Page 1

GE Consumer & Industrial

Power Protection

M

ISM_Cabinet_GE_01

T

SitePro 10 – 500 kVA / 400Vac CE / From Series 6 & SitePro A 10 – 300 kVA / 480Vac UL / Series 6

Manufactured by:

GE Consumer & Industrial SA

General Electric Company

CH – 6595 Riazzino (Locarno)

Switzerland

T +41 (0)91 / 850 51 51

F +41 (0)91 / 850 51 44

www.gedigitalenergy.com

Operating Manual

Uninterruptible Power supply

Digital Energy™

ISM

Intelligent Synchronization Module

SG Series 80 –200 kVA / 400Vac CE & SG Series 10 –500 kVA / 480Vac UL

GE imagination at work

Page 2

Model:

Date of issue: 01.10.2005

File name: OPM_ISM_OPT_10K_M50_0GB_V021

Revision: 2.1

Identification No.

Up-dating

Revision Concerns Date

2.0 GE House-style & Configuration Warnings in Section 4 - Installation 15.01.2005

2.1 GE Consumer & Industrial SA 01.10.2005

COPYRIGHT © 2005 by GE Consumer & Industrial

ISM - Intelligent Synchronization Module / Series 0

All rights reserved.

The information contained in this publication is intended solely for the purposes indicated.

The present publication and any other documentation supplied with the ISM system is not to be

reproduced, either in part or in its entirety, without the prior written consent of GE.

The illustrations and plans describing the equipment are intended as general reference only and are

not necessarily complete in every detail.

The content of this publication may be subject to modification without prior notice.

Modifications reserved Page 2/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 3

Dear Customer,

We thank you for selecting our products

and are pleased to count you amongst

our very valued customers at GE.

We trust that the use of the ISM

Intelligent Synchronization Module,

developed and produced to the highest

standards of quality, will give you

complete satisfaction.

Please read carefully the Operating

Manual, which contains all the

necessary information and describes all

you need to know about the use of the

ISM.

Thank you for choosing GE!

Manufactured by:

g

GE Consumer & Industrial SA

General Electric Company

CH – 6595 Riazzino (Locarno)

Switzerland

Distributed by:

Your service contact:

Modifications reserved Page 3/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 4

Table of contents Page

SAFETY RULES............................................................................................................................................... 5

1

1.1 IMPORTANT SAFETY RULES...............................................................................................................................................................6

1.2 SAFETY SYMBOLS AND WARNINGS ..............................................................................................................................................7

2 DESCRIPTION................................................................................................................................................ 8

2.1 SCB - SYNCHRONIZATION OF CRITICAL BUSES.......................................................................................................................8

2.1.1 STS - Static Transfer Switch ...................................................................................................................................................................9

2.2 SERVICE AND TECHNICAL SUPPORT.......................................................................................................................................... 10

2.3 WARRANTY............................................................................................................................................................................................ 10

2.4 RECYCLING AT THE END OF SERVICE LIFE..............................................................................................................................10

3 LAYOUT........................................................................................................................................................ 11

3.1 LAYOUT ISM .......................................................................................................................................................................................... 11

4 INSTALLATION............................................................................................................................................ 12

4.1 TRANSPORT........................................................................................................................................................................................... 12

4.1.1 Dimensions and weight ........................................................................................................................................................................ 12

4.2 DELIVERY................................................................................................................................................................................................13

4.3 STORAGE................................................................................................................................................................................................ 13

4.4 PLACE OF INSTALLATION................................................................................................................................................................ 14

4.5 ELECTRICAL WIRING ......................................................................................................................................................................... 15

4.6 CONTROL BUS CABLES CONNECTION...................................................................................................................................... 18

4.7 UPS CONFIGURATION REQUIREMENTS....................................................................................................................................20

5 CONTROL PANEL........................................................................................................................................ 21

5.1 CONTROL PANEL ................................................................................................................................................................................ 21

5.2 TABLE OF FUNCTIONS AND INDICATIONS ON CONTROL PANEL.................................................................................. 21

6 LCD SCREEN................................................................................................................................................ 24

6.1 METERING MODE................................................................................................................................................................................ 25

6.2 ALARM..................................................................................................................................................................................................... 26

6.2.1 Events (Alarms and Messages) .......................................................................................................................................................... 27

6.2.1.1 Alarms list ...............................................................................................................................................................................................................27

6.2.1.2 Messages list......................................................................................................................................................................................................... 28

6.2.1.3 Event report ISM .................................................................................................................................................................................................. 29

6.3 USER PARAMETERS ...........................................................................................................................................................................30

7 OPERATION................................................................................................................................................. 31

7.1 PROCEDURES FOR SCB - SYNCHRONIZATION OF CRITICAL BUSSES.......................................................................... 31

8 MAINTENANCE ...........................................................................................................................................32

9 NOTES.......................................................................................................................................................... 33

9.1 NOTES FORM........................................................................................................................................................................................ 33

10 ANNEXE ...................................................................................ERRORE. IL SEGNALIBRO NON È DEFINITO.

10.1 TECHNICAL DIAGRAMS............................................................................. ERRORE. IL SEGNALIBRO NON È DEFINITO.

Modifications reserved Page 4/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 5

1 SAFETY RULES

With this document, GE gives to the user all the necessary information about the correct installation

and connection of the ISM.

Please read carefully this Operating Manual before installing or operating the equipment.

If any problems are encountered with the procedures contained in this Operating Manual, please

contact the nearest Service Centre before you proceed.

All ISM installation, maintenance and service work should be performed by qualified service personnel

only.

The KNOWLEDGE and the FULLY compliance of the safety instructions and the warning

contained in this manual are

THE ONLY CONDITION

to avoid any dangerous situations during installation, operation, maintenance work, and

to preserve the maximum reliability of the UPS system.

NOTE !

While every care has been taken to ensure the completeness and accuracy of this

manual, GE assumes no responsibility or liability for any losses or damages

resulting from the use of the information contained in this document.

GE

Refuses any responsibility in case of non-observance,

unauthorised alterations or improper use of the

delivered UPS.

Modifications reserved Page 5/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 6

1.1 IMPORTANT SAFETY RULES

SAVE THESE INSTRUCTIONS

This manual contains important instructions for model ISM - Intelligent Synchronization Module that

should be followed during installation and maintenance of the unit.

GENERAL

• Move the cabinet in a horizontal position in its original package to the final destination room.

• To lift the cabinets, use a forklift or lifting belts with spreader bars.

• Check for sufficient floor and elevator loading capacity.

• Check carefully the integrity of the ISM equipment.

In case you note some visible damage, do not put the ISM under voltage, but contact the nearest

Service Centre.

• WARNING! RISK OF ELECTRICAL SHOCK: Do not remove covers; there are no user serviceable parts

inside.

• This unit contains potentially hazardous voltages.

• All maintenance and service work should be performed by qualified service personnel.

INSTALLATION

• This equipment must be installed and connected only by trained personnel.

• This equipment is intended for use in a controlled indoor environment free of conductive

contaminants and protected against animals intrusion.

• WARNING! HIGH EARTH LEAKAGE CURRENT: earth connection is essential before connecting to AC

input!

• Do not install the equipment in an excessively humid environment or near water.

• Avoid spilling liquids on or dropping any foreign object into the equipment.

• The unit must be placed in a sufficiently ventilated area; the ambient temperature should not

exceed 35°C (95°F).

• It is important that air can move freely around and through the unit.

• Do not block the air vents.

• Avoid locations in direct sunlight or near heat sources.

STORAGE

• Store the equipment in a dry location; storage temperature must be within -25°C to 55°C

(-13°F to 131°F).

WARNING !

The installation and cabling of the options must be

performed by a QUALIFIED SERVICE PERSON.

Before operating be sure the installation is completely

switched off and voltage free

Modifications reserved Page 6/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 7

1.2 SAFETY SYMBOLS AND WARNINGS

Safety warnings

The text of this manual contains some warnings to avoid risk to the persons and to avoid damages to

the UPS system and the supplied critical loads.

The non-observance of the warnings reminding hazardous situations could result in human injury and

equipment damages.

Please pay attention to the meaning of the following warnings and symbols:

WARNING !

Referred to procedures or operations which could cause damages to the persons or

to the system, when not correctly operated.

NOTE !

Warns the user about important operations or procedures described in this manual.

Safety symbols

When the text includes one or more of the following symbols, that means exist a potentially hazardous

situations.

Please remind the meaning of each symbol.

CAUTION

Related to all the potentially hazardous situations which may result in injury.

DANGER OF PARTS ELECTRICALLY LIVE

Related to all the situation with potentially hazardous voltage.

DANGER OF EXPLOSION

Used to indicate conditions where exploding parts can cause serious injury.

DANGER OF CRUSHING

Used when moving the equipment due to the heavy weight.

DANGER OF OVERHUNG LOAD

Used when the equipment is lifted by a crane.

DO NOT TOUCH

Risk of parts with hazardous voltages or parts in movement.

Modifications reserved Page 7/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 8

2 DESCRIPTION

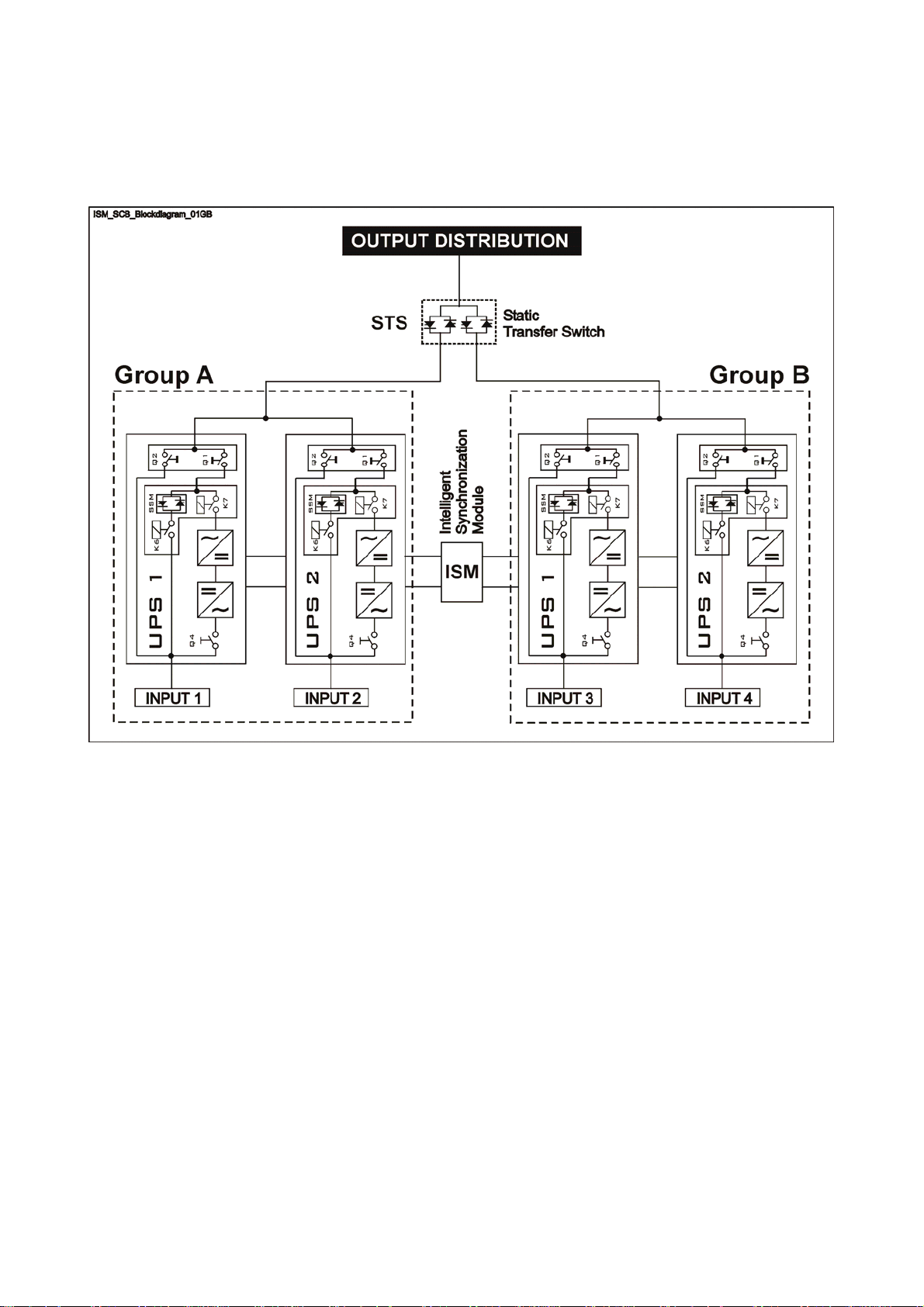

2.1 SCB - SYNCHRONIZATION OF CRITICAL BUSES

Fig. 2.1-1 SCB – Synchronization of Critical Busses block diagram

The UPS configuration in Fig. 2.1-1 enhances security, reliability and safety of a system for the power

supply to extremely critical loads.

Basically it is composed of 4 major blocks, see Fig 2.1-1:

• UPS Group A: this group can be minimum 1, maximum 6 units.

• UPS Group B: this group can be minimum 1, maximum 6 units.

• ISM – Intelligent Synchronization Module.

ISM (Intelligent Synchronization Module) allows synchronizing of two independent groups of parallel

UPS’s, each having a maximum of 6 UPS units of equal rating from 10 – 500 kVA.

• STS – Static Transfer Switch.

A Static Transfer Switch can select between 2 sources (UPS groups).

As standard the Static Transfer Switch will supply the load from the preferred source.

In case the source would fail it will transfer the load to the second source.

A condition is that both sources are synchronized continuously, also on battery operation.

Each group of UPS’s are independent and capable to supply the full load, eventually redundant.

Each unit in the group is synchronized to its Master, which in return synchronizes to the utility voltage, if

available.

Modifications reserved Page 8/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 9

r

r

t

Features & benefits:

• Redundant Power Supply providing highest reliability.

• Redundant Communication Bus tolerating an accidental cable cut.

• CRC Code (Cyclic Redundancy Check) for error free communication.

• High Precision Synchronization offering seem less transfer from one source to the other.

• Top and Bottom Cable access for easy installation.

• Compatible with GE SitePro (only series 6) and SG Series UPS and with GE’s unique RPA concept.

• Global Power Supply Voltage for worldwide usage (208, 400 or 480 VAC – 50 / 60 Hz).

• Synchronizes 2 groups of max. 6 UPS units (ranging from 10 - 500 kVA) each offering great

flexibility.

• User Friendly Control Panel providing complete information on the spot.

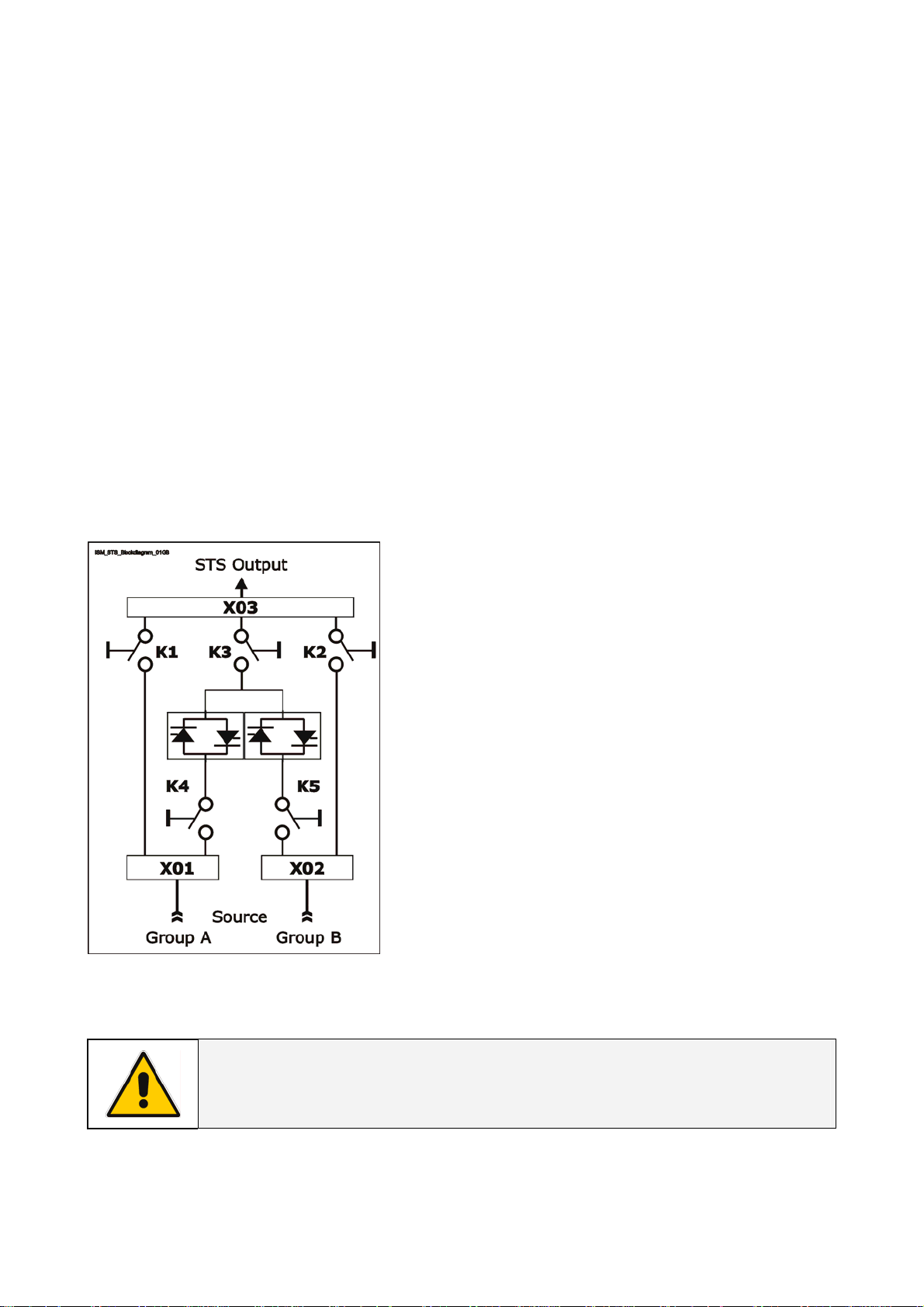

2.1.1 STS - Static Transfer Switch

Fig. 2.1.1-1 STS - Static Transfer Switch block diagram

The STS is designed for the switching of two alternative

power sources without interruption of the supply to

energy receivers.

The STS is connected to two sources of electrical powe

with terminal X01 for the Group A source and X02 fo

the Group B source.

Depending on current settings and system status, one

of the two sources (Group A or Group B) is connected to

the output terminal X03 (STS Output).

K1, K2, K3, K4 and K5 are manually operated circui

breakers.

K1 and K2 are normally open, while K3, K4 and K5 are

normally closed.

X01, X02 and X03 are terminals.

NOTE !

For installation procedures and functional descriptions of the STS, please

consult the appropriate Operating Manual.

Modifications reserved Page 9/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 10

2.2 SERVICE AND TECHNICAL SUPPORT

Stamp of your Dealer or local responsible of the Technical Assistance

(see page 3)

For any request of technical support please

contact the supplier who provided the system.

2.3 WARRANTY

GE operates through its authorised agents and warrants that the standard products will be free of

defects in materials and workmanship for a period of 12 months, after the date of the invoice, or such

other period as may be specified.

NOTE !

This warranty does not cover failures of the product which result from incorrect

installation, misuse, alterations by persons other than authorised agents, or

abnormal working conditions.

2.4 RECYCLING AT THE END OF SERVICE LIFE

NOTE !

This product has been designed to respect the environment, using materials and

components respecting eco-design rules.

It does not contain CFCs (Carbon Fluor Clorid) or HCFCs (Halogen Carbon Fluor

Clorid).

GE, in compliance with environment protection recommends to the User

that the ISM equipment, at the end of its service life, must be recovered

conforming to the local applicable regulations.

Modifications reserved Page 10/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 11

3 LAYOUT

3.1 LAYOUT ISM

ISM_Cabinet_GE_01

M

T

ISM_LBS_Cabinet open_01

Fig. 3.1-1 ISM general view

Fig. 3.1-2 ISM internal view

SYNC

SYNC

AUTO

ISM_LBS_Cabinet open_02

MAINTENANCE MAINTENANCE

INVERTER OK

BYPASS OK

ISM_LBS_Control panel_01

INVERTER

BYPASS

METERING

ALARMS

PARAMETERS

OFF

SYNC MASTER

A B

STS

LOAD

Fig. 3.1-4 Control panel

ALARM SERVICE

GROUP BGROUP A

+

-

ENTER

INVERTER

BYPASS

INVERTER OK

BYPASS OK

B SYNC TO AA SYNC TO B

MUTE

Fig. 3.1-3 ISM internal view

Modifications reserved Page 11/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 12

4 INSTALLATION

4.1 TRANSPORT

The ISM is fixed on a transport socket suitable for a forklift, which includes a special layer of Ethafoam to

protect the equipment against the transport shock.

Normally the ISM is packaged within a carton box.

On request the equipment can be packaged in a wooden case.

Move the ISM in its original package to the final destination room.

Do not stack other packages on top: they could damage the cabinet.

NOTE !

When moving the ISM, pay attention to:

WARNING !

When loading / downloading and when

moving the ISM, it is forbidden:

When loading / downloading and when

moving the ISM, pay attention to:

4.1.1 Dimensions and weight

m

m

0

5

3

"

8

7

.

3

1

m

m

4

6

2

"

9

3

.

0

m

m

3

4

"

0

7

.

1

1.66"

42mm500mm42mm

1

FRAGILE

SENSITIVE

TO DAMPNESS

m

m

3

4

"

0

7

.

1

0.55"

14mm

1

9

0

m

m

7

.

4

8

"

Dimensions ISM

SENSITIVE

TO HEAT

SENSITIVE

TO FROST

350 mm x 190 mm x 584 mm

M

T

13.78” x 7.48” x 23.00 inches

19.69"1.66"

23.00"

584mm

ISM

ISM_Cabinet dimension s_GE_01

20 Kg / 44 lbs 30 Kg / 66 lbs

Weight ISM

ISM with

standard package

Fig. 4.1.1-1 ISM cabinet dimensions

NOTE !

The weight is marked outside the package!

Modifications reserved Page 12/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 13

4.2 DELIVERY

When delivered, check carefully the package integrity and the physical conditions of the ISM

equipment.

In case of any damage sustained during transport, immediately inform the carrier and contact your

local Service Centre.

A detailed report of the damage is necessary for any insurance claim.

NOTE !

A damaged ISM must never be installed or connected to power!

4.3 STORAGE

The equipment is carefully packed for transport

and storage so that it is in a perfect condition

when eventually installed.

Never leave an ISM outside the building and do

not store the ISM one on top of the other.

It is recommended to store the ISM in its original

package in a dry, dust free room and far away

from chemical substances, with temperature

not exceeding -25°C to 55°C (-13°F to 131°F).

Some important functions of the ISM are defined by parameters stored in a RAM memory.

The RAM is supplied by a small backup battery located on the Control Unit board.

If the storage time of the ISM exceeds 1 year, these functions should be verified by an authorised

Service Centre before putting the ISM into operation.

NOTE !

In case of storage of the ISM pay attention to:

FRAGILE

SENSITIVE

TO DAMPNESS

SENSITIVE

TO HEAT

SENSITIVE

TO FROST

Modifications reserved Page 13/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 14

4.4 PLACE OF INSTALLATION

The ISM should be installed in a restricted area where only qualified personnel should be admitted.

The place of installation should be clean, dust-free, and provided with proper ventilation or air-

conditioning.

We strongly advice that the ambient temperature should not exceed 20° to 25°C / 68° to 77°F (max.

35°C / 95°F).

NOTE !

The installation of the ISM must be executed by QUALIFIED PERSONNEL ONLY.

A single-phase power outlet should be provided near the ISM for connection of power tools or test

equipment. This outlet must be grounded.

ISM positioning

G

R

O

U

P

A

Min.

400mm / 16"

G

R

O

ISM_Cabinet_GE_03

M

T

ISM_LBS_Cabinet disposition_01GB

U

P

S

3

U

P

S

2

U

P

S

1

U

P

S

1

Fig. 4.4-1 ISM positioning

U

P

U

P

B

S

2

U

P

S

3

The ISM should be mounted flush to a wall.

Clearance around the front of the ISM should be sufficient to enable free passage of personnel with

the door fully open, and to allow sufficient airflow for the ventilation.

Recommended minimum clearance between the ceiling and the top of the ISM should be 400 mm

(16 “) for proper cooling air exhaust.

NOTE !

The bolts used for fixing the ISM to the wall must be adequate for its weight.

Modifications reserved Page 14/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 15

4.5 ELECTRICAL WIRING

WARNING !

The installation and connection must be performed by QUALIFIED SERVICE

PERSONNEL only.

Refer to the “Safety prescriptions - Installation” described on page 6.

Carefully read the following recommendations before proceeding:

• Ensure that the AC external isolators are Off, and prevent their inadvertent operation.

• Do not close any external isolators prior the commissioning of the equipment.

• The input / output cables must be put in order and fixed, taking care to avoid risk of short-circuit

between different poles.

• The earthing connection of the electrical system must be in accordance with local regulation.

Input overcurrent protection and wire sizing

Fig. 4.5-1 Input overcurrent protection and wire sizing

For correct rating of fuses and cable sections for input power of the ISM see data indicated in the

tables below.

Fuses AgL or Circuit breakers

Group A: F5 – F6 & Group B: F7 – F8 2 x (2 x 2 A)

Wire sizing

Group A: L1 + L2 + PE & Group B: L1 + L3 + PE

Min. 3 x 1.5 mm

2

/ Max. 3 x 2.5 mm

Min. 3 x 16 AWG / Max. 3 x 14 AWG

2

NOTE !

The delivery and installation of fuses and input connections of the ISM are at the

customer’s expense, unless agreed otherwise.

Modifications reserved Page 15/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 16

Openings for input and output cable connections

B

ISM_LBS_Cabinet input cable_01

A

B

B

Fig. 4.5-2 Opening on top/bottom of the cabinet for input and output cables

Connection of power supply cables

A

ISM openings are provided

either on top or on the

bottom of the cabinet for

the connection of input and

output cables.

Pay attention to the

position of these openings,

when choosing the

placement of the ISM.

Position of the input and the

output can be modified by

exchanging the cover plates

“A and B” (see Fig. 4.5-2).

0

Fig. 4.5-3 Transformer TR1 and TR2

ISM_LBS_TR1-TR2_01

NOTE !

Verify the input voltage for power supply and connect the cable without label to the

corresponding input of the terminal.

Possible voltages are 208V, 400V and 480V (Phase – Phase. See Fig. 4.5-3).

Modifications reserved Page 16/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 17

Fuses rating

NOTE !

Verify for correct fuse rating “F1 - F2

- F3 - F4” on dependence of the

power supply input voltage,

according to the table below.

In case of replacement the same

type and the same rating must be

F1-F2-F3-F4

ISM_LBS_F1-2-3-4_01

Fig. 4.5-4 Fuses rating

used.

The replacement of fuses must be

performed by QUALIFIED SERVICE

PERSONNEL only.

For 208 VAC 0.75 A Fuse type Class CC – Time Delay – 13/32” x 1 1/2” – 600 VAC

For 400 VAC 0.3 A Fuse type Class CC – Time Delay – 13/32” x 1 1/2” – 600 VAC

For 480 VAC 0.3 A Fuse type Class CC – Time Delay – 13/32” x 1 1/2” – 600 VAC

Connection of power supply input cables

L1

L2

PE

GROUP AGROUP B

L1

L3

PE

Input glands are suitable for cables having diameters: from 6 mm to 12 mm / 2.37” to 4.73”

L1 Phase L1 from Output Load Group A PE Ground from Output Load Group A

L2 Phase L2 from Output Load Group A

Fig. 4.5-4 Connection of power supply input cables

ISM_LBS_Connection power_01

ISM Input A

Group A Group B

ISM Input B

L1 Phase L1 from Output Load Group B PE Ground from Output Load Group B

L3 Phase L3 from Output Load Group B

Modifications reserved Page 17/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 18

4.6 CONTROL BUS CABLES CONNECTION

WARNING !

The installation and connection must be performed by QUALIFIED SERVICE

PERSONNEL only.

Refer to the “Safety prescriptions - Installation” described on page 6.

Carefully read the following recommendations before proceeding:

• Ensure that the AC external isolators are Off, and prevent their in adverted operation.

• Do not close any external isolators prior to the commissioning of the equipment.

• The input / output cables must be put in order and fixed, taking care to avoid risk of short-circuit

between different poles.

• The earthing connection of the electrical system must be in accordance with local regulations.

The standard length of the control

bus cable between ISM and the

first unit of each group is 12 m / 40

ft.

Maximum distance between ISM

and the last unit of each group is

85 m / 279 ft.

L max. :

85 m – [(No. of UPS – 1) x 12 m]

279 ft – [(No. of UPS – 1) x 40 ft]

Maximal number of UPSs in one

Fig. 4.6-1 Diagram showing the maximum allowable length of communication cables

group is 6.

ISM_LBS_CBC connection_01GB

Fig. 4.6-2 Connection of the cables of the communication

Control bus cables

JA1

Group A

JB2

JB1

J53

Group B

P6

JA2

JA1

JB2

JB1

J63

Control bus cables

P5

JA2

J52

J62

bus to P5 / P6 – Parallel bus interface

ISM_LBS_CBC connection_02GB

Control bus cables

Group A

Control bus cables

Group B

Fig. 4.6-3 Internal connection of the communication bus cables

Modifications reserved Page 18/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 19

G

R

O

U

P

ISM_LBS_CBC connection_03GB

Q1

OFF

ON

OFF

ON

Q2

U

P

S

3

Control bus cables routing

Fig. 4.6-4 Connection of the communication bus cables from ISM to UPS’s Group A and Group B

U

P

S

A

Q1

OFF

OFF

ONON

Q2

2

Q1

OFF OFF

ONON

Q2

U

P

S

1

Control bus cables Group A

From ISM to UPS 1 / Group A

See Fig. 4.6-5/6

Control bus cables Group B

(from ISM to UPS 1 / Group B)

I

S

M

F

i

g

.

4

.

6

-

1

P5

P6

See Fig. 4.6-5/6

/

2

G

R

O

U

P

B

Q1

OFF

ON

OFF

ON

Q2

U

P

S

1

Q1

OFF

ON

OFF

ON

Q2

U

P

S

2

Q1

OFF

ON

OFF

ON

Q2

U

P

S

3

Place and fix the cables JA and JB with the appropriate clamps inside the UPS cabinets.

Pay attention to the fact, that routing of cables shall allow the removal of the protection covers.

NOTE !

Pay attention when cabling and routing the bus cables JA and JB inside the UPS

cabinet.

In case the unit should be removed from the system, the control bus cables Group A

and Group B must be removed from the cabinet without disconnecting them from

the metal plates where are located the sockets JA and JB. Please contact your

Service Centre.

For reliability reasons the cables JA and JB connecting the units should be run in separated

protected conduits, as well as separated from the power cables.

It is important that the cable JA is as long as cable JB.

ISM_LBS_RPA-IM0048_01

JB1

JP1 JP2

IM 0048

JP2

JP1

JP4

JP3

JB

ISM_LBS_RPA-IM0048_02GB

JB

Control Bus cable from ISM

JP2JP1

IM 0048

JB

JP2

JP1

JP4

JP3

JA1

JP4

JP3

JA

JA

Control Bus cable from ISM

JP4

JP3

JA

Fig. 4.6-5 PCB “P34 – Parallel Bus Interface” of UPS number 1 of either

Group A or B, prior to the connection with ISM

The Jumpers JP1, JP2, JP3 and JP4 ARE

INSERTED.

Fig. 4.6-6 PCB “P34 – Parallel Bus Interface” of UPS number 1 of

either Group A or B, after

the connection with ISM

The Jumpers JP1, JP2, JP3 and JP4 MUST BE

REMOVED.

NOTE !

Since the position of PC Board “P34 – Parallel Bus Interface” inside the UPS changes

between the various UPS output powers, it’s recommended to consult the

appropriate Operating Manual for cable connections.

Modifications reserved Page 19/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 20

4.7 UPS CONFIGURATION REQUIREMENTS

WARNING !

The installation and connection must be performed by QUALIFIED SERVICE

PERSONNEL only.

Refer to the “Safety prescriptions - Installation” described on page 6.

NOTE !

The UPSs are already correctly configured, if they have been ordered and supplied

with the ISM.

Otherwise please make sure that UPSs connected with the ISM mount:

• P13 - IM0086 RPA Board with same software version as on the ISM.

• Following software versions on P3 - IM0007 Control Board:

- For SitePro units: U2, U3: version 2.08 or higher; U36: version 7.0 or higher.

- For SG Series units: U2, U3: version 3.06 or higher; U36: version 7.0 or higher.

Modifications reserved Page 20/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 21

5 CONTROL PANEL

5.1 CONTROL PANEL

ALARM SERVICE

GROUP BGROUP A

+

-

ENTER

INVERTER

BYPASS

INVERTER OK

BYPASS OK

B SYNC TO AA SYNC TO B

MUTE

METERING

ALARMS

PARAMETERS

SYNC

OFF

SYNC MASTER

A B

STS

LOAD

SYNC

AUTO

INVERTER

BYPASS

MAINTENANCE MAINTENANCE

INVERTER OK

BYPASS OK

ISM_LBS_Control panel_01

Fig. 5.1-1 General Control Panel

5.2 TABLE OF FUNCTIONS AND INDICATIONS ON CONTROL PANEL

ISM_LBS_CP 1_01

SYNC

AUTO

SYNC

OFF

Fig. 5.2-1 Control Panel – Part 1

SYNC

AUTO

SYNC AUTO – Green LED

When lit, it indicates that the sync command is active and that the inverters of

Group A and B will be synchronized to the selected “Super Master”.

The “Super Master” will be automatically chosen.

SYNC

OFF

SYNC OFF – Red LED

When lit, it indicates that the sync command is disabled due to one or both of the

following conditions:

• SYNC command is OFF;

• One of the two (2) UPS groups is not present.

ALARM

ALARM – Yellow LED

General alarm condition.

It blinks when one or more alarm is activated. The internal buzzer is ON.

The LED remains lighted (with alarm condition still present) and the buzzer stops

as the key “mute” has been pressed.

SERVICE

SERVICE – Yellow LED

When lit it indicates that a regular maintenance service is needed.

May be reset by a service technician only. See Section 8 – Maintenance.

ALARM SERVICE

Modifications reserved Page 21/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 22

A

GROUP BGROUP A

INVERTER

BYPASS

MAINTENANCE MAINTENANCE

SYNC MASTER

AB

INVERTER

BYPASS

INVERTER

BYPASS

MAINTENANCE

INVERTER OK

BYPASS OK

A SYNC TO B

B SYNC TO

ISM_LBS_CP 2_01

A

B

INVERTER OK

BYPASS OK

STS

LOAD

INVERTER OK

BYPASS OK

B SYNC TO AA SYNC TO B

Fig. 5.2-2 Control Panel – Part 2

SYNC MASTER A (B) – Green LED

Pushbuttons commands:

A When pressed, Group A will be the synchronization “Super Master” and Group

B will synchronize to Group A.

The “SYNC MASTER A” LED will be lit.

Pressing this button disables the automatic “Super Master” selection.

B When pressed, Group B will be the synchronization “Super Master” and Group

A will synchronize to Group B.

The “SYNC MASTER B” LED will be lit.

Pressing this button disables the automatic “Super Master” selection.

The SYNC MASTER A (B) green LED, indicates whether Group

A or B is the Super Master.

OUTPUT SYNC – Green LED

When lit, it indicates that the UPS outputs of Groups A and B are synchronized

and within the allowed limits.

This indication is derived from comparing the output of the second UPS group to

the output of the selected “Super Master” group.

When blinking, it indicates that the UPS outputs of Groups A and B are

synchronizing.

OUTPUT – Green LED

The corresponding LED will be lit, depending on the UPS output status of Group A

(or B): INVERTER, BYPASS (Automatic Bypass) or MAINTENANCE (Manual Bypass).

INVERTER OK – Green LED

When lit it indicates that the inverter power to UPS Group A (or B) is available and it

is within the allowed tolerance.

BYPASS OK – Green LED

When lit, it indicates that the bypass power to UPS Group A (or B) is available and it

is within the allowed tolerance.

A SYNC TO B – Green LED

When lit, it indicates that the UPS outputs of Groups A and B are synchronized and

within the allowed limits. Group B is the synchronization Super Master.

B SYNC TO A – Green LED

When lit, it indicates that the UPS outputs of Groups A and B are synchronized and

within the allowed limits. Group A is the synchronization Super Master.

Modifications reserved Page 22/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 23

MUTE

ISM_LBS_CP 2_01

Fig. 5.2-3 Control Panel – Part 3

LAMP TEST

Key to test the control panel LED’s and buzzer.

(Pressing this key causes all the LED’s to light and the buzzer to

sound 3 times).

MUTE

METERING

ALARMS

PARAMETERS

MUTE

Key to reset general alarm and buzzer.

+

-

ENTER

ISM_CP LCD_01

Fig. 5.3-1 Control Panel - LCD screen

See Section 6 – LCD SCREEN

Modifications reserved Page 23/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 24

6 LCD SCREEN

METERING

ALARMS

PARAMETERS

ISM_CP LCD_01

+

-

ENTER

Fig. 6-1 LCD screen

The user interface consists of a back lit LCD screen having:

• 4 lines with 20 characters (standard version for Latin characters);

and

• 6 keys (the function is described for each operating mode).

The operation is extremely simple and is structured on three important main menus related to the ISM

operation, as follows:

METERING An ISM must offer some metering information for the user to be able to examine

the operating status at any time.

ALARMS In case of abnormal functioning, the ISM must keep a history of what has

happened as a series of events.

PARAMETERS The user must be able to program certain functions of the ISM (user parameters,

accessible without password) to his needs.

LCD screen standard version

METERING

LCD screen

+

ALARMS

PARAMETERS

4 rows x

20 characters

-

ENTER

The 3 buttons existing on the left side of the screen are used to activate the operating modes, while the

buttons on the right side are used to carry out functions inside these operating modes.

Modifications reserved Page 24/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 25

6.1 METERING MODE

The metering mode is entered any time when the metering button is pressed.

While in this mode the LCD will display a series of screens containing metering information.

In this mode the buttons perform the following functions:

METERING Scrolls forward to the next screen.

ALARMS Abandons the metering mode and enters the alarms mode.

PARAMETERS Abandons the metering mode and enters the parameters mode.

+ Scrolls forward to the next screen.

– Scrolls backward to the previous screen.

ENTER Displays the main screen for this mode.

METERING

ALARMS

PARAMETERS

INTELL. SYNC MODULE

A: LOAD ON INVERTER

B: LOAD OFF

This screen displays the current status of the synchronization command and the UPS outputs (for both

Group A and B).

The information offered by this screen consists of:

• Synchronization: The status of the synchronization command (A sync to B, B sync to A or Sync

OFF).

• Group A: The source of the power supplied to the Load (LOAD ON INVERTER, LOAD ON

BYPASS, LOAD ON MAN. BYP. or LOAD OFF).

• Group B: The source of the power supplied to the Load (LOAD ON INVERTER, LOAD ON

BYPASS, LOAD ON MAN. BYP. or LOAD OFF).

METERING

ALARMS

PARAMETERS

OUTPUT STATUS

This screen displays the load of UPSs output (for both Group A and B).

The information offered by this screen consists of:

• Synchronization status between UPSs of Group A and B;

• The load amount as a percentage of the nominal load of Group A (referred to the most loaded

phase);

• The load amount as a percentage of the nominal load of Group B (referred to the most loaded

phase).

METERING

ALARMS

PARAMETERS

MISCELLANEOUS

ISMOperTime

SW Version

S/N:

This screen displays miscellaneous information.

The information offered by this screen consists of:

• The total operating time of the ISM (in hours).

• The software version.

• The serial number.

A sync to B

Synchronized

Load A = 50%

Load B = 20%

:

:

72-97756

123451h

XXX-YYY

+

-

ENTER

+

-

ENTER

+

-

ENTER

Modifications reserved Page 25/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 26

6.2 ALARM

The alarms mode is entered any time when the ALARMS button is pressed.

The LCD will display a series of screens corresponding to the last 256 events, one event per screen.

The buttons perform the following functions:

METERING Abandons alarms mode and enters metering mode.

ALARMS Next screen.

PARAMETERS Abandons the alarms mode and enters the parameters mode.

+ Scrolls forward to the next screen.

– Scrolls backward to the previous screen.

ENTER Displays the main screen for this mode.

The events displayed are the standard GE events as described in the Section 6.2.1 - EVENTS (Alarms

and Messages).

The information displayed includes:

• The exact date and time when the event occurred.

• The number of the event, 255 being the most recent event, and 0 the oldest.

• The standard GE code for the event and the machine status word.

• An explicit text description of the event.

METERING

ALARMS

PARAMETERS

The initial screen of this mode is the one showing the most recent event.

15.09.2003 22:11:51

NR = 255 Status=FA12

4000: SETUP VALUES

LOST

+

-

ENTER

Modifications reserved Page 26/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 27

6.2.1 Events (Alarms and Messages)

Each of the following listed events can be displayed on the LCD screen.

Alarms and Messages are differently specified because the alarms are indicating an abnormal

functioning of the ISM (which are additionally signalled with the LED alarm and acoustically with the

buzzer), while the messages indicate the various states of operation of the ISM (stored in the events list,

but not activating the LED alarm and the buzzer).

When in alarms mode, the LCD screen displays a time ordered sequence of screens corresponding to

the last 256 alarms and messages, each screen indicating:

The number of the event (255 = the most recent).

The date and time when the event occurred.

The standard code and the status word.

An explicit text description of the events.

6.2.1.1 Alarms list

Code Alarm Meaning

Parameters are lost and have been replaced with default

values.

Call nearest Service Centre for intervention.

4000

SETUP VALUES

LOST

Verification of correct ID number setting on the control board

IM0007. Must always be set to 8.

4001

REGULATION

BOARD FAILURE

Verification of the correct function of the parallel board IM0086

and IM0007.

In case of failure detection the functions of the ISM will be

disabled.

Detection of missing communication:

The synchronization between Group A and B is disabled by the

ISM.

4005

GROUP FAILURE

ON ISM SYSTEM

Despite command for Group A and B synchronization, a phase

shift error was detected superior to the value set in the

respective parameter.

4579

GROUP A AND B

NOT SYNCHRONIZED

If the error condition persists for more than 2 seconds (value

set by service parameter), this alarm will be issued.

When starting synchronization, the alarm will be issued if the

error condition persists for more than 10 seconds (value set by

service parameter).

Modifications reserved Page 27/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 28

6.2.1.2 Messages list

Code Message Meaning

4576

4577

4578

4582

4583

SYNCHRONIZE

TO GROUP A

SYNCHRONIZE

TO GROUP B

GROUP A AND B

SYNCHRONIZED

COMMAND NOT TO

SYNCHRONIZE

COMMAND TO

SYNCHRONIZE

The command for the synchronization of Group A and B is active

and Group A was chosen to be the Super Master.

The command for the synchronization of Group A and B is active

and Group B was chosen to be the Super Master.

The command for the synchronization of Group A and B is active

and the phase error measured between the inverters of Group A

and B stays below the value specified in the respective

parameter.

ISM disabled the synchronization between Group A and B,

because the either key SYNC OFF was pressed or missing

communication was detected.

ISM enabled the synchronization between Group A and B,

because either the key SYNC AUTO or one of the keys SYNC

MASTER A or SYNC MASTER B was pressed.

Modifications reserved Page 28/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 29

6.2.1.3 Event report ISM

In case of failure or malfunctioning, before calling the nearest Service Centre, please note the most

important data of your UPS and the most recent events.

In order to make the diagnosis easier from our Diagnostic Centre we suggest that you make a copy of

this page, fill it out with the requested data and send it by fax.

ISM No.:

__ __ __ __ __ - __ __ __ __ - __ __ __ __ Series No.: …………….…...

Customer: ..........................................……………..…. Place: ..................…..……………………….......................…........

Date: ...……..... / .....…...... / .....……..….....….. Sent by: .....…................………………………....................….......…

On the LCD panel, enter the alarms mode and record the alarms/messages in the list below indicating at least 5

events before the failure time.

Remark: exact data and time are very important.

Description of repair actions taken:

Event

No.

255

Event

Code

UPS

Status

Date

Time

H. M. S

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

Actual situation:

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

Remarks:

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

.........................……………………………........…………………..........................………............................................………...............

254

253

252

251

250

249

248

247

246

245

244

243

242

241

240

239

238

237

.........................……………………………........…………………..........................………............................................………...............

236

235

Modifications reserved Page 29/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 30

6.3 USER PARAMETERS

The parameters mode is entered any time when the PARAMETERS button is pressed.

The LCD will display a series of screens containing the user parameters, accessible without password

protection.

The buttons perform the following functions:

METERING Abandons parameters mode and enters metering mode.

ALARMS Abandons parameters mode and enters alarms mode.

PARAMETERS Scrolls forward to the next screen.

+ Scrolls forward to the next screen.

– Selects from the current screen the parameter to edit.

ENTER Starts the editing for the currently selected parameter.

NOTE !

During parameters mode there is no means to perform scroll back on the display.

Example of operation within parameters mode:

Purpose: To correct a wrong parameter:

PROCEDURE DATE TIME LANG.

- Enter parameters mode (PARAMETERS). The first screen is displayed.

- Scroll to the next screen (+). The second screen is displayed.

- Move the selection (underscore cursor) to the next parameter in this page (-).

- Enter Edit mode for the currently selected parameter (ENTER).

√ √ √

√

√

√ √ √

METERING

ALARMS

PARAMETERS

D M Y

Date: 1

Time: 12:15:45

DATE AND TIME

5.09.2003

+

-

ENTER

1- DATE AND TIME

• D = Day M = Month Y = Year.

• Date The set value is thoroughly checked to be a correct format “dd.mm.yyyy”.

• Time The set value is thoroughly checked to be a correct format “hh.mm.ss”.

METERING

ALARMS

PARAMETERS

Language = ENGLISH

LCD DISPLAY

+

-

ENTER

2- LCD DISPLAY

• Language This parameter allows the choice of language used to display the information.

Valid choice is English.

Modifications reserved Page 30/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 31

7 OPERATION

WARNING !

Before connecting hazardous voltages, make sure that:

• The cables for ISM supply and communication are correctly connected and in

accordance with existing standards;

• The equipment frame has been correctly grounded to the earth;

• All panels, which had been previously removed to allow ISM connection, have been

correctly reinstalled;

• Make sure fuse holders “F1, F2, F3, F4” inside the ISM cabinet and “F5, F6, F7, F8” in

the distribution cabinet(s) are closed.

7.1 PROCEDURES FOR SCB - SYNCHRONIZATION OF CRITICAL BUSSES

Procedure for SCB - Synchronization of Critical busses start-up

As soon as one of the UPS’s, either from Group A or Group B supplies the load, the ISM system will

automatically start-up.

NOTE !

As the ISM system starts-up, an Alarm is issued and the Buzzer starts sounding if the

synchronization at the last shutdown was disabled (“SYNC OFF”).

To enable synchronization, press either the key “SYNC AUTO” for automatic choice of the

synchronization source, or “SYNC MASTER A” / “SYNC MASTER B” to choose manually one of the two.

Condition for the above is that at least one UPS of a group has it’s electronics supplied and at least one

parallel group supplies the load, and consequently the ISM.

To switch from automatic to manual synchronization, press one of the keys marked “SYNC MASTER A”

or “SYNC MASTER B”, depending on which group is desired to be the Super Master.

To change from manual synchronization to automatic, press the key “SYNC AUTO”.

To disable synchronization press key “SYNC OFF”.

NOTE !

If a parallel system with an active synchronization command is shutdown (including

electronics), the command for synchronization will be disabled and the “Alarm 4005 Group failure on ISM system” is issued, together with an acoustical signal from the

buzzer.

Procedure for SCB - Synchronization of Critical busses shutdown

If no UPS of either Group A or B supplies the load, the ISM system is shutdown automatically.

Modifications reserved Page 31/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 32

8 MAINTENANCE

An ISM system, like other electrical equipment, needs periodic preventive maintenance.

A regular maintenance check of your installation guarantees higher reliability of your ISM.

Preventive maintenance work on the ISM can be done only by trained Service Technicians.

We therefore recommend you sign a Maintenance and Service contract with the local Service Centre

organisation.

The ISM follows the same service program and intervals as for UPS systems.

Service check

If this LED lights up during the normal operation, that means that the unit has not been serviced for the

last 20’000 hours by a GE Trained Technician.

We highly recommend that you contact your Service Centre for preventive maintenance work.

ISM room conditions and temperature

The ISM room has to be maintained clean and free from dust.

A high temperature of the ISM room affects the lifetime of several components inside the equipment.

Component with limited lifetime

We recommend the replacement of component such as lithium battery for the backup of data on the

control boards of the units every 50’000 hours.

Modifications reserved Page 32/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 33

9 NOTES

9.1 NOTES FORM

It is recommended to note in this section Notes, with dates and short descriptions, of all the operations

performed on the ISM, such as: maintenance, components replacement, abnormal situations, etc. .

Date Description Done by

Modifications reserved Page 33/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Page 34

Modifications reserved Page 34/34

OPM_ISM_OPT_10K_M50_0GB_V021.doc Operating Manual ISM – Intelligent Synchronization Module

Loading...

Loading...