Page 1

GE

Oil & Gas

HygroPro

Aluminum Oxide

Moisture Transmitter

Applications

This aluminum oxide moisture transmitter

measures moisture concentration in gases and

non-aqueous liquids from trace to ambient levels.

It is suitable for a wide range of industries:

• Petrochemical

• Natural gas

• Industrial gas

• Semiconductor

• Furnace gas/heat treating

• Power generation

• Air dryer

• Pharmaceutical

• Aerospace

Features

• Intrinsically safe

• Ambient to ppb moisture measurement; using

aluminum oxide moisture sensor

• Built-in temperature and pressure sensors

• Non-volatile calibration data storage

• Calibrations traceable to National Institute of

Standards and Technology (NIST)

• Requires only twisted pair cabling

• Complete program capability via six-button

keypad

• Integrated display/user interface

• Analog and digital outputs

Page 2

The HygroPro moisture transmitter is an intrinsically

safe, compact, loop-powered moisture transmitter

designed specifi cally to meet the demands of rugged

industrial applications. With certifi ed intrinsically safe

electronics (when installed with proper protection)

packaged in an IP67/Type 4X housing, the HygroPro

is ideal for use in pipeline natural gas, petrochemical,

power generation and other industrial gas or

non-aqueous liquid applications.

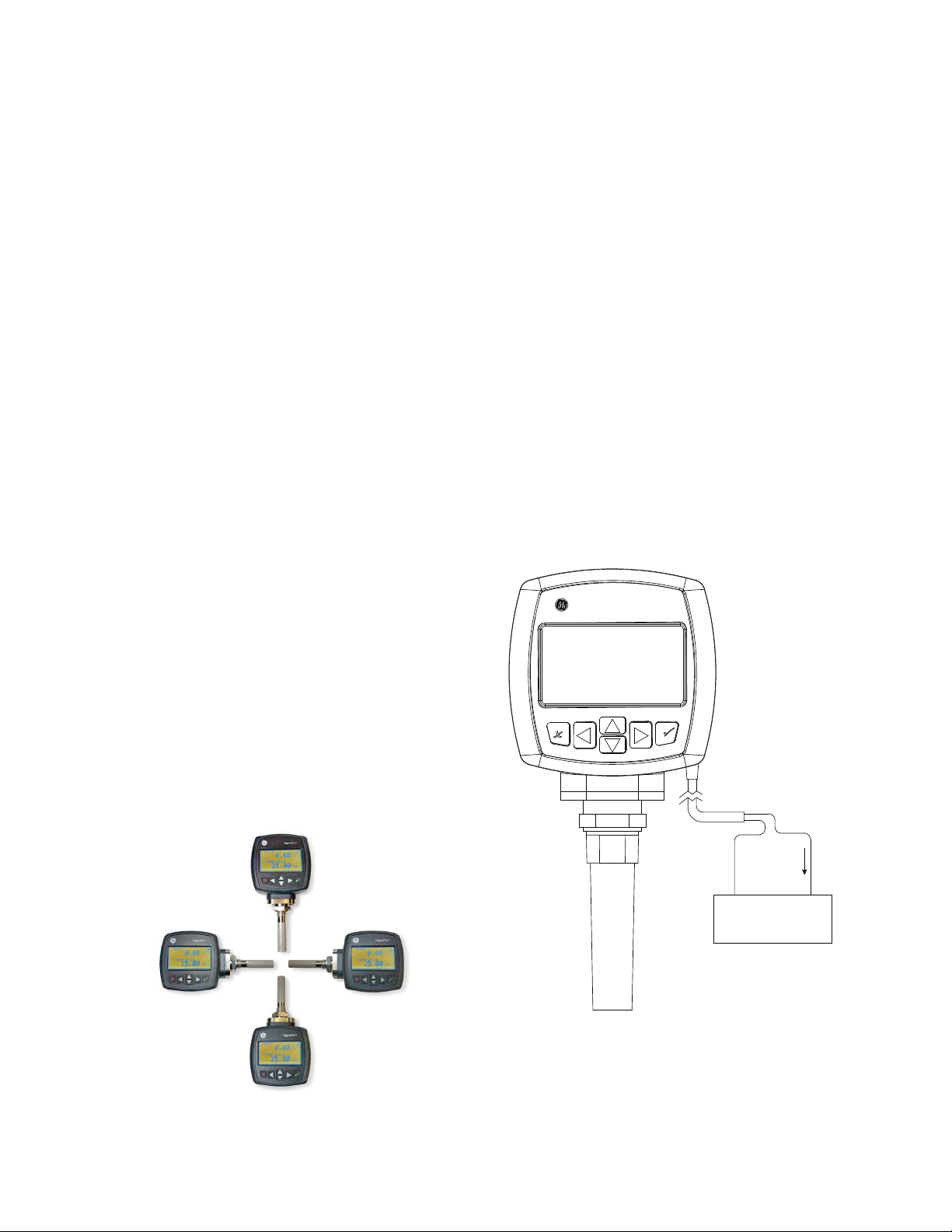

The HygroPro features an integrated backlit display

and six-button keypad to provide viewing of up to

three parameters simultaneously and to allow easy

navigation of the software for confi guration of the

display, analog and digital (RS485) outputs, and other

user functions and diagnostics. Via the RS485 interface,

the HygroPro built-in multidrop capability allow multiple

units to be connected on a single network.

Using an industry-proven aluminum oxide moisture

sensor, the HygroPro features a built-in temperature

thermistor and pressure transducer to provide

realtime measurement for calculation of parameters

such as ppm

in gases, ppmw in liquids, pounds per

v

million standard cubic feet in natural gas or percent

relative humidity. Three sensors mounted on a single

probe mount provide installation fl exibility when

space is limited. In addition, the HygroPro display

can be oriented in four different orientations to allow

installation of the moisture sensor in the top, bottom or

side of a process pipe or sample cell.

Advanced Moisture Sensor Technology

The HygroPro combines a technologically advanced

aluminum oxide moisture sensor with state-of-theart software and electronics for unequaled overall

performance.

NIST-Traceable Calibration

Superior sensitivity, speed of response, calibration

stability, and wide dynamic range have made GE

aluminum oxide moisture probes the standard

of performance and value in industrial moisture

measurement. They are suitable for laboratory and

industrial moisture measurement applications in gases

and non-aqueous liquids over a wide range of process

conditions.

All moisture probe calibrations are traceable to the NIST.

The rugged, compact HygroPro transmitter is designed

specifi cally for installations where space is at a

premium. It can be installed directly in the process

stream or, if necessary, in a sample system. If required,

GE can design and build a sample conditioning system

to meet unique application demands.

HygroPro

™

The HygroPro consists of a display/keypad housing, and

a replacement transducer element (RTE), which contains

the aluminum oxide moisture sensor, temperature

thermistor, and pressure transducer and associated

electronics. The RTE is fi eld replaceable by simply

removing a small mounting plate and disconnecting a

cable. Also, since the calibration data for the moisture

and pressure sensors are stored in a non-volatile

EEPROM in the RTE, a user does not need to enter any

calibration data manually when changing an RTE.

+

12 to 30 VDC

Power and Digital

Measurement

Circuits

Standard Analog Output Connection

Ground

-

Page 3

HygroPro Specifi cations

Dew Point/Frost Point Calibration Ranges

• Overall: 68°F to -166°F (20°C to -110°C)

• Standard: 68°F to -112°F (20°C to –80°C)

Operating Temperature

–4°F to 140°F (–20°C to 60°C)

Storage Temperature

158°F (70°C) maximum

Warm-Up Time

Meets specifi ed accuracy in three minutes

Calibrated Accuracy @ 77°F (25°C)

• ±3.6°F (±2°C) from -85°F to 50°F (–65°C to 10°C)

dew/frost point

• ±5.4°F (±3°C) from –112°F to –86°F (–80°C to –66°C)

dew/frost point

Repeatability

• ±0.9°F (±0.5°C) from –85°F to 50°F (–65°C to 10°C)

dew/frost point

• ±1.8°F (±1.0°C) from –112°F to –86°F (–80°C to –66°C)

frost point

4 in. (102 mm) 2.6 in. (65 mm)

™

HygroPro

g

8 in. (201 mm)

2.7 in. (68 mm)

HygroPro Dimensions

Mechanical

Sample Connection

• 3/4-16 in. (19 mm) straight male thread with O-ring

• G 1/2 with optional adaptor

Response Time

Less than fi ve seconds for a 63% step change in

moisture content in either wet-up or dry-down cycle

Electrical

Power

• Voltage: 12 to 30 VDC

(loop-powered, customer supplied)

• Output: 4 to 20 mA analog, RS485 digital

• Output Resolution: 0.01 mA/12 bits

• Load: Max R = (PSV x 33.33) - 300

Example: (24 x 33.33) - 300 = 500

• Cable: 6 ft (2 m), standard (consult factory for custom

lengths); cable includes molded weatherproof

connector with fl ying leads

Display

• 128 x 64 LED backlit LCD

• Display from one to three parameters and diagnostics

Operating Pressure

5 Hg to 5000 psig (345 bar)

Enclosure

Type 4X/IP67

Dimensions

• H x W x D: 7.88 x 3.99 x 2.56 in. (200 x 101 x 65 mm)

• Weight: 1.2 lb (550 g)

European Compliance

Complies with EMC Directive 2004/108/EC

and PED 97/23/EC for DN<25

Hazardous Area Certifi cation

• C-US Class I, Division 1, Groups A,B,C&D, Type 4X

II 1 G EEx ia IIC T4 (ATEX)

•

• Ex ia IIC T4 (IEC Ex)

Page 4

Moisture Sensor

Sensor Type

Thin-fi lm aluminum oxide moisture sensor

Calibration

Each sensor is individually computer-calibrated against

known moisture concentrations, traceable to NIST.

Calibration Interval

Sensor recalibration by GE is recommended every six to

twelve months depending on application.

Flow Rate

Gases: Static to 100 m/s linear velocity at 1 atm

Built-In Temperature Sensor

Type

NTC thermistor

Operating Range

-22°F to 158°F (-30°C to 70°C)

Accuracy

±0.9°F (±0.5°C) overall

Response Time (Maximum)

One second in well stirred oil or 10 seconds in still air

for a 63% step change in increasing or decreasing

temperature

Built-In Pressure Sensor

HygroPro

Digital Communications Wiring Connection

and Networking Capability

™

- Black

+ White

Power and Digital

Communication

Circuits

RS485

RS485-RS232

Converter Box

PanaView™

Computer

RS232

Ground

Chassis

Type

Solid state/piezoresistive

Available Ranges

• 30 to 300 psig (3 to 21 bar)

• 50 to 500 psig (4 to 35 bar)

• 100 to 1000 psig (7 to 69 bar)

Accuracy

±1% of full scale (FS)

Pressure Rating

Three times the span of the specifi ed range to a

maximum of 7500 psig (518 bar)

• 300 to 3000 psig (21 to 207 bar)

• 500 to 5000 psig (35 to 345 bar)

www.gemeasurement.com

© 2016 General Electric Company. All Rights Reserved. Specifi cations are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product

names mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affi liated with GE.

920-145E

Loading...

Loading...