Page 1

GE

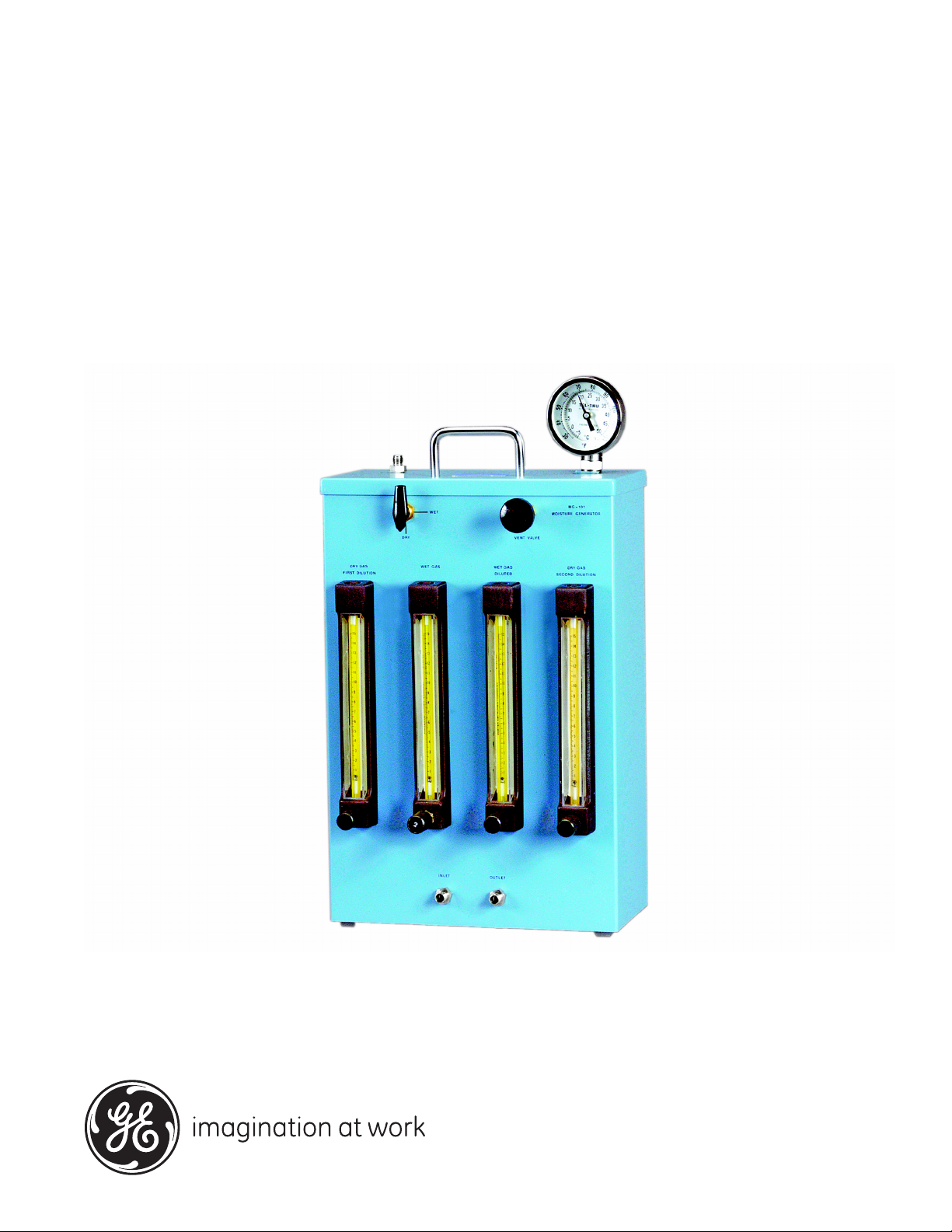

Measurement & Control Moisture

MG-101

User’s Manual

910-115 Rev. E

March 2012

Page 2

Page 3

GE

Measurement & Control

MG-101

Field Moisture Calibration System

User’s Manual

910-115 Rev. E

March 2012

www.ge-mcs.com

©2012 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Preface

Information Paragraphs

Note paragraphs provide information that provides a deeper understanding of the situation, but is not essential to

•

the proper completion of the instructions.

• Important paragraphs provide information that emphasizes instructions that are essential to proper setup of the

equipment. Failure to follow these instructions carefully may cause unreliable performance.

• Caution! paragraphs provide information that alerts the operator to a hazardous situation that can cause damage to

property or equipment.

• Warning! paragraphs provide information that alerts the operator to a hazardous situation that can cause injury to

personnel. Cautionary information is also included, when applicable.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national codes,

regulations, rules and laws related to safety and safe operating conditions are met for each

installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As equipment

can move suddenly and without warning, do not enter the work cell of this equipment during

automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before you

perform maintenance procedures on the equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

MG-101 User’s Manual iii

Page 6

Preface

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE)

take-back initiative, directive 2002/96/EC.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Visit http://www.ge-mcs.com/en/about-us/environmental-health-and-safety/1741-weee-req.html

take-back instructions and more information about this initiative.

for

iv MG-101 User’s Manual

Page 7

Contents

Information Paragraphs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Auxiliary Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Environmental Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Chapter 1. General Information

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Theory Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Initial Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.1 Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.2 Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.3 Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chapter 2. Setup and Operation

2.1 Preliminary Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2.1 Calibrating the Moisture Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.2 Using Data Table 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.2.3 Using Data Table 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.2.4 System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.2.5 Preparation for Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Chapter 3. Specifications

3.1 Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2 Operating Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Appendix A. Supplemental Information

A.1 Formulas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

A.2 Typical Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

A.2.1 Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

A.2.2 Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

A.3 Vapor Pressure and Calibration Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

MG-101 User’s Manual v

Page 8

Contents

[no content intended for this page]

vi MG-101 User’s Manual

Page 9

Chapter 1. General Information

Chapter 1. General Information

1.1 Introduction

The MG-101 Field Calibration System is a portable moisture generator used for checking and, if necessary,

recalibrating GE Sensing moisture probes. The MG-101 can generate dew/frost points in the range of -75 to +20°C

(-103 to +68°F) dew/frost point temperature. It is a totally mechanical device requiring only a supply of dry nitrogen,

and it is inherently explosion-proof. Although specifically designed for calibrating GE Sensing moisture probes, the

MG-101 can be used for any application requiring accurate and repeatable moisture samples.

1.2 Theory Of Operation

Precise moisture concentrations are generated by passing dry nitrogen through a water saturator and mixing the

resulting saturated stream with a dry nitrogen stream from the same source, for a first dilution.

This resulting first dilution is then further diluted in a second mixing stage, resulting in dew/frost point temperatures as

low as -75°C (-103°F).

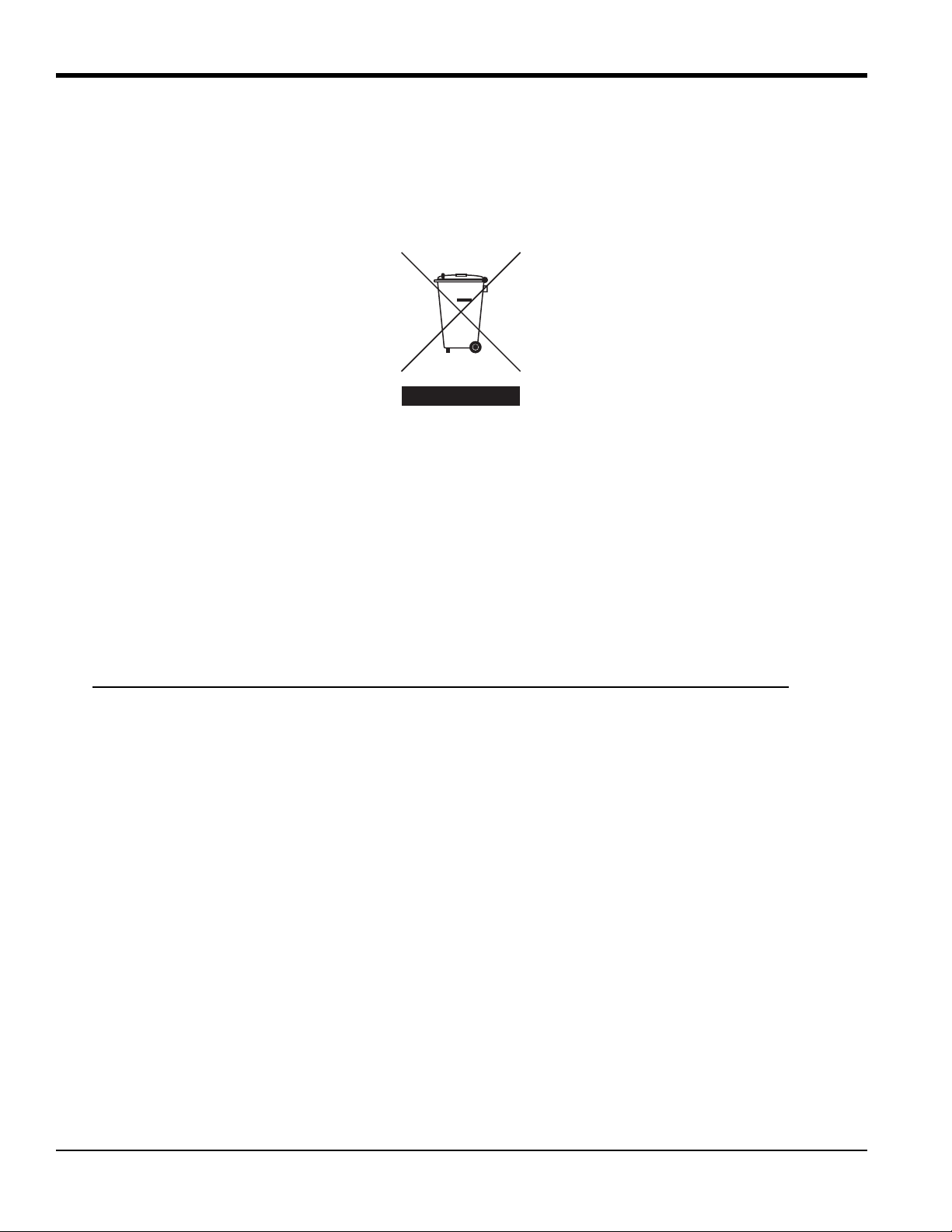

The MG-101 consists of the following components:

• Pressure regulator

• Four adjustable rotameters (flowmeters with valves)

• Saturator bottle

• Filter

• Temperature gauge

• Vent valve

See the diagram and explanation in Figure 1 on page 2 for a description of how the MG-101 works.

MG-101 User’s Manual 1

Page 10

Chapter 1. General Information

Regulator

Pressure

Dry Gas

Inlet

A

Dry Gas

Wet Gas

Flowmeter

5µ Filter

Temp

Saturator

Bottle

Gas

Outlet

B

C

D

E

First Dilution

Flowmeter

Dry Gas

Second

Dilution

Flowmeter

Wet Gas

Diluted

Flowmeter

F

Vent Valve

Dry Down

Valve

1.2 Theory of Operation (cont.)

As shown in Figure 1 below, dry nitrogen enters at the dry gas inlet A, passes through the fixed internal pressure

regulator, and splits into the following three streams:

• B - dry gas “first dilution”

• C - wet gas

• D - dry gas “second dilution”

Stream

to form a “Wet gas diluted” mixture (stream

generate the desired output mixture (stream

Obtaining an accurate output mixture requires careful adjustment of the rotameter valves as described in “Setup and

Operation” on page 5. Calibration of all rotameters and the thermometer is traceable to NIST standards.

Note: The rotameter scales are used in later steps to reference a lookup table. By themselves, they do not indicate

B (the dry gas “first dilution”) is mixed with stream C (the wet gas) after it passes through the saturator bottles

E). This is then mixed with stream D (the “dry gas second dilution”) to

F).

units of flow.

Figure 1: Flow Schematic

2 MG-101 User’s Manuall

Page 11

Chapter 1. General Information

1.3 Initial Considerations

This section presents some general guidelines to ensure accurate results with the MG-101.

1.3.1 Operating Range

While the driest dew/frost point temperature capability specified for the MG-101 is -75°C (-103°F), the actual limit is

determined by the moisture content of the dry nitrogen source and by the ambient temperature.

The driest dew/frost point temperature the MG-101 can produce is the dew/frost point temperature of the dry nitrogen

source plus 25°C (45°F). If dry nitrogen of this quality is not available, please contact GE Sensing for assistance. The

wettest dew/frost point temperature that can be generated is determined by the ambient temperature, and it must be at

least 10°C (18°F) below the ambient temperature.

1.3.2 Operating Environment

The MG-101 is designed to be used indoors or in an environment where ambient temperature changes are not extreme

and where the instrument will not be subject to dramatic heating or cooling. It is important to ensure that the

temperature of the calibrator and especially the saturator bottle will not change between the beginning and the end of

the calibration cycle.

IMPORTANT: Changes in the saturator bottle temperature after the calibration parameters have been established will

cause errors in the generated dew/frost point temperature.

CAUTION!

The MG-101 can be damaged by freezing. Do not operate it in freezing temperatures.

1.3.3 Operating Requirements

You will need the following additional equipment to set up and operate the MG-101 calibrator:

• Nitrogen, preferably from a liquid source

Note: Nitrogen gas cylinders may be used, but the supply gas must be at least 25°C (45°F) drier than the driest

dew/frost point temperature to be generated. Two nitrogen cylinders connected in parallel and plumbed to the

inlet of the MG-101, will increase the stability of the gas supply.

• Stainless steel pressure regulator to set the inlet pressure to 55 psig

• 1/4” OD stainless steel tubing

• An appropriate test chamber

Note: GE Sensing Sample Cell #2830 is preferred for M2 Type probes

• A hygrometer to monitor the moisture sensor for either:

• the dew/frost point reading, if simply verifying the moisture sensor performance, or

• the sensor output signal, if generating a new calibration curve

Note: The hygrometer used for the calibration can be either a dedicated instrument for use only with the moisture

generator or the process instrument that will be used with the recalibrated sensor after the calibration is

completed.

MG-101 User’s Manual 3

Page 12

Chapter 1. General Information

[no content intended for this page]

4 MG-101 User’s Manual

Page 13

Chapter 2. Setup and Operation

Saturator Bottle

Fill Mark

Fill Tubing

Petcock

Screws (2)

Chapter 2. Setup and Operation

2.1 Preliminary Setup

IMPORTANT: Be sure you read and understand “Initial Considerations” on page 3 before proceeding.

To prepare the MG-101 for operation, complete the following steps:

1. Remove the back panel by removing the two small screws at the bottom (see Figure 2 below).

2. Fill the supplied plastic squeeze bottle with distilled (not

bottom of the saturator bottle (see Figure 2 below). This length of plastic tubing should be left permanently

attached to the fitting at the bottom of the saturator bottle.

deionized) water and connect it to the fill tubing at the

Figure 2: MG-101 Rear View with Panel Removed

MG-101 User’s Manual 5

Page 14

Chapter 2. Setup and Operation

Vent Valve

Wet/Dry

Selection Valve

Inlet Fitting

Outlet Fitting

2.1 Preliminary Setup (cont.)

3. Open the petcock.

4. Fully open the vent valve on the front panel by turning it counter-clockwise, and turn the

VALVE

to WET (see Figure 3 below).

WET/DRY SELECTOR

5. Using the squeeze bottle, fill the saturator bottle until the water level reaches the fill mark on the bottle (see

Figure 2 on page 5).

6. Close the petcock and reinstall the back panel.

Figure 3: MG-101 Front Panel

6 MG-101 User’s Manuall

Page 15

Chapter 2. Setup and Operation

MG-101

Calibration

Chamber

Nitrogen

Supply Tank

Pressure Regulator

2.1 Preliminary Setup (cont.)

7. Connect the nitrogen supply to the MG-101 inlet fitting via the stainless steel pressure regulator using, 1/4” OD

stainless steel tubing (see Figure 4 below).

Note: Swagelok

®

fittings are preferred throughout the installation.

8. Connect the calibration chamber to the MG-101 outlet fitting, using 1/4” OD SS tubing. Then, leak test the

connection.

Note: GE Sensing Sample Cell #2830 is the preferred calibration chamber for M2 Type probes

9. At the outlet of the calibration chamber, connect at least 5 ft (1.5 m) of 1/4” OD tubing as a vent to atmosphere.

The tubing may be coiled to save space.

10. Insert the sensor to be calibrated into the calibration chamber and tighten it sufficiently to ensure a leak-proof seal,

but be careful not to over-tighten the sensor.

Figure 4: A Typical MG-101 Test Setup

MG-101 User’s Manual 7

Page 16

Chapter 2. Setup and Operation

Glass Ball (black)

Steel Ball (silver)

Valv e

2.2 Operating Procedure

To operate the MG-101, refer to Figure 5 below and Figure 6 on page 9 to complete the following steps:

1. Fully close all four rotameter valves by turning them clockwise.

2. Set the

CAUTION!

WET/DRY selector valve to DRY.

This valve must always be in the WET position before the “WET GAS” flowmeter valve is opened,

and it must remain in the DRY position until the “WET GAS” flowmeter valve is closed.

3. Set the pressure regulator on the nitrogen gas inlet line to approximately 55 psig.

4. Make sure the vent valve at the top of the front panel is fully open.

5. Fully open the valve on the

WET GAS DILUTED rotameter.

Note: The rotameters are dual-range, floating-ball types, each having both a steel ball and a glass ball. When

reading the rotameters be careful to watch either

directed (numbers in tables are followed by an

the steel ball or the glass ball (see Figure 4 below) as

S or a G to designate the ball material).

Figure 5: Rotameter Valve and Balls

8 MG-101 User’s Manuall

Page 17

Chapter 2. Setup and Operation

Temperature

Gauge

Vent Valve

Wet/Dry

Selector Valve

Dry Gas

Second Dilution

Wet Gas

Rotameters

Wet Gas

Dry Gas

First Dilution

Diluted

2.2 Operating Procedure (cont.)

6. Open and adjust the valves on both the DRY GAS FIRST DILUTION and the DRY GAS SECOND DILUTION rotameters, so

that the steel ball indicates approximately

“10” on the rotameter scales.

7. Adjust the vent valve so that the steel ball on the

WET GAS DILUTED rotameter also reads approximately “10.”

IMPORTANT: Leak test all connections from the nitrogen supply to the calibration chamber before proceeding.

8. Allow the nitrogen to purge through the entire system at the rotameter settings defined in the previous steps. The

calibration system will begin to dry down and eventually come to equilibrium with the dry nitrogen supply gas.

The time required to achieve equilibrium will vary depending on the moisture level of the nitrogen (approximately

6 to 18 hours will be required).

9. After the calibration system has reached equilibrium, set the valve on the

WET/DRY rotameter to the WET position.

Figure 6: Rotameters and Valves

MG-101 User’s Manual 9

Page 18

Chapter 2. Setup and Operation

2.2.1 Calibrating the Moisture Samples

To generate calibrated moisture samples, proceed as follows:

Note: Be sure to start with the driest calibration value and proceed to the wetter values, because you cannot readily

go from a wetter valve to a drier value. Wetter to drier changes always require a longer equilibration period.

For example, if you are calibrating a moisture probe over the range of -60°C dew/frost point temperature to

+10°C dew/frost point temperature, start with the -60°C dew/frost point temperature.

1. Check the saturator bottle temperature on the temperature gauge.

2. For each moisture calibration point you wish to generate, look at

Above the line which reads “Generated Dew Points (Deg C),” is a row of values headed “Ambient Temperature

(Deg C).” Find the column corresponding as closely as possible to the temperature measured in Step 1 above, and

read down the column of dew/frost points (dew points) in the table below this temperature heading.

Note: The moisture value you wish to generate may be in either

“drier” calibration points are in Data Table 3 while “wetter” values are in Data Table 2.

At this point, the MG-101 operating procedure depends on which table contains your calibration point:

Data Tables 2 and 3 (supplied with the MG-101).

Data Table 2 or Data Table 3. You will find that

• If your calibration point is in Data Table 3, go to “Using Data Table 3” on page 11.

• If your calibration point is in Data Table 2, go to “Using Data Table 2” on page 12.

10 MG-101 User’s Manuall

Page 19

Chapter 2. Setup and Operation

2.2.2 Using Data Table 3

For calibration points found in Data Table 3, refer to Figure 6 on page 9 and proceed as follows:

1. Fully open the vent valve by turning it counter-clockwise.

CAUTION!

Make the following adjustments slowly, being careful not to overshoot the target value. NEVER

ALLOW THE SYSTEM TO GO TO A VALUE WETTER THAN THE TARGET VALUE. If you overshoot a

value in the wetter direction, you will have to allow the system to equilibrate (dry down) again

before you can proceed.

Data Table 3, look below the body of the table for Notes 1 and 2. Adjust both the valves on the DRY GAS FIRST

2. In

DILUTION

IMPORTANT: Be sure to read the steel ball or glass ball (

3. Consult

headed

4. By referring to the desired dew/frost point temperature in

headed

remain fully open) to obtain the value indicated in

and the DRY GAS SECOND DILUTION rotameters to the values listed.

S or G), as indicated in the table.

Data Table 3 for the desired dew/frost point temperature and find the corresponding value in the column

WET GAS. Adjust the WET GAS valve to obtain the value indicated in the table.

Data Table 3, find the corresponding value in the column

WET GAS DILUTED. Adjust the vent valve (but not the valve on the WET GAS DILUTED rotameter, which must

Data Table 3.

After stabilizing, the system output will be at the selected dew/frost point temperature and it is ready for use. The

stabilization period depends on the dew/frost point temperature you are using. In general, the following times are

required:

• For dew/frost point temperatures of -60°C (-76°F) and drier, allow 2 hours

• For dew/frost point temperatures of -60°C (-76°F) to -40°C (-40°F), allow 1 hour

• For dew/frost point temperatures of -40°C (-40°F) and wetter, allow 30 minutes

After you have completed the calibration or other calibrated moisture operation at this dew/frost point temperature,

either shut down the system (see “System Shutdown” on page 12), or repeat the steps in this section for the next

calibration point.

MG-101 User’s Manual 11

Page 20

Chapter 2. Setup and Operation

2.2.3 Using Data Table 2

For calibration points found in Data Table 2, refer to Figure 6 on page 9 and proceed as follows:

1. Fully close the vent valve by turning it clockwise.

CAUTION!

Make the following adjustments slowly, being careful not to overshoot the target value. NEVER

ALLOW THE SYSTEM TO GO TO A VALUE WETTER THAN THE TARGET VALUE. If you overshoot a

value in the wetter direction, you will have to allow the system to equilibrate (dry down) again

before you can proceed.

2. Fully close the

3. Consult

headed

Data Table 2 for the desired dew/frost point temperature and find the corresponding value in the column

DRY GAS (SECOND DILUTION). Adjust the valve on the DRY GAS SECOND DILUTION rotameter to obtain the

DRY GAS FIRST DILUTION VALVE by turning it clockwise.

value shown in the table.

IMPORTANT: Be sure to read the steel ball or glass ball (

4. By referring to the desired dew/frost point temperature in

column headed

other, but not both). Adjust the valve on the

WET GAS or the column headed WET GAS DILUTED (a given value appears in one column or the

WET GAS rotameter (but not on the Wet Gas Diluted rotameter, which

must remain fully open) to obtain the reading indicated on either the

S or G), as indicated in the table.

Data Table 2, find the corresponding value in either the

WET GAS or the WET GAS DILUTED rotameter

scales (whichever is indicated in the table).

IMPORTANT: Be sure to read the steel ball or glass ball (

S or G), as indicated in the table.

After equilibrium has been established, the MG-101 will be delivering a calibration gas with the selected dew/frost

point temperature.

After you have completed the calibration or other calibrated moisture operation at this dew/frost point temperature,

either shut down the system (see “System Shutdown” below), or repeat the steps in this section for the next calibration

point.

2.2.4 System Shutdown

If you are not planning another calibration run, you must shut the system down as follows:

1. Fully open the vent valve by turning it counter-clockwise.

2. Fully close the

3. Fully close the

4. Fully close the

5. Set the

12 MG-101 User’s Manuall

WET/DRY VALVE to DRY.

WET GAS VALVE by turning it clockwise.

DRY GAS FIRST DILUTION VALVE by turning it clockwise.

DRY GAS SECOND DILUTION VALVE by turning it clockwise.

Page 21

Chapter 2. Setup and Operation

Saturator Bottle

Fill Tubing

Petcock

Screws (2)

2.2.5 Preparation for Shipping

To ship or to move the MG-101, refer to Figure 7 below and empty the saturator bottle as follows:

1. Remove the rear panel by removing the two small screws at the bottom.

2. Fully open the vent valve by turning it counter-clockwise.

3. Place the end of the fill tubing in a container below the level of the saturator bottle and open the petcock.

4. When the saturator bottle is completely empty, close the petcock and the vent valve, and reinstall the rear panel.

Figure 7: Emptying the Saturator Bottle

MG-101 User’s Manual 13

Page 22

Chapter 2. Setup and Operation

[no content intended for this page]

14 MG-101 User’s Manual

Page 23

Chapter 3. Specifications

3.1 Performance Specifications

Chapter 3. Specifications

Generated Dew/Frost Point

Temperature Range

Accuracy ±1°C (±1.8°F)

-75°C (-103°F) up to 10°C (18°F) below ambient temperature

3.2 Operating Specifications

Inlet Gas Supply Must be a minimum of 25°C (45°F) drier than the driest sample to be generated

Flow Rate 9.2 liters/minute (19.6 SCFH), maximum

Inlet Pressure 55-60 psig

Outlet Pressure Ambient pressure

Power Requirements None

3.3 Physical Specifications

Dimensions (W x H x D) 12” x 18” x 6” (304.8 mm x 457.2 mm x 152.4 mm)

Inlet and Outlet Connections 1/4” Swagelok® tube fittings

Note: See Figure 8 on page 16 for a dimensional drawing of the MG-101.

MG-101 User’s Manual 15

Page 24

Chapter 3. Specifications

18.00”

(457 mm)

12.00” (305 mm)

3.3 Physical Specifications (cont.)

Figure 8: MG-101 Moisture Generator Outline Dimensions

16 MG-101 User’s Manual

Page 25

Appendix A. Supplemental Information

P

w

F

w

PsF

w1Pd1Fd1

+

F

w1Fd1

+

------------------------ ---------------

P

dFd

×+

F

wFd

+

----------------------- ----------------------------- -------------------------=

P

w

F

w

FwFd+

-------------------

F

w1

F

w1Fd1

+

-------------------------

P

s

=

Appendix A. Supplemental Information

A.1 Formulas

The moisture content generated by the MG-101, as determined by the water vapor pressure, is calculated with the

following equation:

where:

= the generated vapor pressure of water

P

w

P

= the saturation vapor pressure of water as determined by the water temperature of the saturator

s

= the vapor pressure of water in the dry nitrogen stream

P

d

F

= the flow rate of the wet gas diluted stream

w

= the flow rate of the wet gas stream

F

w1

= the flow rate of the dry gas second dilution stream

F

d

F

= the flow rate of the dry gas first dilution stream

d1

(1)

In general, P

<< PsFw and Pd1Fd1 << PsFw1. Thus, Equation 1 above simplifies to:

dFd

(2)

The value of P

and the dew point (from the calculated value pw) are determined from a chart of vapor pressure of water

s

as a function of temperature (see Table 1 on page 19). Equation 1 above produces an error of less than 2°C (3.6°F)

dew/frost point temperature at the lowest generated dew/frost point temperatures, and virtually no error at higher

dew/frost point temperatures. The advantage of Equation 2 above is that a precise determination of the dew/frost point

temperature of the gas supply is not necessary. It is good practice, however, to use the hygrometer to determine an

approximate dew/frost point temperature of the dry gas supply. To obtain the lowest dew/frost point temperatures

within the specified accuracy, the dry gas supply should not exceed 3% of the desired mixture concentration.

MG-101 User’s Manual 17

Page 26

Appendix A. Supplemental Information

P

w

F

w

FwFd+

-------------------

F

w1

F

w1Fd1

+

-------------------------

P

s

=

P

w

347cc min⁄

347cc min⁄ 4500cc min⁄+

------------------------- ---------------------------- --------------

140cc min⁄

140cc min⁄ 4500c c min⁄+

------------------------ ----------------------------- --------------

17.353mmHg()⋅=

A.2 Typical Examples

The following examples show typical calculations based on the equations presented on the previous page.

A.2.1 Example 1

Data Table 2 is provided with the MG-101 to enable you to use the field calibration system to check sensor probe

calibration without calculating the value of p

point temperature by Equation 2 on the previous page. To use

“Dry Gas Setting” and either “High Wet Gas Setting” or “Low Wet Gas Setting.” Moving horizontally across the table,

read the generated dew/frost point temperature under the appropriate temperature reading.

Note: The term “Flowmeter” used in the data tables and is equivalent to the word “rotameter” used in this manual.

A.2.2 Example 2

To determine generated dew/frost point temperatures other than those listed in Data Table 2, Equation 2 on the previous

page must be used, as shown in the following example. If,

. Data Table 2 was compiled by calculating pw and thus, the dew/frost

w

Data Table 2, set the rotameters per the columns headed

Dry Gas first dilution flowmeter setting F

Dry Gas second dilution flowmeter setting F

Wet Gas flowmeter setting = 20 cc/min F

Wet Gas diluted flowmeter setting F

w

= 4,500 cc/min

d1

= 4,500 cc/min

d

= 140 cc/min

w1

= 347 cc/min

Thermometer reading T = 20°C

and, P

= 17.535 mm Hg at 20°C (from Table 1 on page 19),

s

Then,

And, Pw = 0.0375 mm Hg, which is equivalent to a dew/frost point temperature of 48°C (by interpolation).

A.3 Vapor Pressure and Calibration Tables

(3)

(4)

Table 1 on page 19 is the vapor pressure of water as a function of temperature.

IMPORTANT: Two tables not included in this manual,

18 MG-101 User’s Manual

factory for each MG-101. These tables are supplied with the unit, and you must use these tables to

operate the MG-101. Since each table is specific to your instrument, you cannot use tables from another

unit. If you lose these tables, contact the factory and duplicates will be provided.

Data Tables 2 and 3, are sets of calibrations generated at the

Page 27

Appendix A. Supplemental Information

Table 1: Vapor Pressure of Water

Note: If the dew/frost point is known, the table yields the partial water vapor pressure (P

or actual gas temperature is known, the table yields the saturated water vapor pressure (P

) in mm of Hg. If the ambient

W

) in mm of Hg.

S

Water Vapor Pressure Over Ice

Temp . (°C) 0 2 4 6 8

-90 0.000070 0.000048 0.000033 0.000022 0.000015

-80 0.000400 0.000290 0.000200 0.000140 0.000100

-70 0.001940 0.001430 0.001050 0.000770 0.000560

-60 0.008080 0.006140 0.004640 0.003490 0.002610

-50 0.029550 0.023000 0.017800 0.013800 0.010600

-40 0.096600 0.076800 0.060900 0.048100 0.037800

-30 0.285900 0.231800 0.187300 0.150700 0.120900

Temp. (°C)0.00.20.40.60.8

-29 0.317 0.311 0.304 0.298 0.292

-28 0.351 0.344 0.337 0.330 0.324

-27 0.389 0.381 0.374 0.366 0.359

-26 0.430 0.422 0.414 0.405 0.397

-25 0.476 0.467 0.457 0.448 0.439

-24 0.526 0.515 0.505 0.495 0.486

-23 0.580 0.569 0.558 0.547 0.536

-22 0.640 0.627 0.615 0.603 0.592

-21 0.705 0.691 0.678 0.665 0.652

-20 0.776 0.761 0.747 0.733 0.719

-19 0.854 0.838 0.822 0.806 0.791

-18 0.939 0.921 0.904 0.887 0.870

-17 1.031 1.012 0.993 0.975 0.956

-16 1.132 1.111 1.091 1.070 1.051

-15 1.241 1.219 1.196 1.175 1.153

-14 1.361 1.336 1.312 1.288 1.264

-13 1.490 1.464 1.437 1.411 1.386

-12 1.632 1.602 1.574 1.546 1.518

-11 1.785 1.753 1.722 1.691 1.661

-10 1.950 1.916 1.883 1.849 1.817

-9 2.131 2.093 2.057 2.021 1.985

-8 2.326 2.285 2.246 2.207 2.168

-7 2.537 2.493 2.450 2.408 2.367

-6 2.765 2.718 2.672 2.626 2.581

-5 3.013 2.962 2.912 2.862 2.813

-4 3.280 3.225 3.171 3.117 3.065

-3 3.568 3.509 3.451 3.393 3.336

-2 3.880 3.816 3.753 3.691 3.630

-1 4.217 4.147 4.079 4.012 3.946

0 4.579 4.504 4.431 4.359 4.287

MG-101 User’s Manual 19

Page 28

Appendix A. Supplemental Information

Table 1: Vapor Pressure of Water (cont.)

Aqueous Vapor Pressure Over Water

Temp. (°C)0.00.20.40.60.8

0 4.579 4.647 4.715 4.785 4.855

1 4.926 4.998 5.070 5.144 5.219

2 5.294 5.370 5.447 5.525 5.605

3 5.685 5.766 5.848 5.931 6.015

4 6.101 6.187 6.274 6.363 6.453

5 6.543 6.635 6.728 6.822 6.917

6 7.013 7.111 7.209 7.309 7.411

7 7.513 7.617 7.722 7.828 7.936

8 8.045 8.155 8.267 8.380 8.494

9 8.609 8.727 8.845 8.965 9.086

10 9.209 9.333 9.458 9.585 9.714

11 9.844 9.976 10.109 10.244 10.380

12 10.518 10.658 10.799 10.941 11.085

13 11.231 11.379 11.528 11.680 11.833

14 11.987 12.144 12.302 12.462 12.624

15 12.788 12.953 13.121 13.290 13.461

16 13.634 13.809 13.987 14.166 14.347

17 14.530 14.715 14.903 15.092 15.284

18 15.477 15.673 15.871 16.071 16.272

19 16.477 16.685 16.894 17.105 17.319

20 17.535 17.753 17.974 18.197 18.422

21 18.650 18.880 19.113 19.349 19.587

22 19.827 20.070 20.316 20.565 20.815

23 21.068 21.324 21.583 21.845 22.110

24 22.377 22.648 22.922 23.198 23.476

25 23.756 24.039 24.326 24.617 24.912

26 25.209 25.509 25.812 26.117 26.426

27 26.739 27.055 27.374 27.696 28.021

28 28.349 28.680 29.015 29.354 29.697

29 30.043 30.392 30.745 31.102 31.461

30 31.824 32.191 32.561 32.934 33.312

31 33.695 34.082 34.471 34.864 35.261

32 35.663 36.068 36.477 36.891 37.308

33 37.729 38.155 38.584 39.018 39.457

34 39.898 40.344 40.796 41.251 41.710

35 42.175 42.644 43.117 43.595 44.078

36 44.563 45.054 45.549 46.050 46.556

37 47.067 47.582 48.102 48.627 49.157

38 49.692 50.231 50.774 51.323 51.879

39 52.442 53.009 53.580 54.156 54.737

40 55.324 55.910 56.510 57.110 57.720

41 58.340 58.960 59.580 60.220 60.860

20 MG-101 User’s Manual

Page 29

Appendix A. Supplemental Information

Table 1: Vapor Pressure of Water (cont.)

Aqueous Vapor Pressure Over Water (cont.)

Temp. (°C)0.00.20.40.60.8

42 61.500 62.140 62.800 63.460 64.120

43 64.800 65.480 66.160 66.860 67.560

44 68.260 68.970 69.690 70.410 71.140

45 71.880 72.620 73.360 74.120 74.880

46 75.650 76.430 77.210 78.000 78.800

47 79.600 80.410 81.230 82.050 82.870

48 83.710 84.560 85.420 86.280 87.140

49 88.020 88.900 89.790 90.690 91.590

50 92.51 93.50 94.40 95.30 96.30

51 97.20 98.20 99.10 100.10 101.10

52 102.09 103.10 104.10 105.10 106.20

53 107.20 108.20 109.30 110.40 111.40

54 112.51 113.60 114.70 115.80 116.90

55 118.04 119.10 120.30 121.50 122.60

56 123.80 125.00 126.20 127.40 128.60

57 129.82 131.00 132.30 133.50 134.70

58 136.08 137.30 138.50 139.90 141.20

59 142.60 143.90 145.20 146.60 148.00

60 149.38 150.70 152.10 153.50 155.00

61 156.43 157.80 159.30 160.80 162.30

62 163.77 165.20 166.80 168.30 169.80

63 171.38 172.90 174.50 176.10 177.70

64 179.31 180.90 182.50 184.20 185.80

65 187.54 189.20 190.90 192.60 194.30

66 196.09 197.80 199.50 201.30 203.10

67 204.96 206.80 208.60 210.50 212.30

68 214.17 216.00 218.00 219.90 221.80

69 223.73 225.70 227.70 229.70 231.70

70 233.70 235.70 237.70 239.70 241.80

71 243.90 246.00 248.20 250.30 252.40

72 254.60 256.80 259.00 261.20 263.40

73 265.70 268.00 270.20 272.60 274.80

74 277.20 279.40 281.80 284.20 286.60

75 289.10 291.50 294.00 296.40 298.80

76 301.40 303.80 306.40 308.90 311.40

77 314.10 316.60 319.20 322.00 324.60

78 327.30 330.00 332.80 335.60 338.20

79 341.00 343.80 346.60 349.40 352.20

80 355.10 358.00 361.00 363.80 366.80

81 369.70 372.60 375.60 378.80 381.80

82 384.90 388.00 391.20 394.40 397.40

83 400.60 403.80 407.00 410.20 413.60

MG-101 User’s Manual 21

Page 30

Appendix A. Supplemental Information

Table 1: Vapor Pressure of Water (cont.)

Aqueous Vapor Pressure Over Water (cont.)

Temp. (°C)0.00.20.40.60.8

84 416.80 420.20 423.60 426.80 430.20

85 433.60 437.00 440.40 444.00 447.50

86 450.90 454.40 458.00 461.60 465.20

87 468.70 472.40 476.00 479.80 483.40

88 487.10 491.00 494.70 498.50 502.20

89 506.10 510.00 513.90 517.80 521.80

90 525.76 529.77 533.80 537.86 541.95

91 546.05 550.18 554.35 558.53 562.75

92 566.99 571.26 575.55 579.87 584.22

93 588.60 593.00 597.43 601.89 606.38

94 610.90 615.44 620.01 624.61 629.24

95 633.90 638.59 643.30 648.05 652.82

96 657.62 662.45 667.31 672.20 677.12

97 682.07 687.04 692.05 697.10 702.17

98 707.27 712.40 717.56 722.75 727.98

99 733.24 738.53 743.85 749.20 754.58

100 760.00 765.45 770.93 776.44 782.00

101 787.57 793.18 798.82 804.50 810.21

22 MG-101 User’s Manual

Page 31

Warranty

Warranty

Each instrument manufactured by GE Sensing is warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to normal operation or replacing the instrument, at

the sole discretion of GE Sensing. Fuses and batteries are specifically excluded from any liability. This warranty is

effective from the date of delivery to the original purchaser. If GE Sensing determines that the equipment was

defective, the warranty period is:

• one year from delivery for electronic or mechanical failures

• one year from delivery for sensor shelf life

If GE Sensing determines that the equipment was damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines specified by GE Sensing, the repairs are not covered

under this warranty.

The warranties set forth herein are exclusive and are in lieu of all other warranties whether

statutory, express or implied (including warranties or merchantability and fitness for a

particular purpose, and warranties arising from course of dealing or usage or trade).

Return Policy

If a GE Sensing instrument malfunctions within the warranty period, the following procedure must be completed:

1. Notify GE Sensing, giving full details of the problem, and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for factory service, GE Sensing will issue a RETURN

AUTHORIZATION NUMBER (RAN), and shipping instructions for the return of the instrument to a service

center will be provided.

2. If GE Sensing instructs you to send your instrument to a service center, it must be shipped prepaid to the authorized

repair station indicated in the shipping instructions.

3. Upon receipt, GE Sensing will evaluate the instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the instrument will be repaired at no cost to the owner and

returned.

• If GE Sensing determines that the damage is not covered under the terms of the warranty, or if the warranty has

expired, an estimate for the cost of the repairs at standard rates will be provided. Upon receipt of the owner’s

approval to proceed, the instrument will be repaired and returned.

MG-101 User’s Manual 23

Page 32

Warranty

[no content intended for this page]

24 MG-101 User’s Manual

Page 33

Page 34

Customer Support Centers

U.S.A .

The Boston Center

1100 Technology Park Drive

Billerica, MA 01821

U.S.A.

Tel: 800 833 9438 (toll-free)

978 437 1000

E-mail: sensing@ge.com

Ireland

Sensing House

Shannon Free Zone East

Shannon, County Clare

Ireland

Tel: +353 (0)61 470291

E-mail: gesensingsnnservices@ge.com

910-115 Rev. E

An ISO 9001:2008 Certified Company

www.ge-mcs.com/en/about_us/quality.html

www.ge-mcs.com

©2012 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Loading...

Loading...