Page 1

DEH40380 R02

g

Power Break® II Switches

800–4000 A Frames, 240–600 Vac

User’s Guide

Page 2

Power Break® II Switches

Getting Started

Since this switch is available in a variety of configurations, please take a moment to compare the catalog number of your

purchased switch with the catalog number key below. Installation of an incorrect switch could result in misapplication,

lack of system coordination, or reduced system selectivity. If you have any questions, call the GE Customer Support

Center at 800-843-3742.

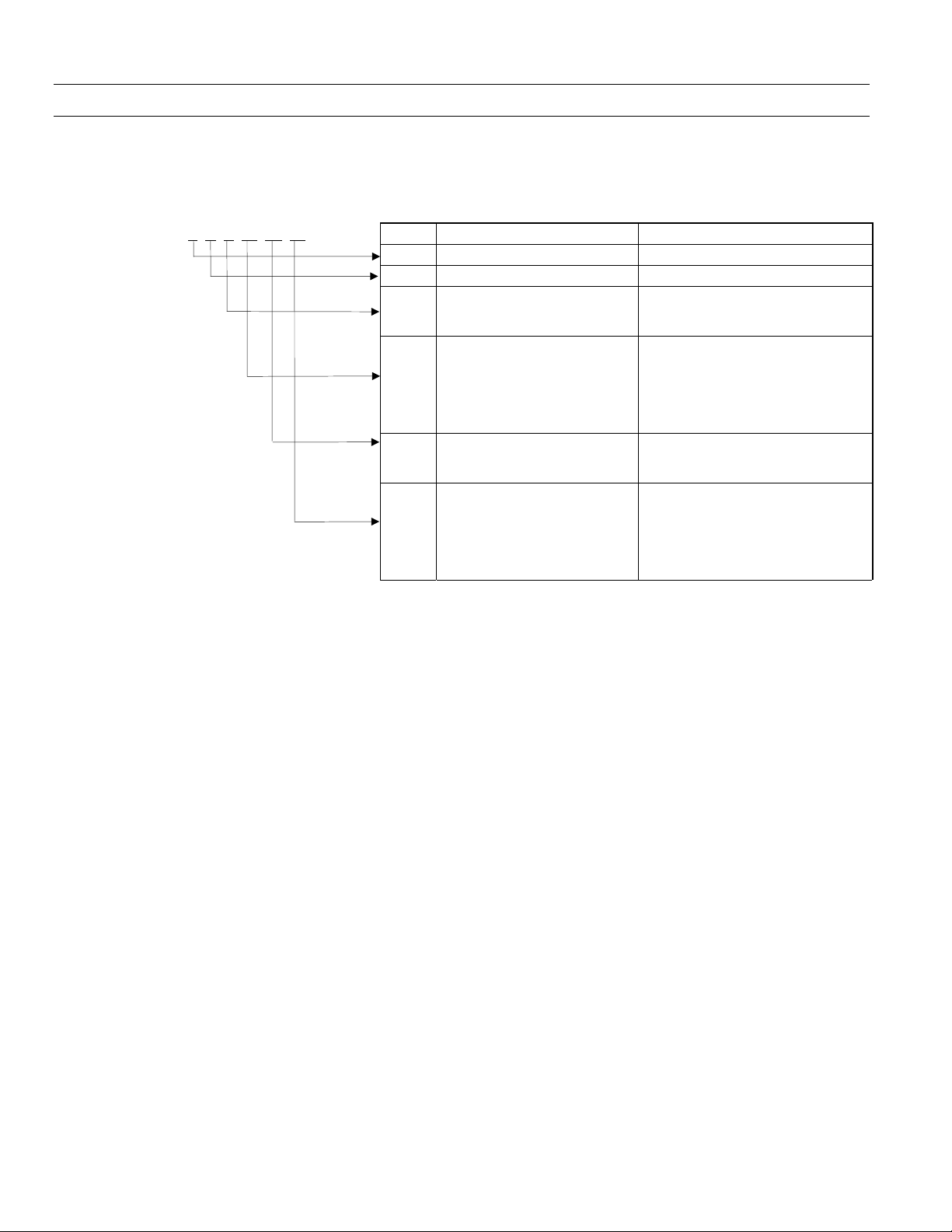

S H D 20 Y2 20 Code Description Function

H Hi-Break

B

08

Y2

08

Power Break® II insulated-case switch catalog numbering system.

S Power Break® II Switch Family

Frame Type

Back-connected

D

Draw-out

F

Front-connected

800 A

16

1600 A

20

2000 A

25

2500 A

30

3000 A

40

4000 A

up to 2000 A CTs

Y3

2500–3000 A CTs

Y4

4000 A CTs

800 A

16

1600 A

20

2000 A

25

2500 A

30

3000 A

40

4000 A

Connection Type

Frame Rating

Power+™ Control Unit

Maximum CT Current Rating

Example – a switch with catalog number SSD20Y220 has the following features:

• Power Break® II (S)

• Hi-Break frame (H)

• Draw-out (D)

• 2000 A frame rating (20)

• Control Unit with 2000 A CT (Y2)

• 2000 A CT rating (20)

Page 3

WARNINGS

CAUTIONS

NOTES

DEH40380

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or

other conditions that could cause personal injury are present in this equipment or may be

associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care is not taken.

Notes call attention to information that is especially significant to understanding and operating the

equipment.

This document is based on information available at the time of its publication. While efforts have

been made to ensure accuracy, the information contained herein does not cover all details or

variations in hardware and software, nor does it provide for every possible contingency in

connection with installation, operation, and maintenance. Features may be described herein that

are not present in all hardware and software systems. GE Industrial Systems assumes no obligation

of notice to holders of this document with respect to changes subsequently made.

GE Industrial Systems makes no representation or warranty, expressed, implied, or statutory, with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness

of the information contained herein. No warrantees of merchantability or fitness for purpose shall

apply.

The following are trademarks of GE Company:

Power Break®, Power+™

© Copyright 2001 GE Company

All Rights Reserved

i

Page 4

Power Break® II Switches

Table of Contents

Chapter 1. Introduction

1-1 Overview ..................................................................................................................................... 1

1-2 Receiving the Switch .................................................................................................................. 1

Storage................................................................................................................................ 1

1-3 Preparation for Installation........................................................................................................ 1

Bolted Electrical Connections............................................................................................ 1

Panel Cutouts and Clearances............................................................................................ 1

Accessory Installation ......................................................................................................... 2

1-4 Switch Installation...................................................................................................................... 3

Chapter 2. Operation

2-1 Standard Features....................................................................................................................... 4

2-2 Operating Instructions............................................................................................................... 4

Sequence of Operations...................................................................................................... 4

Operating Instructions for Manually Operated Switchs..................................................... 4

Additional Instructions for Motor-Operated Switchs......................................................... 6

Padlock Operation.............................................................................................................. 6

Periodic Operational Checks.............................................................................................. 6

Wiring Notes ....................................................................................................................... 6

2-3 Trip Unit Setup .......................................................................................................................... 7

Chapter 3. Accessory Operation

3-1 Lug and Adapter Kits ................................................................................................................. 8

Lug Kits (800–2000 A Frames)........................................................................................... 8

Lug Kits with Straps (2500–4000 A Frames) ...................................................................... 8

T-Studs................................................................................................................................ 8

Adapter Kits ........................................................................................................................ 8

3-2 Plug-In Accessory Compartment................................................................................................ 9

3-3 Bell Alarm–Alarm Only.............................................................................................................. 9

Operation ........................................................................................................................... 9

3-4 Bell Alarm with Lockout............................................................................................................. 9

Operation ......................................................................................................................... 10

3-5 Shunt Trip................................................................................................................................ 10

Operation ......................................................................................................................... 10

3–6 Shunt Trip with Lockout......................................................................................................... 11

Operation ......................................................................................................................... 11

3-6 Undervoltage Release............................................................................................................... 11

Operation ......................................................................................................................... 11

3-8 Motor Operator Mechanism .................................................................................................... 12

Remote Operation............................................................................................................ 12

Automatic Operation........................................................................................................ 12

3-9 Remote Close............................................................................................................................ 12

Remote Operation............................................................................................................ 12

ii

Page 5

Power Break® II Switches

Table of Contents

3-10 Key Interlock Mounting Provision..........................................................................................13

Operation.......................................................................................................................... 13

3-11 Mechanical Counter ............................................................................................................... 14

3-12 Auxiliary Switch Module......................................................................................................... 14

Operation.......................................................................................................................... 14

3-13 Door Interlock.........................................................................................................................15

Operation.......................................................................................................................... 15

3-14 Push Button Cover.................................................................................................................. 15

Operation.......................................................................................................................... 15

Chapter 4. Trouble-Shooting Guide

............................................................................................ 17

iii

Page 6

Power Break® II Switches

List of Figures

1. Locations of the front-panel escutcheon cutout and mounting holes, 800–2000 A frames. .................. 2

2. Locations of the front-panel escutcheon cutout and monting plate, 2500–4000 A frames....................2

1

3. Locations of the

2000 A frames.......................................................................................................................................... 3

4. Locations of the

2500–3000 A back-connected frames. ..................................................................................................... 3

5. Locations of the 3/4-inch diameter through holes for mounting the switch in equipment, 4000 A

front-connected frame. ........................................................................................................................... 3

6. Front of the switch, showing the locations of standard features.............................................................4

7. Front of the switch, with the Trip Unit and top cover removed............................................................. 4

8. Side view of the switch, showing the padlock hasp extended.................................................................6

9. Terminal block mounted on the right side of the switch.......................................................................7

10. Locations of the plug-in accessory modules In the compartment on the front of the switch................ 9

11. Bell Alarm–Alarm Only module............................................................................................................. 9

12. Bell Alarm–Alarm Only connections on the right terminal block. ........................................................9

13. Bell Alarm with Lockout module..........................................................................................................10

14. Bell Alarm with Lockout connections on the right terminal block. ..................................................... 10

15. Shunt Trip module............................................................................................................................... 10

16. Shunt Trip with Lockout module......................................................................................................... 11

17. Undervoltage Release module. .............................................................................................................11

18. Motor Operator Mechanism.................................................................................................................12

19. Remote Close accessory......................................................................................................................... 13

20. Side view of the switch, showing the padlock tab extended with the Key Interlock installed. ............. 13

21. Mechanical Counter. ............................................................................................................................ 14

22. Auxiliary Switch Module with 12 switches. ...........................................................................................14

23. Auxiliary switch wiring diagram. ..........................................................................................................14

24. Door Interlock accessory installed on the switch.................................................................................. 15

25. Push Button Cover. ............................................................................................................................... 16

/4

–20 x 3/8-inch deep screw inserts for mounting the switch in equipment, 800–

3

/8–16 x 7/16-inch deep screw inserts for mounting the switch in equipment,

iv

Page 7

Power Break® II Switches

List of Tables

1. Weights of the various switch frame sizes, with and without a motor operator......................................1

2. Bolt sizes and mounting torques for bus connections.............................................................................1

3. Sequence of operations that may be performed with Power Break II circuit switches............................5

4. Accessory connections to the right terminal block B. .............................................................................7

5. Catalog numbers and wire sizes of Lug Kits for 800–2000 A frames. ......................................................8

6. Catalog numbers and specifications of Lug Kits with Straps for 2500–4000 A frames. ..........................8

7. Catalog numbers and ratings of T-Studs.................................................................................................8

8. Catalog numbers and ratings of Adapter Kits.........................................................................................8

9. Bell Alarm–Alarm Only catalog numbers...............................................................................................9

10. Bell Alarm with Lockout catalog numbers............................................................................................10

11. Catalog numbers and voltages for the Shunt Trip................................................................................10

12. Catalog numbers and voltages for the Shunt Trip with Lockout..........................................................11

13. Catalog numbers and voltages for the Undervoltage Release...............................................................12

14. Catalog numbers and operating voltages for the Motor Operator Mechanism. ..................................12

15. Catalog numbers and operating voltages for the Remote Close accessory...........................................13

16. Catalog numbers of Key Interlock models. ...........................................................................................13

17. Auxiliary Switch Module catalog numbers............................................................................................14

18. Auxiliary switch positions on the terminal board on the left side of the switch, Block A.....................15

v

Page 8

Page 9

Power Break® II Switches

Chapter 1. Introduction

1-1 Overview

Power Break® II insulated-case switches are designed to

serve low-voltage power circuits and equipment. They are

available with and Power+™ Control Units for operation

of accessories and optional ground-fault detection.

1-2 Receiving the Switch

Unpack the switch and inspect it for shipping damage.

Ensure that the switch has the proper current, voltage,

and interruption ratings for the application by comparing

the catalog number with the table in the Getting Started

section on the inside front page.

The weights of the various frame sizes are listed in Table

1, for reference.

Frame Rating Operation

800 A

1600 A or 2000

A

2500 A

Front Connect

2500 A

Back Connect

3000 A

Front Connect

3000 A

Back Connect

4000 A

Type

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Table 1. Weights of the various switch frame sizes, with and

without a motor operator.

Storage

The switch should be placed in service immediately in its

permanent location. However, if it must be stored for an

indefinite period, it should be carefully protected against

condensation, preferably by storage in a warm dry room.

Switches for outdoor equipment should be stored in that

equipment only when power is available and heaters are in

operation, to prevent condensation.

The switch should be stored in a clean location, free from

corrosive gases or fumes. In particular, protect the switch

from moisture and cement dust, as that combination may

be corrosive.

If the switch is stored for any length of time, it should be

inspected periodically to ensure good mechanical

condition.

Weight

(lb)

71

80

79

88

178

187

167

176

179

188

216

225

320

329

1-3 Preparation for Installation

Bolted Electrical Connections

Using an industry-accepted solvent, remove any foreign

material from the line and load strap surfaces and the

corresponding surfaces of the connecting bus. Ensure that

the mating surfaces are smooth and free of burrs and

nicks.

Place the bus connections in position and align the

mounting holes. Insert and fasten the mounting bolts and

washers according to specifications in Table 2.

Bus Connection

Switch Frame Bolt Diam. Torque

800A (1)

1600-2000A (2) 1/2 in. 300

2500 A (4) 3/8 in. 225

3000 A (4) 3/8 in. 225

4000 A (6) 1/2 in. 300

1

/2 in. 300

Table 2. Bolt sizes and mounting torques for bus connections.

Panel Cutouts and Clearances

Use the following information to prepare the equipment

and assure proper clearances for installation and

operation of the switch.

Figures 1 and 2 show the front-panel escutcheon cutout

patterns and the locations of the switch mounting bolts.

The standard door cutout dimensions require a trim plate

on the switch. The optional dimensions are for flush front

or nonhinged door construction and the trim plate may

be omitted. Ventilation cutouts are required for stationarymounted switches rated 1600 A and larger and for drawout switches rated 2000 A and larger. Ventilation cutouts

not

are

frame switches or for stationary-mounted 800 A frame

switches.

Because of arc chamber venting, the minimum throughair distance from the top of the switch’s molded case to

grounded metal for 800–2000 A switches is 4.50 inches

[114 mm] in an area 5.31 inches x 16.00 inches [135 mm x

406 mm], centered over the vent screens. (Refer to outline

drawings 10054370, Sheets 1–5, for details.)

For 2500–4000 A switches, the minimum through-air

distance from the top of the switch’s molded case to

grounded metal is 8.00 inches [203 mm] in an area 9.00

inches x 16.00 inches [227 mm x 406 mm], over the vent

screens. (Refer to outline drawings 10055629, Sheets 1–7,

for details.)

required for draw-out-mounted 800 A or 1600 A

(in-lb)

1

Page 10

Power Break® II Switches

Chapter 1. Introduction

Figure 1. Locations of the front-panel escutcheon cutout and

mounting holes, 800–2000 A frames.

Accessory Installation

The following accessories may be installed in the switch.

Refer to Chapter 3 of this publication for catalog numbers

and to the instruction sheet supplied with each accessory

for installation instructions.

• Lugs and Adapters

• Motor Operator Mechanism

• Remote Close

• Undervoltage Release

• Shunt Trip

• Shunt Trip with Lockout

• Bell Alarm–Alarm Only

• Bell Alarm with Lockout

• Auxiliary Switch Module

• Mechanical Counter

• Key Interlock Mounting Provision

• Push Button Cover

• Door Interlock

• Mechanical Interlock

Figure 2. Locations of the front-panel escutcheon cutout and

mounting plate, 2500–4000 A frames.

2

Page 11

1-4 Switch Installation

Ensure that all accessory connections are secure. Line up

the bolt holes in the enclosure with the attachment points

on the switch, illustrated in Figures 3, 4 and 5, insert the

bolts and tighten. Use

between the line and load terminals to support the switch.

nonmagnetic

material in the area

Power Break® II Switches

Chapter 1. Introduction

1

Figure 3. Locations of the

for mounting the switch in equipment, 800–2000 A frames.

Figure 4. Locations of the

for mounting the switch in equipment, 2500–3000 A back-

/4–20 x 3/8-inch deep screw inserts

3

/8–16 x 7/16-inch deep screw inserts

connected frames.

3

Figure 5. Locations of the

mounting the switch in equipment, 4000 A front-connected

/4-inch diameter through holes for

frame.

3

Page 12

Power Break® II Switches

Chapter 2. Operation

2-1 Standard Features

Power Break II switches are equipped with the following

standard features. The letters are keyed to the switch

photographs in Figures 6 and 7.

A Indicator:

B Indicator:

C

ON button

D

OFF button

E Manual charging handle

F Integral 36-point terminal block (12 auxiliary

switches, A-B type), Block “A”

G Integral 36-point terminal block (all other con-

nections), Block “B”

H Sealable hinged cover

I Cover mounting screws (4)

K Control Unit interchangeable rating plug

L Test set connection port

M Standard padlock provision

N Dust-resistant ventilation slots

ON – Red

OFF – Green

CHARGED – Yellow

DISCHARGED – White

Figure 7. Front of the switch, with the Control unit and top

cover removed.

2-2 Operating Instructions

Sequence of Operations

The sequence of operations that may be performed on the

switch are listed in Table 3. Refer to Chapter 3 for

information about accessory operation.

Figure 6. Front of the switch, showing the locations of

standard features.

Operating Instructions for Manually

Operated Switch

Charging the Mechanism Springs

Pull the operating handle down about 90° (until it stops).

Repeat five more times to fully charge the springs.

will not close the switch contacts.

will show

springs are fully charged, the handle locks in the stored

position.

NOTE:

are fully charged and the handle is stored fully in.

NOTE:

isée à moins que les ressorts soient réarmés tout à fait, et

le levier est complètement remis à la position

d’emmagasinage.

CHARGED on a yellow background. When the

The switch cannot be closed unless the springs

La fermeture de l'interrupteurne peut être réal-

The charge indicator

This

4

Page 13

Power Break® II Switches

Chapter 2 – Operation

On/Off

Indicator

OFF DISCHARGED Open Discharged Mechanism may be charged

OFF CHARGED Open Charged Contacts may be closed

ON DISCHARGED Closed Discharged Mechanism may be recharged or

ON CHARGED Closed Charged Contacts may be opened

Charge

Indicator

Main Switch

Contacts

Condition of

Charging Springs

Next Permissible Operating Function

Contacts may be opened

Table 3. Sequence of operations that may be performed with Power Break II switches.

Closing the Switch

Close the switch contacts with either of the following

methods:

• Depress the ON button on the front of the switch.

• Energize the (optional) Remote Close accessory by

applying rated voltage to terminals 16 and 34 on

terminal block B.

CAUTION:

If the switch latch is held in the tripped

position by any of the following conditions and an

attempt is made to close the main switch contacts, the

mechanism will “crash” (the closing springs discharge

with no motion of the switch contact arms). The switch

has been designed and tested to withstand more than

100 crash operations, but repeated attempts to close a

locked-out switch will damage the switch mechanism.

CAUTION:

the switch latch is held in the tripped position by any of

the following conditions:

• The Bell Alarm with Lockout was not reset after a

ground fault lockout.

• The Undervoltage Release is not energized.

The main switch contacts cannot be closed if

• The Key interlock or padlock is in the locked OFF

condition.

• The draw-out interlock is engaged with the carriage

between the TEST and T CONNECTED positions.

• The walking beam interlock or mechanical interlock

is activated.

• The Shunt Trip with Lockout is energized.

These conditions must be corrected before the switch

can be closed.

ATTENTION:

Les contacts de l'interrupteur principal

peuvent être fermés où le loquet de l'interrupteur est

maintenu en position déclenchée à cause de toute des

conditions suivantes:

• Si la réarmeture du déclencheur n’est pas réalisée

après le verrouillage en position “ouvert” provenant

du courant de surcharge.

• Si le minimum de tension (UVR) n’est pas sous

tension.

• Le déclenchement shunt avec blocage est actionné.

Ces conditions doivent être corrigées avant l'interrupteur

peut être fermé.

ATTENTION:

position de déclenchement dans n’importe quelle des

conditions suivantes et que l’on tente de fermer les

contacts de l'interrupteur principal, le mécanisme subira

un “crash” (les ressorts de fermeture se détendent sans

que les bras des contacts du disjoncteur ne bougent).

L'interrupteur a été conçu et testé pour résister à plus de

100 opérations de type “crash,” cependant des tentatives

répétées ayant pour but de fermer un interrupteur

bloqué endommageront le mécanisme de l'interrupteur.

• Si le verrou de clé ou le cadenas est verrouillé en

position OFF.

• Si le chariot du verrou débrochable est localisé entre

les positions TEST et CONNECTED.

• L’enclenchement par support mobile ou

Si le cliquet de l'interrupteur est tenu en

enclenchement mécanique est activé.

5

Page 14

Power Break® II Switches

Chapter 2. Operation

Opening the Switch

Open the switch contacts with either of the following

methods:

• Depress the OFF button on the front of the switch.

• Energize the (optional) Shunt Trip or Shunt Trip

with Lockout accessory or de-energize the (optional)

Undervoltage Release accessory.

Additional Instructions for Motor-Operated

Switches

Charging the Mechanism Springs

The mechanism closing springs may also be charged by

the following method:

• Short terminals 17 and 35 on the right terminal

block, with a push button or similar device, for a

minimum of five seconds.

• If power is lost during the charge cycle, finish

charging the springs by cycling the charging handle

until the indicator shows

background. When the springs are fully charged, the

handle locks in the stored position.

Automatic Operation

Connect terminals 17 and 35 on the terminal block on the

right side of the switch with a jumper wire. The Motor

Operator will automatically recharge the switch closing

springs whenever the switch closes.

CAUTION:

ATTENTION:

fermeture automatique.

Do not wire switches for automatic close.

Ne pas câbler les interrupteurs pour la

Padlock Operation

The padlock prevents the switch from closing by holding

the trip latch in the tripped position. To install the

padlock, use the following procedure:

1. Trip the switch (press the OFF button).

2. Grasp the padlock tab (see Figure 6) and pull it out

until it is fully extended, as illustrated in Figure 8.

Note that if the switch contacts are closed, the

padlock tab will not extend.

3. Insert the padlock; the switch will not close.

As many as three

one time.

1

/4" to 3/8" padlocks may be attached at

CHARGED on a yellow

Figure 8. Side view of the switch, showing the padlock tab

extended.

Periodic Operational Checks

Approximately once a year, verify that the switch is

operating correctly by opening and closing the

mechanism.

Wiring Notes

Figure 9 illustrates the terminal block installed on the

right side of the switch. Table 4 lists the device connections to the terminal block. Each terminal point will

accept the following connections:

• Bare stripped wire – one #12 AWG or two #14 AWG.

• Ring or spade connectors – two per terminal.

The terminal screws should be tightened to 7–9 in-lb

torque.

The left terminal block is blank unless the optional

Auxiliary Switch Module accessory is ordered. See Table

16 for the device connections to the Auxiliary Switch

Module terminal block.

6

Page 15

Figure 9. Terminal block mounted on the right side of the

switch.

Terminal Terminal

18 Motor Operator + 36 Motor Operator –

17 Remote Charge 35 Remote Charge

16 Remote Close + 34 Remote Close –

15 Bell Alarm only Com 33 Charge Indicator

14 Bell Alarm only NO 32 Shunt Trip

13 Bell Alarm only NC 31 Shunt Trip

12 Lockout Common 30 Undervoltage Release

11 Lockout NO 29 Undervoltage Release

10 Lockout NC 28 Reserved

9 Reserved 27 Reserved

8 Reserved 26 Zone-Select Input –

7 commnet – 25 Zone-Select Input +

6 commnet + 24 Zone-Select Output –

5 C Phase Volts 23 Zone-Select Output +

4 B Phase Volts 22 Draw-Out Switch

3 A Phase volts 21 Draw-Out Switch

2 24 Vdc – 20 N Tap

1 24 Vdc + 19 N Common

Do not apply voltage; see wiring diagram.

Not a user connection.

Table 4. Accessory connections to the right-side terminal block

B.

Power Break® II Switches

Chapter 2. Operation

2-3 Control Unit Setup

See DEH–40381 for detailed instructions on setting up

Power+ Control Units.

7

Page 16

Power Break® II Switches

Chapter 3. Accessory Operation

Following are the operation procedures for each of the

available switch accessories. See the user guides supplied

with the accessories for installation and removal.

3-1 Lug and Adapter Kits

Lug Kits (800–2000 A Frames)

Direct-mounting lugs bolt directly to the line or load strap

of the switch. Order one Lug Kit per line or load pole. Lug

Kit catalog numbers and wire sizes are listed in Table 5.

Cat. No. Wires Wire Sizes Amps

TPLUG106

TPLUG206 2 #2–600 kcmil CU/AL 600

TPLUG308 3 300-750 kcmil CU/AL 800

TPLUG408 4 500–800 kcmil CU/AL 1600

1

2

Table 5. Catalog numbers and wire sizes of Lug Kits for 800–

Lug Kits with Straps (2500–4000 A Frames)

Lug Kits with Straps include copper straps that connect

directly to switch T-studs (must be ordered separately) to

provide proper phase clearances for mounting lugs. Order

one Lug Kit with Straps per line or load side. Catalog

numbers are listed in Table 6.

Cat. No.

TSLUG08 9 3 800

TSLUG12 12 4 2500 or 1200

TSLUG16 15 5 3/0-800 3000 1600

TSLUG20 18 6 kcmil 2000

TSLUG25 21 7 Cu/Al 2500

TSLUG30 27 9 3000 3000

TSLUG40 33 11 4000 4000

Table 6. Catalog numbers and specifications of Lug Kits with

Lugs

per Kit

Straps for 2500–4000 A frames.

#2–600 kcmil CU/AL

1/0–250 kcmil CU/AL

2000 A frames.

Max.

Wires

per Pole

Wire

Range

Frame

Size (A)

400

Max.

Amps

T-Studs

T-Studs bolt directly to the line or load terminals of the

switch. Order one T-Stud per line or load pole. T-Stud

catalog numbers and ratings are listed in Table 7.

Cat. No. Material Frame (A)

SP08FCA Al 800 800 Front

SP08FCC Cu 800 800 Front

SP20FCA Al 1600–2000 2000 Front

SP20FCC Cu 1600–2000 2000 Front

SPS20FCA Al 2500 2000 Front

SPS20BCA Al 2500 2000 Back

SPS25FCC Cu 2500 2500 Front

SPS25BCC Cu 2500 2500 Back

SPS30FCC Cu 3000 3000 Front

N/A

SPS40FCC Cu 4000 4000 Front

SPS40LFCC Cu 4000 4000 Front

Integral T-Studs are not removable on 3000 A back-connected switches.

Long studs may be used in place of or alternated with SPS40FCC if

desired.

Cu 3000 3000 Back

Max.

Amps

Switch

Connect

Table 7. Catalog numbers and ratings of T-Studs.

Adapter Kits

Adapter Kits bolt directly to the line or load terminals on

the rear of the switch. They provide proper phase-to-phase

clearances for mounting lugs or busbars. Order one

Adapter Kit per three-phase line or load side. Lugs must

be ordered separately. Adapter Kit catalog numbers and

ratings are listed in Table 8.

Cat. No. Frame (A)

TPLUGA08 800

TPLUGA16

TPLUGA20

Premounts in equipment, allowing cabling or bussing to be completed

before switch mounting.

3/0–800 kcmil Cu/Al wire range.

Anderson No. VCEL-075-12H1 or equivalent.

1600

1600–2000

Table 8. Catalog numbers and ratings of Adapter Kits.

Lug Odering Information

(Per Line or Load Side)

9 TPLUG108

or 9 Crimp Lugs

18 TPLUG108

or 18 Crimp Lugs

18 TPLUG108

or 18 Crimp Lugs

Lugs

Lugs

Lugs

8

Page 17

Power Break® II Switches

Chapter 3. Accessory Operation

3-2 Plug-In Accessory Compartment

Several of the accessories are installed in the accessory

compartment on the front of the switch. Figure 10

illustrates this compartment and the locations of each of

the plug-in accessory modules.

Figure 10. Locations of the plug-in accessory modules in the

compartment on the front of the switch.

3-3 Bell Alarm–Alarm Only

The Bell Alarm–Alarm Only module, shown in Figure 11,

provides a switch to remotely indicate that the switch has

tripped. It is reset either automatically when the switch is

reclosed or manually when the reset button on the front

of the Bell Alarm–Alarm Only module is pressed.

Catalog No. Contact Rating

SPBAA240 6 A at 240 Vac

0.25 A at 250 Vdc

0.50 A at 125 Vdc

SPBAA600 6 A at 600 Vac

0.25 A at 250 Vdc

0.50 A at 125 Vdc

600 V version is not UL listed.

Table 9. Bell Alarm–Alarm Only catalog numbers.

Operation

The Bell Alarm–Alarm Only provides normally open (NO)

and normally closed (NC) outputs available at the

terminal block on the right side of the switch, as

illustrated in Figure 12. The outputs change state

whenever a switch ground fault trip occurs. This trip can

be caused by a ground fault condition detected by the

Control Unit.

The Bell Alarm–Alarm Only accessory resets automatically,

returning the outputs to their normal configuration, when

the switch is reclosed. The Bell Alarm–Alarm Only can

also be reset manually, before the switch is reclosed, by

pressing the reset button on the front of the module.

Figure 11. Bell Alarm–Alarm Only module.

The Power+™ Control Unit activates the Bell Alarm–

Alarm Only for protection trips only.

The catalog numbers for the Bell Alarm–Alarm Only are

listed in Table 9. For installation instructions see GEH–

6275.

Figure 12. Bell Alarm–Alarm Only connections on the right

terminal block. The contacts are shown in the reset state.

3-4 Bell Alarm with Lockout

The Bell Alarm with Lockout module, shown in Figure 13,

prevents reclosing of the switch after a ground fault trip

until the Bell Alarm with Lockout is reset. It can only be

reset by pressing the button on the top of the module.

This module also provides a switch to remotely indicate

that the switch has tripped.

The Power+™ Control Unit activates the Bell Alarm with

Lockout for ground fault protection trips only.

The catalog numbers for the Bell Alarm with Lockout are

listed in Table 10. For installation instructions see GEH–

6278.

9

Page 18

Power Break® II Switches

Chapter 3. Accessory Operation

Figure 13. Bell Alarm with Lockout module.

3-5 Shunt Trip

The Shunt Trip module, shown in Figure 15, allows the

switch to be tripped electrically from a remote location.

Catalog No. Contact Rating

SPBAL240 6 A at 240 Vac

0.25 A at 250 Vdc

0.50 A at 125 Vdc

SPBAL600 6 A at 600 Vac

0.25 A at 250 Vdc

0.50 A at 125 Vdc

The 600 V version is not UL listed.

Table 10. Bell Alarm with Lockout catalog numbers.

Operation

The Bell Alarm with Lockout prevents reclosing of the

switch after a ground fault trip until the reset button on

the front of the module is pressed. This trip can be caused

by a ground fault condition detected by the Control Unit.

In addition, the Bell Alarm with Lockout provides

normally open (NO) and normally closed (NC) alarm

outputs available at the terminal block on the right side of

the switch, as illustrated in Figure 14. These outputs are

returned to their normal state when the Bell Alarm with

Lockout reset button is firmly pressed.

Figure 14. Bell Alarm with Lockout connections on the right

terminal block. The contacts are shown in the reset state.

Figure 15. Shunt Trip module.

If the switch is equipped with a Power+™ Control Unit, it

is configured so that only ground fault trips will activate a

Bell Alarm–Alarm Only or Bell Alarm with Lockout.

The catalog numbers for the Shunt Trip for various

voltage applications are listed in Table 11. For installation

instructions see GEH–6284 or GEH–6519.

Catalog

Number

SPST012 12 Vdc 3.0 200

SPST024

SPST048

SPST120

SPST208 208 Vac 1.5 50

SPST240

SPST480 480 Vac 0.375 21

SPST600 600 Vac 0.3 17

24–600 Vac devices are rated for 50/60 Hz.

Peak inrush current is present for 2–6 ms after activation. This number is

provided so that fuses and supplies can be chosen appropriately.

Ratings for 480 Vac and 600 Vac devices are at the input of the upstream

transformer, included with the accessory and specified in GEH–6519,

which powers the device. For voltage and current ratings at the switch

terminal block, see SPST120.

Voltage

Rating

24 Vac

24 Vdc

48 Vac

48 Vdc

120 Vac

125 Vdc

240 Vac

250 Vdc

Peak Inrush

Current, A

Nominal RMS

Current, mA

1.5 140

1.5 110

1.5 85

1.5 40

Table 11. Catalog numbers and voltages for the Shunt Trip.

Operation

Apply control voltage to terminals 31 and 32 of the

terminal strip on the right side of the switch to open the

switch. The Shunt Trip will cause the switch to open when

the control voltage is greater than 75% of the dc-rated

value or 55% of the ac-rated value.

10

Page 19

Power Break® II Switches

Chapter 3. Accessory Operation

3–6 Shunt Trip with Lockout

The Shunt Trip with Lockout module, shown in Figure

16, allows the switch to be opened electrically from a

remote location and prevents the switch from closing

while the accessory is energized.

Figure 16. Shunt Trip with Lockout module.

If the switch is equipped with a Power+™ Control Unit, it

is configured so that only ground fault trips will activate a

Bell Alarm–Alarm Only or Bell Alarm with Lockout.

The catalog numbers for the Shunt Trip for various

voltage applications are listed in Table 12. For installation

instructions see GEH–6284 or GEH–6519.

Catalog

Number

SPSTL012 12 Vdc 19 300

SPSTL024

SPSTL048

SPSTL120

SPSTL208 208 Vac 1.9 60

SPSTL240

SPSTL480 480 Vac 0.75 20

SPSTL600 600 Vac 0.60 16

24–600 Vac devices are rated for 50/60 Hz.

Peak inrush current is present for 2–6 ms after activation. This number is

provided so that fuses and supplies can be chosen appropriately.

Ratings for 480 Vac and 600 Vac devices are at the input of the upstream

transformer, included with the accessory and specified in GEH–6519,

which powers the device. For voltage and current ratings at the switch

terminal block, see SPSTL120.

Table 12. Catalog numbers and voltages for the Shun t Trip

Voltage

Rating

24 Vac

24 Vdc

48 Vac

48 Vdc

120 Vac

125 Vdc

240 Vac

250 Vdc

Peak Inrush

Current, A

15 300

7.5 200

3.0 80

1.5 45

with Lockout.

Nominal RMS

Current, mA

3-7 Undervoltage Release

The Undervoltage Release (UVR) module, shown in

Figure 17, opens the switch when the input control voltage

drops to 35–60% of its rated value and prevents an open

switch from closing until the input control voltage is

greater than 80% of the rated value.

If the switch is equipped with a Power+™ Control Unit, it

is configured so that only ground fault trips will activate a

Bell Alarm–Alarm Only or Bell Alarm with Lockout.

Figure 17. Undervoltage Release module.

The catalog numbers for the UVR for various voltage

applications are listed in Table 13. For installation

instructions see GEH-6285 or GEH–6520.

Operation

Apply control voltage to terminals 29 and 30 of the

terminal strip on the right side of the switch. When the

applied control voltage is above 80% of the UVR’s rated

value, the switch can be closed. When the voltage drops to

35–60% of the rated value, the UVR will open the switch.

Operation

Apply control voltages to terminals 31 and 32 of the

terminal strip on the right side of the switch to open the

switch. The Shunt Trip with Lockout will cause the switch

to open when the control voltage is greater than 75% of

the dc-rated value or 55% of the ac-rated value.

11

Page 20

Power Break® II Switches

Chapter 3. Accessory Operation

Catalog

Number

SPUV012DC 12 Vdc 19 300

SPUV024DC 24 Vdc 15 140

SPUV048DC 48 Vdc 7.5 70

SPUV125DC 125 Vdc 3 30

SPUV250DC 250 Vdc 1.5 15

SPUV024AC 24 Vac 15 370

SPUV048AC 48 Vac 7.5 210

SPUV120AC 120 Vac 3 80

SPUV208AC 208 Vac 1.9 60

SPUV240AC 240 Vac 1.5 45

SPUV480AC 480 Vac 0.75 20

SPUV600AC 600 Vac 0.60 16

24–600 Vac devices are rated for 50/60 Hz.

Peak inrush current is present for 2–6 ms after activation. This number is

provided so that fuses and supplies can be chosen appropriately.

Ratings for 480 Vac and 600 Vac devices are at the input of the upstream

transformer, included with the accessory and specified in GEH–6520,

which powers the device. For voltage and current ratings at the switch

terminal block, see SPUV120AC.

Voltage

Rating

Peak Inrush

Current, A

Nominal RMS

Current, mA

Table 13. Catalog numbers and voltages for the Undervoltage

Release.

3-8 Motor Operator Mechanism

The Motor Operator Mechanism, shown in Figure 18,

provides a means of remotely or automatically charging

the springs that close the switch. Table 14 lists the catalog

numbers for the available Motor Operator Mechanism

models. For installation instructions see GEH-6281.

Catalog No. Voltage Rating

SPE024 24 Vdc

SPE048 48 Vdc

SPE072 72 Vdc

SPE120 120 Vac

SPE125 125 Vdc

SPE240 240 Vac

Table 14. Catalog numbers and operating voltages for the

Motor Operator Mechanism.

Remote Operation

The switch closing springs can be charged remotely by

shorting terminals 17 and 35 on the terminal block on the

right side of the switch, with a push button or similar

device, for a minimum of five seconds.

Automatic Operation

Connect terminals 17 and 35 on the terminal block on the

right side of the switch with a jumper wire. The Motor

Operator will automatically recharge the switch closing

springs whenever the switch closes.

CAUTION:

Do not wire switches for both automatic

charge and automatic close.

ATTENTION:

Ne pas câbler les interrupteurs pour tous

les deux l’armement automatique et la fermeture

automatique.

3-9 Remote Close

Figure 18. Motor Operator Mechanism.

The Remote Close accessory, shown in Figure 19, provides

a means of remotely closing the switch after the springs

have been charged. Table 15 lists the catalog numbers for

the available models. For installation instructions see

GEH-6283.

Remote Operation

The switch can be closed remotely, provided that the

springs are charged, by applying the rated voltage to

terminals 16 and 34 on the terminal block on the right

side of the switch.

The Remote Close accessory is continuously rated and has

an anti-pump feature that prevents a motor-operated

switch from repeatedly closing into a fault. Closing control

voltage must be removed and reapplied for each switch

closure.

12

Page 21

Figure 19. Remote Close accessory.

Catalog No. Voltage Rating

SPRCS024 24 Vdc

SPRCS048 48 Vdc

SPRCS072 72 Vdc

SPRCS120 120 Vac

SPRCS125 125 Vdc

SPRCS240 240 Vac

Power Break® II Switches

Chapter 3. Accessory Operation

2. Grasp the padlock tab and pull it out, as illustrated in

Figure 20. Note that if the switch contacts are closed,

the padlock tab will not pull out.

3. Turn the key, securing the padlock tab in the

extended position. The switch cannot be closed

until the Key Interlock is disengaged.

4. Rotate the secondary padlock lever out and assemble

padlocks as desired.

Table 15. Catalog numbers and operating voltages for the

Remote Close accessory.

3-10 Key Interlock Mounting Provision

The Key Interlock Mounting Provision provides mounting

for one to four key locks. The GE catalog number is SPK4.

The key locks must have a zero extension when the bolt is

withdrawn with 0.75-inch extension when the bolt is

extended. The lock may be up to 1.50 inch wide. Catalog

numbers for suitable locks from ABB-Kirk® and Superior

Interlock are listed in Table 17. For installation

instructions see GEH-6279.

#

Locks

1 KFN00001_ S105827Y 2.38"

2 KFN00002_ S105828Y 3.38"

3 KFN00003_ S105829Y 4.38"

4 KFN00004_ S105827-4Y 5.48"

Final digit may be 0, 1, 2, or 3 depending on key removable positions.

Table 16. Catalog numbers of Key Interlock models.

Operation

The Key Interlock prevents the switch from closing by

holding the padlock tab extended, thus keeping the trip

latch in the tripped position. A secondary padlock lever is

included with the Key Interlock, since the Key Interlock

blocks easy access to the standard padlock hasp. To

operate, use the following procedure:

1. Open the switch (press the

ABB-Kirk®

Cat. No.

Superior

Cat. No.

OFF button).

Approx. Lock

Length

Figure 20. Side view of the switch, showing the padlock tab

extended with the Key Interlock installed.

CAUTION:

Repeated attempts to close a locked-out

switch will damage the switch mechanism.

ATTENTION:

Les tentatives à maintes fermer un

interrupteur verrouillê en position “ouvert” endommageront le mêcanisme de l'interrupteur.

13

Page 22

Power Break® II Switches

Chapter 3. Accessory Operation

3-11 Mechanical Counter

The Mechanical Counter, shown in Figure 21, counts the

number of times the switch is closed. The catalog number

of the Mechanical Counter is SPCOUNTER. For

installation instructions see GEH-6280.

Figure 21. Mechanical Counter.

3-12 Auxiliary Switch Module

The Auxiliary Switch Module, shown in Figure 22,

provides remote indication of the switch main contact

position through the terminals on the terminal block on

the left side of the switch.

Auxiliary Switch Modules are available with 4, 8, and 12

switches with ratings of 6 A at 240 Vac or 600 Vac. Additional ratings of 0.5 A at 125 Vdc and 0.25 A at 250 Vdc

apply to all models. Catalog numbers are listed in Table

17. For installation instructions see GEH-6274.

Figure 22. Auxiliary Switch Module with 12 switches.

# Switches 240 Vac 600 Vac

4 SPAS240AB4 SPAS600AB4

8 SPAS240AB8 SPAS600AB8

12 SPAS240AB12 SPAS600AB12

600 Vac devices are not UL listed.

Table 17. Auxiliary Switch Module catalog numbers.

Operation

Each auxiliary switch provides two outputs that can be

used to indicate switch main contact position. The A

output is open or closed the same as the switch, while the

B output is the opposite to the switch contacts. Figure 23 is

a wiring diagram of each auxiliary switch.

The connections for the auxiliary switch outputs are

found on the terminal block on the left side of the switch

and are listed in Table 18.

Figure 23. Auxiliary switch wiring diagram.

14

Page 23

Terminal (upper) Terminal (lower)

1 Auxiliary 12 A 19 Auxiliary 11 A

2 Auxiliary 12 B 20 Auxiliary 11 B

3 Auxiliary 12 common 21 Auxiliary 11 common

4 Auxiliary 10 A 22 Auxiliary 9 A

5 Auxiliary 10 B 23 Auxiliary 9 B

6 Auxiliary 10 common 24 Auxiliary 9 common

7 Auxiliary 8 A 25 Auxiliary 7 A

8 Auxiliary 8 B 26 Auxiliary 7 B

9 Auxiliary 8 common 27 Auxiliary 7 common

10 Auxiliary 6 A 28 Auxiliary 5 A

11 Auxiliary 6 B 29 Auxiliary 5 B

12 Auxiliary 6 common 30 Auxiliary 5 common

13 Auxiliary 4 A 31 Auxiliary 3 A

14 Auxiliary 4 B 32 Auxiliary 3 B

15 Auxiliary 4 common 33 Auxiliary 3 common

16 Auxiliary 2 A 34 Auxiliary 1 A

17 Auxiliary 2 B 35 Auxiliary 1 B

18 Auxiliary 2 common 36 Auxiliary 1 common

Table 18. Auxiliary switch positions on the terminal board on

the left side of the switch, Block A.

3-13 Door Interlock

The Door Interlock, shown in Figure 24, prevents the

casual opening of the enclosure door, particularly while

the switch is

Interlock is SPDIL. For installation instructions see GEH-

6276.

Operation

The Door Interlock prevents the opening of the enclosure

door unless the locking lever is disengaged. The lever can

be disengaged easily with the switch

greater difficulty with the switch

ON. The catalog number of the Door

OFF or with somewhat

ON, as described below.

Power Break® II Switches

Chapter 3. Accessory Operation

Figure 24. Door Interlock accessory installed on the switch.

Opening Door with Switch On

The Door Interlock can be defeated, to allow opening the

enclosure door with the switch

padlock tab cannot be lifted. Depress the interlock spring

with a screwdriver in the slot on the top of the locking

lever and push the lever counter-clockwise to disengage it

from the spring. Remove the screwdriver, then continue

rotating the locking lever until it clears the door.

ON, even though the

3-14 Push Button Cover

The Push Button Cover, shown in Figure 25, prevents

accidental or unauthorized closing or opening of the

switch with the local push buttons. It consists of two

unbreakable, individually sealable Lexan® shields, one

over the

button. The catalog number is SPPBCOVER. For

installation instructions see GEH-6282.

PUSH ON button and one over the PUSH OFF

Opening Door with Switch Off

To open the enclosure door when the switch is OFF, pull

up on the padlock tab and slide the Door Interlock lever

counter-clockwise until it no longer obstructs the door.

When the door is reclosed, simply slide the lever back into

the locking position.

Operation

Close the cover and put a sealing wire or wire tie in the

slot. Each of the covers may be sealed independently.

15

Page 24

Power Break® II Switches

Chapter 3. Accessory Operation

Figure 25. Push Button Cover.

16

Page 25

Power Break® II Switches

Chapter 4. Trouble-Shooting Guide

The following guide is provided for trouble-shooting and

isolating common problems. It does not cover every

possible situation. Contact the GE Insustrial Systems

Customer Support Center at 800-843-3742 if any problem

is not resolved by these procedures.

Symptom Possible Cause Corrective Action

1. The switch does not

close when the

button is pressed and

there is no sound of the

closing spring releasing.

2.

The switch does not

close when the

button is pressed, but

the closing spring is

heard to release.

3.

The switch can be

opened locally, but not

remotely.

ON

ON

The closing spring is not fully

charged.

The Bell Alarm with Lockout is

deployed.

The Undervoltage Release is

not energized.

The Control Unit is not

properly installed.

The Control Unit detected a

fault and immediately tripped

the switch.

The Shunt Trip is energized.

The switch is locked in the

position by a padlock or key

interlock.

The switch is interlocked with

another switch with a walking

beam.

If a draw-out switch, it is not

fully inserted in the

substructure (between the

TEST and CONNECTED

positions.

There is a problem with the

Shunt Trip.

There is a problem with the

Undervoltage Release.

On a manually operated switch, operate the handle

until the indicator shows

On an electrically operated switch, check that the

voltage to the motor operator is at least 85% of

nominal. See GEH–6281,

Mechanism.

Correct the condition that initiated the bell alarm,

then depress the yellow plunger on the Bell Alarm

with Lockout module to reset the lockout. See GEH–

6278,

See GEH–6285,

energizing the UVR.

See DEH–40381,

Control Unit installation procedure.

Clear the fault, then recharge the closing spring and

close the switch. For fault diagnostics, see DEH–

40381,

See GEH–6284, S

energizing the unit.

After ensuring that the safety reason for locking the

OFF

switch no longer applies, remove the padlock or key

interlock. See GEH–-6279,

Provision

See GEH–6286,

removal procedure.

Ensure that the switch is fully racked in to the

substructure. See GEH–6272,

Bell Alarm with Lockout

Undervoltage Release

Power+™ Control Units,

Power+™ Control Units.

hunt Trip

.

Walking-Beam Interlock

800–4000 Amperes

See the trouble-shooting instructions in GEH–6284,

hunt Trip

S

See the trouble-shooting instructions in GEH–6285,

.

Undervoltage Release

CHARGED.

Motor Operator

.

, for instructions on de-

Key Interlock Mounting

Draw-Out Substructure,

.

.

, for details on

for the

, for the

17

Page 26

Power Break® II Switches

Chapter 4. Trouble-Shooting Guide

For any other problems related to Power Break II

accessories, consult the corresponding User’s Guide:

• GEH–6271,

• GEH–6272,

Ampere

• GEH–6274,

• GEH–6275,

• GEH–6276,

• GEH–4546,

• GEH–6278,

• GEH–6279,

• GEH–6280,

• GEH–6281,

• GEH–6282,

• GEH–6283,

• GEH–6284,

(except 480 and 600 Vac)

• GEH–6519,

Lockout, 480 & 600 Vac

• GEH–6285,

600 Vac)

• GEH–6520,

• GEH–6286,

• GEH–6440,

• GEH–6460,

• DEH–40381,

Draw-Out 800–4000 Ampere Frames

Draw-Out Substructure, 800–4000

Auxiliary Switch Module

Bell Alarm – Alarm Only

Door Interlock

Lugs & Adapters for 800–2000 A Frames

Bell Alarm with Lockout

Key Interlock Mounting Provision

Mechanical Counter

Motor Operator Mechanism

Push Button Cover

Remote Close

Shunt Trip and Shunt Trip with Lockout

Shunt Trip and Shunt Trip with

Undervoltage Release

(except 480 and

Undervoltage Release, 480 & 600 Vac

Mechanical Interlock

Draw-Out Substructure Rail Kit

Secondary Disconnect

Power+™ Control Units

18

Page 27

Page 28

g

GE Industiral Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH40380 R02 0701 © 2001 General Electric Company

Loading...

Loading...