Page 1

GE Energy

Position Switch Kit

Accessory Kit for Retrofill CB

This position switch actuator, mounted on the cassette using simple hardware,

is an actuator or actuator bracket. It makes a strong contact with the position

switch assembly when the racked-in breaker provides mechanical pressure

against the arm.

imagination at work

Page 2

Table of Contents

Related Publications ..................................................................................................................................................................2

Estimated Time to Complete Tasks ......................................................................................................................................... 2

General Description ...................................................................................................................................................................2

Ordering Info ............................................................................................................................................................................................................... 4

Compartment Switch Options ............................................................................................................................................................................ 4

AKD-5—AK25 Position Switch Actuator .................................................................................................................................. 4

Description ................................................................................................................................................................................................................... 4

AK25 Cassette ............................................................................................................................................................................................................ 5

AKD-5—AK50 Position Switch Actuator .................................................................................................................................. 6

Description ................................................................................................................................................................................................................... 6

Installation .................................................................................................................................................................................................................... 7

AKD-6—Position Switch Actuator ............................................................................................................................................ 8

Description ................................................................................................................................................................................................................... 8

Installation .................................................................................................................................................................................................................... 8

AKD-8—Position Switch Actuator ............................................................................................................................................ 9

Notes ..........................................................................................................................................................................................10

Position Switch Kit for Retrofill CB

1

DEH-41530 02/12

Page 3

Related Publications

Publication Publication Number

Brochure DEA-532

Snapshot DEE-543

Installation Manual AKD8 DEH-41549

Installation Manual AKD6 DEH-41548

Installation Manual AKD5 DEH-41547

Accessory: Door Interlock (Door Interlock Kit) DEH-41529

Accessory Retrofill Doors Assembly DEH-41563

Accessory: Position Switch Plate & Position Switch

Assembly & Wiring (Position Switch Kit)

Accessory: Neutral Rogowski CT Disconnect

(Neutral Assemblies)

Accessory: Programmer Disconnects DEH-41532

Accessory: Finger Clusters (Cluster Assemblies) DEH-41533

Accessory: Secondary Disconnects DEH-41534

FAQ DEQ-171

Application Guide DET-753

Guideform Spec DET-754

Spare/Renewal Parts Guide DET-755

DEH-41530

DEH-41531

Estimated Time to Complete Tasks

It takes about 15 minutes to install or replace the assembly.

General Description

For the retrofill, the following information is for either installing or replacing the mechanism for the position

switch (not the position switch itself) on the retrofill circuit breaker; the position switch assembly is already

mounted in the compartment; if not, it can be ordered as an option. The mechanical subassembly is a simple

ancillary lever-and-tension device that pushes against the position switch arm when the retrofill breaker is

racked in completely. This device, mounted on the cassette using simple hardware, is called the actuator or actuator

bracket. Its purpose is to make a strong contact with the position switch when the racked-in breaker provides

mechanical pressure against the arm. The mechanical force on the lever and tension mechanism then activates

the position switch. The position switch, when activated, determines that the racked-in circuit breaker is connected.

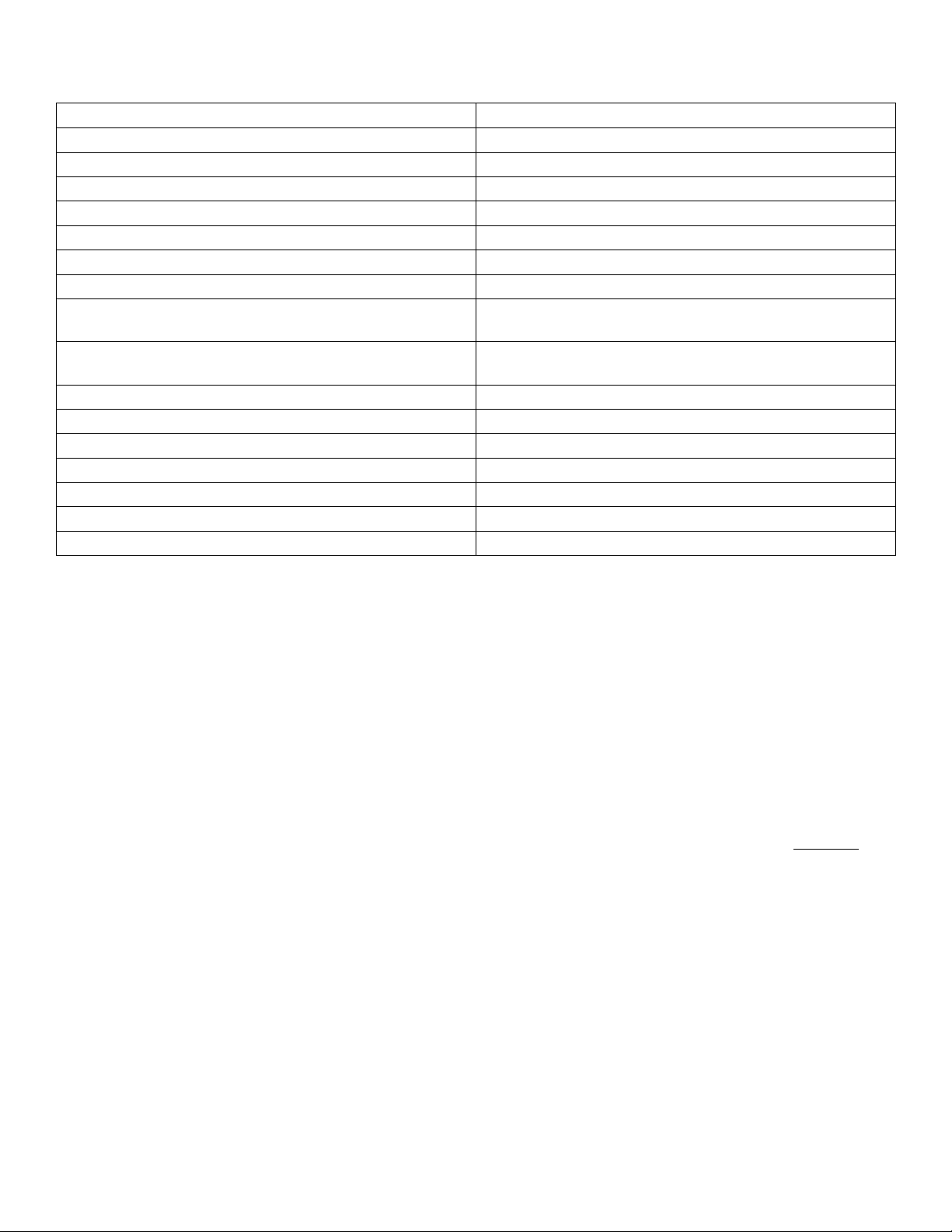

Figure 1 is an example of an installed position switch. It is activated mechanically when the breaker is racked in.

DEH-41530 02/12

Position Switch Kit for Retrofill CB

2

Page 4

Figure 1. Position Switch, an Example

The mechanical subassembly comes with mounting hardware, lever, and bracket. Depending on the switchgear,

this simple device is mounted in different locations.

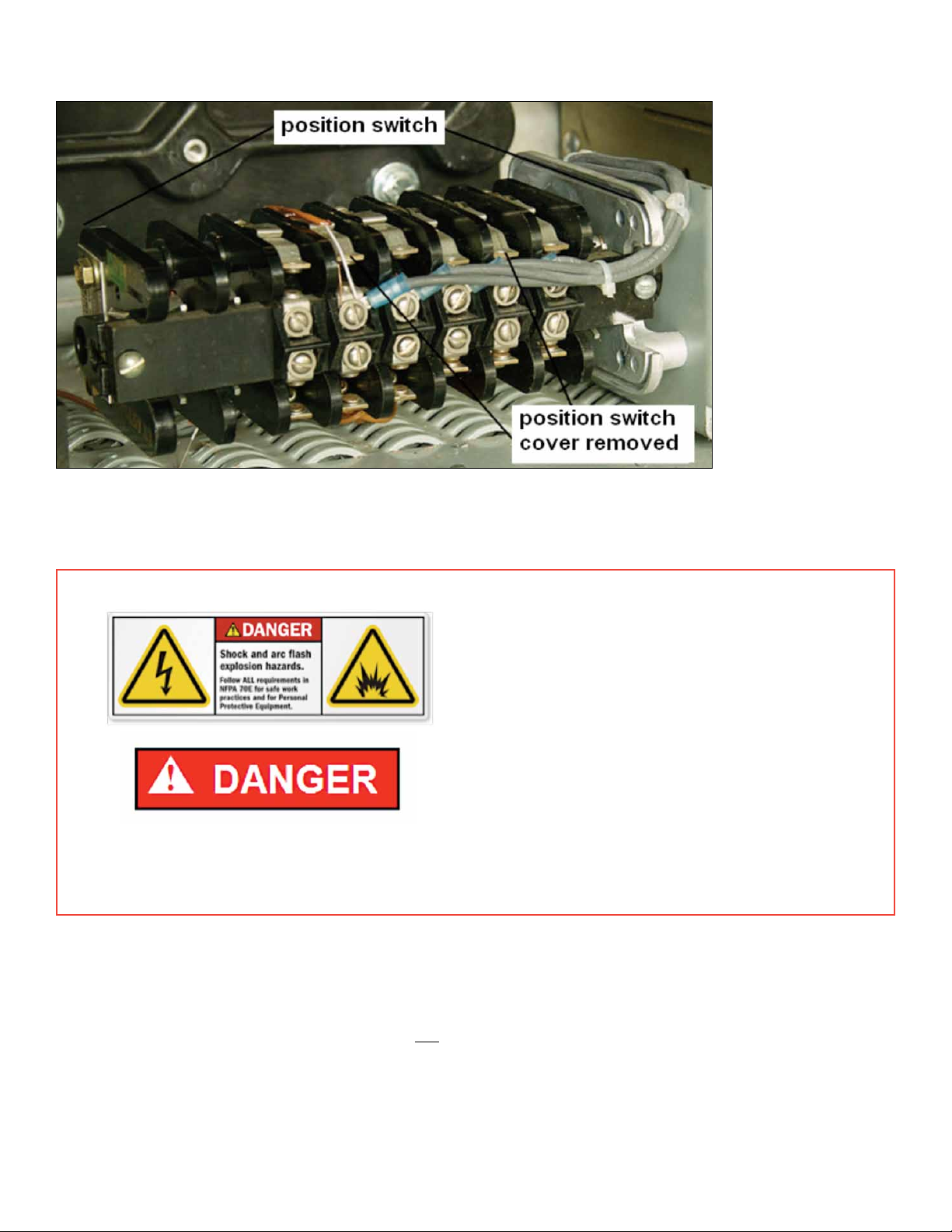

• Turn off all power to switchgear. Tagout

and lockout main source, up-stream or

main breaker.

• Failure to comply with these instructions

will result in death or serious injury from

severe burns caused by arc flashing that

has exceedingly high temperatures.

• Always wear personal protection equipment

according to OSHA standards and appropriate

to the severity of potential burns.

• Ensure only qualified personnel install, operate, service, and maintain all electrical equipment.

Note:

• ItisstronglyadvisedthattheLVS(lowvoltageswitchgear)beswitchedoff/de-energizedbeforeyouassemble

and mount the position switch actuator.

• Thecompartmentpositionswitchassemblyisnot part of the retrofill kit. If the customer desires to install or

replace a position switch assembly in the compartment, the customer can order it separately. Refer to Table 1.

Position Switch Kit for Retrofill CB

3

DEH-41530 02/12

Page 5

Ordering Info

Table 1. Retrofill Portion—Position Switch Assemblies Ordering Information

AK50

AK25

AKD6

AKD8

10106296G1

10106269G1

10106480G1

Not Applicable

Position Switch Actuation Assembly – AK50

Position Switch Actuation Assembly – AK25

Position Switch Actuation Activator Assembly – AKD6

No separate order required.

Compartment Switch Options

Available as an option for mounting within the base of the cassette/substructure or compartment, the position

switch provides six single-pole changeover contacts for local or remote electrical indication of the circuit breaker

status: CONNECTED, TEST, and DISCONNECTED. The DISCONNECTED position is indicated only when the minimum

isolating distances between contacts on both the main (primary disconnects) and auxiliary (secondary

disconnects) have been achieved. This option is in addition to the mechanical indicators, which are fitted as

standard components. When installed, the switch is IP2X-protected and includes wiring to a terminal block on

the left side of the cassette. Table 2 displays the available normally-open and normally closed switches. The

ratings for position switches are shown in Table 3.

Table 2. Position Switches

Table 3. Position Switch Ratings

(Common NO/NC Contact Configuration)

Switch Configuration Catalog # Ratings

One NO/NC switch per position GCPS1R AC

Set of two NO/NC switches per position GCPS2R DC

120Vac 6 A

250Vac 6 A

125Vac 0.5 A

250Vac 0.25 A

AKD-5—AK25 Position Switch Actuator

Description

The position-switch actuator assembly for the AK25 should be mounted on the bottom plate of the cassette assembly

of the AK25 retrofill. The actual actuator assembly consists of two plates, one each on the top and bottom of the

baseplate. The top plate of the actuator interfaces with the breaker when it is racked in and its motion is transferred

to the bottom plate, which interfaces with the position switch lever on the legacy compartment.

Completing the racking in of the EntelliGuard breaker into the cassette corresponds to the end-of-stroke of the

positionswitchsysteminthecompartmentforAK25inAKD-5LVS.Figure 2 shows the exploded view of the AK25

retrofill position-switch actuator (actually a bracket assembly); Figure 3 displays the assembly from the bottom.

DEH-41530 02/12

Position Switch Kit for Retrofill CB

4

Page 6

Figure 2. AKD-5—AK25 Retrofill Breaker, Actuator for

Position Switch Assembly (Exploded View)

Figure 3. AKD-5—AK25 Retrofill Breaker, Actuator for

Position Switch Assembly (Bottom View)

AK25 Cassette

Note: While racking the EntelliGuard ACB breaker into the cassette, while actually racking in the breaker, the position

indicator window begins to read “connected”. This position indicator means that the retrofit system has activated

theexistingpositionswitchintheLVS.

Installing the position switch actuator needs to be done before the cassette is racked into the compartment.

Steps for installing the position switch actuator are as follows:

1. Place the retrofit EntelliGuard ACB cassette assembly for AK25 on an elevated surface, such as a table, to mount

the position switch actuator assembly on to the base plate. Sufficient space should be available at the bottom of

the cassette and the mounting table to provide easy access for inserting the 3-pin bracket from the bottom.

2. Unpack the position switch actuator components and mount them as shown in the exploded view in Figure 4.

Position Switch Kit for Retrofill CB

5

DEH-41530 02/12

Page 7

Figure 4. AKD-5—AK25 Retrofill Breaker, Actuator for Position Switch Assembly (Top View)

3. Insert the 3-pin bracket from the bottom of the base of the cassette assembly, such that the two pins are

within the longer slot and the single pin goes inside the smaller slot of the plate.

4. PlacetheL-bracketfromthetopofthecassetteassembly,suchthatthepinsfromthebottom3-pinplate

get inserted into the top plate.

5. Secure the connection by fastening the nuts and washers provided in the actuator kit.

6. Mount the extension springs between the groove of the pin on this actuator assembly and the fixed pin

provided on the cassette base plate.

7. Check that the position switch actuator on the cassette is now installed and ready to function as the breaker

is being racked in the compartment.

8. Mount the cassette assembly on the rails of the AK25 cabinet in the AKD-5 and rack the cassette into the

compartmentoftheAKD-5LVS.

AKD-5—AK50 Position Switch Actuator

Description

The position switch actuator assembly for the AK50 should be mounted on the bottom right side of the cassette

assembly of the AK50 retrofill. The actuator assembly consists of a linkage system that interfaces with the racking

shaft assembly at one end and the position switch actuator arm at the other. Completing the racking in of the

EntelliGuard breaker in the cassette corresponds to the end-of-stroke of the position switch system in the

compartmentforAK50inAKD-5LVS.

DEH-41530 02/12

Position Switch Kit for Retrofill CB

6

Page 8

Figure 5, below, shows the AK50 position switch actuator assembly in an exploded view. The position switch actuator

for the AK50 is a field-fit type of assembly and is assembled on the retrofill cassette before inserting the cassette into

the compartment of the AKD-5.

It needs to be ensured that the cassette is in the “disconnected” state. This can be verified by checking the racking

position status in the window located at the right side window, located on the frame of the AK50 retrofil cassette,

placed at the front. The position-switch actuator kit for the AKD5-AK50 retrofits needs to be installed on the bottom

rear side of the right side sheet of the AK50 retrofit cassette.

This installation can be done by placing the cassette on a work table. The cassette should be placed such that there

is enough overhang of the side where there’s room to insert the position switch actuator components from underneath. Alternately, the installation can also be achieved by placing the cassette assembly on the retrofit AK50, that is,

on the telescopic rails of the AKD5 compartment that is being retrofit.

Installation

1. Once the access for installing the position switch actuator is achieved, slide the assembly up from the bottom

of the cassette. When inserted, the plate is placed on the outside of the cassette side sheet and the movable

flaps are on the inside.

2. Lineuptheholesonthecassettesidesheetwiththeholesontheactuatorassembly.

3. Fasten the three M6-bolts and 6-mm washers, provided with the actuator assembly, to the three holes on the

cassette side sheet. Two holes are placed on the side and one hole on back of the cassette assembly.

4. Check that the position switch actuator on the cassette is now installed and ready for use as the breaker is

being racked into the compartment.

5. Mount the cassette assembly on the rails of the AK50 cabinet in the AKD-5 and rack the cassette into the

compartmentoftheAKD-5LVS.

Figure 5. AKD-5—AK50, Actuator for Position Switch Assembly

(Exploded View)

Note: While racking the EntelliGuard ACB

breaker into the cassette, as you rack in the

breaker, the position indicator window reads

“connected”. This position indicator means that

the retrofit system has activated the existing

positionswitchintheLVS.

Position Switch Kit for Retrofill CB

7

DEH-41530 02/12

Page 9

AKD-6—Position Switch Actuator

Description

PositionswitchactuatorbracketcanbeinstalledonallversionsofRetrofillEntelliGuardACBforAKD6LVS.Stepsfor

installing are below:

Retrofills use the legacy position switch already mounted in the cubicle. If a new position switch has to be installed,

refer to legacy position switch installation manual.

Installation

1. Unpack the position switch bracket. Each bracket is provided with a pair of M6X16mm Allen-type bolts

and washers.

2. Place the bracket on the bottom right side of the AKD6 base. 2 locating holes are provided for mounting

of the position switch bracket.

3. Fasten the 2 bolts to the locating holes after placing the washers so securely mount the bracket

4. The bracket is ready for use.

Note: Individual hardware for the position switch actuator cannot be ordered separately. The item numbers given below

are for reference only (Table 4). The assembly comes as a unit or a kit. Order the actuator assembly by part number.

Table 4. AKD-6 Position Switch Actuator Components

Level Item or Part Number Description Quantity

1

1

1

1

10105289P1

10100950P4

10100380P1

10100545P1

POSITION SWITCH BRKT, AKD6 1

WASHER M6 2

SERRATEDBELLEVILLEWASHERM6 2

CAP HEAD SCREW M6X16 2

DEH-41530 02/12

Position Switch Kit for Retrofill CB

8

Page 10

AKD-8—Position Switch Actuator

Position switch actuator comes pre-installed on all versions of Retrofill EntelliGuard ACB. Therefore, no installation is

required (Figure 6). Retrofills use the legacy position switch already mounted in the cubicle. If a new position switch

has to be installed, refer to legacy position switch installation manual.

Figure 6. AKD-8—Actuator for Position Switch Assembly (Exploded Views)

Surfaces which activate the position

switch for AKR30/30H/30L/50/50H

Surfaces which activate the

position switch for AKR30R

Position Switch Kit for Retrofill CB

9

DEH-41530 02/12

Page 11

Notes

DEH-41530 02/12

Position Switch Kit for Retrofill CB

10

Page 12

GE Energy

41 Woodford Avenue

Plainville, CT 06062

www.geindustrial.com

© 2012 GE Company

imagination at work

DEH-41530 02/12

Loading...

Loading...