Page 1

GE

Sensing

HygroTrace

Moisture Transmitter

User’s Guide

Page 2

GE

Sensing

HygroTrace

Moisture Transmitter

User’s Guide

916-102A3

September 2007

The HygroTrace Moisture Transmitter is a GE Panametrics product.

GE Panametrics has joined other GE high-technology sensing businesses

under a new name—GE Sensing.

Page 3

September 2007

Warranty

Each instrument manufactured by GE Infrastructure Sensing,

Inc. is warranted to be free from defects in material and

workmanship. Liability under this warranty is limited to

restoring the instrument to normal operation or replacing the

instrument, at the sole discretion of GE. Fuses and batteries

are specifically excluded from any liability. This warranty is

effective from the date of delivery to the original purchaser. If

GE determines that the equipment was defective, the warranty

period is:

• one year from delivery for electronic or mechanical failures

• one year from delivery for sensor shelf life

If GE determines that the equipment was damaged by misuse,

improper installation, the use of unauthorized replacement

parts, or operating conditions outside the guidelines specified

by GE, the repairs are not covered under this warranty.

The warranties set forth herein are exclusive and are in lieu

of all other warranties whether statutory, express or

implied (including warranties or merchantability and fitness

for a particular purpose, and warranties arising from course

of dealing or usage or trade).

iii

Page 4

September 2007

Return Policy

If a GE Infrastructure Sensing, Inc. instrument malfunctions

within the warranty period, the following procedure must be

completed:

1. Notify GE, giving full details of the problem, and provide the

model number and serial number of the instrument. If the

nature of the problem indicates the need for factory

service, GE will issue a RETURN AUTHORIZATION NUMBER

(RAN), and shipping instructions for the return of the

instrument to a service center will be provided.

2. If GE instructs you to send your instrument to a service

center, it must be shipped prepaid to the authorized repair

station indicated in the shipping instructions.

3. Upon receipt, GE will evaluate the instrument to determine

the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty,

the instrument will be repaired at no cost to the owner and

returned.

• If GE determines that the damage is not covered under the

terms of the warranty, or if the warranty has expired, an

estimate for the cost of the repairs at standard rates will be

provided. Upon receipt of the owner’s approval to proceed,

the instrument will be repaired and returned.

iv

Page 5

September 2007

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Sample System Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Insertion into the Sample System/Process. . . . . . . . . . . . . . . 3

Standard Wiring Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Digital Communications Wiring Connections . . . . . . . . . . . . 7

Powering Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using the HygroTrace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Keypad Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

The Default Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unlocking the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Accessing the Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Entering Numeric Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting Up the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4-20 Analog Output and Error Reporting . . . . . . . . . . . . . . 14

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

User. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Menu Item Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Moisture Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

v

Page 6

September 2007

Introduction

The GE Sensing HygroTrace is a compact moisture transmitter

designed for measuring ultra-low water content in the ultra high

purity and semiconductor markets and related applications. The

HygroTrace measures water content in nitrogen or argon gas in

the range of 0 to 100 ppb

calibrated range. The unit features an integrated display and a sixbutton keypad, and is housed in an aluminum enclosure. The

HygroTrace operates on 24 VDC and provides 4-20 mA analog

and RS485 digital outputs.

The HygroTrace uses an aluminum oxide sensor manufactured

with semiconductor techniques. The patented measurement

technique enables the HygroTrace to respond very quickly to

both dry-to-wet and wet-to-dry situations. The technique applies

a temperature pulse to ‘dry’ the sensor. Then, the re-adsorption

rate is measured while holding a constant sensor temperature.

This measurement is proportional to the moisture concentration

in the sample gas. As a result, the HygroTrace offers the

sensitivity and response time needed to effectively measure parts

per billion levels of moisture.

with trending analysis beyond the

v

Installation

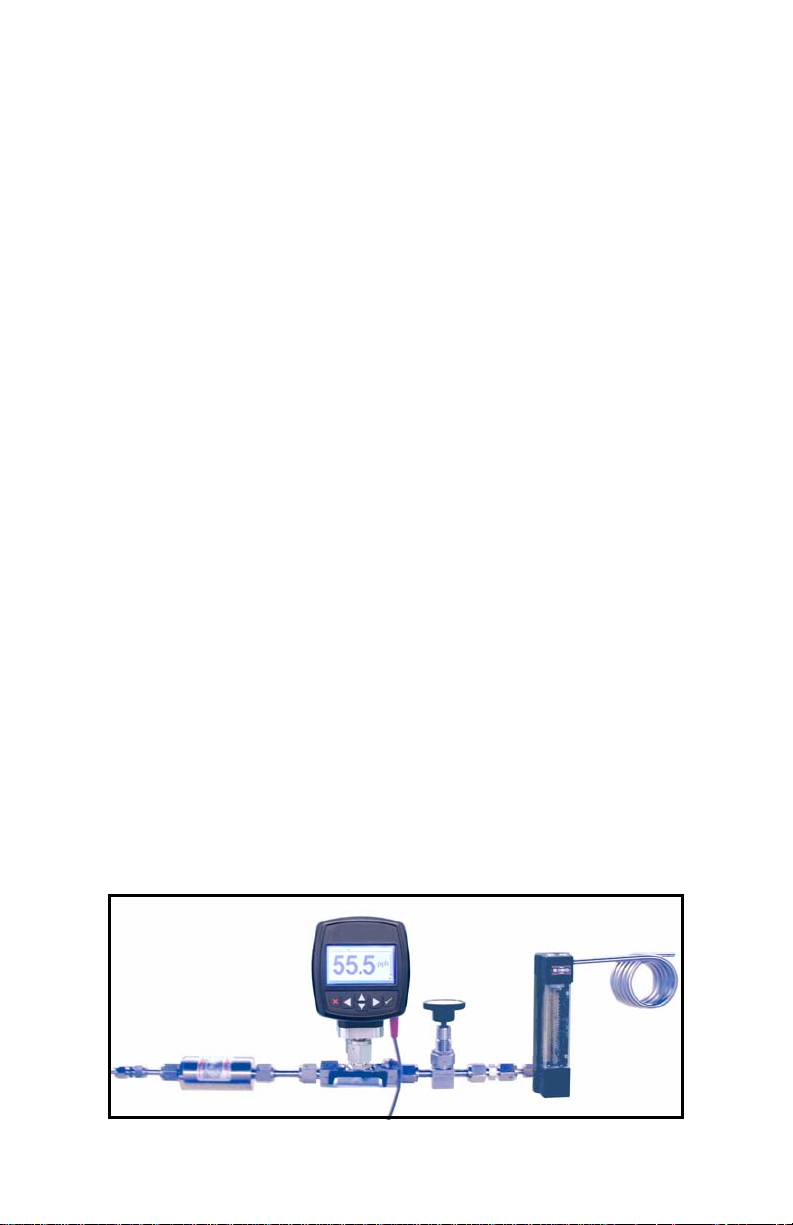

Sample System Guidelines

The HygroTrace transmitter is typically installed in a sample

system or on the bypass stream of an ultra-high purity gas

distribution system. The factory recommends that the unit be

installed in a sample system to protect the sensor from coming in

contact with damaging elements in the process, and to allow the

transmitter to be removed for service without interrupting the

main process gas flow.

Before constructing a sample system, consult a GE Sensing

applications engineer and adhere to the guidelines below. See

Figure 1 on page 2 for an example of a sample system.

HygroTrace Moisture Transmitter 1

Page 7

September 2007

Sample System Guidelines (cont.)

• A sample system should be kept very simple. It should

contain as few components as possible and all or most of

those components should be located downstream of the

measurement location.

• Sample system components should not be made of material

that will affect measurement. Most common filters and

pressure regulators are not suitable for sample systems

because they have wetted parts that may adsorb or release

moisture, etc. into the sample system. They may also allow

ambient contamination to enter the sample system. If

possible, use stainless steel material for all wetted parts.

• The transmitter should be installed perpendicular to the

sample inlet. For dimensions and other requirements see

Specifications on page 26.

Note: A typical sample system for the hygrometer will use VCR

components.

Note: At least 5 feet of 1/4” tubing, if vented to the atmosphere,

should be installed on the outlet to prevent back diffusion

of ambient moisture into the sample tee cell of the

HygroTrace.

• Sample systems should be leak-tested prior to operation to

verify the integrity of the connections, components and

fittings. Tighten any loose fittings.

IMPORTANT: Caution must be taken when pressurizing or

depressurizing the sample system to prevent

damage to the moisture sensor.

Figure 1: Sample System Example

2 HygroTrace Moisture Transmitter

Page 8

September 2007

Insertion into the Sample System/Process

!CAUTION!

If the HygroTrace is being installed directly into

the process line, consult the factory for proper

installation instructions and precautions before

beginning the following procedure.

!CAUTION!

No maintenance of the sensor can be performed in the

field. Accessing the sensor chamber will break the VCR

seal and should be done only at the factory.

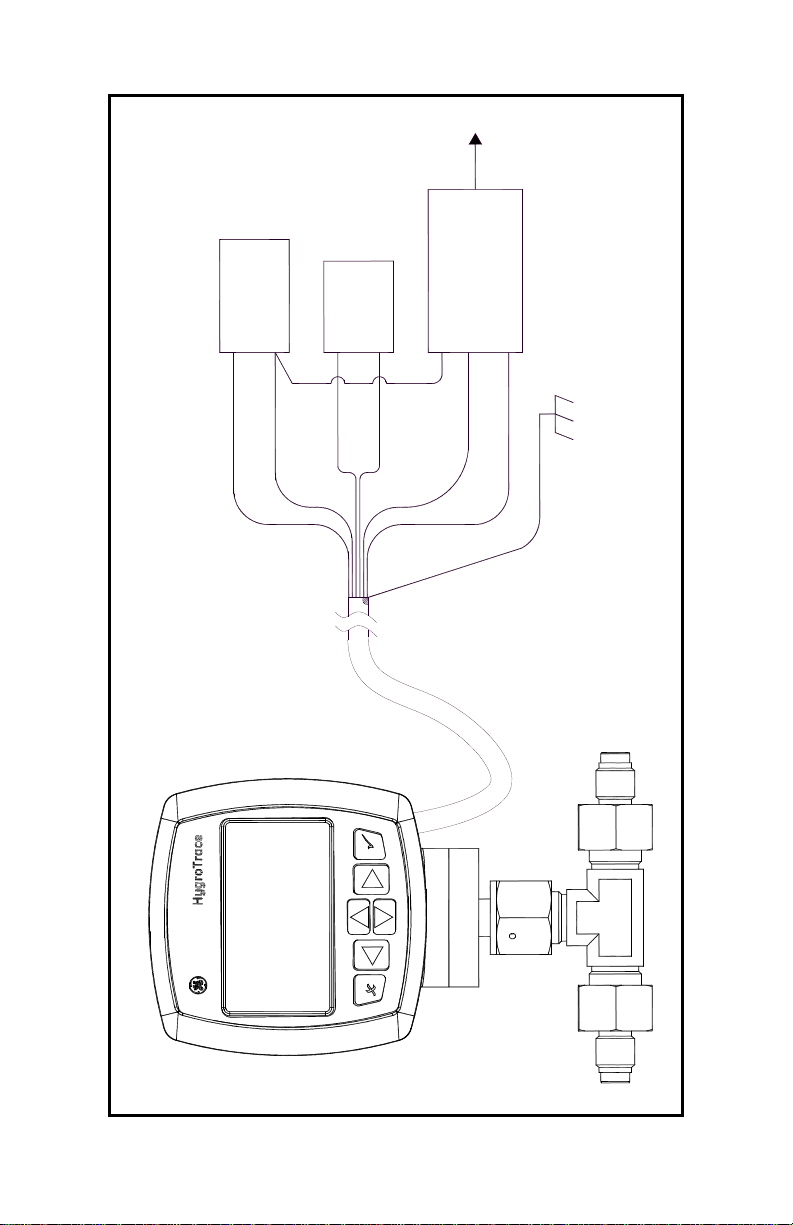

To install the transmitter, refer to Figure 2 below and use a

wrench to thread the female 1/4” fittings of the sample system or

process line onto the 1/4” male VCR fittings of the tee sample

cell configuration.

1/4” VCR (Male)

2 places

Tee Sample Cell

Figure 2: HygroTrace Installation

HygroTrace Moisture Transmitter 3

Page 9

September 2007

Standard Wiring Connections

Note: The HygroTrace is not certified for use in Hazardous

(Classified) locations.

This procedure is for those units not connected to a computer.

The transmitter must be wired using the factory-supplied cable

(two meters in length). If an alternate length is required, please

contact the factory for assistance.

Note: If cables need to be lengthened, r efer to Table 1 on page 5

to splice an extension onto the existing cable. Connect

positive to positive and negative to negative.

Use the following steps to wire the transmitter to the system.

1. Align the red dot with the red mark (see Figure 3 below) and

push the connector on the transmitter cable into the mating

connector on the transmitter module. Make sure the pins are

properly aligned. Once it is inserted, push the cable connector

until it locks into place.

Figure 3: Transmitter Cable Connection

4 HygroTrace Moisture Transmitter

Page 10

September 2007

Standard Wiring Connections (cont.)

2. Using the flying leads at the other end of the transmitt er cable,

connect the transmitter to the power supply and data

acquisition system (DAS) as shown in Figure 4 on page 6.

Refer to Table 1 below for a description of the leads in the

factory-supplied cable.

Table 1: Cable Lead Connections - No PC

Lead Connection Description

Red (+) 24VDC 1 AMP

Black (–) 24VDC 1 AMP

Orange (+) 4-20mA Output

Blue (–) 4-20mA Output

Cable Braid System Ground

3. Trim any unused leads back to the outer cable jacket in order

to remove the bare tinned wire and prevent accidental short

circuits.

The HygroTrace is now ready for operation.

Note: To remove the probe cable, pull back the spring-loaded

sleeve and pull the cable out of the connector.

HygroTrace Moisture Transmitter 5

Page 11

September 2007

+24V 1 AMP

+

RS232

TO PC

RS232

RS485 TO

CONVERTER

POWER

SUPPLY

–

+

4-20mA

METER

–

COMMON

+ RS485

– RS485

SYSTEM

GROUND

RED

BLACK

ORANGE

BLUE

WHITE

GREEN

BRAID

CABLE

Figure 4: Standard Wiring Connections (ref. dwg #702-684)

6 HygroTrace Moisture Transmitter

Page 12

September 2007

Digital Communications Wiring Connections

If the unit is to be operated using PanaView™ instrumentation

software installed on a computer, an RS232/RS485 converter

must be used and the wiring must be set up as follows.

The transmitter must be wired using the factory-supplied cable

(two meters in length).

Note: To lengthen cables, refer to Table 2 below to splice an

extension onto the existing cable. Connect positive to

positive, negative to negative, and ground to ground.

Note: EMI ferrite shielding may be required for communication

through an ungrounded serial port. Please consult the

factory for guidance.

Use the following steps to wire the transmitter to the system.

1. Align the red dot with the red mark (see Figure 3 on page 4)

and push the connector on the transmitter cable into the

mating connector on the transmitter module. Make sure the

pins are properly aligned. Secure the connectors by pushing

the cable connector until it locks in place.

2. Using the flying leads at the other end of the transmitt er cable,

connect the transmitter to the power supply, the data

acquisition system (DAS) and the computer as shown in

Figure 4 on page 6. Refer to Table 2 below for a description of

the leads in the factory-supplied cable.

Table 2: Cable Lead Connections - with PC

Lead Connection Description

Red (+) 24VDC 1 AMP

Black (–) 24VDC 1 AMP

Orange (+) 4-20mA Output

Blue (–) 4-20mA Output

White (+) RS485

Green (–) RS485

Cable Braid System Ground

HygroTrace Moisture Transmitter 7

Page 13

September 2007

Digital Communications Wiring Connections (cont.)

3. Trim any unused leads back to the outer cable jacket in order

to remove the bare tinned wire and prevent accidental short

circuits.

The HygroTrace is now ready for operation.

Note: To remove the probe cable, pull back the spring-loaded

sleeve and pull the cable out of the connector.

Powering Up

After the HygroTrace is wired as described in the previous

sections, power may be applied to the unit. The transmitter takes

up to 60 seconds to initialize and begin normal operation. If the

sensor has been exposed to ambient conditions of less than

10% RH for less than 72 hours, the HygroTrace will meet its

specified accuracy within 24 hours following startup.

8 HygroTrace Moisture Transmitter

Page 14

Using the HygroTrace

Keypad Features

September 2007

Cancel

Left

Figure 5: HygroTrace Keypad

The HygroTrace has only six keys: four arrow keys, a Cancel

key and an Enter key.

Use the arrow keys to navigate among menu choices, and to

increment/decrement numeric entries.

Use the Cancel key to cancel a numeric entry change, or exit

a menu.

Use the Enter key to accept a numeric entry or select a menu

option.

Up

Down

Enter

Right

HygroTrace Moisture Transmitter 9

Page 15

September 2007

The Default Display

Figure 6 on page 11 shows the normal, default display of the

HygroTrace/TFM.

• Menu Prompt Area - Titles, prompts, status displayed here.

• Measurement - 3 ½ digits (0 - 1999). Automatic decimal

placement based on range.

• Unit Symbol - ppb = Parts Per Billion water by volume.

• Keypad Lock Indicator - Unlock sequence required to modify

settings.

• Measurement Progress Bar - HygroTrace takes

~2 minutes to acquire data and complete the measurement.

The progress bar gives a visual indication of the measurement

status.

• Warning/Error Indicator - In the absence of an error, this

region is blank. Errors that effect the quality of the

measurement (e.g. heater failure) are indicated in ALL

CAPITAL letters. Warnings that indicate problems detected

with the measurement are indicated in Mixed Case letters.

Refer to Table 3 below.

Table 3: Warning/Error Messages

No. Label Type Description

0 Status OK ---- No Errors detected.

The calculated PPBv value is greater

Sns Ovr Rng

3

12 Acquiring... WARN

101 HTR FAIL LO ERROR

102 HTR FAIL HI ERROR The heater exceeded 200°C.

Sns Too Wet

204

10 HygroTrace Moisture Transmitter

WARN

WARN

than the highest calibration point,

and is an extrapolation.

Displayed at startup while the

HygroTrace collects data for the first

measurement.

The heater failed to reach the desired

temperature in the time allotted.

The sensor is exposed to excessive

moisture conditions.

Page 16

September 2007

Menu Prompt Area

Measurement

Units Symbol

Warning/Error Indicator

Measurement

Progress Bar

Keypad Lock

Indicator

Figure 6: Default Display

Unlocking the Keypad

After power-on, the HygroTrace keypad is locked. It is necessary

to enter the keypad unlock sequence to make any changes to the

HygroTrace.

Similar to a mobile phone, the HygroTrace will prompt the

operator to unlock if any key is pressed. A passcode is required to

use certain factory service features only.

To unlock the keypad, press Cancel , Enter , Cancel in

sequence.

Accessing the Menus

After successfully unlocking the keypad, the HygroTrace will

display the Main Menu (see Figure 7 on page 12). Use the arrow

keys to highlight the menu item desired. Refer to the Menu Map,

Figure 9 on page 23.

Press Enter to select the highlighted item. Many menu items

will display another menu. Use Cancel to return to the

previous menu page. Pressing Cancel from the Main Menu

will return the screen to the Measurement Display.

HygroTrace Moisture Transmitter 11

Page 17

September 2007

Accessing the Menus (cont.)

Note: Menu items displayed with an ellipsis (…) will bring up

more choices, while those without take immediate action.

Figure 7: Main Menu

Entering Numeric Values

Since the HygroTrace has no numeric keypad, numeric values

are entered using a “combination lock” style of entry:

Use the left arrow key and right arrow key to select the

digit to change. The digit selected will be indicated with a .

Use the up arrow key and down arrow key to increment

or decrement the digit.

Note: If incrementing or decrementing a digit would cause the

numeric value to exceed its allowable range (maximum/

minimum value), the digit will not change.

Press Enter to save the new value and return, or Cancel to

return, leaving the original value intact.

Figure 8: Numeric Entry

12 HygroTrace Moisture Transmitter

Page 18

September 2007

Setting Up the Transmitter

After proper installation, the HygroTrace Transmitter can be set

up to accommodate the user’s requirements. Typically, the user

may need to configure the analog outputs, trim the analog

outputs, and program the digital outputs. Refer to the Menu Map,

Figure 9 on page 23, and complete the following steps. Upon

startup, the HygroTrace proceeds through several displays until a

screen similar to the following appears:

The symbol in the lower right corner

indicates that the screen is locked.

To unlock the screen, press

Cancel, Enter, Cancel.

Note: In most instances; use the Enter key to save an entry and/

or move ahead to the following screen; use the Cancel key

to reject an entry and/or return to the previous screen.

9

Display

When the screen is unlocked, the

Main Menu appears with several

options. To set up the display, select

Display... and press Enter. The

following screen appears:

To show the primary ppb

select Measurement and press

Enter. A screen similar to the

following appears:

Press Cancel to return to the Main

Menu.

display,

v

Diagnostics - has limited access. The service passcode is

required. For a description, see Diagnostics on page 29.

HygroTrace Moisture Transmitter 13

Page 19

September 2007

4-20 Analog Output and Error Reporting

The HygroTrace has a single 4-20 mA analog (recorder) output.

Normally, the output reports the measurement in ppb

user-specified range. The default range is 0-100 ppb

that is, 4 mA represents the zero (0 ppb

the span (100 ppb

The recorder output can exceed this range, within limits. A

measurement greater than the span will be reported up to

20.5 mA, and a reading below the zero will be reported down to

3.8 mA. Faults are indicated by readings outside this range.

) value.

v

), and 20 mA represents

v

using a

v

;

v

These faults will be indicated by a 3.5 mA signal

:

• No Data - transmitter has not completed a measurement cycle,

so it cannot report.

• No Calibration - transmitter was not programmed with

calibration data.

• Out of Range - measurement cannot be determined with the

given calibration.

These faults will be indicated by a 21.1 mA signal

:

• Heater Fail Low - heater failed to reach the operating setpoint.

• Heater Fail High - heater exceeded its operating limit.

Limits are taken from the NAMUR Recommendation NE 043.

Measurement is valid from 3.8 mA to 20.5 mA.

Fault is indicated by ≤3.6 mA or ≥21.0 mA.

The HygroTrace has a special operating mode used to dry the

sensor (see Sensor Dry Down on page 19). When in Dry Down

mode, the unit will report a fixed output of 20.5 mA, the

maximum valid measurement. When returned to normal

operation, the output returns to reporting the actual measurement.

In the case of a measurement exceeding the maximum calibration

value, the output will be limited to the maximum valid signal,

20.5 mA. The HygroTrace will never produce a negative reading

(less than 0 ppb).

14 HygroTrace Moisture Transmitter

Page 20

Outputs

Recorder Zero

September 2007

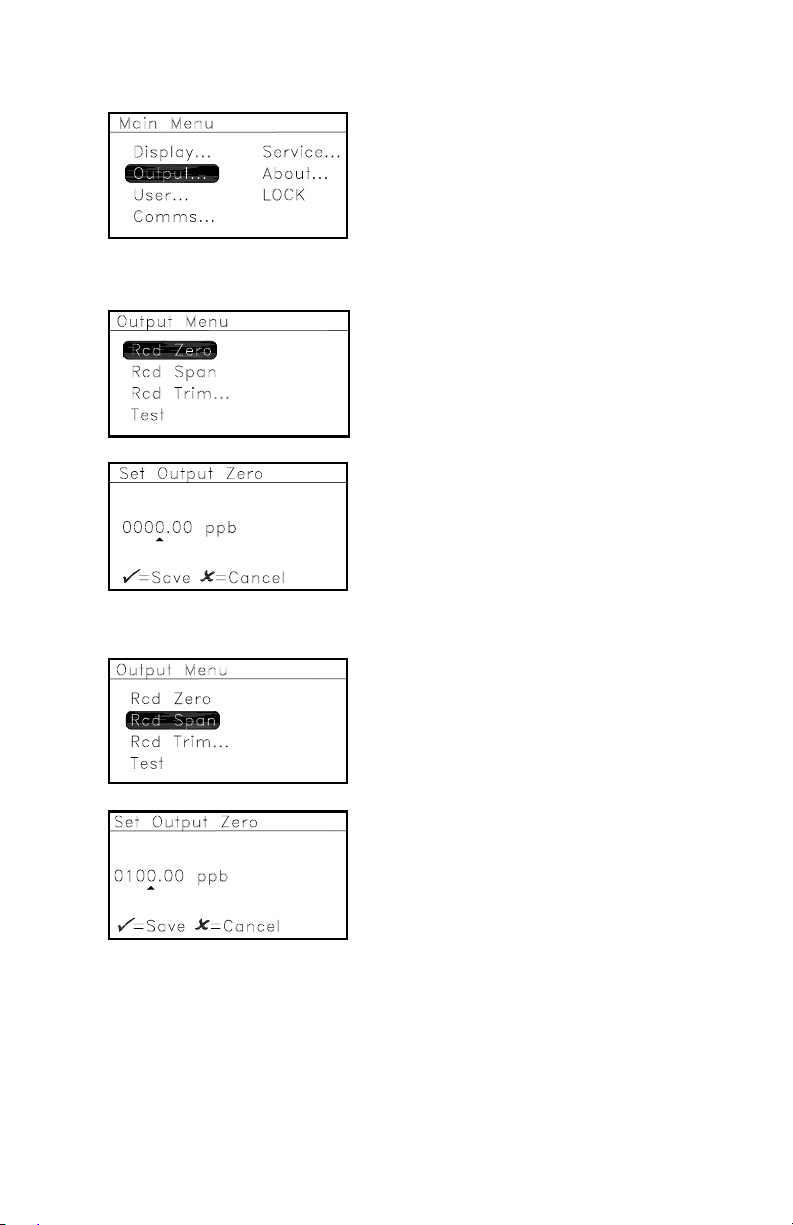

To set up outputs, from the Main

Menu select Output... and press

Enter. The following screen

appears:

To specify the ppb reading

equivalent to 4 mA, select Rcd Zero

and press Enter. A screen similar to

the following appears:

Use the arrow keys to change the

output value. Press Enter to save (or

Cancel to keep the previous value),

and return to the Output Menu.

Recorder Span

To specify the ppb reading

equivalent to 20 mA, select Rcd

Span and press Enter. A screen

similar to the following appears:

Use the arrow keys to change the

output value. Press Enter to save (or

Cancel to keep the previous value),

and return to the Output Menu.

HygroTrace Moisture Transmitter 15

Page 21

September 2007

Recorder Trim

To adjust/calibrate the 4-20 mA

output, select Rcd Trim... and press

Enter. The following screen

appears:

To return an adjusted 4-20mA

calibration to the factory defaults,

press Enter. The following screen

appears.

Note: Resetting the Trim erases any previous values before

calibrating the output.

Select YES or NO and press Enter, or

press Cancel. If you select NO or

press Cancel, the unit returns to the

previous screen and no change is

made to the 4-20mA calibration.

If you select YES, the following screen appears to adjust and

calibrate the 4-20mA signal.

With Trim Zero highlighted, to

adjust the 4 mA output from the

factory default, press Enter and a

screen similar to the following

appears.

Note: The HygroTrace will attempt to output exactly 4.00 mA.

The operator should read the output, in mA, at the DAS or

other indicator, and enter that value as follows.

Use the arrow keys to change the

output value. Press Enter to save (or

Cancel to keep the previous value),

and return to the Recorder Trim

menu.

16 HygroTrace Moisture Transmitter

Page 22

September 2007

Recorder Trim (cont.)

If a new Trim Zero was saved, the

Trim Span is now highlighted. To

adjust the 20 mA output from the

factory default, press Enter and see

a screen similar to the following:

Note: The HygroTrace will attempt to output exactly

20.00 mA. The operator should read the output, in mA, at

the DAS or other indicator, and enter that value in the

following screen.

Use the arrow keys to change the

output value. Press Enter to save (or

Cancel to keep the previous value),

and return to the Recorder Trim

menu. Press Cancel twice to return

to the Main Menu.

Test

To force the 4-20 mA output to a

specified percent of scale, select

Test on the Output Menu and press

Enter. A screen similar to the

following appears.

Use the arrow keys to change the test

value. Press Enter to save (or

Cancel to keep the previous value),

and return to the Output Menu.

Press Cancel to return to the Main

Menu.

HygroTrace Moisture Transmitter 17

Page 23

September 2007

User

PPB Offset

To specify an offset value in PPB

and add to the measured PPB value,

or to dry down the sensor, select

User... on the Main Menu, press

Enter and see the following screen:

Use the arrow keys to enter the user

passcode (2719), press Enter and the

following screen appears. The User

Mode indicator U appears in the

lower right corner of the screen.

T o specify a PPB of fset value, select

PPB Offset, press Enter and the

following screen appears:

U

Use the arrow keys to enter the PPB

offset desired, press Enter and the

screen returns to the User Settings

Menu.

U

Clear PPB Offset

To clear the PPB offset entered

above, select Clear PPB Offset and

press Enter. The following screen

appears. Press Cancel to return to

the Main Menu or proceed to the

U

next option.

Select YES or NO and press Enter, or

press Cancel. If you select NO or

press Cancel, the unit returns to the

previous screen and the PPD offset

is not cleared.

U

If you select YES, the PPB Offset is cleared and the unit returns to

the previous screen.

18 HygroTrace Moisture Transmitter

Page 24

September 2007

Sensor Dry Down

Following factory calibration, the HygroTrace is vacuum

packaged to minimize sensor uptake of ambient moisture during

shipment and storage. Once the unit is installed in the process or

sample system, it is recommended that the user establish a

nominal sample flow of 1 SLM and initiate a manual dry down of

the sensor using the Sensor Dry Down option in the User

Settings Menu.

The initiation of this dry down cycle depends on the exposure of

the unit to ambient moisture conditions. The criteria for exposure

is detailed below . It is recommended that the heater control be set

to 190°C for 24 hours following initial installation. The dry down

cycle must be manually started and stopped by the user.

General rule of thumb: >72 hours @ <10% RH or

>24 hours @ >40% RH

This sensor-drying procedure can be repeated following

prolonged exposure to ambient moisture conditions. This will

ensure the highest accuracy for moisture measurement.

Note: When in Dry Down mode, the unit will report a fixed

output of 20.5 mA, the maximum valid measurement.

When returned to normal operation, the output will return

to reporting the actual measurement.

T o initiate a manual dry down of the

sensor, select Sensor Dry Down in

the User Settings Menu. Press Enter

and the following screen appears:

U

Press Enter to start the Sensor Dry

Down (or press Cancel to not

begin

a sensor dry down cycle) and return

to the previous screen. If you

pressed Enter, the Sensor Dry Down

U

has begun.

Note: The sensor will be heated to and r emain at 190°C until the

user stops this cycle.

HygroTrace Moisture Transmitter 19

Page 25

September 2007

Sensor Dry Down (cont.)

To stop the Sensor Dry Down, select

it again on the User Settings Menu,

press Enter, and this screen appears.

Press Enter to stop the Sensor Dry

Down (or press Cancel to continue)

U

and return to the previous screen.

Note: If you pressed Enter, the Sensor Dry Down has ended.

Communications

Baud Rate

To change the baud rate, select

Comms... on the Main Menu, press

Enter and the following screen

appears:

Select Baud Rate... and press Enter.

A screen similar to the following

appears.

Use the arrow keys to select a new

baud rate and press Enter. The

number at the top right side of the

screen changes. Press Cancel to

return to the Comms Menu.

20 HygroTrace Moisture Transmitter

Page 26

September 2007

Node ID

Note: If more than one HygroTrace is on the RS485 network,

each unit must have a unique ID.

To change the node ID, select Node

ID on the Comms Menu, then press

Enter and the following screen

appears:

Use the arrow keys to change the

node ID value. Press Enter to save

(or Cancel to keep the previous

value), and return to the Comms

Menu.

Test

To test the serial connection over

RS485, select Test and press Enter.

The HygroTrace will transmit a

short message, “HygroTrace Comm

Test - Node 16”, over RS485 for

testing the serial connection.

To return to the Main Menu, press Cancel.

Service - has limited access. The service passcode is required.

For a description of the service menu, see Service on page 30.

HygroTrace Moisture Transmitter 21

Page 27

September 2007

About

To access HygroTrace copyright and software version

information, and instrument data such as unit and sensor serial

numbers, the number of sensor hours and the system uptime:

Select About on the Main Menu

screen and press Enter. The

following screen appears:

+

To access HygroTrace copyright

and serial number information,

select ID on the About HygroTrace

screen and press Enter. A screen

+

similar to the following appears:

To return to the About HygroTrace

menu, press Cancel. To access up

time information, select System

Status and press Enter. A screen

similar to the following appears.

+

To return to the About HygroTrace

menu, press Cancel. T o access

software version information

specific to the unit, select Software

+

Versions and press Enter. A screen

similar to the following appears.

Press Cancel twice to return to the

Main Menu.

+

LOCK

To lock the unit from further

changes, select LOCK on the Main

Menu and press Enter. To restore

access to the unit menus, press

Cancel, Enter, Cancel.

+

22 HygroTrace Moisture Transmitter

Page 28

September 2007

Coeff A

Coeff B

About LOCK

Dump

Update

Params

Service**

Main

User*

57600

Baud Rate

PPB Offset ID

38400

19200

100°C

9600

60°C

50°C

Erase

OFF

150°CHeater Test..

190°C

Resume

Reboot

Cal Data

1200

2400

Reset Trim

Trim Zero

Node ID

Trim Span

Test

Test

Rcd Span

Rcd Trim

Notes:

*User passcode required.

**Service passcode required . Contact factory for assistance.

Display Output Comms

Rcd Zero

Diagnostic**

Figure 9: Menu Map

HygroTrace Moisture Transmitter 23

Page 29

September 2007

Menu Item Descriptions

Display

1. Measurement - Show the primary ppb

display

v

2. Diagnostics - (Service passcode required

)

Output

1. Rcd Zero - Specify the ppb reading equivalent to 4 mA

2. Rcd Span - Specify the ppb reading equivalent to 20 mA

3. Rcd Trim - Adjust/calibrate the 4-20 mA output

a. Reset Trim - Clear trim values prior to recalibrating output

b. Trim Zero - Adjust the 4 mA output

c. Trim Span - Adjust the 20 mA output

4. Test - Force the 4-20 output to a specified percent of scale

User - (User passcode required

)

1. PPB Offset - Enter PPB Offset

2. Clear PPB Offset - Clear PPB Offset

3. Sensor Dry Down - Dry the Sensor

Comms

1. Baud Rate - Specify the data rate for RS485 communications

2. Node ID - Specify the PanaView Network Node ID

3. Test - Force meter to transmit an ID message for test purposes

Service - (Service passcode required

)

1. Update - Update the unit software.

2. Params - Access the parameter storage.

a. Dump - Dump the parameter storage.

b. Erase - Erase the EPROM.

3. Heater Test - Test the heater.

a. 50°C to 190°C - Select the temperature for testing.

b. OFF - Turn the heater off.

c. Resume - Resume normal measurement operation.

24 HygroTrace Moisture Transmitter

Page 30

September 2007

Menu Item Descriptions (cont.)

4. Cal Data - Change the calibration data.

a. Bulk Limit - Set the bulk limit.

b. Cal Curve - Set a calibration point and edit PPB and ZH

values.

c. Extrapolation - Set coefficient A and/or B.

5. Reboot - Reboot and return to the initial screen.

About - Display Product, Copyright, and Version information.

LOCK - Lock the keypad.

HygroTrace Moisture Transmitter 25

Page 31

September 2007

Specifications

General

Measurement Range:

• 0 to 100 ppb

Compatible Gases:

with trend indication beyond the calibrated range

v

• Nitrogen and Argon

Process Gas Temperature Range:

• 14°F to 95°F (–10°C to 35°C)

Storage Temperature:

• –40°F to 158°F (–40°C to 70°C)

Operating Temperature:

• 14°F to 95°F (–10°C to 35°C)

Warm-Up Time:

• Meets specified accuracy within 24 hours, after sensor

exposure <72 hours @ 25°C and 60% RH

Calibrated Uncertainty @ 77°F (25°C):

• ±20% of reading or ±5 ppb

Response Time:

, whichever is greater

v

• Less than 20 min. for 95% of 25 ppb

26 HygroTrace Moisture Transmitter

step change

v

Page 32

Electrical

Power:

• 20 to 28VDC, 20 Watts

Analog Output:

• 4 to 20 mA, 400Ω load max

Digital Output:

• RS485

Output Resolution:

• 14 bits

Display:

• 128 X 64 LED backlit LCD

• Display of primary measurements and diagnostics

Mechanical

September 2007

Sample Connection:

• In-line flow, ¼" male VCR process connection

Sample Flow Rate:

• 1 to 4.3 SCFH (0.5 to 2 SLM)

Operating Pressure:

• 0-10 psig (0 to 0.69 bar)

Proof Pressure:

• 3000 psig (207 bar)

Enclosure:

• Aluminum construction; black color; powder coated finish

• Overall Dimensions (H x W x D): 7.3 in x 4.6 in x 2.5 in

(185 mm x 117 mm x 63.5 mm)

• Weight: 2.5 lbs (1.13 kg)

HygroTrace Moisture Transmitter 27

Page 33

September 2007

Moisture Sensor

Sensor Type:

• Thin-film aluminum oxide moisture sensor

Calibration:

• Each sensor is individually computer-calibrated against known

moisture concentrations.

Calibration Interval:

• Sensor recalibration by GE is recommended every 6 to 12

months depending on the application.

Certification

• Complies with EMC Directive 89/336/EEC and

PED 97/23/EC for DN < 25

• UL 508

Figure 10: Certification Label (for information only)

28 HygroTrace Moisture Transmitter

Page 34

September 2007

Appendix

The Diagnostics and Service menus are intended for factorytrained personnel only, and access is limited by requiring a

service passcode. These menus allow the factory default data,

including calibration data and sensor parameters, to be adjusted.

Please contact an applications or service engineer at GE Sensing

if access to these menus is required. Normal operation of the

HygroTrace does not require access to the information contained

in these menus.

Diagnostics

A Diagnostics Display page can be selected from the Display

Menu (see Figure 11 below), but can be accessed only by using

the service passcode.

= Heating

= Cooling

... = Holding at Temp.

+ = Acquiring Data

= = Calculating Result

Hygrometry

Voltage

Number

of Data

Samples

Heater

Temperature

Menu: x

H:+1.234567 60.2°C

100

N: 85 R :0.855

M:+1.195886e–05

2

Control Status

ppb

Slope

of Fitted Line

Correlation

Coefficient

of Fitted Line

Calculated

Result

Service Mode

Indicator

Figure 11: Diagnostics Display

HygroTrace Moisture Transmitter 29

Page 35

September 2007

!CAUTION!

No maintenance of the sensor can be performed in the

field. Accessing the sensor chamber will break the VCR

seal and should be done only at the factory.

Service

To access the Service Menu, select

Service... on the Main Menu and

press Enter. The following screen

appears:

Use the arrow keys to enter the

Service Passcode. Press Enter and

the following screen appears:

Update

Due to product improvements or software enhancements, it may

be necessary to install new software provided by GE Sensing.

This is done over the RS485 digital communications link, using a

PC application capable of performing an XMODEM file transfer.

Note: For updates, the baud rate setting on the COMMS menu is

ignored. Updates will use the following parameters:

Baud Rate: 38400

Word Size: 8 bits

Stop Bits: 1

Parity: None

Flow Control: None/disabled

To update the instrument software,

select Update on the Service Menu,

press Enter and the following screen

appears:

+

30 HygroTrace Moisture Transmitter

Page 36

September 2007

Update (cont.)

Select YES or NO and press Enter, or

press Cancel. If you select NO or

press Cancel, the unit returns to the

previous screen. If you select YES,

the following screen appears.

+

The HygroTrace software is

updated and the unit reboots (returns

to power up, proceeds through

several initiation displays and

returns to normal operation).

Parameter Storage

Dump

This function transmits the contents of the EEPROM used for

calibration and parameter storage via the RS485 digital link. It is

provided to assist GE Sensing service personnel in maintaining

the product.

To dump the parameter storage,

select Dump, press Enter and the

following message appears at the top

of the screen for a few seconds.

+

When the dump is complete, Param

Storage reappears.

HygroTrace Moisture Transmitter 31

Page 37

September 2007

Erase

Note: Erase will delete ALL calibration and user settings. The

HygroTrace will be incapable of performing accurate

measurements until this data is restored.

Note: This function is provided to assist GE Sensing service

personnel in maintaining the product.

To erase the EPROM, select Erase,

press Enter and the following

message appears at the top of the

screen for a few seconds.

+

Select YES or NO and press Enter, or

press Cancel. If you select NO or

press Cancel, the unit returns to the

previous screen. If you select YES,

the following message appears.

+

When the erasure is complete,

Param Storage reappears. To return

to the Service Menu, press Cancel.

Heater Test

T o perform a test of the heater, select

Heater Test..., press Enter and a

screen similar to the following

appears:

+

Use the arrow keys to select the

appropriate temperature to test, and

press Enter. The temperature in the

upper right corner of the screen

should approximate the one selected.

+

To turn off the test, select OFF and press Enter. The temperature

in the upper right corner of the screen returns to its original value.

To resume normal operation, select RESUME and press Enter.

Press Cancel to return to the Service Menu.

32 HygroTrace Moisture Transmitter

Page 38

September 2007

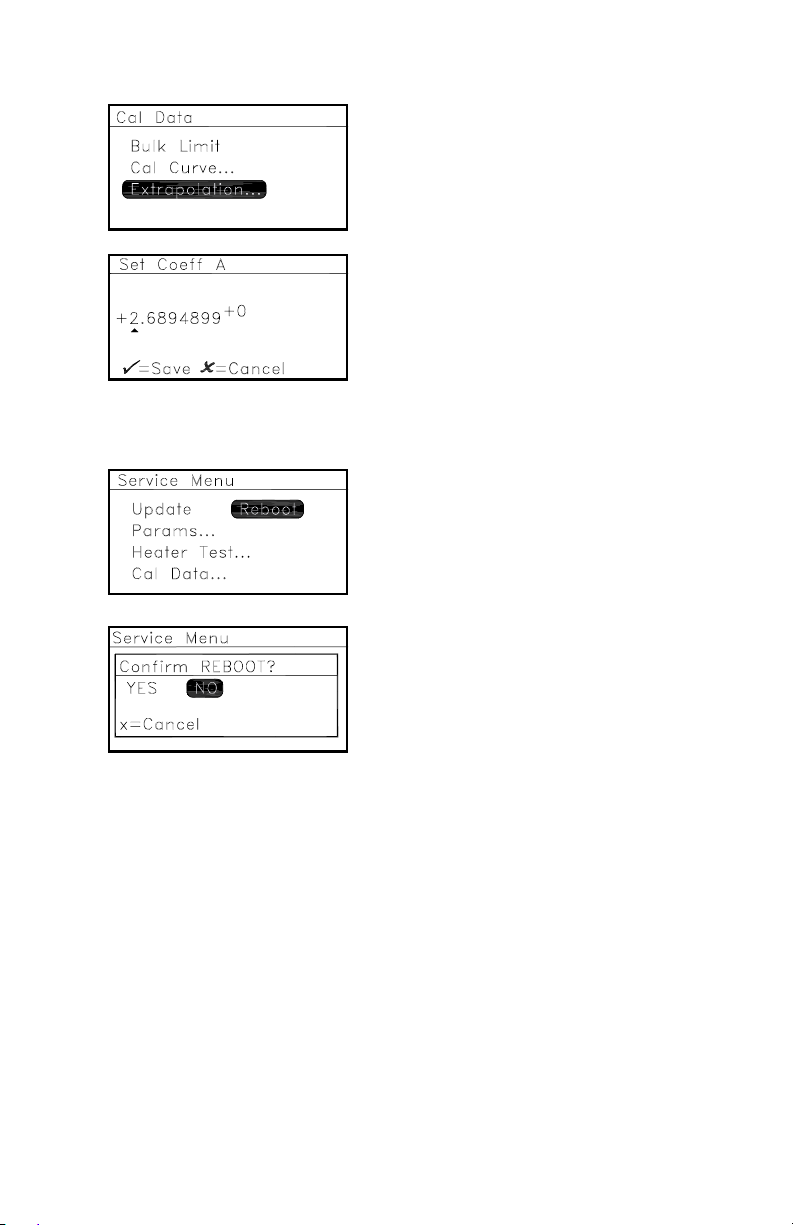

Calibration Data

T o change the calibration data, select

Cal Data... on the Service Menu,

press Enter and the following screen

appears:

+

Bulk Limit

To set the bulk limit, select it on the

screen and press Enter. The

following screen appears:

+

Use the arrow keys to change to the

desired value and press Enter (or

Cancel to keep the previous value).

The screen returns to the Cal Data

menu.

+

Calibration Curve

To edit the calibration curve, select Cal Curve... on the Cal Data

menu and press Enter. The following screen appears:

To set a calibration point, highlight

Select Cal Point, press Enter and the

following screen appears.

+

Use the arrow keys to enter the

desired calibration point to change

and press Enter (or Cancel to keep

the previous value). The screen

+

returns to Edit Cal Curve.

Proceed in the same way to Edit PPB Value and/or ZH Value to

change the PPB and/or ZH value for a particular calibration point.

Then select the next calibration point and repeat the process.

When Edit Cal Curve is complete, press Cancel to return to the

Cal Data menu.

HygroTrace Moisture Transmitter 33

Page 39

September 2007

Extrapolation

Reboot

To set coefficients A and/or B, select

Extrapolation... and press Enter.

Select the coefficient to change,

press Enter and a screen similar to

the following appears:

+

Use the arrow keys to change to the

desired value and press Enter (or

Cancel to keep the previous value).

The screen returns to the

+

Extrapolation menu. Press Cancel

twice to return to the Service Menu.

T o reboot the meter and return to the

initial screen, select Reboot and

press Enter. The following screen

appears.

+

Select YES or NO and press Enter, or

press Cancel. If you select NO or

press Cancel, the unit returns to the

previous screen. If you select YES, a

reboot occurs.

+

Note: The HygroTrace returns to power up, proceeds through

several initiation displays and returns to normal

operation.

34 HygroTrace Moisture Transmitter

Page 40

USA

1100 Technology Park Drive

Billerica, MA 01821-4111

Web: www.gesensing.com

Ireland

Sensing House

Shannon Free Zone East

Shannon, Co. Clare

Ireland

Loading...

Loading...