Page 1

GE

Sensing

HygroTrace

g

Ultra-Low Moisture

Transmitter

Features

• Rapid speed of response to both wet up and dry

down conditions comparable to high-end analyzers

• Accurate moisture measurement from 0 to

100 ppb

v

• Innovative measurement technique using newly

patented aluminum oxide sensor technology

• Simplified, compact “flow-through” tee sample

cell design

• Stainless steel VCR fittings

• CE certification and UL 508

• Easy-to-read large display

• Analog and digital outputs for full integration

• Compatible with PanaView™ interface software

• Installs out of the box in minutes

Applications

HygroTrace uses a newly patented technique to provide

accurate and reliable measurement at trace moisture

levels. Combining over 70 years of experience in

aluminum oxide sensor technologies by Panametrics and

General Eastern, this robust sensor provides the

sensitivity and speed of response in the ppbvrange

matched only by traditionally expensive analyzers.

• Ultra high purity (UHP) nitrogen and argon

• Cylinder, tank and truck filling applications

• Gas distribution systems in semiconductor

fabrication facilities

• Tool and machine manufacturers

HygroTrace is a new addition to

the extensive Panametrics and

General Eastern product lines

for ultra-low PPB moisture

applications.

Page 2

GE

Sensing

HygroTrace is a compact moisture transmitter designed

to meet the technical requirements of the semiconductor

industry. HygroTrace offers accuracy not commonly

found in a transmitter and the speed of response of a

full-featured analyzer at a fraction of the cost. Now you

can monitor multiple points of measurements for less

than the cost of one analyzer and without installation

constrictions. HygroTrace’s unique and innovative sensor

measurement technique responds to wet up and dry

down conditions in minutes, minimizing moisture

intrusion in your process.

HygroTrace is designed for installation where space is at

a premium. The sensor is mounted on a “flow-through”

tee sample cell that can be installed directly into the

process stream or on a bypass leg of a gas distribution

network. No custom machining is required. The sample

cell uses a small volume sample and is composed of

components that minimize moisture adsorption that

adversely effects measurements.

HygroTrace features an integral backlit display to

provide easy viewing and a keypad to configure the

display, outputs, and other user functions and

diagnostics. The RS485 interface enables the transmitter

to be fully integrated into existing systems for OEM

applications and networks.

Patented Sensor Measurement

Technique

Traditionally, aluminum oxide sensors have not been

widely used for measuring trace levels of moisture

(<100 ppbv) due to sensor response time and calibration

stability at these levels. However, aluminum oxide

sensors offer many benefits to users, including a wide

measurement range, simple installation and minimal

temperature, pressure or gas composition effects.

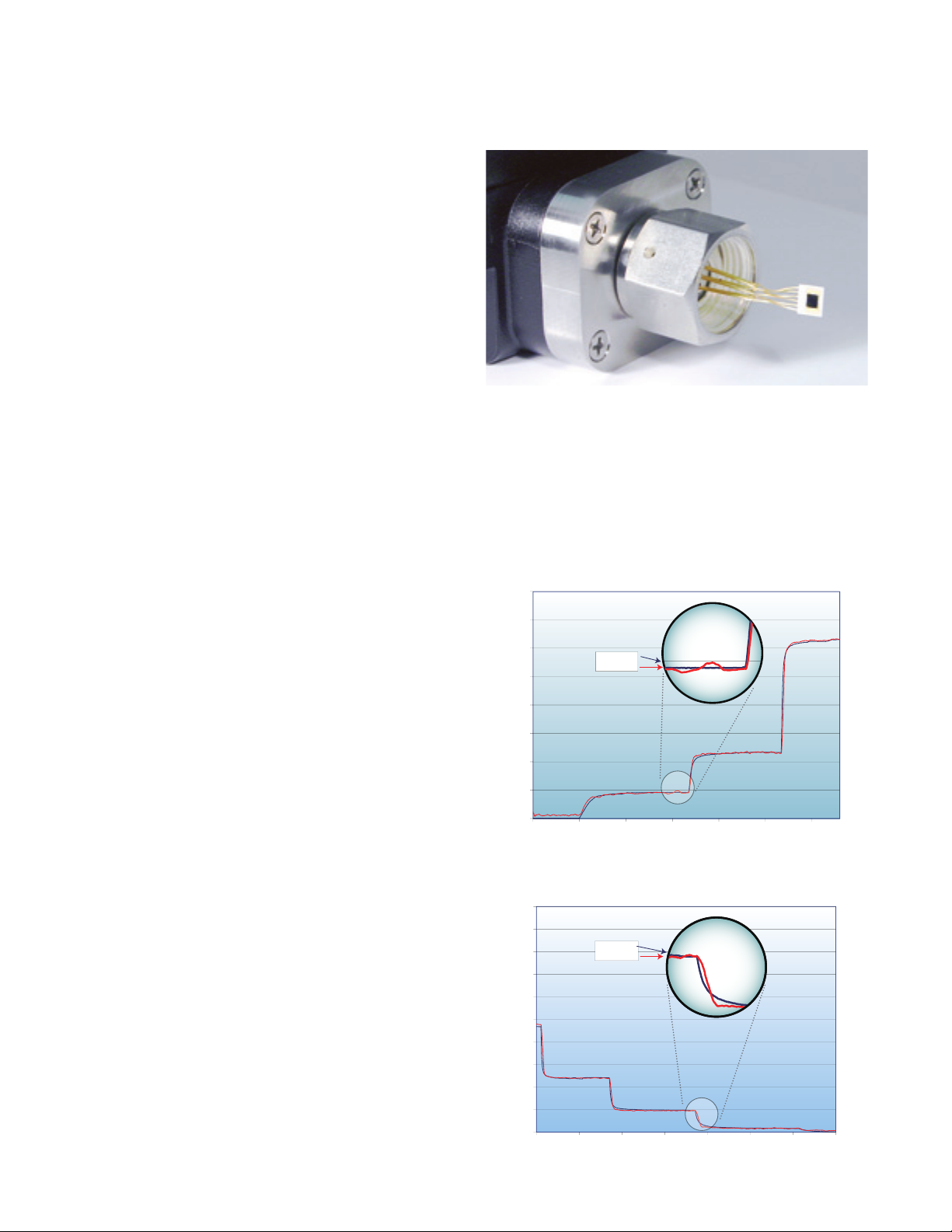

By further investigating aluminum oxide moisture sensor

technology, GE Sensing has developed a new sensor,

manufactured with semiconductor techniques, that

applies a temperature pulse to ‘dry’ the sensor. Then the

re-adsorption rate is measured while holding a constant

sensor temperature. This measurement is proportional to

the moisture concentration in the sample gas.

The short measurement window length effectively filters

the long time constant variations in hardware and sensor

response. Only short time constant, oxide surface

adsorption contributes to the measurement. The end

product is a robust thin film sensor design that provides

the sensitivity and response time needed to effectively

measure parts per billion levels of moisture.

Wet Up Response

Dry Down Response

0

02

04

06

08

001

021

041

061

081

002

53035202510150

କ܄ခၾ)PPBv*

ચ௶

ecarTorg

yH

ΞΑΠܢۼ)শۼȫ

08

07

06

05

04

03

କ܄ခၾ)PPBv*

02

01

0

ચ௶

ecarTorgyH

ΞΑΠܢۼ)শۼȫ

035202510150

Page 3

GE

Sensing

HygroTrace

Specifications

Measurement Range

0 to 100 ppbvwith trend indication beyond the

calibrated range

Compatible Gases

Nitrogen and argon

Process Gas Temperature Range

14ºF to 95ºF (-10ºC to 35ºC)

Storage Temperature

-40ºF to 158ºF (-40ºC to 70ºC)

Warm-Up Time

Meets specified accuracy within 24 hours, after sensor

exposure <72 hours @ 25ºC and 60% RH

Calibrated Accuracy @ 77ºF (25ºC)

±20% of reading or ±5 ppbv, whichever is greater

Response Time

Less than 20 minutes for 95% of 25 ppbvstep change

Electrical

Power

20 to 28 VDC, 20 watts

Output: 4 to 20 mA analog, RS485 digital

Output Resolution: 14 bits

Display

128 X 64 LED backlit LCD

Display one measurement parameter and diagnostics

Mechanical

Sample Connection

In-line flow, ¼ inch (6.35mm) VCR process connection

Sample Flow Rate

1 to 4.3 SCFH (0.5 to 2 SLM)

Operating Pressure

0 to 10 psig (0 to 0.69 bar)

Proof Pressure

3000 psig (207 bar)

Enclosure

Aluminum construction; black color; powder coated finish

Dimensions: (h x w x d)

Overall: 7.3 in x 4.6 in x 2.5 in

(185 mm x 117 mm x 63.5 mm)

Weight: 2.5 lbs (1.13 g)

Certifications

Complies with EMC Directive 89/336/EEC and

PED 97/23/EC for DN < 25

UL 508

3.99 2.56

4.77

7.29

1/4”

VCR )ဎ*

Page 4

g

©2007 GE. All rights reserved.

920-382D

All specifications are subject to change for product improvement without notice.

GE

®

is a registered trademark of General Electric Co. Other company or product

names mentioned in this document may be trademarks or registered trademarks

of their respective companies, which are not affiliated with GE.

www.gesensing.com

GE

Sensing

Moisture Sensor

Sensor Type

Thin-film aluminum oxide moisture sensor

Calibration

Each sensor is individually computer-calibrated against

known moisture concentrations

Calibration Interval

Sensor recalibration by GE is recommended every

6 to 12 months depending on application

ࣱ

+

+24V 1AMP

ഩႁ

ރݯ

-

τϋΐ

ΉȜήσ

༎ழ

ฒ

ႂ

+

4-20mA

ιȜΗȜ

-

ވ

RS485 +

RS485 -

ΏΑΞθ୪౷

RS485

RS232

་۟ܕ

RS232

PC

Loading...

Loading...