Page 1

g

GEH6271 Installation Instructions R04

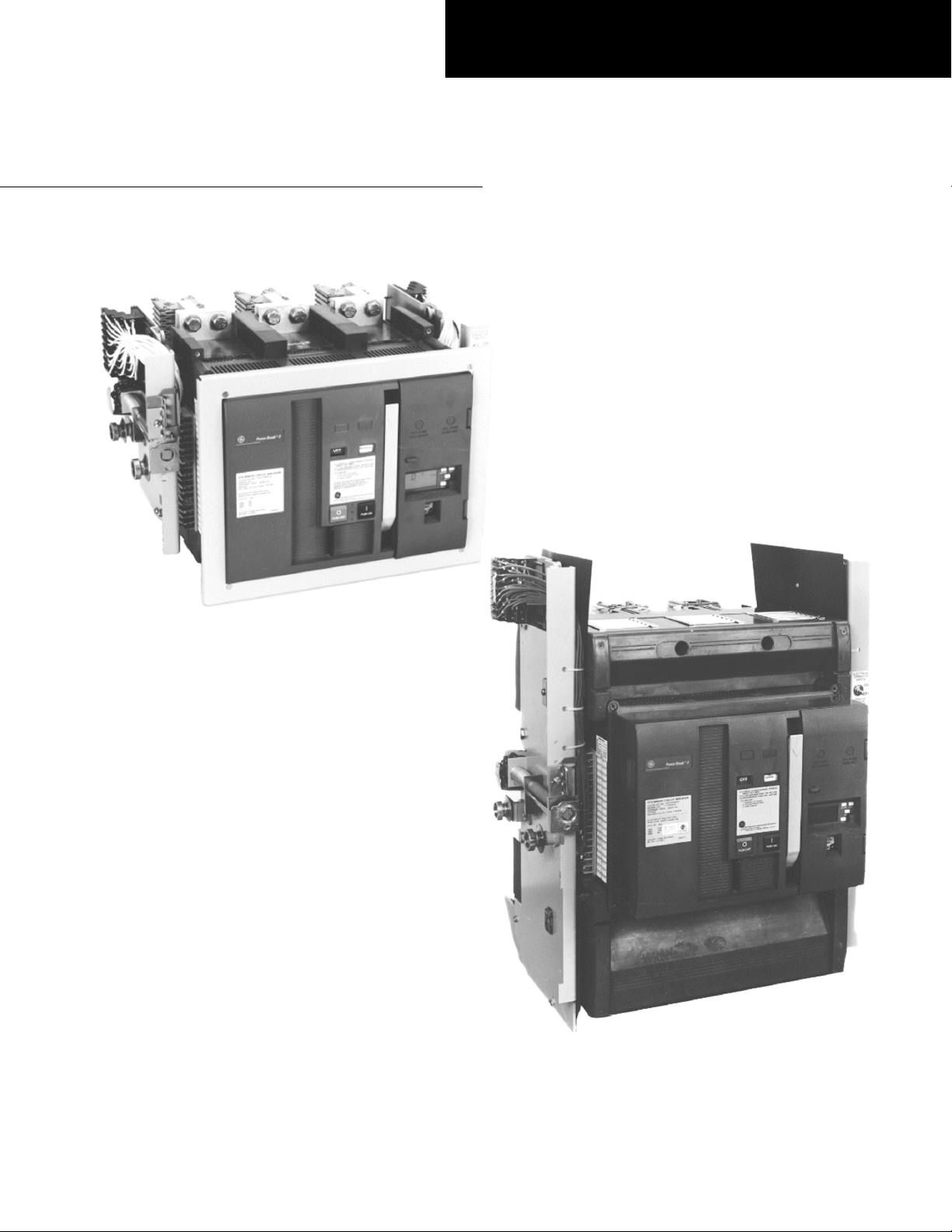

Power Break® II Devices

Draw-Out 800–4000 Ampere Frames

Page 2

Page 3

WARNINGS

CAUTIONS

NOTES

GEH6271

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or

other conditions that could cause personal injury are present in this equipment or may be

associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care is not taken.

Notes call attention to information that is especially significant to understanding and operating the

equipment.

This document is based on information available at the time of its publication. While efforts have

been made to ensure accuracy, the information contained herein does not cover all details or

variations in hardware and software, nor does it provide for every possible contingency in

connection with installation, operation, and maintenance. Features may be described herein that

are not present in all hardware and software systems. GE Industrial Systems assumes no obligation

of notice to holders of this document with respect to changes subsequently made.

GE Industrial Systems makes no representation or warranty, expressed, implied, or statutory, with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness

of the information contained herein. No warrantees of merchantability or fitness for purpose shall

apply.

The following are trademarks of GE Company:

Power Break®, MicroVersaTrip PM™, MicroVersaTrip Plus™, Power+™, POWER LEADER™

© 2001 GE Company

All Rights Reserved

i

Page 4

Power Break® II Devices

Draw-Out Device Installation

Table of Contents

Description.............................................................................................................................................. 1

Features......................................................................................................................................1

Installing the Device ...............................................................................................................................3

Removing the Device ..............................................................................................................................5

Maintenance Procedures ........................................................................................................................ 6

Lubrication .............................................................................................................................................6

List of Figures

1. Rear view of the Power Break® II draw-out device................................................................................. 1

2. Left side of device, showing padlock accessory and racking shaft lockout plate. ................................... 1

3. Right side of the device, showing the rejection feature, drawout position indicator, and electric

operator cutoff switch. ............................................................................................................................2

4. Lifting Bar attached to a draw-out device for manual lifting. ................................................................3

5. Lifting Bar attached to a draw-out device for lifting with a hoist........................................................... 3

6. Device installed on rails, ready to be pushed into the substructure........................................................4

7. Wrench attached to the device racking shaft. ........................................................................................4

8. Compartment position indicator on the front of the device. .................................................................4

9. Withdrawing the substructure rails......................................................................................................... 5

10. Rotating the device forward for inspection. ...........................................................................................5

List of Tables

1. Catalog numbers of draw-out circuit breakers and corresponding substructures. .................................1

2. Catalog numbers of draw-out switches and corresponding substructures.............................................. 1

3. Illustration of the rejection-scheme logic, showing which circuit breakers may be installed in

which substructures.................................................................................................................................2

4. Illustration of the rejection-scheme logic, showing which switches may be installed in which

substructures. ..........................................................................................................................................2

ii

Page 5

Power Break® II Devices

Draw-Out Device Installation

Description

Types SSD and SHD Power Break II draw-out circuit

breakers are used in types SPS and SPH substructures, with

appropriate catalog numbers listed in Table 1. Power

Break II switches are used only with type SPH

substructures, with appropriate catalog numbers listed in

Table 2. Draw-out construction permits activation of a new

feeder, allows rapid replacement of a device, and

facilitates inspection and maintenance of the draw-out

device with no need to de-energize the entire switchboard.

Draw-Out Breaker Substructure

SSD08X2## SPSDOS08

SHD08X2## SPHDOS08

SSD16X2## SPSDOS16

SHD16X2## SPHDOS16

SSD20X220 SPSDOS20

SHD20X220 SPHDOS20

SSD25X### SPSDOS25

SHD25X### SPHDOS25

SSD30X3## SPSDOS30

SHD30X3## SPHDOS30

SSD40X4## SPSDOS40

SHD40X4## SPHDOS40

Note: In the circuit breaker catalog number, replace “X”

with “B” for MicroVersaTrip Plus™ or MicroVersaTrip

PM™ Trip Units or with “D” for Power+™ Trip Units

Table 1. Catalog numbers of draw-out circuit breakers and

corresponding substructures.

Draw-Out Switch Substructure

SHD08Y2## SPHDOS08

SHD16Y2## SPHDOS16

SHD20Y2## SPHDOS20

SHD25Y### SPHDOS25

SHD30Y3## SPHDOS30

SHD40Y4## SPHDOS40

Table 2. Catalog numbers of draw-out switches and corresponding

substructures.

Rollers. The rollers on the sides of the device ride on

retractable rails in the draw-out substructure for easy

installation and removal.

Draw-Out Mechanism. A racking shaft powers a centrally

mounted screw through a chain drive into a fixed nut in

the substructure. A special speed wrench is supplied with

an integral

1

2 -inch square-drive socket to aid in

installation and removal.

Racking Shaft Wrench Lockout Plate. This interlock prevents

engagement of the wrench when the device contacts are

closed.

Rollers

Shutter

Actuator

Disconnects

Primary

Secondary

Disconnects

Draw-Out

Interlock

Draw-Out

Mechanism

Bypass Switch

Actuator

Figure 1. Rear view of the Power Break® II draw-out device.

Features

The features described below are illustrated in Figures 1,

2, and 3.

Primary Disconnects. Primary power is fed through multiplefinger primary disconnects when the device is in the

connected position.

Secondary Disconnects. Control power is provided through

the secondary disconnects in the test and connected

positions only. All accessories terminate at dedicated

positions regardless of the combination of accessories

installed.

Draw-Out Padlock

Accessory

Cat. No. TDOPC

Racking Shaft

Wrench Lockout

Plate

Figure 2. Left side of the device, showing the padlock accessory and

racking shaft lockout plate.

1

Page 6

Power Break® II Devices

Draw-Out Device Installation

Rejection

Feature

Draw-Out

Position

Indicator

Figure 3. Right side of the device, showing the rejection feature, draw-

out position indicator, and electric operator cutoff switch.

Draw-Out Position Indicator. Indicates whether the device is

in the connected, test, or disconnect position.

Electric Operator Cutoff Switch. Prevents cycling of the springcharging motor during installation or removal of a device.

Draw-Out Interlock. This feature trips a closed device if the

wrench interlock is deliberately defeated. The device is

tripped before the primary disconnects part as the device

is racked out and before the primary disconnects engage

as the device is racked in.

Rejection Feature. This feature prevents insertion of a device

into a substructure of lower ampere rating or higher shortcircuit rating. It does not reject a device with incompatible

control wiring. See the label on the device or Tables 1 or 2

for the proper substructure catalog number. (Also shown

in Figure 8.)

Tables 3 and 4 illustrate the rejection scheme logic. Note

that devices may be safely used in higher-rated

substructures. However, local and industry codes and

standards require that conductors be sized to the

substructure. Therefore, installing devices in substructures

with higher ratings is possible, but not economical.

Draw-Out Padlock Accessory. When a padlock is installed,

this feature works with the racking shaft lockout plate to

prevent engagement of the racking shaft wrench.

Shutter Actuator. A stud actuates the optional shutter

accessory.

By-Pass Switch Actuator

. Operates the optional by-pass

switch accessory.

Lifting Bar. The Lifting Bar, catalog number TDOLB, is

available for safe handling of the draw-out device, as

illustrated in Figures 4 and 5.

Note: In the device catalog number, replace “X” with “B” for

MicroVersaTrip Plus™ or MicroVersaTrip PM™ Trip Units or

with “D” for Power+™ Trip Units

Table 3. Illustration of the rejection-scheme logic, showing which

circuit breakers may be installed in which substructures.

Table 4. Illustration of the rejection-scheme logic, showing which

switches may be installed in which substructures.

2

Page 7

Power Break® II Devices

Draw-Out Device Installation

Installing the Device

Use the following procedure to install the draw-out device

into the substructure.

1. Attach the Lifting Bar, catalog number TDOLB, by

locating the hooks on the bar beneath the shoulder

studs of the device, as illustrated in Figures 4 and 5.

2. Pull out the substructure rails until they drop into the

horizontal locked position. Lower the device so that

the grooves in the rollers drop over the rails.

3. Make sure the grooves in all rollers straddle the rails,

as illustrated in Figure 6, then remove the Lifting Bar

and push the device into the substructure until it

stops in the

rails and push them in to the stored position.

CAUTION: The device must be

connected. If the device is charged, press the ON button

to close the device contacts, then press the OFF button to

open the contacts.

ATTENTION: Le mécanisme doit être à OFF avant qu’il

ne soit embroché. Si le ressort de fermeture de

mécanisme est chargé, fermer les contacts de mécanisme

par action sur le bouton ON, puis appuyer sur le bouton

OFF pour ouvrir les contacts.

DISCONNECTED position. Then lift the

OFF before it is

Pipe

Lifting Bar

Shoulder

Stud

Figure 4. Lifting Bar attached to a draw-out device for manual lifting.

4. Engage the 12-inch square end of the racking shaft

with the supplied wrench, catalog number TDORT,

and rotate the shaft clockwise to draw the device into

the

TEST or CONNECTED position, as illustrated in

Figure 7. The compartment position indicator is

shown in Figure 8.

NOTE: If the device does not fit the structure, check the

rejection relationship, illustrated in Figure 8, to verify

that a correctly rated device is being installed. Table 1

lists the correct draw-out substructure for each device

frame.

NOTE: Si le mécanisme ne rentre pas dans le berceau,

vérifier le détrompeur illustré dans les figure 8, qui

empêche l’insertion d’un mauvais calibre de mécanisme.

La Table 1 définis le berceau convenable à chaque taille

de mécanisme.

Figure 5. Lifting Bar attached to a draw-out device for lifting with a

hoist.

3

Page 8

Power Break® II Devices

Draw-Out Device Installation

Substructure

Rejection

Feature

.06 in

minimum

Device

Rejection

Feature

Figure 6. Device installed on rails, ready to be pushed into the

substructure.

Racking Tool

Figure 7. Wrench attached to the device racking shaft.

Compartment

Position Indicator

Figure 8. Compartment position indicator on the front of the device.

4

Page 9

Removing the Device

Use the following procedure to remove the draw-out

device from the substructure.

Power Break® II Devices

Draw-Out Device Installation

CAUTION: The device must be

connected and removed.

ATTENTION: Le mécanisme doit être à OFF avant qu’il

ne soit débroché et déposé.

1. Engage the 1 2 -inch square end of the racking

shaft with the supplied wrench, catalog number

TDORT, as illustrated in Figure 7, and rotate the

shaft counter-clockwise to withdraw the device to the

TEST or DISCONNECTED position. The compartment

position indicator is shown in Figure 8.

2. Pull the substructure rails out as far as possible until

they drop into the horizontal locked position, as

illustrated in Figure 9.

3. From the

out on the rails until the front rollers fall into the

detent, as illustrated in Figure 6.

4. The device can now be rotated about the front roller

by pulling forward, as illustrated in Figure 10, for

inspection of the rear of the device, or it can be

completely removed after attaching the Lifting Bar,

as illustrated in Figures 4 and 5.

DISCONNECTED position, pull the device

OFF before it is dis-

Figure 10. Rotating the device forward for inspection.

Figure 9. Withdrawing the substructure rails.

5

Page 10

Power Break® II Devices

Draw-Out Device Installation

Maintenance Procedures

A regular maintenance schedule should be established to

obtain the best service and reliability. Plant operating and

local conditions dictate the frequency of inspections

required.

A permanent record should be kept of all maintenance

work. It will be a valuable reference for subsequent

maintenance work and station operation. Records should

include reports of tests performed, condition of

equipment, and repairs and adjustments.

Maintenance employees must follow all recognized safety

practices, such as those contained in the National

Electrical Safety Code and in company or other safety

regulations. Solid insulation surrounding an energized

conductor in power apparatus must never be relied upon

to provide protection to personnel.

Draw-out structure and connections should be given the

following overall maintenance at least annually.

Maintenance frequency depends on the severity of service

and atmospheric conditions. Equipment subject to highly

repetitive operation may require more frequent

maintenance.

While some of these steps can be done with the device in

the tilt-out position, a complete check can only be made

after removing the device from the rails.

WARNING: Before attempting any work on draw-out

devices, ensure that all sources of power—primary and

secondary—have been de-energized.

AVERTISSEMENT: Avant de commencer toute

intervention sur des mécanismes débrochable, vérifier

que toutes les alimentations de puissance, à la fois

primaire et secondaire, sont coupées.

1. Thoroughly clean the equipment by removing all

dust and other accumulations. Wipe or vacuum clean

the buses and supports. Do not use compressed air

for blowing out equipment.

2. Inspect buses and/or terminal lug connections for

signs of overheating or weakening of insulating

supports. Check indicating devices and mechanical

and key interlocks for proper functioning. Lubricate

all moving and rubbing parts with a suitable

lubricant, such as Mobil 28 red grease.

3. Check primary and secondary disconnecting surfaces

for signs of abnormal wear or overheating. If

required, clean contacts with a suitable solvent.

Discoloration of silvered surfaces is not harmful

unless atmospheric conditions cause deposits, such as

sulfides, on the contact surfaces.

4. Check to see that all anchor bolts and structure bolts

are tight. Inspect all cable or bus connections for

signs of overheating and tighten all loose

connections. Check that all secondary connections

are secure and all control wiring is intact.

5. After cleaning with the device removed, measure and

record resistances to ground and between phases of

insulation on buses and connections. Since definite

limits cannot be given for satisfactory resistance

values, keep a record of resistance readings so that

weakening of insulation from one maintenance

period to the next can be recognized by comparing

readings. Readings should be taken under similar

conditions each time, if possible, and the record

should include temperature and humidity.

High potential tests are not required, but if it seems

advisable, based on insulation resistance tests or after

repairs, test voltage should not exceed 75% of the

factory test voltage, which is two times the rating plus

1000 volts.

6. Operate each device in the

proper functioning. This is particularly important for

devices that normally remain in either the opened or

closed positions for long periods.

7. When the equipment is subject to unusual

conditions, such as contaminating fumes and

excessive moisture, schedule maintenance at more

frequent intervals. In this case, this procedure may

not be sufficient and additional precautions may be

necessary to protect the equipment.

TEST position to ensure

Lubrication

All the areas subject to friction are liberally coated at the

factory with Mobil 28 red grease. If the contact surfaces,

the device power screw, and the interlock pin are cleaned

during maintenance, coat the primary disconnect contact

surfaces, the threads of the nut or screw, and the interlock

pin with Mobil 28.

6

Page 11

Page 12

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEH6271 R04 0501 © 2001 General Electric Company

g

Loading...

Loading...