Page 1

GE

Measurement & Control Moisture

HygroPro

User’s Manual

916-099 Rev. D

November 2012

Page 2

Page 3

GE

Measurement & Control

HygroPro

Moisture Transmitter

User’s Manual

916-099 Rev. D

November 2012

www.ge-mcs.com

©2012 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page - proceed to next page]

ii

Page 5

Contents

Chapter 1: Installation

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Sample System Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3 Mounting the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4 Wiring the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4.1 Standard Wiring Connections . . . . . . . . . . . . . . . . . . . . . . .6

1.4.2 Hazardous Area Wiring Connections . . . . . . . . . . . . . . . .11

Chapter 2: Operation

2.1 Powering Up & Programming. . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.1.1 Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.1.2 Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.2 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.2.1 Unlocking the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.2.2 Entering the Setup Program. . . . . . . . . . . . . . . . . . . . . . . .22

2.2.3 Selecting Measurement Parameters. . . . . . . . . . . . . . . . . .23

2.2.4 Setting Up the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2.2.5 Setting Up the Analog Output . . . . . . . . . . . . . . . . . . . . . .26

2.2.6 Entering the Node ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.2.7 Setting Up the RS485 Output . . . . . . . . . . . . . . . . . . . . . .29

2.3 Advanced Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2.3.1 Setting Up the Pressure/Temperature Displays . . . . . . . . .30

2.3.2 Entering Sensor Calibration Data . . . . . . . . . . . . . . . . . . .31

2.3.3 Locking and Unlocking the Keypad . . . . . . . . . . . . . . . . .33

2.3.4 Locking and Unlocking the Menus . . . . . . . . . . . . . . . . . .33

HygroPro User’s Manual Page iii

Page 6

Contents

Chapter 3: Service & Maintenance

3.1 The Service Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.2 Moisture Probe Error Conditions. . . . . . . . . . . . . . . . . . . . . . . . 36

3.3 Cleaning the Moisture Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.3.1 Preparing to Clean the Probe . . . . . . . . . . . . . . . . . . . . . . 36

3.3.2 Replacing the RTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3.3 Removing the Transmitter from the System . . . . . . . . . . 38

3.3.4 Removing the Probe from the Transmitter. . . . . . . . . . . . 38

3.3.5 Cleaning the Sensor and the Shield . . . . . . . . . . . . . . . . . 40

3.3.6 Installing the Probe in the Transmitter . . . . . . . . . . . . . . . 41

3.3.7 Evaluating the Cleaned Probe . . . . . . . . . . . . . . . . . . . . . 41

Chapter 4: Specifications

4.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3 Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4 Moisture Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.5 Built-In Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.6 Built-In Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.7 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Page iv HygroPro User’s Manual

Page 7

Chapter 1: Installation

1.1 Introduction

The HygroPro Moisture Transmitter is a compact, intrinsically-safe,

loop-powered, 4-20 mA transmitter that provides accurate dew/frost

point measurements over a range of –110 to 20°C (-166 to 68°F). It

features an integrated display and a six-button keypad, and it is

housed in an IP67/Type 4X enclosure.

The HygroPro transmitter uses an aluminum oxide moisture sensor,

and it includes a temperature thermistor and a pressure transducer on

a common mount for calculation of parameters such as:

• ppm

• ppm

in gases

v

in liquids

w

• pounds per million standard cubic feet in natural gas

• process relative humidity.

IMPORTANT: To install the HygroPro in a hazardous (classified) area,

see Hazardous Area Wiring Connections on page 15.

HygroPro User’s Manual Page 1

Page 8

Chapter 1: Installation

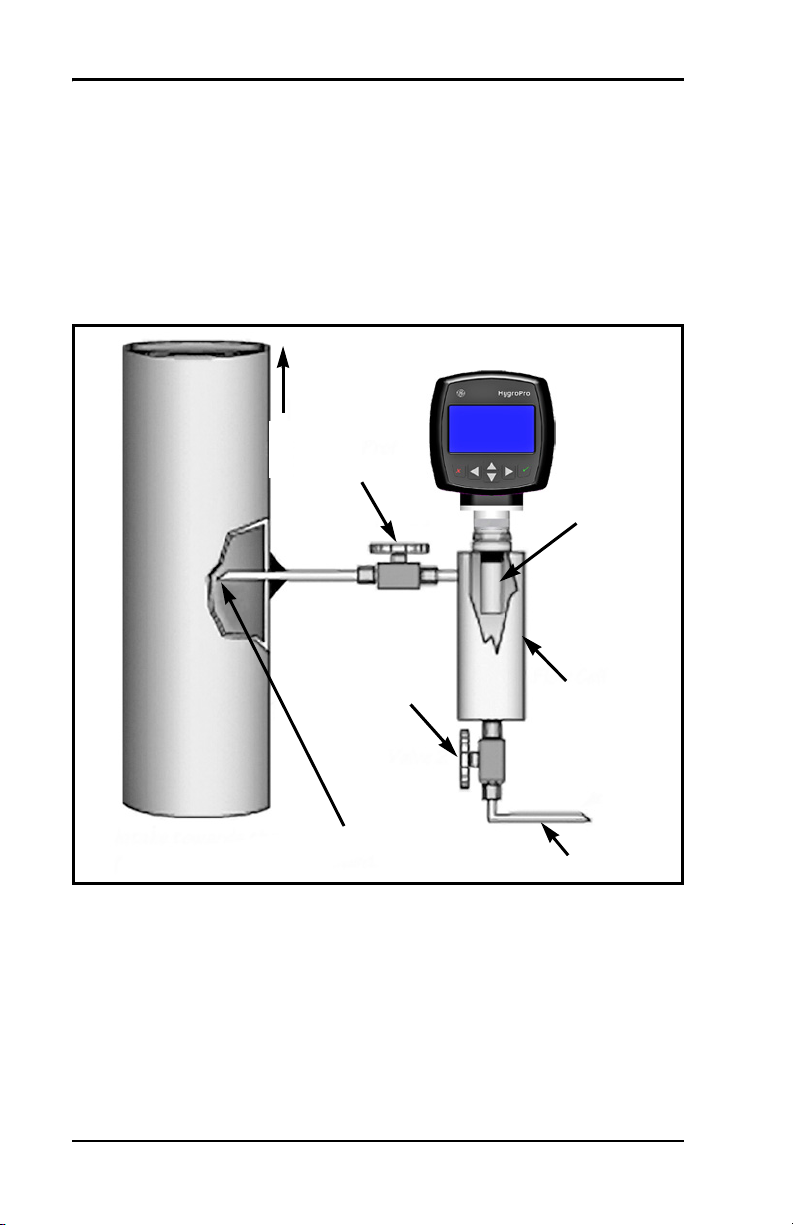

Flow

Probe

Valve 1

Valve 2

Flow Cell

See note below

Intake near the center of the

pipe is recommended.

HygroPro

Needle

Needle

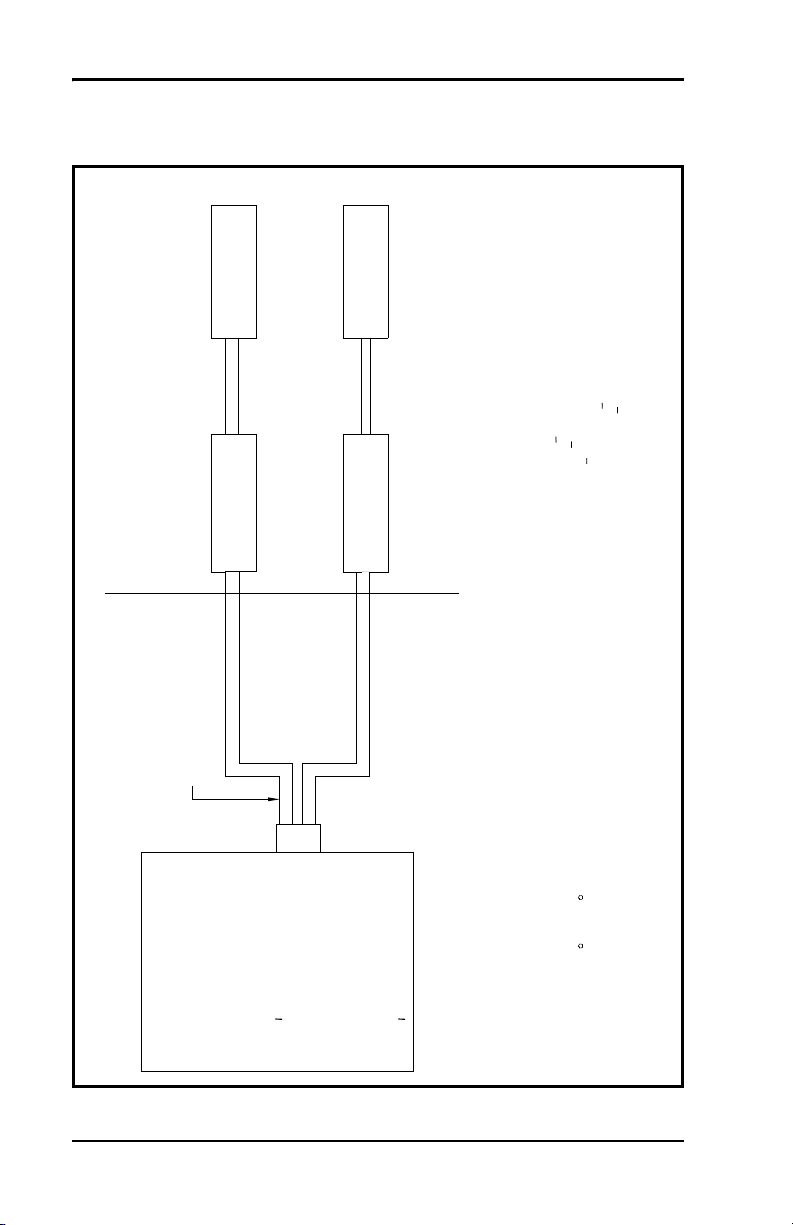

1.2 Sample System Guidelines

The HygroPro transmitter can be installed in a sample system or

directly in the process line. However, GE recommends that the unit be

installed in a sample system to protect the probe from potentially

damaging components in the process stream. Figure 1 below shows a

typical sample system.

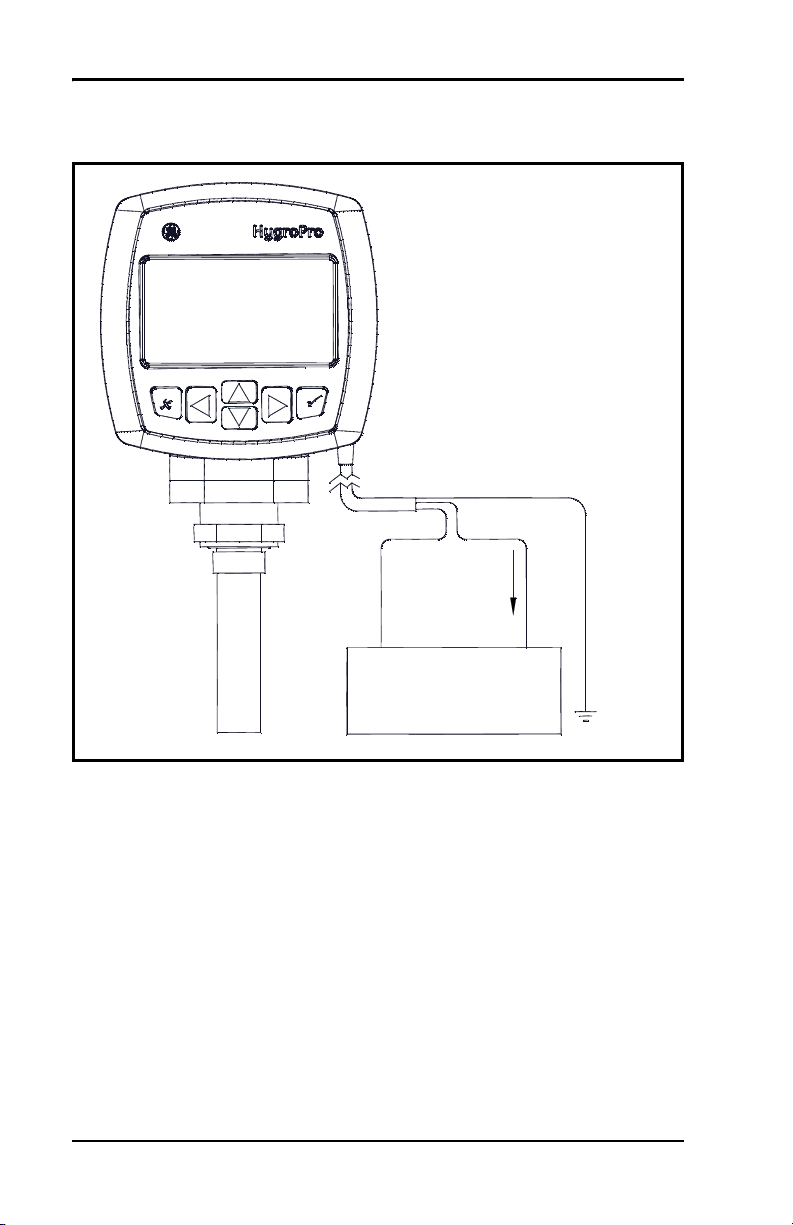

Figure 1: A Typical Sample System

Note: At least 5 ft (1.5 m) of 1/4” (6 mm) tubing vented to

atmosphere will ensure an accurate process sample and avoid

diffusion of ambient air moisture back into the process.

Page 2 HygroPro User’s Manual

Page 9

Chapter 1: Installation

1.2 Sample System Guidelines (cont.)

In the sample system shown in Figure 1 on the previous page, fully

open Valve 1 and use Val v e 2 to regulate the sample flow for

measurements at process system pressure. For measurements at

atmospheric pressure, fully open Valve 2 and use Valve 1 to regulate

the sample flow.

Before constructing a sample system, consult a GE application

engineer and observe the following guidelines:

• The sample system should be very simple and should contain as

few components as possible. All or most of those components

should be located downstream of the measurement point.

• Sample system components must not affect moisture readings.

Most common filters and pressure regulators are not suitable for

sample systems because the wetted parts adsorb moisture or

release moisture into the sample system. They may also allow

ambient contamination to enter the sample system. If possible, use

stainless steel for all wetted parts.

• The HygroPro probe should be oriented perpendicular to the

sample system inlet. For dimensions and other sample system

requirements see Mechanical Specifications on page 46.

• Sample systems should be tested for leaks prior to operation, using

a Snoop leak detector, to verify the integrity of connections,

components and fittings.

IMPORTANT: When pressurizing or depressurizing the sample system,

be careful to avoid shock damage to the moisture sensor.

HygroPro User’s Manual Page 3

Page 10

Chapter 1: Installation

Probe Hex Nut

3/4-16 UNF-2A

Shield

1.3 Mounting the Transmitter

!CAUTION!

If the HygroPro will be installed directly into the process

line, consult GE for proper installation instructions and

precautions before proceeding.

Refer to Figure 2 below and complete the steps on the next page to

install the HygroPro transmitter.

Figure 2: HygroPro Installation

Page 4 HygroPro User’s Manual

Page 11

Chapter 1: Installation

1.3 Mounting the Transmitter (cont.)

1. Make sure the sintered or stainless-steel shield is in place over the

sensor. This shield protects the aluminum oxide sensor from

damage during operation.

2. Using the integral 3/4-16 straight male thread, screw the probe end

of the transmitter into the process or sample system fitting. Make

sure not to damage the threads.

Note: A 3/4-16 to G 1/2 thread adapter is available from GE.

3. Using a 1-1/8” wrench on the probe hex nut, tighten the probe

securely into the process or sample system fitting.

!CAUTION!

Do not apply torque to the transmitter electronic module

to tighten the unit into its fitting.

Note: If there is insufficient space to rotate the HygroPro during

installation, remove the Replaceable Transducer Element

from the transmitter, install it in the fitting, then re-install the

the transmitter onto the RTE.

(RTE)

1.4 Wiring the Transmitter

Proceed to the appropriate section for instructions on:

• Standard Wiring Connections (proceed to next page)

• Hazardous Area Wiring Connections (proceed page 15)

HygroPro User’s Manual Page 5

Page 12

Chapter 1: Installation

1.4.1 Standard Wiring Connections

The HygroPro is a 4-20 mA loop-powered device that can use the

same two wires for its measurement signal lines and its power supply

lines. Follow the instructions in this section only for units not

requiring hazardous (classified) area protection.

IMPORTANT: To install the HygroPro in a hazardous (classified) area,

see Hazardous Area Wiring Connections on page 15.

The transmitter must be wired using the factory-supplied, 2-meter

cable. If a different cable length is required, please contact the factory

for assistance.

Note: If a longer cable is required, you may splice an extension onto

the standard cable. Be sure to connect leads of the same color

together. For example, connect blue lead to blue lead, brown

lead to brown lead, etc.

The HygroPro may be connected to either of the following types of

external systems:

• an external device that can provide the loop power to the

HygroPro and can also receive and display the 4-20 mA

measurement output from the HygroPro (proceed to next page)

• an external power supply to provide power to the HygroPro plus a

personal computer (PC) running GE’s PanaView™ interface

software (proceed to page 13)

Page 6 HygroPro User’s Manual

Page 13

Chapter 1: Installation

1.4.1a Standard Connections - Without a PC

IMPORTANT: To install the HygroPro in a hazardous (classified) area,

see Hazardous Area Wiring Connections on page 15.

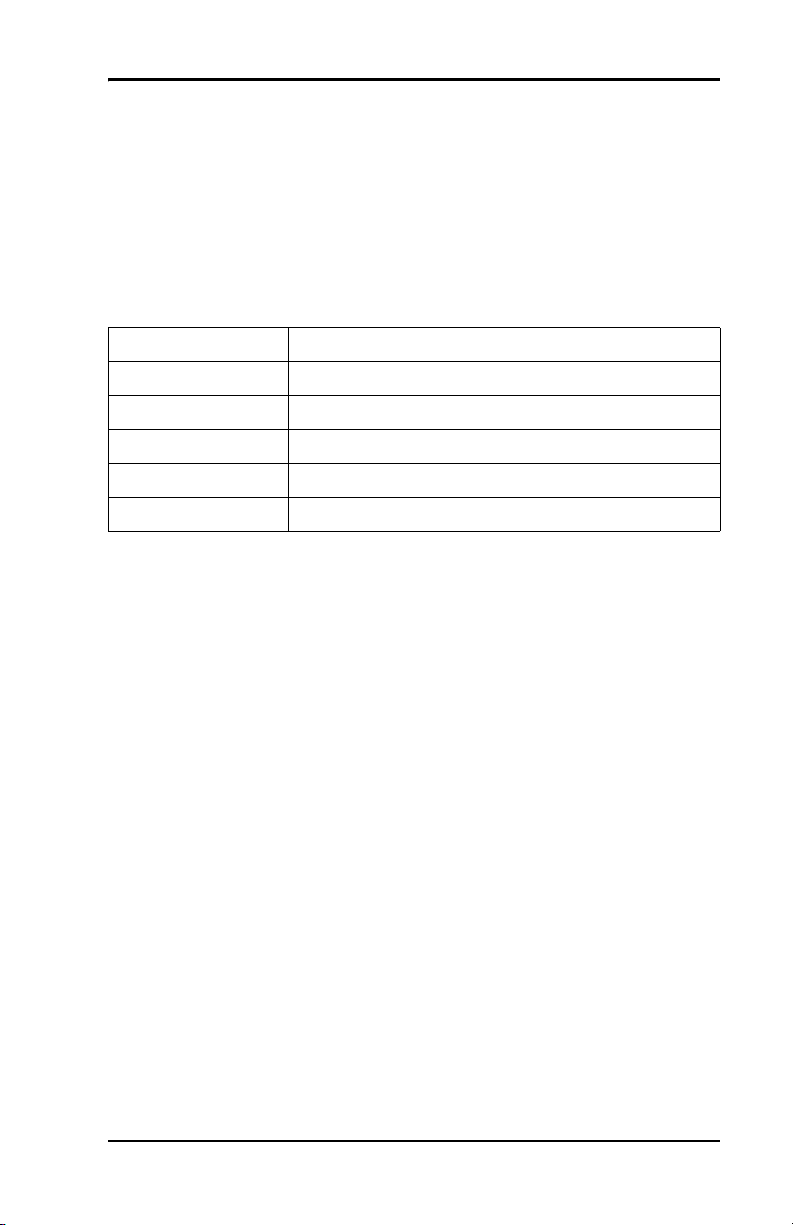

Refer to Figure 3 on the next page and Table 1 below, and complete

the following steps to wire the transmitter.

Table 1: Cable Leads - Without a PC

Lead Connection Description

Blue Power Supply (+) [12-28 VDC]

Brown Power Supply (–) [Return]

Shield Earth Ground [recommended]

1. Push the female connector end of the factory-supplied cable into

the mating male connector on the transmitter module. Make sure

the pins are properly aligned. Then, secure the connectors together

by sliding the metal sleeve on the cable over the connectors and

turning it clockwise until it is tight.

2. Using the flying leads at the other end of the factory-supplied

cable, connect the transmitter to the external system.

Note: The blue and brown leads also carry the measurement signal

current output of 4-20 mA.

3. Trim any unused leads even with the outer cable jacket to remove

any bare wire and prevent accidental short circuits.

HygroPro User’s Manual Page 7

Page 14

Chapter 1: Installation

12-28 VDC

Return

Power and

Measurement

Circuits

+–

Shield

Earth

Ground

brownblue

1.4.1a Standard Connections - Without a PC (cont.)

Figure 3: Standard Connections - Without a PC

Page 8 HygroPro User’s Manual

Page 15

Chapter 1: Installation

1.4.1b Standard Connections - With a PC

IMPORTANT: To install the HygroPro in a hazardous (classified) area,

see Hazardous Area Wiring Connections on page 15.

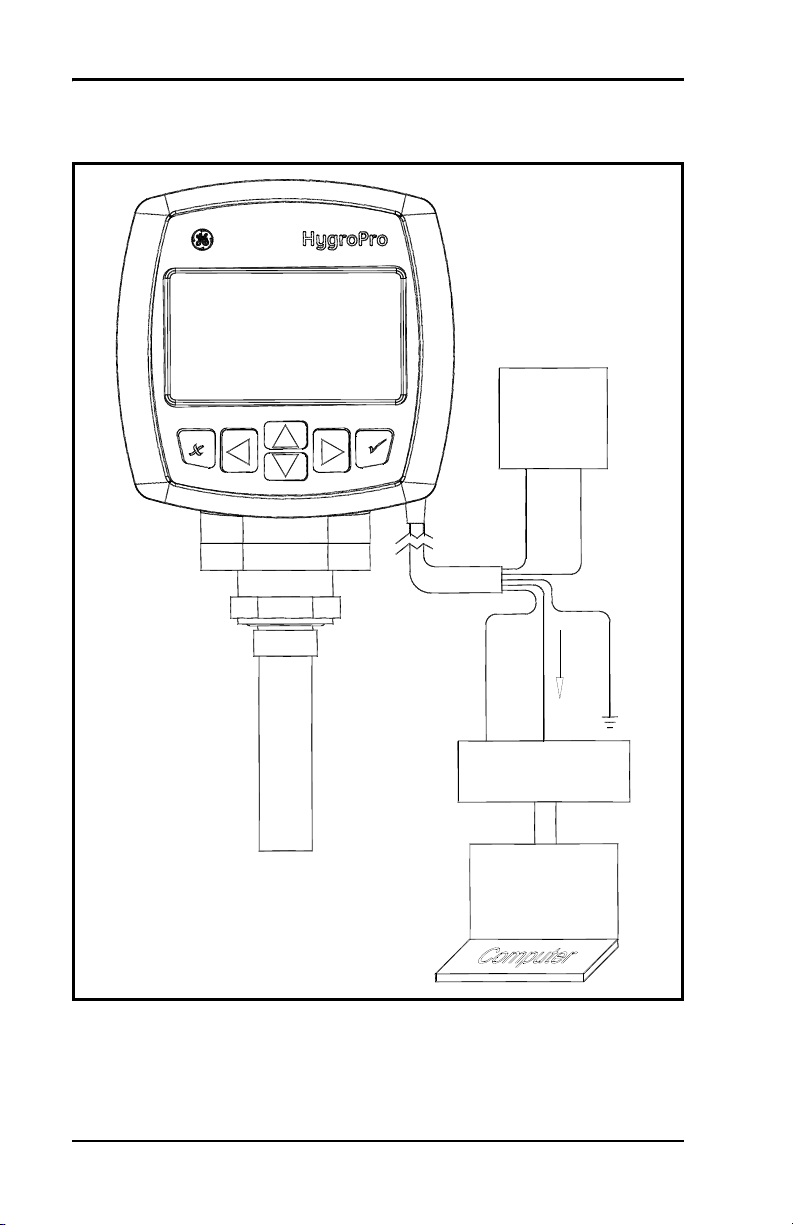

Refer to Figure 4 on the next page and Table 2 below, and complete

the following steps to wire the transmitter.

Table 2: Cable Leads - With a PC

Lead Connection Description

Blue Power Supply (+) [12-28 VDC]

Brown Power Supply (–) [Return]

White RS485-RS232 Converter (+) [positive]

Black RS485-RS232 Converter (–) [negative]

Ground Earth Ground

1. Connect an RS485-RS232 converter (customer-supplied) to an

available serial port on the PC.

2. Push the female connector end of the factory-supplied cable into

the mating male connector on the transmitter module. Make sure

the pins are properly aligned. Then, secure the connectors together

by sliding the metal sleeve on the cable over the connectors and

turning it clockwise until it is tight.

3. Using the flying leads at the other end of the factory-supplied

cable, connect the transmitter to the external system.

4. Trim any unused leads even with the outer cable jacket to remove

any bare wire and prevent accidental short circuits.

HygroPro User’s Manual Page 9

Page 16

Chapter 1: Installation

+ White

Earth

Power

?Black

Ground

PanaView

RS232

RS485 ? RS232

Converter Box

24 VDC

Supply

Blue

Brown

+–

1.4.1b Standard Connections - With a PC (cont.)

Figure 4: Standard Connections - With a PC

Page 10 HygroPro User’s Manual

Page 17

Chapter 1: Installation

1.4.2 Hazardous Area Wiring Connections

Before installing and using the HygroPro in a hazardous (classified)

area, be sure to read and understand all applicable reference materials.

This includes:

• all EU or North American Standards and Directives (see Tab le 3

and Tab l e 4 on page 17)

• all local safety procedures and practices

• the FM Schematic drawing (see Figure 5 on the next page)

• this user’s manual

Note: It is the installer’s responsibility to follow all applicable

standards and procedures.

!WARNING!

The procedures in this section must be performed only

by trained technicians who have the necessary skills

and qualifications.

HygroPro User’s Manual Page 11

Page 18

Chapter 1: Installation

Hazardous or Non-Hazardous Location

Class I, Division 1, Group ABCD

Class II, Division 1, Group EFG

Class III, Division 1

Non-Hazardous Location

HygroPro

Loop Terminal

Safety Entity Parameters:

Vmax = 28 V

Imax = 93.3 mA

Pi = 0.653 W

Ci = 0

Li = 62 uH

RS485 Comm Terminal

Safety Entity Parameters:

Vmax = 3.72 V

Imax = 228 mA

Pi = 212 mW

Ci = 0

Li = 62 uH

Notes:

1. Installation shall be in accordance with the National Electrical Code

(ANSI/NFPA 70) or Part One of the Canadian Electrical Code (C221),

as applicable.

2. The subject equipment is FM Approved, and FM Approved for Canada for the

following Hazardous (Classified) Locations and Protection Methods:

Intrinsically Safe, Class I, II, III, Division 1, Group ABCDEFG, T4

T Ambient: -40 C to 60 C

Enclosure: IP 67

3. Galvanically Isolated FM Approved (US) or Canadian Certified (for Canada)

associated apparatus installed in accordance with the manufactruer's instructions.

blue

brown

black

white

Associated Apparatus

Note 3

Loop-Power Device

Note 4

RS485 Comm

Note 4

Associated Apparatus

Note 3

4. Equipment to which associated apparatus is connected shall not

use or generate in excess of 250V.

5. Maintain the following relationship between Intrinsic Safety (Entity)

Parameters of HygroPro and associated apparatus:

HygroPro Vmax > associated apparatus Voc

HygroPro Imax > associated apparatus Isc

HygroPro Pi > associated apparatus Po

HygroPro Ci + Ccable < associated apparatus Ca

HygroPro Li + Lcable < associated apparatus La

Use cable P/N 230-049-01

1.4.2 Hazardous Area Wiring Connections (cont.)

Figure 5: FM Schematic (ref. dwg #752-262)

Page 12 HygroPro User’s Manual

Page 19

Chapter 1: Installation

1.4.2a Applicable Standards and Directives

When the HygroPro is installed in hazardous areas with potentially

explosive atmospheres, it complies with the ATEX directive 94/9/EC,

the EU standards listed in Table 3 below, and the North American

FM/CSA and IEC standards listed in Tab l e 4 below.

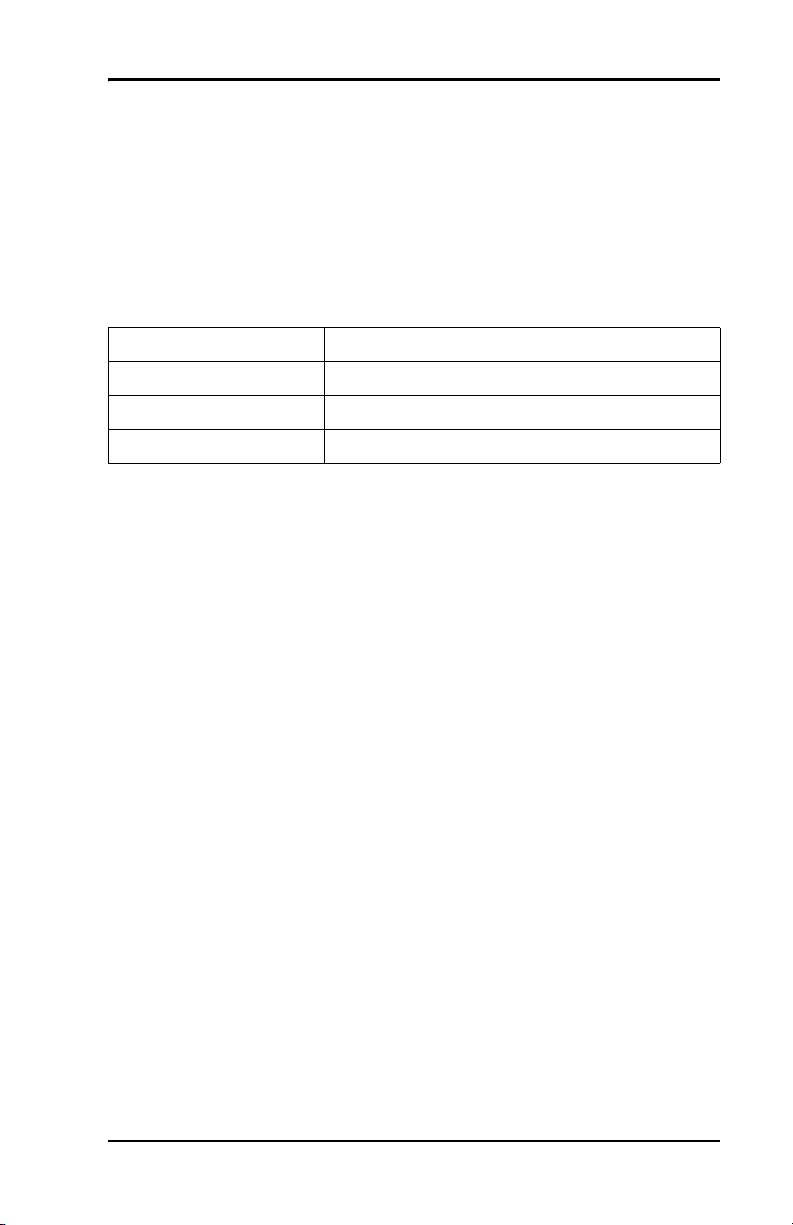

Table 3: European Union (EU) Standards

Title Number Date

General requirements EN 60079-0 2000

Intrinsic safety “i” EN 50020 2002

Group II, Category 1G, Zone 0 equipment EN 60079-26 2004

Table 4: North American Standards

Title Number Date

Electrical Equipment for Use in Hazardous

(Classified) Locations General

Requirements

Intrinsically Safe Apparatus and Associated

Apparatus for use in Class I, II, & III,

Division 1, and Class I, Zone 0 & 1

Hazardous (Classified) Locations

Electrical Equipment for Measurement,

Control and Laboratory Use

Intrinsically Safe and Non-incendive

Electrical for Use in Hazardous Locations

Safety Requirements for Electrical

Equipment for Measurement, Control, and

Laboratory Use - Part 1: General

Requirements (Adopted IEC 61010-1:2001,

MOD) (Tri-National standard, with UL

61010-1 and ISA 82.02.01)

Degrees of Protection Provided by

Enclosures (IP Code)

Degrees of Protection Provided by

Enclosures (IP Code)

Class No. 3600 Nov. 1998

Class No. 3610 Oct. 1999

Class No. 3810 Jan. 2005

CSA-C22.2

No. 157

CSA-C22.2

No. 61010-1

ANSI/IEC

60529

CSA-C22.2

No. 60529

1992,

Reaffirmed

2002

July 2004

2004

2005

HygroPro User’s Manual Page 13

Page 20

Chapter 1: Installation

1.4.2b Compliance Requirements

The HygroPro installation must comply with EN 60079-14 in Europe

and with the National Electrical Code (ANSI/NFPA 70) or part one of

the Canadian Electrical Code (C22.1), as applicable, in North

America. In other regions, additional local codes may also apply.

1.4.2c Electrical Connections

The HygroPro transmitter is certified intrinsically-safe for use in

zone 0. However, the external power must be provided by one of the

following methods:

• an isolated, intrinsically-safe, 24 VDC power supply mounted in

the safe area

• an isolated zener barrier mounted in the safe area and installed

between a standard 24 VDC power supply and the HygroPro

Refer to Figure 6 on the next page for a typical hazardous (classified)

area HygroPro wiring diagram. This installation uses an MTL706

zener barrier, in accordance with the second option listed above.

If using serial communications with a PC, an isolated RS232-RS485

converter mounted in the safe area between the computer and

HygroPro must be used. The converter is typically powered by its

own standard 24 VDC power supply.

!WARNING!

Do NOT power an RS232-RS485 converter from the

same intrinsically-safe 24 VDC power supply used

to power the HygroPro.

Page 14 HygroPro User’s Manual

Page 21

1.4.2c Electrical Connections (cont.)

Chapter 1: Installation

Figure 6: Hazardous Area Connections

HygroPro User’s Manual Page 15

Page 22

Chapter 1: Installation

1.4.2d Requirements for External Devices

When connecting the HygroPro to external devices, the allowable

total load capacitance and inductance for those devices are listed in

the manufacturer’s datasheets. The entity parameters of the external

devices (e.g. voltage, current and power) must be equal to or lower

than the same specifications for the HygroPro.

The entity parameters for the HygroPro are listed in Ta b le 5 below.

Table 5: HygroPro Entity Parameters

Loop Power Supply

Ui = 28 V Pi = 0.653 W Li = 62 µH

= 93.3 mA Ci = 0

I

i

RS485 Digital Output

Ui = 3.72 V Pi = 212 mW Li = 62 µH

= 228 mA Ci = 67 µF at 5.36 V

I

i

Page 16 HygroPro User’s Manual

Page 23

Chapter 1: Installation

1.4.2e Special Conditions for Safe Operation

The “X” at the end of the HygroPro ATEX certificate number,

Bas06ATEX0019X, indicates that special conditions are required for

safe operation in Europe. These conditions are:

1. The equipment must be protected against impact or friction with

ferrous metals.

2. The bare ends of the connecting cable must be terminated in such

a way that the terminations are afforded a degree of protection of

not less than IP20 ingress protection.

3. The HygroPro is incapable of withstanding the 500 VAC test

between all inputs and frame for one minute. Therefore, the

HygroPro must be earthed by connecting the outer grounding

screw on the HygroPro with the equipotential bonding system.

Follow the local standards and electrical codes regarding the

equipotential bonding system.

!WARNING!

Never connect or disconnect the HygroPro in the

hazardous area when supply power or the

communication circuit is energized. Isolate the supply

lines in the non-hazardous area first.

Following the same special conditions listed above is recommended

for regions outside of Europe as well.

HygroPro User’s Manual Page 17

Page 24

Chapter 1: Installation

Page 18 HygroPro User’s Manual

Page 25

Chapter 2: Operation

2.1 Powering Up & Programming

After the HygroPro has been installed as described in Chapter 1,

Installation, power may be applied to the unit. The transmitter

requires up to 60 seconds to initialize and begin normal operation.

The unit will meet its specified accuracy within 3 minutes.

Figure 7 below shows a close-up view of the HygroPro display and

keypad, and Figure 8 on the next page shows a complete menu map

of the HygroPro setup program.

Figure 7: HygroPro Display and Keypad

HygroPro User’s Manual Page 19

Page 26

Chapter 2: Operation

Startup Screen

[escape] - [enter] - [escape ]

unlock - [enter]

Passcode

Lock Keypad

Lock Menus

# of Views

Display

Output

Calibrate Const Pressure

Const Temperature

Node ID

RS485 Service*

* Factory-level passcode is required

to access the Service menu.

1

2

3

Normal

Reverse

Contrast

Hygro ° C

[22 options]

Pressure FP

Measure

4-20mA

Special

Type

NAMUR

Span

Zero

Zero

Range

Span

Base TrimTrim

Span Trim

%

Mode

Normal

Test

Live

Constant

2400

4800

9600

Baud Rate

None

Odd

Parity

Even

1

Stop Bits

2

7Data Bits

8

Versions

Upgrade

Default Analyzer

Row 1

Row 16

Hygro Curve

Save Table?

Zero mV

Span PSIg

Press Curve

Zero PSIg

Span mV

Temp °C 1

CS 6

CS Table

CS 1

Temp °C 6

Live

Constant

Units 1

Units 16

2.1.1 Menu Map

Figure 8: Programming Menu Map

Page 20 HygroPro User’s Manual

Page 27

Chapter 2: Operation

2.1.2 Keypad

After entering the setup program, the keys on the HygroPro keypad

(see Figure 7 on page 23) perform the following functions:

• enter - confirm a selection or move to the next screen

• escape - cancel a selection or move to the previous screen

• up - scroll upward through a list of options or increase the value of

a selected character

• down - scroll downward through a list of options or decrease the

value of a selected character

• left - move the cursor to the next character to the left

• right - move the cursor to the next character to the right

2.2 Basic Setup

The HygroPro transmitter is easily programmed to meet the user’s

requirements by referring to the menu map in Figure 8 on the

previous page and following the instructions in this section.

2.2.1 Unlocking the Display

Upon startup, the following screen appears on the HygroPro display:

The symbol in the upper right corner

indicates that the screen is locked.

To unlock the screen, press

escape, enter, escape.

HygroPro User’s Manual Page 21

Page 28

Chapter 2: Operation

2.2.2 Entering the Setup Program

To enter the setup program, complete the following steps:

Using the arrow keys, highlight the

opened lock and press enter.

Select Passcode and press enter.

Note: The default operator-level passcode is 2719.

Enter your passcode using the up and

down keys to change the value of each

passcode digit, and the left and right

keys to move from one digit to the next.

When the passcode is correct, press

enter.

Note: To enter the Service menu, the factory-level passcode must be

entered.

Page 22 HygroPro User’s Manual

Page 29

Chapter 2: Operation

2.2.3 Selecting Measurement Parameters

To select the measurement parameters, complete the following steps:

To select the number of measurements to

be displayed on each screen, select

# of Views and press enter.

Use the up and down keys to select the

number of views desired and press

enter. Then, press enter again to return

to the previous menu.

Press escape to see the view setup. To

change a measurement parameter, use

the arrow keys to highlight the parameter

name and then press enter.

Use the up and down arrow keys to

select a measurement parameter and then

press enter twice.

Note: As an example, Dew Point has been selected as the

measurement parameter to be changed.

HygroPro User’s Manual Page 23

Page 30

Chapter 2: Operation

2.2.3 Selecting Measurement Parameters (cont.)

Use the up and down arrow keys to

select a unit of measure and press enter

twice.

Repeat the previous steps to make any other desired measurement

parameter changes. Then, continue as follows:

• If the operator-level passcode was used, highlight the lock symbol

and press enter again to return to the DISPLAY menu.

• If the service-level passcode was used, continue the programming

steps below.

If the number of decimal places is

acceptable, press escape. To change the

number of decimal places, press enter.

Use the up and down keys to change the

number of decimal places and press

enter.

The programming sequence is now complete and you are returned to

View menu.

the

Page 24 HygroPro User’s Manual

Page 31

2.2.4 Setting Up the Display

To set up the display, complete the following steps:

Use the up and down keys to select

Display and press enter. Then, enter

your passcode and press enter.

Use the up and down keys to select

Display and press enter.

If the display type is acceptable, press

escape to return to the previous menu.

To change the display type, use the up

and down keys to select

Reverse and press enter.

Chapter 2: Operation

Normal or

If you wish to change the display Contrast, at the above screen,

highlight that choice and press enter.

Use the arrow keys to change the

Contrast value and press enter. Then

press escape twice to return to the main

menu.

HygroPro User’s Manual Page 25

Page 32

Chapter 2: Operation

2.2.5 Setting Up the Analog Output

To set up the analog output, complete the following steps:

After entering your password, use the

right arrow key to scroll to Output and

press enter.

Select the Measure option and press

enter.

Use the arrow keys to scroll to the

desired output parameter and press

enter.

In the Output menu, select Type and press enter. The following

screen appears:

Select the desired output Type and press

enter.

Page 26 HygroPro User’s Manual

Page 33

Chapter 2: Operation

2.2.5 Setting Up the Analog Output (cont.)

If Special was chosen at the previous prompt, the following screen

appears:

Select Zero and press enter.

Use the arrow keys to enter the zero

value for the special output and press

enter.

Repeat the above two steps to enter the

Span value for the special

output. In the Output menu, select Range and press enter. The

following screen appears:

Enter the Zero and Span values for the

range, using the same procedure as

above.

HygroPro User’s Manual Page 27

Page 34

Chapter 2: Operation

2.2.5 Setting Up the Analog Output (cont.)

In the Output menu, select Trim and press enter. The following

screen appears:

Enter your values for the

Span Trim and %, using the same

Base Trim,

procedures as on the previous page.

When you select the Mode option at the above prompt, choose either

Test to verify the output or Normal for normal operation.

2.2.6 Entering the Node ID

The Node ID is a unique network identifier that enables the HygroPro

to be connected to a multi-drop network when used with PanaView™

interface software. To enter your Node ID, proceed as follows:

Enter your passcode to access the setup

program. Then use the arrow keys to

select the Node ID menu. Press enter.

Use the arrow keys to enter the desired

Node ID value and press enter.

Page 28 HygroPro User’s Manual

Page 35

Chapter 2: Operation

2.2.7 Setting Up the RS485 Output

To set up the RS485 output, complete the following steps:

Enter your passcode to access the setup

program. Then use the arrow keys to

select the RS485 menu. Press enter.

To enter the Baud Rate, press enter.

Use the up and down keys to select the

desired value and press enter.

Repeat the above procedure to enter the following RS485 parameters:

• Parity

• Stop Bits

• Data Bits

You have now completed the initial setup process.

HygroPro User’s Manual Page 29

Page 36

Chapter 2: Operation

2.3 Advanced Setup

The following sections describe the procedures for completing the

configuration of your HygroPro transmitter.

2.3.1 Setting Up the Pressure/Temperature Displays

The following steps set the displayed pressure and temperature values

to Live (changing with the current measurements) or Constant

(remaining the same, regardless of the current measurements). If

Constant is selected, the desired numerical value must be set.

To set the pressure display, enter your

password and use the arrow keys to

select Const Pressure. Press enter.

Use the arrow keys to select either Live

Pressure or Constant Pressure and

press enter.

If you selected Constant Pressure, use

the arrow keys to select Press... and press

enter.

Use the arrow keys to enter the desired

pressure value and press enter. The

screen will be updated to show the new

pressure value.

Page 30 HygroPro User’s Manual

Page 37

Chapter 2: Operation

2.3.1 Setting Up the Pressure/Temperature Displays (cont.)

To set the temperature display, enter

your password and use the arrow keys to

select Const Temperature. Press enter.

Use the same procedure to set the

temperature mode, and if Constant

Temperature is selected, to enter the

constant temperature value.

2.3.2 Entering Sensor Calibration Data

Enter your password and use the arrow

keys to scroll to Calibrate. Press enter.

Select Hygro Curve and press enter.

Select

Row1 and press enter.

HygroPro User’s Manual Page 31

Page 38

Chapter 2: Operation

2.3.2 Entering Sensor Calibration Data (cont.)

Select the desired units and press enter.

Use the arrow keys to enter a value and

press enter.

Repeat the previous steps until all of your Hygro Curve data points

have been entered.

To save the data you have entered, scroll

to the bottom of the Hygro Curve

options list to the SAVE HYGRO TABLE?

section. Then, select Save and press

enter.

IMPORTANT: Any data not saved at the above prompt will be lost.

Repeat the above process to enter any available Press Curve and

CS Table data points.

Note: The CS Table is required only if ppm

measurements will be

w

made. Consult GE for the table values to use for your

application.

Page 32 HygroPro User’s Manual

Page 39

Chapter 2: Operation

2.3.3 Locking and Unlocking the Keypad

To lock the keypad to prevent it from being used, enter the user

program as described on page 26.

Use the down arrow key to select Lock

Keypad on the initial screen and press

enter twice. The keypad is now locked.

To unlock the keypad, just re-enter the user program as described on

page 26. No further programming steps are required.

2.3.4 Locking and Unlocking the Menus

To lock the menus to prevent them from being changed, enter the user

program as described on page 26.

Use the down arrow key to select Lock

Menus on the initial screen and press

enter twice. The menus are now locked.

To unlock the menus, just re-enter the user program as described on

page 26. No further programming steps are required.

HygroPro User’s Manual Page 33

Page 40

Chapter 2: Operation

Page 34 HygroPro User’s Manual

Page 41

Chapter 3: Service & Maintenance

3.1 The Service Menus

IMPORTANT: The service menus are accessible only by using the

factory-level passcode.

After entering the Factory Level

passcode, use the arrow keys to scroll to

Service and press enter.

To check the version levels of your

HygroPro firmware, select Versions and

press enter. The information for your

unit is displayed.

The following HygroPro service menu options are also available:

• Upgrade - used to install an updated firmware version

• Default Analyzer - used to reset all settings to the factory defaults

Select the desired

and press enter. Then, follow the

on-screen instructions.

After completing the above step, respond

to the ARE YOU SURE? question. Be sure

to respond Yes, if you wish to save the

new information.

HygroPro User’s Manual Page 35

Service menu option

Page 42

Chapter 3: Service & Maintenance

3.2 Moisture Probe Error Conditions

IMPORTANT: All moisture probes require periodic cleaning to

maintain optimum accuracy. Consult the GE service

center for the recommended probe cleaning interval for

your application.

If there is a problem with the moisture probe during operation, the

HygroPro is programmed to indicate the error condition via its

analog output signal. To indicate a probe error condition, the analog

output signal is forced to the following values:

• 22 mA to indicate a short circuit in the probe

• 3.5 mA to indicate an open circuit in the probe

If you have one of the above error conditions, follow the probe

cleaning instructions in the next section.

3.3 Cleaning the Moisture Probe

To clean your HygroPro moisture probe, carefully follow the

instructions in this section.

3.3.1 Preparing to Clean the Probe

CAUTION!

Be sure to perform the probe cleaning procedure in a

well-ventilated area. Observe all necessary safety

precautions when handling the cleaning solvents

Page 36 HygroPro User’s Manual

Page 43

Chapter 3: Service & Maintenance

3.3.1 Preparing to Clean the Probe (cont.)

To clean the moisture probe, the following items are required:

• Two glass (NOT metal) containers with approximately 300 ml of

reagent-grade hexane or toluene in each container.

• One glass (NOT metal) container with approximately 300 ml of

distilled (

IMPORTANT: Make sure the containers are deep enough to completely

NOT deionized) water.

submerge the moisture probe. Do not place the

transmitter module into the solvents. Insert only the

moisture sensor into the solvents.

• Rubber or latex gloves

• An oven set at 50°C ± 2°C (122°F ± 3.6°F)

• 1-1/8” wrench

3.3.2 Replacing the RTE

To maximize HygroPro performance, GE recommends recalibration

of the aluminum oxide moisture sensor on the Replaceable

Transducer Element (

interval depends on the specific application. To accomplish this,

either return the RTE to GE for recalibration or install a new RTE.

The HygroPro electronics will automatically read and store the

calibration data whenever a new or recalibrated RTE is installed.

IMPORTANT: The programmed probe calibration data should not be

changed without consulting GE.

HygroPro User’s Manual Page 37

RTE) every 6 to 12 months. The optimum

Page 44

Chapter 3: Service & Maintenance

3.3.3 Removing the Transmitter from the System

Complete the following steps to remove the transmitter from the

installation site:

1. Refer to Figure 2 on page 8 and use a 1-1/8” wrench on the probe

hex nut to unthread the transmitter from the fitting on the sample

system or process line.

2. Record the dew point of the ambient air.

3. Disconnect the cable from the transmitter module.

3.3.4 Removing the Probe from the Transmitter

To remove the probe from the transmitter, refer to Figure 9 on the

next page and proceed as follows:

1. Loosen the four captive screws on the bottom of the transmitter.

2. Carefully remove the metal plate without touching the sensor.

3. Carefully pull the probe out of the transmitter.

4. Disconnect the probe cable by turning the locknut at the top of the

probe. Then, detach the sensor.

Page 38 HygroPro User’s Manual

Page 45

Chapter 3: Service & Maintenance

Cable Locknut

Probe

Captive Screws

Metal Plate

3.3.4 Removing the Probe from the Transmitter (cont.)

Figure 9: Removing the Probe from the Transmitter

HygroPro User’s Manual Page 39

Page 46

Chapter 3: Service & Maintenance

3.3.5 Cleaning the Sensor and the Shield

CAUTION!

Do not place the transmitter module into the solvents.

Insert only the sensor portion of the instrument. Do not

allow the sensor to come into contact with the surfaces of

cleaning containers or with any other hard surface.

1. While wearing protective gloves, place the sensor in the first

container of hexane or toluene and allow it to soak for 10 minutes.

2. Remove the sensor from the hexane or toluene and soak it in the

container of distilled water for 10 minutes.

3. Remove the sensor from the distilled water and soak it in the

second (clean) container of hexane or toluene for 10 minutes.

4. Remove the sensor from the hexane or toluene and set it aside in a

clean area.

5. Repeat steps 1 to 3 to clean the shield. To ensure the removal of

any contaminants that may have become embedded in the porous

walls of the shield, swirl the shield in the solvents during the

soaking procedure.

6. Remove the shield from the hexane or toluene.

7. Carefully replace the shield over the exposed sensor without

touching the sensor.

8. Place the sensor with the installed shield in an oven set at

50°C ± 2°C (122°F ± 3.6°F) for 24 hours.

Page 40 HygroPro User’s Manual

Page 47

Chapter 3: Service & Maintenance

3.3.6 Installing the Probe in the Transmitter

To install a new or cleaned probe in the transmitter, complete the

following steps:

1. Reconnect the probe cable to the top of the probe by turning the

locknut.

2. Carefully push the probe into the transmitter.

3. Replace the metal plate without touching the sensor.

4. Tighten the four captive screws on the metal plate into the bottom

of the transmitter.

3.3.7 Evaluating the Cleaned Probe

Note: All new probes are calibrated at the factory, and no evaluation

is required after installation.

1. Reconnect the probe cable to the transmitter module and measure

the ambient air dew point. Make sure to measure the same ambient

air as measured during removal of the transmitter.

2. Compare the two ambient air readings. If the new ambient air

reading is within ±2°C (±3.6°F) of the first reading, the cleaned

probe is properly calibrated and normal operation may be

resumed.

3. If the probe is still not reading the ambient air accurately, repeat

the cleaning procedure using soaking times that are five times

those used in the previous cleaning sequence. Repeat the cleaning

cycles until two consecutive ambient air readings are identical.

If the above cleaning procedure does not result in accurate readings,

contact GE for assistance.

HygroPro User’s Manual Page 41

Page 48

Chapter 3: Service & Maintenance

Page 42 HygroPro User’s Manual

Page 49

Chapter 4: Specifications

Chapter 4: Specifications

4.1 General

Dew Point/Frost Point Calibration Range

• 68° to –112°F (20° to –80°C)

Operating Temperature:

• –4° to 140°F (–20° to 60°C)

Storage Temperature:

• 158°F (70°C) maximum

Warm-Up Time

• Meets specified accuracy within three minutes

Calibrated Accuracy (Dew/Frost Point)

• ±3.6°F (±2°C) from –85° to 50°F (–65° to 10°C)

• ±5.4°F (±3°C) from –112° to –86°F (–80° to –66°C)

Repeatability (Dew/Frost Point)

• ±0.9°F (±0.5°C) from –85° to 104°F (–65° to 40°C)

• ±1.8°F (±1.0°C) from –112° to –86°F (–80° to –66°C)

Response Time

• Less than five seconds for 63% of a step change in moisture

content in either a wet-up or dry-down cycle

HygroPro User’s Manual Page 43

Page 50

Chapter 4: Specifications

4.2 Electrical

Power

• Input: 12 to 30 VDC (loop-powered, customer supplied)

• Output: 4 to 20 mA analog, RS485 digital

• Output Resolution: 0.01 mA/12 bits

• Maximum Load Resistance: = (PSV x 33.33) – 300,

where PSV = Power Supply Voltage

Example: Given a 24 VDC Power Supply,

Max. Load Resistance 33.33

) – 300 = 500

• Cable: 6 ft (2 m), standard (consult GE for custom lengths)

Input Parameters for Loop-Powered Intrinsic Safety

U

= 28V Pi = 0.653W Li = 62µH

i

= 93.3mA Ci = 0

I

i

RS485

U

= 3.72V Pi = 212mW Li = 62µH

i

I

= 228mA Ci = 67µF at 5.36V

i

Page 44 HygroPro User’s Manual

Page 51

Chapter 4: Specifications

4.3 Mechanical

Sample Connection

• 3/4-16 (19 mm) straight male thread with O-ring

• G ½ with optional adapter

Operating Pressure

• 5 m Hg to 5,000 psig (345 bar)

Enclosure

• Type 4x / IP67

Dimensions

• Overall (H x W x D):

7.88 x 3.99 x 2.56 in. (200 x 101 x 65 mm)

• Weight: 1.2 lb (550 g)

HygroPro User’s Manual Page 45

Page 52

Chapter 4: Specifications

4.4 Moisture Sensor

Sensor Type

• Thin-film aluminum oxide moisture sensor probe

Calibration

• Each sensor is individually computer-calibrated against known

moisture concentrations, traceable to

Calibration Interval

NIST

• Sensor recalibration at GE is recommended every six to twelve

months, depending on the application

Flow Rate

• Gases: Static to 100 m/s linear velocity at a pressure of 1 atm.

• Liquids: Static to 10 cm/s linear velocity at density of 1 g/cc

4.5 Built-In Temperature Sensor

Type

• Nonlinear NTC thermistor (resultant temperature linearized by

microprocessor)

Measurement Range

• –22° to 158°F (–30° to 70°C)

Accuracy

• ±0.9°F (±0.5°C) overall

Response Time (Maximum)

• One second in well stirred oil, or 10 seconds in still air, for a 63%

step change in increasing or decreasing temperature

Page 46 HygroPro User’s Manual

Page 53

Chapter 4: Specifications

4.6 Built-In Pressure Sensor

Type

• Solid state/piezoresistive

Available Ranges

• 30 to 300 psig (3 to 21 bar)

• 50 to 500 psig (4 to 35 bar)

• 100 to 1000 psig (7 to 69 bar)

• 300 to 3000 psig (21 to 207 bar)

• 500 to 5000 psig (35 to 345 bar)

Note: Psig ranges are based on a constant pressure, with the value

provided at the time of order placement.

Accuracy

• ±1% of full scale (FS)

Warm-up Time

• Meets specified accuracy within 3 minutes

Pressure Rating

• Three times the span of the available range,

to a maximum of 7500 psig (518 bar)

HygroPro User’s Manual Page 47

Page 54

Chapter 4: Specifications

4.7 Certifications

European Compliance

• Complies with EMC Directive 2004/108/EC and PED 2006/95/EC

for DN<25

Figure 10: HygroPro Certification Label

Page 48 HygroPro User’s Manual

Page 55

Warranty

Warranty

Each instrument manufactured by GE Sensing is warranted to be free from defects

in material and workmanship. Liability under this warranty is limited to restoring

the instrument to normal operation or replacing the instrument, at the sole

discretion of GE Sensing. Fuses and batteries are specifically excluded from any

liability. This warranty is effective from the date of delivery to the original

purchaser. If GE Sensing determines that the equipment was defective, the warranty

period is:

• one year from delivery for electronic or mechanical failures

• one year from delivery for sensor shelf life

If GE Sensing determines that the equipment was damaged by misuse, improper

installation, the use of unauthorized replacement parts, or operating conditions

outside the guidelines specified by GE Sensing, the repairs are not covered under

this warranty.

The warranties set forth herein are exclusive and are in lieu of all

other warranties whether statutory, express or implied (including

warranties or merchantability and fitness for a particular purpose,

and warranties arising from course of dealing or usage or trade).

HygroPro User’s Manual 49

Page 56

Warranty

Return Policy

If a GE Sensing instrument malfunctions within the warranty period, the following

procedure must be completed:

1. Notify GE Sensing, giving full details of the problem, and provide the model

number and serial number of the instrument. If the nature of the problem

indicates the need for factory service, GE Sensing will issue a RETURN

AUTHORIZATION NUMBER (RAN), and shipping instructions for the

return of the instrument to a service center will be provided.

2. If GE Sensing instructs you to send your instrument to a service center, it must

be shipped prepaid to the authorized repair station indicated in the shipping

instructions.

3. Upon receipt, GE Sensing will evaluate the instrument to determine the cause

of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the instrument will be

repaired at no cost to the owner and returned.

• If GE Sensing determines that the damage is not covered under the terms of the

warranty, or if the warranty has expired, an estimate for the cost of the repairs at

standard rates will be provided. Upon receipt of the owner’s approval to

proceed, the instrument will be repaired and returned.

50 HygroPro User’s Manual

Page 57

GE

Sensing

DECLARATION

OF

CONFORMITY

DOC-0001, Rev. A

We,

1100 Technology Park Drive

declare under our sole responsibility that the

HygroPro Moisture Transmitter

to which this declaration relates, is in conformity with the following standards:

• EN 60079-0: 2000

• EN 60079-26: 2004

• II 1 G EEx ia IIC T4; Baseefa06ATEX0019X (Baseefa, Buxton, Derbyshire, UK - NoBo

1180)

• EN 61326-1: 2006, Class A, Table 2, Industrial Locations

• EN 61326-2-3: 2006

Other standards used:

• EN 50020: 2002

following the provisions of the 2004/108/EC EMC and 94/9/EC ATEX Directives.

Where products were initially assessed for compliance with the Essential Health and Safety

Requirements of the

ATEX Directive 94/9/EC using earlier harmonized standards, a subsequent review has

determined that “technical knowledge” is unaffected by the current harmonized standards

listed above.

The unit listed above and any ancillary equipment supplied with it do not bear CE marking

for the Pressure Equipment Directive, as they are supplied in accordance with Article 3,

Section 3 (sound engineering practices and codes of good workmanship) of the Pressure

Equipment Directive 97/23/EC for DN<25.

GE Sensing

Billerica, MA 01821

USA

Billerica - August 2010

Issued Mr. Gary Kozinski

Certification & Standards, Lead Engineer

Page 58

Page 59

Page 60

Customer Support Centers

U.S.A.

The Boston Center

1100 Technology Park Drive

Billerica, MA 01821

U.S.A.

Tel: 800 833 9438 (toll-free)

978 437 1000

E-mail: sensing@ge.com

Ireland

Sensing House

Shannon Free Zone East

Shannon, County Clare

Ireland

Tel: +35 361 470291

E-mail: gesensingsnnservices@ge.com

916-099 Rev. D

www.ge-mcs.com

©2012 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Loading...

Loading...