General ARHA30LB, ARHA30LBTU, AOHA30LBTL, ARHA36LB, ARHA36LBTU Service Manual

...

SPLIT TYPE

ROOM AIR CONDITIONER

SERVICE

INSTRUCTION

Models Indoor unit Outdoor unit

AR*A30LBTU

AR*A36LBTU

DUCT

INVERTER

type

AO*A30LBTL

AO*A36LBTL

R410A

CONTENTS

1. SPECIFICATIONS

SPECIFICATIONS.......................................................................................................... 01-01

2. DIMENSIONS

DIMENSIONS.................................................................................................................. 02-01

3. REFRIGERANT SYSTEM DIAGRAM

REFRIGERANT CIRCUIT............................................................................................... 03-01

4. CIRCUIT DIAGRAM

CIRCUIT DIAGRAM........................................................................................................ 04-01

5. DESCRIPTION OF EACH CONTROL OPERATION

5-1 COOLING OPERATION............................................................................................

5-1-1 COOLING CAPACITY CONTROL......................................................................

5-2 HEATING OPERATION.............................................................................................

5-2-1 HEATING CAPACITY CONTROL......................................................................

5-3 DRY OPERATION......................................................................................................

5-3-1 INDOOR UNIT CONTROL.................................................................................

5-4 AUTO CHANGEOVER OPERATION........................................................................

5-5 INDOOR FAN CONTROL.........................................................................................

5-6 OUTDOOR FAN CONTROL......................................................................................

5-7 COMPRESSOR CONTROL......................................................................................

5-8 TIMER OPERATION CONTROL...............................................................................

5-9 ELECTRONIC EXPANSION VALVE CONTROL....................................................

5-10 PREVENT TO START FOR 3 MINUTES (3 MINUTES ST)....................................

5-12 4-WAY VALVE EXTENSION SELECT....................................................................

5-13 AUTO RESTART.....................................................................................................

5-14 PUMP DOWN (For AR*30/ 36/ 45LUAN/ 45/ 54LUAK)..........................................

05-01

05-01

05-02

05-02

05-03

05-03

05-04

05-05

05-07

05-08

05-09

05-10

05-10

05-11

05-11

05-11

5-15 COMPRESSOR PREHEATING...............................................................................

5-16 FRESH AIR CONTROL...........................................................................................

5-17 EXTERNAL ELECTRICAL HEATER CONTROL....................................................

5-18 DEFROST OPERATION CONTROL.......................................................................

5-19 OFF DEFROST OPERATION CONTROL...............................................................

5-20 ECONOMY OPERATION.........................................................................................

5-21 VARIOUS PROTECTIONS......................................................................................

5-22 FORCED COOLING OPERATION..........................................................................

5-23 COMPRESSOR STOP CONTROL..........................................................................

05-11

05-12

05-12

05-13

05-15

05-16

05-17

05-18

05-18

6. REFRIGERANT CAUTION -R410A-

6-1 R410A TOOLS............................................................................................................ 06-01

6-2 PRECAUTION FOR INSTALLATION.........................................................................

6-3 PRECAUTION FOR SERVICING...............................................................................

6-4 NEW REFRIGERANT R410A.....................................................................................

6-5 DEFFERENCE FROM CONVENTIONAL MODEL (R22) AND PRECAUTIONS.......

06-02

06-04

06-05

06-08

7. TROUBLE SHOOTING

7-1 ERROR DISPLAY......................................................................................................

7-1-1 WIRED REMOTE CONTROLLER DISPLAY......................................................

7-1-2 OUTDOOR UNIT DISPLAY................................................................................

7-2 TROUBLE SHOOTING WITH ERROR CODE..........................................................

7-3 TROUBLE SHOOTING WITH NO ERROR CODE....................................................

7-4 SERVICE PARTS INFORMATION............................................................................

07-01

07-01

07-03

07-04

07-30

07-35

8. APPENDING DATA

8-1 CAPACITY TABLE..................................................................................................... 08-01

8-2 OPERATION RANGE.................................................................................................

8-3 ELECTRIC CHARACTERISTICS...............................................................................

8-4 SAFETY DEVICE........................................................................................................

8-5 FUNCTION SETTING.................................................................................................

8-5-1 INDOOR UNIT....................................................................................................

8-5-2 Procedures to change the Function Setting........................................................

8-5-3 Procedures to change the Function Setting for wireless RC...............................

8-5-4 WIRED REMOTE CONTROLLER......................................................................

8-6 EXTERNAL INPUT & OUTPUT..................................................................................

9. INSTALLATION MANUAL

08-03

08-04

08-05

08-06

08-06

08-08

08-09

08-11

08-12

R410A

DUCT type

INVERTER

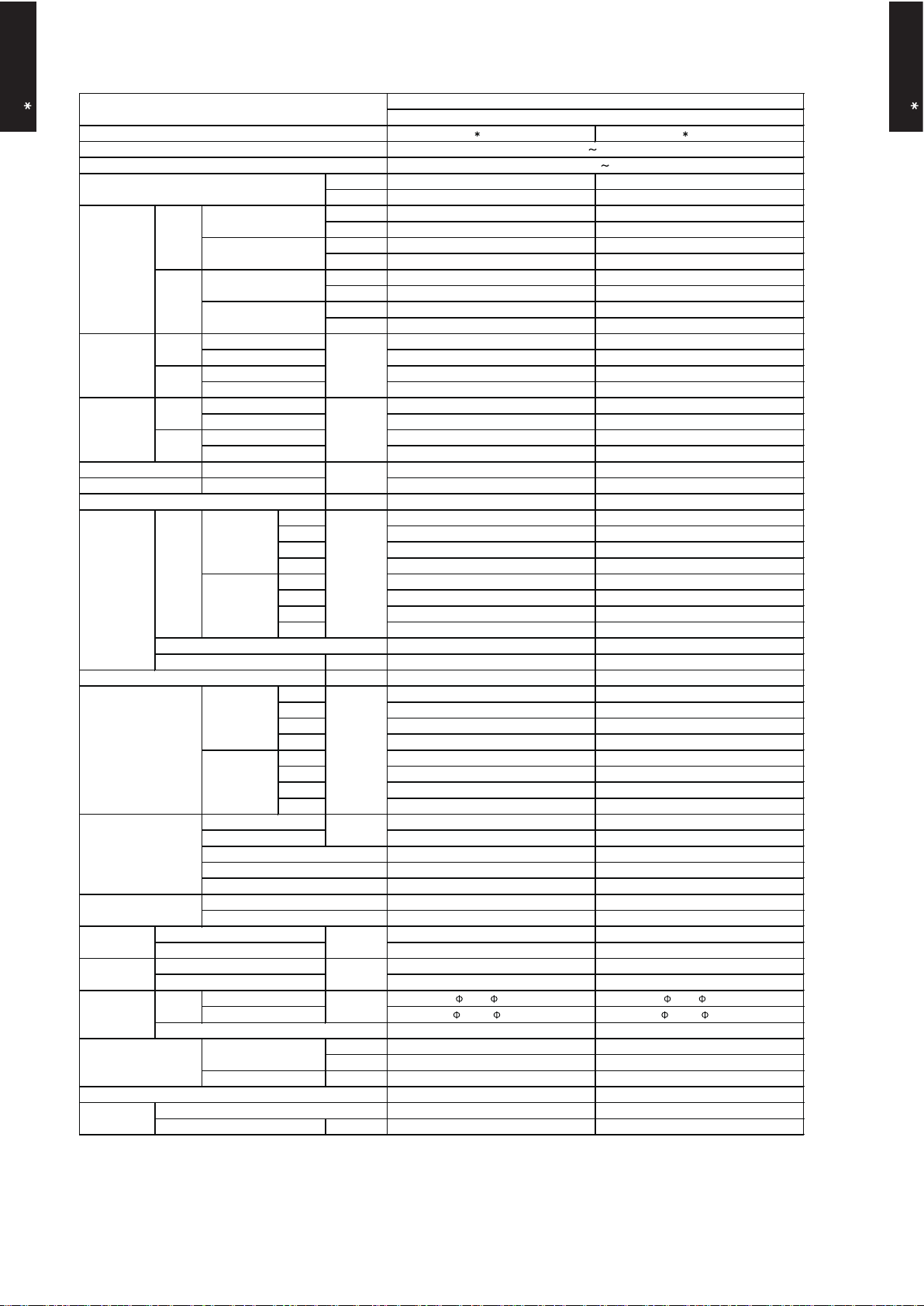

1 . SPECIFICATIONS

01-01

DUCT TYPE

AR A30-36L

DUCT TYPE

AR A30-36L

AR A30LBTU AR A36LBTU

Cooling A A

Heating A A

kW 8.50 9.40

BTU/h 29000 32100

kW 2.80 - 10.00 2.80 - 11.20

BTU/h 9500 - 34100 9500 - 38200

kW 10.00 11.20

BTU/h 34100 38200

kW 2.70 - 11.20 2.70 - 12.70

BTU/h 9200 - 38200 9200 - 43300

2.65 2.93

3.88 4.56

2.68 3.10

3.88 4.56

11.6 12.8

17.0 20.0

11.7 13.6

17.0 20.0

3.21 3.21

3.73 3.61

l/h (pints/h) 2.5(5.3) 3.0 (6.3)

High 1950 1950

Med 1620 1620

Low 1270 1270

Quiet 980 980

High 2100 2100

Med 1620 1620

Low 1270 1270

Quiet 980 980

Sirocco × 2 Sirocco × 2

W 197 197

Pa 30 to 150 30 to 150

High 42 42

Med 37 37

Low 32 32

Quiet 29 29

High 42 42

Med 37 37

Low 32 32

Quiet 29 29

294 × 1000 × 39.9 294 × 1000 × 39.9

1.40 1.40

3 × 14 3 × 14

Copper Copper

Aluminium Aluminium

Steel Steel

- -

270 × 1135 × 700 270 × 1135 × 700

300 × 1320 × 790 300 × 1320 × 790

40 (88) 40 (88)

47 (104) 47 (104)

9.52 ( 3/8 in.) 9.52 ( 3/8 in.)

15.88 ( 5/8 in.) 15.88 ( 5/8 in.)

Flare Flare

°C 18 to 32 18 to 32

%RH 80 or less 80 or less

°C 16 to 30 16 to 30

Wired Wired

Steel Steel

mm Outer diameter : 38.0 / Inner diameter : 36.0 Outer diameter : 38.0 / Inner diameter : 36.0

Note :

Specifications are based on the following conditions.

Cooling : Indoor temperature of 27°CDB/19°CWB. and outdoor temperature of 35°CDB/24°CWB.

Heating : Indoor temperature of 20°CDB/15°CWB. and outdoor temperature of 7°CDB/6°CWB.

Standard static pressure : 47 Pa

Pipe length : 5 m, Height difference : 0 m.(Outdoor unit - Indoor unit)

Sound pressure level : Install a 2m duct to the outlet port and a 1m duct to the suction poit and measure.

The maximum current and the maximum input value are the maximum value when operated within the operation (temperature)range.

Heating

Size

Liquid

Gas

Method

Cooling

Net

Gross

Net

Gross

Pipe type

Fin type

Material

Colour

Recommended static pressure

Dimensions (H × W × D)

Fin pitch

Rows × Stages

Model name

EER

COP

Moisture removal

DUCTED MODEL

INVERTER HEATPUMP

230V 50Hz

198 - 264V 50Hz

dB(A)

Remote controller type

Drain pipe

Material

Operation range

kg(lb.)

Connection pipe

Size

mm

Weight

m3/h

Fan

Dimensions

(H × W × D)

mm

Airflow

rate

Enclosure

Heat exchanger type

Sound pressure level

Heating

Cooling

Heating

Heating

Cooling

Cooling

Heating

Type × Q'ty

Motor output

Rated

*Max.

Rated

*Max.

kW/kW

Input power

Cooling

kW

Heating

Rated

*Max.

Current

Cooling

A

Power source

Available voltage range

Capacity

Cooling

Heating

European energy label

Type

mm

Rated

Min.-Max.

Rated

Min.-Max.

Rated

*Max.

1. SPECIFICATIONS FOR INDOOR UNIT

01-02

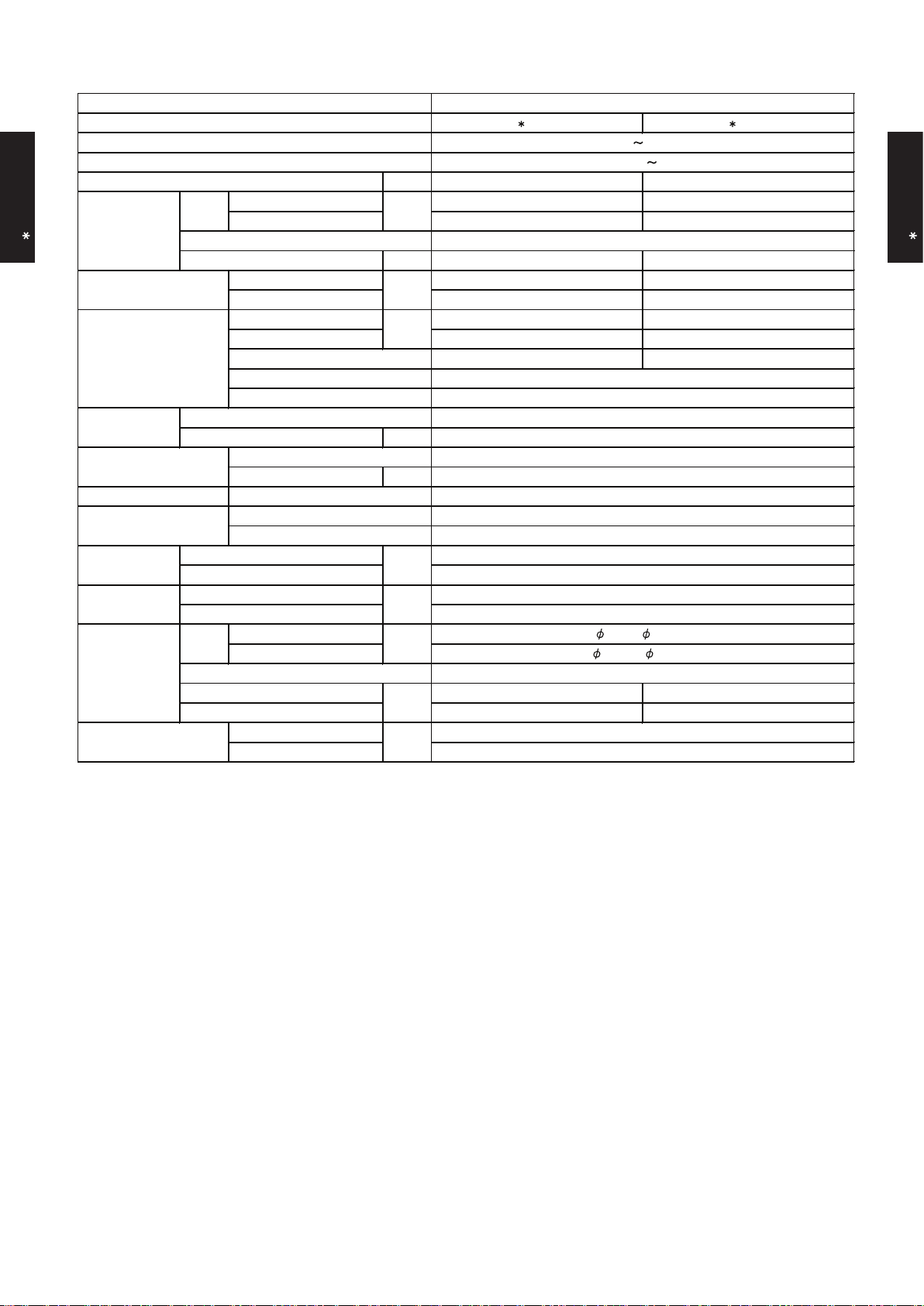

2. SPECIFICATIONS FOR OUTDOOR UNIT

OUTDOOR UNIT

AO A30-36L

OUTDOOR UNIT

AO A30-36L

AO A30LBTL AO A36LBTL

Power source

Available voltage range

A 15.0 15.0

Cooling 3600 4000

Heating 3800 3800

Type × Q'ty

Motor output W 103 103

Cooling 53 54

Heating 55 55

Dimensions (H × W × D)

798 × 900 × 36.4 798 × 900 × 36.4

Fin pitch 1.30 1.30

Rows x Stages 2 × 38 2 × 38

Pipe type

Fin type

Motor output W

Charge g

Material

Colour

Net

Gross

Net

Gross

Liquid

Gas

Method

Max. length 50(chargeless:20) 50(chargeless:20)

Max. height difference 30 30

Cooling

Heating

Note :

Specifications are based on the following conditions.

Cooling : Indoor temperature of 27 °CDB / 19 °CWB.and outdoor temperature of 35 °CDB/24 °CWB.

Heating : Indoor temperature of 20 °CDB / 15 °CWB.and outdoor temperature of 7 °CDB/6 °CWB.

Pipe length : 5 m, Height difference : 0 m.(Outdoor unit - Indoor unit)

°C

Operation range

Type

Model name

Fan

Airflow

rate

m3/h

dB(A)

mm

mm

Weight

kg(lb.)

Dimensions

(H × W × D)

Refrigerant oil

Type

Enclosure

Heat exchanger type

Starting current

Compressor

Type × Q'ty

Refrigerant

Type

Sound pressure level

m

Connection pipe

Size

mm

INVERTER HEATPUMP

230V 50Hz

198-264V 50Hz

Propeller × 1

9.52 ( 3/8 in.)

Copper

Aluminium

Steel sheet

Beige (10YR7.5/1.0NN)

Twin Rotary × 1

1700

R410A

PVE

2100

15.88 ( 5/8 in.)

Flare

-15 to 46

-15 to 24

830 × 900 × 330

62 ( 136 )

70 ( 154 )

970 × 1050 × 445

DUCT type

R410A

INVERTER

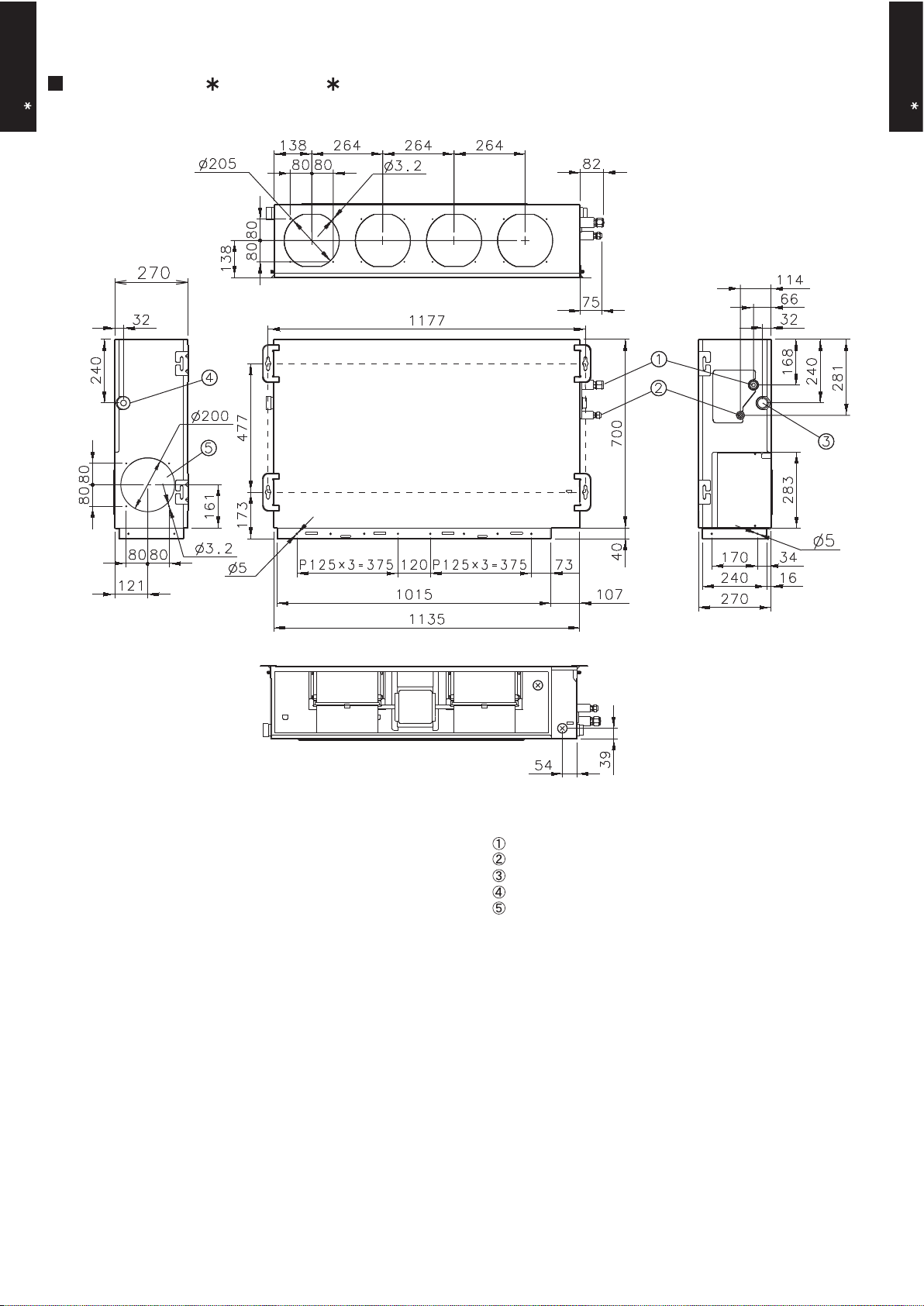

2 . DIMENSIONS

DUCT TYPE

AR A30-36L

DUCT TYPE

AR A30-36L

2. DIMENSIONS

Refrigerant piping flare connection (Gas)

Refrigerant piping flare connection (Liquid)

Drain piping connection

Drain piping connection with cap.

Knock out hole for fresh air.

Front view

Top view

Side view (L)

Side view (R)

Rear view

MODEL : AR A30L, AR A36L

(Unit : mm)

02-01

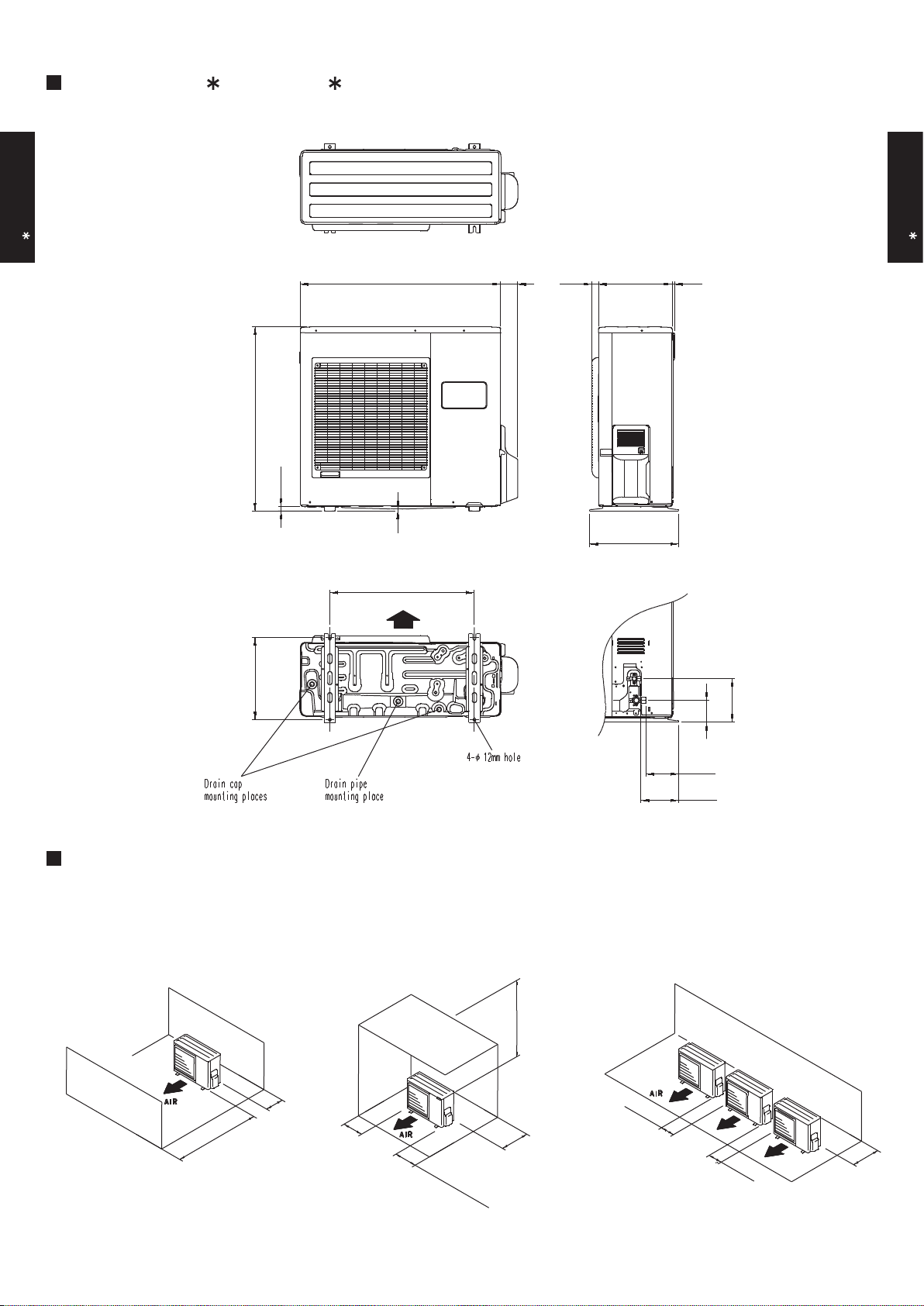

02-02

MODEL : AO A30L, AO A36L

MOUNTING POSITION

(Unit : mm)

When there are obstacles at the

back or front sides.

When there are obstacles at the

back, side(s), and top.

When there are obstacles at the

back, side with the installation of

more than one unit.

603

Air flow

900

650

830

370

99

196

21

9

77

31 330

400

170

147

12

600 m

m

or

mo

re

250

m

m

or more

250

m

m

or more

300

mm

or

m

o

re

600 mm or more

100

m

m

or more

30

0

m

m

or

m

o

r

e

1

0

0

mm

o

r mo

re

25

0

mm

or

more

(

S

ervic

e s

pace)

Top view

Front view

Side view

Bottom view

OUTDOOR UNIT

AO A30-36L

OUTDOOR UNIT

AO A30-36L

DUCT type

R410A

INVERTER

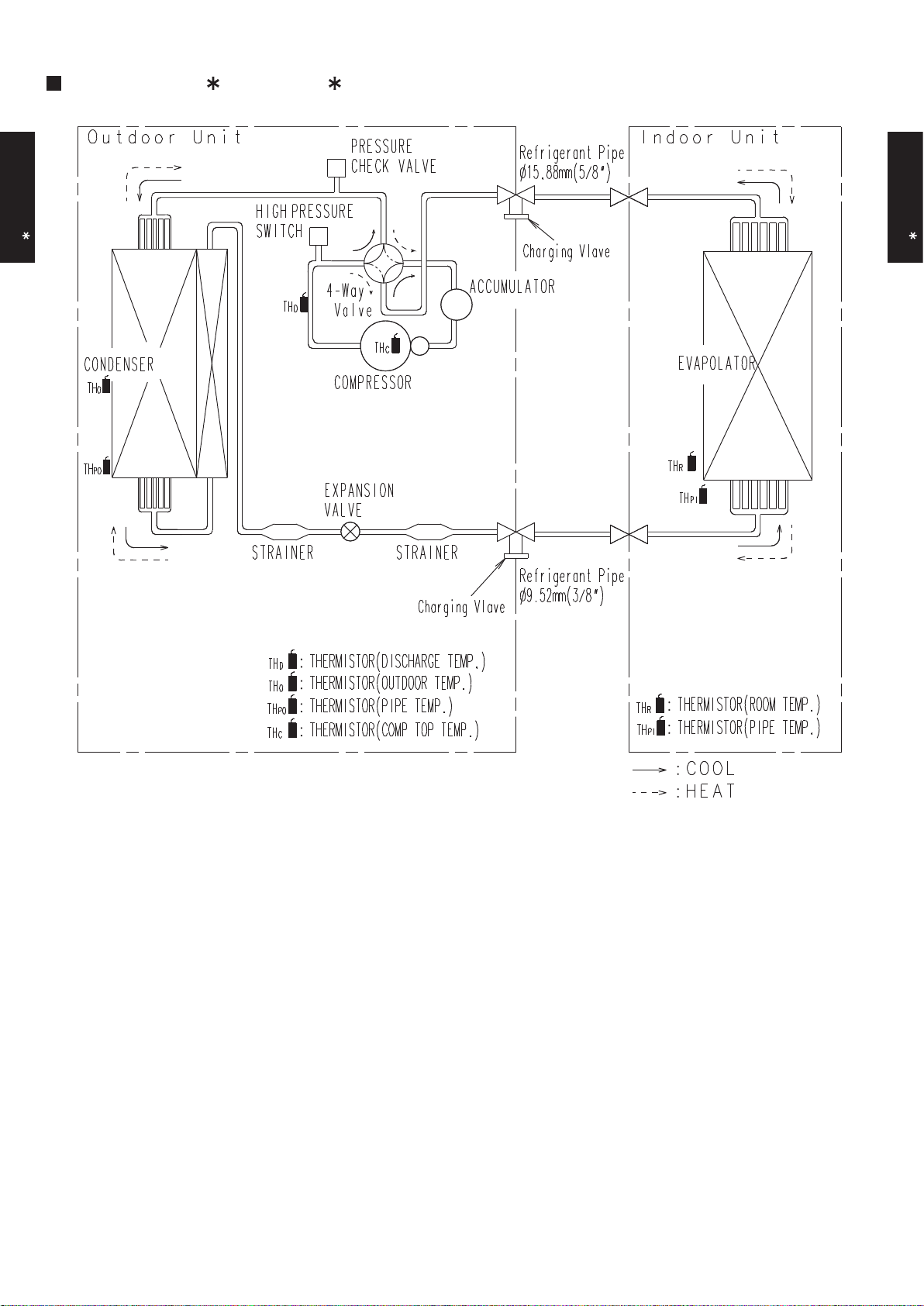

3 . REFRIGERANT SYSTEM DIAGRAM

03-01

3. REFRIGERANT CIRCUIT

MODEL : AO A30L, AO A36L

OUTDOOR UNIT

AO A30-36L

OUTDOOR UNIT

AO A30-36L

DUCT type

R410A

INVERTER

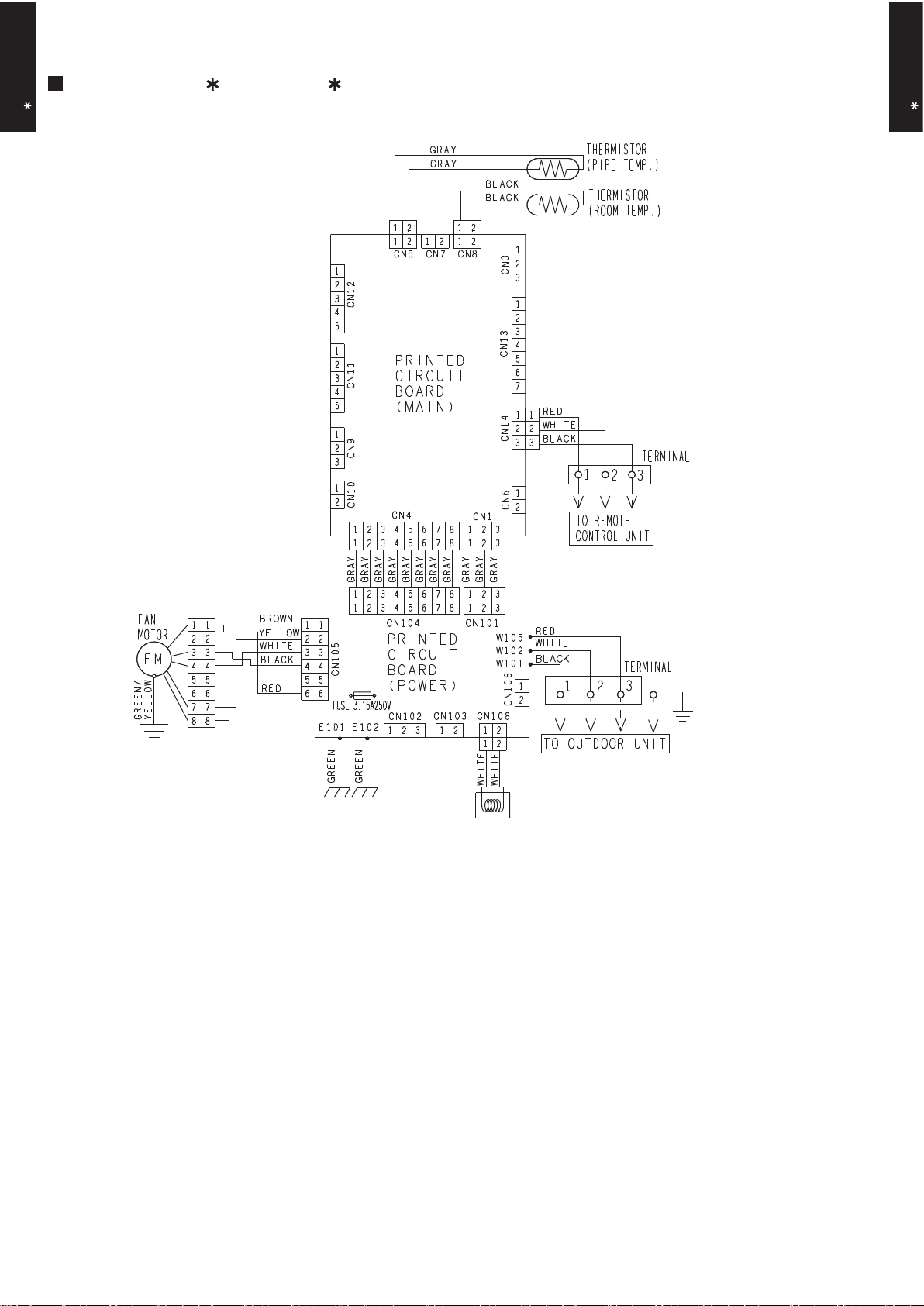

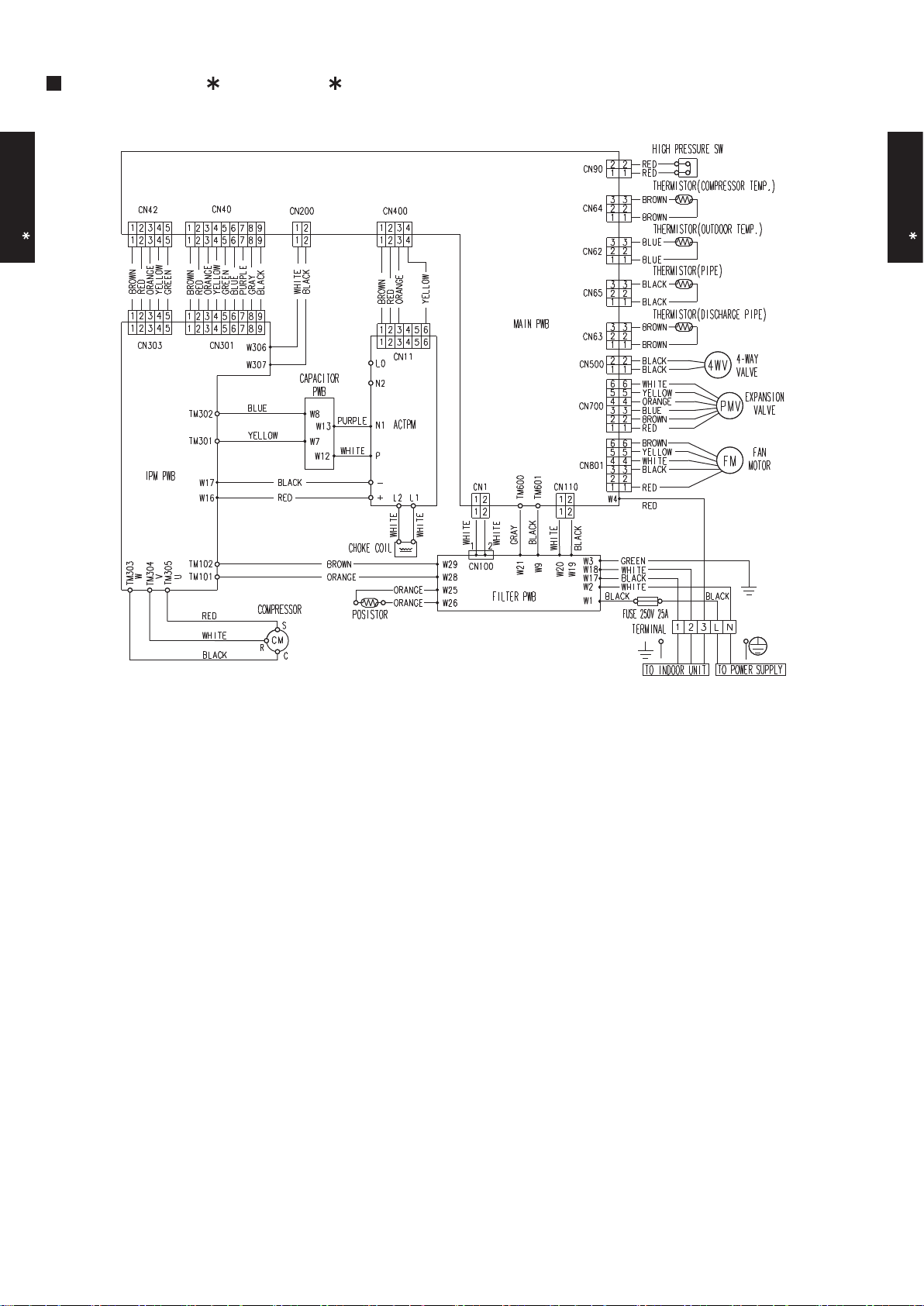

4 . CIRCUIT DIAGRAM

04-01

DUCT TYPE

AR A30-36L

DUCT TYPE

AR A30-36L

5.CIRCUIT DIAGRAM

MODEL : AR A30L, AR A36L

COIL

04-02

4.CIRCUIT DIAGRAMS

MODEL : AO A30L, AO A36L

OUTDOOR UNIT

AO A30-36L

OUTDOOR UNIT

AO A30-36L

DUCT type

R410A

INVERTER

5 . DESCRIPTION OF EACH

CONTROL OPERATION

5. DESCRIPTION OF EACH CONTROL OPERATION

36°C

34°C

32°C

30°C

21°C

19°C

12°C

10°C

2°C

0°C

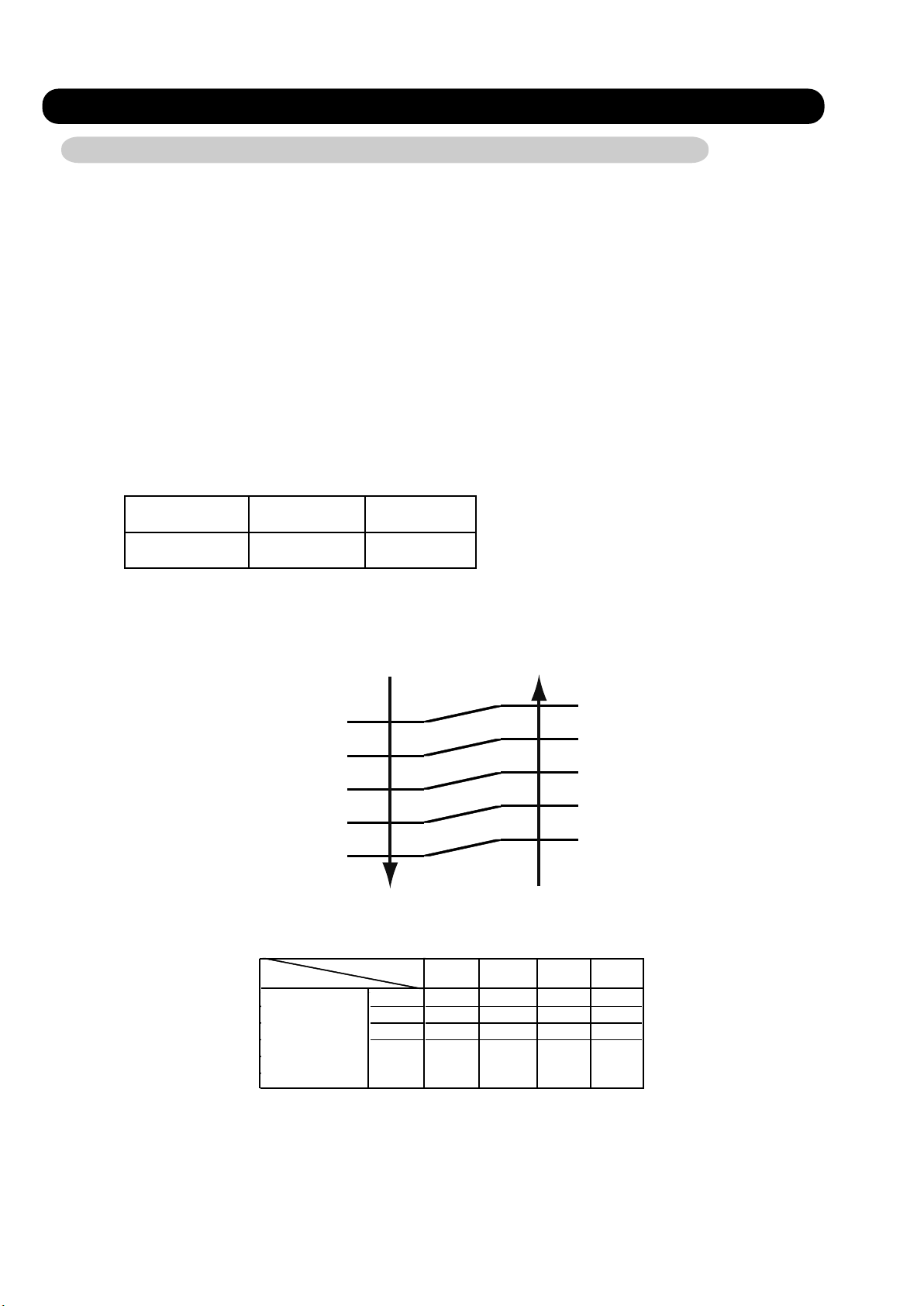

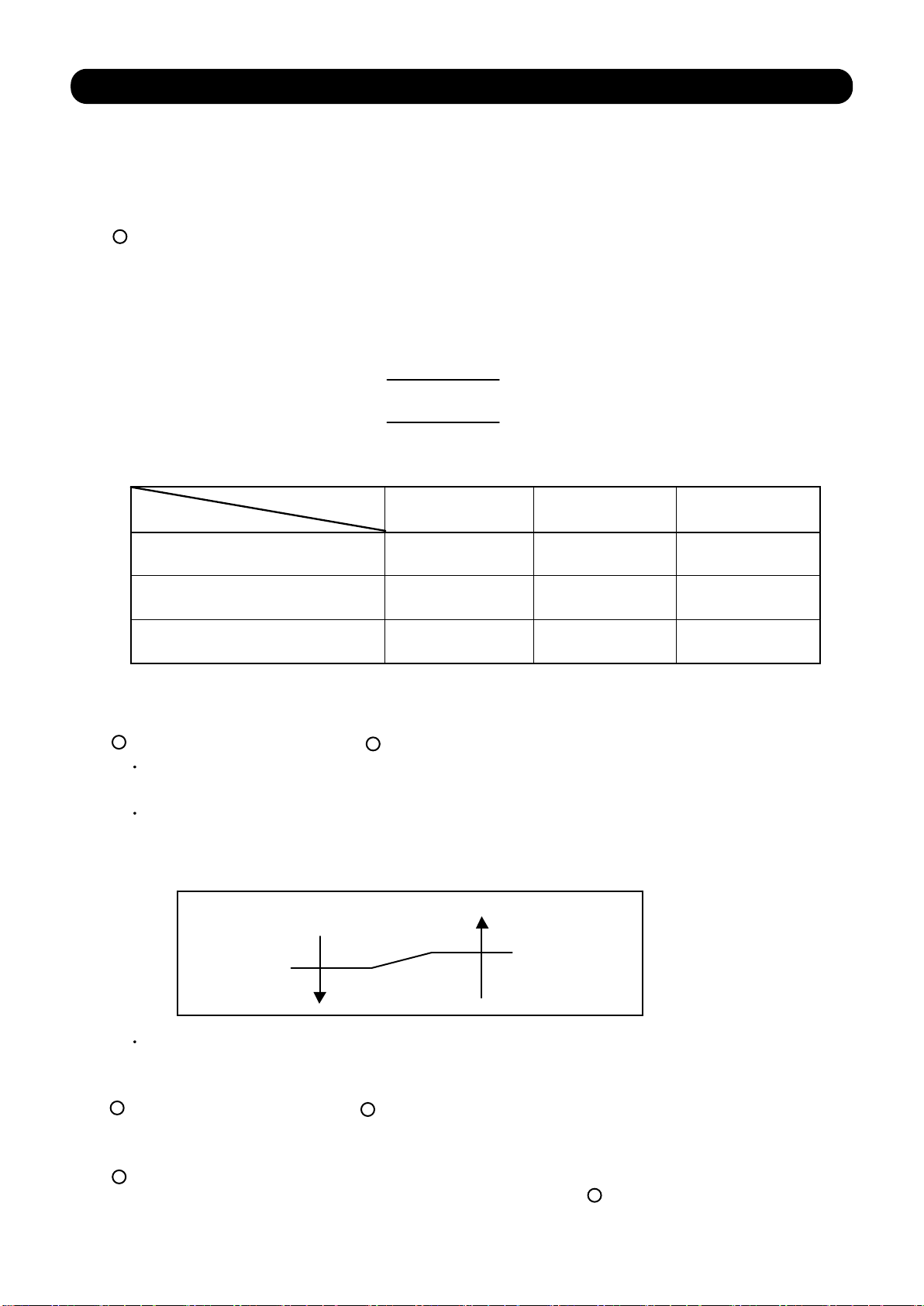

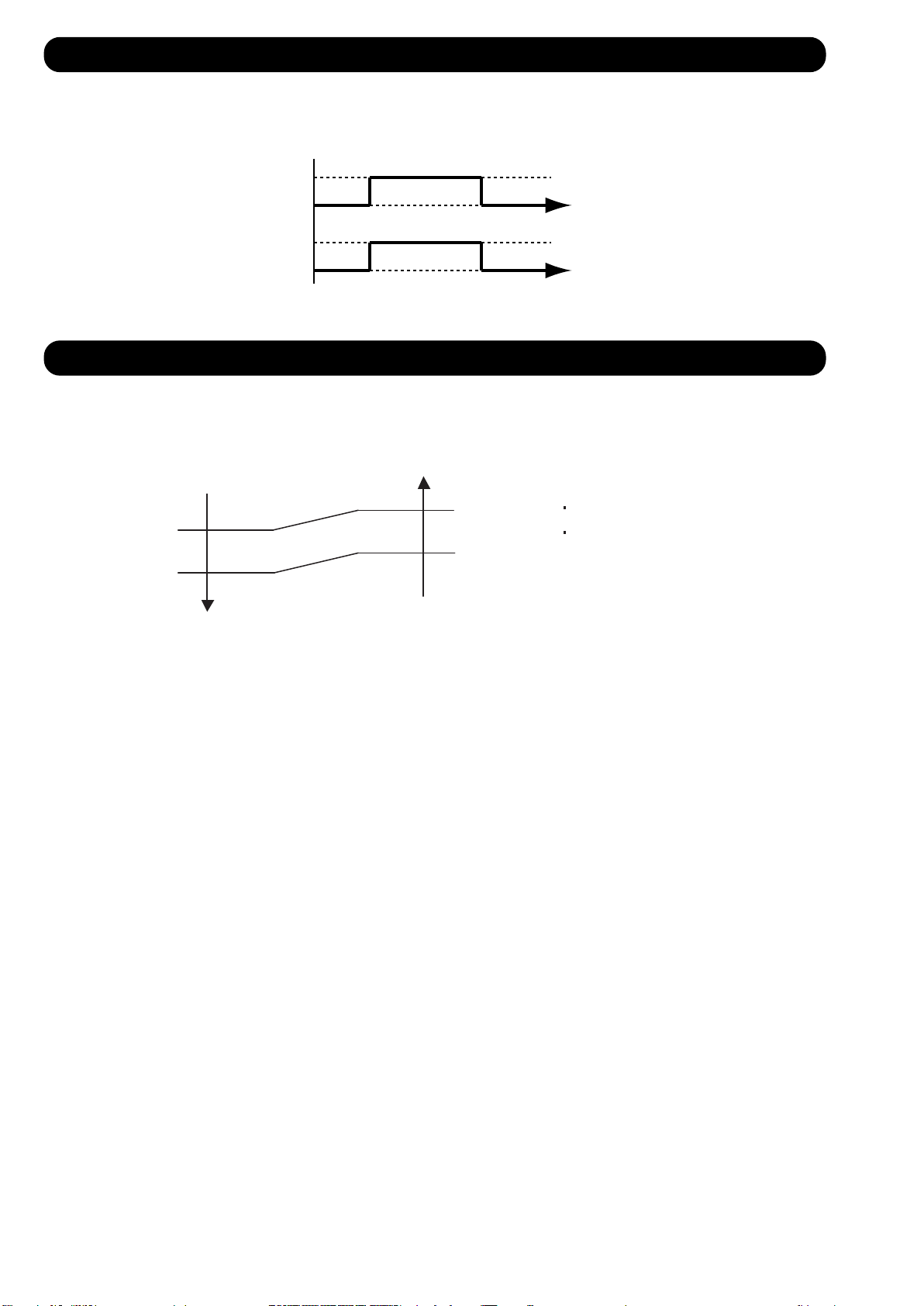

5-1. COOLING OPERATION

5-1-1 COOLING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

The maximum frequency is limited in the range shown in Figure 1 based on the fan speed mode

and the outdoor temperature.

* If the room temperature is 2 °C higher than a set temperature,

the compressor operation frequency will attain to maximum frequency.

* If the room temperature is 2.5 °C lower than a set temperature, the compressor

will be stopped.

* When the room temperature is between +2 °C to -2.5 °C of the setting temperature,

the compressor frequency is controlled within the range shown in Table1.

( Table 1 : Compressor Frequency Range )

AR*A30LBTU

AR*A36LBTU

minimum

frequency

23Hz 94Hz

maximum

frequency

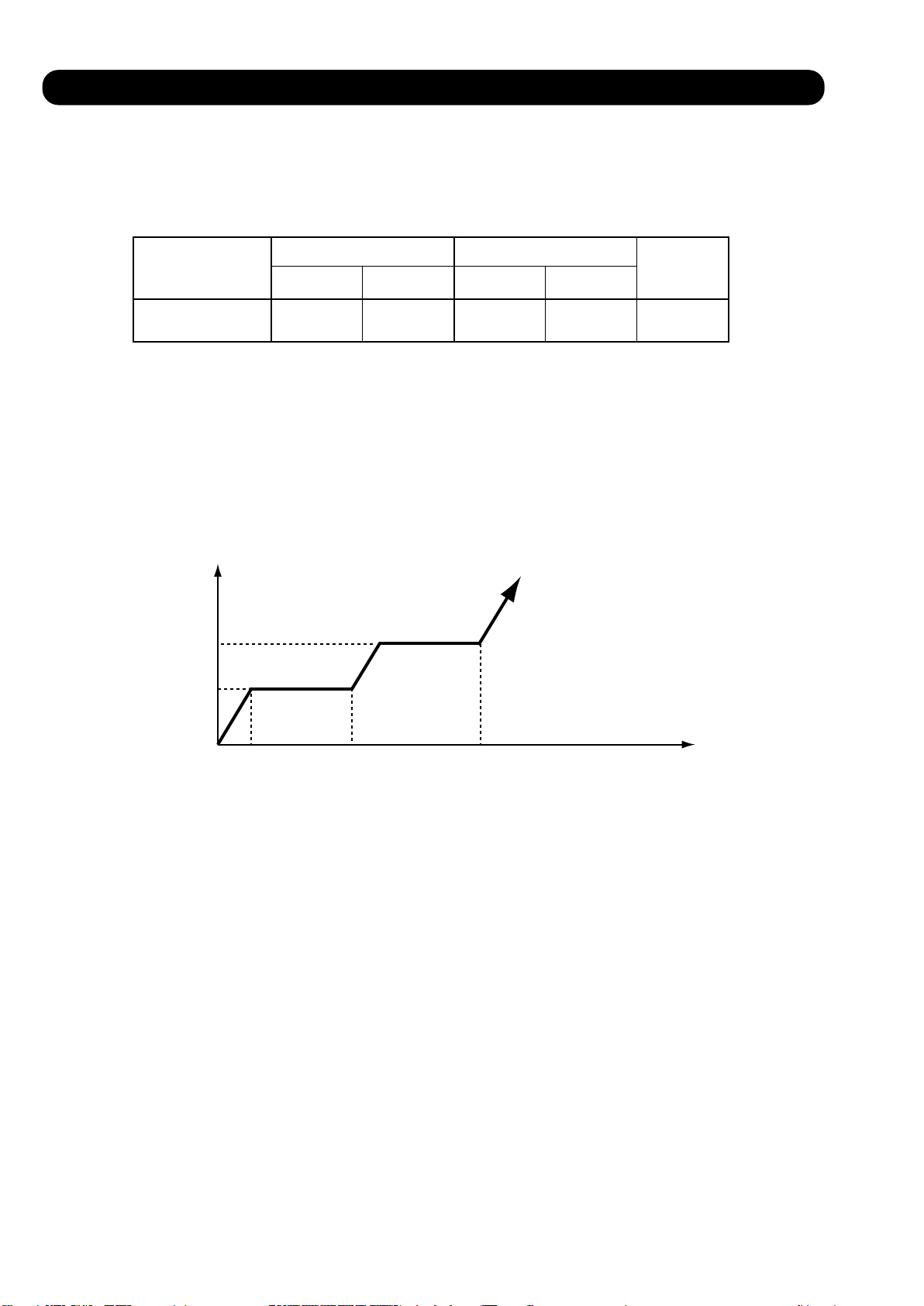

( Fig. 1 : Limit of Maximum Frequency based on Outdoor Temperature )

Outdoor air

temperature

When the room

temperature drops

A zone

B zone

C zone

D zone

E zone

F zone

When the room

temperature rises

Fan speed mode

AR*A30LBTU

AR*A36LBTU

A zone

B zone

C zone

D .E .F

zone

Hi

94Hz 76Hz 64Hz 51Hz

94Hz 76Hz 64Hz 51Hz

85Hz 64Hz 57Hz 51Hz

64Hz 57Hz 51Hz 45Hz

05-01

Me Lo Qu

5-2. HEATING OPERATION

19°C

17°C

14°C

12°C

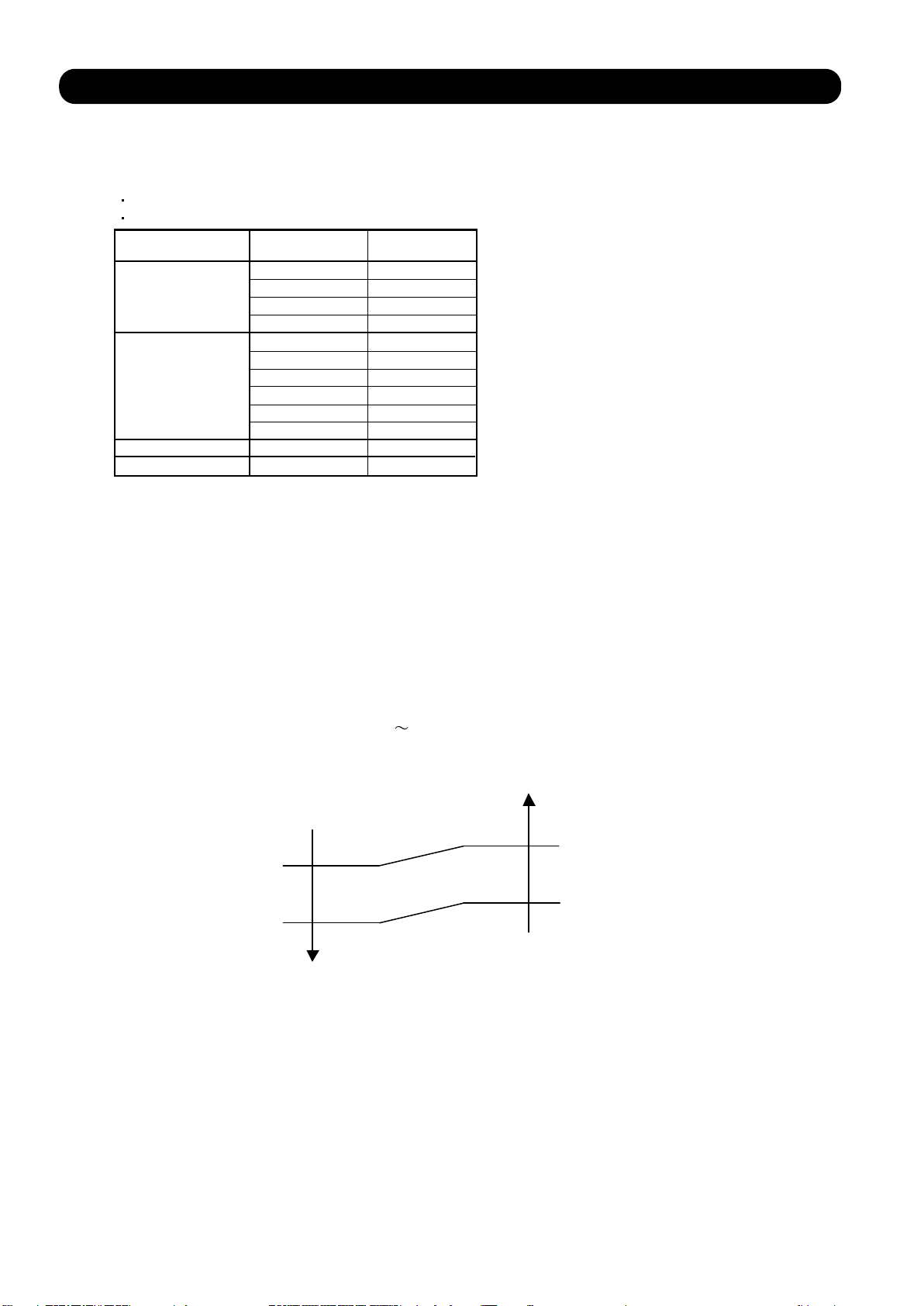

5-2-1 HEATING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

The maximum frequency is limited in the range shown in Figure 2 based on the outdoor temperature.

* If the room temperature is lower 3 °C than a set temperature,

the compressor operation frequency will attain to maximum frequency.

* If the room temperature is higher 2.5 °C than a set temperature, the compressor

will be stopped.

* When the room temperature is between +2.5 °C to -3 °C of the setting temperature,

the compressor frequency is controlled within the range shown in Table2.

( Table 2 : Compressor Frequency Range )

AR*A30LBTU

AR*A36LBTU

minimum

frequency

23Hz

maximum

frequency

120Hz

( Fig.2 : Limit of Maximum Frequency based on Outdoor Temperature )

Outdoor air

temperature

When the room

temperature rises

A zone

B zone

C zone

AR*A30LBTU

AR*A36LBTU

When the room

temperature drops

Fan speed mode

A zone

B zone

C zone

Hi Me

120Hz 88Hz 76Hz 67Hz

Lo Qu

05-02

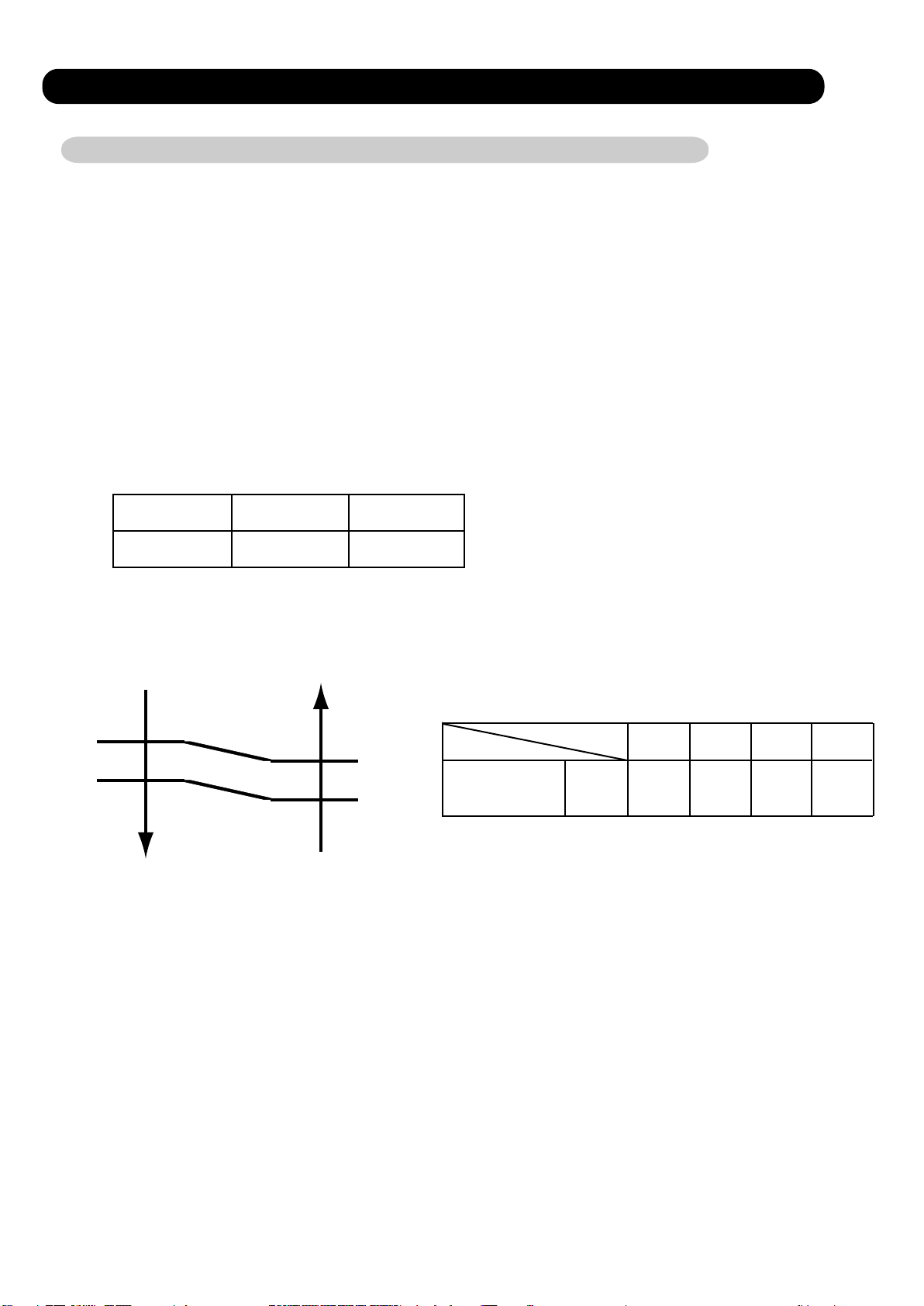

5-3. DRY OPERATION

5-3-1 INDOOR UNIT CONTROL

The compressor rotation frequency shall change according to set temperature and room

temperature variation which the room temperature sensor of the indoor unit has detected

as shown in the Fig 3.

( Table 3 : Compressor frequency )

[ AR*A30LBTU ]

[ AR*A36LBTU ]

Temperature zone

Operating frequency

X zone

Y zone

51Hz

0Hz

( Fig.3 : Compressor Control based on Room Temperature )

Room

temperature

Ts+0.5 °C

X zone

Compressor ON

Ts+1.5 °C

Ts : Setting temperature

Y zone

Compressor OFF

( Fig.4 : Indoor Fan Control )

Compressor

ON

OFF

Room

temperature

Indoor fan

Dry air flow

S-Lo

OFF

10 30 60 180 60 180 60 10 30

[ AR*A30/36LBTU : Dry air flow 550rpm, S-Lo 350rpm ]

05-03

(sec)

5-4. AUTO CHANGEOVER OPERATION

When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum

mode from among the HEATING, COOLING and MONITORING modes. During operation, the

optimum mode is automatically swiched in accordance with temperature changes. The temperature

can be set between 18°C and 30°C in 1 °C steps.

When operation starts, only the indoor fan is operated for 1 minute. (Air flow mode: S- Lo)

1

After 1 minute, depends on the room temperature and outdoor unit's operarion mode,

the operation mode is selected in accordance with the below.

( Fig.5 : Operation mode selection based on Outdoor Temperature )

[ For AR*A30/ 36LBTU ]

C zone

Outdoor

temperature

( Table 4 : Operation mode selection table )

Outdoor temperature zone

Room temperature :Tb

Tb > Ts +2 °C

32°C

-15°C

B zone

A zone

A zone

Monitoring

B zone

Cooling

(Automatic Dry)

C zone

Cooling

(Automatic Dry)

Ts +2 °C > Tb > Ts -2 °C

Ts -2 °C > Tb

Ts : Setting temperature

2

When COOLING was selected at , the air conditioner operates as follow:

The same operation as COOLING OPERATION of item 5-1 above is performed.

However, the setting temperature is raised 1°C and the room temperature correct coefficient value is 0°C

When the compressor frequency have been below 23Hz for 8 minutes or the room temperature reaches

"setting temperature -1.5°C" , operation is automatically switched to DRY OPERATION of item 5-3 above

is performed.

However, compressor control based on room temperature is as follows.

If the room temperature reaches "setting temperature +2°C" during DRY operation,

operation returns to COOLING operation.

=

Room

temperature

Ts - 1.5°C

=

1

Compressor :ON

Compressor :OFF

Monitoring

Heating

Ts - 0.5°C

Monitoring

Heating

Monitoring

Monitoring

3

When HEATING was selected at , the same operation as HEATING OPERATION of item 5-2

above is performed. However, the room temperature correct coefficient value is 0°C.

4

When the compressor was stopped for 6 consecutive minutes by the temperature control function

after the COOLING or HEATING operation mode was selected at above, operation is switched

to MONITORING and the operation mode is selected again.

1

1

05-04

5-5. INDOOR FAN CONTROL

1. Fan speed

( Table 5 : Indoor Fan Speed )

AR*A30LBTU

AR*A36LBTU

Operation mode Air flow mode Speed (rpm)

Cooling

Heating

Dry

Monitoring

2. FAN OPERATION

The airflow can be switched in 5 steps such as AUTO, QU, LOW, MED, HIGH, while the indoor

fan only runs.

When [AUTO] is selected, the indoor fan motor runs continuously [MED] mode.

Hi 1170

Me

Lo

Qu

Hi 1270

Me+

Me

Lo

Qu

Cool Air Prevention

Auto

S-Lo 370

980

790

630

980

790

630

630

3. COOLING OPERATION

Switch the airflow [AUTO], and the indoor fan motor will run according to a room temperature,

as shown in Figure 5.

On the other hand, if switched in [HIGH] [QU], the indoor motor will run at a constant airflow of [COOL]

operation modes QU, LOW, MED, HIGH,as shown in Table 6.

( Fig.6 : Airflow change - over ( Cooling : AUTO ) )

TR : Room temperature

TR-Ts > 2 °C

=

2 °C > TR-Ts > 1 °C

=

1 °C > TR-Ts

HIGH mode

MED mode

LOW mode

When the room

temperature drops

TR-Ts > 2.5 °C

=

2.5 °C > TR-Ts > 1.5 °C

1.5 °C > TR-Ts

When the room

temperature rises

=

Ts : Setting temperature

05-05

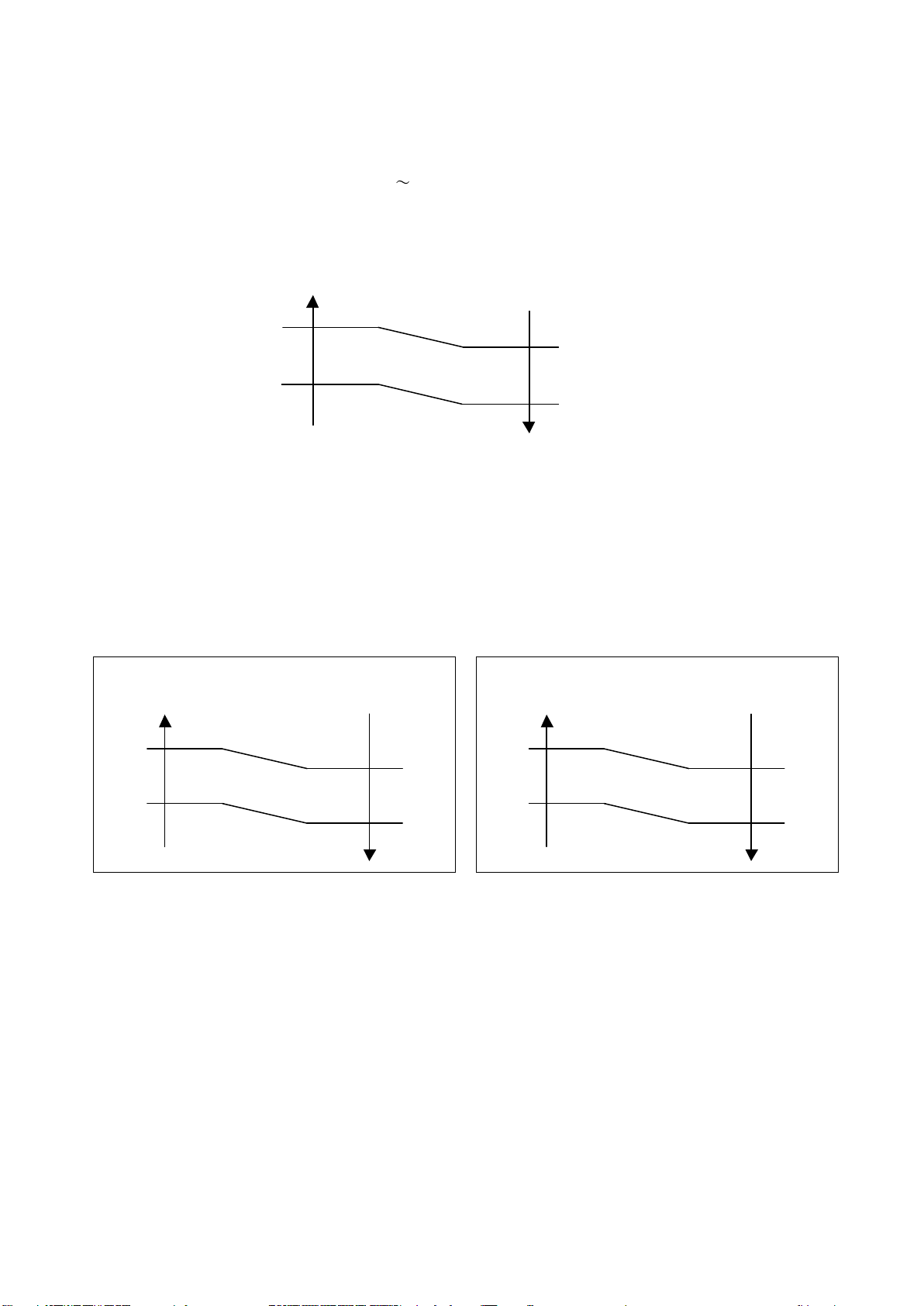

4. HEATING OPERATION

Switch the airflow [AUTO], and the indoor fan motor will run according to a room temperature,

as shown in Figure 7.

On the other hand, if switched in [HIGH] [QU], the indoor motor will run at a constant airflow

of [HEAT] operation modes QU, LOW, MED, HIGH, as shown in Table 5.

( Fig.7 : Airflow change - over ( Heating : AUTO ) )

TR : Room temperature

Ts : Setting temperature

TR-Ts > - 1 °C

=

- 1 °C> TR-Ts > - 2 °C

- 2 °C> TR-Ts

=

When the room

temperature rises

LOW mode

MED mode

HIGH mode

When the room

temperature drops

TR-Ts > - 1.5 °C

=

- 1.5 °C> TR-Ts > - 2.5 °C

- 2.5 °C> TR-Ts

=

5. COOL AIR PREVENTION CONTROL (Heating mode)

When the compressor operates, the maximum value of the indoor fan speed is set as shown in Figure 8,

based on the detected temperature by the indoor heat exchanger sensor on heating mode.

When the compressor does not operate, the indoor fan motor operates [S-Lo] mode.

( Fig.8 : Cool Air Prevention Control )

(1) Fan mode : HIGH (2) Fan mode : MED, LOW, QUIET

Indoor heat exchanger

temperature

HIGH mode

37°C

LOW mode

30°C

S-LOW mode

Indoor heat exchanger

temperature

32°C

24°C

Indoor heat exchanger

temperature

SETTING

FAN MODE

37°C

LOW mode

30°C

S-LOW mode

Indoor heat exchanger

temperature

32°C

24°C

6. DRY OPERATION

Refer to the Figure 4.

During the dry mode operation, the fan speed setting can not be changed.

05-06

5-6. OUTDOOR FAN CONTROL

1. Outdoor Fan Motor

1-1. For AO*A30/ 36LBTL ( AB*A30 / 36LBT , AR*A30 / 36LBTU )

Following table shows the fan speed of the outdoor unit.

Table 6 : Fan speed of the outdoor unit

Outdoor temperature [Ta]

AO*A30LBTL

AO*A36LBTL

AO*A30LBTL

AO*A36LBTL

Outdoor temperature zone

D zone ( Normal )

12°C

F zone

2°C

G zone

Ta > 12°C

12°C > Ta > 2°C

2°C > Ta

Heating

900/ 780/ 700/ 550/ 450 rpm

10°C

0°C

Cooling

900/ 850/ 780/ 700/ 500 rpm

340/ 320/ 250/ rpm

260/ 250/ rpm

Dry

500 rpm

340/ 320/ 250/ rpm

260/ 250/ rpm

The outdoor fan speed is changed in the range of the speed shown in the above table,

based on the frequency of the compressor.

(When the compressor frequency increases, the outdoor fan speed is also changed to

higher speed. If the compressor frequency decreases, the outdoor fan speed is changed

to the lower speed as well.)

After starting up the outdoor fan, it operates with the following speed for initial 20 seconds.

Table 7 : Fan speed when starting up outdoor fan

Outdoor temperature zone

AO*A30LBTL

AO*A36LBTL

COOL D zone (Normal) / HEATING

COOL F,G zone

After operating the defrost control function on heating mode except economy operation,

its speed becomes 900rpm (AO*A30 / 36LBTL)

regardless of the compressor frequency.

However, it returns to the normal speed control when the defrosting operation does not function

for 240 minutes after releasing the defrost operation or when the outdoor temperature sensor

detection value becomes higher than 5°C.

Fan speed

500 rpm

200 rpm

05-07

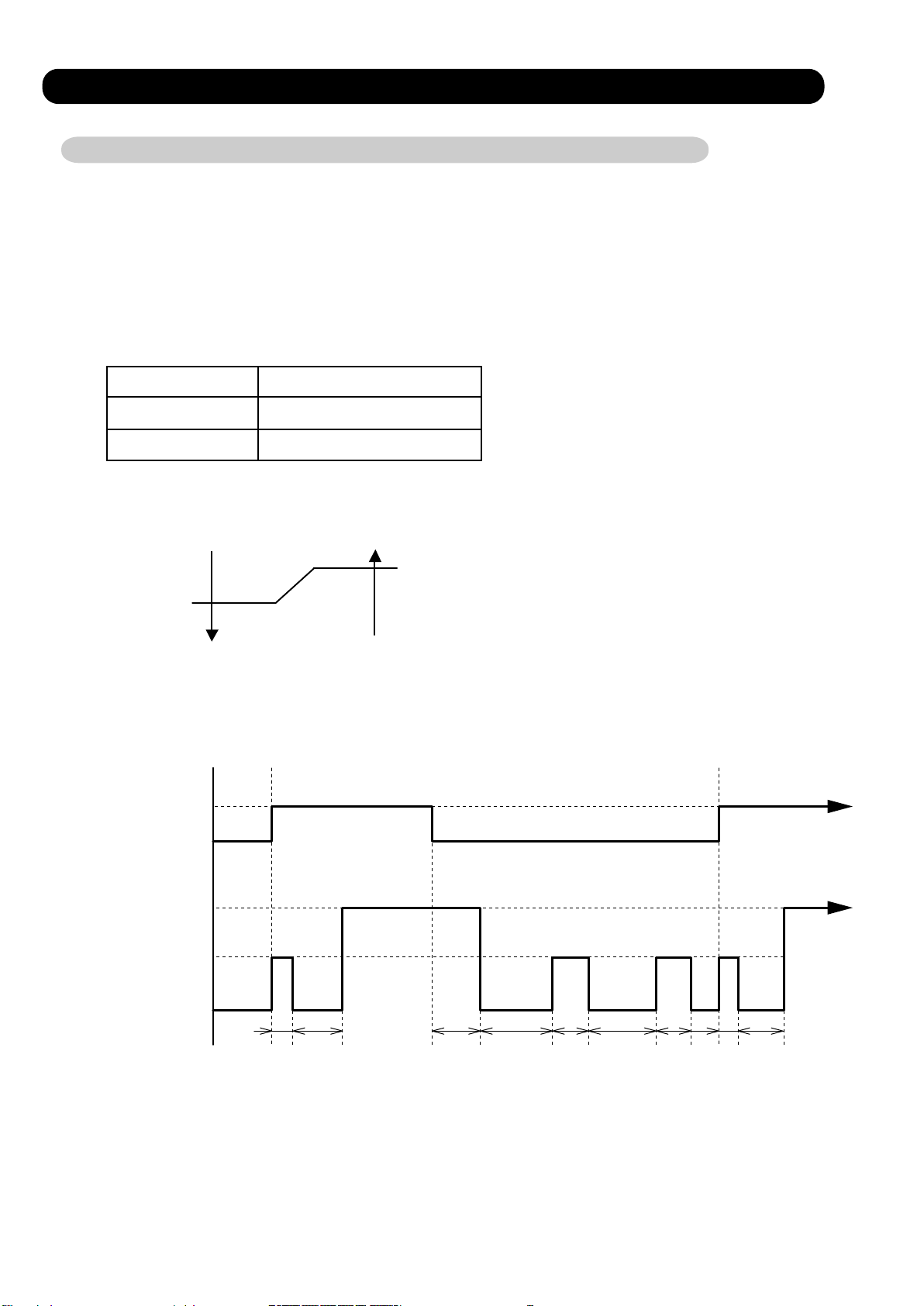

5-7. COMPRESSOR CONTROL

1. OPERATION FREQUENCY RANGE

The operation frequency of the compressor is different based on the operation mode as

shown in Table 9.

(Table 9 : Compressor Operation Frequency Range)

Cooling Heating

Min Max Min Max

Dry

AO*A30LBTL

AO*A36LBTL

23Hz

94Hz

23Hz

120Hz

51Hz

2. OPERATION FREQUENCY CONTROL AT START UP

2-1. For AO*A30/ 36LBTL

The compressor frequency soon after the start-up is controlled as shown in Figure 13.

(Fig.8 : Compressor Control at Start-up)

59Hz

40Hz

46sec

60sec 100sec

05-08

5-8. TIMER OPERATION CONTROL

5-8-1 Wired Remote Controlle

AR-6TC1

ON / TIMER

OFF / TIMER

WEEKLY TIMER

TEMPERATURE SET BACK TIMER

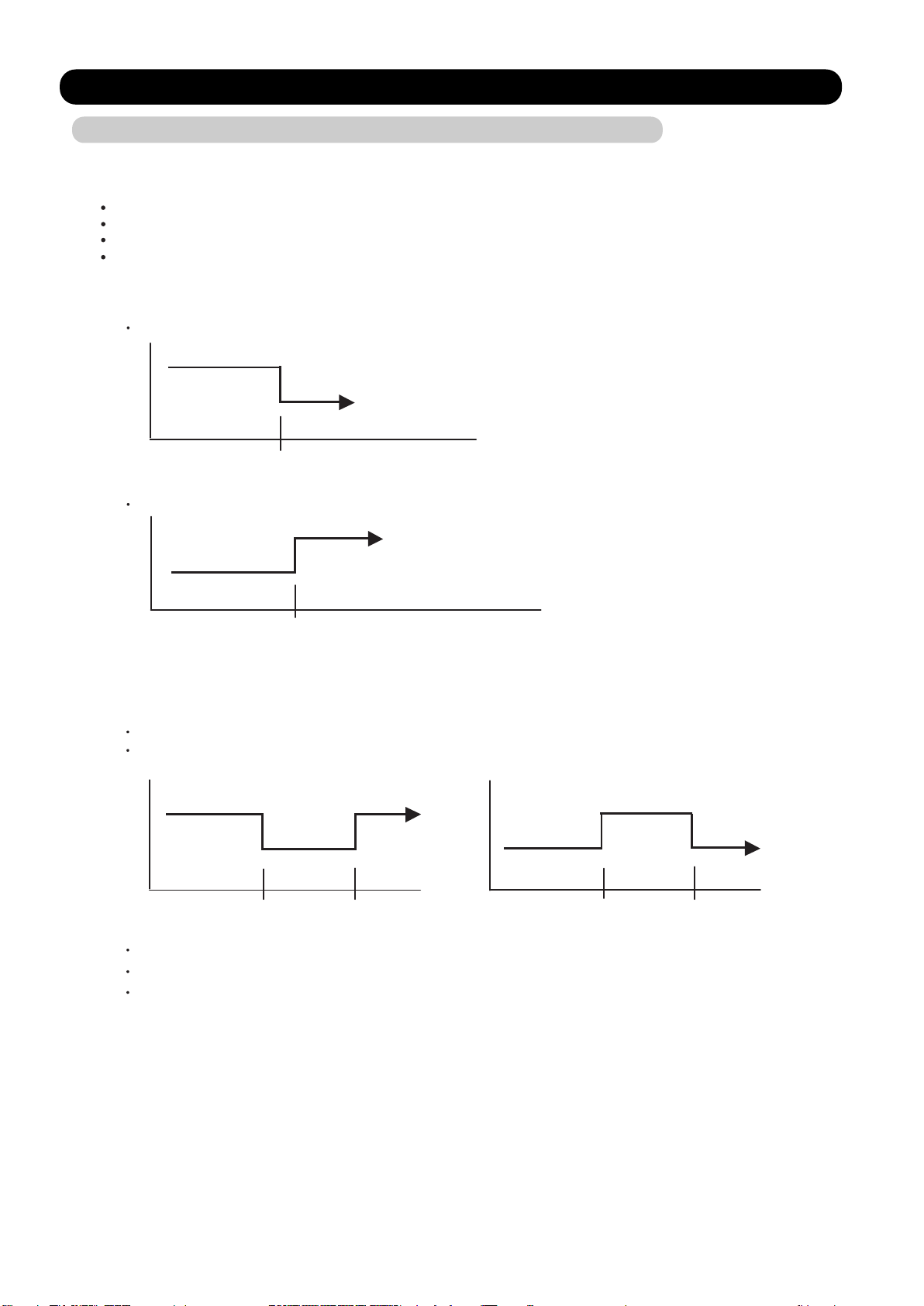

1. ON / OFF TIMER

OFF timer : When the clock reaches the set time, the air conditioner will be turned off.

Operation mode

Stop mode

Set time of timer

ON timer : When the clock reaches the set time, the air conditioner will be turned on.

Operation mode

Stop mode

Set time of timer

2. WEEKLY TIMER

2-1. WEEKLY TIMER

Use this timer function to set operating time for each day of the week.

The weekly timer allows up to two ON and OFF time to set up per day.

Operation mode

Stop mode

Set time

The operating time can be set in 30 min increments only.

The OFF time can be carried over to next day.

The ON timer and the OFF timer functions cannot be set with using the weekly timer.

Both ON and OFF time must be set.

Operation mode

Stop mode

Set time Set time Set time

Operation mode

Stop mode

05-09

2-2. DAY OFF setting

The DAY OFF setting is only available for days for which weekly settings already exist.

If the operating time carries over to the next day (during a next day setting), the effective

DAY OFF range will be set as shown below.

Normal

DAY OFF

Operation mode

Operation mode

Stop mode

Stop mode

Preceding day Next day

Setting day

Stop mode

Next day setting

DAY OFF

Stop mode

Operation mode

Stop mode

Preceding day Next daySetting day

Operation mode

Stop mode

The DAY OFF setting can only be set one time. The DAY OFF setting is cancelled automatically

after the set day has passed.

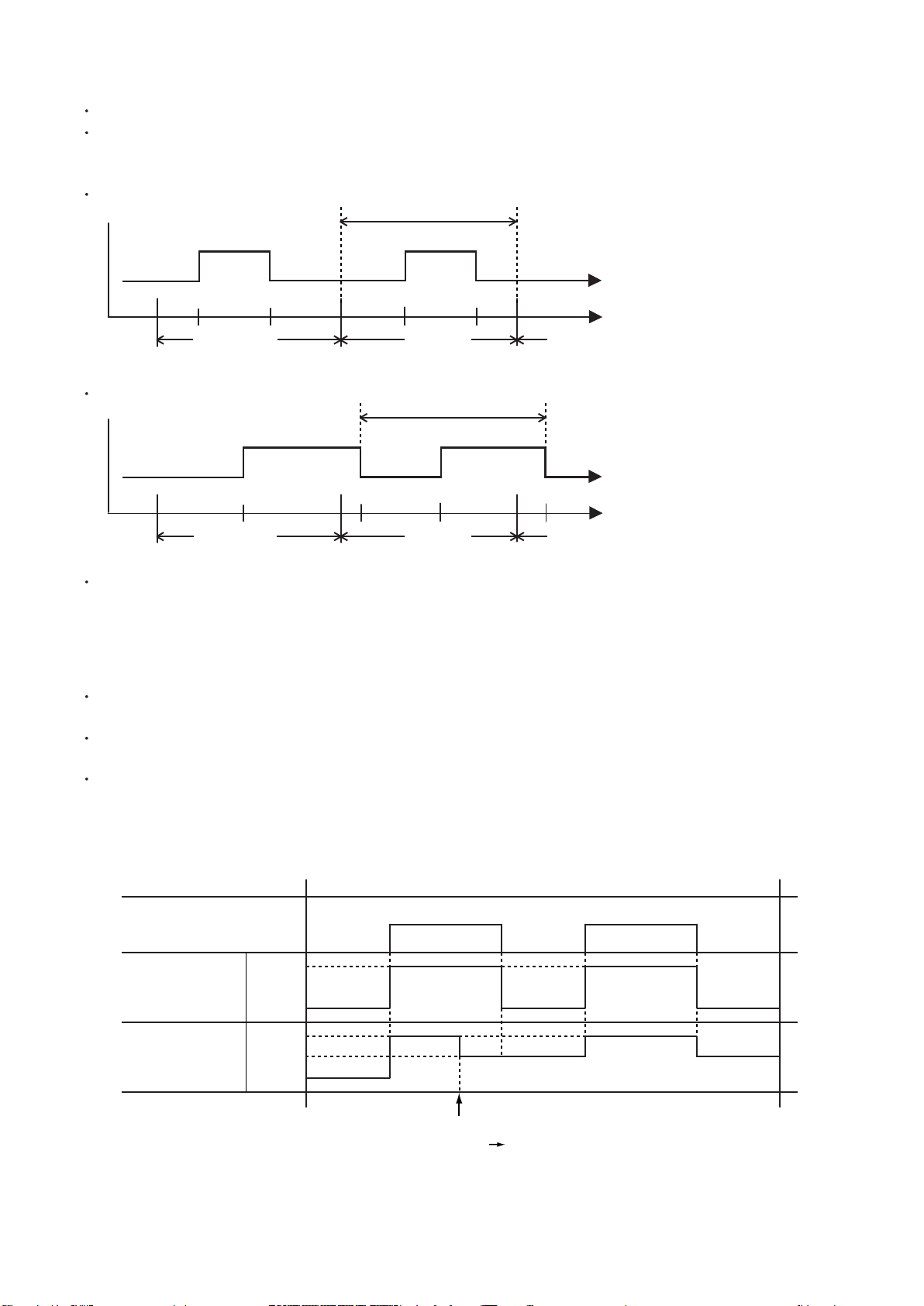

3. TEMPERATURE SET BACK TIMER

The SET BACK timer only changes the set temperature for 7 days, it cannot be used to start or stop

air conditioner operation.

The SET BACK timer can be set to operate up to two times per day but only one temperature setting

can be used.

During the COOL/DRY mode, the air conditioner will operate at a minimum of 18°C even if

the SET BACK temperature is set to 17°C or lower.

Case of SET BACK timer on the Cooling operation.

( Setting temperature :22°C, SET BACK temperature :26°C)

SET BACK setting

Operation

temperature

*1

Operation

temperature

*1: During the SET BACK function,

the setting temperature is changed.

26°C

22°C

26°C

24°C

22°C

ON OFF OFFON

Chenge the setting temperature:

22°C 24°C

+1

05-09

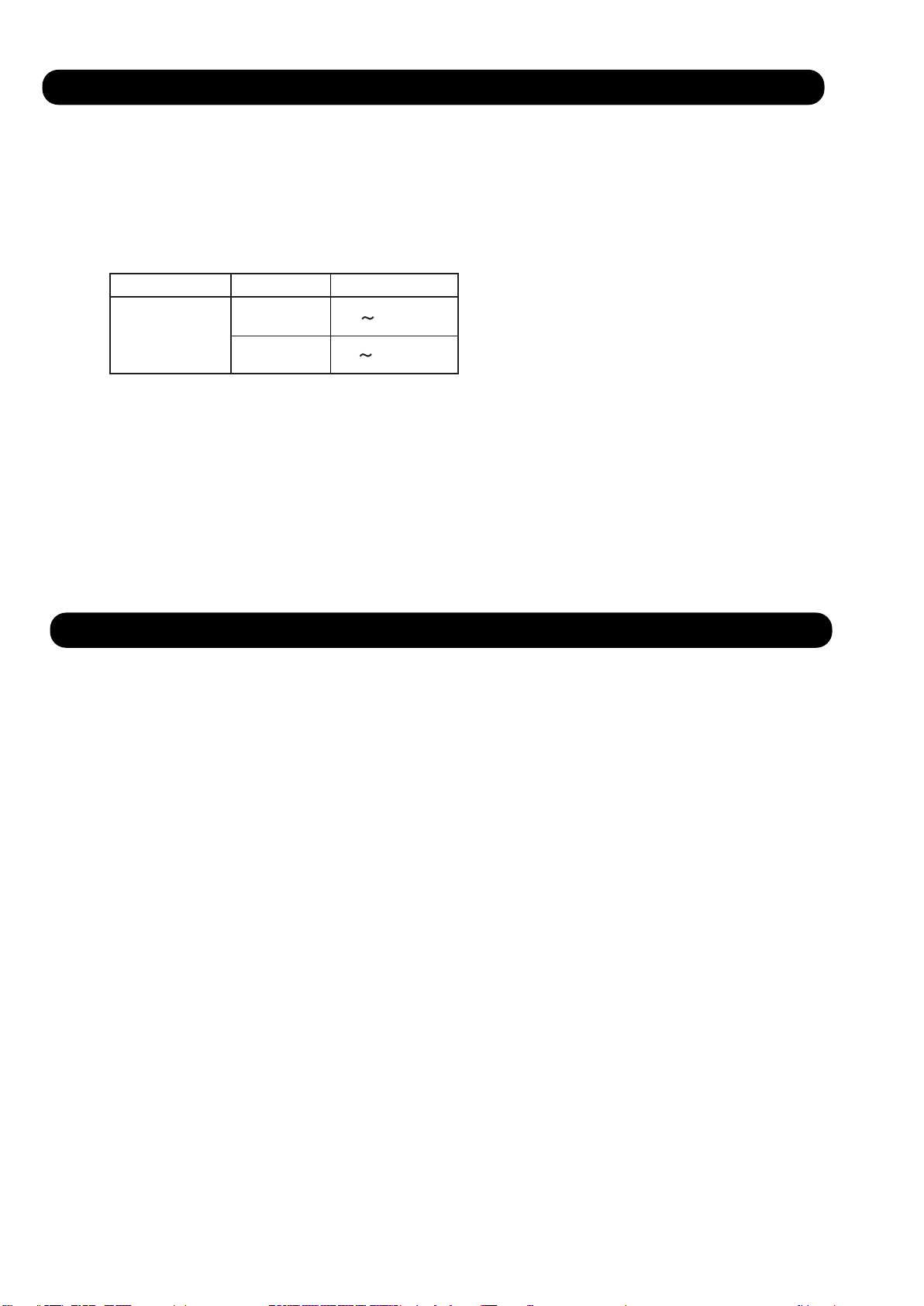

5-9. ELECTRONIC EXPANSION VALVE CONTROL

The most proper opening of the electronic expansion valve is calculated and controlled under the

present operating condition based on the following values.

The compressor frequency, the temperatures detected by the discharge temperature sensor, the

indoor heat exchanger sensor, the outdoor heat exchanger sensor, and the outdoor temperature

sensor.

(1) Pulse range of EEV

Pulse range

53 480 pulse

40 480 pulse

AR*A30LBTU

AR*A36LBTU

Operation

Cooling/ Dry

Heating

(2) The EEV is set up at 480 pulses when the compressor is stopped.

(3) Intialization (Input of 528 pulses toward closing direction) is operated under

the following condition.

* When the power is turned on.

* 4 hours has passed since the last initialization, and 3 minutes has passed after

the compressor stop.

(If 12 hours has passed since the last initialization, the compressor is compulsorily stopped.)

5-10. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST )

The compressor won't enter operation status for 3 minutes after the compressor is stopped,

even if any operation is given.

05-10

5-12. 4-WAY VALVE EXTENSION SELECT

At the time when the air conditioner is switched from the cooling mode to heating mode,

the compressor is stopped, and the 4-way valve is switched in 3 minutes later

after the compressor stopped.

5-13. AUTO RESTART

When the power was interrupted by a power failure, etc. during operation, the operation contents

at that time are memorized and when power is recovered, operation is automatically resumed with

the memorized operation contents.

When the power is interrupted and recovered during timer operation, timer operation is canceled,

but only setting time is memorized.

[Operation contents memorized when the power is interrupted]

Operation mode

Set temperature

Set air flow

Timer mode and timer time

Thermistor detected position (When using the Wired Remote Controller)

5-14 PUMP DOWN ( For AR*A30/ 36LBTU )

Perform the following procedures to collect the refrigerant when moving the indoor unit or the outdoor unit.

When the product is stopped:

1. Press the PUMP DOWN switch (SW2) on the outdoor unit.

(The LED on the outdoor unit circuit board starts lighting.)

2. The pump down operation (cooling operation) begins right away.

After operation starts, close the 3-way valve (liquid).

3. After 2-3minutes, operation stops. Close the 3-way valve (gas) within 1minute after operations stops.

4. The LED will go out 3minutes after it stops. Disconnect the power supply after confirming that

the LED has gone out.

When the product is operating:

1. Press the PUMP DOWN switch (SW2) on the outdoor unit. The LED on the outdoor unit circuit board starts

lighting, and operation stops.

At this point, recovery has not been completed, so do not close the 3-way valves (liquid and gas).

2. The pump down operation (cooling operation) begins after 3minutes.

Close the 3-way valve (liquid) after operation starts.

3. After 2-3minutes, operation stops. Close the 3-way valve (gas) within 1minute after operations stops.

4. The LED will go out 3minutes after it stops. Disconnect the power supply after confirming that

the LED has gone out.

5-15. COMPRESSOR PREHEATING

When the outdoor heat exchanger temperature is lower than 5°C and the heating operation

has been stopped for 30 minutes, power is applied to the compressor and the compressor is heated.

(By heating the compressor, warm air is quickly discharged when operation is started.)

When operation was started, and when the outdoor temperature rises to 7°C or greater,

preheating is ended.

05-11

5-16. FRESH AIR CONTROL

The fan motor for Fresh Air is operated in synchronization with the indoor fan operation

as shown in Figure 11.

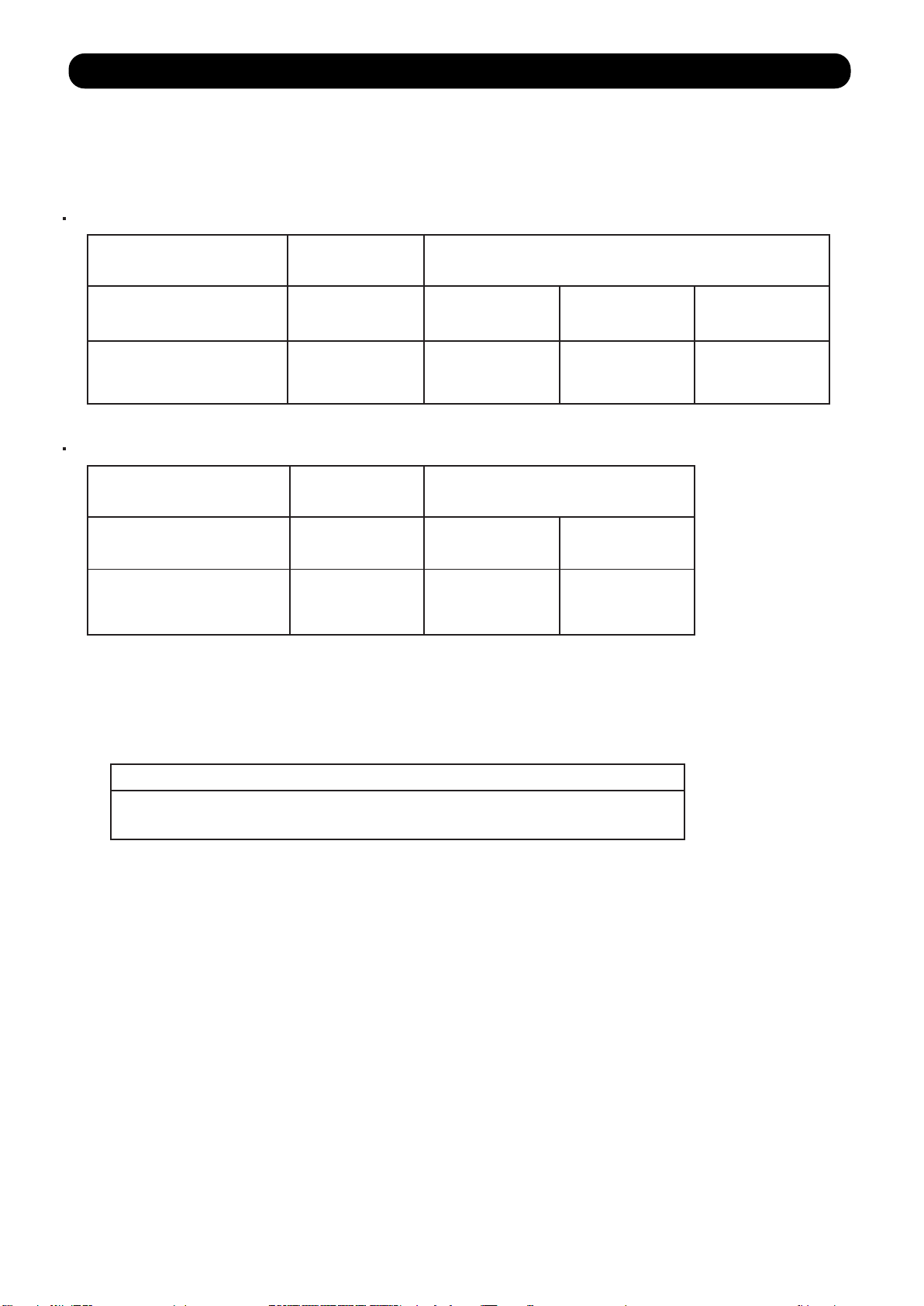

(Fig.11 : Fresh air control)

Fan motor

(Indoor unit)

Fan motor

(for Fresh Air)

Operation

Stop

Operation

Stop

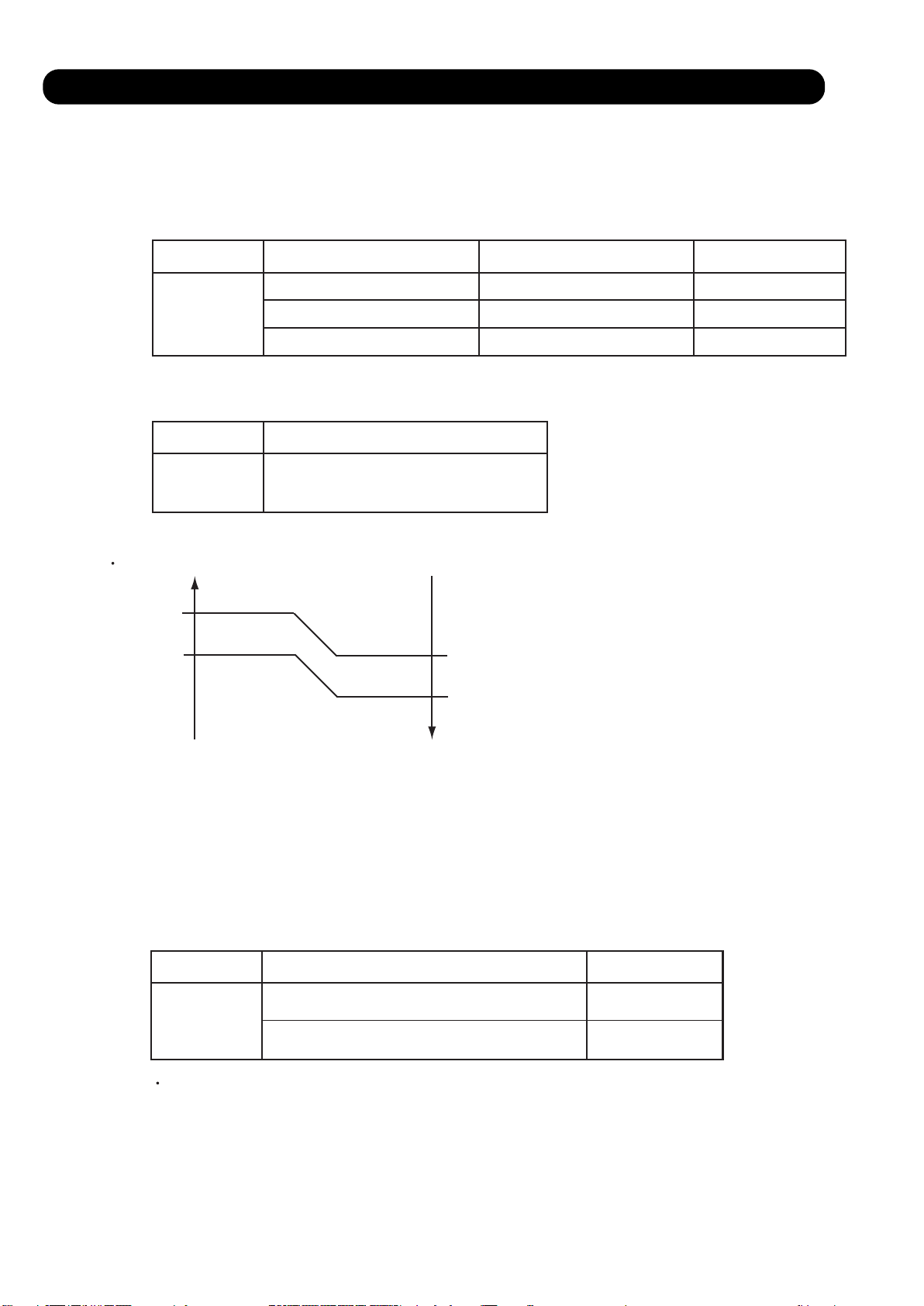

5-17. EXTERNAL ELECTRICAL HEATER CONTROL

The external electrical heater is operated as shown in Figure 12.

(Fig.12 : External electrical heater control)

When the room

temperature rises

Heater : OFF

Ts -1°C

Ts -3°C

Ts -12°C

Heater : ON

Heater : OFF

Ts -10°C

Ts : Setting temperature

When the compressor stop,

External electrical heater is OFF.

When the room

temperature drops

05-12

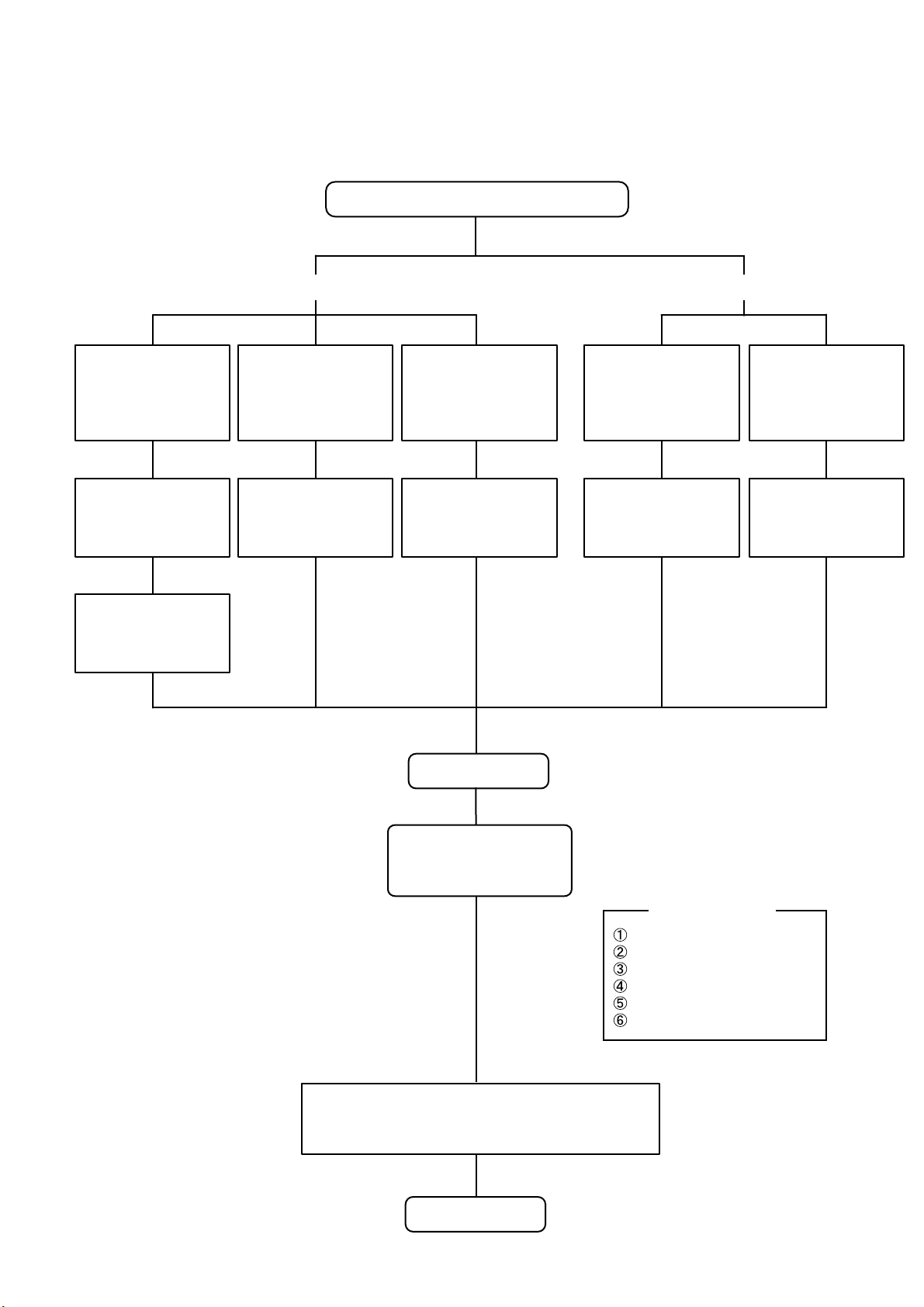

5-18 . DEFROST OPERATION CONTROL

1. CONDITION OF STARTING THE DEFROST OPERATION

The defrost operation starts when the outdoor heat exchanger temperature sensor detects

the temperature lower than the values shown in Table 12.

(Table 12 : Condition of starting Defrost Operation)

1st time defrosting after starting operation

Compressor contiguous

operation time

Compressor integrating

operation time

Operation

temperature

Below 10 min.

Less than 17 min.

Does not operate

17 to 62 min.

- 9°C

Above 10 min.

62 min. to 4 hours

- 5°C

Defrosting after 2nd time upon starting operation

Compressor contiguous

operation time

Compressor integrating

operation time

Operation

temperature

Below 10 min.

Less than 35 min.

Does not operate

Above 10 min.

35 min. to 4 hours

- 6°C

After 4 hours

- 3°C

2. CONDITION OF THE DEFROST OPERATION COMPLETION

Defrost operation is released when the conditions become as shown in Table 13.

After 4 hours

- 3°C

(Table 13 : Defrost Release Condition)

Release Condition

Outdoor heat exchanger temperature sensor value is higher than +13°C or

Compressor operation time has passed 15 minutes.

05-13

3. Defrost Flow Chart

The defrosting shall proceed by the integrating operation time

and outdoor heat exchanger emperature as follows.

Heating operation start : Compressor ON

(Not defrosted for 10 minutes)

Compressor integrating

operation:

Over 17 minutes to

below 62 minutes

Outdoor

heat exchanger

temperature:

Below - 9°C

Outdoor temp Outdoor heat exchanger

temperature:

Above 5 degC

(In case of 1st defrost)

Compressor integrating

operation:

Over 62 minutes to

below 240 minutes

Outdoor

heat exchanger

temperature:

Below - 5°C

Compressor integrating

operation:

Over 240 minutes

Outdoor

heat exchanger

temperature:

Below - 3°C

(In case of 2nd and later defrost)

Compressor integrating

operation:

Over 35 minutes to

below 240 minutes

Outdoor

heat exchanger

temperature:

Below - 6°C

Compressor integrating

operation:

Over 240 minutes

Outdoor

heat exchanger

temperature:

Below - 3°C

Defrost start

Defrost Indicator:

[Operation lamp]

7 sec ON / 2 sec OFF

Outdoor fan : OFF

Compressor frequency : 0 Hz

EEV : 480pulse

4-way valve : OFF

Outdoor fan : OFF

Compressor frequency : 70Hz

Outdoor heat exchanger temperature: Over 13°C

or

Compressor ON time: Over 15 minutes

Defrost end

AR*A30/ 36LBTU

05-14

Loading...

Loading...