Page 1

Galaxy Vector Controller

GCM2, GCM3

Product Manual

Select Code 167-792-115

Comcode 108894403

Issue 4

January 2008

Page 2

Page 3

Product Manual

Select Code 167-792-115

Comcode 108894403

Issue 4

January 2008

Galaxy Vector Controller

GCM2, GCM3

Notice:

The information, specifications, and procedures in this manual are

subject to change without notice. Lineage Power assumes no

responsibility for any errors that may appear in this document.

© 2008 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 4

Page 5

Galaxy Vector Controller GCM2, GCM3

Table of Contents

1 Introduction

General Information 1 - 1

Customer Service Contacts 1 - 2

Customer Service, Technical Support,

Product Repair and Return, and Warranty Service 1 - 2

Customer Training 1 - 2

On-Line Power Systems Product Manuals 1 - 2

EasyView Software 1 - 2

2 Product Description

Overview 2 - 1

Batteryless Operation 2 - 1

GCM2 or GCM3 Control Board 2 - 3

User Interface Control Panel 2 - 3

BLJ3 Terminal Connection Board 2 - 7

Control Signal Inputs 2 - 13

BLJ3 Power Connections 2 - 13

BTJ2/BTJ3 Termination Board 2 - 14

BTJ2/BTJ3 Fuses and Connectors 2 - 15

3 Operation

Office Alarm Contacts 3 - 1

Alarm Descriptions 3 - 1

System Features 3 - 9

Battery Recharge Current limit 3 - 15

Battery Discharge Test 3 - 15

Plant Generator/Battery Test (PBT) 3 - 18

Remote Access and Monitoring 3 - 18

Remote Rectifier Standby 3 - 19

Dial-out On Alarm 3 - 19

Issue 4 January 2008 Table of Contents - 1

Page 6

Galaxy Vector Controller GCM2, GCM3

4 Installation and Configuration

Wiring 4 - 1

Front Panel Operation 4 - 5

View Active Alarms Mode 4 - 5

Configuration 4 - 6

Battery Discharge Test Results 4 - 11

Battery Discharge Test Enable 4 - 12

Shunt Type/Size 4 - 12

Shunt Size 4 - 13

System Float Mode Settings 4 - 13

Very Low Voltage Threshold 4 - 14

Battery Recharge Current Limit Settings 4 - 14

Battery Thermal Compensation Settings 4 - 14

Low Voltage Disconnect Contactor 1 and 2 Settings 4 - 15

Plant Boost Mode Settings 4 - 16

Converter Settings 4 - 17

Voltage Calibration 4 - 17

Reserve Operation Engine 4 - 18

Serial Bus Updating and Clearing 4 - 18

Software Release Information 4 - 18

5 Troubleshooting

Replacing Circuit Packs 5 - 1

Checking the highest battery temperature 5 - 1

Inaccurate Plant Voltage Readings 5 - 2

Temperature Probe Alarm is present 5 - 3

Unexplained Rectifier Failure Alarm and Multiple

Rectifier Failure Alarm 5 - 3

Unexplained Converter Failure Alarm and Multiple Converter

Failure Alarm 5 - 3

Rectifier Id conflict alarm is asserted 5 - 3

Converter Id (Cid) 5 - 3

6 Product Warranty

2 - Table of Contents Issue 4 January 2008

Page 7

Galaxy Vector Controller GCM2, GCM3

Appendix A Communications

Modem A - 1

Port Settings A - 1

Logging in A - 2

Galaxy Gateway A - 4

Introduction A - 4

Preparation A - 5

Precautions A - 5

Tools/Equipment Required A - 6

Unpacking the Galaxy Gateway A - 6

Vector Controller Configuration A - 7

Gateway Installation for Vector Controller A - 7

Galaxy

Configuring Network Communications A - 10

Logging In to the Galaxy Gateway A - 10

Configuring Static Network Parameters A - 11

Logging Out of the Galaxy Gateway A - 12

Post Installation Procedures A - 13

Gateway Cable Connections A - 8

Appendix

Objects and Attributes B - 1

B

T1.317 Objects and Attributes

Commands B - 6

ala Report Active Alarms B - 6

bye Log-off B - 6

cha Change Value B - 7

login Login B - 7

ope Operate a Control B - 7

pas Change Passwords B - 7

sta Report Status B - 8

Error Messages B - 8

Appendix C Regulatory Statements

FCC Part 68 Regulatory Statement C - 1

Industry Canada Certification C - 2

Issue 4 January 2008 Table of Contents - 3

Page 8

Page 9

Galaxy Vector Controller GCM2, GCM3

List of Figures

Figure 2-1: Galaxy Vector Controller in a Typical GPS Plant 2 - 2

Figure 2-2: Galaxy Vector Controller in a Flexent Outdoor Plant 2 - 2

Figure 2-3: Galaxy Vector Controller GCM2 or GCM3 2 - 3

Figure 2-4: 848597563 Control Panel 2 - 4

Figure 2-5: Galaxy Vector Controller Display Menu Flow 2 - 6

Figure 2-6: Galaxy Vector Controller BLJ3 Terminal

Connection Board 2 - 7

Figure 2-7: Vector Controller BTJ2/BTJ3 Terminal

Connection Board

(Used in Outdoor Systems) 2 - 14

Figure 3-1: Battery Thermal Compensation Set Points

(Standard) 3 - 11

Figure 3-2: Battery Thermal Compensation Set Points (Flexent) 3 - 12

Figure 4-1: 210E Thermistor Multiplexer Connections to BLJ3 4 - 3

Figure 4-2a: 210E Thermistor Multiplexer Connections with

847157674 Cable Set to BTJ2/BTJ3 4 - 4

Figure 4-2b: 210E Thermistor Multiplexer Connections with

8478669412 Cable Set to BTJ2/BTJ3 4 - 5

Figure A-1: BSM3 Modem Board A - 1

Figure A-2a: GPS with Metal Door and Vector Controller A - 4

Figure A-2b: GPS with Plastic Door (DA) and Vector Controller A - 5

Figure A-3: Gateway Connection to BLJ3 Terminal Board. A - 9

Issue 4 January 2008 List of Figures - 1

Page 10

Page 11

Galaxy Vector Controller GCM2, GCM3

List of Tables

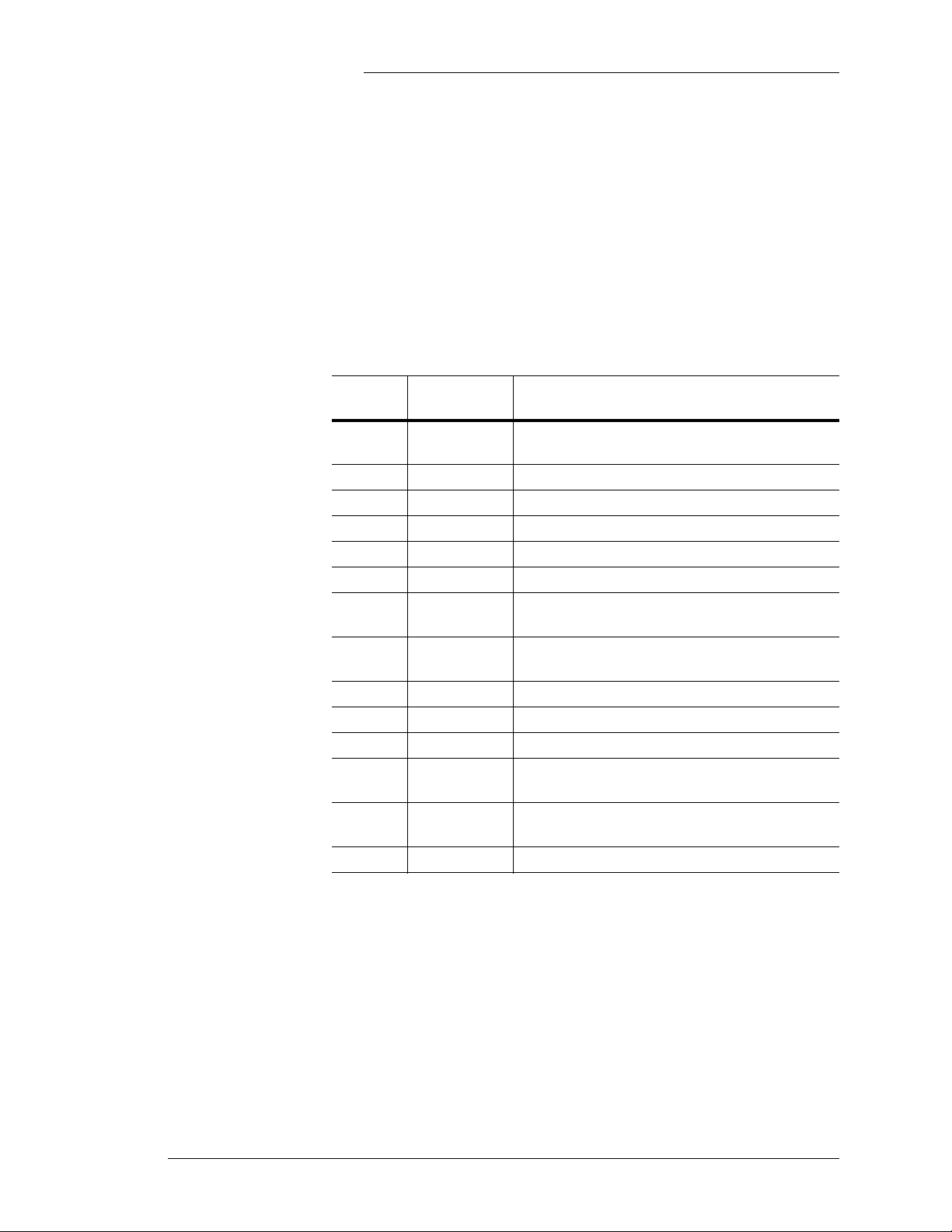

Table 2-A: Galaxy Vector Controller Specifications 2 - 1

Table 2-B: 848597563 Control Panel Keys and Functions 2 - 4

Table 2-C: Control Panel LEDs and Functions 2 - 5

Table 2-D: BLJ3 Alarm Input Terminals 2 - 8

Table 2-E: LVD Contactor Configuration Jumpers 2 - 8

Table 2-F: LVD Drive Terminals 2 - 9

Table 2-G: BLJ3 Office Alarm Relay Output Terminals 2 - 9

Table 2-H: Battery Shunt Inputs 2 - 10

Table 2-I: Plant Voltage Sense Inputs 2 - 11

Table 2-J: J12 Jumper 2 - 11

Table 2-K: BLJ3 Control Signal Inputs 2 - 13

Table 2-L: Power Connections BLJ3 2 - 13

Table 2-M: BTJ2/BTJ3 Power Connections (J21) 2 - 15

Table 2-N: BTJ2/BTJ3 LVD1 Control Connections (J23) 2 - 16

Table 2-O: BTJ2/BTJ3 LVD2 Control Connections (J4) 2 - 16

Table 2-P: BTJ2/BTJ3 Office Alarm Relay Output

Connections (J6) 2 - 17

Table 2-Q: BTJ2/BTJ3 Thermal Input Connections (J9-J12) 2 - 18

Table 2-R: BTJ2/BTJ3 RS-232 Connections (J13) 2 - 18

Table 2-S: BTJ2/BTJ3 Display Connections (J14) 2 - 19

Table 3-A: Alarm Identification Standard Assignments 3 - 3

Table 3-B: Office Alarm Relay and Front Panel LED

Standard Assignments 3 - 4

Issue 4 January 2008 List of Tables - 1

Page 12

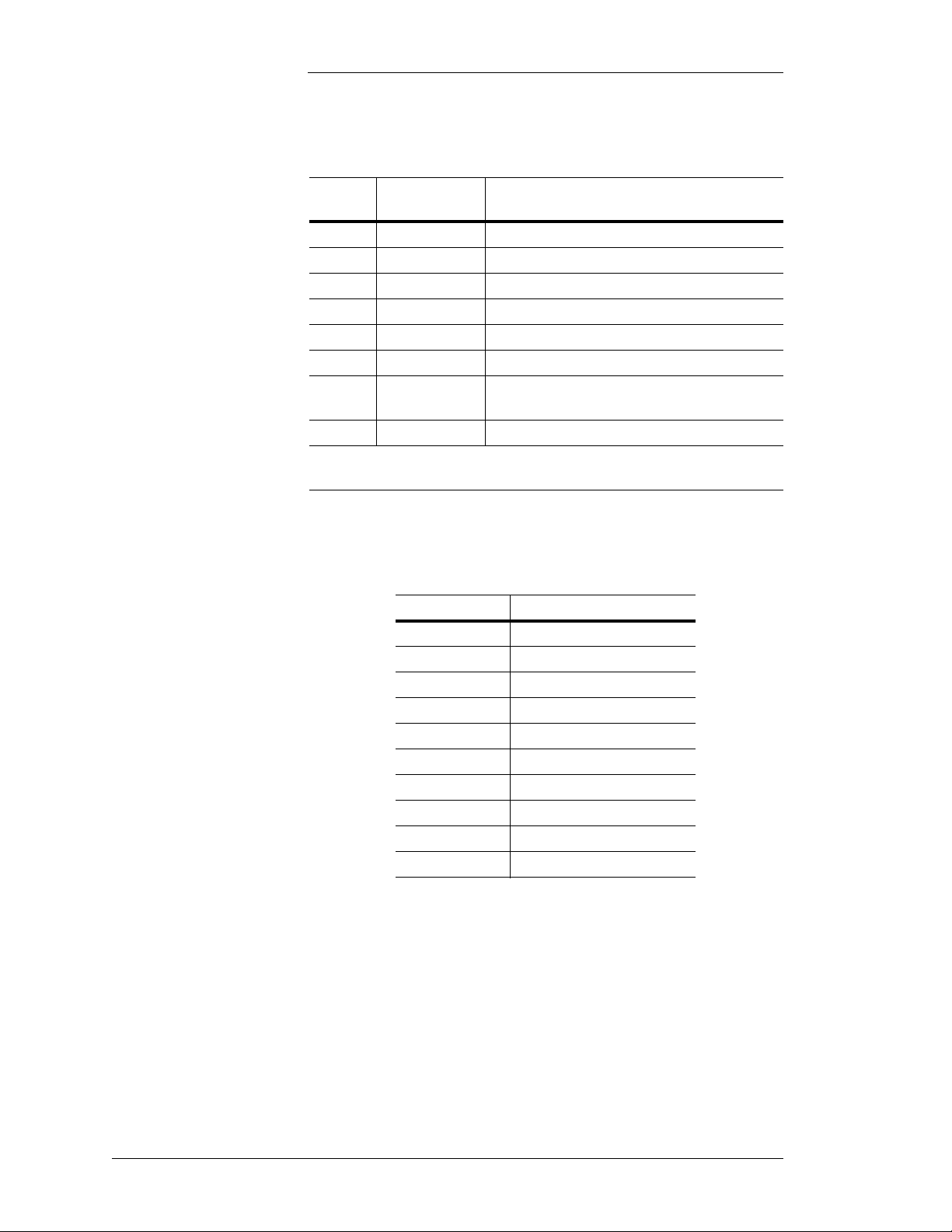

Galaxy Vector Controller GCM2, GCM3

Table 4-A: Configuration Parameters 4 - 8

Table 5-A: Replacement Circuit Packs and Temperature Modules 5 - 1

Table B-1: Power System B - 2

Table B-2: DC Plant B - 2

Table B-3: Alarm Thresholds B - 2

Table B-4: Rectifier Management B - 2

Table B-5: Rectifiers (xx is 01 to 24) B - 3

Table B-6: Battery Reserve Management B - 3

Table B-7: Battery Sections B - 3

Table B-8: Controller Battery Temperature Channels B - 3

Table B-9: Converter Plant B - 4

Table B-10: Boost Management B - 4

Table B-11: Battery/Load Contactor B - 4

Table B-12: Slope Thermal Compensation B - 5

Table B-13: Call-Out B - 5

Table B-14: Serial Ports B - 5

Table B-15: Alarm Messages B - 6

Table B-16: Error Messages B - 8

2 - List of Tables Issue 4 January 2008

Page 13

Galaxy Vector Controller GCM2, GCM3

1 Introduction

General Information

This product manual describes the Lineage Power GCM2 and

GCM3 versions of the Galaxy Vector Controller. These

controllers are an integral part of various Lineage Power GPS

(Galaxy Power System) and OPS (Outdoor Power System)

series power plants. They provide control and alarm monitoring

functions over a digital serial interface that interconnects plant

rectifiers and converters. Control includes the setting of

converter output voltage, rectifier output voltage, current limit,

high voltage shutdown, rectifier restart, sequencing and boost

mode. This serial digital communication interface helps

automate the installation and setup process. For example, the

need to use potentiometers to separately set individual rectifier

and converter output voltage levels is eliminated. Versions of the

Vector Controller are available for both +24Vdc (GCM2) and 48Vdc (GCM3) plants, including the 24V Flexent Wireless™

indoor and outdoor systems and H569-453 (+24V) / H569-454

(-48V) OPS systems.

The following Lineage Power rectifiers can interface with the

Galaxy Vector Controller:

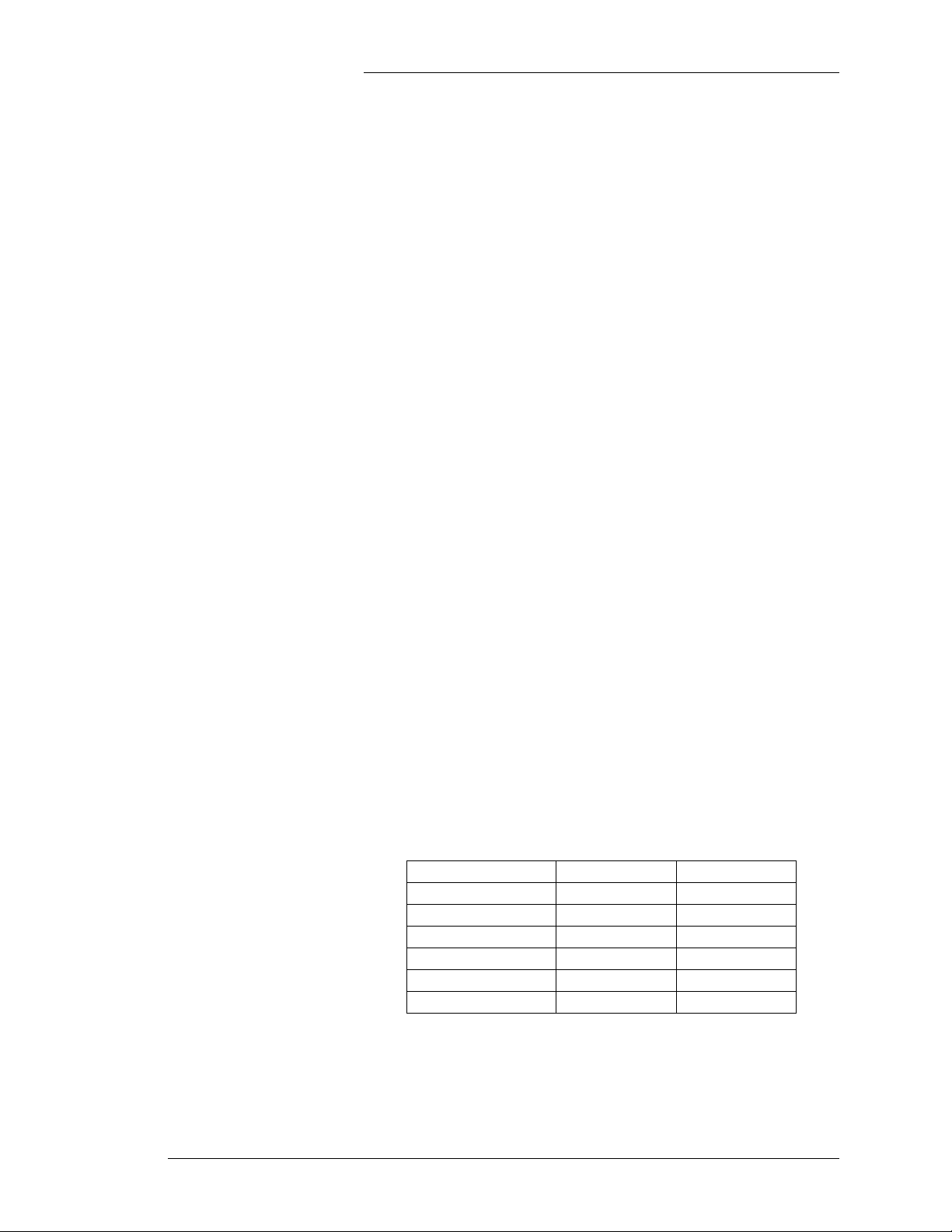

Model Vdc Current

570A -48V 100A

595A, 595B, 595C -48V 200A

596A / 596D -48V 50A / 100A

596B +24V 100A / 125A

596F (Flexent) +24V 100A

NP -48 24-50A

Note: The Galaxy to Rectifier protocol supports many different

features and variables. Not all rectifiers support the complete

feature set.

Issue 4 January 2008 Introduction 1 - 1

Page 14

Galaxy Vector Controller GCM2, GCM3

In addition to rectifier and converter control, the Vector

Controller provides:

• Visual alarm and plant status on the user front panel display

assembly

• Form C or transfer type contacts for the various alarm

conditions for external use

• Modem or network interface

• Low voltage battery disconnect

This manual describes the basic features, operation, installation

and configuration, acceptance testing, troubleshooting, and

repair of the Galaxy Vector Controller.

Customer Service Contacts

Customer Service, Technical Support, Product Repair and Return, and Warranty Service

For customers in the United States, Canada, Puerto Rico, and the

US Virgin Islands, call 1-800-THE-1PWR (1-800-843-1797).

This number is staffed from 7:00 am to 5:00 pm Central Time

(zone 6), Monday through Friday, on normal business days. At

other times this number is still available, but for emergencies

only. Services provided through this contact include initiating

the spare parts procurement process, ordering documents,

product warranty administration, and providing other product

and service information.

For other customers worldwide the 800 number may be accessed

after first dialing the AT&T Direct country code for the country

where the call is originating, or you may contact your local field

support center or your sales representative to discuss your

specific needs.

Customer Training Lineage Power offers customer training on many Power Systems

products. For information call 1-972-284-2163. This number is

answered from 8:00 a.m. until 4:30 p.m., Central Time Zone

(Zone 6), Monday through Friday.

Downloads and Software

To download the latest product information, product software

and software upgrades, visit our web site at

http://www.lineagepower.com

1 - 2 Introduction Issue 4 January 2008

Page 15

Galaxy Vector Controller GCM2, GCM3

2 Product Description

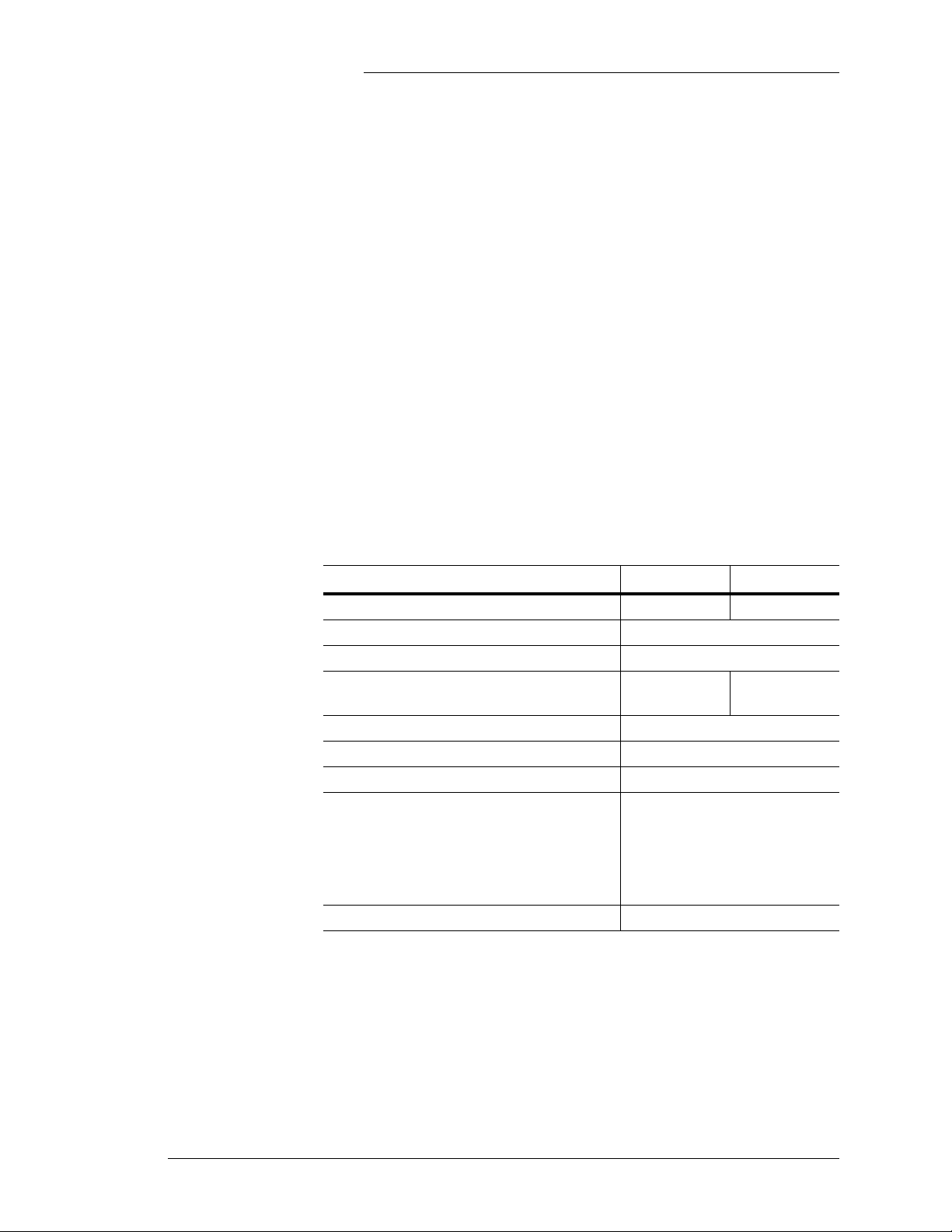

Overview The Galaxy Vector Controller is mounted on the inside front

door of a GPS plant with the user interface panel accessible from

the front of the door. See Figure 2-1. In the Flexent Outdoor

system, the controller is installed behind a swing-out control/

display panel. See Figure 2-2. Basic controller specifications are

summarized in Table 2-A.

Table 2-A: Galaxy Vector Controller Specifications

GCM2 GCM3

Input voltage range 19 - 30V 36 - 60V

Maximum input power 4.5W

Form C Alarm contact ratings 60V at 0.3A

Plant voltage measurement accuracy

(±.05% of full scale + 1 count)

Plant voltage measurement resolution .01V

Plant current measurement accuracy ±1% of full scale

Plant current measurement resolution 1A

Thermistor temperature measurement accuracy

Operating temperature range -40°C to +85°C

±30mV ±40mV

• ±3°C for battery temperatures

from -5°C to +55°C

• ±5°C for battery temperatures

from -10°C to -5°C

• ±5°C for battery temperatures

from +55°C to +85°C+

Batteryless Operation The Vector Controller is suitable for use in power plants with or

without batteries. In batteryless plants, the loss of ac power

causes an immediate loss of dc power to the controller and the

activation of all office alarm relays. When ac power is restored,

plant rectifiers will return to their last specified voltage set point,

and the controller will automatically return to its last

configuration.

Issue 4 January 2008 Product Description 2 - 1

Page 16

Galaxy Vector Controller GCM2, GCM3

GCM

BLJ3

LCD Display

Assembly

Inside of Cabinet Door

Figure 2-1: Galaxy Vector Controller in a Typical GPS Plant

BTJ2 Board

Controller Display

(shown in open position)

Vector Controller

Figure 2-2: Galaxy Vector Controller in a Flexent Outdoor Plant

2 - 2 Product Description Issue 4 January 2008

Page 17

Galaxy Vector Controller GCM2, GCM3

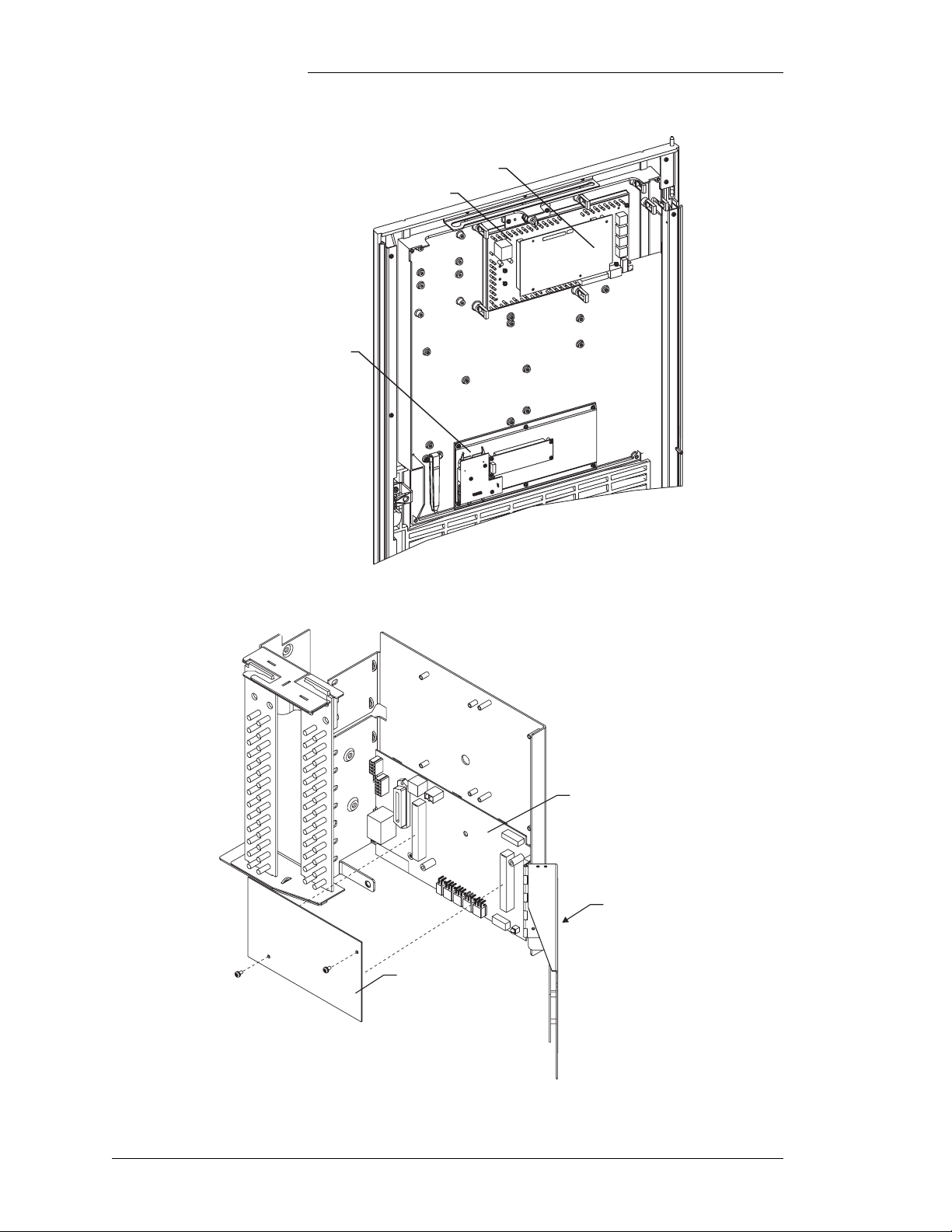

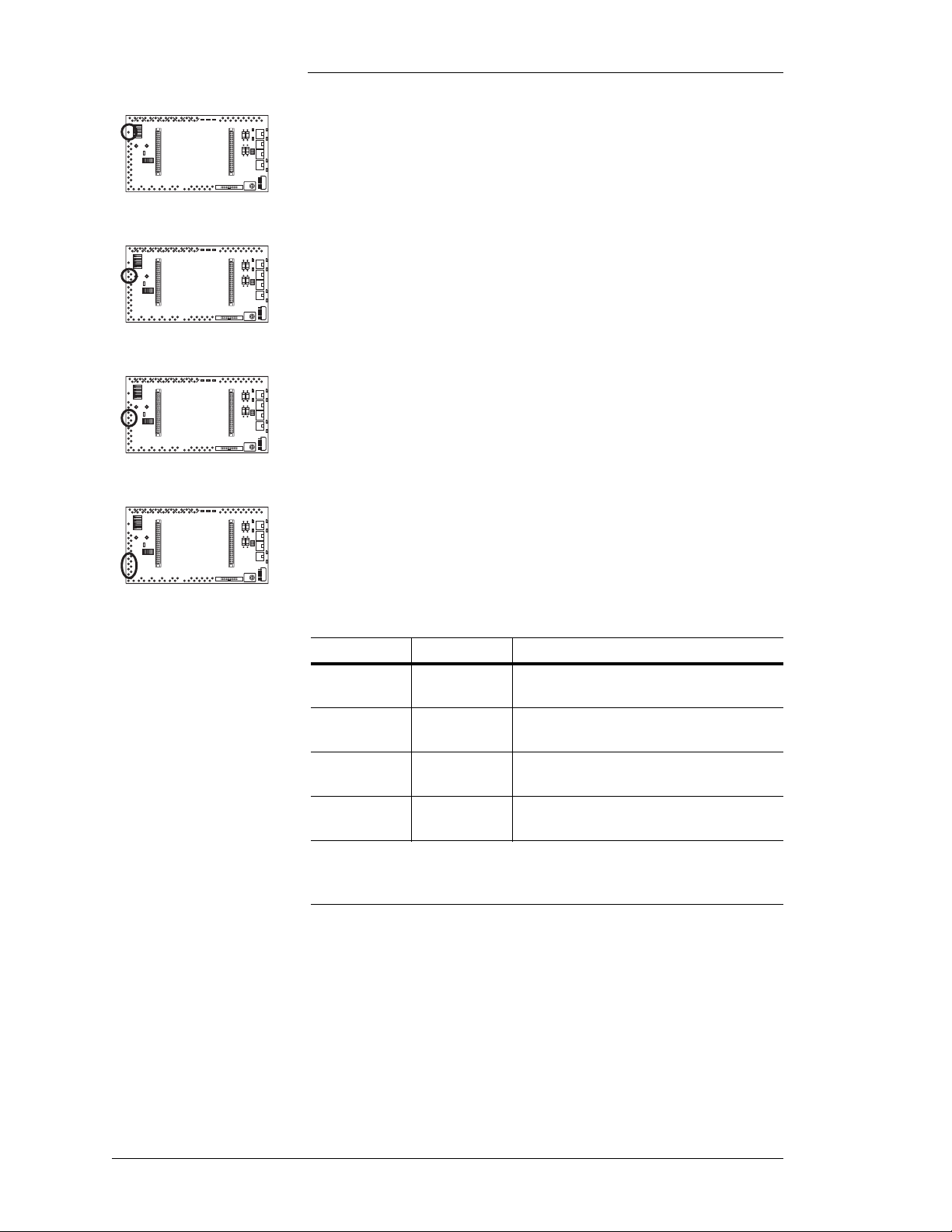

GCM2 or GCM3 Control Board

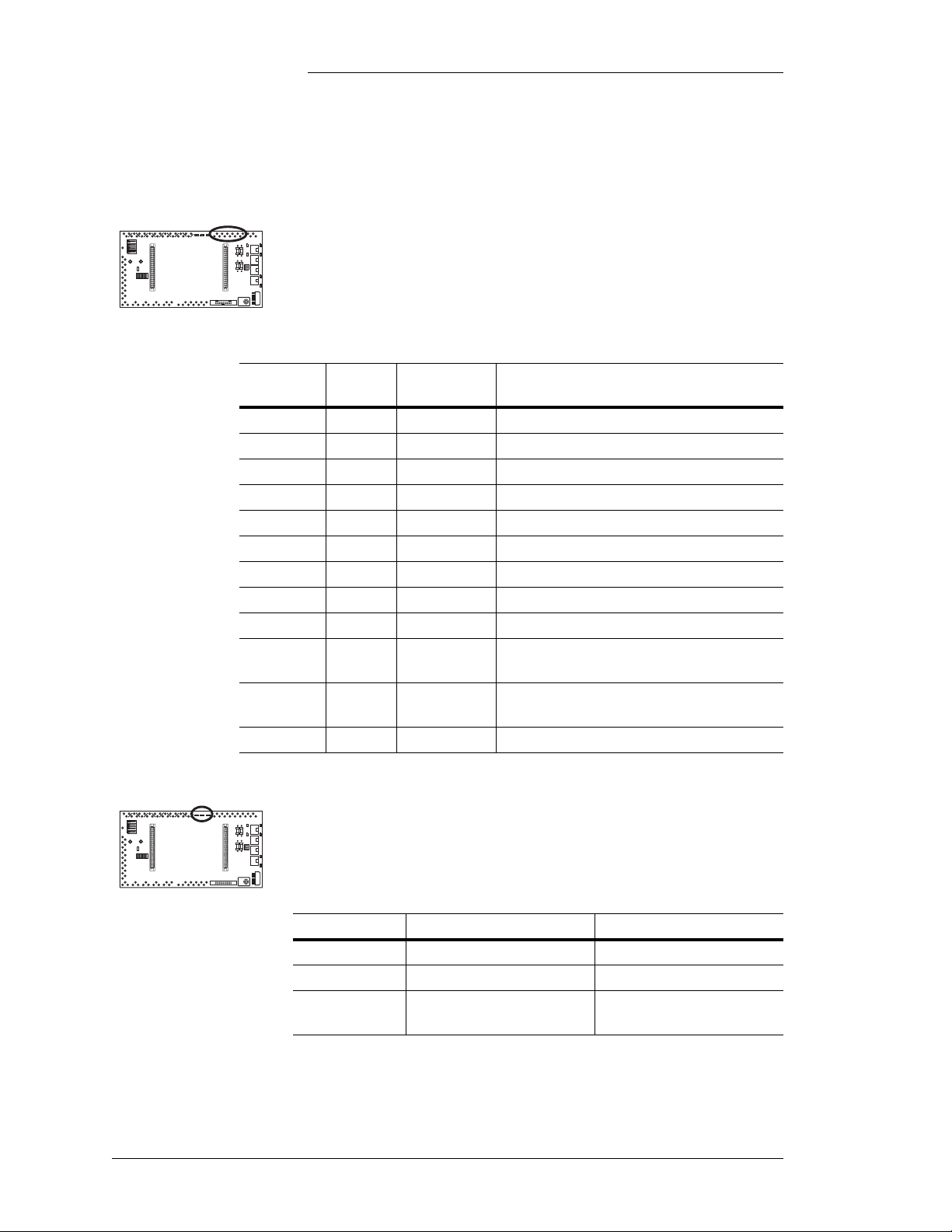

Figure 2-3 shows the Galaxy Vector Controller board. This

board consists of an embedded microcontroller, A/D converters,

timers, memory, and input/output alarm and control circuitry

with connections to the terminal connection boards. There are

two versions of the control board: GCM2 for +24V systems, and

GCM3 for -48V systems. IC27 is the memory IC that contains

the firmware which determines the controller operation, and the

preset voltage and temperature thresholds for plant operation.

Software is updated by replacing IC27. A simpler upgrade

method is to replace the controller board. This avoids directly

handling, and possibly causing damage to the memory IC. There

are no hardware user-configurable items on the GCM boards.

IC27 - Peripheral Support and Memory IC

IC1 - Microcontroller

User Interface Control Panel

J1 J3

IN

+

OUT-

OUT+

Figure 2-3: Galaxy Vector Controller GCM2 or GCM3

Figure 2-4 shows a view of the 848597563 user interface control

panel. This assembly interfaces with the BLJ3 or BTJ2/BTJ3

connection boards via a 26 pin ribbon attached to P2. The

848597563 provides a comprehensive user interface to the

controller. It is used to view plant voltage and load, configure

thresholds and other system parameters, view active alarms and

to initiate system operations. This interface consists of a 4 line x

20 alphanumeric character LCD, a nine key keypad, and three

status LEDs. A standard DB9 connector is available for local

terminal access, or remote access using an optional BSM3

modem board. The modem board also provides isolation to the

local terminal connection. Note: If the BSM3 is not connected

J1 and J3 - Connect to

BLJ3 or BTJ2 Boards

Issue 4 January 2008 Product Description 2 - 3

Page 18

Galaxy Vector Controller GCM2, GCM3

then the local port is referenced to the battery side of the power

system. Some teminal connections are referenced to true ground.

For these cases, a commercially available external port isolation

device is required. The BSM4 may also be purchased to

internally perform this isolation.

Galaxy Vector Controller

Figure 2-4: 848597563 Control Panel

Four softkeys are located directly to the left of the display. The

labels and functions of these buttons change dynamically as you

make selections and perform system operations. Softkey labels

appear in the display window and are preceded by a "←".

+27.74V 820A

FLOAT-COMPENSATED

CUTOFF

View Alarms (5)

AUDIBLE ALRM

Four navigation keys (up, down, left, and right arrow keys) are

located to the right of the display. These keys are used to

navigate through the controller menus.

The home key, located directly to the left of the four

softkeys, brings you:

• to the main menu from the default screen or any sub-menu

• to the default screen from the main menu

Table 2-B lists the user interface control panel keys and

functions.

Table 2-B: 848597563 Control Panel Keys and Functions

Key Function

Softkeys

Left and Right

Arrow Keys

Up and Down

Arrow Keys

Home Key Return to top level of menu structure or default screen

Move through the various features and menu structure of

the controller

Move through digits in edit screens

Scroll or select a configuration option or value in an edit

screen

2 - 4 Product Description Issue 4 January 2008

Page 19

Galaxy Vector Controller GCM2, GCM3

Three alarm status LEDs give a visual indication of system

status. The Major and Minor alarm LEDs indicate when alarms

are present, and then the actual alarm descriptions can be

displayed on the LCD by pressing the Alarms softkey. LED

indications are described in Table 2-C.

Table 2-C: Control Panel LEDs and Functions

LED Indication

MAJOR (red)

MINOR (amber)

OK (green)

A Major alarm is active. If the MAJOR LED is lit,

MINOR and OK LEDs will not be lit.

A Minor alarm is active. If the MINOR LED is lit,

there are no Major alarms active and the MAJOR

and OK LEDs will not be lit.

No alarms are active. If the OK LED is lit, MAJOR

and MINOR LEDs will not be lit.

The default screen displays system voltage and current, system

mode (FLOAT or BOOST and other system conditions), and any

active alarms. The display will return to the default screen from

any menu whenever there has been no user initiated activity for

three minutes.

All power system attributes are characterized into three main

categories by the Vector Controller:

•Status

• Operations

• Configuration

as shown in Figure 2-5. Under Configuration are all of the

system parameters that can be edited.

Configuration edit screens have values and settings that can be

customized. There are two types of edit screens, numeric and

scroll lists. Numeric edit screens are those on which you modify

numbers by changing the individual digits in the number. An

example is the Float Set Point screen. Scroll list edit screens are

modified by pressing the UP and DOWN buttons to scroll

through a list of possible settings. These lists may include

numeric values or text. Selecting a Shunt Type is an example of

a scroll list edit.

Issue 4 January 2008 Product Description 2 - 5

Page 20

Main Menu

View Status

Galaxy Vector Controller GCM2, GCM3

Battery Test Results

Batteries

Converters

Rectifier Current

Current

Temperature Probes

TYPE

VOLTAGE

CURRENT

Float Voltage Alrms

HIGH MAJOR

HIGH MINOR

BD MAJOR

LOW MAJOR

Control/

Operations

Configuration

Alarm Thresholds

Enable/Disable

Info

SOFTWARE VER

Float Voltages

Rectifiers

Shunts

Batteries

Contactors

Converters

Boost

Communication

Ports

Calibrate to Meter

Boost Voltage Alrms

BATT TEMP MJ

Start/Stop

Battery Test

Start

Lamp Test

Update Serial Link

Start/Stop Boost

Set Point

Voltage Alarms

Current Limit

No. On Engine

Type

Shunt 1 Rated

Shunt 2 Rated

Type

Batt Test Enable

Batt Temp

Management

Limit Recharge

Contactor 1

Contactor 2

Set Point

Shutdown At

Shutdown Enable

Restart At

HIGH MAJOR

HIGH MINOR

BATTERY TEST

BOOST FEATURE

AUTO BOOST

CONV SHUTDOWN

TEMP COMP

LOW TEMP COMP

RECHARGE LIMIT

High Major

High Minor

BD Major

Low Major

Temp Alarm

Temp Compensation

Limit Enable

Limit At

Boost Enable

Set Point

Boost Voltage Alrms

Auto Boost

Manual Dur

Boost Current Lmt

Local Port

Modem Port

System Voltage

Converter Voltage

Temp Comp Enable

High Temp Comp

Nominal Temp

Low Temp Comp

High Major

High Minor

Auto Boost Enable

Auto Duration

Baud Rate

Handshake

Baud Rate

Handshake

Rings to Answer

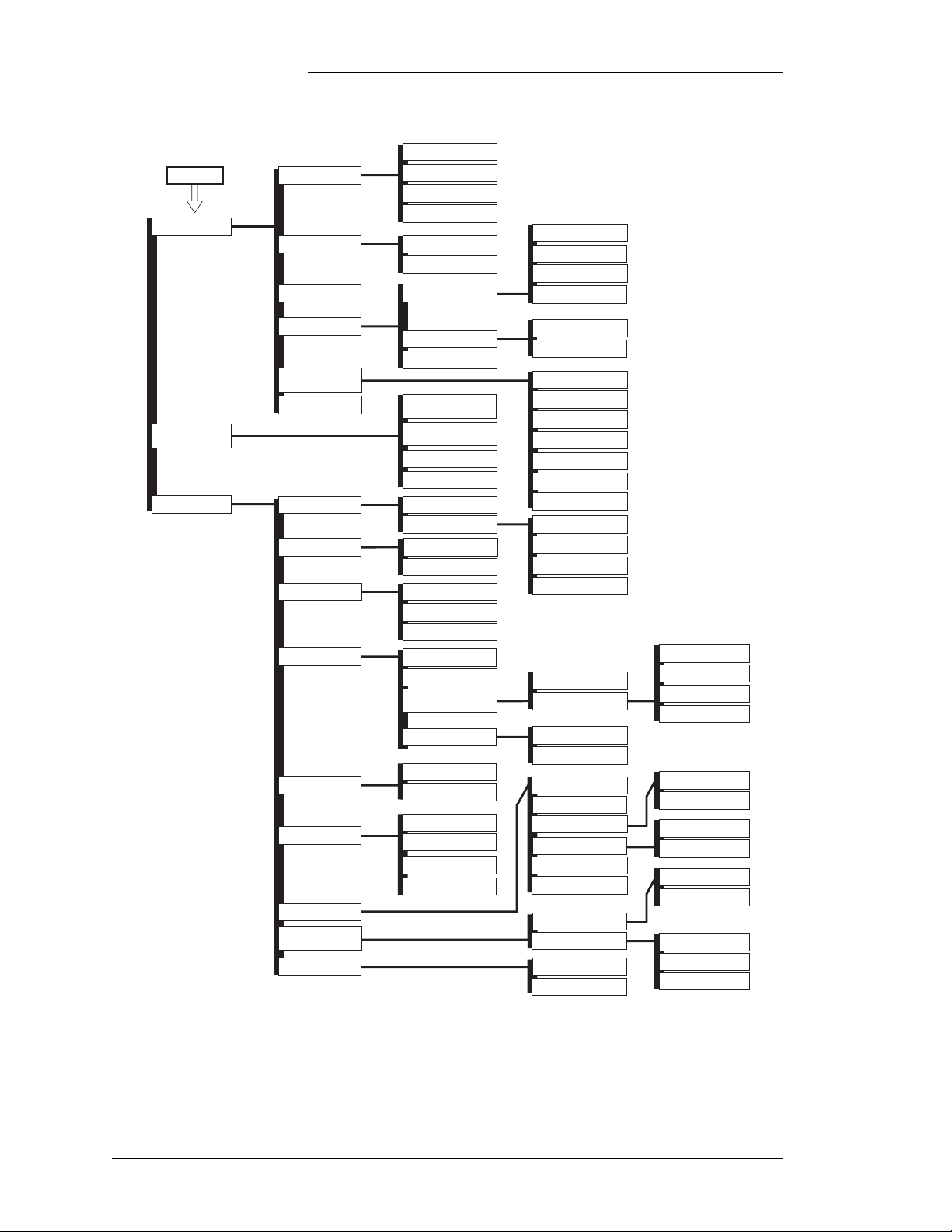

Figure 2-5: Galaxy Vector Controller Display Menu Flow

2 - 6 Product Description Issue 4 January 2008

Page 21

Galaxy Vector Controller GCM2, GCM3

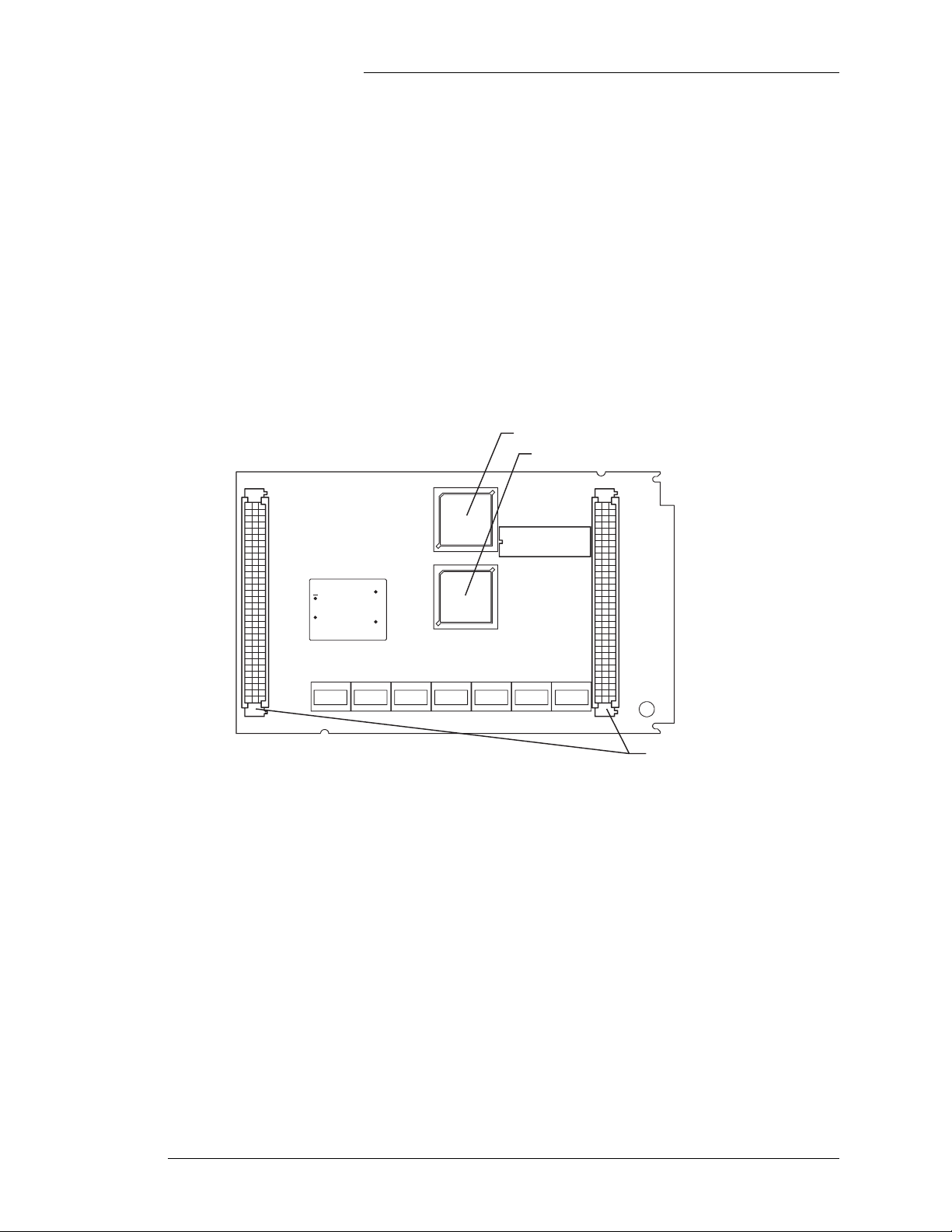

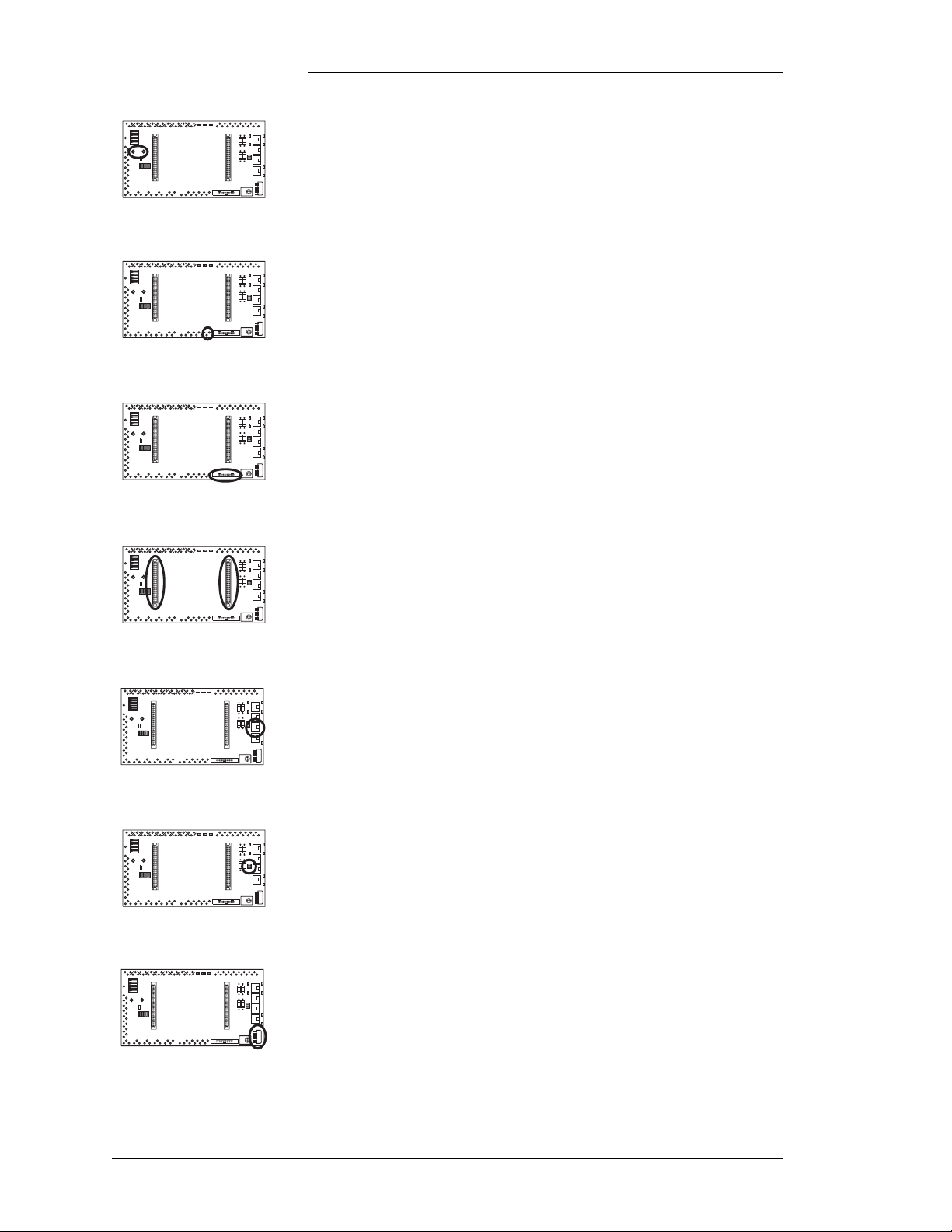

BLJ3 Terminal Connection Board

Fuses

Power In/Out

Shunts 1 and 2

Unused

Alarm Outputs

Thermal Inputs

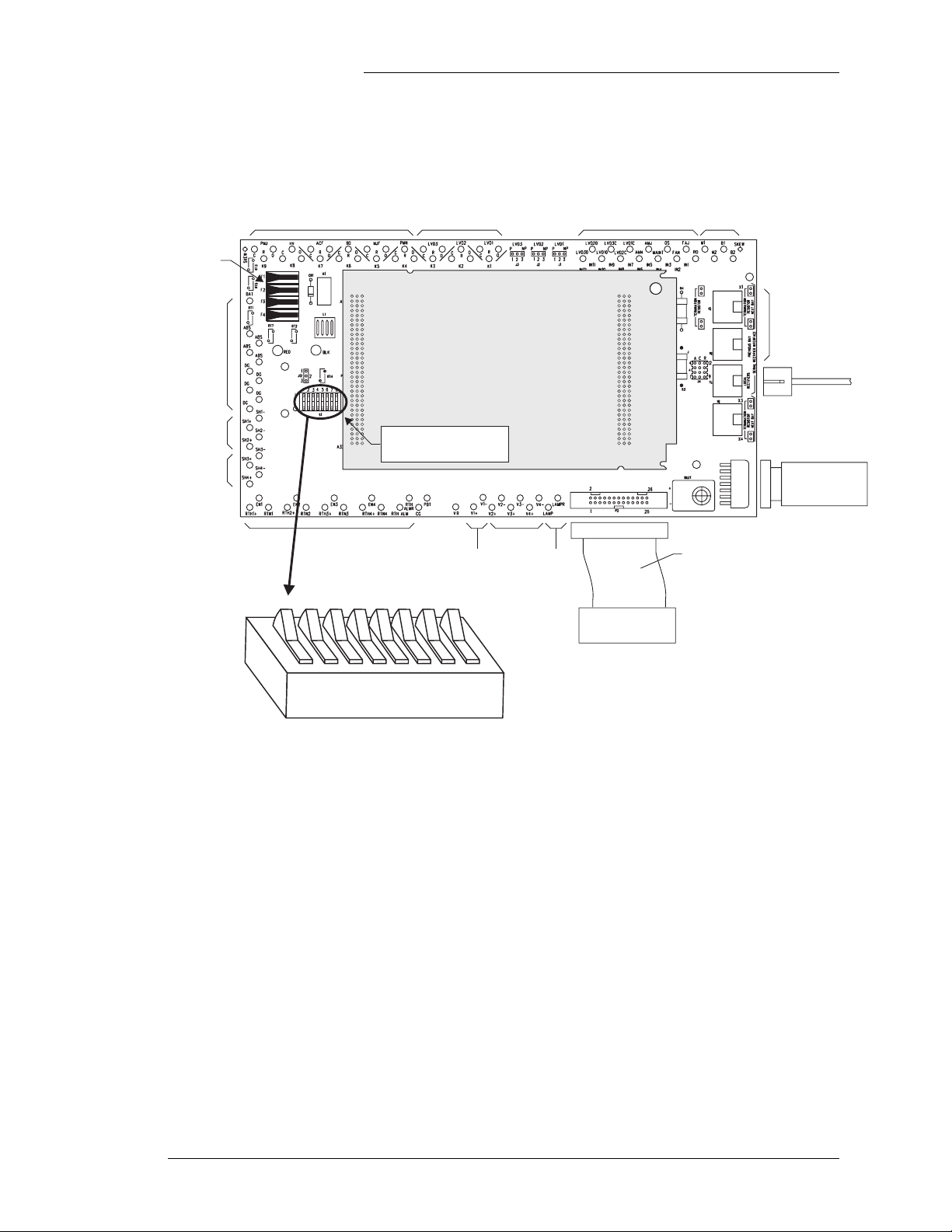

Figure 2-6 shows the BLJ3 Terminal Connection Board. Not all

BLJ3 terminals are used by the Vector Controller. The following

pages describe the required connections.

Contactors

Vector Controller

Vector Controller Board

Board Not Shown

(GCM2, GCM3)

System Configuration

DIP Switches

Plant Voltage

Regulation Input

Alarm Inputs

Unused

Bay

Alarm Out

Unused

Unused

To Rectifiers

Unused

To Modem/

Gateway/

Local Terminal

26 Conductor

Ribbon Cable

1

Front Panel

Control/Display

0

1S12345678

S1.1: Front Panel Configuration

- Enabled (shown)

0

- Disabled

1

S1.2: Software Mode

- Standard (shown)

0

- Flexent Default Configuration Parameters

1

1,2

S1.3: Option Card Availability

0

- Modem

1

- Galaxy Gateway Card (Internet)

1. Setting both SW1.2 and SW1.5 to "1" will result in activating the HV alarm cont act.

2. SW1.2 setting will only be read by the software when the GCM is powered up.

3. HV alarm contacts used for 2ACF alarm instead of HV alarm.

S1.4: Rectifier Class

01- Standard GPS Rectifiers

- NP Rectifiers

S1.5: Alarm Contact Select

0

- Standard HV, High Voltage

3

1

- VLV, Very Low Voltage

S1.6: - Set to 0

S1.7: Power Battery Test

- Disabled (shown)

0

- Active

1

S1.8: - Set to 0

1

Figure 2-6: Galaxy Vector Controller BLJ3 Terminal Connection Board

Issue 4 January 2008 Product Description 2 - 7

Page 22

Galaxy Vector Controller GCM2, GCM3

SH3+, SH3-, SH4+, SH4-, V2+, V2-, V3+, V3-, V4+, V4-, B1,

B2, M1, M2: These input terminals are not used by the Vector

controller.

Alarm input (IN1 - IN12): Basic office and contactor state

alarm inputs. Individual pin descriptions are shown in Table

2-D.

Table 2-D: BLJ3 Alarm Input Terminals

Terminal Name

IN1 FAJ Closure to Batt Fuse major alarm input

IN2 FAN Not used

IN3 OS Not used

IN4 MAINT Open to Batt Maintenance (open connector)

IN5 AMJ Closure to Batt Auxiliary major alarm input

IN6 AMN Not used

IN7 LVD1C Not used

IN8 LVD2C Not used

IN9 LVD3C Not used

IN10 LV D1 O Closure to Batt

IN11 LVD 2O Closure to Batt

IN12 LV D3 O Not used

Alarm

Asserted

Description

Low voltage disconnect contactor 1 open

status input

Low voltage disconnect contactor 2 open

status input

J1, J2, J3: LVD1, LVD2, and LVD3 contactor configuration

jumpers used to detect the presence of contactors. Table 2-E

shows configuration information.

Table 2-E: LVD Contactor Configuration Jumpers

Jumper Across Pins 1 and 2 Across Pins 2 and 3

J1 LVD1 present LVD1 not present

J2 LVD2 present LVD2 not present

J3

2 - 8 Product Description Issue 4 January 2008

LVD3 present

(not available)

LVD3 not present

(default for GCM)

Page 23

Galaxy Vector Controller GCM2, GCM3

LVD1, LVD2, LVD3: Form C relay contact outputs for LVD

contactor control. These terminals are connected to BJN

contactor drive boards. LVD1 and LVD2 contacts are rated for

2 amps. LVD3 is not available in GCM controller applications.

Table 2-F shows relay state information.

Table 2-F: LVD Drive Terminals

Terminal

Contactor Relay O C R

LV D1 K1

Normally open

contact

LV D3 K3

Normally closed

contact

Return (common)LV D2 K2

Office alarm relay outputs: All alarm output relays are isolated

Form C or transfer type contacts, consisting of normally open

(NO) and normally closed (NC) contacts, with a common return

(RTN) contact. The de-energized state of these relays is the

alarm state. An alarm condition results in a closure of the

normally closed contact to the return contact, and an open

between the normally open and return contacts. Individual relay

pin descriptions are shown in Table 2-G.

Table 2-G: BLJ3 Office Alarm Relay Output Terminals

Terminal

Alarm Relay Alarm Description C O R

PMN K4 Power Minor

MJF K5 Major Fuse

BD K6 Battery on Discharge

ACF K7 Single AC Fail

High Voltage /

HV/2ACF/VLV* K8

PMJ K9 Power Major

* Relay assignment is determined by the settings of S1.2 and S1.5:

HV alarm S1.2-0, S1.5=0

2ACF alarm S1.2=1, S1.5=0

VLV alarm S1.2=0, S1.5=1

Setting both switches to 1 results in activating HV. The S1.2 setting is only read during GCM power up.

Multiple AC Fail /

Very Low Voltage

Normally open

contacts.

Closed to R

when alarm

condition exists.

Normally

closed contacts.

Open to R when

alarm condition

exists.

Return

(common)

Issue 4 January 2008 Product Description 2 - 9

Page 24

Galaxy Vector Controller GCM2, GCM3

BAT: Connection to the battery discharge bus for controller

power, and fused through F2 (1 1/3A). It is +24V for the GCM2,

and -48V for the GCM3.

ABS: Auxiliary Battery Supply: connection to the battery

discharge bus for user application (four terminals available), and

fused through F1 (2A).

DG: Connection to battery return (discharge ground) bus. DG

(five terminals available) provides the return for BAT (controller

power), and ABS user applications if required.

Battery shunt inputs: The GCM recognizes two of the four

available shunt inputs on the BLJ board. Shunt inputs are 50mv

full scale. The BLJ3 requires 100K 1% resistors in series

with the shunt. See Table 2-H.

Table 2-H: Battery Shunt Inputs

Terminal Signal Name Description

SH1+ Shunt1+

SH1– Shunt1–

SH2+ Shunt2+

SH2– Shunt2–

Note: When no shunt is available to connect to Shunt 2 inputs, the Shunt 2

inputs must be jumpered together. When both shunts are used, they must

both be configured as “Load” or “Battery” shunts. They cannot be mixed.

The more positive lead of a battery shunt

during discharge

The more negative lead of a battery shunt

during discharge

The more positive lead of a battery shunt

during discharge (See note)

The more negative lead of a battery shunt

during discharge (See note)

2 - 10 Product Description Issue 4 January 2008

Page 25

Galaxy Vector Controller GCM2, GCM3

Voltage Sense Inputs: The GCM recognizes one of the four

voltage sense inputs on the BLJ board. Sense inputs are 50mv

full scale. Each of these leads should be fused at the source.

See Table 2-I.

Table 2-I: Plant Voltage Sense Inputs

Terminal Signal Name Description

V1+ Vsense+

V1- Vsense–

Positive remote voltage regulation

sense point for GCM.

Negative remote voltage regulation

sense point for GCM.

J12: This jumper is factory set, and determines the controller

ground (CG) reference. The controller ground reference is set

according to the location of the plant shunts being monitored. If

the shunts are located in the Battery side of the DC bus then J12

should be set to position 1-2. If the shunts are located in the

Discharge Ground (DG) side of the DC bus then J12 should be

set to position 2-3. For +24V and -48V GPS, J12 should be set

to position 1-2.

Table 2-J: J12 Jumper

Jumper +24V System -48V System

J12 Across pins 1 and 2

Thermal probe connections: Four thermistor or 210E module

inputs. Each thermistor is connected to the RTH#+ and RTN#,

where # = 1 through 4. A strap is required across RTH#+ and

EN#+ for each thermistor input used. The strap is not required

when using 210E modules. For the indoor system, the thermal

probe and cable are factory installed.

RTH ALM, RTH ALMR: Thermistor alarm input and return

from 210E module. See Section 4 for 210E module connections.

CG: Controller Ground is the GCM reference ground, and

should be connected to the bus on which shunt(s) are mounted.

This pin should be used to reference the 210E ground to the

Vector Controller ground.

Issue 4 January 2008 Product Description 2 - 11

Page 26

Galaxy Vector Controller GCM2, GCM3

TPT1, TPT2: Thermistor protected test points for access to

system voltage.

LAMP, LAMPR: The LAMP terminal is used to send battery

voltage to the bay lamp. LAMPR is the LAMP return, and is

connected to DG.

P2: 26 pin connector to the user interface control panel

(848597563).

P1, P3: Two 96 pin connectors on which the GCM board

mounts.

J7: A RJ45 connector for the serial rectifier interface.

J4: For the Vector Controller function, these jumpers must be

used to short each C and R pin on the J4 and J11.

P4: RS-232 serial communication port used with the optional

BSM3 modem board or the EBW1 Gateway board (see

Appendix A).

2 - 12 Product Description Issue 4 January 2008

Page 27

Control Signal Inputs

Galaxy Vector Controller GCM2, GCM3

Table 2-K: BLJ3 Control Signal Inputs

BLJ3 Power Connections

(+) PWR Controller BAT F2 Charge Bus (Rectifier bus)

(-) PWR Controller DG Discharge Return Bus

LVD power #1 See note 1 NA Charge Bus (Rectifier bus)

LVD power #2 See note 1 NA Battery Bus

Aux. Bat. Source

Note 1: LVD control power, from the power buses for the indoor system, is connected to the

BJNx LVD controller board

Note 2: BLJ3 user available fused (F1) power terminations are labeled ABS. DG terminations are

also provided for user termination on the BLJ3. These terminations are labeled DG.

Description

Control Signal

Name

RO Reserve Operation closure to BAT

PBT Power Battery Test closure to BAT

Description Indoor Input Connection

Power connections from the system to the BLJ3 (factory wired).

Table 2-L: Power Connections BLJ3

Input

Termination

ABS

See note 2

Associated

Fuse

F1 NA

Plant Termination

Issue 4 January 2008 Product Description 2 - 13

Page 28

Galaxy Vector Controller GCM2, GCM3

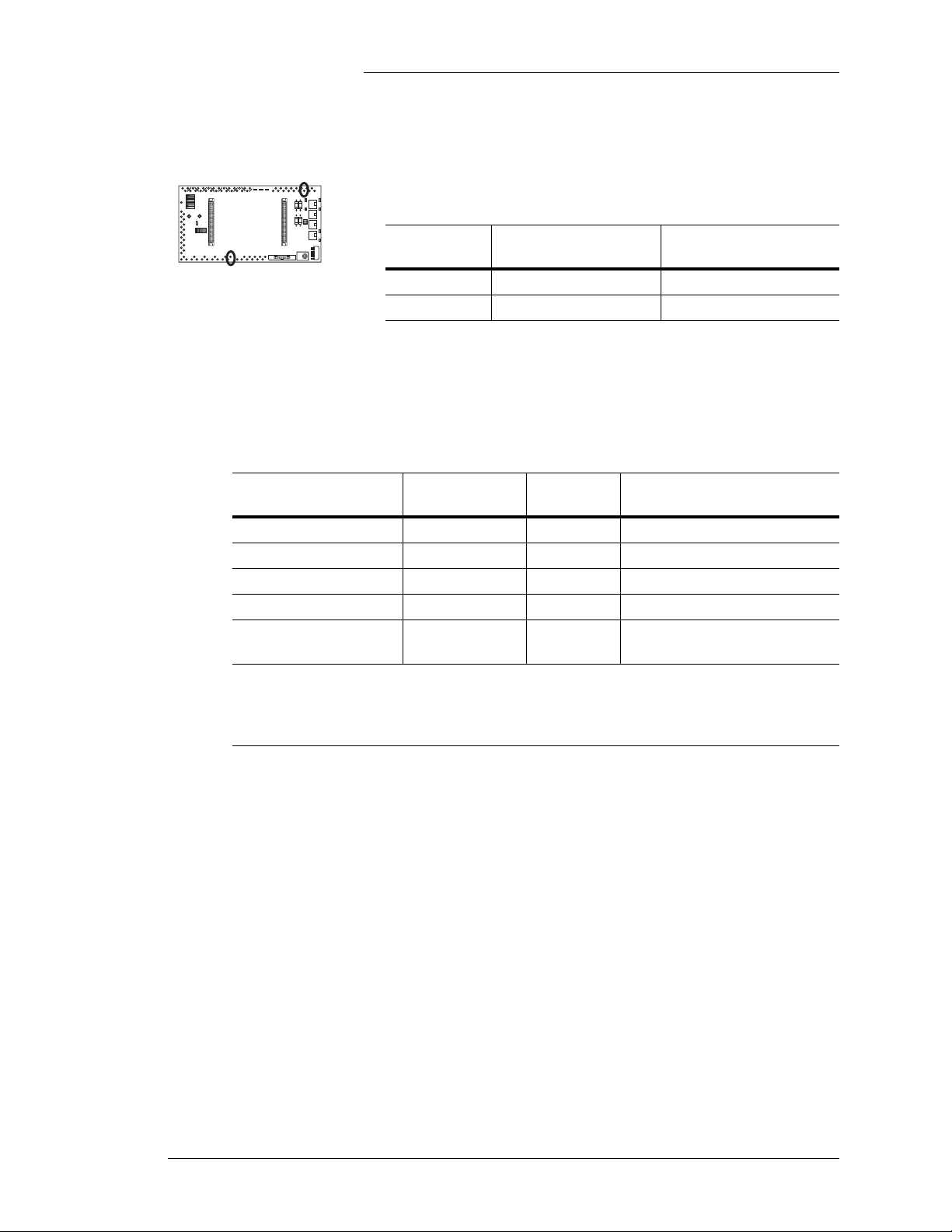

BTJ2/BTJ3 Termination Board

LVD 1

J23

ALARM

OUT

Fuses

F1

F2

F3

F4

F5

J21

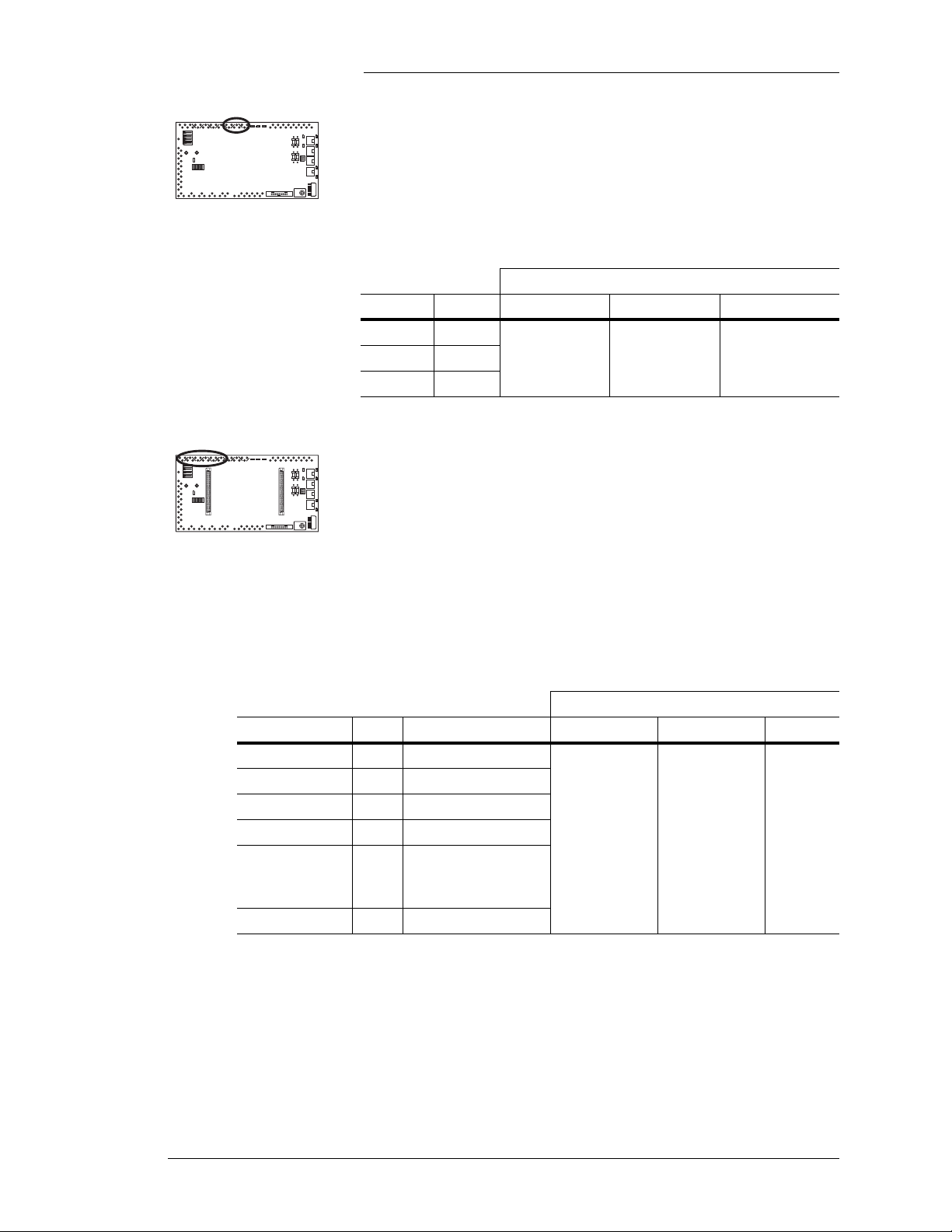

Figure 2-7 shows the BTJ2 (+24V) or BTJ3 (-48V) termination

board used as the terminal and controller interface for Vector

outdoor power systems. S1 is the system configuration DIP

switch.

J5

J6

J7

J2 J27

AMJ (BATT FUSE)

J6

P1

LVD 2

Vector Controller Board

(GCM2, GCM3)

LVD Forced Closed LED

FAJ

(DIST)

TEMPERATURE PROBES

#1

#2 #3 #4

RS232

CONNECTION

J13

DISPLAY J14

P3

PWR

S1.1: Front Panel Configuration

0

- Enabled (shown)

1

- Disabled

S1.2: Software Mode

- Standard (shown)

0

- Flexent Default Configuration Parameters

1

S1.3: Option Card Availability

- Modem

0

- Galaxy Gateway Card (Internet)

1

S1.4: Rectifier Class

01- Standard GPS Rectifiers

- NP Rectifiers

1. Setting both SW1.2 and SW1.5 to "1" will result in activating the HV alarm cont act.

2. SW1.2 setting will only be read by the software when the GCM is powered up.

3. HV alarm contacts used for 2ACF alarm instead of HV alarm.

J4 J28 J9 J10 J11 J12

1

0

1S12345678

1,2

3

S1

1

0

S1.5: Alarm Contact Select

- Standard HV, High Voltage

0

- VLV, Very Low Voltage

1

8

1

1

S1.6: - Set to 0

S1.7: - Set to 0

S1.8: Low Voltage Disconnect

- Controller Controlled (shown)

0

- Manual Force Closed

1

Figure 2-7: Vector Controller BTJ2/BTJ3 Terminal Connection Board

(Used in Outdoor Systems)

2 - 14 Product Description Issue 4 January 2008

Page 29

Galaxy Vector Controller GCM2, GCM3

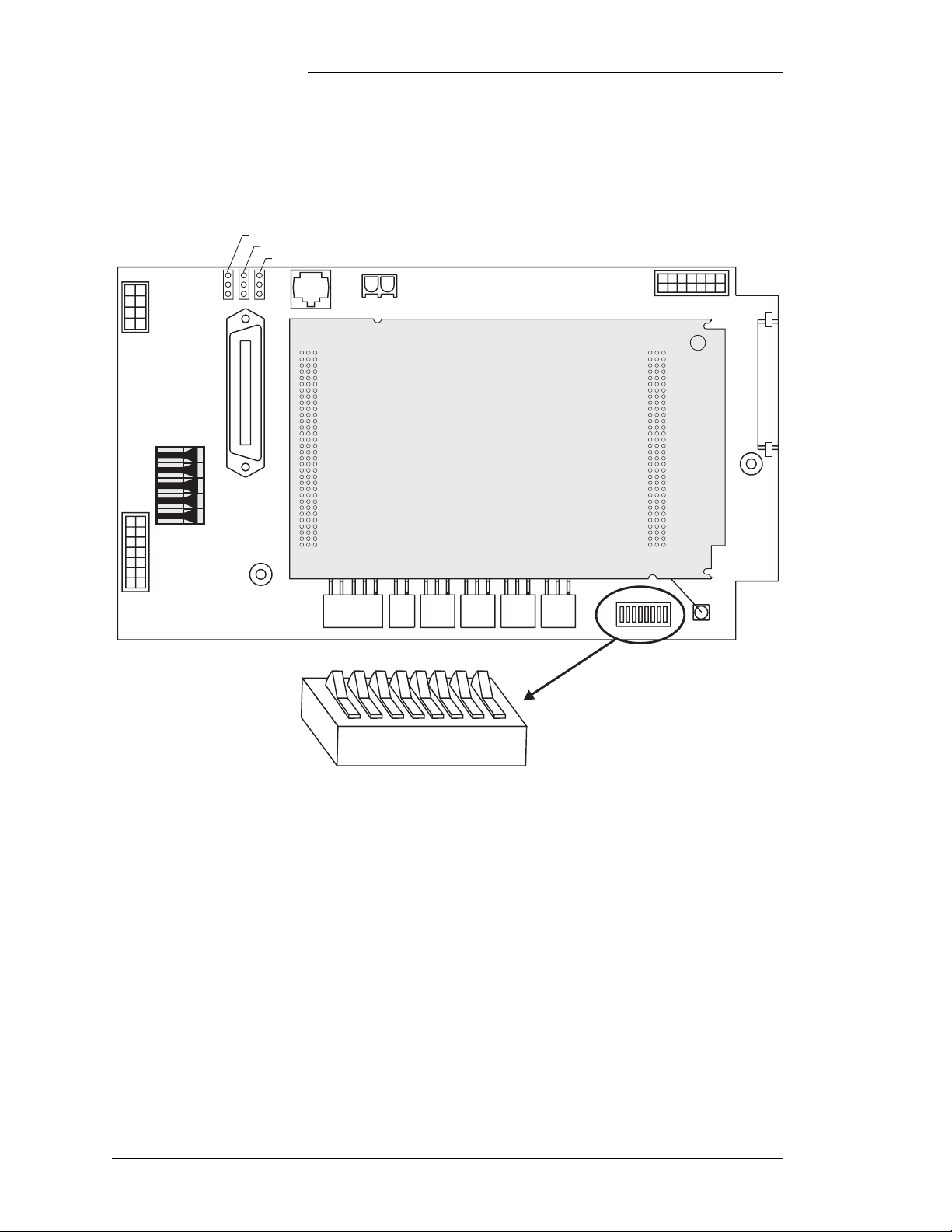

BTJ2/BTJ3 Fuses and Connectors

All fuses are 5A.

• F1 – GCM Controller power

• F2 – Regulation battery fuse (Vsense)

• F3 – LVD power from Charge Bus (Rectifier)

• F4 – LVD power from Battery Bus

• F5 – Spare

Power connections: Power and sense connections from the

system to the BTJ2/BTJ3 are shown in Table 2-M.

Table 2-M: BTJ2/BTJ3 Power Connections (J21)

Pin

Number

1 Shunt 1 (Chg)

2 NC

3 NC

4 Shunt 2 (Chg) Reserved for future use

5 NC

6 NC

7

8 Shunt 1 (Disch)

9 DG Controller power input ground

10 Vsense (Grd) Connection to DG bus, remote sense

11 Shunt 2 (Disch) Reserved for future use

12

13

14 Vsense (Chg) Connection to the charge bus, remote voltage sense

Signal Name Description

Connection to battery shunt terminal nearest charge

bus (rectifier bus)

Controller

Power

LVD Battery

Bus

LVD Charge

Bus

Controller power input connection to the charge bus

(rectifier bus)

Connection to the battery shunt terminal nearest the

batteries

Battery bus power for LVD circuitry on the BTJ2/

BTJ3

Charge bus power for LVD circuitry on the BTJ2/

BTJ3

J2: RJ45 connector for rectifier communication. Pins 1 and 2 are

the communication pair. Pin 3 is isolated ground. Pin 4 is chassis

ground. All rectifiers are connected to this connector in a daisy

chain fashion.

Issue 4 January 2008 Product Description 2 - 15

Page 30

Galaxy Vector Controller GCM2, GCM3

J23: LVD1 control.

Table 2-N: BTJ2/BTJ3 LVD1 Control Connections (J23)

Pin

Number

1 LV D _N O Form-C output (see Note)

2 LVD_C Form-C output (see Note)

3 LVD_NC Form-C output (see Note)

4 Coil Controlled bus voltage to contactor coil

5 Maint RTN Current limited bus voltage for Maint alarm

6 Maint IN Maintenance alarm input

7 LVD1 RTN

8 LVD 1 S t ate Low voltage disconnect signal

Note: These outputs can be used to drive an external contactor board if

Signal Name Description

Current limited bus voltage for LVD1 state

(LVD open alarm)

J15-17 are jumpered in the 2-3 position.

J4: LVD2 control.

Table 2-O: BTJ2/BTJ3 LVD2 Control Connections (J4)

Pin Number Signal Name

1 LVD2_NC

2 LVD2_C

3 LVD2_NO

4 NC

5 LV D2 _S TATE

6 NC

7 NC

8 NC

9 NC

10 NC

J5: Not used.

2 - 16 Product Description Issue 4 January 2008

Page 31

Galaxy Vector Controller GCM2, GCM3

J6: Office alarm outputs.

Table 2-P: BTJ2/BTJ3 Office Alarm Relay Output Connections

(J6)

Alarm

PMJ

PMN

BD

MJF

HV/2ACF/VLV

ACF

R O/S IN Rectifier On Standby Signal J6-28

PBT IN Plant Battery Test Signal J6-29

PBT/OS RT N Plant Battery Test / Rect On Standby Rtn J6-30

Note 1: NO (normally open) contacts are open when an alarm state exists.

NC (normally closed) contacts are open when an alarm state exists.

Note 2: Relay assignment is determined by the setting of S1.2 and S1.5:

HV alarm S1.2-0, S1.5=0

2ACF alarm S1.2=1, S1.5=0

VLV alarm S1.2=0, S1.5=1

Setting both switches to 1 results in activating HV. The S1.2 setting is only read

during GCM power up.

Signal

(Note 1)

NO Power Major Normally open J6-1

RTN Power Major Return J6-2

NC Power Major Normally closed J6-3

NO Power Minor Normally open J6-4

RTN Power Minor Return J6-5

NC Power Minor Normally closed J6-6

NO Battery on Discharge Normally open J6-7

RTN Battery on Discharge Return J6-8

NC Battery on Discharge Normally closed J6-9

NO Major Fuse Normally open J6-10

RTN Major Fuse Return J6-11

NC Major Fuse Normally closed J6-12

NO Multiple AC Fail Normally open J6-14

RTN Multiple AC Fail Return J6-15

NC Multiple AC Fail Normally closed J6-16

NO Single AC Fail Normally open J6-22

RTN Single AC Fail Return J6-23

NC Single AC Fail Normally closed J6-24

Description

Number

Pin

J27: AMJ (Auxiliary major battery fuse) requires a closure

between pins 1 and 2 to activate alarm.

J28: FAJ (Distribution fuse alarm major) requires bus voltage at

pin 1 to activate alarm. Pin 1 connects to J2 pin 1 of the alarm

board, which provides this alarm signal. The input to the alarm

Issue 4 January 2008 Product Description 2 - 17

Page 32

Galaxy Vector Controller GCM2, GCM3

board is from the load circuit breakers. Pin 3 provides DG

connection to the alarm board. This DG connection provides DG

for alarm board LED operation. Pin 2 is a current limited

(50-ma) battery bus supply for possible future use.

J9-J12: Thermal inputs.

Table 2-Q: BTJ2/BTJ3 Thermal Input Connections

(J9-J12)

Pin

Number

1 RTH ALM

2 NC

3 NC

4 RTH +

5 RTH RTN

6 RTH EN

Description

J13: RS-232 connection.

Table 2-R: BTJ2/BTJ3 RS-232 Connections (J13)

Pin

Number

1 TXD

2 RTS

3 DTR

4 RXD

5 CTS

6 DSR

7 DCD

8 NC

9 MODEM GRN

10 MODEM YEL

11 DGND 100 ohm terminated

12 MODEM PRESENT

13 +5 Volts

14 DGND

Description

2 - 18 Product Description Issue 4 January 2008

Page 33

Galaxy Vector Controller GCM2, GCM3

J14: Local user interface and display connector.

Table 2-S: BTJ2/BTJ3 Display Connections (J14)

Pin

Number

1 +5 Volts

2 Display connected

3 DGND

4 Key Mon AE

5 Key Mon BE

6 Key Mon CE

7 Key Mon DE

8 Key Mon EE

9 KEYPRESS

10 DGND

11 NC

12 NC

13 MOSI

14 SCLK

15 DGND

16 LED SELECT

17 OUT ENABLE

18 DGND

19 PMJ LED

20 DGND

21 CNRL LED

22 DGND

23 NC

24 NC

25 Plant Voltage +

26 Plant Voltage -

Description

Issue 4 January 2008 Product Description 2 - 19

Page 34

Page 35

Galaxy Vector Controller GCM2, GCM3

3 Operation

Office Alarm Contacts

Alarm Descriptions

The basic Galaxy VC issues PMJ, PMN, MJF, BD, ACF and

HV/2ACF/VLV office alarms off the BLJ3 and BTJ2/BTJ3

boards. Refer to Table 2-G and 2-N, respectively, for a

description of their output terminals. Refer to Table 3-A for a

listing of the various available alarms. Refer to Table 3-B for a

listing of alarm relays and their associated front panel LEDs.

To see active alarms, press the Active Alarm softkey, then use

the ∧ or ∨ keys to page through alarms. See Tables 3-A and 3-B.

The alarms are listed in order of severity. Some abbreviations are

required to fit the LCD screen.

Very Low Voltage Alarms and Battery on Discharge

When rectifier output is insufficient to maintain the load current

at the set voltage (typically because of an ac power failure), the

plant bus voltage drops. When this voltage drops below the

battery voltage, the batteries start providing current to the load.

Any time that the plant voltage is below the threshold selected

for BD, the Battery on Discharge alarm activates. If the plant

voltage continues to drop, a second, lower threshold can be

reached, activating a Very Low Voltage alarm. Default values

for these thresholds are set at the factory. These thresholds can

be changed by the operator in the configuration menu as

described in the Installation and Configuration section of this

manual (Section 4). S1.5 set to “1” will allow the relay dedicated

for HV/ACF/VLV, K8, to be asserted for the VLV condition.

Note that a BD alarm does not necessarily mean that the batteries

are discharging, only that the present voltage is lower than the

set point for this alarm. This alarm may be activated by an

incorrectly set BD threshold or plant voltage set point.

Issue 4 January 2008 Operation 3 - 1

Page 36

Galaxy Vector Controller GCM2, GCM3

Following the restoration of ac power after a battery discharge of

significant depth, this alarm remains active for some time during

the recharge period, until the batteries have recharged to a level

which allows the plant voltage to rise above the BD threshold.

BD threshold default is set at 25.54V standard (Flexent 25.0V)

in 24V systems and 51.1V in 48V systems with slope thermal

compensation disabled. In systems with slope thermal

compensation, the BD threshold should be 0.5V below the slope

upper temperature voltage for 24V systems, and 1.0V below the

slope upper temperature voltage for 48V systems. The slope

upper temperature equals:

Float Set Point - (number of cells) · E · (F-D)

See Figure 3-1 for system settings E, F, and D

These levels generally avoid nuisance alarms from transient

conditions yet provide alarm indications early in a true BD

event, so that sufficient time is provided for maintenance

personnel to respond before battery reserve is exhausted. VLV

should be activated towards the end of the battery reserve

voltage to indicate a critical service condition.

3 - 2 Operation Issue 4 January 2008

Page 37

Galaxy Vector Controller GCM2, GCM3

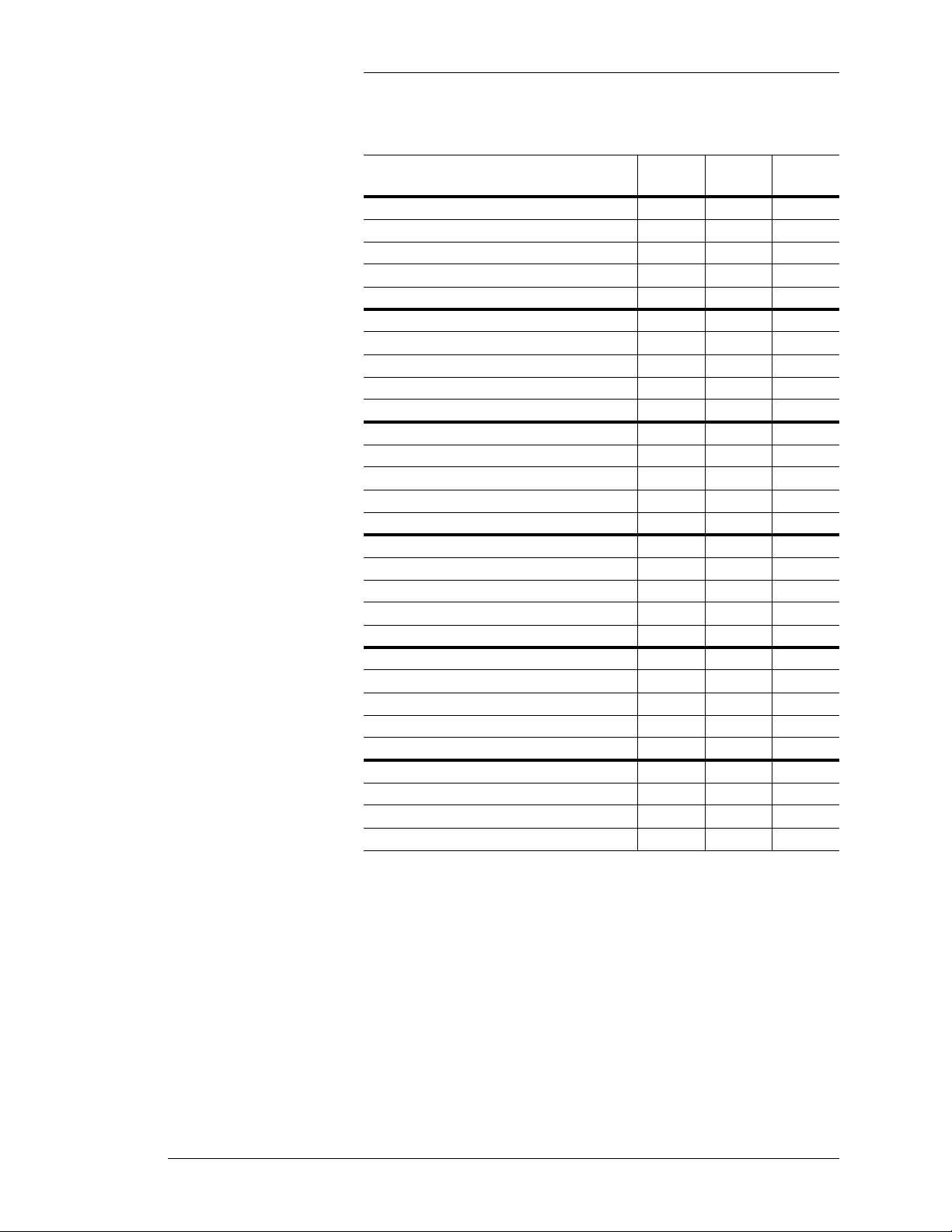

Table 3-A: Alarm Identification Standard Assignments

Description

No active alarms present Norm Green None

Very low voltage Major Red None

Battery on discharge Major Red BD

High float voltage Minor Yellow None

Very high voltage Major Red HV

Voltage sense fuse alarm Major Red None

AC fail Minor Yellow ACF

Multiple AC fail Major Red ACF

Rectifier fail Minor Yellow None

Multiple rectifier fail Major Red None

Rectifier ID conflict Major Red None

Rectifier manual off alarm Minor Yellow None

Rectifier AC phase alarm Minor Yellow None

Converter fail Minor Yellow None

Multiple converter fail Major Red None

Converter ID conflict Minor Yellow None

Converter distribution alarm Major Red MJF

Converter fan fail minor Minor Yellow None

Converter fan fail major Major Red None

Fuse alarm major Major Red MJF

Auxiliary input major Major Red None

Load Share imbalance Minor Yellow None

Contactor 1 open Major Red None

Contactor 1 failed Major Red None

Contactor 2 open Major Red None

Contactor 2 failed Major Red None

High battery temperature Major Red None

Temperature probe failure Minor Yellow None

Maintenance open alarm Major Red None

Alarm

Status

BMW

LED

GVM

Relay

Issue 4 January 2008 Operation 3 - 3

Page 38

Galaxy Vector Controller GCM2, GCM3

Table 3-B: Office Alarm Relay and Front Panel LED Standard Assignments

Asserted Condition Alarm Relays Front Panel LEDs

Very high voltage [HV] PMJE, (HV or none) MAJ (red)

High float voltage [HFV] PMNE MIN (yellow)

Battery on discharge [BD] PMJE, BD MAJ (red)

Very low voltage [VLV] PMJE, (VLV or none) MAJ (red)

Single ac fail [ACF] PMNE, ACF MIN (yellow)

Multiple ac fail [MACF] PMJE, (2ACF or none) MAJ (red)

Single rectifier fail [RFA] PMNE MIN (yellow)

Multiple rectifier fail [MRFA] PMJE MAJ (red)

Single converter fail [CFA] PMNE MIN (yellow)

Multiple converter fail [MCFA] PMJE MAJ (red)

Major fuse (Controller, FAJ input) [MJF] PMJE, MJF MAJ (red)

Low voltage battery disconnect [LVBD] PMJE MAJ (red)

Low voltage load disconnect [LVLD] PMJE MAJ (red)

LVD1 fail [LVDA] PMJE MAJ (red)

LVD2 fail [LVDA] PMJE MAJ (red)

Controller fail [CTLR] PMJE MAJ (red)

Slope thermal compensation active LCD

Defective battery temperature probe [TPA] PMNE MIN (yellow)

Voltage sense fuse alarm PMJE MAJ (red)

Rectifier manual off alarm PMNE MIN (yellow)

Rectifier phase alarm PMNE MIN (yellow)

Rectifier half power alarm PMNE MIN (yellow)

Auxiliary major alarm PMJE MAJ (red)

Battery thermal alarm PMJE MAJ (red)

Controller unpowered

Connector open PMJE, PMNE MAJ (red)

Alarm cut off LCD

Display volts LCD

Display amps LCD

PMJE, PMNE, MJF, BD,

ACF, HV

High Float Voltage Minor Alarm and Very High Voltage

Major Alarm and Shutdown

Because of the importance of protecting the batteries and load

from overvoltage conditions, three high voltage thresholds are

provided. Two are controlled by the Vector and one backup

threshold is hard-wired internally in Lineage Power rectifiers.

3 - 4 Operation Issue 4 January 2008

Page 39

Galaxy Vector Controller GCM2, GCM3

The two lowest thresholds are preset at the factory but can be

adjusted through the Vector control panel or remotely. The third

threshold (ISHVSD) is generated by the controller by adding

1.50V to the very high voltage threshold. This value is then

transmitted to the rectifier and stored. Each rectifier compares its

own output voltage to this threshold value and initiates internal

shutdown if the value is exceeded. “Very High Voltage” and

“High Float Voltage” are set in the Vector in the Configuration

mode. See Section 4, Installation, Configuration and Operation.

The Vector is equipped to detect a high voltage condition on the

system bus. Such a high voltage condition may typically be

caused by lightning-induced transients on the commercial ac or

a rectifier failure may cause an individual rectifier to go high. To

prevent a high voltage condition from damaging the connected

load, the Vector also sends a signal for the rectifiers to shut down

if the plant voltage goes above a second threshold.

When the system voltage increases above the threshold for

“High Float Voltage,” it issues the High Float Voltage minor

alarm. If the voltage continues to rise and reaches the threshold

for “Very High Voltage,” that alarm is issued as a major alarm

and a shutdown signal is issued simultaneously to the plant

rectifiers. Any rectifier which is producing at least 10% of its

rated capacity and is 10% over the average of all rectifier outputs

in the plant, responds to this shutdown signal by shutting down

with a RFA or ALM condition active and reports back to the

Vector. A restart attempt initiated by the controller occurs 4

seconds after the controller receives the RFA signal from the

rectifier. The rectifier then attempts to restart three times. During

the restart sequence, the rectifier, recognizing that its output

current exceeds the average rectifier current, shuts down and

tries again up to three times.

For plants with the battery thermal lower temperature

compensation disabled, the High Float Voltage threshold is

usually set approximately 0.75V above float for a 48V plant and

0.5V above float for a 24V plant. High Voltage shutdown

threshold is then usually set approximately 2.5V above float for

a 48V plant and 1.0V above float for a 24V plant. In plants with

battery thermal lower temperature compensation enabled, the

High Float Voltage threshold is usually set approximately 0.8V

above the maximum voltage due to low temperature in a 48V

plant and 0.5V in a 24V plant.

Issue 4 January 2008 Operation 3 - 5

Page 40

Galaxy Vector Controller GCM2, GCM3

Very High Voltage shutdown is usually 0.5V above the High

Float Voltage threshold for 48V plants and 0.25V above the

High Float Voltage threshold in 24V plants. Like the BD and

VLV thresholds, these are set in the Galaxy VC in the

configuration mode as described in the Installation,

Configuration and Operation section of this manual (Section 4).

S1.2 set to “0” will assign the HV/2ACF/VLV alarm contact to

the standard default of HV for the Very High Voltage shutdown

condition.

Voltage Sense Fuse Alarms

A lack of voltage on the Vsense +/- pair to the Vector Controller

as a result of a broken connection or a blown fuse while the

Vector is still powered results in a Voltage Sense Fuse alarm. A

voltage of 16.xx volts is displayed.

Sanity Fail in the Vector microprocessor or loss of power to the

Vector result in operation of the PMJ alarm. This PMJ defaults

to the alarm state if the controller is removed from the BLJ3.

AC Fail and Multiple AC Fail Alarms

If the proper ac input voltage is not available to any system

rectifier which is connected to the serial rectifier bus, an AC Fail

alarm (ACF) activates as a PMN. More than one ACF results in

a Multiple AC Fail alarm, changing this alarm status to a PMJ.

Note: S1.2 set to “1” will allow the HV/2ACF/VLV alarm

contact to be assigned to the Multiple AC Fail condition.

However, this will also cause the Flexent default configuration

values to be used any time the GCM is rebooted at power up.

Rectifier Failure and Multiple Rectifier Failure Alarms

Various rectifier failure modes cause a rectifier failure signal to

be issued to the controller, such as high voltage, temperature

over threshold, fan failure, and rectifier circuit breaker/fuse

open. Additionally, when rectifiers are removed or fail to

communicate with the Vector, a RFA alarm is generated. This

RFA alarm is cleared by updating the serial line in the

Operations and Control menu (see Configuration, Section

4).The RFA signal results in a RFA and Power Minor alarm

being issued by the Vector. More than one RFA at any time

results in a Multiple Rectifier Failure alarm and Power Major.

The Vector does not attempt restarts for RFAs caused by TA

(Thermal Alarm), CB/fuse trip, or Fan Failure.

3 - 6 Operation Issue 4 January 2008

Page 41

Galaxy Vector Controller GCM2, GCM3

Rectifier ID Conflict Alarm

This alarm occurs when rectifier ID numbers are duplicated or

are zero. Refer to the rectifier manuals for setting and viewing

the rectifier ID numbers.

Rectifier Manual Off Alarm

Whenever the rectifier is manually turned to standby, this alarm

occurs. A switch on the front panel for each rectifier allows the

user to manually turn the rectifier on or standby. When the

switch is in standby position, the alarm is active.

Rectifier Phase Alarm

This alarm is for multiphase rectifier. When AC is lost in one or

more phase but not all phases, this alarm occurs.

Converter Failure and Multiple Converter Failure Alarm

Converter failure alarms are generated for various reasons.

These include failure in the converter, the converter is removed,

the converter interface board is removed, or communication is

lost with the converter interface board. The removed CFA is

cleared by updating the serial line in the Operations and Control

menu (see Configuration, Section 4).

Converter ID Alarm

This alarm occurs when converter ID numbers are other than 1

through 8, or are duplicated. Refer to the converter section of the

plant manual for setting and viewing ID numbers.

Converter Distribution Alarm

Any fuse or breaker open at the converter output side (-48v

distribution) causes this alarm.

Converter Fan Fail Minor and Converter Fan Fail Major

The converter carrier 597B has two fans. If one fan in a carrier

fails, the controller reports a Converter Fan Minor alarm. If both

fans fail, the controller reports a Converter Fan Major alarm.

Major and Minor Fuse and Auxiliary Alarms

To create these alarms, the respective alarm inputs must be

connected to Bat or battery voltage or, in the case of J27 on the

BTJ2/BTJ3 board, a connection between two terminals must be

made. This battery voltage typically has a series 1K ohm resistor

between Bat and the alarm input.

Issue 4 January 2008 Operation 3 - 7

Page 42

Galaxy Vector Controller GCM2, GCM3

The operation of an output distribution fuse or circuit breaker

places battery voltage onto the FAJ input of the BLJ3 or

BTJ2/BTJ3 board, activating the Major Fuse alarm.

Auxiliary Major on the BLJ3 board can be user-assigned for any

supplemental alarm monitoring for which a battery voltage

signal (through 1K ohms) can be obtained, which is asserted by

a signal to the AMJ terminal on the BLJ3 board. Auxiliary Major

on the BTJ2/BTJ3 board is usually reserved for an open battery

fuse alarm or for a major alarm generated by the environmental

controller for the cabinet, and is generated by a closure between

the two pins of J27 of the BTJ2/BTJ3.

Auxiliary Minor is only available on the BLJ3 board and can be

user-assigned for any supplemental alarm monitoring for which

a battery voltage signal (through 1K ohms) can be obtained,

which is asserted by a signal to the AMN terminal on the BLJ3

board.

Load Share Imbalance Alarm

This alarm is generated when the current share function is

enabled and the rectifiers do not share the current equally or

within the current share boundaries. The controller monitors the

current (I

) delivered by each of the rectifiers and determines

rect

the total current delivered by the plant as the sum of all rectifier

currents. The average rectifier current (I

) is calculated by

avg

dividing the total current by the number of active rectifiers in the

plant. If, for any rectifier, actual rectifier current I

from the average rectifier current I

by 10A or more for 5

avg

is different

rect

minutes, then the controller issues a Rectifier Current Imbalance

Alarm. This alarm retires when the difference between the I

and I

drops below 10A.

avg

rect

Contactor 1 Open, Contactor 2 Open, Contactor 1 Failure,

Contactor 2 Failure Alarm

A Contactor Open alarm is reported whenever the Vector senses

that a contactor is open. This alarm is processed as a PMJ.

A Contactor Fail alarm is reported whenever the Vector senses

that a contactor that should be open or closed is in the opposite

state (closed or open). This alarm is also processed as a PMJ.

High Battery Temperature Alarms

3 - 8 Operation Issue 4 January 2008

Page 43

Galaxy Vector Controller GCM2, GCM3

Temperature Probe Failure

See Figure 3-1. The Vector reports a High Battery Temperature

Alarm when the temperature rises above the configured set

point. See Section 4, “Installation, Configuration and

Operation,” for information on battery thermal compensation

settings. It reports a Thermal Probe Alarm when thermal

compensation is enabled and a temperature probe is

disconnected or returns a grossly inaccurate reading to the

Thermal Compensation circuit.

Open Maintenance Alarm

Input Number 4 (MAINT) of the BLJ3 terminal connection

board should be connected to battery voltage during normal

operating conditions. This connection may be looped through

one or more circuit packs so that if the connection path is

interrupted, the Open Maintenance Alarm is activated.

System Features

Load and Battery Contactor Features and Alarms

The Vector has two distinct circuits for controlling the state of

external Load and Battery Disconnect Contactors. Terminals

LVD1 and LVD2 on the BLJ3 board, or J23 and J4 on the

BTJ2/BTJ3 board provide the interface from the controller to

separate contactor driver circuits which must be furnished as

part of the plant circuitry.

Each contactor can be configured as none, load, or battery.

When configured as a battery contactor:

• The contactor is open when the plant voltage is less than the

respective low voltage battery disconnect threshold.

• The contactor is closed when the plant voltage is greater

than the respective low voltage battery reconnect threshold.

At power up, the contactor is closed and there is an 18

second delay before the controller determines the correct

state of the contactor.

When configured as a load contactor:

• The contactor is open when the plant voltage is less than the

respective low voltage load disconnect threshold.

• The contactor is closed when the plant voltage is greater

than the respective low voltage load reconnect threshold.

Issue 4 January 2008 Operation 3 - 9

Page 44

Galaxy Vector Controller GCM2, GCM3

Additionally, there must be no active ac failure and rectifier

phase alarms, since the load would immediately disconnect

after reconnecting. At power up, there is an 18-second delay

before the load is reconnected to allow the rectifiers to walk

in.

Refer to the Alarm Descriptions section for alarms associated

with these two contactors (Contactor Open and Contactor Fail).

Refer to the associated plant documentation for information on

connecting these Load and Battery Disconnect driver circuits to

the BLJ3 terminal connection board or the BTJ2/BTJ3

connection board.

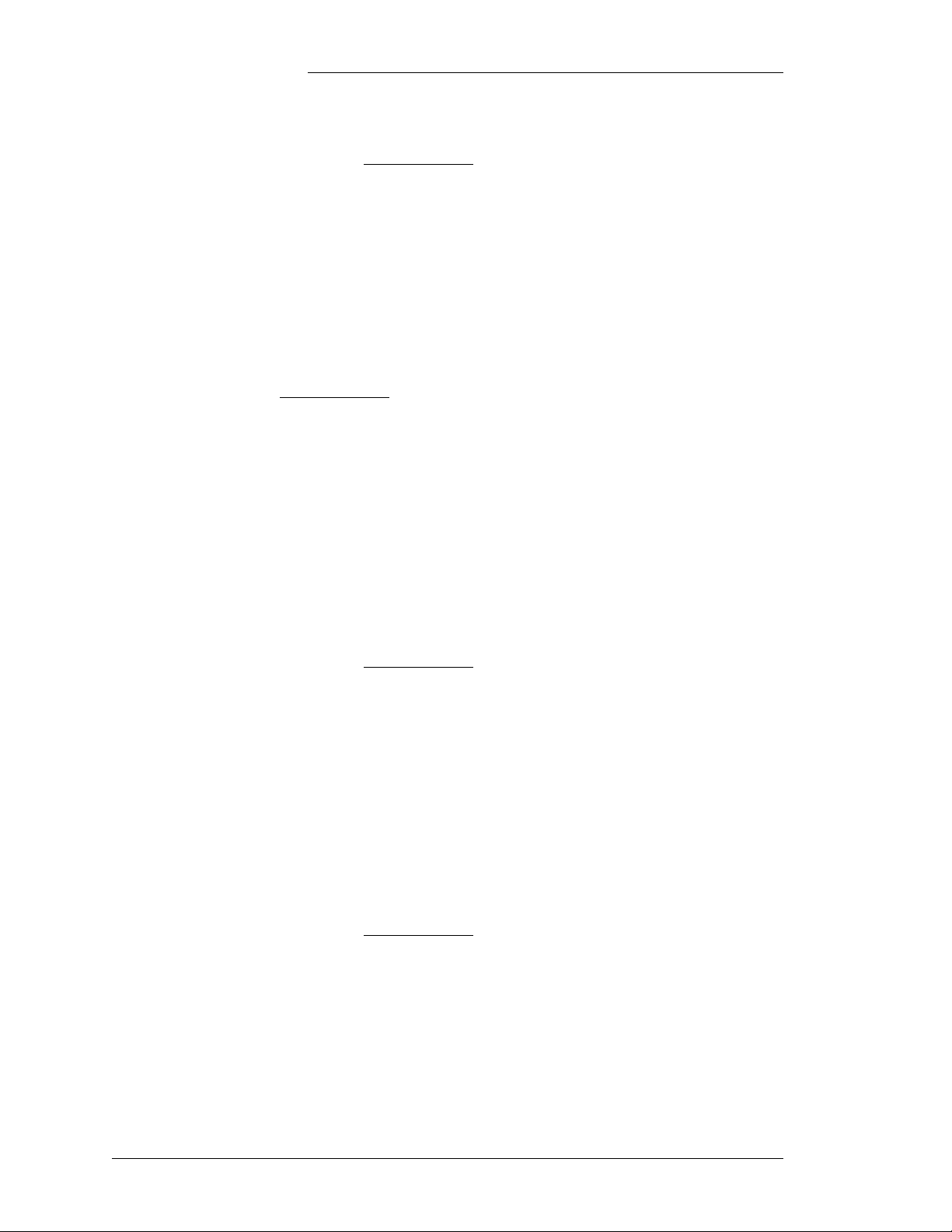

Thermal Compensation Features and Alarms

The Vector has a flexible Thermal Compensation feature which

provides voltage compensation from that level established by the

Plant Float Set-Point (FSP), dependent on the highest

temperature monitored by thermistors located at the plant

batteries. Thermal Compensation should only be enabled when

the controller is used in a plant containing “sealed” or valve

regulated “maintenance free” batteries. This feature requires the

use of external thermistors at the plant batteries to monitor cell

temperatures. Refer to the Installation section for more details on

wiring and configuring this feature.

Thermal Compensation lowers plant voltage from the FSP for

monitored battery temperatures which are above the ideal

temperature established during configuration as the Battery

Thermal Slope Nominal Temperature. Lowering the plant

voltage helps to keep the batteries at their optimum state of

charge while protecting them from thermal runaway. Thermal

runaway is a complex sealed battery phenomenon where, for a

number of reasons, one or more cells in a string are unable to

dissipate the internal heat generated by their charging current

and experience an increase in internal temperature. By lowering

the float voltage as cell temperature increases, the float current

is lowered to a point where this destructive behavior can be

avoided. If a cell failure is imminent and the cell temperature

continues to rise above the threshold configured for Battery

Thermal Step Temperature, the plant voltage drops in a single

step to a level which helps keep from overcharging and

damaging the remaining cells in the string. Refer to Figure 3-1

for a graphical view of Battery Thermal Compensation and the

relationship of its various set points. Figure 3-2 shows the same

information for the Flexent system.

3 - 10 Operation Issue 4 January 2008

Page 45

Temperature

Compensation

Voltage Adjustment

(volts per cell)

C(D–A)

•

0

E(F–D)

•

Galaxy Vector Controller GCM2, GCM3

Refer to the Alarm Descriptions section for the Battery Thermal

Alarm and Temperature Probe Failure Alarm.

The Vector can also increase plant voltage above the FSP for

colder environments. Again, this seeks to keep batteries in such

an environment at their optimum charge state. Since this feature

results in an increase in plant voltage, it is activated through a

second enable switch during configuration. Again, refer to

Figure 3-1 or 3-2.

A - Battery Low Temperature Voltage

Increase Threshold (-5 to +20 °C)

B - Low Temperature Voltage

Compensation Disabled

B - Battery Low Temperature Compensation

Voltage Increase (Enable/Disable)

C - Battery Low Temperature Voltage

Increase (1mV to 5mV / Cell / °C)

D - Battery Temperature At Which There

Is No Voltage Compansation (15 to 30 °C)

E - High Battery Temperature Decrease

Voltage Rate (1mV to 5mV / Cell / °C)

F - High Battery Temperature Voltage

Decrease Upper Threshold Limit (30 to 55 °C)

G -High Battery Temperature

Alarm Threshold (30 to 85 °C)

H - High Battery Temperature

Step Down At (45 to 85 °C)

1

2

–0.17

Default Settings

Cell Temperature ( C)

55 65 7545255

1. The Battery High Temperature Alarm occurs when the temperature rises above the High Battery

Temperature Alarm Threshold ( ) set point. It retires when the temperature decreases to 10 °C below

G

this set point set point (45 °C default).

2. Plant voltage decreases 0.17 volts per cell when the temperature increases above the High Temperature

Voltage Step Down At ( ) set point. It is increased 0.17 volts per cell when the temperature decreases to

H

10 °C below this set point, as indicated by the dashed line (65 °C default).

Figure 3-1: Battery Thermal Compensation Set Points (Standard)

Issue 4 January 2008 Operation 3 - 11

Page 46

Temperature

Compensation

Voltage Adjustment

(volts per cell)

C(D–A)

•

0

E(F–D)

•

Galaxy Vector Controller GCM2, GCM3

A - Battery Low Temperature Voltage

Increase Threshold (-5 to +20 °C)

B - Battery Low Temperature Compensation

Voltage Increase (Enable/Disable)

C - Battery Low Temperature Voltage

Increase (1mV to 5mV / Cell / °C)

D - Battery Temperature At Which There

Is No Voltage Compansation (15 to 30 °C)

B - Low Temperature Voltage

Compensation Disabled

E - High Battery Temperature Decrease

Voltage Rate (1mV to 5mV / Cell / °C)

F - High Battery Temperature Voltage

Decrease Upper Threshold Limit (30 to 55 °C)

G -High Battery Temperature

Alarm Threshold (30 to 85 °C)

H - High Battery Temperature

Step Down At (45 to 85 °C)

1

2

–0.17

Default Settings

Cell Temperature (°C)

1. The Battery High Temperature Alarm occurs when the temperature rises above the High Battery

Temperature Alarm Threshold ( ) set point. It retires when the temperature decreases to 10 °C below

this set point set point (65 °C default).

2. Plant voltage decreases 0.17 volts per cell when the temperature increases above the High Temperature

Voltage Step Down At ( ) set point. It is increased 0.17 volts per cell when the temperature decreases to

10 °C below this set point, as indicated by the dashed line (65 °C default).

H

G

65 755325–5

Figure 3-2: Battery Thermal Compensation Set Points (Flexent)

Note: Any time that Battery Thermal Compensation is actively

changing the plant voltage above or below that set by the FSP

parameter during configuration, the LCD indicates the mode by

displaying the message “Float - Compensated”. This is not an

alarm condition, only an indication to the user that plant voltage

is different than that set by the FSP parameter.

Rectifier Sequencing

Rectifier Sequencing is a feature which allows the Vector to

bring the plant rectifiers back on line one at a time following an

ac power interruption. This serves to minimize their impact on

3 - 12 Operation Issue 4 January 2008

Page 47

Galaxy Vector Controller GCM2, GCM3

the ac service, especially useful in avoiding loading down an

emergency generator with an inrush surge.

The Reserve Operation (RO) engine signal (closure, available

only on the BLJ3 board) notifies the Vector that a backup engine

is supplying stable ac power to the rectifiers. A certain number

of rectifiers are then started in sequence. The number of

rectifiers which should be on when the engine is in use is

configurable. Refer to Section 4 for details. The number of ON

rectifiers is usually determined by the capacity of the engine.

When a rectifier reports an ACF to the Vector, it places that

rectifier into standby. As rectifiers report good ac, they are

turned on at 1 second intervals. When the controller senses the

RO signal, it pauses 10 seconds and starts the configured number

of rectifiers at 1 second intervals.

While RO is active, the Vector maintains the configured number

of rectifiers on. When RO retires, the Vector turns the remaining

rectifiers on at 1 second interval.

Shunt Types and Sizes

The Vector provides three separate methods and up to two

separate shunt signals for use in determining the plant current to

display. The access connections to the 2 shunt signals are on the

BLJ3 board SH1+/- and SH2+/- as shown in Figure 2-6, or on

the BTJ2/BTJ3 J21 plug as shown in Table 2-M. These signals

shall be a maximum of 50 mV signals that can represent a range

of 0-9999 amps. Refer to the configuration section of this

manual for additional details.

Float Mode Controls and Thresholds

Float mode is the default mode of operation and is active if the

Boost mode is not active. Plant voltage, while in Float mode, is

determined by the configuration parameter System Float Set

Point (FSP), and may be adjusted by the Battery Thermal

Compensation feature, if it is enabled. There is no individual

adjustment of plant rectifiers in this digital serial bus interface

arrangement. Load share among plant rectifiers is automatic in

all system modes and takes effect within several seconds of a

new rectifier being added to the bus and turned on.

The FSP chosen should correspond to the battery type used and

the battery manufacturer’s recommendations. For example,

Lineage Power KS20472 Round Cell (flooded) battery floats at

2.17 volts per cell (VPC). A 12 cell, 24V plant would therefore

Issue 4 January 2008 Operation 3 - 13

Page 48

Galaxy Vector Controller GCM2, GCM3

have a FSP of 2.17 x 12 = 26.04V. The Lineage Power KS23619

Enhanced VR (Valve regulated) battery floats at 2.27 VPC, if

Battery Thermal Compensation is enabled or 2.25 VPC if used

without Battery Thermal Compensation. A 12 cell, 24V plant

using this battery would have a desired FSP of 2.27 x 12 =

27.24V with or 2.25 x 12 = 27.00V without Battery Thermal

compensation.

Rectifier Current Limit in Float mode (FCL) is an adjustable

configuration parameter from 30% to 110% of rectifier capacity.

This parameter can be important in limiting the recharge current

available following a deep discharge in a plant using a “sealed”

or valve-regulated battery type to a level which is safe for that

battery and not cause unnecessary internal pressure buildup and

venting. Typically, this maximum safe recharge rate for “sealed”

or valve-regulated battery types in the industry is in the range of

1/10 of the 8 or 10 hour rating. Refer to your specific battery

manufacturer for recommendations regarding the battery type

used. The following typical example shows the use of the FCL

feature to maintain the maximum recharge rate decided upon.

Consider a plant with three strings of 2VR375E Lineage Power

KS23619 Enhanced VR Series batteries, four 100A rectifiers

and a 200 amp typical load. When ac power returns following a

significant discharge, 200 amps are available for recharging

these batteries, a rate of 67A per string (200A / 3 strings).

Recharge should be limited to approximately 40A per string

(1/10 of 375) however, reducing the possibility of venting and

life depreciation of the batteries. Calculate current limit for

limiting recharge to 40A per string as follows:

CL = [Plant Load + (Max Recharge per String × # Strings) /

(Rect Cap × # Rect) ] × 100

CL = [ 200 + (40 × 3) / (100 × 4)] × 100

CL = [(200 + 120) / 400] × 100

CL = (320 / 400) × 100 = 80%

Check for N + 1 redundancy with this CL value with the

following statement:

Plant Load < [Rect Cap × (# Rect - 1) × CL] / 100

200 < [100 × (4 -1) × 80] / 100

3 - 14 Operation Issue 4 January 2008

Page 49

Galaxy Vector Controller GCM2, GCM3

200 < [(100 × 3) × 80)] / 100

200 < (300 × 80) / 100

200 < 240

Float mode adjustments are also available for High Float

Voltage Float Threshold which activates the High Float Voltage

(alarm only) minor when exceeded and the High Voltage Float

threshold which activates the High Voltage major alarm and

rectifier shutdown. Battery on Discharge Float Threshold and

Very Low Voltage Threshold are additional Float mode

configuration parameters. Refer to the Alarm Descriptions

section for additional information regarding these alarms.

Battery Recharge

Current limit

Battery Discharge

Tes t

The battery recharge current limit feature enables the Vector

Controller to limit the recharge current flowing into a battery

section during the charge cycle. This feature is available only in

plants that have at least one battery shunt to monitor the battery

current. It can be enabled or disabled using the front panel

display or EasyView® Interface. The recharge current flowing

into the battery section can be limited to any value between 10

and 1000A.

The Vector Controller can monitor up to two shunts connected

to two battery sections, each battery section can contain one or

more battery strings. The controller limits the current flowing

through the shunts thereby limiting the charging current into the

batteries. This feature has no impact on the discharge current

flowing from the battery. The controller maintains the recharge

current within 10% of the set level.

The purpose of the test is to verify the battery capacity connected

to the plant. The reserve time can be predicted after the test and

stored in the memory for future retrieval. By discharging about

20% of the battery capacity, the controller can predict the total

reserve time if 100% battery capacity is discharged at the same

load condition.

This function can be enabled in the configuration process by

enabling the battery test in the appropriate configuration menu.

Refer to Section 4 for detail. If the function is enabled, this test

can be activated by accessing the operations menus and

manually pressing the Battery Test Start softkey. The battery test

Issue 4 January 2008 Operation 3 - 15

Page 50

Galaxy Vector Controller GCM2, GCM3

can be stopped in the same manner, by pressing the Battery Test

Start softkey again during the test.

Note: The battery type should be configured before starting. The

Vector assumes one type of battery per system. The battery type

may be configured as either valve regulated or flooded.

During the test, rectifiers are set at a lower voltage. The set

voltage is the maximum of {LVD1 threshold +ΔV, the LVD2

threshold +ΔV, or EDV}, where EDV (the end voltage) = 22V

for 24V plant and 44V for 48V plant, ΔV = 0.6V for 24V plant

and 1.2V for 48 plant. The plant mode is returned to float mode

automatically if this set voltage is reached during the test.

The test stops automatically whether it is successful or not. Refer

to the configuration process in Section 4. During the test, the

default screen of the LED indicates a battery test is active. Any

alarm occurring during the test aborts the test, and causes the

system to return to float mode.

The last test results, battery reserve time, and load current are

stored in memory. The user can retrieve them under the

operations menu. Refer to the configuration process in Section 4.

Boost Mode Controls and Thresholds

Boost mode is a feature of the Vector which allows the user to

temporarily raise the system voltage to a higher, predetermined

level for a specified period of time. This feature may be useful in

systems using a flooded battery type where the batteries are

displaying symptoms of an undercharged state such as differing

cell voltages or in the case of the Lineage Power KS20472

Round Cell, lead-sulfate crystals visible on the vertical positive

plate columns. Boost mode may also be used to accelerate the

recharge of discharged strings to their full charge condition.

Plant voltage, while in Boost mode, is determined by the

configuration parameter Plant Boost Set- Point. Refer to “Plant

Boost Mode Settings” in Section 4. Like Float mode, there is no

individual adjustment of plant rectifiers. Load share among plant

rectifiers is automatic.

Boost voltage is determined from the battery manufacturer’s

recommendations, but must also be less than the maximum

voltage rating of all connected loads since Boost Mode raises the

entire system bus voltage. Typical boost levels and durations

used might include 2.25 VPC for 96 hours, 2.27 VPC (volts per

3 - 16 Operation Issue 4 January 2008

Page 51

Galaxy Vector Controller GCM2, GCM3

cell) for 72 hours, or 2.30 VPC for 48 hours. Do not exceed the

maximum voltage rating of any connected load.

Boost is typically not used with “sealed” or valve regulated

battery types. If it is used, it is generally completed at

significantly lower levels than that of flooded battery design to

avoid the build up of pressure and venting noted under the Float

mode section on Float Current Limit. When Boost mode is

disabled in the configuration menu, the feature cannot be

initiated.

Once enabled, Boost mode is entered by accessing the

operations menu and pressing the Boost softkey. The default

LCD screen shows that the system is in Boost mode of operation.

The present Boost duration is also displayed in hours. This Boost

duration can be edited with 0 and 24 hour minimum and

maximum values (0 = forever). Pressing the Step Boost mode

softkey returns the system to the Float mode. If a High Voltage,

High Float Voltage or RFA alarm occurs while in Boost mode,

the plant returns immediately to Float mode. AC Fail and Phase

Fail alarms does not affect Boost mode.

Boost mode has its own configuration parameters for Rectifier

Boost Current Limit, High Float Voltage Boost Threshold, and

High Voltage Boost Threshold, all of which control these

respective features and alarms whenever Boost mode is active.

Auto Timed Boost

The plant goes into Boost mode automatically if the following

conditions occur:

• Auto Boost is enabled

• Autoboost factor is configured from 1 to 9.