Page 1

GE

Sensing

FGA311

Panametrics In Situ Flue Gas Oxygen Analyzer

User’s Manual

910-160C1

March 2006

The FGA 311 In Situ Flue Gas Analyzer is a GE Panametrics product. GE Panametrics has joined other GE

high-technology sensing businesses under a new name—GE Industrial, Sensing.

Page 2

March 2006

Warranty Each instrument manufactured by GE Infrastructure Sensing, Inc. is

warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to

normal operation or replacing the instrument, at the sole discretion of

GE Infrastructure Sensing, Inc. Fuses and batteries are specifically

excluded from any liability. This warranty is effective from the date of

delivery to the original purchaser. If GE Infrastructure Sensing, Inc.

determines that the equipment was defective, the warranty period is:

• one year for general electronic failures of the instrument

• one year for mechanical failures of the sensor

If GE Infrastructure Sensing, Inc. determines that the equipment was

damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines

specified by GE Infrastructure Sensing, Inc., the repairs are not

covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties of merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

Return Policy If a GE Infrastructure Sensing, Inc. instrument malfunctions within the

warranty period, the following procedure must be completed:

1. Notify GE Infrastructure Sensing, Inc., giving full details of the

problem, and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for

factory service, GE Infrastructure Sensing, Inc. will issue a RETURN

AUTHORIZATION number (RA), and shipping instructions for the

return of the instrument to a service center will be provided.

2. If GE Infrastructure Sensing, Inc. instructs you to send your

instrument to a service center, it must be shipped prepaid to the

authorized repair station indicated in the shipping instructions.

3. Upon receipt, GE Infrastructure Sensing, Inc. will evaluate the

instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Infrastructure Sensing, Inc. determines that the damage is not

covered under the terms of the warranty, or if the warranty has

expired, an estimate for the cost of the repairs at standard rates

will be provided. Upon receipt of the owner’s approval to proceed,

the instrument will be repaired and returned.

iii

Page 3

March 2006

Table of Contents

Chapter 1: General Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

The Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

The Heater Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2: Installation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Line Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Selecting the Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mounting the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Wiring the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Wiring the Line Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Wiring the Control Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Factory Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Reference Air and Calibration Gas Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Chapter 3: Operation and Programming

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Preventing Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Taking Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Data Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Programming Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Programming with Manual Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Description of Switches and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Manual Programming Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Programming from a Computer Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

RS232 Serial Port Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

The OPTS Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Trim Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Extra Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Chapter 4: Calibration

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Recommended Calibration Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Measuring the Calibration Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

The Calibration Gas System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Calibrating the Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Calibrating with the Manual Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Calibrating with a PC Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Resume Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

v

Page 4

March 2006

Table of Contents (cont.)

Chapter 5: Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Sensor/Heater Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Temperature Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

ER2 Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

ER3 Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

ER4 Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Output Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

All Outputs Inactive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

No RS232 Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Oxygen Reading Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

ER1 Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Oxygen Percentage Always Reads 20.93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Oxygen Percentage Unchanged for more than 15 Minutes . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Oxygen Reading Lower Than Expected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Oxygen Reading Higher Than Expected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Chapter 6: Service and Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Probe Tip Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Cover Removal and Reinstallation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Sensor/Heater Sub-Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Removing the Sensor/Heater Sub-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Installing the Sensor/Heater Sub-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Printed Circuit Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Removing the Printed Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Installing the Printed Circuit Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

EPROM Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Chapter 7: Specifications

Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Functional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Appendix A: The Nernst Equation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Equilibrium Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

The FGA 311 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

vi

Page 5

March 2006

Table of Contents (cont.)

Appendix B: FGA 311 Drawings

Appendix C: CE Mark Compliance

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

LVD Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D: Data Records

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

User Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Test and Calibration Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

vii

Page 6

Chapter 1

Page 7

General Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

The Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

The Heater Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Page 8

March 2006

Introduction The FGA 311 In Situ Flue Gas Oxygen Transmitter monitors the

combustion efficiency of a boiler or furnace by measuring the

percentage of oxygen in the flue gases. This self-contained instrument

is installed so that its zirconium oxide oxygen sensor is located

directly in the stream of the flue gases. The measurements may be

recorded via the built-in 4-20 mA output or transmitted to a computer

terminal via the built-in RS232 interface.

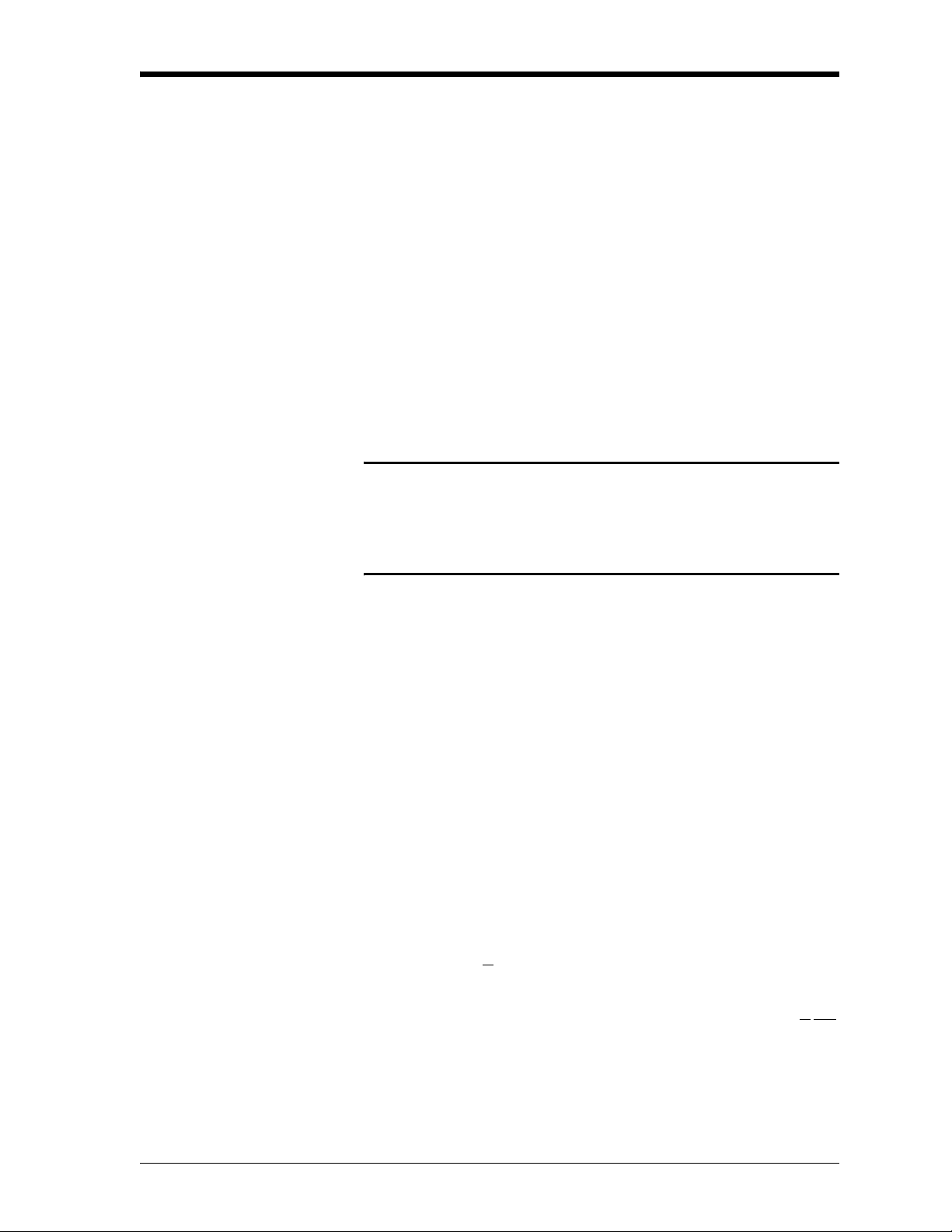

The FGA 311 is available with either the standard weatherproof

enclosure or the optional explosion-proof enclosure, as shown in

Figure 1-1 on page 1-2. However, the operation and the internal

components are the same for both configurations.

The FGA 311 consists of the following sub-assemblies:

• An aluminum enclosure, which includes a breather port, the unit’s

mounting threads, a calibration gas connection and a reference air

connection. In addition, the enclosure houses the printed circuit

board and provides two ports for electrical conduit or cable glands.

• All of the electrical components, including the replaceable fuse,

are mounted on the printed circuit board (PCB). All electrical

connections for the line power, 4-20 mA recorder output and

RS232 interface are made to the PCB.

• A probe assembly that extends into the flue gas stream.

• A heater sub-assembly that maintains the oxygen sensor at the

proper operating temperature for efficient operation.

• A zirconium oxide oxygen sensor to measure the percentage of

oxygen in the flue gases.

• A filter assembly that protects the oxygen sensor from particulates

in the flue gas stream.

The FGA 311 has been designed to permit troubleshooting,

maintenance and adjustment of the instrument without removing the

unit from the flue.

General Information 1-1

Page 9

March 2006

Standard

(Weatherproof)

Explosion-Proof

(Flameproof)

Side Views

Flame Arrestor

R

I

S

R

O

V

U

S

T

T

E

N

S

I

O

N

N

D

E

S

I

G

R

E

N

E

U

O

S

A

P

E

N

D

O

N

O

T

O

P

E

N

E

L

W

I

H

End Views

N

O

D

N

E

P

H

I

W

L

E

N

E

P

O

T

O

A

S

O

U

E

N

E

R

G

I

S

E

D

N

O

I

S

N

E

T

S

U

V

O

R

S

I

R

Flame Arrestors

Figure 1-1: The FGA 311 Enclosures

1-2 General Information

Page 10

March 2006

Principles of Operation In an ideal combustion process, a precise ratio of air to fuel is burned

efficiently to yield only heat, water vapor, and carbon dioxide.

However, because of burner aging, imperfect air to fuel mixtures,

variable firing rates and/or inaccurate ignition timing, this situation

rarely happens.

A sure sign of a less than ideal combustion process is the presence of

excess oxygen in the flue gases. The level of this excess oxygen is

easily monitored with the FGA 311 In Situ Flue Gas Oxygen

Transmitter, and the information can then be used to make the

necessary adjustments to improve the efficiency of the combustion

process. The following two major components are included in the

FGA 311 analyzer:

• a zirconium oxide oxygen sensor

• a loop-controlled heater circuit

These components are described in the sections that follow.

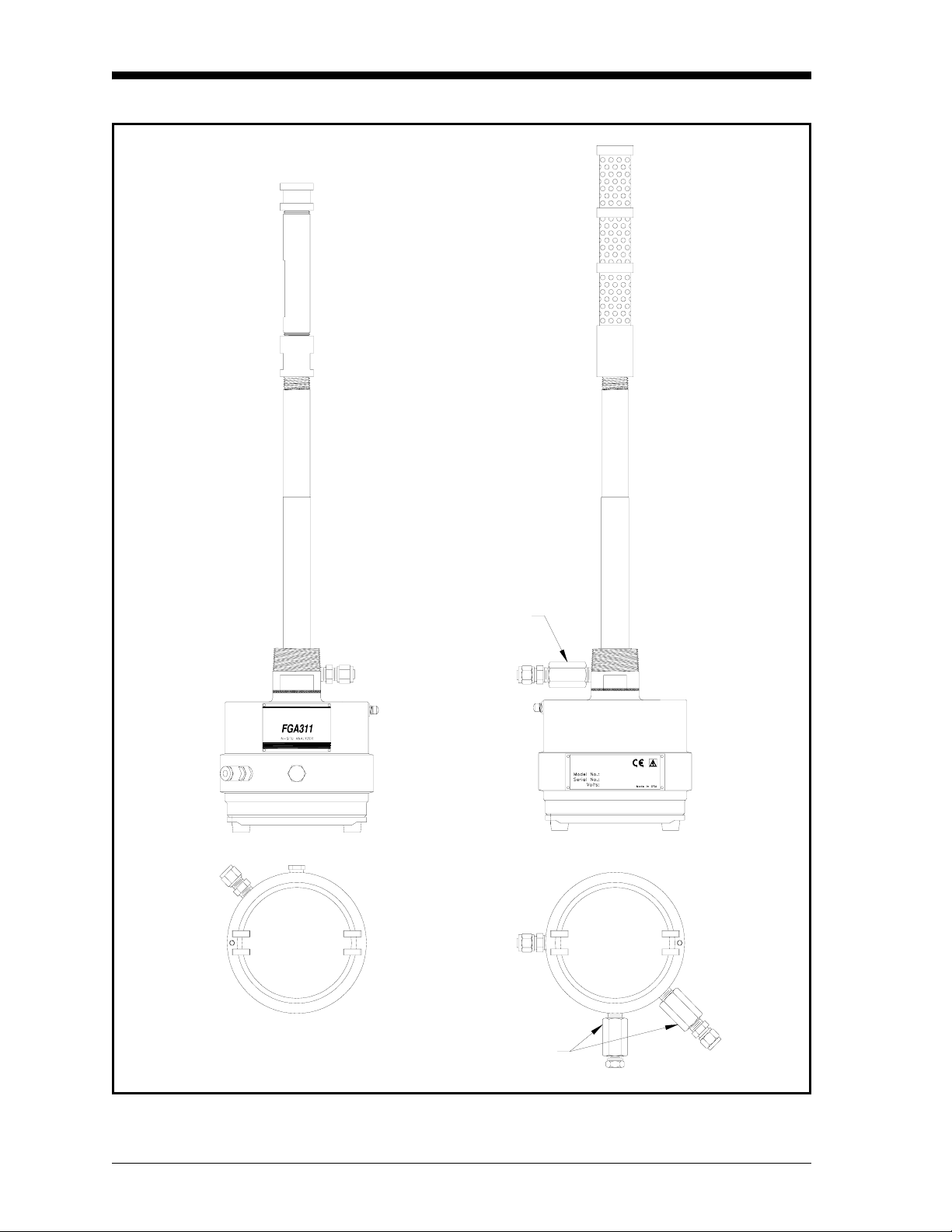

The Oxygen Sensor The inside and outside of the zirconium oxide oxygen sensor are

coated with a porous platinum catalyst, forming two electrodes. Flue

gases flow past the outside of the sensor, while atmospheric air

circulates freely on the inside of the sensor. The atmospheric air is

used as the reference gas for the oxygen measurements. See the

oxygen sensor sub-assembly shown in Figure 1-2 below.

At the normal operating temperature (650° to 1100°C) of the sensor,

the oxygen molecules in the atmospheric reference air (20.93%

oxygen) are electrochemically reduced at the inner electrode. The

resulting oxygen ions seek an equilibrium with the lower oxygen

concentration on the sample gas side of the sensor, by migrating

through the porous ceramic toward the outer electrode.

Packing ScrewSleeveO-Ring

O-Ring Packing Oxygen Cell

Figure 1-2: The FGA 311 Oxygen Sensor

General Information 1-3

Page 11

March 2006

The Oxygen Sensor

(cont.)

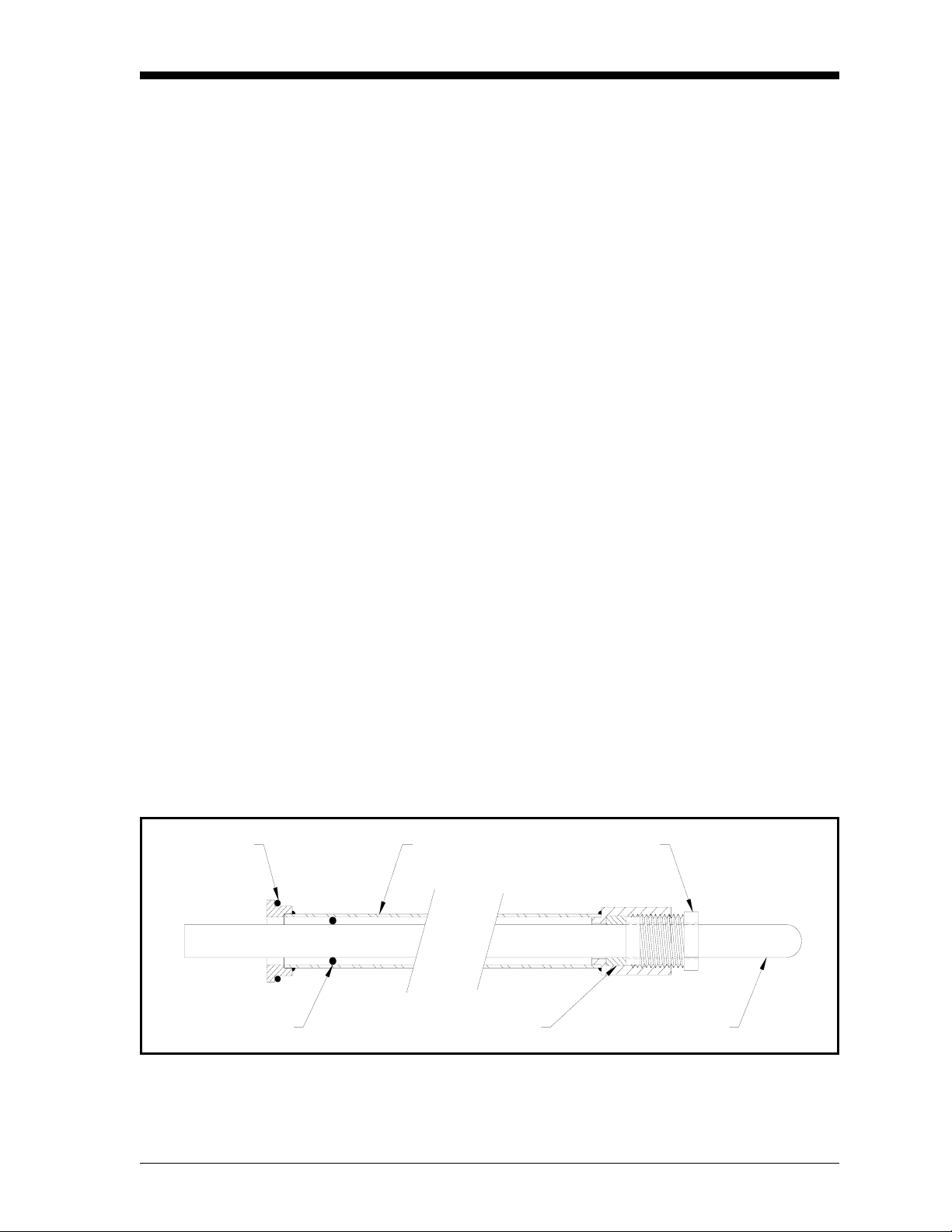

At the outer electrode, the oxygen ions give up their extra electrons

and revert to oxygen molecules, before being swept away by the flue

gas stream. This exchange of electrons at the electrodes generates a

voltage gradient across the sensor. See Figure 1-3 below.

The lower the concentration of oxygen in the flue gases, the greater

the rate of ion migration through the ceramic and the higher the

resulting voltage gradient across the sensor. In fact, the sensor’s

voltage output rises logarithmically as the percentage of oxygen in

the flue gases decreases. This enables the FGA 311 to accurately

measure very small levels of oxygen in the flue gases.

Oxygen ions migrate through the Zirconium Oxide

from Inside to Outside

O

2

O

O

2

2

O

2

O

2

From Outside

Electrode

When O concentration in sample gas falls,

cell voltage rises with increased O migration rate.

Volts

2

O

2

Zirconium Oxide Ceramic

with Lattice Imperfections

From Inside

Electrode

2

Figure 1-3: Oxygen Migration Through the Sensor

1-4 General Information

Page 12

March 2006

The Heater Control Circuit

The oxygen sensor temperature in the FGA 311 is maintained by a

heater, which is part of a complex temperature control loop. This

circuit constantly monitors the oxygen sensor temperature, compares

it to the set point temperature (700°C), and turns the heater ON or

OFF accordingly. The specific type of control circuit used is called a

Proportional Integral Derivative (PID) loop, because of the three

adjustable parameters involved:

• Proportional Band: Because the system cannot respond

instantaneously to temperature changes, the actual temperature of

the oxygen sensor oscillates about the set point. In general,

increasing the proportional band reduces the magnitude of these

temperature oscillations.

• Integral Action: A consequence of increasing the proportional

band is the introduction of an offset between the set point and the

control point. The integral portion of the control loop acts to move

the control point back toward the set point within a specified

period of time. Thus, decreasing this integration time reduces the

offset more quickly.

• Derivative Action: The derivative portion of the control loop

applies a corrective signal based on the rate at which the actual

temperature is approaching the set point. In effect, the derivative

action reduces overshoot by counteracting the control signal

produced by the proportional and integral parameters.

The heater control circuit is configured at the factory for optimum

performance. Because of the strong interaction between the three

parameters involved, properly setting up the PID loop is a very

complex matter. As a result, randomly changing the P, I and/or O

parameters can seriously degrade the performance of the FGA 311.

IMPORTANT: Always contact the factory before attempting to

change the default P, I and/or O values.

General Information 1-5

Page 13

Chapter 2

Page 14

Installation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Line Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Selecting the Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mounting the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Wiring the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Reference Air and Calibration Gas Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Page 15

March 2006

Introduction This chapter gives directions for the proper installation and wiring of

the FGA 311. The following specific topics are included:

• unpacking the unit

• selecting the site

• mounting the analyzer

• wiring the analyzer

!WARNING!

To ensure safe operation of the FGA 311, it must be

installed and operated as described in this manual. In

addition, be sure to follow all applicable local safety codes

and regulations for installing electrical equipment.

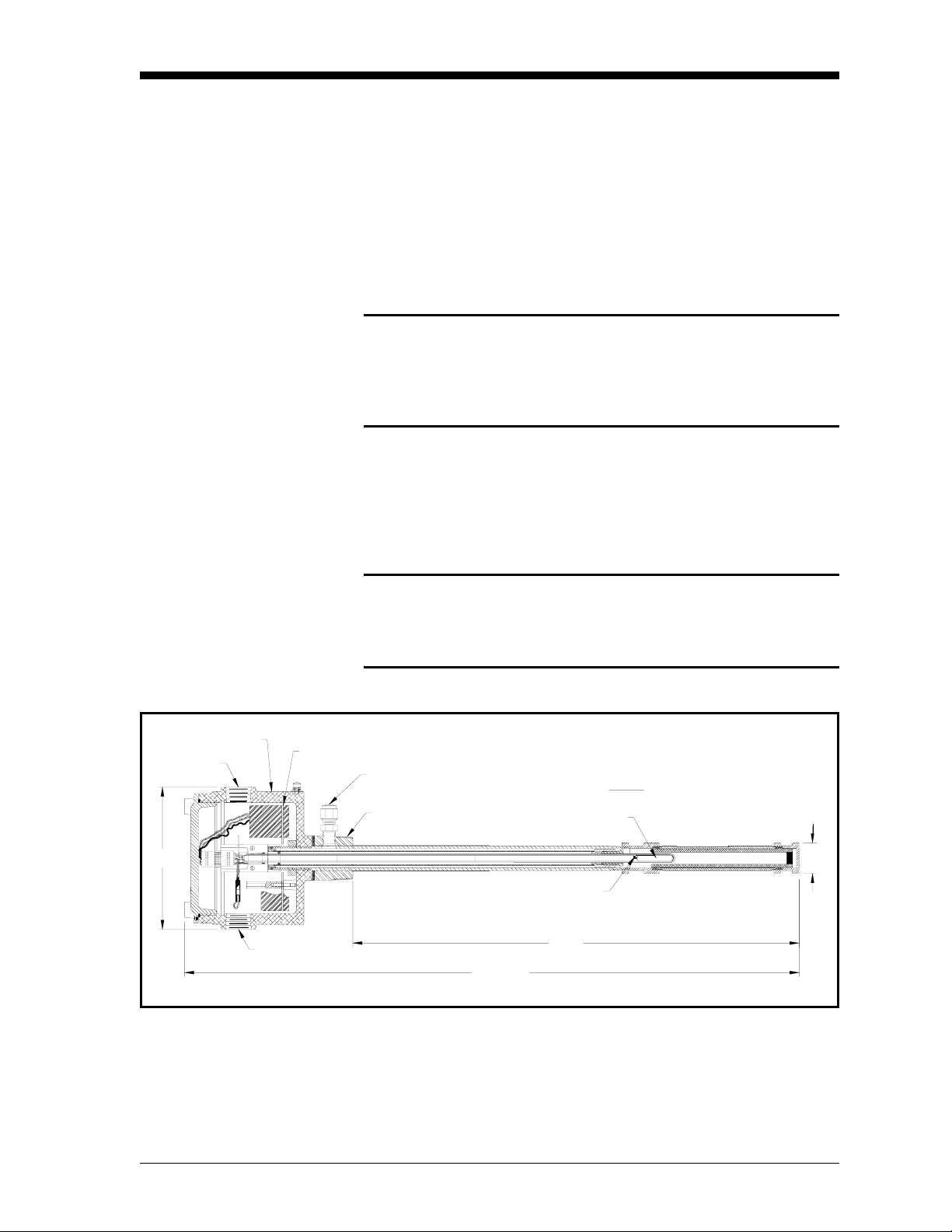

Unpacking the Unit Remove the analyzer from its shipping container and make sure that

all items on the packing slip have been received. If anything is

missing, contact the factory immediately. The analyzer, as shown in

Figure 2-1 below, is shipped fully assembled and ready to install.

3/4" NPT

6"

Enclosure

6

6

5

5

4

4123

123

3/4" NPT

Caution!

When unpacking the analyzer, be careful not to damage

the probe. It is covered with a porous ceramic filter that

will easily crack if it is knocked against a hard surface.

PC Board

Calibration Gas Inlet

1-1/2" NPT

26-1/4"

Heater

19"

Probe

Sensor

Figure 2-1: The FGA 311 In Situ Flue Gas Analyzer

1-1/4"

Installation 2-1

Page 16

March 2006

Line Power Requirements Each FGA 311 analyzer is factory-configured for the proper line

voltage, as specified at the time of purchase. The available options

include the following:

• Japan = 100 VAC

• U.S.A. = 110/120 VAC

• Europe = 220 VAC

• Australia = 240 VAC.

Caution!

To change the line voltage to the unit, contact the factory

for instructions. DO NOT make such a change without first

obtaining proper instructions.

Selecting the Site Environmental and installation factors should already have been

discussed with a GE Sensing applications engineer or field sales

person before the FGA 311 arrives.The analyzer must be installed

either in a furnace or boiler wall or in a flue duct. Ideally, the end of

the probe assembly should extend approximately 1 ft (30.5 cm) into

the flue gas stream. Also, the analyzer should be positioned so that

the probe holes are on the downstream side of the probe (see

Figure 2-2 on page 2-4).

• For furnaces, locate the analyzer close to the combustion zone,

typically within the radiant section and always before the

convection section. Make sure that the probe’s maximum operating

temperature is not exceeded and that the probe is not situated in a

non-homogeneous flue gas mixture.

IMPORTANT: If the ambient temperature in the vicinity of the probe

can exceed 650°C (1202°F), a high temperature

probe assembly is required.

• For boilers, locate the analyzer downstream of the heat exchanger

and just before the economizer air heater, if one is installed. The

analyzer should not be placed downstream of any air heater,

because of possible air leaks that can cause inaccurate readings.

In general, the sample point should be an area of high turbulence,

which will ensure a good homogeneous mixture of the flue gases.

Conditions to be avoided would include air leaks upstream of the

sample point and dead spaces in the vicinity of the sample point.

2-2 Installation

Page 17

March 2006

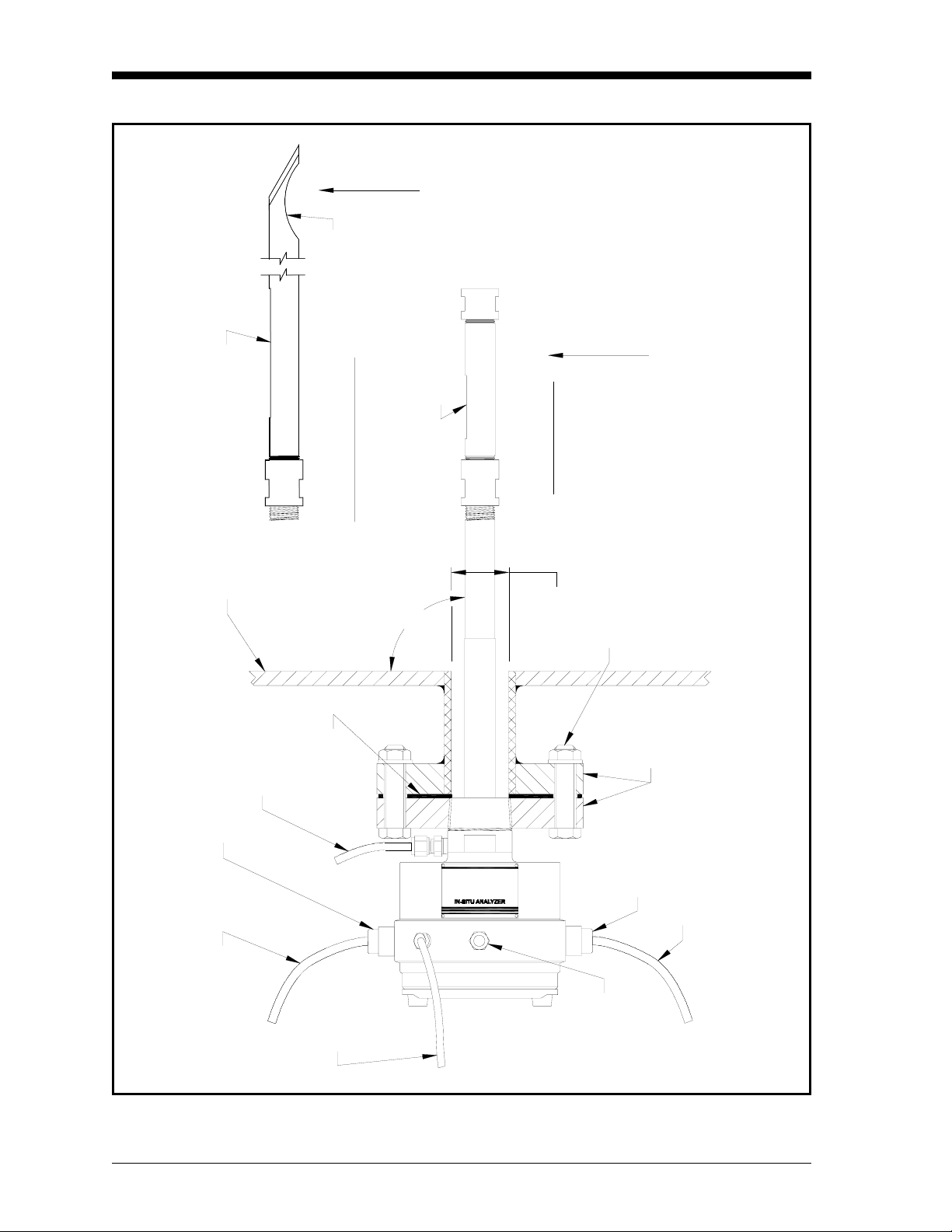

Mounting the Analyzer The FGA 311 has integral male 1-1/2” NPT mounting threads. This

permits a flange to be threaded onto the analyzer, and the resulting

assembly is then bolted to a mating flange on the furnace/boiler wall

or flue duct.

Note: For installations where the FGA 311 may be exposed to water

or other fluids, install the unit with the breather (see

Figure 2-2 on page 2-4) facing downward.

Do not use any thread sealant during the installation. Upon

heating, Teflon tape will melt and other sealants may emit

gases that interfere with the oxygen readings.

Carefully follow the instructions on page 2-5 to mount the FGA 311

In Situ Flue Gas Oxygen Transmitter. The unit may be mounted in

either a horizontal or vertical orientation.

IMPORTANT: Direct mounting of the FGA 311 into a threaded hole

using its mounting threads is not recommended.

Always use a mounting flange.

To prepare the installation site for mounting the analyzer, complete

the following preliminary steps:

1. Fasten a short section of pipe having at least a 2” inside diameter

into the process wall.

IMPORTANT: Make sure that the pipe is long enough to permit

installation of the flange mounting hardware and that

the flange is oriented with its bolt holes straddling

the vertical and horizontal center lines.

2. Weld a mating flange onto the end of the pipe, as shown in

Figure 2-2 on page 2-4.

Note: Standard available factory options include 3”-300 lb ANSI,

4”-150 lb ANSI and DN80 PN16 mounting flanges. A

separate mating flange can also be supplied with the unit.

Installation 2-3

Page 18

March 2006

GAS

FLOW

Input Scoop

GAS

Holes

Holes

FLOW

Standard Probe

Mounting Wall

Cable Gland

Calibration

1m, 1.5m & 2m Probes

90°

2" Min.

Hardware

Flanges

Gas Line

Gasket

FG311

Cable Gland

Control Cable

Power Cable

Reference

Air Line

Breather

Figure 2-2: Flange Mounting the FGA 311

2-4 Installation

Page 19

March 2006

Mounting the Analyzer

(cont.)

Before mounting the FGA 311 analyzer assembly onto the mating

flange, mark the enclosure in line with the probe holes. Then,

complete the following steps:

IMPORTANT: The probe holes must be positioned on the

downstream side of the probe. See Figure 2-2 on

page 2-4 for the proper orientation.

1. Slide the gasket over the probe assembly and up against the

mounting flange on the analyzer.

Note: Be sure to use a suitable high temperature gasket for this

application.

2. Orient the analyzer so the probe holes are properly positioned on

the downstream side of the probe, and slide the probe through the

hole in the mounting wall until the two flanges meet.

3. Secure the analyzer in place by fitting bolts into the matching

flange mounting holes and fastening the bolts with nuts and

washers. Make sure that the gasket is properly positioned between

the two flanges.

This completes the mounting of the FGA 311. The required external

connections are discussed in the following sections.

Installation 2-5

Page 20

March 2006

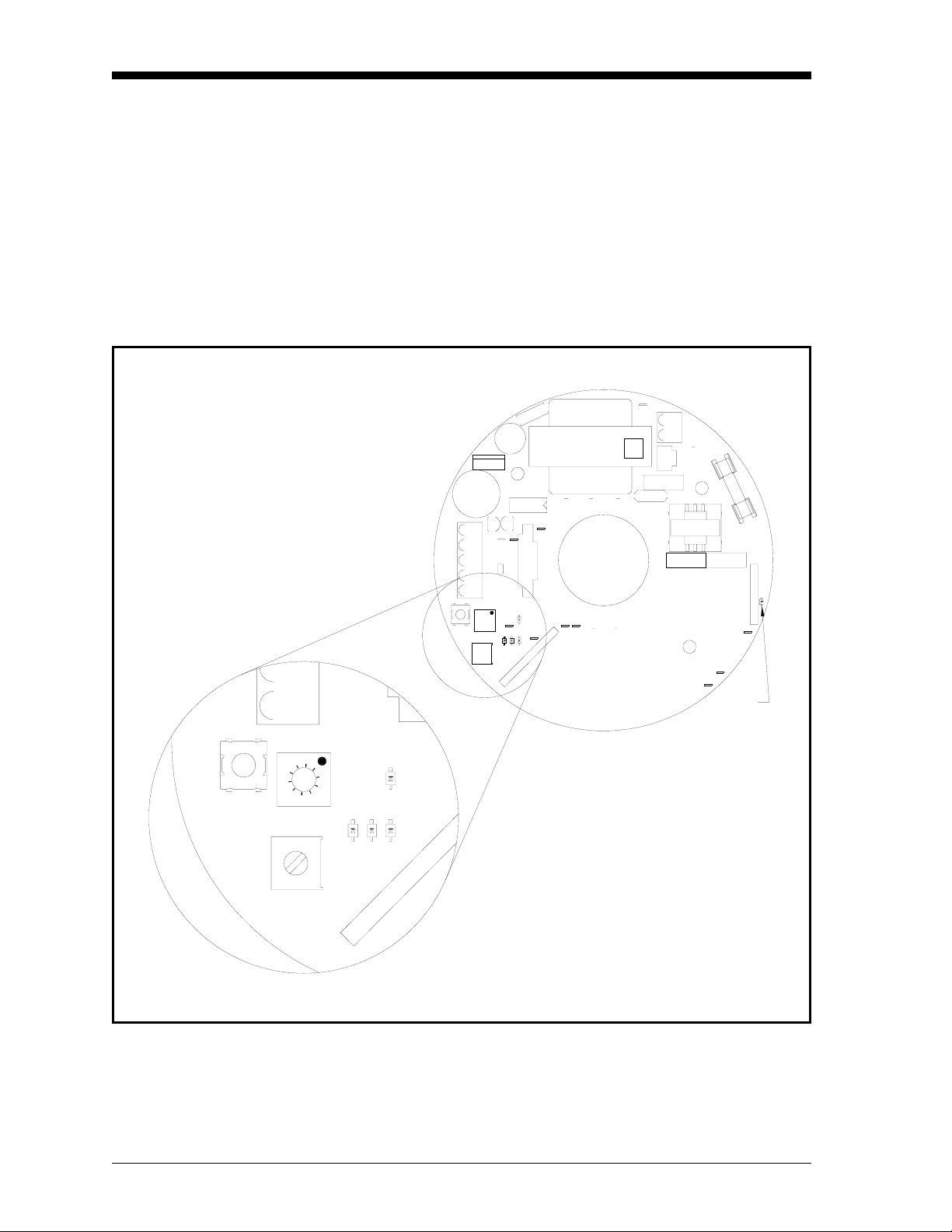

Wiring the Analyzer Connect the power and control signal wiring as described below and

as shown in Figure 2-3 on page 2-7, which shows the printed circuit

board mounted within the open FGA 311 enclosure. The necessary

connectors are supplied with the unit, and they are plugged into the

mating connectors on the printed circuit board prior to shipment. DO

NOT power up the unit until instructed to do so!

ATTENTION EUROPEAN CUSTOMERS!

In order to meet CE Mark requirements, all electrical cables

must be installed as described in Appendix C, CE Mark

Compliance.

Wiring the Line Power Use one of the 3/4” NPT connections on the enclosure for installation

of the power cable gland or conduit. The FGA 311 has been preset at

the factory for the line voltage specified at the time of purchase.

Never connect a different line voltage to the unit without first

obtaining instructions from the factory.

!WARNING!

Improper connection of the power line or connection to the

wrong voltage may result in an electrical hazard.

Note: For compliance with the European Union’s Low Voltage

Directive (73/23/EEC), this unit requires an external power

disconnect device such as a switch or circuit breaker. The

disconnect device must be marked as such, clearly visible,

directly accessible, and located within 1.8 m (6 ft) of the

FGA 311.

The FGA 311 is designed to comply with the LVD Directive

per the requirements of EN 61010 with the following

exception: The 230 VAC unit passes with a test voltage of

1,800 VAC. (Refer to Table D.10 of Annex D in EN 61010.)

Connect the line power to terminal block TB1, as shown in Figure 2-3

on page 2-7, by completing the following steps:

1. Connect the

2. Connect the

LINE (black) lead to pin #1 on TB1.

NEUTRAL (white) lead to pin #2 on TB1.

3. Connect the

GROUND (green) lead to the earth ground screw inside

the enclosure.

Proceed to the next section to wire the control signals.

2-6 Installation

Page 21

March 2006

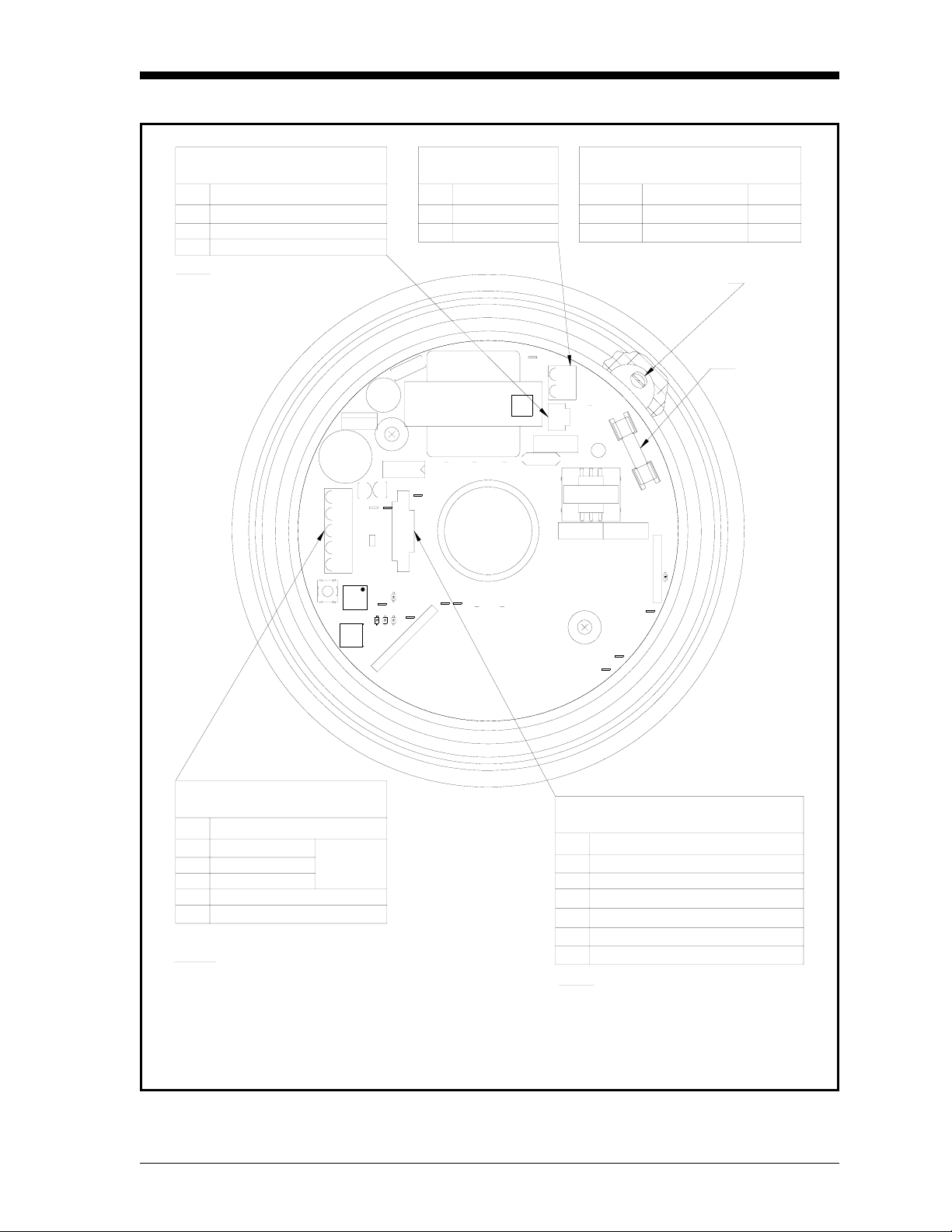

Heater Connections

J3 Terminal Block

Pin

1

2

3

Description

Heater

No Connection

Heater

NOTE: These connections are made

at the factory.

U15

+

C1

1

E4

TB2

MODE

CAL

S3

ADJ

S1

S2

TB1 Power*

Terminal Block

Description

Pin

1

Line

Neutral

2

Power Voltage Options

Factory Installed

Power Jumpers Fuse

115V W1,W3,W4,W5 1/2A

W2,W6230V 1/4A

*Ground wire goes to

earth gnd connection.

6

7

8

2

3

C1

+

C2

U5

1

3

9

2

1

R

U

V

0

1

E

4

3

R

1

FAULT

10E85

2

1

S

S

D

D

W4

W6 W5

E6

J2

4

E11 E12

S

D

E9

25

3

S

D

J1

W2

1

703-1216

T1

TB1

E3

1

W3

J3

C16

F1

3

L1

4

C15

U18

5

S

D

E7

E2

E1

E5

3

1

5

4

W1

RT1

C14

1

2

Fuse

RS232 Analog Output

TB2 Terminal Block

Pin Description

1Return

2 Receive

3Send

4 4-20 mA Out–

5 4-20 mA Out+

RS232

Thermocouple and Sensor

J2 Terminal Block

Pin

1

Thermocouple +

2

Thermocouple –

3

Zirconium Oxide Oxygen Sensor +

Zirconium Oxide Oxygen Sensor –

4

Description

Future Use (CJC+)5

NOTES:

1. PC Board may be oriented differently,

depending on how the unit is installed.

Future Use (CJC–)6

NOTE: These connections are made

at the factory.

2. J1 is reserved for future use.

(Shown with sensor/heater assembly and cable removed for clarity.)

Figure 2-3: Connections to the FGA 311 PC Board

Installation 2-7

Page 22

March 2006

Wiring the Control Signals Use the remaining 3/4” NPT port on the FGA 311 enclosure for

connecting the control cable gland or conduit. For cable runs of less

than 5 m (16.4 ft), standard twisted pair cable may used for these

connections. However, shielded cable should be used for longer cable

lengths and/or for CE Mark compliance.

IMPORTANT: This symbol indicates Caution - risk of electric

shock:

The control signal connections are made to the printed circuit board

on terminal block TB2, as shown in Figure 2-3 on page 2-7. To make

the necessary connections, complete the following steps:

1. Connect the RS232 serial port leads to TB2 as follows:

Note: The serial port connection should be made with a GE Sensing

#704-668 cable assembly or its equivalent. To assemble an

equivalent cable, refer to Figure B-6 in Appendix B of this

manual.

a. Connect the

Ground lead (the green wire from pin #5 of the

DB9 connector on the PC) to pin #1.

b. Connect the

Receive lead (the red wire from pin #2 of the DB9

connector on the PC) to pin #2.

c. Connect the

Transmit lead (the white wire from pin #3 of the

DB9 connector on the PC) to pin #3.

2. Connect the 4-20 mA analog output leads to TB2 as follows:

a. Connect the 4-20 mA

b. Connect the 4-20 mA

Return (-) lead to pin #4.

Signal (+) lead to pin #5.

Proceed to the next section for a description of the internal, factoryinstalled wiring.

2-8 Installation

Page 23

March 2006

Factory Connections In addition to the user connections described above, the following

connections are made at the factory to terminal blocks J2 and J3.

• Thermocouple connections to J2 on pins #1 (+) and #2 (-).

• Oxygen sensor connections to J2 on pins #3 (+) and #4 (-).

• Heater connections to J3 on pins #1 and #3.

For reference purposes only, these factory connections are shown in

Figure 2-3 on page 2-7.

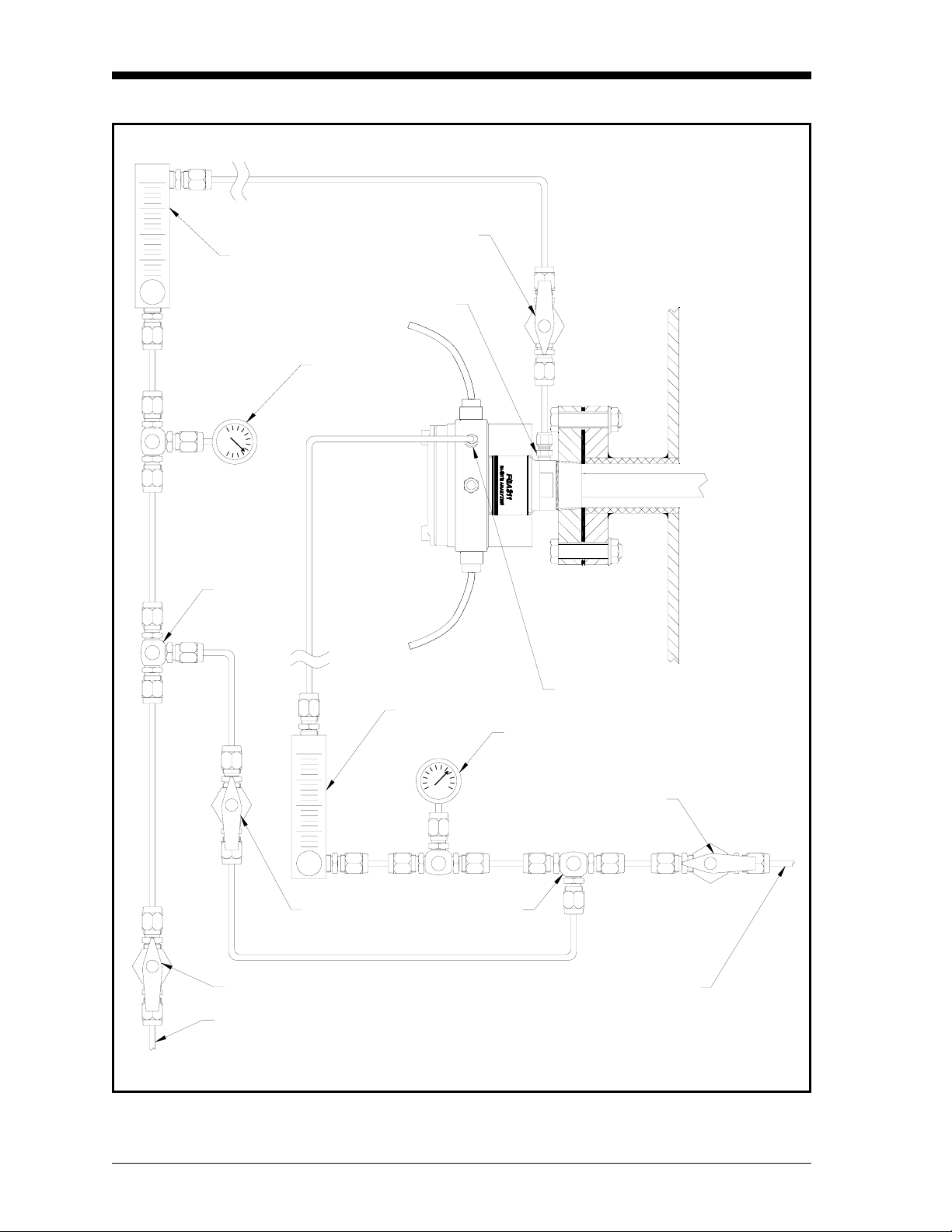

Reference Air and Calibration Gas Lines

During normal operation, the FGA 311 requires a constant supply of a

reference air for the zirconium oxide oxygen sensor. The

recommended gas for this purpose is instrument air (containing

20.93% oxygen) at a flow rate of 20-50 cc/min. Connect this gas

supply, with 1/4” tubing, to the 1/4” compression fitting provided.

Refer to Figure 2-4 on page 2-10 for the location of this connector.

Also, a separate gas supply is required for calibration of the

instrument. This line should be connected, with 1/4” tubing, to the

remaining 1/4” compression fitting on the FGA 311. See Figure 2-4

on page 2-10 for the location of this connector.

Note: The calibration gas port must remain capped, if no permanent

plumbing is attached. See Chapter 4, Calibration, for a

discussion of the recommended calibration gases and

procedures.

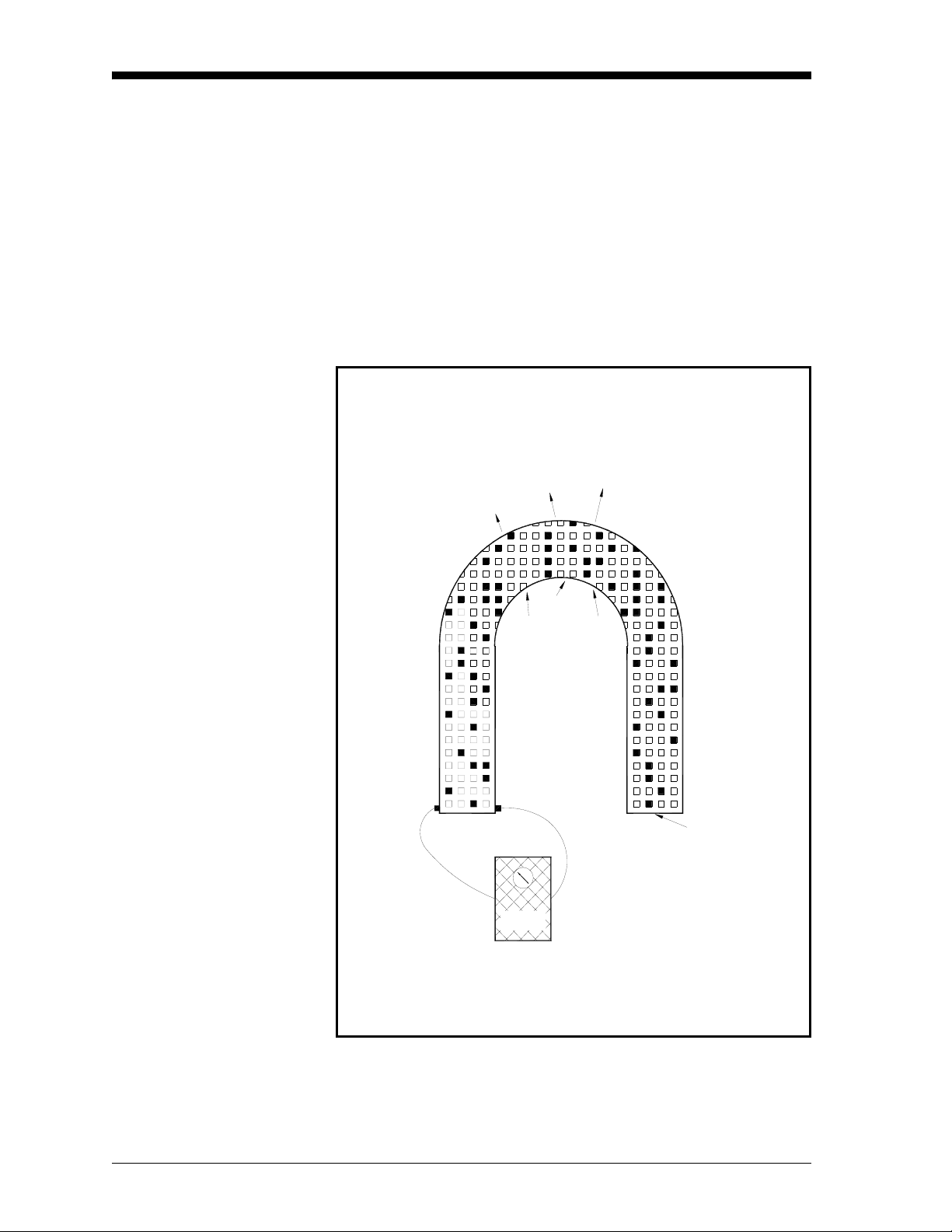

In addition to the basic reference air and calibration gas lines, a

variety of ancillary equipment is recommended. A typical system that

will ensure efficient and reliable operation of the FGA 311 is

illustrated in Figure 2-4 on page 2-10.

Installation 2-9

Page 24

March 2006

Valve

Flowmeter

Calibration Gas Inlet

Gauge

Tee

Valve

Valve

Calibration Gas Supply

Reference Air Inlet

Flowmeter

Gauge

Valve

Tee

Reference Air Supply

Figure 2-4: A Typical FGA 311 System

2-10 Installation

Page 25

Chapter 3

Page 26

Operation and Programming

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Preventing Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Taking Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Data Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Programming Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Programming with Manual Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Programming from a Computer Terminal . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Page 27

March 2006

Introduction Since the FGA 311 In Situ Flue Gas Oxygen Transmitter is a

monitoring device, operation of the installed analyzer is simple. Once

it has been properly installed and set up, it will simply begin taking

readings. However, the analyzer should be allowed to warm up for at

least one hour (three hours if possible) prior to use. See Chapter 2,

Installation, if all of the required installation requirements have not

yet been completed.

Calibration of the unit should be checked once or twice a week for the

first month of operation and once every 2-3 months thereafter. See

Chapter 4, Calibration, for the correct procedures.

!WARNING!

To ensure safe operation of the FGA 311, it must be

installed and operated as described in this manual. In

addition, be sure to follow all applicable local safety codes

and regulations for installing electrical equipment

Preventing Common Problems

Because of the extreme conditions in monitoring flue gases and the

complexity of the FGA 311’s measurement techniques, some simple

precautions should be taken with the instrument. Failure to observe

these basic procedures can lead to operational difficulties.

Compliance with the following instructions will help to eliminate

such common problems:

• Do not use pipe thread compounds on any part of the FGA 311.

Many pipe thread compounds emit combustible vapors that may

cause inaccurate readings.

• Do not handle the sensor assembly any more than is absolutely

necessary. Although some scratches on the platinum electrode can

be tolerated, rubbing the coating should be avoided. Also, the

transfer of skin oils to the electrode can cause erroneous readings.

• Scrubbing the sensor while washing it or washing a hot sensor can

damage or destroy it. Clean the sensor only by rinsing it with clean

water, after the sensor has cooled.

• Installing a cold probe assembly into a hot flue gas stream can

cause damage to the filter and/or sensor. Always allow the probe

assembly to gradually heat up to normal operating temperature,

before subjecting it to hot flue gases.

If any problems not covered in this manual are encountered, contact a

GE Sensing representative for assistance.

Operation and Programming 3-1

Page 28

March 2006

Powering Up Before powering up the unit, start the flow of reference air. Be sure

that the reference air source is connected to the correct port, as shown

in Figure 2-4 on page 2-9. As stated in Chapter 2, Installation, the

recommended reference air is instrument air (20.93% oxygen) at a

flow rate of 20-50 cc/min.

Note: The zirconium oxide oxygen sensor can not provide accurate

readings without a known oxygen percentage on the reference

side of the cell. Allow the reference air to flow for at least five

minutes prior to operation.

Power may now be applied to the unit. Since the FGA 311 does not

have its own power switch, the main disconnect must be used to

power the analyzer on. Simply place this switch in the ON position,

and allow the analyzer to warm up for at least one hour (three hours if

possible) before taking any readings.

Note: For compliance with the European Union’s Low Voltage

Directive (73/23/EEC), this unit requires an external power

disconnect device such as a switch or circuit breaker. The

disconnect device must be marked as such, clearly visible,

directly accessible, and located within 1.8 m (6 ft) of the

FGA 311.

The FGA 311 is designed to comply with the LVD Directive

per the requirements of EN 61010 with the following

exception: The 230 VAC unit passes with a test voltage of

1,800 VAC. (Refer to Table D.10 of Annex D in EN 61010.)

The red fault light (DS4) and one of the green oxygen range

indicators (DS1, DS2 or DS3) on the printed circuit board will blink

until the FGA 311 has reached its normal operating temperature of

700°C. Then, the fault light will go out and the range indicator will

glow steadily.

3-2 Operation and Programming

Page 29

March 2006

Taking Measurements After the FGA 311 has warmed up, the voltage output of the

zirconium oxide oxygen sensor will vary logarithmically with the

oxygen concentration in the flue gases, according to the Nernst

equation (see Appendix A, The Nernst Equation, for details):

20.93

EmV()48.274

In Equation 3-1 above, “E” is the voltage in millivolts generated by

the sensor at an operating temperature of 700°C.

The built-in thermocouple temperature sensor in the FGA 311

automatically adjusts the constant used in the Nernst equation to

reflect the precise actual temperature of the oxygen sensor. In

addition, the non-linear output voltage signal generated by the oxygen

sensor is internally converted into a linear 4-20 mA output current

signal, which is sent to pins 4 and 5 of terminal block TB2. The 4-20

mA current range corresponds to a flue gas oxygen range of 0% to the

programmed O

ammeter or a recording device to these terminals, the oxygen content

of the flue gases may be continuously monitored.

range (5, 10 or 25%). By connecting a digital

2

-------------

log•=

%O

2

(3-1)

Data Records Appendix D, Data Records, at the back of this manual provides

several tables for entering all of the relevant data pertaining to the

installation and programming of the FGA 311. Be sure to maintain

the accuracy of this data on a regular basis. In the event of problems

with the unit, the data records may provide valuable information to

assist in the troubleshooting procedure.

Menu Map A complete menu map of the FGA 311’s built-in software is shown in

Figure 3-3 on page 3-22. Refer to this figure as needed to supplement

the step-by-step programming instructions that follow.

Programming Options The following two methods for programming the FGA 311 In Situ

Flue Gas Oxygen Transmitter may be used to navigate through the

User Program:

• manual switches, which are located inside the enclosure, on the

analyzer’s printed circuit board

• a terminal or computer, utilizing the unit’s built-in RS232 serial

interface

Note: The entire

programming switches.

EXTRA menu is not accessible via the manual

Operation and Programming 3-3

Page 30

March 2006

Programming with Manual Switches

CAL

S3

MODE

9

8

7

6

5

4

Manual programming of the FGA 311 is accomplished with a series

of switches and LEDs located on the printed circuit board. These

components, which are shown in Figure 3-1 below, may be accessed

by removing the cover from the FGA 311.

Although the menu map shown in Figure 3-3 on page 3-22 does apply

to both the manual programming mode and the RS232 programming

mode, some of the programming options are not available via the

manual switches. Specifically, the entire EXTRA menu can not

accessed via the PC board switches.

6

78

W2

W1

T1

TB1

E3

1

W3

C14

J3

C16

F1

3

L1

4

C15

U18

E7

E2

E1

E5

3

1

5

RT1

1

2

DS5

0

1

2

3

TB2

S1

5 10

E8

1

FAULT

4

S

D

25

E9

2

3

1

C

U15

+

C2

1

U5

+

C1

1

CAL

S3

TB2

MODE

ADJ

9

2

1

R

U

V

E4

0

1

E

4

3

R

1

S1

FAULT

10E85

25

3

2

1

S

S

S

D

D

D

S2

34

W4

W6 W5

E6

J2

4

E11 E12

S

D

E9

1

J1

703-1216

5

S

D

1

2

3

S

S

S

D

D

S2

D

ADJ

Figure 3-1: Circuit Board Switches and LEDs

3-4 Operation and Programming

Page 31

March 2006

Description of Switches and LEDs

The following switches and lights will be found on the printed circuit

board of the FGA 311:

• MODE Switch S1: a 10-position rotary switch that is used to select

the desired menu option.

• ADJ Switch S2: a rotary encoder switch used to adjust the value of

numeric menu options selected with Switch S1.

• CAL Switch S3: a push-button switch used to enter and exit

programming mode and to confirm the programming option set

with Switch S1.

• DS1-DS3: three green LEDs that are used to indicate the selected

oxygen range setting.

• DS4: a red LED that is used as a fault indicator.

• DS5: a yellow LED that indicates the heater duty cycle.

The specific menu options that may be selected with the 10-position

rotary

MODE Switch S1 are listed in Table 3-1 below.

Table 3-1: MODE Switch S1 Positions

Switch Position Menu Option

0TST

1AIR

2GAS

3RNG

4TRIM_O2 4mA

5 TRIM_O2 20mA

6Not Used

7Not Used

8Not Used

9Not Used

Note: Only six of the ten positions on Switch S1 (0-5) are currently

active. Positions 6–9 are not used at this time.

Navigating through the FGA 311’s built-in User Program software is

easily accomplished by completing the detailed steps in the following

section.

Operation and Programming 3-5

Page 32

March 2006

Manual Programming Instructions

Use the following instructions to program the FGA 311 with the

printed circuit board switches:

Set Switch S1 = 0 Push

CAL Switch S3 and hold for 5

seconds to access the TST option.

The red Fault LED (

DS4) will light

if the sensor is bad, or the three

green LEDs (

DS1-DS3) will light if

the sensor is good. Press Switch S3

and hold for 5 seconds to

EXIT

programming mode.

Set Switch S1 = 1 Push

CAL Switch S3 and hold for 5

seconds to set the AIR calibration.

A green LED will blink until the

calibration is complete. Press

Switch S3 and hold for 5 seconds

to

EXIT programming mode.

IMPORTANT: Always complete the

attempting the

LED may glow temporarily during the

AIR calibration before

GAS calibration. Also, The red fault

GAS

calibration procedure.

Set Switch S1 = 2 Push

CAL Switch S3 and hold for 5

seconds to set the

Adjust the value with

GAS calibration.

ADJ Switch

S2 until a green LED starts

blinking. Press Switch S3 and hold

for 5 seconds to EXIT programming

mode.

Note: Refer to Chapter 4, Calibration, for a detailed description of

the calibration procedures.

Set Switch S1 = 3 Push

CAL Switch S3 and hold for 5

seconds to access the RANGE

option. The current O

range LED

2

will blink. Adjust the value with

ADJ Switch S2 until the green

LEDs start blinking. Press Switch

S3 and hold for 5 seconds to EXIT

programming mode.

3-6 Operation and Programming

Page 33

Manual Programming

Instructions (cont.)

March 2006

Set Switch S1 = 4 Push

CAL Switch S3 and hold for 5

seconds to access the TRIM_O2

4mA option. Adjust the value with

ADJ Switch S2 until the output

signal reads 4 mA. Press Switch

S3 and hold for 5 seconds to EXIT

programming mode.

Note: For the TRIM_O2 function, always adjust the 4 mA setting

before

the 20 mA setting. This will ensure optimum accuracy

of the instrument.

Set Switch S1 = 5 Push

CAL Switch S3 and hold for 5

seconds to access the TRIM_O2

20mA option. Adjust the value

with

ADJ Switch S2 until the

output signal reads 20 mA. Press

Switch S3 and hold for 5 seconds

to EXIT programming mode.

After the programming has been completed, reinstall the cover on the

FGA 311 enclosure. Do not operate the FGA 311 permanently with

the cover removed.

Operation and Programming 3-7

Page 34

March 2006

Programming from a Computer Terminal

In the following instructions, the actual terminal screen display is

shown in the left column, while the required user response is shown

in the right column. Keyboard inputs are indicated by square brackets

(i.e. [ESC] means to press the “escape key” on the keyboard). Also, to

change a displayed numeric value, use the

[+] and [-] keys to adjust the

current value to the desired setting.

For reference, the screen display of a typical menu line is shown in

Figure 3-2 below. This figure pictures the menu line that appears on

the terminal screen, as soon as the User Program has been accessed.

Note the location of the selection brackets, which highlights the

current menu choice.

Menu Choices

TRIM EXTRA[OPTS]

Selection Brackets

Figure 3-2: A Typical Menu Line

Navigating through the User Program is easy, using the keystrokes in

Table 3-2 below and the instructions in the following sections.

Table 3-2: Computer Terminal Keyboard Entries

Desired Action Keyboard Entry

Move from run mode to programming mode [ESC]

Move from programming mode to run mode

Move selection brackets

Enter numerical data

Confirm selection or entry

Start entry over again

Move up one level in program

[ESC]

[SPACE]

, [-]

[+]

[ENTER]

[BACKSPACE]

[BACKSPACE]

Note: The use of any keys on the keyboard other than those listed in

Table 3-2 above will not be recognized by the FGA 311. Any

such keyboard entries will simply be ignored by the analyzer.

[+] is a shifted key, and the [SHIFT] key must be held while

Also,

striking it.

3-8 Operation and Programming

Page 35

March 2006

RS232 Serial Port Settings Before the FGA 311 may be programmed via its built-in RS232

interface, the serial port of the personal computer (PC) must be

configured to the following specifications:

• 9600 Baud

• 8 Data Bits

• 1 Stop Bit

• No Parity

• Xon/Xoff Flow Control

Note: If the RS232 connection still does not work, try reversing the

leads on pins 2 and 3 of terminal block

Refer to the computer’s documentation for the correct procedures to

configure and access the serial port. Then, proceed to the next section

to begin programming the analyzer.

The OPTS Menu Use the following procedure to move through the OPTS menu.

TB2.

RUN 20.93% O2 700.0C Press

Note: While in the

time by pressing the

[OPTS] TRIM EXTRA Make sure

OPTS menu, you may return to run mode at any

[ESC] key.

[ESC] to move from run mode

to the main menu.

OPTS is highlighted and

then press

[ENTER].

Oxygen Sensor Test IMPORTANT: The oxygen sensor test must be done while the

instrument is measuring

[TST] AIR GAS RNG Make sure TST is highlighted and

then press

TEST PASSED xxx.x% One of these two screens will

appear. Press

TEST FAILED xxx.x%

to the

GAS (not AIR).

[ENTER].

[BACKSPACE] to return

OPTS menu.

Press

[ESC] to return to run mode, or proceed to the next section to

continue programming the

Operation and Programming 3-9

OPTS menu.

Page 36

March 2006

Air Measurement

Calibration

TST [AIR] GAS RNG Press [SPACE] to select AIR and

then press

[ENTER].

Gas Measurement

Calibration

AIR 20.93%O2 xxx.xC Press

[ENTER] to accept the new

offset value and

return to the

just press

OPTS menu.

the

[BACKSPACE] to

OPTS menu. To abort,

[BACKSPACE] to return to

Note: Refer to Chapter 4, Calibration, for a detailed description of

the calibration procedures.

[ESC] to return to run mode, or proceed to the next section to

Press

continue programming the

OPTS menu.

TST AIR [GAS] RNG Press [SPACE] to select GAS and

then press

GAS [x.xx]%O2 xxx.xC Adjust the

and

[ENTER].

O2 value with the [+]

[-] keys. Press [ENTER] to

accept the new value and

[BACKSPACE] to return to the OPTS

menu. To abort, just press

[BACKSPACE] to return to the OPTS

menu.

Press [ESC] to return to run mode, or proceed to the next section to

continue programming the

OPTS menu.

Set Oxygen Range

TST AIR GAS [RNG] Press [SPACE] to select RNG and

then press

[O2_RNG] TEMP_RNG Make sure

then press

5% [10%] 25% Press

oxygen range and press

Press

RNG menu.

3-10 Operation and Programming

[ENTER].

O2_RNG is selected and

[ENTER].

[SPACE] to select the desired

[ENTER].

[BACKSPACE] to return to the

Page 37

March 2006

Trim Menu Use the following procedure to move through the TRIM menu.

Trim Oxygen Output

RUN 20.93%O2 700.0C Press

[ESC] to move from run mode

to the User Program.

Note: While in the

time by pressing the

OPTS [TRIM] EXTRA Press

TRIM menu, you may return to run mode at any

[ESC] key.

[SPACE] to select TRIM and

then press

[ENTER].

[TRIM_O2] TRIM_TEMP Make sure TRIM_O2 is highlighted

and press

[ENTER].

Note: For the TRIM_O2 function, always adjust the 4 mA setting

before the

20 mA setting. This will ensure that the instrument

operates at optimum accuracy.

TRIM_O2 mA: [4] 20 Make sure “

then press

4” is highlighted and

[ENTER].

4mA_O2 [xxx] ADJUST Using

[+] and [-], adjust the value

to obtain an output signal of 4 mA.

[ENTER] to accept the new

Press

value. Press

[BACKSPACE] to back

up one menu level.

TRIM_O2 mA: 4 [20] Press

20mA_O2 [xxx] ADJUST Using

[SPACE] to select “20” and

then press

[ENTER].

[+] and [-], adjust the value

to obtain an output signal of 20

mA. Press

new value. Press

[ENTER] to accept the

[BACKSPACE]

twice to return to the

Press

[ESC] to return to run mode, or proceed to the next section to

continue programming the

TRIM menu.

TRIM menu.

Operation and Programming 3-11

Page 38

March 2006

Extra Menu Use the following procedure to move through the EXTRA menu.

RUN 20.93%O2 700.0C Press [ESC] to move from run mode

to the User Program.

Selecting Terminal Type

Note: While in the

time by pressing the

OPTS TRIM [EXTRA] Press

[COM] ERR PID FRZ RESP OFST

[TTY] ANSI Press

EXTRA menu, you may return to run mode at any

[ESC] key.

[SPACE] to select EXTRA and

then press

[ENTER].

Make sure COM is selected and

then press

[SPACE] to select the desired

option and then press

return to the

[BACKSPACE].

[ENTER].

[ENTER]. To

EXTRA menu, press

Note: Select TTY to interface the FGA 311 with a Teletype terminal,

or select ANSI to use a computer terminal that communicates

via the standard ASCII character set. For most modern

personal computers, select the ANSI option.

[ESC] to return to run mode, or proceed to the next section to

Press

continue programming the

EXTRA menu.

3-12 Operation and Programming

Page 39

Error Handling Set Up

March 2006

COM [ERR] PID FRZ RESP OFST

Press [SPACE] to select ERR and

then press

[ENTER].

This sub-menu permits set up of the responses of the FGA 311 to

various error situations. The following error states may be configured

via this menu:

• ER1: the Sensor Failure! error message.

• ER2: the Warning: Warming Up! error message.

• ER3: the Open Thermocouple! error message.

• ER4: the Heater Failure! error message.

When all of the desired error handling options have been set, press

[ESC] to return to run mode, or proceed to the next section to continue

programming the

Proceed to the desired section(s) now to set any or all of the available

error handling functions.

EXTRA menu.

ER1: the

Sensor Failure! error message

[ER1] ER2 ER3 ER4 Make sure ER1 is highlighted and

then press

[ENTER].

Proceed to either the “Disable ER1” or “Set ER1” prompt.

[ER1-OFF] ER1-SET To disable

[Disable ER1]

is highlighted and then press

[ENTER]. Press [BACKSPACE] to back

ER1, make sure ER1-OFF

up one menu level.

ER1-OFF [ER1-SET] To set

[SET ER1]

ER1, press [SPACE] to select

ER1_SET and press [ENTER].

ER1 [xx.x] mA Enter the desired value and press

[ENTER]. Press [BACKSPACE] to back

up one menu level.

Operation and Programming 3-13

Page 40

March 2006

Error Handling Set Up

(cont.)

ER2: the Warning: Warming Up! error message.

ER1 [ER2] ER3 ER4 Press

[SPACE] to select ER2 and

then press

[ENTER].

Proceed to either the “Disable ER2” or “Set ER2” prompt.

[ER2-OFF] ER2-SET To disable

[Disable ER2]

is highlighted and then press

[ENTER]. Press [BACKSPACE] to back

ER2, make sure ER2-OFF

up one menu level.

ER2-OFF [ER2-SET] To set

[SET ER2]

ER2, press [SPACE] to select

ER2_SET and press [ENTER].

ER2 [xx.x] mA Enter the desired value and press

[ENTER]. Press [BACKSPACE] to back

up one menu level.

ER3: the

ER1 ER2 [ER3] ER4 Press

Open Thermocouple! error message.

[SPACE] to select ER3 and

then press

[ENTER].

Proceed to either the “Disable ER3” or “Set ER3” prompt.

[ER3-OFF] ER3-SET To disable

[Disable ER3]

is highlighted and then press

[ENTER]. Press [BACKSPACE] to back

ER3, make sure ER3-OFF

up one menu level.

ER3-OFF [ER3-SET] To set

[SET ER3]

ER3, press [SPACE] to select

ER3_SET and press [ENTER].

ER3 [xx.x] mA Enter the desired value and press

[ENTER]. Press [BACKSPACE] to back

up one menu level.

3-14 Operation and Programming

Page 41

March 2006

Error Handling Set Up

(cont.)

ER4: the Heater Failure! error message.

ER1 ER2 ER3 [ER4] Press

[SPACE] to select ER4 and

then press

[ENTER].

Proceed to either the “Disable ER4” or “Set ER4” prompt.

[ER4-OFF] ER4-SET To disable

[Disable ER4]

is highlighted and then press

[ENTER]. Press [BACKSPACE] to back

ER4, make sure ER4-OFF

up one menu level.

ER4-OFF [ER4-SET] To set

[SET ER4]

ER4, press [SPACE] to select

ER4_SET and press [ENTER].

ER4 [xx.x] mA Enter the desired value and press

[ENTER]. Press [BACKSPACE] to back

up one menu level.

Operation and Programming 3-15

Page 42

March 2006

Set Up Heater Control Although the default values for the P and I parameters of the

FGA 311 PID heater control circuit are suitable for most applications,

it may sometimes be necessary to fine-tune these parameters. Refer to

Chapter 1, General Information, for a discussion of the PID circuit. If

an adjustment is indicated, proceed as follows:

IMPORTANT: Always consult the factory before changing the P

and/or I values.

COM ERR [PID] FRZ RESP OFST

Press [SPACE] to select PID and

then press

[ENTER].

Proceed to the appropriate section to set the desired parameter.

SET: specify the temperature set point (normally 700°C).

[SET] P I O DEFAULT Make sure

then press

SET is highlighted and

[ENTER].

SET [xxx] Degrees C Enter the desired set point value

and press

Press

[ESC] to return to run mode, or proceed to the next section to

continue programming the

PID sub-menu.

[ENTER].

P: set the proportional band value.

SET [P] I O DEFAULT Press

[SPACE] to select “P” and then

press

[ENTER].

P [xxx] Degrees C Enter the desired proportional

band value and press

[ESC] to return to run mode, or proceed to the next section to

Press

continue programming the

3-16 Operation and Programming

PID sub-menu.

[ENTER].

Page 43

March 2006

Set Up Heater Control

(cont.)

I: set the integration time value.

SET P [I] O DEFAULT Press

[SPACE] to select “I” and then

[ENTER].

press

I [xxx] Seconds Enter the desired integration time

value and press

Press

[ESC] to return to run mode, or proceed to the next section to

continue programming the

PID sub-menu.

[ENTER].

O: set the overheat value.

SET P I [O] DEFAULT Press

[SPACE] to select “O” and then

[ENTER].

press

P [xxx] Degrees C Enter the desired overheat value

and press

[ENTER].

Note: The overheat value should be set to the highest process

temperature (acceptable values are 600 – 1200°C). The

default value is 820°C.

Press

[ESC] to return to run mode, or proceed to the next section to

continue programming the

DEFAULT: restore the factory default

PID sub-menu.

SET, P, I and O values.

SET P I O [DEFAULT] To restore the default values, press

[SPACE] to select DEFAULT and press

[ENTER].

[ESC] to return to run mode, or proceed to the next section to

Press

continue programming the

EXTRA menu.

Operation and Programming 3-17

Page 44

March 2006

Freeze a Reading In some situations, it may be helpful to freeze an output reading for

viewing at a more convenient time. To accomplish this, perform the

following steps:

COM ERR PID [FRZ] RESP OFST

[FREEZE] UNFREEZE Press

Press [SPACE] to select “FRZ”

and then press

[SPACE] to select the desired

menu choice and press

Press

[BACKSPACE] to back up one

[ENTER].

[ENTER].

menu level.

[ESC] to return to run mode. If FREEZE was selected above, the

Press

output display will constantly show the last good reading, until the

UNFREEZE option is selected in this sub-menu.

Setting the Response Time The response time of the FGA 311 may be adjusted using this sub-

menu. A shorter response time will provide by more accurate data by

updating the display more frequently, but a longer response time will

provide a more stable display that is free from flicker.

COM ERR PID FRZ [RESP] OFST

Press [SPACE] to select RESP

and then press

[ENTER].

RESP [xx] Seconds Enter the desired response time

(values from 1 to 30 seconds are

acceptable) and press

[ESC] to return to run mode, or return to a previous section to

Press

continue programming the

PID sub-menu.

[ENTER].

3-18 Operation and Programming

Page 45

March 2006

Setting the Duty Cycle/

Offset

The offset value is subtracted from the “Raw O2 mV” value with the

difference showing in the “O2 mV” value. The amount of duty cycle/

offset table entries can range from 0 to 5 and they do not have to be

entered in any type of order. The calculation of the offset value to

subtract depends on the following cases:

1. One duty cycle/offset entry only: The offset entry in this case

will be used universally, that is, the same offset will be used no

matter what the duty cycle.

2. More that one activated entry and measured duty cycle falls

between two entered duty cycle values from the table: The

software will choose the closest duty cycle values above and

below the measured duty cycle. The offset value will be

interpolated based on the chosen entries.

3. Measured duty cycle value falls above or below any table

value: The offset value will clamp to the lowest or highest table

entry in terms of duty cycle.

4. No entry activated or whole table de-activated: The offset value

will be zero.

COM ERR PID FRZ RESP [OFST]

Press [SPACE] to select "OFST”

and then press

[ENTER].

Use Offset Table YES [NO] Observe the Offset enable Yes/

No menu and press the “D” key.

Run time data should appear or disappear depending on the prior

setting. Selecting “NO” from the offset enable choices will give a

message of “DUTY CYCLE OFFSET TABLE ENABLED.” No table

should appear below (that is, if “D” had been pressed to clear any

previous display of the table).

Use Offset Table [YES] NO Press

[SPACE] to select “YES”

and then press

[ENTER].

The offset table should appear at the bottom of the screen. The offset

table gives the user entered Duty Cycle values with their

corresponding offset values. Also the line above the table headers

should read that the offset is enabled in addition to displaying the

current % duty cycle reading and the calculated offset value.

Operation and Programming 3-19

Page 46

March 2006

Setting the Duty Cycle/

Offset (cont.)

DC/Ofst Entries [1] 2 3 4 5 Select number “1” from the DC/

Offset Entries menu and press

[ENTER].

Use Entry 1 [YES] NO Select “Yes” for Use Entry 1 and

press

[ENTER].

Choosing “Yes” activates a DC/Offset entry and will be used for

offset calculations. The table entry for entry 1 should now show

“Enabled.” The offset reading above the table should now display a

value other than zero.

Entry 1 [DC] Offset To change the DC value, select

“DC” and press

[ENTER].

Entry 1 DC [Offset] To change the Offset value,

select “Offset” and press

[ENTER].

All entries (1-5) are edited in the same way. Press

[ESC] to return to

run mode.

3-20 Operation and Programming

Page 47

TST

TST PASSED xxx.x%

TST FAILED xxx.x%

COM

TTY

ANSI

ER1

ER1_OFF

ER1_SET

March 2006

ER1 xx.x mA

OPTS

TRIM

AIR

GAS

RNG

TRIM_O2

AIR 20.93% O2 xxx.xC

GAS x.xx%O2 xxx.xC

O2_RNG

TRIM_O2 mA: 4 20

5 10 25

4mA_O2 xxx ADJUST

20mA_O2 xxx ADJUST

ERR

PID

ER2

ER3

ER4

SET

P

I

ER2_OFF

ER2_SET

ER3_OFF

ER3_SET

ER4_OFF

ER4_SET

SET xxx Degrees C

P xxx Degrees C

I xxx Seconds

ER2 xx.x mA

ER3 xx.x mA

ER4 xx.x mA

Figure 3-3: FGA 311 Menu Map

O O xxx Degrees C

EXTRA*

* not accessible

using

manual switches

FRZ

RESP

OFST [1] 2 3 4 5

The user will respond "Yes" or "No" to some options.

DEFAULT

FREEZE

UNFREEZE

RESP xx Seconds

DUTY CYCLE

OFFSET

Operation and Programming 3-21

Page 48

Chapter 4

Page 49

Calibration

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Recommended Calibration Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Measuring the Calibration Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

The Calibration Gas System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Calibrating the Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Resume Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Page 50

March 2006

Introduction As stated in Chapter 3, Operation and Programming, the calibration

of the FGA 311 In Situ Flue Gas Oxygen Transmitter should be

checked once or twice a week during the first month of operation and

every 2-3 months thereafter. Changes in calibration may result from

aging of the oxygen sensor, and within limits, temperature calibration

adjustments can compensate for such variations.

!WARNING!

To ensure safe operation of the FGA 311, it must be

installed and operated as described in this manual. In

addition, be sure to follow all applicable local safety codes

and regulations for installing electrical equipment.

IMPORTANT: This symbol indicates Caution - risk of electric

shock:

Recommended Calibration Gas

Calibration of the FGA 311 analyzer requires a calibration gas of

precisely known composition. The following calibration gas is

recommended by GE Sensing:

• 5.0% O

+ 95.0% N

2

2

Note: The calibration gas cylinder must be certified as to the exact

composition of the gas.

A 5.0% O

calibration gas should produce an oxygen sensor voltage

2

output of 30.0 ± 1.5 mV, at the usual sensor operating temperature of

700°C. The corresponding 4-20 mA analog output will depend on the

programmed oxygen range, as shown in Table 4-1 below.

Table 4-1: Calibration Gas Current Outputs

O

Range 0% O

2

2

5% O

2

Max.% O

2

5% 4.0 mA 20.0 mA 20.0 mA

10% 4.0 mA 12.0 mA 20.0 mA

25% 4.0 mA 7.2 mA 20.0 mA

Other calibration gases may be used, as long as the oxygen content of

the calibration gas is approximately equal to the oxygen percentage in

the flue gases to be measured. Of course the voltage output of the

oxygen sensor and the corresponding 4-20 mA analog output will

differ from those noted above. Also, these values will vary if the

oxygen sensor temperature is different from the standard 700°C.

Calibration 4-1

Page 51

March 2006

Measuring the Calibration Response

Refer to Appendix A, The Nernst Equation, to calculate the expected

oxygen sensor output voltage at whatever O

% and operating

2

temperature are being used. Calculate the corresponding 4-20 mA

analog output signal using Equation 4-1 below.

oxygen percentage

current (mA) 4=16

For example, if the calibration gas is 2% O

------------------------ ---------------------

•+

range setting

and the O2 range is set to

2

(4-1)

5%, the mA output should be 4 + 16 (2/5) = 10.4 mA. Figure 4-1 on

page 4-3 shows a graphical representation of the procedure. For the

same example, pick the applicable range curve (R = 5). Then, move

from the chosen oxygen percentage (2.0) on the horizontal axis up to

the range curve, and move across to the vertical axis to read the

correct analog output (10.4 mA).

To monitor the analyzer’s response to the calibration gas, remove the

lead from pin 4 (–) or pin 5 (+) on terminal block TB2 and install a

digital ammeter between the removed lead and the pin. The current

should measure within ±0.3 mA of the 5% O

readings listed in Table

2

4-1 on page 4-1. Alternatively, the oxygen sensor voltage output may

be measured directly by connecting a digital voltmeter across pins 3

(+) and 4 (–) of terminal block J2.

The Calibration Gas System