Page 1

GE

Sensing

FGA 311

Panametrics In Situ Flue

Gas Oxygen Transmitter

FGA 311 is a Panametrics

product. Panametrics has joined

other GE high-technology sensing

businesses under a new name

_

GE Industrial, Sensing.

An in situ oxygen transmitter for use in:

• Natural gas or oil-fired utility boilers

• Natural gas or oil-fired process heaters

Applications

Features

• In situ flue gas transmitter

• Fast, easy installation and service

• Weatherproof and explosion-proof packages

• Field-programmable ranges

• RS232 communications

• Temperatures up to 1920°F (1050°C)

• Leave-in-place housing—replace sensor without

uncoupling flange from process

g

Page 2

GE

Sensing

Panametrics In Situ Oxygen Flue Gas

Transmitter

The FGA 311 is a simple, low-cost, in situ, flue gas

oxygen transmitter. The zirconium oxide oxygen sensor is

installed directly into the flue stack or furnace wall. For

low-temperature applications, a heater is included to

maintain a constant temperature on the zirconium oxide

sensor. The FGA 311 is available in both weatherproof

and explosion proof configurations. Typical applications

for the FGA 311 include natural gas-fired utility and

municipal boilers, as well as natural gas-fired process

heaters. The FGA 311 is ideal for boiler and furnace

manufacturers due to its low-cost, basic transmitter

configuration.

Easy Installation

The FGA 311 can be supplied with standard NPT fittings

or it can be mounted on existing process flanges, making

installation quick, easy and inexpensive.

The electrical connections for the FGA 311 are as simple

as 115 to 230 VAC for power and a 4 to 20 mA

output signal.

Easy Configuration

Output ranges for the FGA 311 are user-selectable via a

switch or the RS232 interface to accommodate changing

measurement needs.

Easy Troubleshooting

Users can quickly connect the FGA 311’s RS232 interface

to a PC and view detailed diagnostics via terminal

emulation. The FGA 311’s microprocessor can report

sensor mV output, heater temperature and other system

status information, allowing the user to determine

quickly any necessary corrective action.

Easy Removal and Replacement of

Sensor and Heater Assembly

Particulates and the corrosives of most flue gases are

very harsh to instrumentation located within the process.

Conventional in situ flue gas oxygen transmitters require

removal of the whole analyzer from the sample point to

replace the sensor and heater assembly. The unique

design of the FGA 311 makes the replacement easy. The

cover on the transmitter housing is unscrewed, the wire

harnesses are disconnected, and the sensor and heater

assembly are unscrewed and removed. The sensor and

heater can then slide out. The transmitter housing and

probe remain in place, reducing labor time and effort for

any sensor and heater replacement needs.

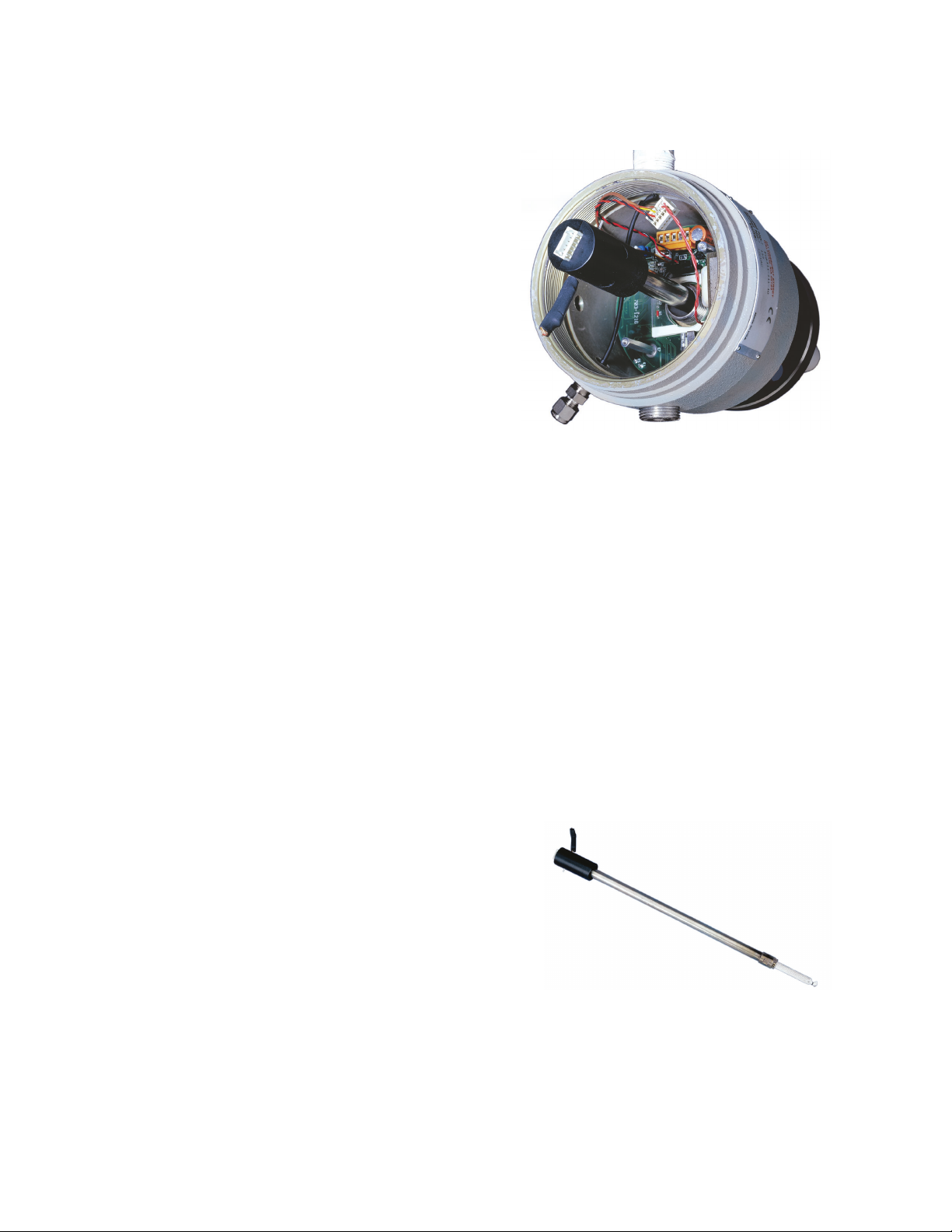

Sensor and heater assembly

Inside the FGA 311 transmitter

Page 3

GE

Sensing

FGA 311

Specifications

Calibration gas inlet

Explosion proof version of FGA 311 in situ oxygen flue gas transmitter.

Performance

Accuracy

±3% of reading or 0.1% O

2

Measurement Resolution

Output 4 to 20 mA: 0.01 mA

RS232 Terminal Interface

0.01% O

2

Response Time

Less than 5 seconds for 63% of step change

Measurement Range

Fully field selectable via RS232 interface or onboard

switches:

• 0% to 5% O

2

• 0% to 10% O

2

• 0% to 25% O

2

Temperature

Process

• Standard: 300°F to 1200°F (150°C to 650°C)

• High temperature: 300°F to 1920°F (150°C to 1050°C)

Electronics

–4°F to 160°F (–20°C to 70°C) ambient

Flame arrestor

1 1/2 in NPT

External

ground screw

1.45 in

(368.3 mm)

19 in

(482.6 mm)

7.75 in

(196 mm)

3/4 in NPT

6.07 in (154.2 mm)

Breather

Flame arrestor

END VIEW

Calibration

Methods

• Semiautomatic by push-button

• RS232 interface

• Digipot adjustment

Recommended Gas Mixtures

5.0% O2, balance N2(dependent on application and

range)

Calibration Gas Flow

2000 cc/min (4 SCFH)

Reference Air

20 to 50 cc/min, clean, dry instrument quality air

(20.93% O2), regulated to 3 psi (0.2 bar)

Page 4

GE

Sensing

FGA 311

Specifications

Functional

Output

• Analog output: 4 to 20 mA DC, 600 S maximum,

isolated

• Digital output: RS232 communications

Power Consumption

• 115 VAC, 75 W

• 230 VAC, 135 W

Process Connection

• Standard: 1 1/2 in NPTM

• Optional: 2 in (50 mm) and larger flanges

Physical

Materials

• Probe: Process wetted or welded parts

• Standard temperature: 316 stainless steel

• High-temperature: Inconel®alloy

Enclosure

Epoxy-coated aluminum

Dimensions

15 lb (6.8 kg); 19 in (482.6 mm) probe length

Mounting

Vertical or horizontal, 1 1/2 in NPT, flanges available in

most sizes

©2005 GE. All rights reserved.

920-027C

All specifications are subject to change for product improvement without notice.

GE®is a registered trademark of General Electric Co. Other company or product

names mentioned in this document may be trademarks or registered trademarks

of their respective companies, which are not affiliated with GE.

www.gesensing.com

g

Hazardous Location Certifications

Explosion-proof/flameproof:

Class I, Division 1, Groups B,C&D

T6 (electronic housing)

T4 (sensor probe)

ISSeP02ATEX028 X, Electronics:

II 2 GD EEx d IIB T6

ISSeP02ATEX028 X, Process:

II 2 GD EEx d IIB T2

Environmental

Weatherproof Type 4x/IP66

European Compliance

Complies with EMC Directive 89/336/EEC, 73/23/EEC LVD

(Installation Category II, Pollution Degree 2)

Order Information

Record selected option in blank indicated at bottom of form.

FGA 311 In Situ Flue Gas Analyzer

Package

1 Weatherproof

2 Explosion-proof; 19 in (0.5 m) only

Power

1 115 V

2 230 V

Probe Length

1 19 in (0.5 m)

2 39 in (1 m)

3 60 in (1.5 m)

4 79 in (2 m)

Temperature

1 Standard temperature, 1202°F (650°C)

maximum

2 High temperature, 1922°F (1050°C)

maximum

Special

0 None

1 Special (consult GE)

FGA 311

-

__ __ __-__ __ Use this number to order product

Loading...

Loading...