operations. For information on other functions, refer to Chapter

3, Advanced Programming.

IMPORTAN T: You must install a switch or circuit breaker on the

input power line. For greatest safety, locate the

circ uit breaker or power switch near the electronics

console. To comply with the Low Voltage Directive,

you must install an external current protection

device.

The following sections cover basic programming functions:

• Getting Started - describes how to power up, gives a description of

the user program, and expla ins how to obtain on-line help.

• Verifying Setup Data - describes how to verify and, if neces sary,

enter setup data f or moistur e, p ressure, oxygen, and an y other input

devices.

• Displaying Measur e ments - expla ins how to displ ay measur ements

using differ ent screen formats.

• Adjusting the Contrast of the Screen - explains how to adjust the

screen for optimal viewing.

• Setting the Clock and Calendar - explains how to set the internal

clock and calendar.

Note: Because they are so essential, the instructions covered in the

Getting Star ted, Verifying and Entering Setup Data and

Displaying Measurement s sections are also inc lude d in the

Start up Guide. If you have read this material, you may skip

those sections of this chapter.

Basic Programming 2-1

Page 20

June 2003

Getting Started The purpose of this section is to give a brief description of the Series

1 user program and explain how to use its front pane l for viewing and

entering data. This section includes the following:

• powering up the meter

• entering data into the user program

• screen and key functions

• entering the passcode

• getting on-line help

Read the following sections c are fully to properly set up and operate

your instrument.

!WARNING!

TO ENSURE THE SAFE OPERATION OF THIS UNIT,

YOU MUST I N STALL A ND OPERAT E T H E SERIES 1

AS DESCRIBED IN THIS MANUAL. IN ADDITION, BE

SURE TO FOLLOW ALL APPLICABLE SAFETY

CODES AND REGULATIONS FOR INSTALLING

ELECTRICAL EQUIPMENT IN YOUR AREA.

Powering Up The Series 1 has a universal power supply that a utomatically adjusts

to line voltages from 90 to 260 VAC. After making electrical

connections (including grounding) as described in Chapter 1,

Installation, of the Start up Guide, pre ss the powe r switch to powe r up

the meter.

IMPORTAN T: .The AC power cord is the main disconnect device.

For compliance with the EU’s Low Voltage Directive

(IEC 1010), this unit requires an external power

disconnect device such as a switch or circuit breaker.

The disconnect device must be marke d as such,

clearly visible, directly accessible, and located

within 1.8 m (6 ft) of the unit.

2-2 Basic Programming

Page 21

Powering Up (cont.) Caution!

Do not op erate the De lta F oxy gen cell for ex t ended

peri ods of time at oxyg en concentrations th at are over

range. Trace and low percent range sensors may be

damaged if expose d t o high levels of ox y gen, such as

air, for l ong periods (>1 hour) while the Se ries 1 is on . If

exposure is unavoidable, either disconnect the oxygen

cell from the Ser ies 1 or equi p the sample system with a

valve that allows the cell t o be switched to purge gas .

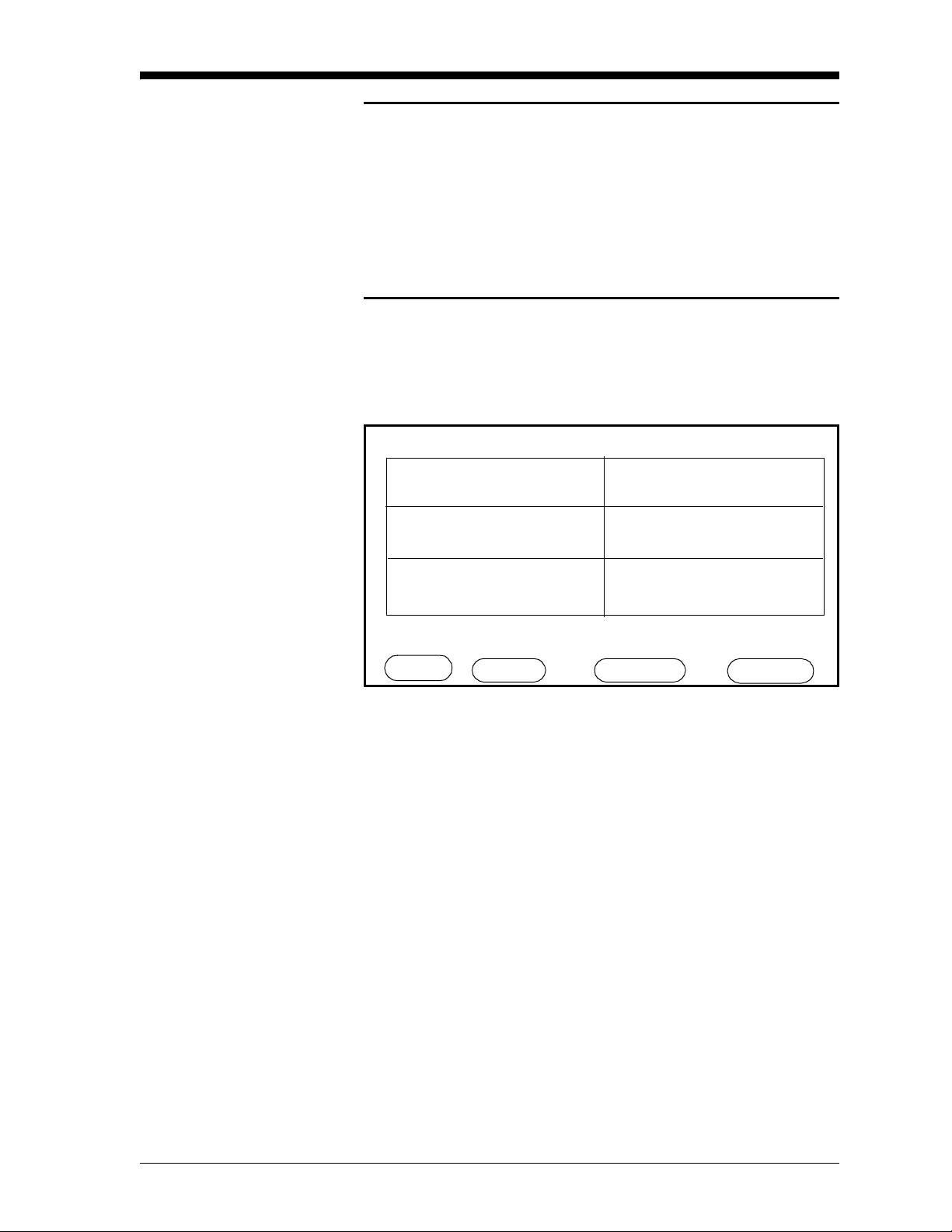

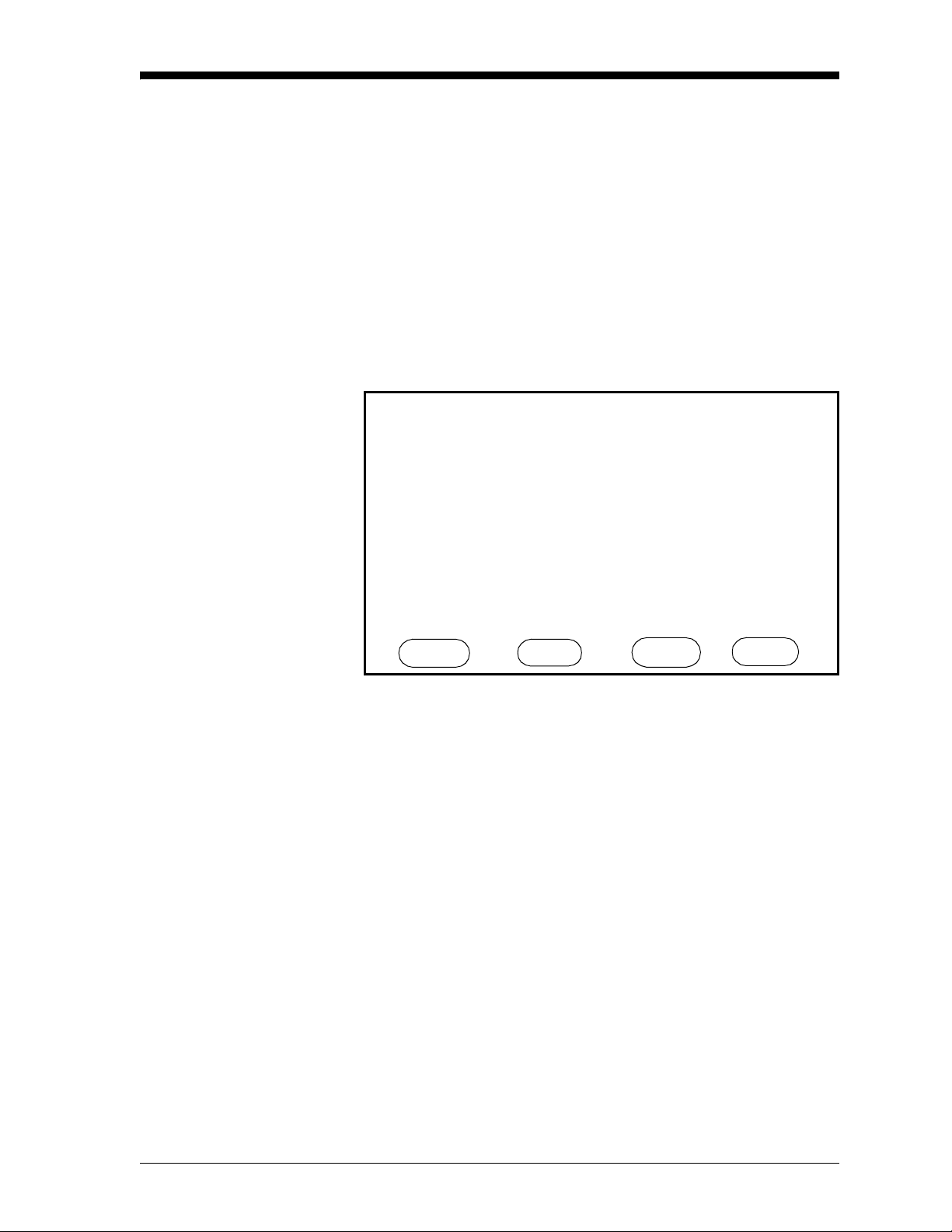

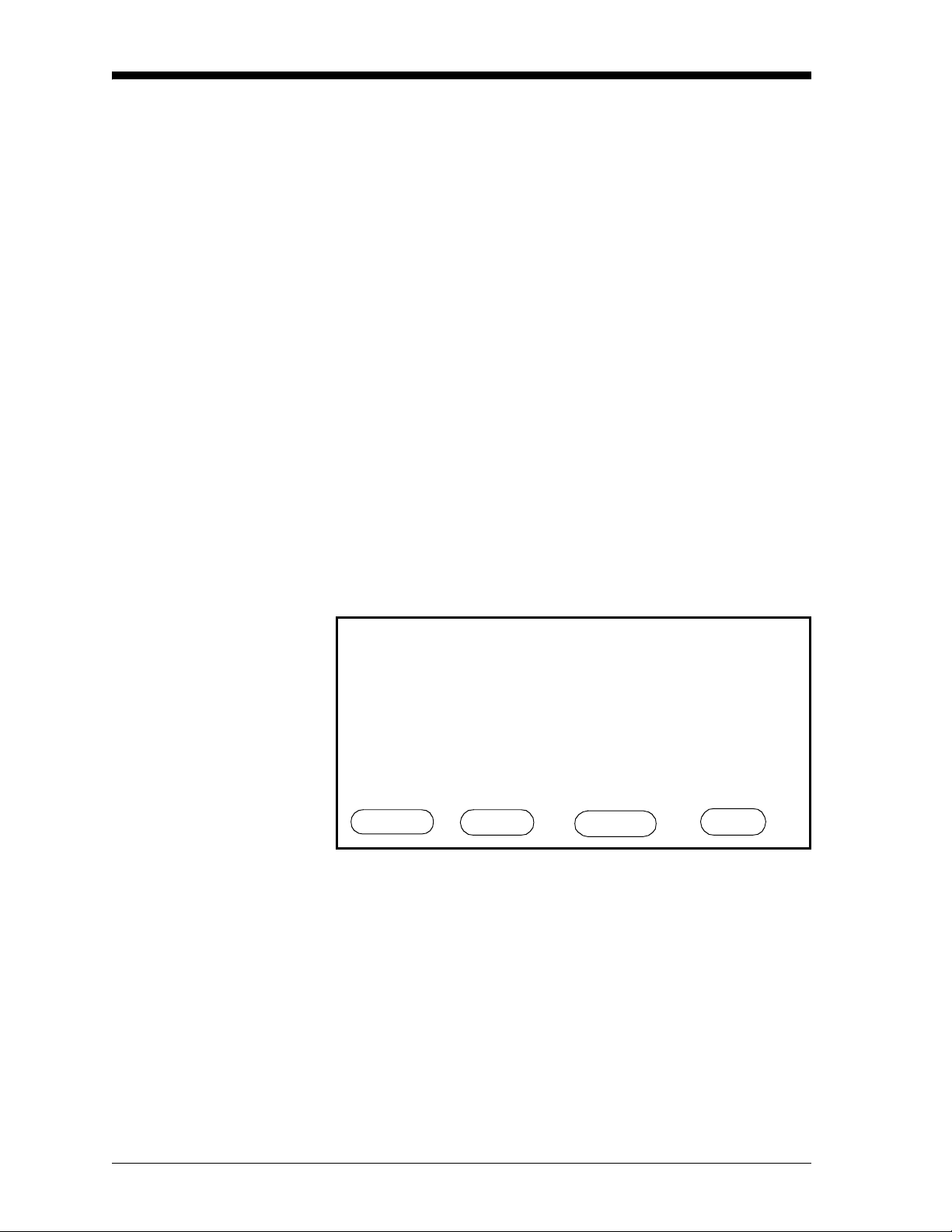

If the meter passes its self-test, the screen begins displaying

measurements in a matrix format similar to the one shown in

Figure 2-1 below.

June 2003

1 Dew Point

-18.0 ° C

2 Temperature

+35.9 °C

3 H

O

2

+0.535 ppm

v

4 Oxygen

48.3 ppb

v

5 Pressure

27.10 PSIg

X Unassigned

Main Menu 11:35 01/22/2000

pg: 1

HELP SELECT SETTINGS OPTIONS

Figure 2-1: Screen Matrix Format After Power Up

Basic Programming 2-3

Page 22

June 2003

123

YES

Entering Data into the User Program

The Series 1 has a user program that enables you to enter data to set

up alarms, recorders, a nd probes, as well as its other features.

The user program c onsists of the following four main menus (refer to

Figures 3-17 and 3-18, page s 3-31 and 3-32, for menu maps of the

user program):

• HELP - provides on-line help for the vari ous menus of the

user program.

• SELECT - lets you select the type of measurement a nd units to

display.

• SETTINGS - enables you to s et up r ecorde rs and al arms, as we ll as

enter probe data for basic operation. (To enter this menu you must

enter the passcode. See page 2-6.)

• OPTI ONS - enables you to set up the screen to display

measurements in text or graphical form. It is also used to perform

advanced functions .

You can use the screen, four menu keys, and the keypad to enter data

into the unit (see Figure 2-2 below).

Screen

POWER

Keypad

4

7

5

8

0-

6NO

9

.

Menu Keys

Figure 2-2: The Moisture Image Series 1 Front P anel

2-4 Basic Programming

Page 23

June 2003

Screen and Key Functions

The screen displays measur ements, up to four menu options, system

messages , and a pointer. The pointer acts as a measurement

indicator, as well as a guide during data entry.

While the unit displays measure ments in the matrix format, the

pointer moves sequenti ally from box to box to indicate measurement

updates. However, while in the user program, you can use the arrow

keys to move the pointer to the desired location for data entry.

The menu options appear at the bottom of the screen. Below the

screen are the corresponding menu keys (refer to Figure 2-3). Each

menu key corr esponds to each of the menu options in the user

program. Up to four n ew menu options appea r each tim e you en t er a

menu.

The line above the menu options is the message line (see Figure 2-3

below). The message line displays the menu title, the time, and the

date. The message line also displays a list of selections de pending on

the menu option you enter.

The page indicator is located in between the message line and the

menu keys. Since the Series 1 is capable of displayi ng up to six pages

of data, the page indicator displays the currently selected pa ge.

Message Line

Main Menu 11:35 01/22/2000

HELP SELECT SETTINGS OPTIONS

Menu Options

Page Indicator

pg: 1

Menu Keys

Figure 2-3: Screen Components

Basic Programming 2-5

Page 24

June 2003

Screen and Key

Functions (cont.)

The keypad to the side of the screen consi sts of 16 keys, incl uding t he

[.] and [-] symbol s , two arrow k eys , and two respon s e key s: [YE S ]

and [NO]. The numeric keys are for numeric entry only; however , the

arrow and response keys have more than one function.

The arrow keys perform two functions:

• Use either arrow key to move the screen pointer to the desired

location for data entry.

• Use the left arrow key as a backspace during number entry.

The response keys perform thre e funct ions:

• Use either the [YES] or [NO] key to respond to questions.

• Use the [NO] key to erase data.

• Press [YES] to confirm a num ber entry or after e rasing data to

retrieve the previ ous number.

Entering the Passcode The Settings Menu is the only menu that requir es a passcode. The

passcode is a four-digit number that enables only author ized users to

enter setup data. The Series 1 pr ompts you to ente r the pa sscode whe n

you enter the Settings Menu. See the end of this chapter for your

default passcode.

2-6 Basic Programming

Page 25

June 2003

Getting On-Line Help The Series 1 offers on- line help screens that contain descriptions and

instructions for various topics. The first menu option in most of the

menus is HELP.

When you press the HELP menu ke y, the screen display gives a list of

help topics as shown in Figure 2-4. This list enables you to get help

for most subjects, regardless of the current menu. To select a topic,

use the arrow keys to move the pointer to the topic you want to view ,

then press [YES]. Use the NEXT and PREVIOUS menu options to

scroll from one page to another. The NEXT menu option brings you

to the following page and the PREV menu options brings you to the

previous page. Press DONE to exit and return to the current menu.

Select Topic, then press YES.

Alarms Entering Text

AutoCal Error Messages

Calibration Error Processing

Clock/Calendar Graphs

Cs Constant

Configuration Legends,Entering

Data Logging Logger,Capacity

Delta-F Tables Logger,Setting

Enhanced Response Logger,Viewing

Entering Numbers Main Menu

Help Topic Index Menu

ABOUT NE X T PREV DONE

Henry’s Law

Figure 2-4: HELP Screen

By pressing the ABOUT key, users can access the history of their

particular Series 1: its serial number, P CI number, software revision

number and date of manufa ctur e. Thi s informati on r emains part of the

HELP file and cannot be changed by the user.

Basic Programming 2-7

Page 26

April 2004

Verifying and Entering Setup Data

Before the Seri es 1 can make measur em en ts, it must ha ve the p ro per

setup data e ntered into its memory. GE Panametrics has entere d all or

most of the setup data for each probe before delivery; however, you

should verify that all the data is corr ect and entered into your unit.

Note: If you want to switch a probe from one channel to another,

you must re-e nter some or all of the setup data as descri bed in

this section.

Verifying setup data consists of three steps:

• Verify that probes are properly activated in the Probe

Configuration Menu as descri bed on page 2-9.

• Verify that calibration data for all necessary probes is properly

entered in th e System Calibration Menu as described on page 2-12.

• Verify tha t app lic ab le hig h and low ref e re nc e value s for the Series

1 measurement circuitry are properly entered into the Reference

Menu as described on page 2-21.

Caution!

All high and low reference v alues are fac t ory s et and

normally do not need adjustmen t . H ow ever, t he factory

may instru c t you to adjust th e high and low moistur e

reference values. If necessary, you should do so as

described in Performing an MH Calibration/Adjustment

Test on page 1-20 of the Service Manual.

Use the following sections to pr operly verify and enter setup data.

IMPORTAN T: While you are reviewing data, you should take the

time to record it on the Program Information List

supplied in Appendix A of the Startup Guide, or on a

separate sheet of paper.

2-8 Basic Programming

Page 27

April 2004

Activating and Changing Probes

Verifying Probe

Configuration Data

Although the probes are physica lly connected to the back of the

electronics unit, you must “tell” the electronics what type of

measurements the probe is capable of makin g. I n addition, if you

want to use a constant va lue rather than a live input, you must “tell”

the electronics that you are using a constant value.

If you do not activate probes, or if you activate them incorrectly, the

unit will display

No Probe o r other error messages.

Once you verify and/or change confi gur ation data, refer to Entering

Calibration Data on page 2-12.

IMPORTAN T: You should record this data on the Program

Information List supplied in Appendix A of the

Start up Guide, or on a separate shee t of paper, and

keep it in a safe place.

1. Enter the Probe Configurat ion Menu (for a menu map, refer to

Figure 3-19 on page 3-32). A screen similar to Figure 2-5 below

appears.

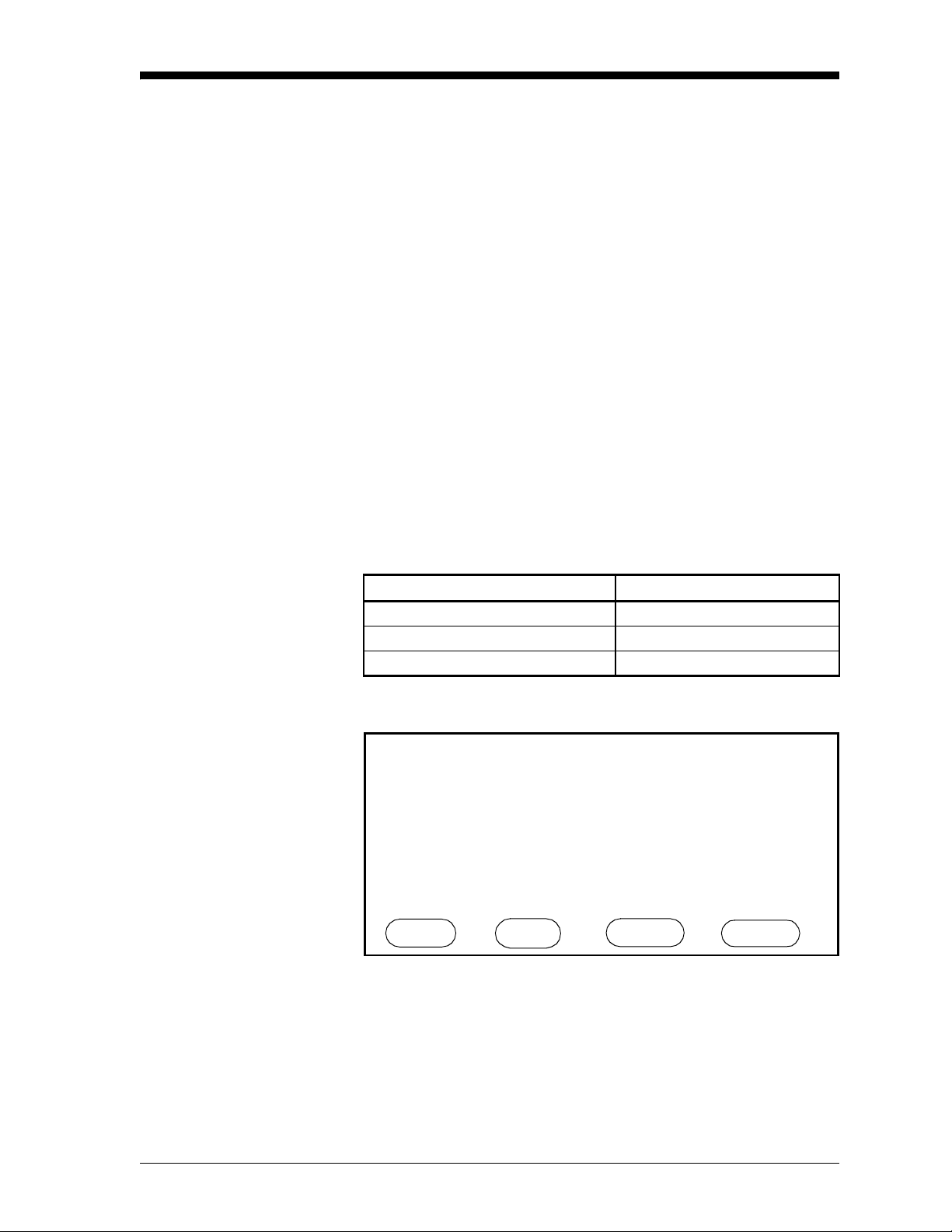

Table 2-1: Entering the Probe Configura tion Menu

Press th e Main Men u key: To enter the:

SETTINGS* Settings Menu

SYSTEM System Settings Menu

CONFIG Probe Configuration Menu

* The Settings Menu will prompt for a passcode (see page 2-6).

SYSTEM CONFIGURATION

Ch O2 HYG T P Aux1 Aux2

1

2

3

4

5

6

Probe Configuration Menu

HELP TAG ERRORS DONE

Figure 2-5: Probe Configuration Menu

Basic Programming 2-9

Page 28

April 2004

Activating and Changing

Probes (cont.)

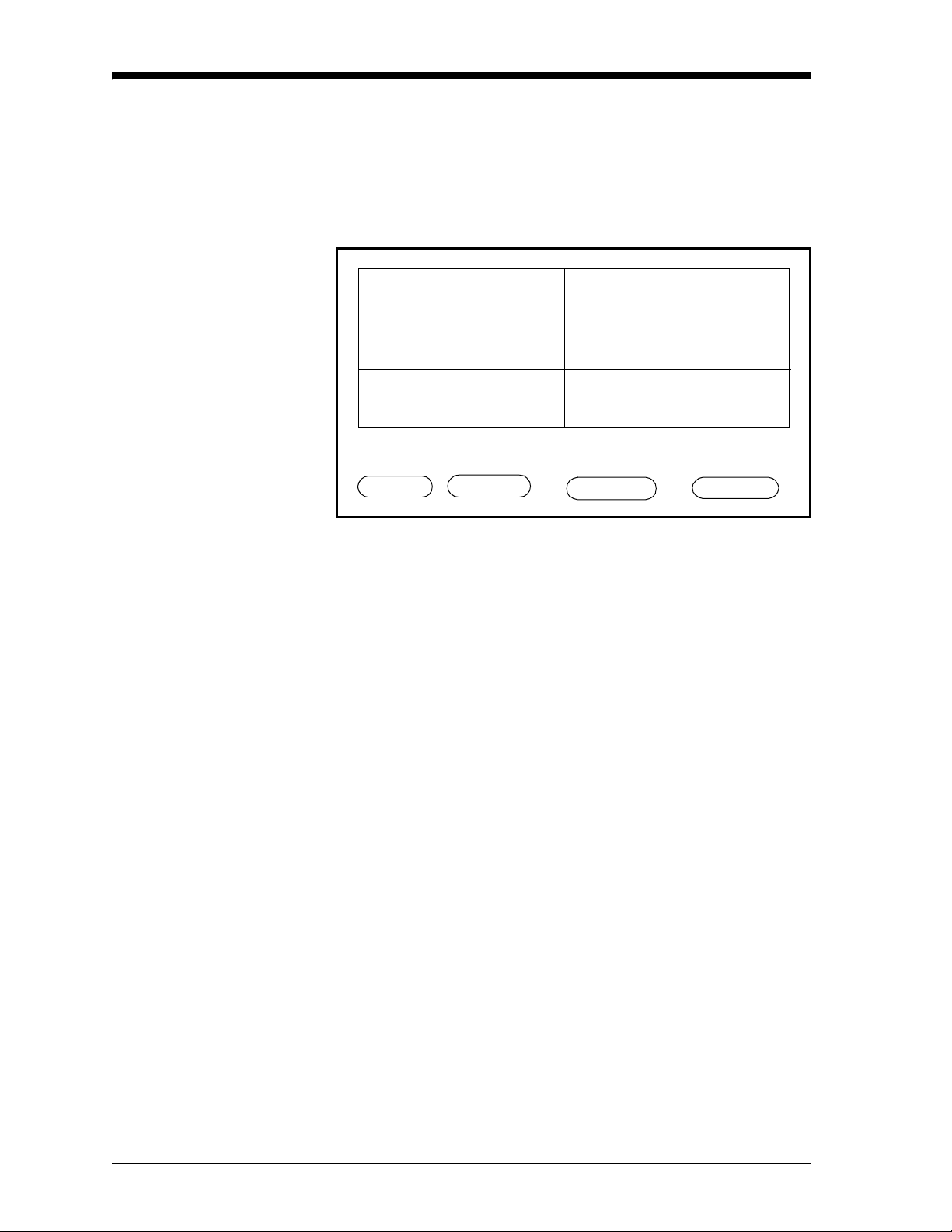

Verify that the correct probe types have been a ctivated for each

channel. To do this, make sure a probe is activated for each

measurement it is capable of taking. For example, if a Moisture

Image Series Probe with the temperature and pressure functions is

connected to channel 1, “MIS” must be select ed in the hygrometry,

temperature, and pressure columns as shown in Figure 2-6 below.

If the optiona l auxiliary inputs are installed and active, you only need

to select whe ther the input is c urrent or voltage. If you do not select

current or voltage, the Series 1 defaults to current.

Note: If you are using an auxil iary input to measur e pressure,

activate Au1 (or Au2 depe nding on which input you ar e using )

in the pres sure column for the desired channel; then activate

curre nt or voltage in the Aux 1(or Aux 2) column.

In addition, if you connect a pressure transducer to the PRESS/

OTHER terminal bloc k, you must activate the TF probe in the

pressure col umn fo r that ch ann el .

If you need to change any data in the Probe Configuration Menu, see

the following sectio n, Ente ring or Changing Probe Configuration

Data. If the data is correct, refer to Tagging the Inputs on page 2-37.

SYSTEM CONFIGURATION

Ch O2 HYG T P Aux1 Aux2

1

2

3

4

5

6

Probe Configuration Menu

MIS MIS MIS

HELP TAG ERRORS DONE

Figure 2-6: MIS Probe Configuration on Channel 1

2-10 Basic Programming

Page 29

April 2004

Entering or Changing

Probe Configuration

Data

Figure 3-19 on page 3-32 for a menu map.

1. From the Probe Configuration Menu (Table 2-1 on page 2-9),

move the pointer to the channel and probe y ou want to select. The

arrow will move only to installed channels.

2. Press [YES].

3. The possible probe types appear on the message line at the bottom

of the screen. Table 2-2 on page 2-12 shows the available probe

types.

If you choose to enter a constant for moisture (Kh), temperature (Kt),

or pressure ( Kp), you must ente r a c onstant value in the User Const ant

Menu. See Entering Constants and User Functions on page 3-9 for

instructions.

4. Move the brac kets t o t he corre ct pr obe t ype, then pre ss [YES]. The

selected probe type displays.

5. Repeat Steps 1 through 4 for each channel.

6. T o exit, press the DONE menu key until Main Menu appears on

the message line.

Note: You can only sele ct probes for an installed channel.

If you are only using Moisture Image Series probes, pr oceed to

Displaying Measurements on page 2-28. If you are using any other

type of input device, pr oceed to Entering Calibration Data

on page 2-12.

Basic Programming 2-11

Page 30

April 2004

Entering or Changing

Probe Configuration

Data (cont.)

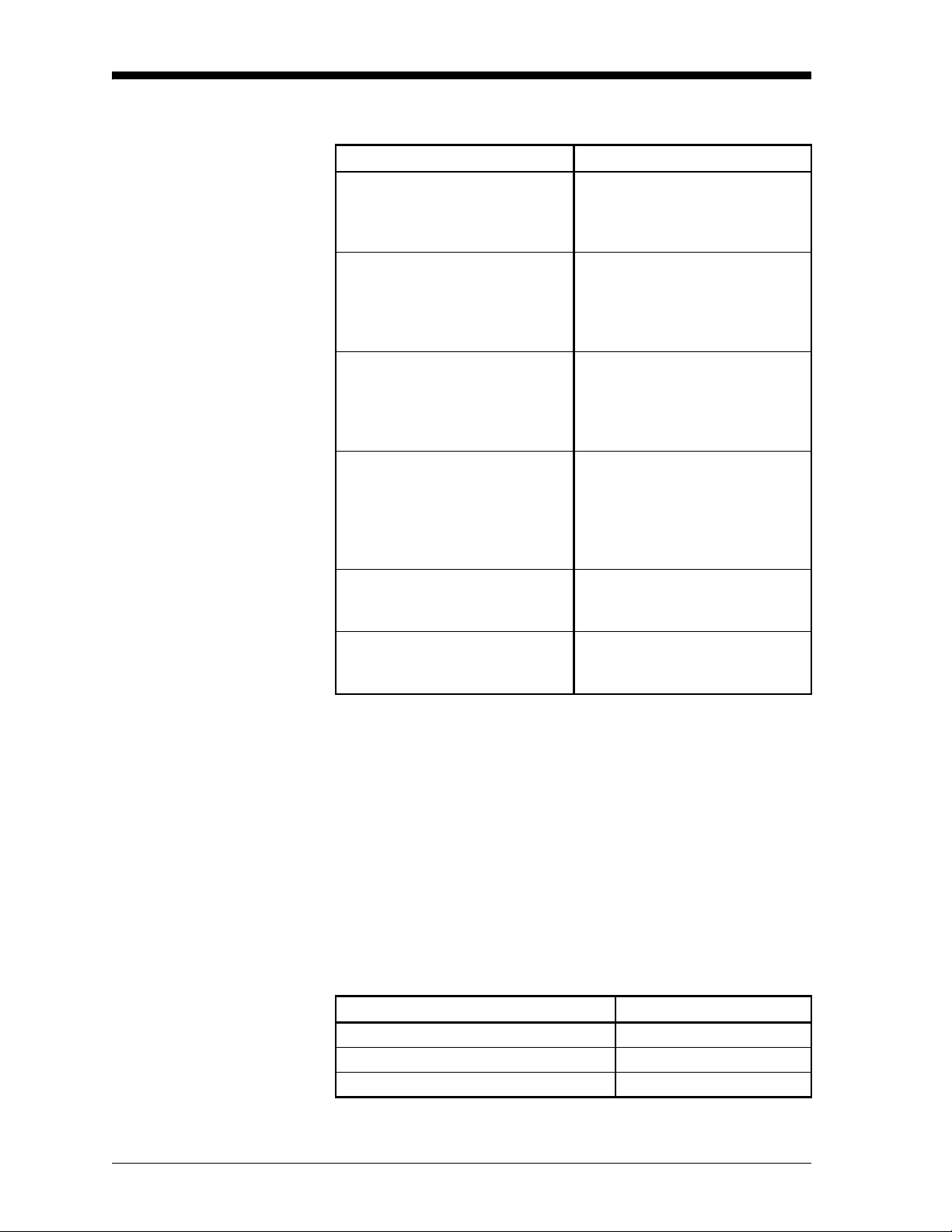

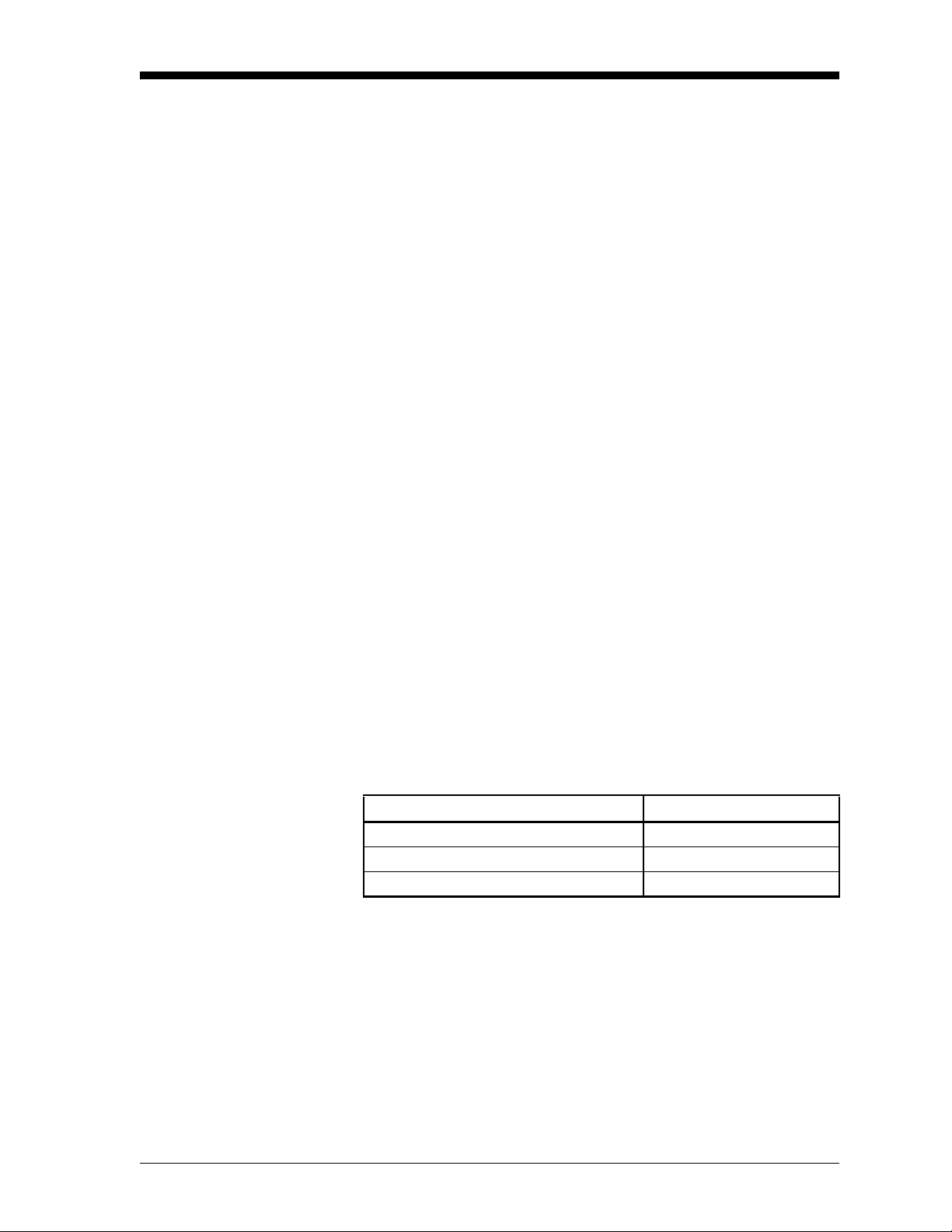

Table 2-2: Probe Types

Measurement Mode Probe Type

– (None)

OXY (Oxygen)

HYG (Hygrometry)

T (Temperature)

P (Pressure)

Aux1 (A u x iliar y 1)

Aux2 (A u x iliar y 2)

% (Percent)

ppM (Parts per Million)

ppB (Parts per Billion)

– (None)

MIS (MIS Probe)

TF (Three-Function Probe)

Mxx (M Series Probe)

Kh (Constant Dew Point)

– (None)

MIS (MIS probe)

TF (Three-Function probe)

Mxx (M-Series probe)

Kt (Constant Temperature)

– (None)

MIS (MIS probe)

TF (Three-Function probe)

Au1 (Auxiliary 1)

Au2 (Auxiliary 2)

Kp (Constant Pressure)

– (None)

I (Current)

V (Voltage)

– (None)

I (Current)

V (Voltage)

Entering Calibration Data

The Series 1 needs calibration data for moisture, oxyge n, and

pressure probes, as well as auxiliary inputs. GE Panametrics has

already entered cali bration data for probes; however, you should

verify this data befor e star tup. You will need to enter this data if you:

• sent the probes back to the factory for calibration

• use a different pr obe

• use a non-GE Panametrics input

T o enter, verify, or change calibration data for any probe type, enter

the System Calibration Menu as described in Table 2-3 below. (see

Figure 3-19 on page 3-32 for a menu map.)

.

Table 2-3: M o vi n g to th e System Ca l ibr ation Men u

Press th e M ai n M en u key: To enter the:

SETTINGS* Settings Menu

SYSTEM System Settings Menu

CALIB System Calibration Menu

*The Settings Menu will prompt for a passcod e (see page 2-6).

2-12 Basic Programming

Page 31

April 2004

Entering Calibration

Data (cont.)

Refer to the appropriate section that follows to verify or enter

calibration data for:

• Moisture Probes, page 2-13

• Delta F Oxygen Cell, page 2-15

• Pressure Sensor or Tr ansmitter , page 2-17

• Optional Auxiliary Input(s), page 2-19

Be sure you have t he Calibration Data Sheets that are supplied with

each GE Panametrics probe. Eac h Calibration Data Sheet consists of

a list of data points that you will need to ent er or verify. Each

Calibration Data Sheet lists its corresponding probe serial number, as

well as the preassigned channel number. Calibration Data Sheets are

usually packed inside the probe cases.

Once you verify and/or enter cal ibration data for each input, refer to

Entering High and Low Reference Values on page 2-21.

IMPORTAN T: Staple Calibration Data Sheets to the Program

Information List (Appe ndix A of the Startup Guide)

and stor e them in a safe place. If they are lost,

contact GE Panametrics for a duplicate . If you alter

any of the calibration data, make sure you make the

change on the Calibration Data Sheet .

Entering Moisture Probe

Calibration Data

You only need to enter calibration data for M and TF Series probes.

It is not necessary to enter calibration data for the Moisture Image

Series Probe unless you send the probe back to GE Panametric s for

calibration withou t its electronic s module. If this is the case, enter the

calibration data for the recalibrated pro be as described in this section.

The Series 1 will automatically download the new calibration data

into the Moisture Image Series Probe elec tronics module.

Note: You do not need to enter calibration data for the Moisture

Image Series Pr obe because it is stor e d i n the probe’s

electr onics module . The Moist ure Image Series Probe uploads

the calibration data int o the Series 1 memory when needed.

Use the procedure below to enter the following data:

• the probe serial number

• the number of data points

• the dew point and MH (or FH, dependi ng on the pr obe) readi ng for

each data point

Basic Programming 2-13

Page 32

April 2004

1

Entering Moisture Probe

Calibration Data (cont.)

Referring to the Calibration Data Sheets, enter calibration data

separately for each probe on the designated channel as described

below. Figure 3-19 on page 3-32 for a menu map.

Note: If you want to enter a constant value, refer to Entering

Constants on page 3-9. It is not necessary to enter the

calibration data if you are using a constant.

1. At the System Calibration Menu (see Table 2-3 on page 2-12),

press the PROBE menu key until the Moisture Probe Calibr ation

screen appears (see Figure 2-7 below) .

2. Use the CHANNEL menu key to cycle to t he desi red cha nnel. The

channel number is indicated in the top right-hand corner of the

screen.The scree n will only display installed channels.

Moisture Probe Calibration Ch

S/N: ND:

## MH DP/°C ## MH DP/°

01 09

02 10

03 11

04 12

05 13

06 14

07 15

08 16

System Calibration Menu Screen 1 of 1

HELP CHANNEL PROBE DONE

Figure 2-7: System Calibration Menu for Mois ture

3. Move the pointer to

S/N and press [YES].

4. Enter the probe serial number from the Calibration Data Sheet,

and press [ YES]. (The serial number is also scribed on the hex nut

of the moisture probe.) The pointer automatically jumps to

ND.

Press [YES] again.

5. Enter the number of data points indic ated on the Calibration Data

Sheet (typicall y 2-16 points for each pr obe), and pres s [YES]. The

pointer automatic ally jumps to the first data point.

6. Move the pointer to 1 and enter the MH (or FH) values and dew

point (in °C) for each data point. Make sure you press [ENT] after

you enter each value.

7. Repeat Step 6 for each data point.

8. Repeat Steps 2 through 7 to enter moisture probe calibration data

for the remaining channels.

To enter calibration data for other probes, refer to the following

sections. To exit, press the DONE menu key until Main Menu

appears on the message line. Then refer to E nter i ng High and Lo w

Reference Values on page 2-21.

2-14 Basic Programming

Page 33

April 2004

Entering Delta F Oxygen

Cell Calibration Data

Note: The information in thi s section appli es to Delta F oxygen cells

only. If you are us ing some other type of oxygen input, refer to

Entering Auxiliary Input Calibration Data on page 2-19.

Your Delta F cell has been factory calibrated using nitrogen as the

reference background ga s. If you want to use the oxygen cell with a

different ba ckground gas than the cell was calibrated for, refe r to the

section Background Gas Correction Factors for the Delta F Oxygen

Cell in Chapt e r 2 of the Service Manual to determine the correct

oxygen current multipl ier.

Use the procedure below to enter the following data:

• the probe serial number

• the zero and span rang e in m icro am p s (µA)

• the zero and span range in parts per million by volume (ppm

ppbr, or percent (%)

Note: Oxygen cells c an be ordered to measure in ppm or percent.

Select the proper oxygen cell units in the Probe Configuration

Menu. The units you select will automatically appear in the

second column.

)

v

Procedure for Entering Delta F Cell Calibration Data

Referring to the Calibration Data Sheets, enter calibration data

separately for each probe on the designated channel as described

below. Figure 3-19 on page 3-32 for a menu map.

IMPORTAN T: Staple Calibration Data Sheets to the Program

Information List (Appe ndix A of the Startup Guide)

and stor e them in a safe place. If they are lost,

contact GE Panametrics for a duplicate . If you alter

any of the calibration data, make sure you make the

change on the Calibration Data Sheet .

1. At the System Calibration Menu (see Table 2-3 on page 2-12),

press the PROBE menu key until the Oxygen Probe Calibration

screen appears. See Figure 2-8.

2. Use the CHANNEL menu key to cycle to the desired channel.

The channel number is indicate d in the top right- hand-corner of

the screen. The screen will only displa y installed channels.

3. Move the pointer to the

S/N line and press [YES].

Basic Programming 2-15

Page 34

June 2003

Entering Delta F Cell

Calibration Data (cont.)

4. Enter the probe serial number from the Calibration Data Sheet,

and press [YES].The serial number is also on the side of the

oxygen cell.

5. Move the pointer to the Zero

6. Enter the microamp (

7. Move the pointer to the Zero ppm (or %) line and press [YES].

8. Enter the zero range value, and press [ YES]. The range units will

be either ppm or %, depending on the cell type/model selected in

the Probe Configuratio n Menu.

9. Repeat Steps 5 through 8 to enter the microamp (

value for the span line.

IMPORTAN T: Leave the O2 Current Multiplier at 1.00 unless you

are using a background gas other than nitrogen. Se e

the section Background Gas Correction Factors for

the Delta F Oxygen Cell in Chapter 2 of the Service

Manual.

Repeat Steps 1 through 9 to enter oxygen calibration data for the

remaining channels.

µA) value and press [YES].

µA line and press [YES ].

µA) and range

Oxygen Probe Calibration Ch

S/N

µA ppm (or %)

Zero: ___ ___

Span: ___ ___

O2 Current Multiplier: 1:00

System Calibration Menu

HELP CHANNEL PROBE DONE

Figure 2-8: System C al i b ra ti o n M en u fo r Oxygen Cell

To enter calibration data for other probes, refer to Entering Moisture

Probe C alibration Data on page 2-13, Entering Pressure Calibration

Data on page 2-17, and Entering Auxiliary I nput Calibr ation Data on

page 2-19. To exit, press the DONE menu key until Main Menu

appears on the message line. Then refer to E nter i ng High and Lo w

Reference Values on page 2-21.

1

2-16 Basic Programming

Page 35

April 2004

Entering Pressure

Calibration Data

Use this section to enter pres sure calibration data for any type of

pressure sensor you a re using, even if t he pr essure sensor is c onnec ted

to an auxiliary input.

To enter pressure calibration data, you must enter

• the probe serial number

• the zero and span range in mV, current, or FP

• the zero and span range in PSIg

Referring to the C alibration Data Sheets supplied by GE Panametrics

or another manufacturer, enter calibration data separately f or each

probe on the designated channel a s descr ibed below. Figure 3-19 on

page 3-32 for a menu map.

IMPORTAN T: Staple Calibration Data Sheets to the Program

Information List (Appe ndix A of the Startup Guide)

and stor e them in a safe place. If they are lost,

contact GE Panametrics for a duplicate . If you alter

any of the calibration data, make sure you make the

change on the Calibration Data Sheet .

Note: If you want to enter a constant value, refer to Entering

Constants and User F unctions on page 3-9. It is not necessary

to enter the calibration data if you are using a constant.

1. At the System Calibration Menu (see Table 2-3 on page 2-12),

press the PROBE menu key until the Pressure Probe Calibration

screen appears. See Figure 2-9 below.

Pressure Probe Calibration Ch

S/N

mV Pressure, PSIg

Zero: ____ ____

Span: ____ ____

System Calibration Menu

HELP CHANNEL PROBE DONE

Figure 2-9: System Calibration Menu for Pressure

1

Basic Programming 2-17

Page 36

April 2004

Entering Delta F Cell

Calibration Data (cont.)

Note: If you are using an auxiliary input to measure pressure, the

first column will be in mA or Volts depending on how you

configured the auxiliary input in Activating and Changing

Probes as described on page 2-9.

2. Use the CHANNEL menu key to cycle to t he desi red cha nnel. The

channel number is indicated in the top right-hand corner of the

screen. The screen will only disp lay installed channels.

3. Move the pointer to

4. Enter the probe seria l number fr om the Cali bration Dat a Sheet and

press [YES].

5. Move the pointer to the

6. Enter the voltage or current value and press [YES].

7. Move the pointer to the

8. Enter the PSIg value and press [YES].

9. Use Steps 5 through 8 to enter the span values.

Repeat steps 1 through 9 to enter pressure calibration data for the

remaining channels.

S/N and press [YES].

Zero mV (mA ) line and press [YES].

Zero PSIg line and press [YES].

To enter calibration data for other probes, refer to Entering Moisture

Probe Cali bration Data on page 2-13, Entering Delta F Oxygen Cell

Calibration Data on page 2-15, and Entering Auxiliary Input

Calibration Data on page 2-19. To exit, press the DONE menu key

until Main Menu appears on the message line. Then refer to Entering

High and Low Reference Values on page 2-21.

2-18 Basic Programming

Page 37

April 2004

Entering Auxiliary Input

Calibration Data

Note: If you ar e using an auxiliary input to measur e pressure, enter

pressure calibration data as described in Entering Pressure

Calibration Data as descr ibed on page 2-17.

This section describes how to enter calibration data for an auxiliary

input (optional). If your device is not supplied by GE Panametrics,

you will have to obtain the calibration data in order to properly set up

the Series 1.

You will need to enter two to 16 data points. If the sensor is linear ,

you only need to enter two data points. Each data point requires a

voltage or current value depending on the probe configuration (see

page 2-9) and a corresponding scale value. Use the procedure below

to enter data.

Figure 3-19 on page 3-32 for a menu map.

IMPORTAN T: Enter the auxiliary calibration data on the Program

Information List (Appe ndix A of the Startup Guide)

and stor e it in a safe place. If it is lost, contact GE

Panametrics for a duplicate.

1. At the System Calibration Menu (see Table 2-3 on page 2-12),

press the PROBE menu key until the Auxiliary Input Calibration

screen appears . There is one s creen eac h for Auxiliary I nput 1 and

Auxiliary Input 2. Make sure you have the correct screen before

verifying or entering da ta (see Figure 2-10 below).

Aux 1 Probe Calibration

ND: Label:[No Label]

# mA (VDC)

01 08

02 09

03 10

04 11

05 12

06 13

07 14

15

System Calibration Menu

HELP CHANNEL PROBE DONE

Figure 2-10: System Calibration Menu for Auxiliary Inputs

[ Aux # ] ## mA [ Aux #]

Ch

1

Basic Programming 2-19

Page 38

April 2004

Entering Auxiliary Input

Calibration Data (cont.)

2. Use the CHANNEL menu key to cycle to t he desi red cha nnel. The

channel number is indicated in the top right-hand corner of the

screen. The screen will only disp lay installed channels.

3. Move the pointer to

4. Enter the number of data points and press [YES]. The Series 1

requires two to 16 calibration data points. If the sensor is linear

you only need to enter two data points.

5. The pointer will move to LABEL. Press [YES] to enter the Label

Entry menu and enter or change the Label (as described in

“Making Tags” on page 2-38).

6. Move the pointer to the Units (or [Aux]) col umn heading. Press

[YES] to edit the Units label used when displa ying the Auxiliary

Input (as described in “Making Tags” on page 2-38).

7. Move the pointer to the first data point in the

column and press [YES]. The unit s for thi s column will dep end on

the units you selected in Activating and Changing Probes on

page 2-9.

8. Enter the voltage or current value and press [YES].

9. Move the pointer to the

ND and press [YES].

mA (or VDC)

Units column and press [YES].

10. Enter the corresponding scale value and press [YES].

11. Use steps similar to 4 through 10 to enter the remaining data

point values.

Repeat steps 1 through 9 to enter auxiliary input calibration data for

the remaining channels .

To enter calibration data for moisture, temperature, and pressure,

refer to the preceding sec tions. To exit, press the DONE menu key

until

Main Menu appears on the message line. Then refer to Entering

High and Low Reference Values on page 2-21.

2-20 Basic Programming

Page 39

April 2004

Entering High and Low Reference Values

The last step in setup is entering high and low reference values. The

Series 1 requires reference values for its measurement circuitry for

moisture, oxyge n, and pressure inputs. The references are factory

calibratio n valu es that are s peci fi c to eac h cha n nel ca rd . Ref ere nc e

values are located on a label placed on the side or front of the unit.

Note: If you receiv e a channel card replacement or change the

instrument program, you need to re-enter the reference data

for that channel.

Table 2-4 shows the key sequences for e ntering the Reference M enu.

(Figure 3-19 on page 3-32 for a menu map.)

Table 2-4: Moving to the Reference Menu

Press th e M ai n M en u key: To enter the:

SETTINGS* Settings Menu

SERVICE System Service Menu

REFS Reference Menu

*The Settings Menu will prompt for a passcod e (see pag e 2-6).

Use the appropriate section that follows to verify or enter re ference

values for the probes.

Once you verify and/or enter reference data for each input, refer to

Displaying Measurements on page 2-28.

IMPORTAN T: You should record this data on the Program

Information List supplied in Appendix A of the

Startup Guide , or on a separate sheet of paper, and

keep it in a safe place.

Basic Programming 2-21

Page 40

April 2004

Entering Mo isture

Reference Values

Use the steps below to change the reference values for moisture

inputs. (Figure 3-19 on page 3-32 for a menu map.)

Caution!

If you modified the supplied cables or are not using GE

Panametrics-supplied cables for moisture probes, you

may be re quired to adj us t th e m ois t ure refere nc e data

as described in Performing an MH C alibration/

Adjustment Test on page 1-20 o f the Service Manual.

IMPORTAN T: You should record reference data on the Program

Information List supplied in Appendix A of the

Startup Guide , or on a separate sheet of paper, and

keep it in a safe place.

1. At the Reference Menu (see Table 2-4 on page 2-21), press the

PROBE menu key until the Moisture Reference Table appears

(see Figure 2-11 below) .

MOISTURE REFERENCE TABLE

Ch HIGH LOW

1

1

2

3

4

5

6

AutoCal Interval: (HH.MM) 01:00

Reference Menu

HELP INTERVAL PROBE DONE

Figure 2-1 1 : Reference Menu for Moisture

2. Compare the data on the screen to the refer ence data printe d on the

label placed on the side or front of the unit, or supplied with a

replacement channel card. If the data is incorrect, use the

procedure below to correct it. If the data is correct, do one of the

following:

• continue to enter reference values for oxygen cell and pressure

inputs as described in the following sections.

• press the DONE menu key until Main Menu appears on the

message line; then refer to Displaying Measurements on

page 2-28. When you exit, the Series 1 automatica lly calibrates

each channel.

2-22 Basic Programming

Page 41

April 2004

Entering Mo isture

Reference Values (cont.)

3. Move the pointer to HIGH for the desired channel, and press

[YES].

4. Enter the high reference value for tha t channel and press [YES].

5. The pointer automatically moves to

Press [YES ].

6. Enter the low reference value for that channel, and press [YES].

7. Repeat steps 3 through 6 to enter the high and low reference

values for the remaining channels.

Note: You may also enter the Auto-Cal Interval while in the

Reference Menu. Simply press the INTERVAL menu key and

enter the desir ed interval. See page 3-7 for more information.

T o enter reference values for oxygen cell and pressu re inputs, refer to

the following sections. To exit, press the DONE menu key until Main

Menu appears on the message line. Then refer to Displaying

Measurements on page 2-28. When you exit, the Series 1

automatically calibrates each channel.

LOW for the same channel.

Basic Programming 2-23

Page 42

April 2004

Entering Delta F Oxygen

Cell Reference Values

IMPORTAN T: The instructions in this section apply to entering

refe rence data for the Delta F oxygen cell only.

Use the steps below to change the reference values for oxygen cell

inputs. (Figure 3-19 on page 3-32 for a menu map.)

Caution!

Do not ad just oxygen c ell referen c e data unless

instructed to do so by the factory.

IMPORTAN T: You should record this data on the Program

Information List supplied in Appendix A of the

Startup Guide , or on a separate sheet of paper, and

keep it in a safe place.

1. At the Reference Menu (see Table 2-4 on page 2-21), press the

PROBE menu key until the Oxygen Cell Refe rence Table appears

(see Figure 2-12 below).

OXYGEN CELL REFERENCE TABLE

HIGH LOW

Ch Zero Span Zero Span

1

2

3

4

5

6

AutoCal Interval: (HH.MM): 01:00

Reference Menu 11:15 6/2/00

HELP INTERVAL PROBE DONE

Figure 2-12: Referenc e Menu for the Delta F Cell

2. Compare the data on the screen to the refer ence da ta printe d on the

label placed on the side or front of the unit. If the data is incor rect,

use the following procedure to correct it. If the data is correct, do

one of the following:

• continue to enter reference values for moisture and pressure

inputs as described in Entering Moisture Reference Value s on

page 2-22, and Entering Pressure Reference Values on

page 2-26.

• press the DONE menu key until Main Menu appears on the

message line; then refer to Displaying Measurements on

page 2-28. When you exit, the Ser i e s 1 automatically calibrates

each channel.

2-24 Basic Programming

Page 43

April 2004

Entering Delta F Oxygen

Cell Reference Values

(cont.)

3. Move the pointer to the Zero line for the high reference for the

desired channel and press [YES] .

4. Enter the zero value for the high reference for that channel and

press [YES]. The p oint er aut o ma tica l ly pr oceeds to the

for the high refere nc e fo r the same channel. Pre ss [Y ES] again.

5. Enter the span value for the high reference for that channel and

press [YES].

6. Move the pointer to the

desired channel and press [YES] .

7. Enter the zero value fo r the low reference for that chan n el an d

press [YES].

8. Move the pointer to the Span line for the low reference fo r the

desired channel and press [YES] .

9. Enter the span value fo r the lo w refere n ce for that channel and

press [YES].

Repeat steps 3 through 9 to enter the high and low reference values

for the remaining channels.

Zero line for the low reference for the

Span line

To enter refere nce va lue s for moi st ur e and pressu re input s , ref er to

Entering Moisture Reference Values on page 2-22 and Entering

Pressure Reference Values on page 2-26. To exi t, press the DONE

menu key until

to Displaying Measurements on page 2-28. When you exit, the

Series 1 automatically calibrates each channel.

Main Menu appears on the message line. Then refer

Basic Programming 2-25

Page 44

June 2003

Entering Pressure

Reference Values

Use the steps below to change the reference values for pressure

inputs. (Figure 3-19 on page 3-32 for a menu map.)

Caution!

Do not adjust pressure reference data unless instructed

to do so by the facto ry.

IMPORTAN T: You should record this data on the Program

Information List supplied in Appendix A of the

Start up Guide, or on a separate shee t of paper, and

keep it in a safe place.

1. At the Reference Menu (see Table 2-4 on page 2-21), press the

PROBE menu key until the Pressure Reference Table appears (see

Figure 2-13 below).

PRESSURE REFERENCE TABLE

Ch HIGH LOW

1

2

3

4

5

6

AutoCal Interval: (HH.MM): 01:00

Reference Menu 11:15 6/2/00

HELP INTERVAL PROBE DONE

Figure 2-13: Referenc e Menu for Pressure

2. Compare the data on the Series 1 screen to the reference data for

the pressure input. If the data is incorrect, use the following

procedure to correct it. I f the dat a is correct, do one of the

following:

• continue to enter reference values for moisture and oxygen

inputs as described in Entering Moisture Reference Value s on

page 2-22 and Entering the Delta F Oxygen Cell Referenc e

Values on page 2-24.

• press the DONE menu key until Main Menu appears on the

message line; then see Displaying Measurements on page 2-28.

When you exi t, the Ser ie s 1 automatically ca librat e s eac h

channel.

2-26 Basic Programming

Page 45

April 2004

Entering Pressure

Reference Values (cont.)

3. Move the pointer to HIGH for the desired channel and press

[YES].

4. Enter the high reference value for tha t channel and press [YES].

5. The pointer automatically moves to

Press [YES ].

6. Enter the low reference value for that channel and press [YES].

7. Repeat steps 3 through 6 to enter the high and low reference

values for the remaining channels.

T o enter reference values for moisture and oxygen inputs, refer to

Entering Moisture Reference Values on page 2-22, and Entering the

Delta F Oxygen Cell Refer ence Values on page 2-25. To exit, press

the DONE menu key until Main Menu appears on the message line.

Then refer to Displaying Measurements on page 2-28. When you exit,

the Series 1 automatically calibrates each channel.

LOW for the same channel.

Basic Programming 2-27

Page 46

June 2003

Displaying Measurements

The Series 1 can display measurements in a matrix format or a line

graph. The first time you power it up, the screen will display

measurements in the matrix format. The matrix format has six pages

and each page consists of six boxes as shown in Figure 2-14. You can

program each box to display any measurement for any channel.

1 Dew Point

-18.0 °C

2 Temperature

+35.9 °C

3 H

O

2

+0.535 ppm

v

4 Oxygen

48.3 ppb

v

5 Pressure

27.10 PSIG

X Unassigned

Main Menu 11:35 01/22/2000

HELP SELECT SETTINGS OPTIONS

pg: 1

Figure 2-14: Matrix Format Screen

Each box in the matrix format is eithe r assigned or unassigned. An

assigned box displays a channel number , meas urement mode, units,

and a value. An unassigned box displays no data. See Figure 2-15 on

page 2-29 for examples of each type of box.

2-28 Basic Programming

Page 47

Displaying

Measurements (cont.)

June 2003

Measurement

Channel

Number

Mode

Units

5 Pressure

27.10 PSIG

Indicators

X Unassigned

Value

Unassigned Box

Figure 2-15: Assigned and Unassigned Boxes

The channel number is from 1 to 6, depending on how many channel

cards are installe d in the unit . Additional channel cards can be

purchased s eparately and inst alle d later (see Installing a Channel

Card on page 2-19 of the Service Manual).

The measurement mode is the parameter currently being measured.

There are a variety of units for each measure ment mode. Table 2-6 on

page 2-31 shows a list of the mea surement mo des and a d escript ion of

the units for each. The table also shows the measurement modes and

units as they are displayed on the screen. An example of a

measurement is shown in Figure 2-16 on the next page.

When select ing a measuremen t mo de , ple ase rem ember that some

measurement modes require mult iple inputs. For example, to display

ppm

, you need moisture and pressure inputs. Table 2-5 below shows

v

a list of measurement modes that require multiple inputs and what

you need to program them.

Table 2-5: Measurement Modes and Required Inputs

To measure: You need the following inputs:

RH Temperature and moisture

PPM

v

PPM

w

MCF/IG Moisture and pressure

MCF/NG Moisture and pressure

PPM

/NG Moisture and pressure

v

Moisture, temperature and saturation

Moisture and pressure

constant data

Basic Programming 2-29

Page 48

June 2003

Displaying

Measurements (cont.)

The shaded area in Figure 2-15 represents the indicator area. When

you program the Series 1 with constan ts or use Enhanced Respons e, a

symbol appears in this area. A “K” indicates a constant is being used

in the measurement and an “E” indicates the meter is using Enhanced

Response to determine the measurement. An example of a

measurement using a constant and Enhanced Response activated is

shown in Figure 2-16 below.

The value is e xpresse d i n the u nits select ed for a de sired mea surement

mode.

Channel

Number

Value

Figure 2-16: Examp l e o f a Displayed Measurement

Measurement

Mode

5 H

O

2

123.45 PPMw

E K

Indicators

Units

2-30 Basic Programming

Page 49

Table 2-6: Measurement Modes and Units for the Series 1

April 2004

Selected

Meas. Mode Description of Units

O

%= Percent Oxygen default Oxygen %

2

/ppM = Parts Per Million Oxygen ppm

O

2

Oxygen

O2/ppB = Parts Per Billion Oxygen ppb

Displayed

Meas. Mode

Displayed

Units

v

v

O2/µA = Microamps (Diagnostic Mode) Oxygen µA

/DVM = Digital Voltmeter (Diagn ostic Mode) Oxygen DVM VDC

O

2

DP/°C = Dew/Frost Point default Dew Point °C

DP/°F = Dew/Frost Point °F Dew Point °F

DP/K = Dew/Frost Point K (Kelvin) Dew Point K

%R.H. = Relative Humidity Rel. Humidity %

Oppm

2

O/MMSCF NG lbs

2