General ARXA25TATA, ARXA30TATA, ARXA36TATA, ARXA45TATA Installation Manual

Installation

Template

Hanger

Special nut A

(large flange)

Special nut B

(large flange)

Coupler heat

insulation

(large)

Coupler heat

insulation

(small)

Nylon fastener

Auxiliary pipe

assembly

Drain hose

insulation

Indoor capillary tube

BR sheet

STANDARD PARTS

The following installation parts are furnished. Use them as

required.

INDOOR UNIT ACCESSORIES

Name and Shape Q’ty Application

1

4

4

4

2

1

1

1

1

1

2

For positioning the

indoor unit

For suspending the

indoor unit from ceiling

For suspending the

indoor unit from ceiling

For indoor side pipe joint

(large pipe)

For indoor side pipe joint

(small pipe)

For fixing the drain hose

For wiring conduit

(gas side) connection

Insulates the drain hose

and vinyl hose

connection

(This part is enclosed with

the 30,000 and 36,000 •

25,000 BTU/h versions.)

65 × 130 × T5

(This part is enclosed with

the 30,000 and 36,000 •

25,000 BTU/h versions.)

CONNECTION PIPE REQUIREMENT

Small Large

Diameter

45,000 BTU/h class 9.52 mm 19.05 mm

36,000 BTU/h class 9.52 mm 19.05 mm

30,000 BTU/h class 9.52 mm 15.88 mm

25,000 BTU/h class 9.52 mm 15.88 mm

ELECTRICAL REQUIREMENT

Table 1

• Use 0.7 mm to 1.2 mm thick pipe.

• Use pipe with water-resistant heat insulation.

• Use pipe that can withstand a pressure of 3,040 kPa.

MAX

MIN

Connection cord

(mm

2

)

2.5

1.5

••

••

•

Always use H07RN-F or equivalent to the connection cord.

••

••

•

Install the disconnection device with a contact gap of at least

3 mm nearby the units. (Both indoor unit and outdoor unit)

Table 2

Duct Type

This air conditioner uses new refrigerant HFC (R407C).

Right

side

Indoor unit

Strong and durable ceiling

Left

Fig. 1

side

WARNING

This mark indicates procedures which, if improperly performed, might lead to the death or serious

injury of the user.

This mark indicates procedures which, if improperly performed, might possibly result in personal

harm to the user, or damage to property.

6" (15 cm)

or more

12" (30 cm)

or more

unit and the ceiling will make work much easier.

(4) Install the unit where the drain pipe can be easily installed.

(5) Providing as much space as possible between the indoor

R407C

Refrigerant

SPLIT TYPE AIR CONDITIONER

INSTALLATION INSTRUCTION SHEET

WARNING!

For authorized service personnel only.

(PART NO. 9363065022)

CAUTION!

set available from our standard parts.

only.

standard parts. This installation instruction sheet describes the correct connections using the installation

1 For the air conditioner to operate satisfactorily, install it as outlined in this installation instruction sheet.

2 Connect the indoor unit and outdoor unit with the air conditioner piping and cords available

with a flame, it produces a toxic gas.

3 Installation work must be performed in accordance with national wiring standards by authorized personnel

4 If refrigerant leaks while work is being carried out, ventilate the area. If the refrigerant comes in contact

5 Do not turn on the power until all installation work is complete.

serviced or moved.

• Be careful not to scratch the air conditioner when handling it.

• After installation, explain correct operation to the customer, using the operating manual.

• Let the customer keep this installation instruction sheet because it is used when the air conditioner is

SELECTING THE

MOUNTING POSITION

Decide the mounting position with the customer as follows:

so that it withstand against the weight of the indoor unit.

should be able to blow all over the room.

INDOOR UNIT

(1) Install the indoor unit on a place having a sufficient strength

(Fig.1).

(2) The inlet and outlet ports should not be obstructed; the air

(3) Leave the space required to service the air conditioner

Hanger

Ceiling

Pass the unit hangers over the bolts installed to the ceiling

and install the unit with the special nut B.

• Install the unit

Fig. 11

Special nut B

(60 to 70 mm)

2-3/8" to 2-3/4"

∅1/2" (1.27 mm)

Fig. 8

CAUTION

Ceiling

Ceiling

4. LEVELING

Base horizontal direction leveling on top of the unit.

Fig. 12

Level

Base vertical direction leveling on the unit (right and left).

Fig. 13

Level

Inlet

Outlet

air

air

5. SERVICE HOLE DIMENSIONS

It shall be possible to install and remove the control box metal.

Fig. 14

AIR

Unit: (mm)

Reference B

CAUTION

Service hole

200

Reference

A

Control box metal

500

Outlet air

50

500 mm from 50 mm below reference A

500 mm from 200 mm from the left from reference B

500

• Vertical dimension

• Horizontal dimension

Inlet air

the unit. Mark the bolt positions from the installation template.

With a concrete drill, drill

for 1/2" (12.7 mm) dia.

Fasten the unit securely with special nuts A and B.

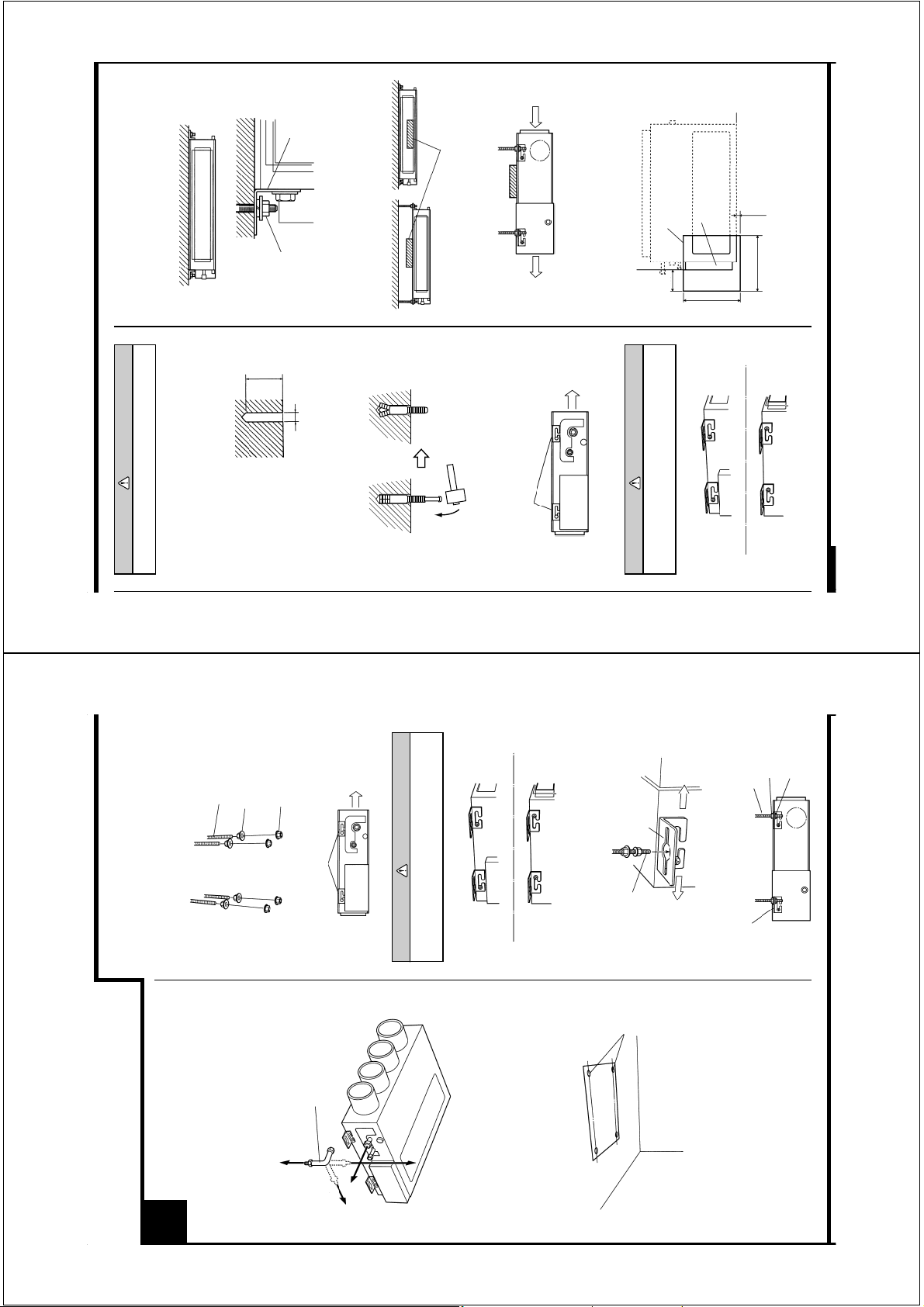

3. INSTALLING THE HANGERS

Installation method (1)

• Install the bolts to the ceiling at a place strong enough to hang

Installation method (2)

A and B.

• Fasten the hanging bolts to the ceiling and install special nuts

Fig. 4

holes (Fig. 8).

Hanging bolt

Special nut A

Special nut B

• Install the hangers to the unit.

completely into the anchor bolts with a hammer.

• Insert the anchor bolts into the drilled holes, and drive the pins

Hanger

Fig. 5

Fig. 9

AIR

CAUTION

Left side

When fastening the hangers, make the bolt

positions uniform.

• Install the hangers to the unit.

Fig. 10

Outlet air

Left side

(Fig. 1)

(Example)

Hanger

Inlet air

Right side

(Fig. 1)

Left side

Left side

(Fig. 1)

When fastening the hangers, make the bolt

positions uniform.

(Example)

Unit

Hanger

Hanger bolt

• Hang the unit.

(1) Pass the hanging bolts through the hangers. (Four places)

Fig. 6

(2) Slide the unit in the arrow direction and fasten it.

Right side

Hanging bolt

Hanger

Fig. 7

(Fig. 1)

Special nut A

Special nut B

Front Outlet

INDOOR UNIT

INSTALLATION

INSTALLATION PROCEDURE

Install the air conditioner as follows:

1

Auxiliary pipe assembly

To top

PREPARATION

1. PIPING CONNECTION DIRECTION AND

• Select piping directions (Fig. 2).

Fig. 2

To side

To rear

To bottom

assembly.

• When bending the piping is difficult, use the auxiliary pipe

Drilling

position

for bolts

Installation template

INSTALLING THE BOLTS

(Fig. 3).

2. DRILLING HOLES FOR BOLTS AND

• Using the installation template, drill holes for bolts (four holes)

Fig. 3

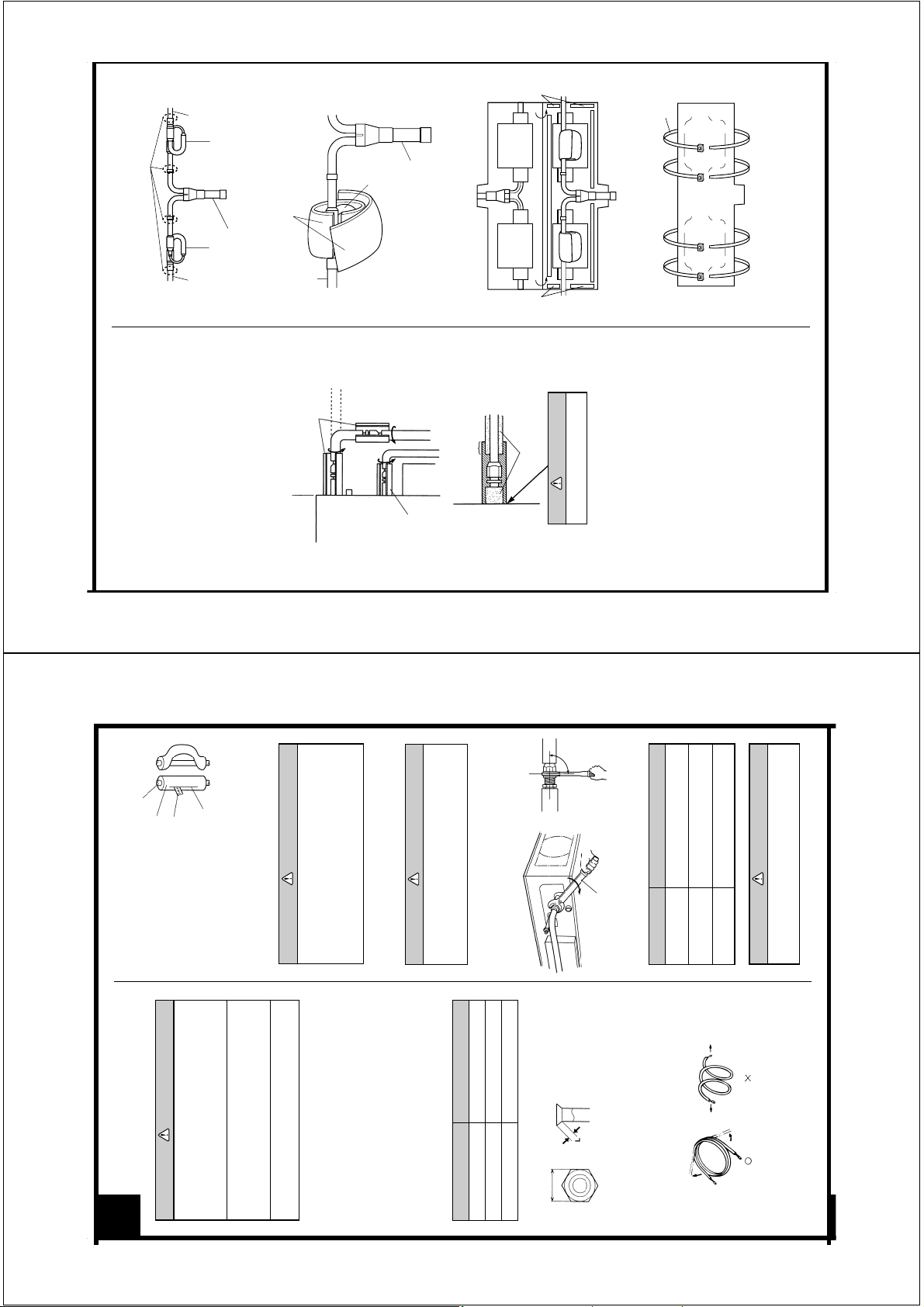

Brazing (all around)

Fig. 21

Indoor

Indoor

unit side

unit side

Connection

pipe

Indoor capillary tube Indoor capillary tube

Connection

pipe

Outdoor unit side

Branch liquid pipe

Fig. 22

BR sheet

Connection

Coupler heat

insulation (large)

pipe

on the pipe

Indoor

capillary tube

Branch liquid pipe

Large pipe

Fig. 23

Tape

Binder

Tape

Fig. 24

Reference A

FOR GAS LEAKING

4. CHECKING THE PIPE CONNECTIONS

For both the indoor and outdoor unit sides, check the joints for

gas leaking by the use of a gas leakage detector without fail when

the pipes are connected.

Pipe

Cutter

Heat insulating

pipe

Fig. 17

where connecting pipes.

5. HEAT INSULATION ON THE PIPE JOINTS

insulation (large) to the pipe at the two places shown below.

• Stick coupler heat insulation (large and small) to the place

• When using auxiliary piping with large pipe, stick coupler heat

Fig. 20

Cut line

CAUTION

Be sure to apply the pipe against the port on the

When bending the pipe, do not

bend it as is. The pipe will be

collapsed. In this case, cut the

heat insulating pipe with a

sharp cutter as shown in Fig.

17, and bend it after exposing

the pipe. After bending the pipe

as you want, be sure to put the

heat insulating pipe back on

the pipe, and secure it with

tape.

3. CONNECTION PIPES

Detach the caps and plugs from the pipes.

indoor unit correctly. If the centering is

Front outlet

Coupler heat

CAUTION

improper, the flare nut cannot be tightened

smoothly. If the flare nut is forced to turn, the

threads will be damaged.

Centering the pipe against port on the indoor unit, turn the

flare nut with your hand.

Small pipe

Cover this portion with heat

insulating material also without fail.

Heat insulating pipe

CAUTION

No gap should remain.

insulation (small)

on the pipe

90˚

Torque wrench

Hold the torque wrench at its grip, keeping it in

the right angle with the pipe as shown in Fig. 19,

in order to tighten the flare nut correctly.

When the flare nut is tightened properly by your hand, use a

torque wrench to finally tighten it.

Fig. 18 Fig. 19

TUBE

versions.

6. CONNECTING AN INDOOR CAPILLARY

These instructions refer to the 25,000 • 30,000 and 36,000 BTU/h

Table 4 : Flare nut tightening torque

Pipe Tightening torque

branch liquid pipe) as shown in Fig. 21.

shown in Fig. 22.

with insulation (Fig. 23) and affix the insulation with tape.

Installation Procedure

(1) Braze each part (connection pipe, indoor capillary tube, and

(2) Wrap the two BR sheets around the indoor capillary tube as

(3) Cover the indoor capillary tube and the branch liquid pipe

•cm (73.5 to 78.4 N•m)

750 to 800 kgf

Large pipe

Large pipe

(9.52 mm dia.)

(15.88 mm dia.)

•cm (78.4 to 98 N•m)

800 to 1,000 kgf

•cm (30.4 to 34.3 N•m)

310 to 350 kgf

Small pipe

instruction sheet for the outdoor unit for details.

(4) Secure the insulation using the binders (Fig. 24).

• If the joint pipe must be installed, refer to the installation

CAUTION

(19.05 mm dia.)

Be sure to connect the large pipe after

connecting the small pipe completely.

CAUTION

CONNECTING THE PIPING

2

the units.

previous installations. Only use parts which

are delivered with the unit.

Prevent mineral oil from getting into the

system as this would reduce the lifetime of

1 Do not use mineral oil on flared part.

2 Never use piping which has been used for

nitrogen gas through them.

3 While welding the pipes, be sure to blow dry

Small (width across flats 22 mm)

Table 3

is not deformed.

the pipe and remove the burrs.

unit and assemble as shown in (Table 3) and insert the

flare nut onto the pipe, and flare with a flaring tool.

1. FLARE PROCESSING

(1) Cut the connection pipe with pipe cutters so that the pipe

(2) Holding the pipe downwards so that cuttings cannot enter

and that there are no cracks.

(3) Remove the flare nut from the indoor unit pipe and outdoor

(4) Check if the flared part “L” (Fig. 5) is spread uniformly

Large (width across flats 27 mm)

Pipe Flare nut

Small pipe (9.52 mm dia.)

Large pipe (15.88 mm dia.)

L dimension

Small pipe (9.52 mm dia.)

1.8 to 2.0 mm

Large pipe (15.88 mm dia.)

2.2 to 2.4 mm

Large pipe (19.05 mm dia.)

2.6 to 3.0 mm

Large (width across flats 36 mm)

Width across flats

Large pipe (19.05 mm dia.)

Fig. 15

NO

by unwinding it.

Extend the pipe

OK

Do not bend the pipes in an angle more than 90°.

When pipes are repeatedly bent or stretched, the material will

harden, making it difficult to bend or stretch them any more.

2. BENDING PIPES

The pipes are shaped by your hands. Be careful not to collapse

them.

Fig. 16

Do not bend or stretch the pipes more than three times.

Loading...

Loading...