Page 1

GE

Sensing

Applications

DigitalFlow

™

ISX878

Panametrics Liquid Flow

Ultrasonic Transmitter

DigitalFlow ISX878 is a Panametrics

product. Panametrics has joined

other GE high-technology sensing

businesses under a new name

_

GE Industrial, Sensing.

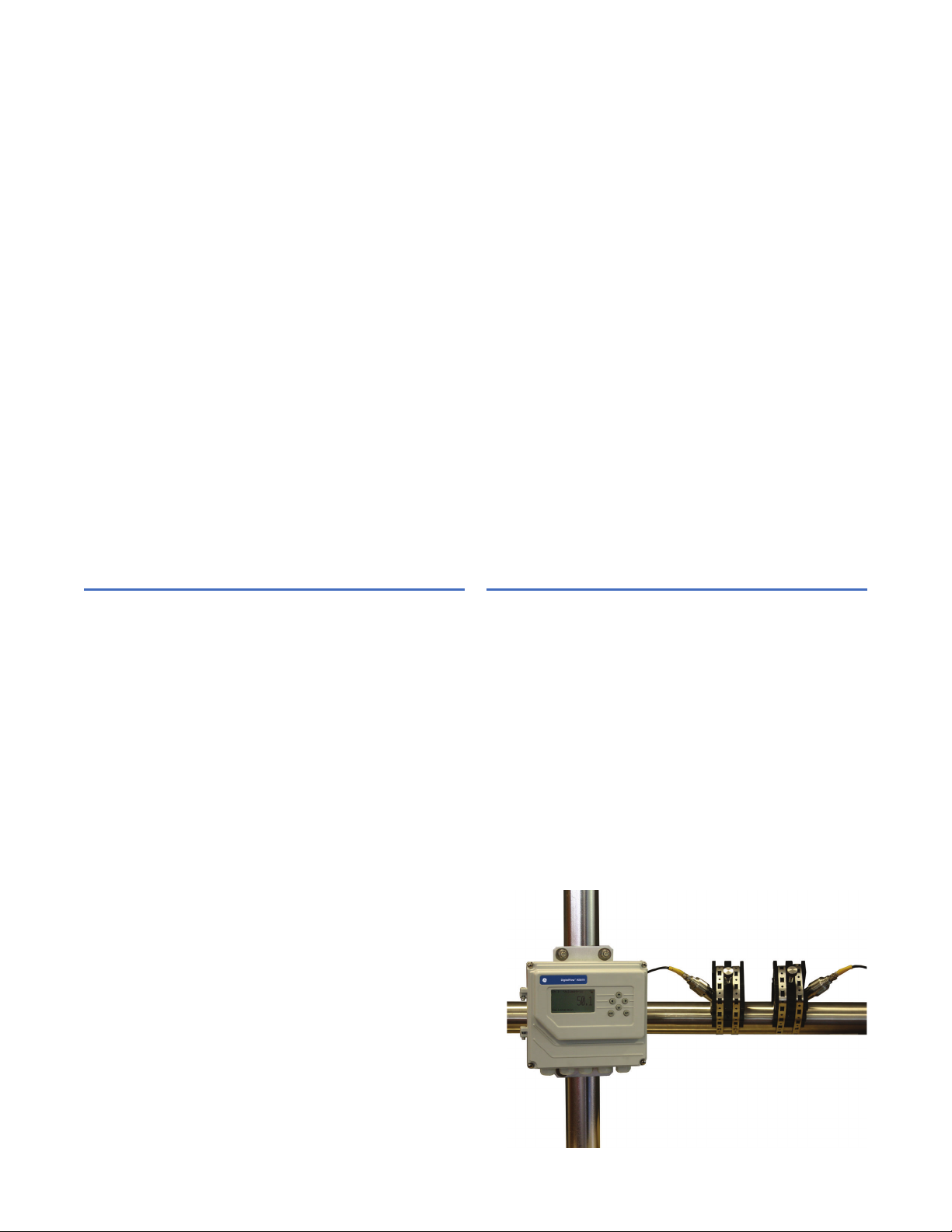

The DigitalFlow ISX878 is an intrinsically safe,

loop-powered, full-featured clamp-on ultrasonic flow

transmitter system for flow measurement of:

• Hydrocarbon liquids

• Petroleum products

• Lubricating oils

• Diesel fuel oil

• Chemicals

• Other liquids

Features

• Intrinsically safe

• Loop-powered

• Low power consumption

• Suitable for pipe sizes from 1/2 in to 16 in

(15 mm to 400 mm) diameter

• Six button keypad

• Large integral display

• Simple meter and transducer installation and setup

• Velocity, volumetric and totalized flow

• Economical non-intrusive flow measurement

g

Page 2

GE

Sensing

The DigitalFLow ISX878 ultrasonic flow transmitter

combines the simplicity of a loop-powered meter

installation with proven, advanced clamp-on ultrasonic

flow transmitter technology. It provides customers with

an economical solution for flow measurement in pipes

up to 16 in (400 mm).

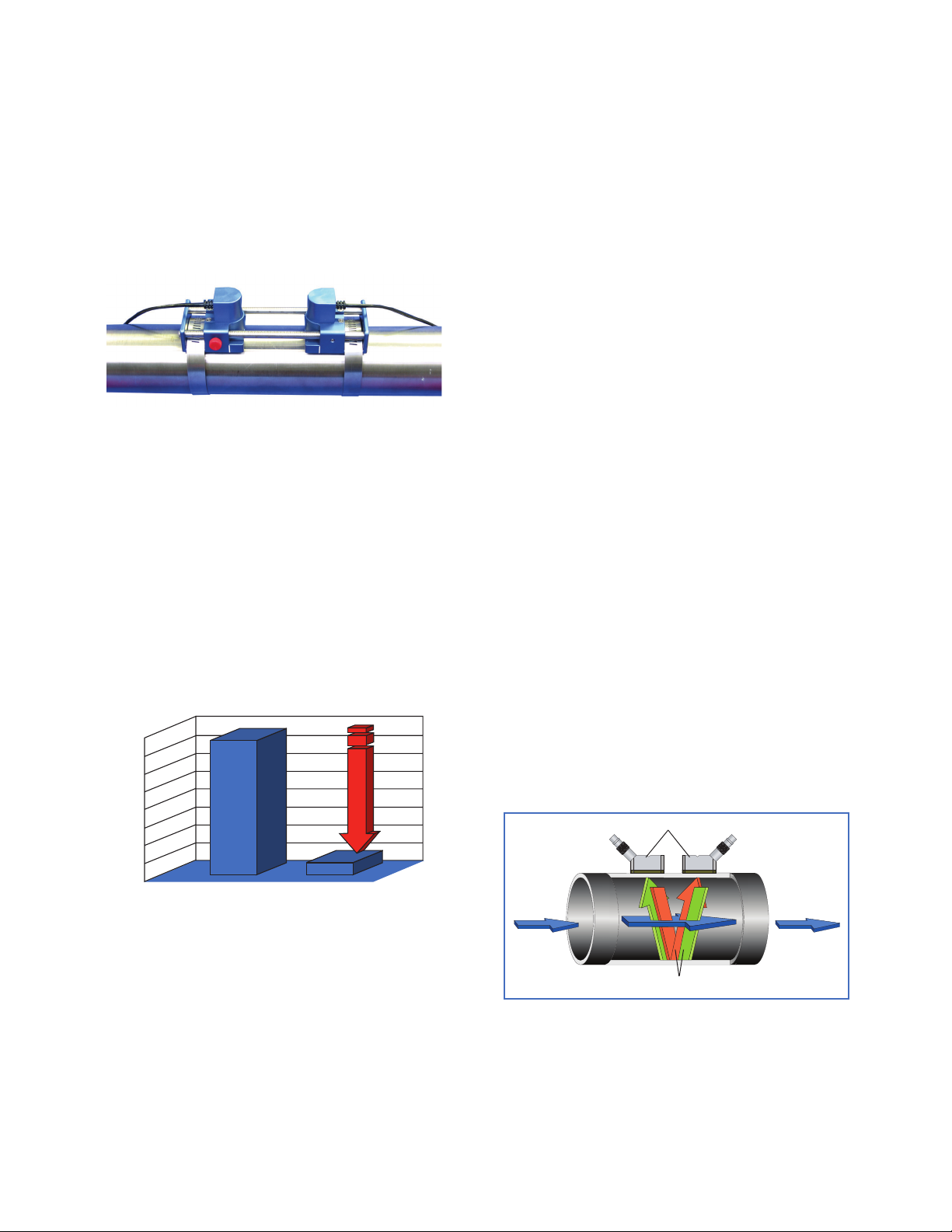

Two-Path Model

An optional second channel provides the capability to

obtain two-path averaging of the flow measurement, at

a single point for increased accuracy.

Uses the Transit-Time Flow

Measurement Technique

The Correlation Transit-Time™ technique uses a pair of

transducers with each transducer sending and receiving

coded ultrasonic signals through the fluid. When the fluid

is flowing, signal transit-time in the downstream direction

is shorter than in the upstream direction; the difference

between these transit-times is proportional to the flow

velocity. The DigitalFlow ISX878 measures the time

difference and uses programmed pipe parameters to

determine flow rate and direction.

Flowmeter Transducers

Fluid

Flow

Ultrasonic Signal Path

Transit-time flow measurement technique

Intrinsically Safe

The DigitalFlow ISX878 provides a low cost solution for

non-intrusive liquid flow measurement in your hazardous

locations. The DigitalFlow ISX878 is able to achieve an

intrinsically safe rating by significantly reducing the

amount of energy required to drive the ultrasonic

transducers. Reducing the drive voltage by a factor of 10

could only be made possible through advancements in

the ultrasonic transducers. The new ISXDR transducers

are considerably more efficient than our previous

piezoelectric models that led the market over the past

two decades.

CPT ISXDR

Small pipe transducers for 1/2 in to 4 in pipes

Lower Cost of Ownership

Intrinsic safety reduces installation costs by eliminating

the need for heavy explosion-proof junction boxes and

conduit. The reduced power usage also allows the

DigitalFlow ISX878 to be a loop-powered device, which

saves on installation costs. This becomes more important

where hazardous locations have significantly higher

costs for running power cables for an AC or DC unit. The

DigitalFlow ISX878 uses an available twisted pair of

instrument cables, fed through a safety barrier, to power

the unit. Since the meter clamps onto the outside of the

pipe, there is no need to shut down a line to install the

meter or to service it. The robust electronics and

transducers have no moving parts to break or wear

down, so annual maintenance can be significantly

reduced, if not entirely eliminated.

Voltage

Page 3

GE

Sensing

ISX878

Specifications

Fluid Types

Acoustically conductive fluids, including water and most

hydrocarbon liquids. Maximum void fraction depends on

transducers, interrogation carrier frequency, path length

and pipe configuration.

Pipe Sizes

1/2 in to 16 in (15 mm to 400 mm) and larger

Pipe Wall Thickness

Up to 0.5 in (13 mm)

Pipe Materials

All metals and most plastics. Consult GE for concrete,

composite materials, and highly corroded or lined pipes.

Flow Accuracy (Velocity)

• Pipe ID≥6 in (150 mm); ±1% to 2% of reading typical

• Pipe ID≤6 in (150 mm); ±2% to 5% of reading typical

Accuracy depends on pipe size and whether measurement

is one-path or two-path. Accuracy to ±0.5% of reading may

be achievable with process calibration.

Repeatability

±0.1% to 0.3% of reading

Range (Bidirectional)

–40 ft/s to 40 ft/s (–12.2 m/s to 12.2 m/s)

Rangeability (Overall)

400:1

Specifications assume a fully developed flow profile

(typically 10 diameters upstream and 5 diameters

downstream of straight pipe run) and flow velocity greater

than 1 ft/s (0.3 m/s).

Measurement Parameters

Volumetric flow, totalized flow and flow velocity

Operation and Performance

Flow Measurement

Patented Correlation Transit-Time mode

Enclosure

Epoxy-coated aluminum weatherproof Type 4X/IP67

Dimensions (h x w x d)

8.8 in x 8.2 in x 3.6 in (220 mm x 210 mm x 90 mm)

Weight

3.9 lb (1.77 kg)

Display

128 x 64 pixel LCD graphic display

Keypad

Six button external keypad

Power Supply

15 to 30 VDC loop power

Power Consumption

700 mW maximum

Memory

FLASH memory; field upgradable

Operating Temperature

–4°F to 140°F (–20°C to 60°C)

Storage Temperature

–4°F to 158°F (–20°C to 70°C)

Standard Inputs/Output

One 4 to 20 mA on power loop

Recommended Safety Barrier

28 VDC, 300 S, 93 mA for 4 to 20 mA

Digital Interface

RS232

European Compliance

System complies with EMC Directive 89/336/EEC

Electronics

Page 4

GE

Sensing

ISX878

Specifications

Clamp-On Flow Ultrasonic Transducers

Temperature Range

–40°F to 194°F (–40°C to 90°C)

Mounting

Stainless steel strap

Certifications

Intrinsically safe

II 1 G EEx ia IIC T4

Transducer Cable

Integral transducer cable up to 100 ft (33 m) with

transducers

Upstream

transducer

Downstream

transducer

15 to 30

VDC

power

supply

Data

acquisition

system

Schematic of loop-power, intrinsically safe installation

Hazardous

Area

Safe Area

Safety barrier (customer supplied)

g

©2004 GE. All rights reserved.

920-135A

All specifications are subject to change for product improvement without notice.

DigitalFlow™ and Correlation Transit-Time™ are trademarks of GE. GE®is a registered

trademark of General Electric Co. Other company or product names mentioned in this

document may be trademarks or registered trademarks of their respective companies,

which are not affiliated with GE.

www.gesensing.com

Loading...

Loading...