Page 1

Galaxy Power System

Verification Procedures

User’s Guide

Select Code 167-792-010

Comcode 108639659

Issue 3

January 2008

Page 2

Page 3

User’s Guide

Select Code 167-792-010

Comcode 108639659

Issue 3

January 2008

Galaxy Power System

Verification Procedures

Notice:

The information, specifications, and procedures in this manual are

subject to change without notice. Lineage Power assumes no

responsibility for any errors that may appear in this document.

© 2008 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 4

Page 5

Galaxy Power System Verification Procedures

Table of Contents

1 Introduction

2 Galaxy SC Controller Performance

Verification Procedures

Introduction 2 - 1

Tools 2 - 1

Precautions 2 - 1

Illustrations 2 - 2

Lamp Test 2 - 6

Alarm Test 2 - 6

Local Alarm Test 2 - 6

Remote Alarm Test 2 - 8

High Float Voltage Alarm/High Voltage Shutdown Alarm Tests 2 - 9

Overview 2 - 9

Preparations 2 - 9

HV/HVSD Test Procedure for Parallel Rectifiers 2 - 10

HFV Test Procedure for Serial Rectifiers 2 - 11

HVSD Test Procedure for Serial Rectifiers 2 - 12

Battery on Discharge Alarm Test 2 - 16

Rectifier Fail Alarm Test 2 - 17

Lucent Serial Rectifiers 595 and 596 Series 2 - 17

J855- or J874-Series Rectifiers 2 - 17

150A SMR Rectifiers 2 - 18

50A SMR Rectifiers 2 - 19

Terminate Rectifier (TR) Test 2 - 20

Fuse Alarm Test 2 - 21

Major Fuse Alarm 2 - 21

Minor Fuse Alarm 2 - 21

Modem/Data Switch 2 - 22

Remote Peripheral Monitoring 2 - 22

Rectifier Sequencing 2 - 22

Energy Management 2 - 23

Meter Calibration from the Front Panel 2 - 25

Voltage Calibration 2 - 25

Current Calibration 2 - 26

Battery Discharge Test 2 - 27

Issue 3 January 2008 Table of Contents - 1

Page 6

Galaxy Power System Verification Procedures

3 Galaxy Millennium Controller Performance

Verification Procedures

Introduction 3 - 1

Tools 3 - 1

Precautions 3 - 1

Lamp Test 3 - 2

Alarm Test 3 - 2

Local Alarm Test 3 - 3

Remote Alarm Test 3 - 5

High Float Voltage Alarm Test 3 - 6

Introduction 3 - 6

Preparations 3 - 6

Testing High Float Voltage Alarms 3 - 6

High Voltage Shutdown Test 3 - 7

Overview 3 - 7

Serial Rectifiers 3 - 8

Battery Plant HVSD Test 3 - 9

Battery on Discharge Alarm Test 3 - 12

Rectifier Fail Alarm Test 3 - 12

Terminate Rectifier (TR) Test 3 - 13

Fuse Alarm Test 3 - 14

Introduction 3 - 14

Major Fuse Alarm (FAJ) 3 - 14

Minor Fuse Alarm (FAN) 3 - 14

Modem/Data Switch 3 - 15

Remote Peripheral Monitoring 3 - 15

Rectifier Sequencing 3 - 15

Energy Management 3 - 16

Meter Calibration from the Front Panel 3 - 17

Voltage Calibration 3 - 17

Current Calibration 3 - 18

Battery Discharge Test 3 - 19

Discharge Menu 3 - 20

Procedure 3 - 22

Test Completion 3 - 23

4 Replacement Procedures

Overview 4 - 1

Memory Backup Battery Replacement for SC/SCF Controller 4 - 2

Backup System Configuration 4 - 2

Replace Memory Backup Battery 4 - 3

Restore System Configuration 4 - 4

Memory Backup Battery Replacement for Millennium Controller 4 - 5

Backup System Configuration 4 - 5

2 - Table of Contents Issue 3 January 2008

Page 7

Galaxy Power System Verification Procedures

Backup System Configuration 4 - 6

Replace Memory Backup Battery 4 - 7

Restore System Configuration 4 - 7

Requirements 4 - 8

System 4 - 8

Batteries 4 - 8

Rectifiers 4 - 8

Rectifier Fan Assembly 4 - 8

Converters 4 - 9

GPS2424 Replacement Procedures 4 - 10

Installing or Replacing a 596B3 Rectifier 4 - 10

Replacing a 596B3 Rectifier Fan Assembly 4 - 12

Replacing a 597A or 597B Converter Carrier 4 - 13

Replacing a 47A Converter Module 4 - 14

Replacing a 128A Converter Interface Card 4 - 14

Replacing a Converter Fan Assembly 4 - 15

GPS4812 Replacement Procedures 4 - 16

Installing or Replacing a 596A Rectifier 4 - 16

Replacing a 596A Rectifier Fan Assembly 4 - 17

GPS4848 Replacement Procedures 4 - 18

Installing or Replacing a 595A or 595B Rectifier 4 - 18

Removing a Rectifier 4 - 21

Replacing a 595A or 595B Rectifier Fan Assembly 4 - 22

Testing 4 - 24

Testing Additional Alarms After Replacing Rectifiers 4 - 24

Testing Rectifiers and Load Share in Bay Expansions 4 - 24

5 Glossary

SC Controller Circuit Boards 5 - 2

SCF Controller Circuit Boards 5 - 4

Millennium Controller Circuit Boards 5 - 8

Issue 3 January 2008 Table of Contents - 3

Page 8

Page 9

Galaxy Power System Verification Procedures

List of Figures

Figure 2-1: Location of Galaxy SC Controller Circuit Boards 2 - 2

Figure 2-2: TB2 and TB3 of Galaxy SC Controller 2 - 3

Figure 2-3: Location of Galaxy SCF Controller Circuit Boards 2 - 4

Figure 2-4: TB2 and TB3 of Galaxy SCF Controller 2 - 5

Figure 3-1: Galaxy Millennium Controller Switch Positions 3 - 2

Figure 4-1: Detail of 596B3 Rectifier Position 4 - 10

Figure 4-2: Detail of Converter Components 4 - 13

Figure 4-3: Cable Connection Between Two Converter

Carriers 4 - 13

Figure 4-4: Detail of 596A Rectifier Position 4 - 16

Figure 4-5: Installing a Rectifier in a Rectifier Shelf 4 - 19

Figure 4-6: Replacing a Rectifier Fan Assembly 4 - 22

Issue 3 January 2008 List of Figures - 1

Page 10

Page 11

Galaxy Power System Verification Procedures

1 Introduction

Overview This manual provides general verification procedures for inspection and

testing of Lineage Power Galaxy Power System (GPS) products. The

test procedures mentioned in this manual correspond to controller

software version 6.5.

The Lucent GPS family of products is designed to operate

maintenance-free, without the need for any regular adjustments or fine

tuning. The output voltage and current limit are set by the controller, and

the information is sent as a broadcast message to all rectifiers. All the

rectifier outputs will be automatically adjusted to this level; no

individual rectifier level voltage adjustment is required.

If, however, the customer requires any kind of routine verification or

inspection (even though Lineage Power does not recommend it), the

techniques described in this manual may be used as guidelines to test all

the alarms.

The tests described here will simulate various alarm conditions and

verify that the controller functions properly.

The fans used in the 595-Series and 596-Series rectifiers have a typical

lifetime of 7 years. The fans in the 597A and 597B 24V/48V converter

carriers have a typical lifetime of 4 to 5 years. Lucent recommends that

these fans be replaced at these intervals as described in Section 4,

Replacement Procedures in this manual.

Note: Fan assemblies should be kept dust-free at all times. Air flow

through the rectifiers is important for the proper operation of the

rectifiers.

Issue 3 January 2008 Introduction 1 - 1

Page 12

Page 13

Galaxy Power System Verification Procedures

2 Galaxy SC Controller

Performance Verification

Procedures

Introduction The procedures in this section may be used to test the different alarms in

a live Galaxy SC Controller system. The procedures are the same for

both rear access and front access Galaxy SC controllers.

Tools The following tools are required to complete the tests described in this

section:

• Digital Voltmeter (DVM) with dc accuracy of at least 0.05%

• Short length of wire or clip lead for jumper

• Jeweler’s screwdriver

Precautions Before performing the test procedures, verify that the following

conditions exist:

• All rectifiers are functioning properly.

• Plant batteries are fully charged and are ready to support a load.

(See Caution below.)

Caution: When Alarm Tests are performed on a live plant, some of

the tests will cause a battery discharge to occur. In this case, ensure

that the plant batteries are capable of supporting the load. It is

recommended that a battery discharge test be performed before

proceeding with other tests.

Follow the steps of the procedures in the order they are given.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 1

Page 14

Galaxy Power System Verification Procedures

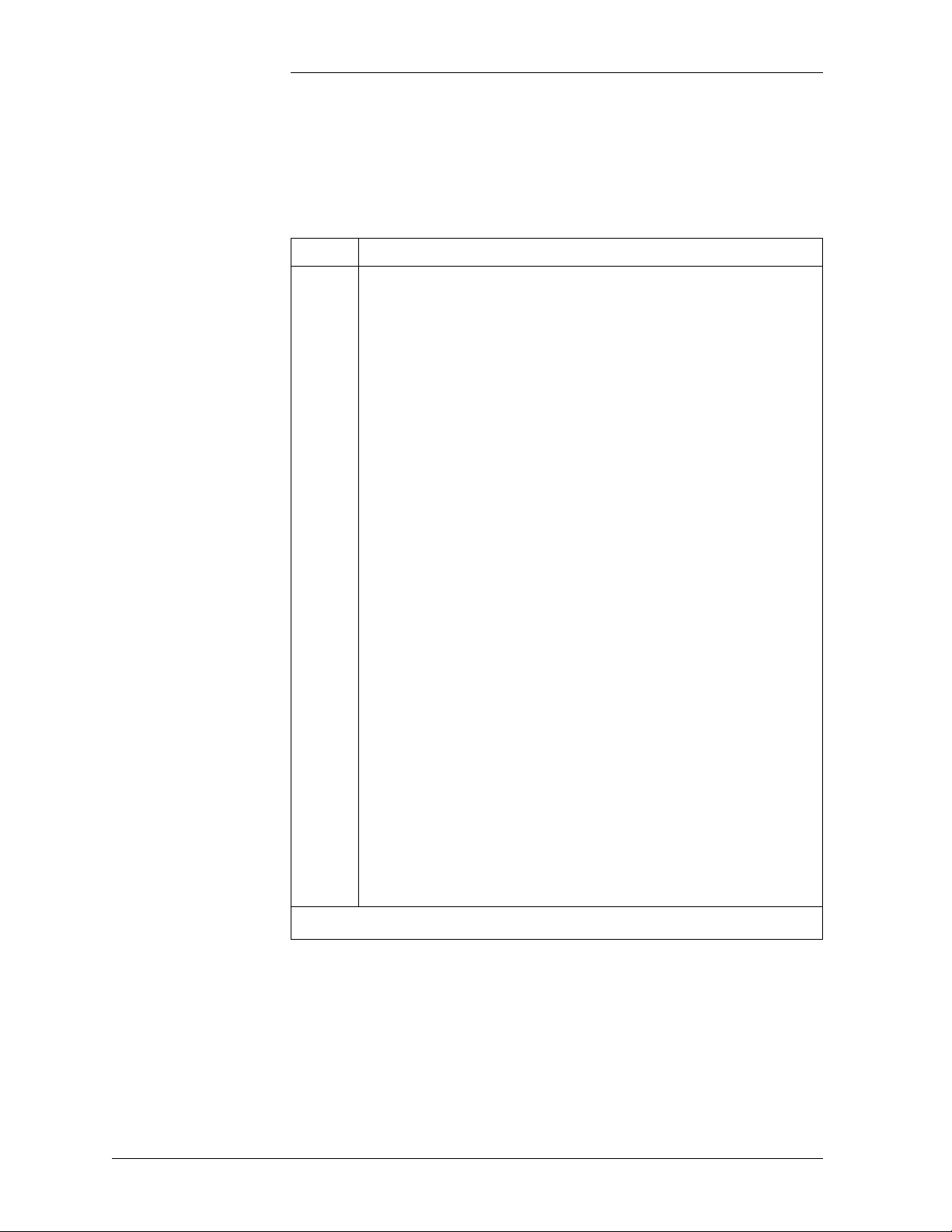

Illustrations Refer to Figures 2-1 and 2-2 for illustrations of the Galaxy SC

Controller.

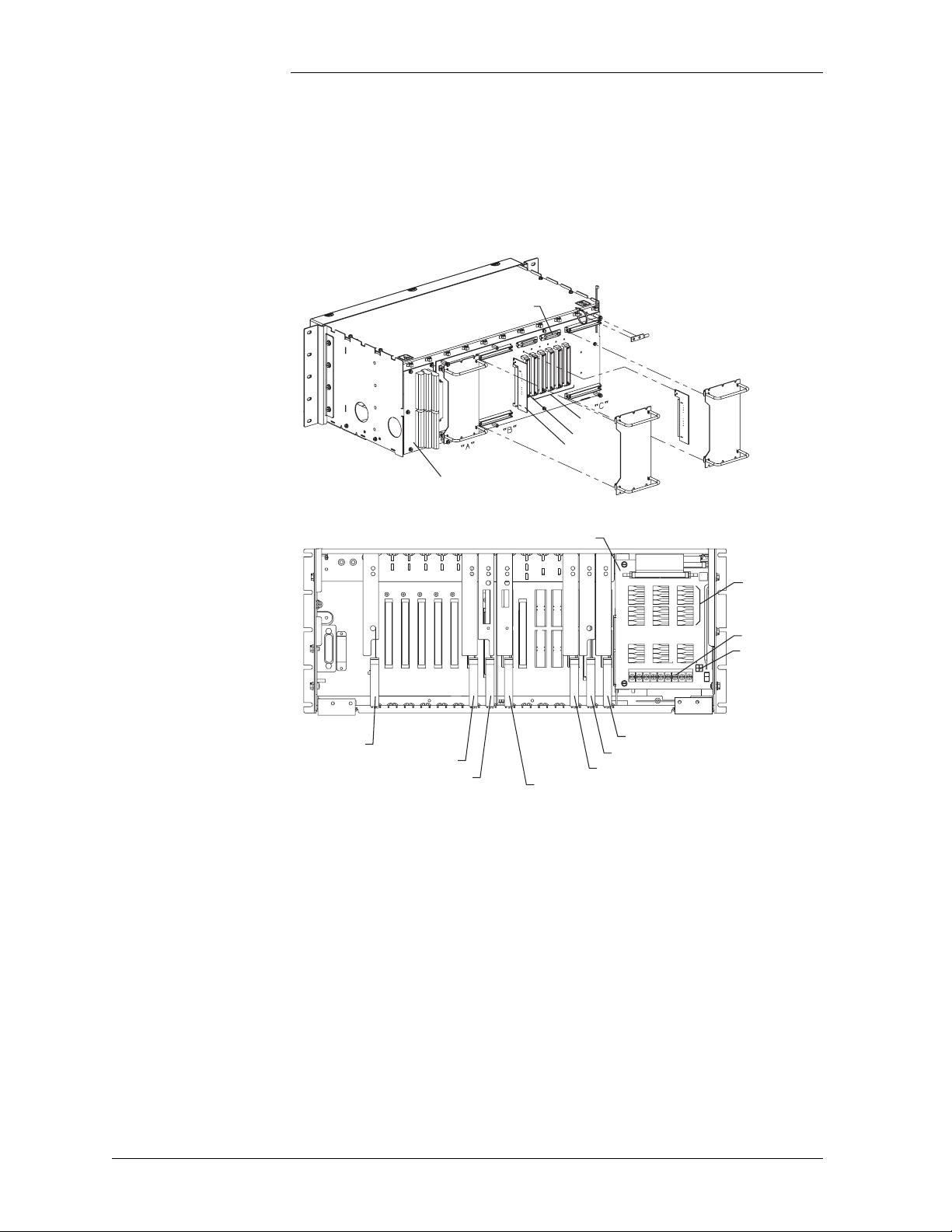

SC Controller

BJJ Intelligent

Power Board

BJT Termination Board

Options Slot 5

BJL Modem Board

BJH Intelligent Controller

Options Slot 4

Options Slot 3

Options Slot 2

Local PC

Port - RS232

Rear View

Option

Modem

Aux Port

BJF Termination

Fuse Board

BJE Alarm Board

BJA Independent Power Board

BJB Independent Controller

BJC Rectifier Interface Board

Regulation

Fuses

TB1

P500

Figure 2-1: Location of Galaxy SC Controller Circuit Boards

2 - 2 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 15

Galaxy Power System Verification Procedures

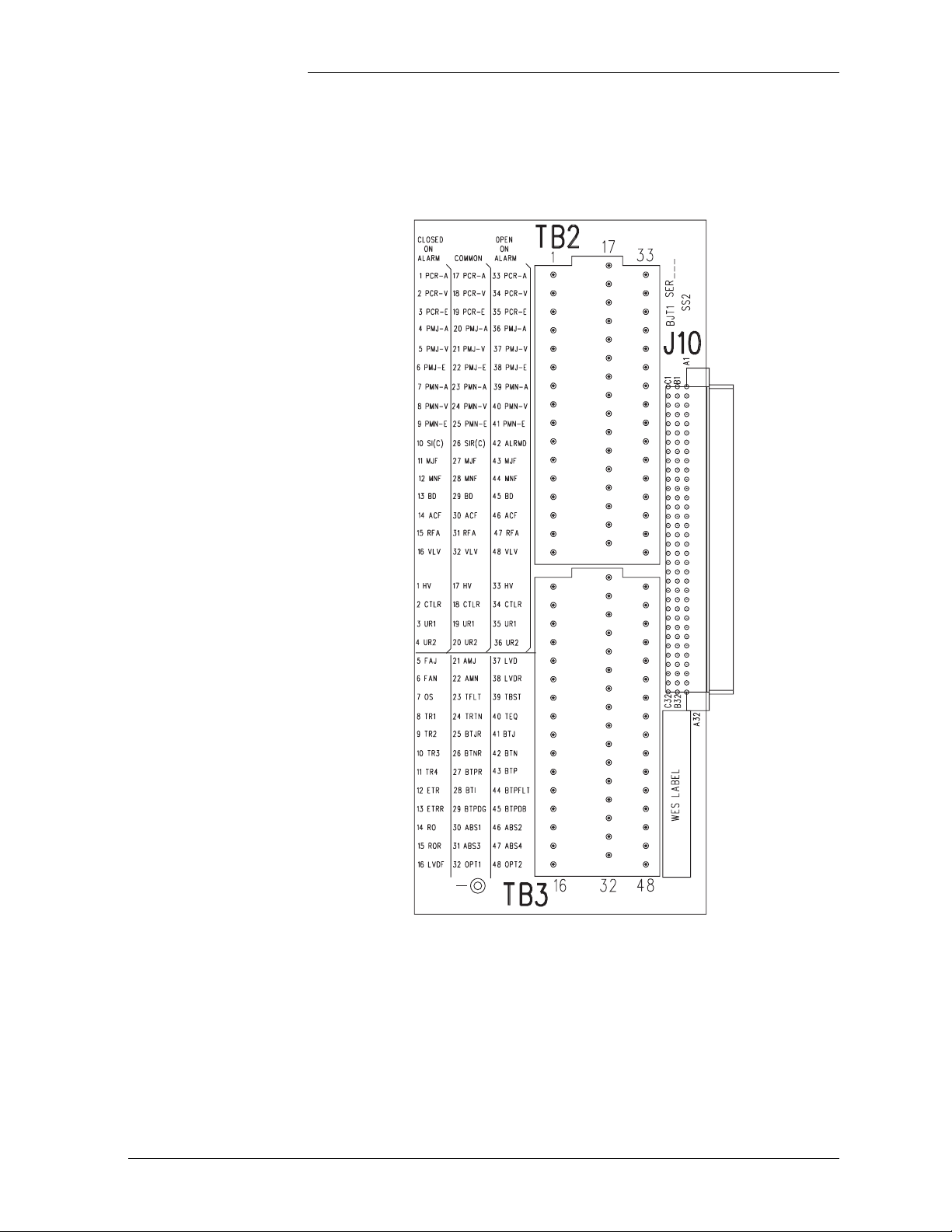

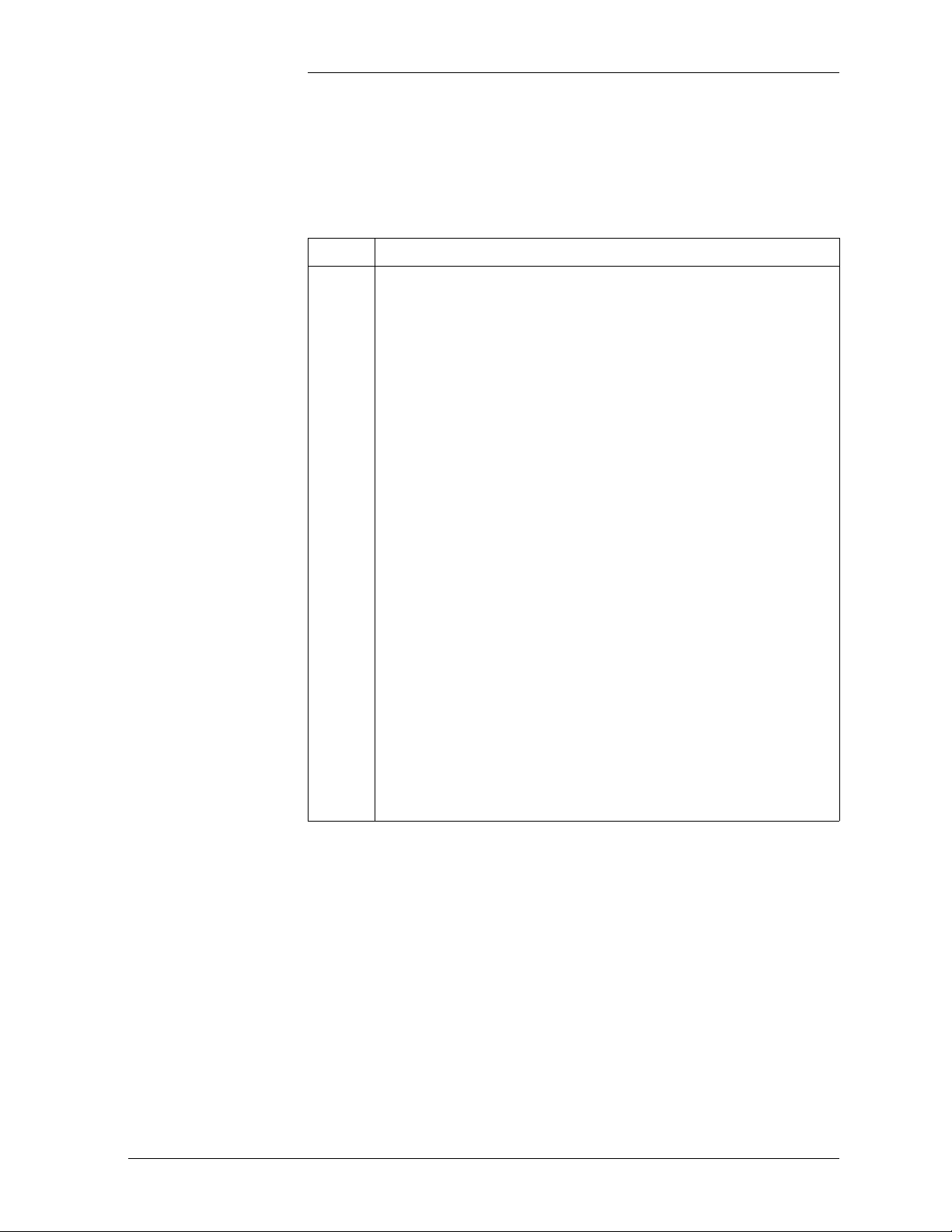

Illustrations, continued

16

32

48

1

FG

17

33

BJT Board

(Galaxy SC Controller)

Figure 2-2: TB2 and TB3 of Galaxy SC Controller

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 3

Page 16

Galaxy Power System Verification Procedures

Illustrations, continued

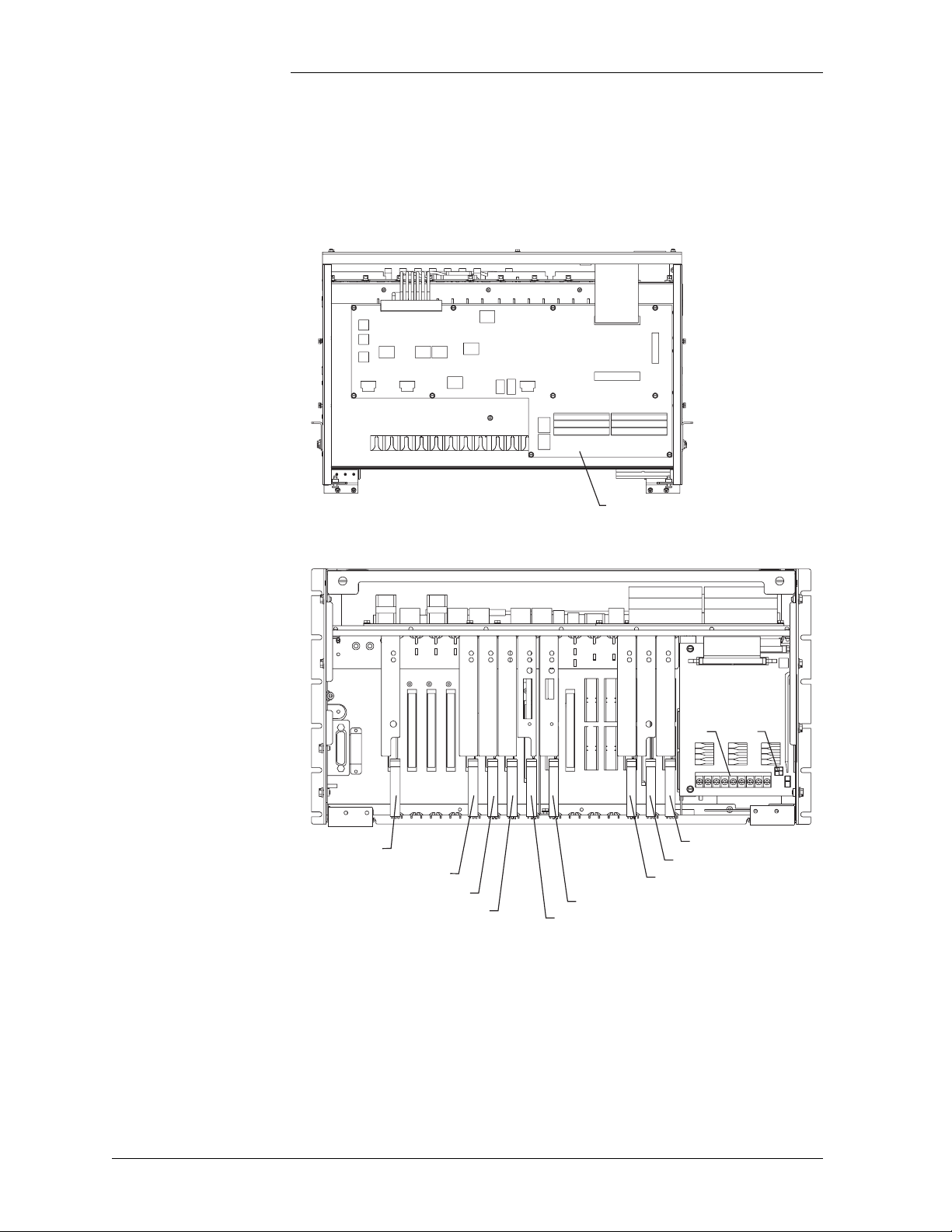

SCF Controller Figures 2-3 and 2-4 are illustrations of the Galaxy SCF Controller.

J2

J1

TB10

J5

P401 P403

TB12

TB11

TB6

Options Slot 4

Options Slot 5

TB7

TB8

J111

J112

BLG1

P110

TB5

TB4

P100

Top View

TB2 TB3

BLG Termination Board

Front View (Door Removed)

TB2 TB3

BJF Termination

Fuse Board

P500TB1

BJJ Intelligent

Power Board

BJK Data Switch

BJM RPM Board

BJL Modem Board

BJB Basic Controller

BJH Intelligent Controller

BJE Alarm Board

BJA Basic Power Board

BJC Rectifier Interface Board

Figure 2-3: Location of Galaxy SCF Controller Circuit Boards

2 - 4 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 17

Galaxy Power System Verification Procedures

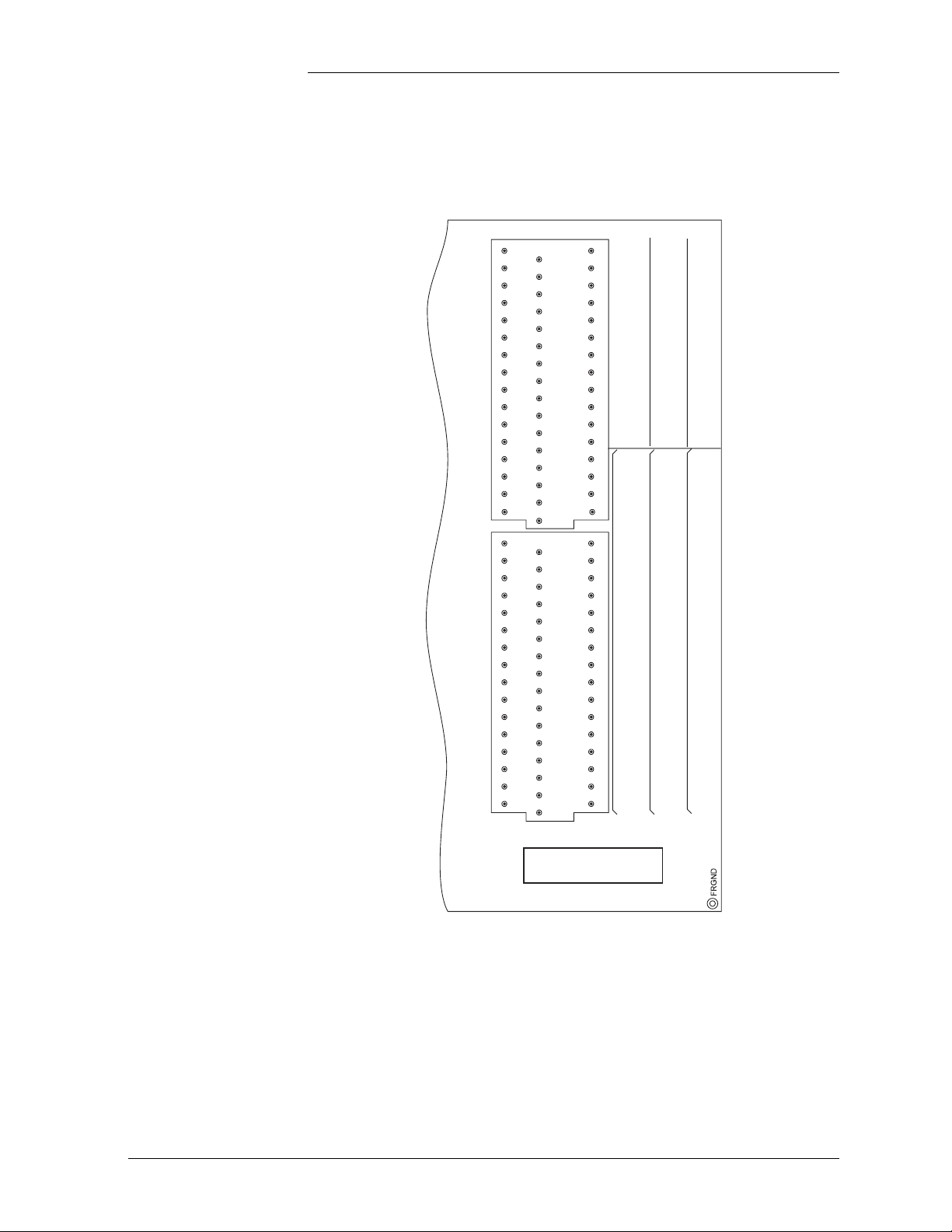

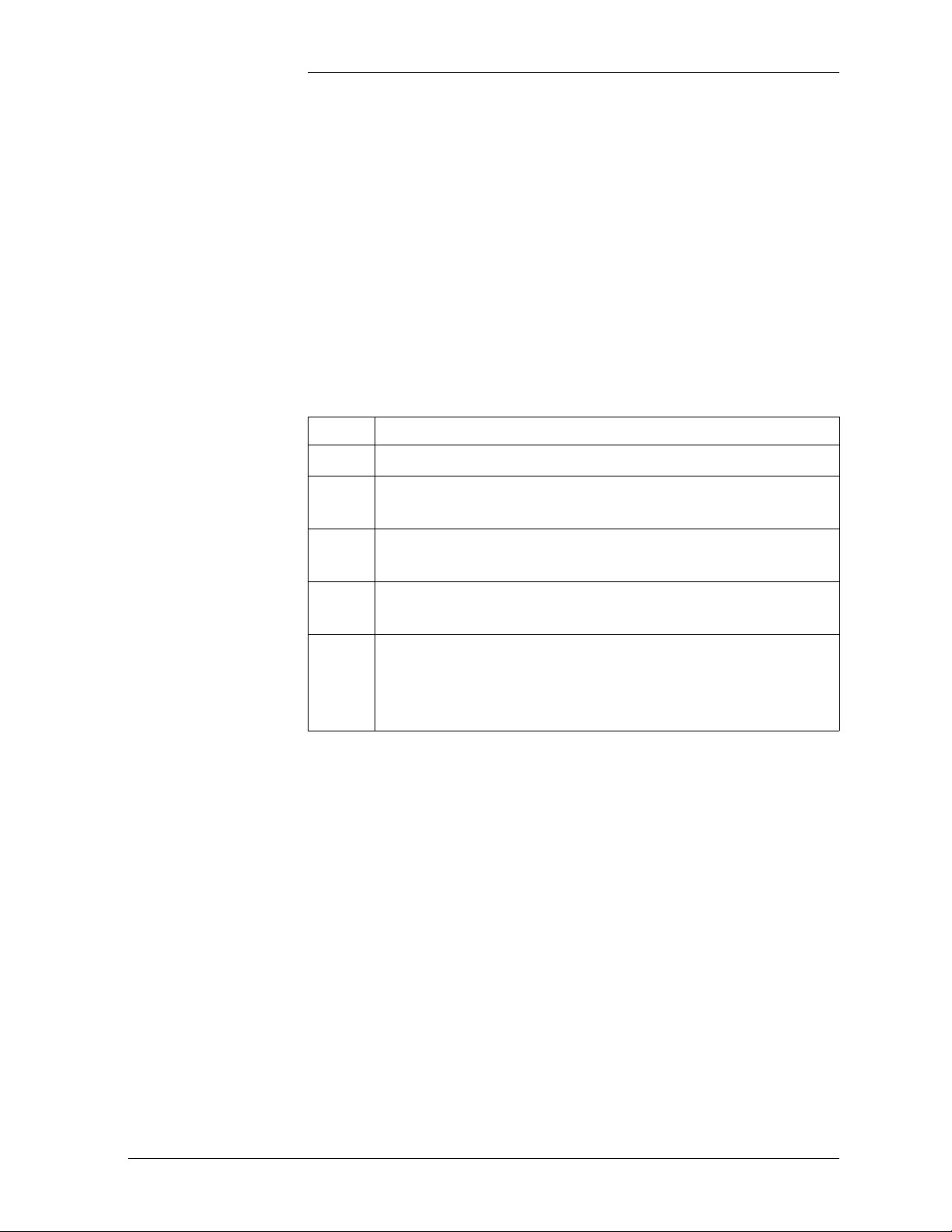

Illustrations, continued

48

48

47

46

45

44

43

42

41

40

TB3

39

38

37

36

35

34

33

48

47

46

45

44

43

42

41

40

TB2

39

38

37

36

35

34

33

33

32

17

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

48 OPT 2

47 ABS4

46 ABS2

45 BTPDB

44 BTPFLT

43 BTP

42 BTN

41 BTJ

40 TEQ

39 TBST

38 LVDR

37 LVD

36 UR2

35 UR1

34 CTLR

33 HV

48 VLV

47 RFA

46 ACF

45 BD

44 MNF

43 MJF

42 ALRMD

41 PMN-E

40 PMN-V

39 PMN-A

38 PMJ-E

37 PMJ-V

36 PMN-A

35 PCR-E

34 PCR-V

33 PCR-A

OPEN

ON

ALARM

32 OPT1

31 ABS3

30 ABS1

29 BTPDG

28 BTI

27 BTPR

26 BTNR

25 BTJR

24 TRTN

23 TFLT

22 AMN

21 AMJ

20 UR2

19 UR1

18 CTLR

17 HV

32 VLV

31 RFA

30 ACF

29 BD

28 MNF

27 MJF

26 SIR(C)

25 PMN-E

24 PMN-V

23 PMN-A

22 PMJ-E

21 PMJ-V

20 PMJ-A

19 PCR-E

18 PCR-V

17 PCR-A

RETURN

16 LVDF

15 ROR

14 RO

13 ETRR

12 ETR

11 T R4

10 TR3

9 TR2

8 TR1

7 OS

6 FAN

5 FAJ

4 UR2

3 UR1

2 CTLR

1 HV

16 VLV

15 RFA

14 ACF

13 BD

12 MNF

11 M JF

10 SI(C)

9 PMN-E

8 PMN-V

7 PMN-A

6 PMJ-E

5 PMJ-V

4 PMJ-A

3 PCR-E

2 PCR-V

1 PCR-A

CLOSED

ON

ALARM

Part of BLG Board

(Galaxy SCF Controller)

Figure 2-4: TB2 and TB3 of Galaxy SCF Controller

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 5

Page 18

Galaxy Power System Verification Procedures

Lamp Test Depress the <LAMP TEST> key on the controller’s front display

interface. All LEDs on the controller front panel, controller boards, and

Lucent serial rectifiers will turn on momentarily and then retire.

Alarm Test

Introduction Alarm Test provides a method of testing the operation of all or any of

the plant alarm relays and their wiring to the connected alarm system.

This test cannot be done if any alarms are active. It may also be desirable

to perform this test occasionally after the plant is in service to verify the

integrity of the office alarms for the power plant.

Alarm Test may be performed locally or from a remote terminal.

The Alarm Test feature will, in succession, operate each of the controller

alarm relays. With the basic controller, the default duration is one

minute. With the intelligent option for the controller, the selection of the

relays to be operated and default duration can be changed using the

EasyView interface.

Local Alarm Test Refer to Figures 2-1 and 2-2 for the SC Controller, and to Figures 2-3

and 2-4 for the SCF Controller.

SW202-5 on the BJB Basic Control Board must be enabled along with

its associated software switch found on the front panel under the path:

MAIN → CONFIG → ALARM → TEST ALM.

If HVSD is desired during the test, BJB SW202-4 must also be enabled,

along with the appropriate software switch found on the front panel

under the path: MAIN → CONFIG → ALARM → TEST HV. Each

rectifier in the plant must have a load of at least 10% of its capacity.

When configured with the optional intelligent controller, the alarm

conditions tested during Alarm Test and their duration may be specified

within EasyView with the path: MAIN → CONFIGURE → ALARM

TEST. As an alternative to the front panel configuration of the Alarm

Test software switch, it may be also configured within EasyView under

the path: CONFIGURE → DC PLANT → HARDWARE &

SOFTWARE CONFIGURED.

Note: Front panel LEDs do not activate during the alarm test. The

alarm relays whose contacts are accessed on TB2 and TB3 (BJT board

on rear of SC controller/BLG on top section of the SCF controller) may

be monitored to follow the progress of alarm testing.

2 - 6 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 19

Galaxy Power System Verification Procedures

Alarm Test, continued

Local Alarm Test,

continued

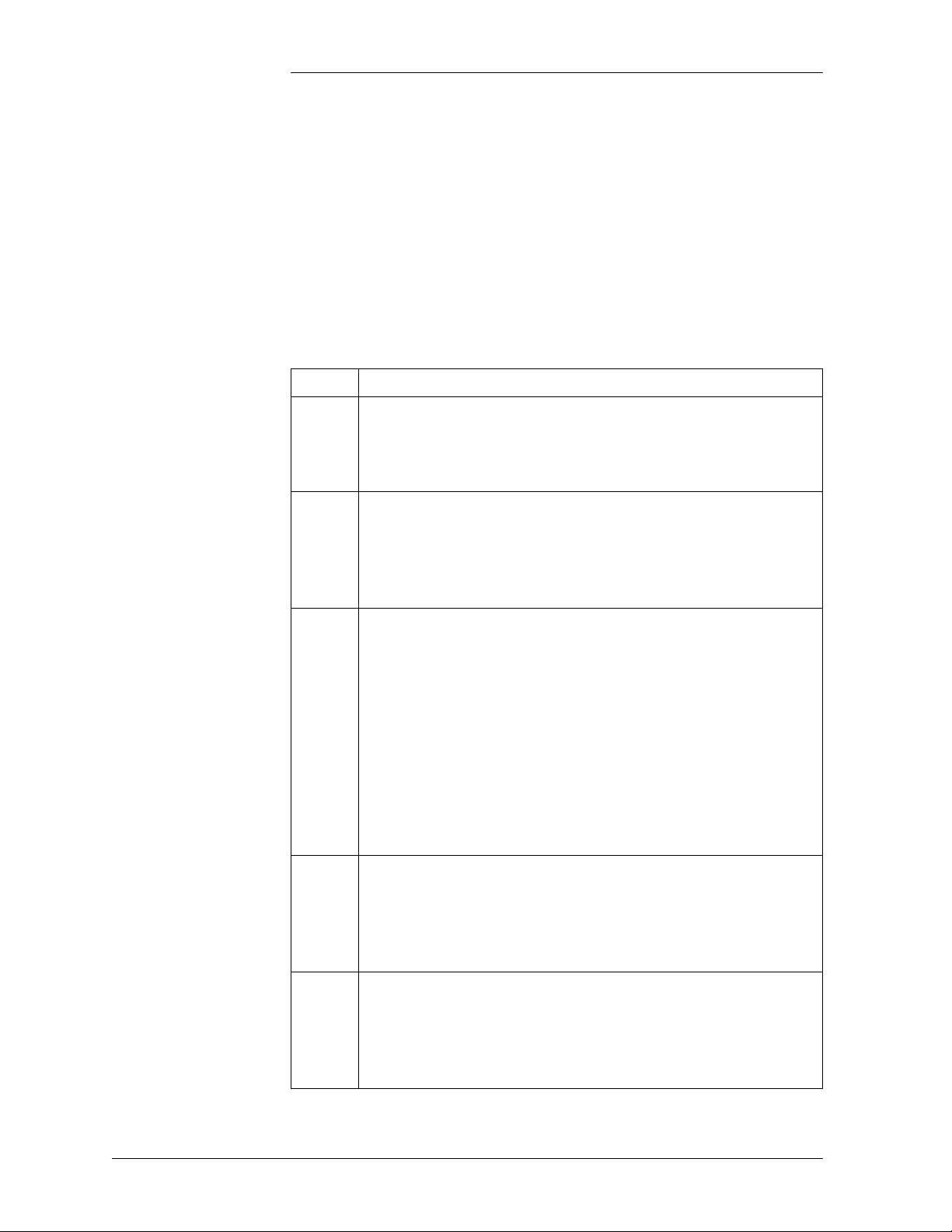

The Alarm Test will operate, in sequence, each of the relays shown

below for a default interval of approximately 60 seconds. This interval

for each relay's activation during this test may optionally be set in an

intelligent controller via EasyView path: MAIN → CONFIGURE →

ALARM TEST.

Initiate Alarm Test locally by momentarily pressing the Alarm Test

switch recessed into the front of the BJB basic controller or press the

<MENU> key to bring up the MAIN screen and follow the path:

MAINT OPER → ALARM TEST. The ALM TEST STAT field of this

same screen can then be used to follow the progress of the Alarm Test.

The progress of the activated relays can be followed during the test by

going straight down the TB2 and TB3 terminal blocks if the connected

alarm system is not yet processing. (See Figure 2-2 for the SC, Figure

2-4 for the SCF.) The progress of relay activation may also be monitored

in the ALM TST STAT field of the MEASURE/STATIS screen of an

Intelligent controller or the MAIN screen in the basic controller.

Rectifier Fail Alarm Test - RFAT*

Power Critical - PCR

Power Major - PMJ

Power Minor - PMN

Major Fuse - MJF

Minor Fuse - MNF

Battery on Discharge - BD

AC Fail - ACF

Rectifier Fail Alarm - RFA

Very Low Voltage - VLV/UR3**

High Voltage - HV

Controller - CTLR

User Relay 1 - UR1**

User Relay 2 - UR2**

*RFAT is an alarm test intended for use with non-serial type rectifiers

that are connected to the “Enhanced Ferro” RIM (J85501F-1 L32) of an

SC controller ONLY.

**UR1, UR2, and UR3 are inhibited if LVD Contactors have been

configured and a Bay Interface Card is not configured in the system.

Note: If the controller has an earlier version of software (<6.0), VLV is

used instead of UR3.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 7

Page 20

Galaxy Power System Verification Procedures

Alarm Test, continued

Remote Alarm Test Using EasyView to perform the Alarm Test, hardware switches

SW202-5 on the BJB board and SW204-2 on the BJH board must first

be enabled, in addition to the software switches located at menu path.

EasyView: CONFIGURE → DC PLANT → HARDWARE AND

SOFTWARE CONFIGURED

Both the Alarm Test and Remote Alarm Test fields must be enabled.

Initiate the test remotely with the EasyView path:

CONTROL → ALARM TEST.

Follow the status of the test remotely with the EasyView path:

STATUS → ALARM TEST.

2 - 8 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 21

Galaxy Power System Verification Procedures

High Float Voltage Alarm/High Voltage Shutdown Alarm Tes t s

Overview The High Float Voltage Alarm Test differs depending on whether

the system uses parallel or serial rectifiers. Both are described in

this section.

The HV test can be done by either raising the plant voltage above the

threshold set for HFV (High Float Voltage) and HVSD (High Voltage

Shutdown) or by lowering the thresholds for these conditions to make

them active.

Note: HFV is an alarm-only that can notify users of an impending HV

condition before the need for a shutdown arises.

Preparations Note the value of plant voltage from the Default screen. Use the

following table to record settings before beginning the test procedures

for both parallel and serial rectifiers:

Plant Nominal Float

Voltage

HV HFV

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 9

Page 22

Galaxy Power System Verification Procedures

High Float Voltage Alarm/High Voltage Shutdown Alarm

Tests, continued

HV/HVSD Test Procedure for Parallel Rectifiers

Do not raise the plant bus voltage if an active load is being served. To

test HVSD under this situation, ensure that sufficient battery reserve is

connected to the plant bus to support the plant load. The battery may

start sharing some load and BD alarms may turn on during this test.

Step Action

1

Disable Load Share on the rectifiers (if equipped) and adjust

the rectifier voltages until each is delivering at least 10% of

its capacity. Turn Off unneeded rectifiers if necessary to

accomplish this.

2

From the Front Display interface, use the path: MAIN →

CONFIG → THRESH and lower the HFV/Float level to 1

volt below the current float voltage. Verify that the Power

Minor relay has activated and the RECT and Minor LEDs

are active.

3

Next, use the path: MAIN → CONFIG → THRESH and

lower the HV/Float level to 1 volt below the current float

voltage. This should activate HVSD, turning Off all plant

rectifiers and placing the plant into a BD (Battery on

Discharge) condition. The BD, RECT, and Major LEDs

should all activate, along with the Power Major, BD, and

RFA alarm relays. After 5 seconds, all rectifiers will restart

and, following walk-in, will begin raising the plant back to

float. When the voltage passes the new HV threshold again,

HVSD will occur again and all rectifiers will remain locked

Off.

4

Use the path: MAIN → CONFIG → THRESH one final

time to reset the HFV and HV Float levels to their desired

normal settings (refer to table where initial settings have

been recorded) and then the path: MAIN → RECT RST to

restart all plant rectifiers, retiring the BD and RECT alarms.

5

Repeat the test for any rectifiers that were turned Off to

achieve the 10% minimum load capacity level of each

rectifier. After all rectifiers have been tested, adjust each to

plant float, if necessary, and reenable Load Share on the

rectifiers, if equipped.

2 - 10 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 23

Galaxy Power System Verification Procedures

High Float Voltage Alarm/High Voltage Shutdown Alarm

Tests, continued)

HFV Test Procedure for Serial Rectifiers

Raising the plant voltage on a working system is left to the discretion of

the user. This test could disrupt power to working equipment. If the test

is performed, verify that the plant is in FLOAT mode and that rectifier

voltage has been set to the normal level after completing the test.

Tests must be done with batteries connected, or else when the rectifiers

shut down, the controller will also shut down.

Step Action

1

From the front panel, follow the path <MENU> → CONFIG

→ THRESH → HFV (FLOAT). Use the <Adjust> keys to

change the value of the HFV threshold to a level below the

plant voltage noted above. Press <ENTER> to save the

change.

2

Observe that the controller initiates a Power Minor alarm

(PMN) and illuminates the RECT and MIN LEDs.

3

Follow the path <MENU> → CONFIG → THRESH →

HFV (FLOAT) and restore the threshold to it's original

setting. Press <ENTER> to save the change.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 11

Page 24

Galaxy Power System Verification Procedures

High Float Voltage Alarm/High Voltage Shutdown Alarm

Tests, continued))

HVSD Test Procedure for Serial Rectifiers

There are three requirements for a serial rectifier to shut down upon a

controller-initiated High Voltage Alarm:

• The plant voltage must be above the level set for HV at the front

panel path: <MENU> → CONFIG → THRESH.

• The rectifier must be delivering a current exceeding 10% of it's

capacity.

• The rectifier's current output must be unbalanced by more than 10%

from the average output currents of the other rectifiers. Because this

is difficult to achieve in a simulation test of properly functioning

serial rectifiers, even with load share disabled, rectifiers are tested

one at a time rather than as a group. Slightly different test

procedures are used for special applications in batteryless plants.

Serial rectifiers have their own internal restart circuits that will function

3 times before the rectifier locks itself out and initiates a High Output

Rectifier Fail Alarm to the controller. If there is a sufficient interval

between restart and a subsequent shutdown the rectifier resets its restart

counter.

The controller initiates a restart signal a few seconds after the first RFA

(HO) alarm is received. After the second RFA (HO) is received, the

controller waits 5 minutes before sending one additional restart signal.

Do not raise the plant bus voltage if an active load is being served. To

test HVSD under this situation, ensure that sufficient battery reserve is

connected to the plant bus to support the plant load. The battery may

start sharing some load and BD alarms may turn on during this test.

2 - 12 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 25

Galaxy Power System Verification Procedures

High Float Voltage Alarm/High Voltage Shutdown Alarm

Tests, continued)

HVSD Test

Procedure for

Serial Rectifiers,

continued

Step Action

1

Turn Off all rectifiers except the rectifier under test by

operating their power switches to STANDBY. Ensure that

the system is loaded to at least 10-90% of the rectifiers’

output capacity.

2

From the front panel follow the path <MENU> → CONFIG

→ THRESH and note the value of the HV (FLOAT)

threshold.

3

Press the <ESC> key to return to the Configuration screen.

4

Follow the path RECT MNGR → [RECT OPER] →

PLANT V (FLOAT) from the Configuration screen.

Note: Menu item in [] used in intelligent controllers only.

5

Use the <ADJUST> keys to change the value of the plant

voltage to a level above the HV (FLOAT) setting noted

above.

6

Press <ENTER> to save the change.

Continued on next page.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 13

Page 26

Galaxy Power System Verification Procedures

High Float Voltage Alarm/High Voltage Shutdown Alarm

Tests, continued)

HVSD Test

Procedure for

Serial Rectifiers,

continued

Step Action

Observe the following:

7

• When the voltage increases to the HV (FLOAT) level the

rectifier shuts down.

• The Green ON LED on the rectifier blinks, the ALM

LED on the rectifier is not lit.

• After 5-6 seconds the rectifier initiates its own restart

signal again, raising the plant voltage.

• The rectifier will shutdown and restart three additional

times.

• Upon the fourth shutdown, the rectifier's ALM LED

lights and the rectifier's display indicates “HO.”

• The controller receives the RFA signal from the rectifier

and initiates a restart signal 5-6 seconds later.

• The rectifier restarts again, raising plant voltage.

• The rectifier shuts down and restarts four additional

times.

• During these shutdowns the Green ON LED on the

rectifier blinks, the ALM LED on the rectifier is not lit.

• Upon the fourth shutdown, the rectifier's ALM LED

lights and the rectifier’s display indicates “HO.”

• An external RFA office alarm is generated.

Continued on next page.

2 - 14 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 27

Galaxy Power System Verification Procedures

High Float Voltage Alarm/High Voltage Shutdown Alarm

Tests, continued)

HVSD Test

Procedure for

Serial Rectifiers,

continued

Step Action

8

The controller will wait 5-6 minutes and issue one final

restart signal, initiating the final sequence of shutdown and

restart events before the rectifier locks out, requiring

personnel intervention.

Prior to this occurring do the following:

a. From the front panel follow the path <MENU> →

CONFIG → RECT MNGR → [RECT OPER] → PLANT

V (FLOAT).

Note: Menu item in [] used in intelligent controllers only.

b. Use the <ADJUST> keys to change the value of the plant

voltage to its normal level. Press <ENTER> to save the

change.

c. Press <MENU> and select MAINT OPER → RECT

RESTART. Press <ENTER> to restart the rectifier.

Note: Restarting the rectifier from the front panel in this

manner, rather than toggling the rectifier's ON/

STANDBY switch, resets the HVSD timer so that another

rectifier can be tested immediately. Testing of the

additional rectifiers in the same manner is at the user’s

discretion

.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 15

Page 28

Galaxy Power System Verification Procedures

Battery on Discharge Alarm Test

Introduction If the BD alarm was observed during the High Voltage Shutdown test

this test can be disregarded.

If the BD alarm was not observed during the HVSD test, perform the

following test procedure:

Procedure

Step Action

1

From the front panel follow the path <MENU> → CONFIG

→ THRLD and observe the setting of the BD (FLOAT)

threshold.

2

Switch some of the rectifiers to STANDBY or OFF, until the

remaining rectifiers go into a current limit and plant voltage

drops below BD (FLOAT) threshold. Observe the active BD

and MAJ LEDs and asserted PMJ and BD relays.

3

Restart the rectifiers to retire alarms and return the plant

voltage to float.

Another way to perform the test is to increase the BD threshold above

the normal plant float voltage, using the following steps:

Step Action

1

From the front panel follow the path <MENU> → CONFIG

→ THRLD and observe the setting of the BD (FLOAT)

threshold.

2

Increase the BD threshold value above the float voltage.

Observe the active BD and MAJ LEDs and asserted PMJ

and BD relays.

3

Reset the BD alarm to the original setting.

2 - 16 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 29

Galaxy Power System Verification Procedures

Rectifier Fail Alarm Test

Introduction If the RFA alarm was observed during the High Voltage Shutdown Test

no separate test is required.

If the High Voltage Shutdown Test is not performed, generate an RFA

(Rectifier Fail Alarm) in each of the plant rectifiers individually, using

the procedures below:

Lucent Serial Rectifiers 595 and 596 Series

J855- or J874-Series Rectifiers

For Lucent 595 and 596 Series rectifiers, follow the steps in the table

below:

Step Action

1

2

Turn the rectifier Off. Wait for the rectifier to power down.

Insert a plastic stick between the front panel grills to block

the fan rotation.

3

Turn the rectifier On. After several seconds, the rectifier

will issue an RFA alarm and the plant will generate a PMN.

4

Remove the fan obstruction and toggle the power switch

Off and back On to restart the rectifier and retire the alarm.

5

Generate an RFA (Rectifier Fail Alarm) in each of the plant

rectifiers individually and verify that the RECT and

MINOR LEDs become active along with the Power Minor

and RFA alarm relays.

For Lineage Power J855-series or J874-series rectifiers an RFA is easily

accomplished by operating the “+V” or “-V” fuse alarm circuit by

inserting a paper clip into the alarm indicating hole of the fuse holder.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 17

Page 30

Galaxy Power System Verification Procedures

Rectifier Fail Alarm Test, continued

150A SMR Rectifiers

For Lineage Power J85702E-series (150A SMR) rectifiers an RFA may

be generated by using the following procedure:

Step Action

1

Set the rectifier to the Single Power Module Assembly

(PMA) Fail option by placing BGB SW100-8 to OPEN.

2

Set the Output CB switch of all three PMAs inside the

rectifier to the Off position,

3

Raise the rectifier voltage (measured via the rectifier voltage

test jacks on the front panel of the rectifier) above the

Backup HVSD level for the rectifier (set via

SW 100-6/7 on the BGB display/control card of the

rectifier).

4

Verify the RFA in the controller.

5

Lower the rectifier voltage once again to plant float and

restart it to retire the RFA.

6

Close the PMA Output CB switch of all three PMAs and

verify normal rectifier operation

Note: Load share should be disabled (BGB SW100-5) anytime rectifier

voltage is adjusted in these rectifiers with the PMA Output CBs closed.

2 - 18 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 31

Galaxy Power System Verification Procedures

Rectifier Fail Alarm Test, continued

50A SMR Rectifiers

Use the following procedure to generate an RFA in Lineage Power 50A

SMR Series rectifiers:

Step Action

1

Set the Output CB switch of the rectifier to the Off position.

2

Raise the rectifier voltage (measured via the rectifier voltage

test jacks on the front panel of the rectifier) above the

Backup HVSD level for the rectifier (set via SW100-6/7 on

the front of the rectifier).

3

Verify RFA in the controller.

4

Lower the rectifier voltage once again to plant float and

restart it to retire the RFA.

5

Close the Output CB switch and verify normal rectifier

operation.

Note: Load share should be disabled (BGB SW100-5) anytime that

rectifier voltage is adjusted in these rectifiers with the Output CBs

closed.

If an intelligent controller is being tested, History for all tested alarms

can be reviewed under the front panel path: MAIN → HISTORY.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 19

Page 32

Galaxy Power System Verification Procedures

Terminate Rectifier (TR) Test

Introduction The TR test may be performed even if rectifier sequencing is not

planned to be utilized, as it provides a convenient means of testing that

the controller recognizes all plant rectifiers and is able to control each

over their assigned ports.

Refer to Figures 2-1 and 2-2 for the BJT board of the rear access SC

controller and to Figures 2-3 and 2-4 for the BLG board of the front

access SCF controller.

Test Procedure One at a time, connect a test lead on the TB3 terminal block of the BJT

(SC) or BLG (SCF) termination board, from position 13 (ETRR/

Ground) to position 8 (TR1), 9 (TR2), 10 (TR3), and 11 (TR4). The

rectifiers will shut down in groups as depicted below and remain Off

until the connection is removed at which time they automatically restart.

TR1: G01, G02, G09, G10, G17, G18

TR2: G03, G04, G11, G12, G19, G20

TR3: G05, G06, G13, G14, G21, G22

TR4: G07, G08, G15, G16, G23, G24

Caution: When this test is performed on a live plant, it may cause a

battery discharge (BD) to occur. Ensure that the battery reserve is able

to support the plant load.

2 - 20 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 33

Galaxy Power System Verification Procedures

Fuse Alarm Test

Major Fuse Alarm Major Fuse Alarm may be tested by placing a blown fuse in the alarm

fuse position of any distribution fuse position in the plant or by inserting

a paper clip into the alarm indicating hole of its fuse holder. For

distribution circuit breakers, temporarily connect the pins 8 and 9 of any

KS22010 or KS22012 style circuit breakers of any breaker together.

For GPS cabinets, fuse alarms may be simulated at the BNL1 or BNL7

alarm card by strapping FAJ on these cards to the hot bus (P4-1 for

BNL1, P5-6 for BNL7).

The DIST and MAJ LEDs and Power Major and MJF alarm relays will

be active. Alarms should be tested in each distribution bay of the plant

to verify the integrity of the alarm bus throughout the plant. If the

distribution bays are equipped with “Bay Fuse Alarm” indicating LEDs,

also verify that this LED activates during these tests for the bay in which

the alarm originates (and not in any other).

For GPS cabinets, the alarm lamp of the cabinet containing the

controller will always activate, in addition to the cabinet containing the

alarm.

Minor Fuse Alarm Refer to Figures 2-1 and 2-3, respectively, for location of the BJF fuse

termination board in the SC and SCF controllers.

Minor Fuse Alarm may be tested by placing a blown fuse in the alarm

fuse position of the plant Capacitor Charge circuit (if equipped) or by

inserting a paper clip into the alarm indicating hole of its fuse holder.

Alternately, replace one of the unused regulation fuses of the BJF fuse

termination board with a blown GMT type fuse. In either case, the MIN

and either DIST or RECT panel LEDs will activate, along with the

Power Minor and MNF alarm relays.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 21

Page 34

Galaxy Power System Verification Procedures

Modem/Data Switch

Remote Peripheral Monitoring

If the Modem (L-AE) and/or Data Switch (L-AH) options have been

provided, they can be tested after wiring and configuration is completed

by dialing into the modem port and, if equipped, passing through to the

devices wired to the equipped Data Switch ports. Refer to the controller

product manual for the T1.317 Data Switch commands required.

Note: If the controller is regularly accessed using a modem, from a

remote monitoring station, this test may not be necessary.

If the Remote Peripheral Monitoring option (L-AG) and J85501G1

monitoring units have been equipped, each channel configured may be

tested for accuracy with a clamp-on ammeter (for Shunt Monitor

channels), voltmeter (for Voltage Monitor channels), or thermometer

(for Temperature channels). If alarms have been configured through the

use of User Defined Event (UDE), they may also be tested by adjusting

their program line to move the thresholds or by adjusting the channel

programming to change the value reported for the channel. Refer to the

Remote Peripheral Monitoring System product manual for complete

feature descriptions of each of these optional monitoring devices.

Rectifier Sequencing

Once set, it is not recommended to change these UDE program lines,

unless it is attempted by a qualified and skilled professional. Refer to the

product manual if it is required to make any adjustments/changes to the

RPM modules or UDE.

If Rectifier Sequencing in an intelligent controller has been enabled (via

EasyView path: MAIN → CONFIGURE → RECTIFIERS), testing can

be completed by temporarily using a shorting clip across TB3 positions

12-13 (ETR/ETRR) on BJT board of the rear access SC controller

(Figure 2-2) and the BLG board of the front access SC controller (Figure

2-4). This will cause all rectifiers configured for Rectifier Sequencing

control to shut Off. Releasing this clip will then cause the rectifiers to

restart sequentially in the manner in which they have been programmed.

2 - 22 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 35

Galaxy Power System Verification Procedures

Energy Management

Overview The Energy Management algorithm exercises all rectifiers on a monthly

basis, guaranteeing that every connected rectifier is operated for at least

24 hours each month. All connected rectifiers that have not operated a

total of 24 hours in the previous monthly cycle will be turned on by the

controller on the first Wednesday of the next month at 10:00 a.m. for 24

hours.

Energy Management is available only in the intelligent controller and

must be enabled in both hardware and software. Enable the hardware

switch by setting SW204-1 on the BJH board to 1. From the front panel

follow the path: <MENU> → CONFIG → RECT CTR → EFFIC to

enable the software switch. Energy Management can be enabled in

EasyView by following the path: CONFIGURE → PLANT →

HARDWARE AND SOFTWARE.

Energy Management is enabled only if all connected rectifiers provide

a load signal to the controller via the VI (Voltage proportional to Load)

circuit within each Lucent J855-series or J874-series rectifier control

circuitry. Controllers using the BJC2 rectifier interface packs, used with

rectifiers that do not issue VI signals, instead monitor the mV signal

directly off the rectifier load shunt. In either case, the Energy

Management algorithm requires that the individual rectifier loads be

reported to the controller accurately. Verify that the load reported via

front panel or EasyView path against each rectifier agrees with the

actual load calculated from its shunt mV reading or read from its front

panel. If necessary, adjust the VI circuit of each rectifier as outlined in

the appropriate rectifier product manual. Accuracy of 2% should be

achieved.

Note: It may not be necessary to perform the following Energy

Management test procedure if the rectifiers used are Lineage Power

serial rectifiers. Also, if a TR (terminate rectifier) status is observed on

the LED display, it indicates that the Energy Management feature is

functioning.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 23

Page 36

Galaxy Power System Verification Procedures

Energy Management, continued

Procedure

Step Action

1

Reset the BJH intelligent controller (see Figure 2-3) and

stabilize the load at some level at which at least one rectifier

becomes unnecessary. After 10 minutes the first unneeded

rectifier will be turned Off by the controller. If additional

rectifiers can be shut down, they will follow individually at

10 minute intervals.

2

If the plant load can be varied, increase it to the point where

another rectifier is necessary after the controller has

completed its shutdowns. One (or more as required) of the

rectifiers will be restarted immediately when the load

exceeds the capacity of the current on-line rectifiers

3

Observe that the BD alarm is inhibited during the rectifier

walk-in period.

2 - 24 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 37

Galaxy Power System Verification Procedures

Meter Calibration from the Front Panel

Voltage Calibration

Step Action

1

Using a calibrated DVM, measure the plant voltage from the

front panel voltage test jacks.

2

From the front panel press <MENU> → CONFIG → PLANT.

Using the Arrow keys, reset the plant voltage reading by

selecting RST PLV. Press <ENTER> to reset. This will

remove any pre-existing user calibrated values if they exist.

3

Press the <MENU> key, wait five seconds, and go back to the

CONFIG → DC PLT screen. Move to ADJ PLV on the menu

and use the <ADJUST> keys to calibrate the plant voltage to

match the reading of the DVM. Press <ENTER> to use the

new calibrated plant voltage.

4

Press the <ESCAPE> key until the default screen is displayed.

Verify that the plant voltage reading reflects the same reading

as shown on the DVM. Note that in a serial plant, the actual

plant voltage reflected by the DVM will change, not the

reading reflected on the display.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 25

Page 38

Galaxy Power System Verification Procedures

Meter Calibration from the Front Panel, continued

Current Calibration

The following procedure is applicable only in plants with Load shunts

in a plant configured for “Centralized Architecture.”

Step Action

1

Using a calibrated DVM, measure the plant load from the

front panel current test jacks in mV.

2

To calculate the plant load, in amperes, as measured by the

DVM, divide the mV DVM reading by the rated shunt mV

value. Multiply this result by the shunt ampere rating. This

value is the plant load measured by the DVM, in amperes.

3

From the front panel press <MENU> → CONFIG → PLANT.

Using the Arrow keys, reset the plant current reading by

selecting RST PLI. Press the <ENTER> key to reset. This will

remove any pre-existing user calibrated values if they exist.

4

Press the <MENU> key, wait five seconds, and go back to the

CONFIG → PLANT screen. Move to ADJ PLI on the menu

and use the <ADJUST> keys to calibrate the plant load to

match the calculated plant load value. Press <ENTER> to use

the new calibrated plant load.

5

Press the <ESCAPE> key until the default screen is displayed.

Verify that the plant load reading reflects the new value.

2 - 26 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 39

Galaxy Power System Verification Procedures

Battery Discharge Test

Overview The Battery Discharge Test feature dynamically tests the health of the

system’s batteries by controlling rectifier voltage to allow the batteries

to discharge into the plant load. A Bell Labs patented algorithm collects

battery information during the discharge and predicts the battery reserve

time. To initiate the test, the plant must be operating in the Float mode

with no active alarms and only serial type rectifiers connected. The test

is completed when approximately 20 percent of anticipated battery

capacity is removed. During the test, slope thermal compensation and

boost modes will be temporarily disabled. The controller Reserve Time

field will display “Test in Progress” and the BAT LED and the BD

external alarm relay will be activated. BD and Very Low Voltage alarm

thresholds will be temporarily inhibited.

It is a good practice to do a discharge test on the batteries, at least once

a year, or more frequently, if required.

Note: The Battery Discharge Test is for informational and planning

purposes only. It does not constitute the basis for warranty resolutions.

The battery test is aborted if any of the following conditions occur:

• 100 minutes elapses and 20 percent capacity has not been removed

• Battery voltage declines to the highest of the following computed

values:

– (1.75 x No. of cells) + 1.2 [48V] or + .6 [24V]

– Highest LVD disconnect threshold + 1.2 [48V] or + .6 [24V]

– Converter disconnect threshold + 1.2 [48V] or + .6 [24V]

– (Configured end cell voltage x No. of cells) + 1.2 [48V] or + .6

[24V]

• A voltage sense fuse operates

• A rectifier fail alarm occurs

• Any serial communication failure occurs

• Any power major alarm occurs

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 27

Page 40

Galaxy Power System Verification Procedures

Battery Discharge Test, continued

Overview,

continued

Discharge Menu This menu allows you to configure the various parameters for the

The intelligent controller provides an enhanced battery discharge test

that makes even greater accuracy possible. Enabling the

“ENHANCED” software switch utilizes the Universal Reserve Time

Prediction algorithm, which takes into account the particular discharge

characteristics of the battery subsystem. The URPT feature requires that

battery temperature be monitored and several related battery parameters

be configured. Ensure that the correct battery model is chosen for the

plant.

Note: The Battery Discharge Test feature is available with controller

software Version 6.5 for the SC controller.

Battery Discharge Test and Reserve Time Predictor features of the

controller:

MENU → BATTERY MANAGEMENT → BAT DISCH

BATTERY DISCHARGE TEST

BAT TEST : EN ENHANCED : EN

BAT TYPE : EN CELL STRING : 12

NUM STRING: 24 END V/CELL : 1.75

BAT CLASS : FLOODED

BAT TEST: Enable Battery Discharge Test by using the <+> and <->

keys to toggle between enable or disable. Press <ENTER> to save.

ENHANCED: Use the <+> and <-> keys to enable enhanced feature, if

intelligent controller is present.

BAT TYPE: Use the <+> and <-> keys to select the battery installed on

site. (The Menu contains a list of 10 batteries.) Press <ENTER> to save.

Note: This feature is only available with the intelligent option.

CELL STRING: Use the <+> and <-> keys to select the number of

cells per string. (Select 12 for a 24V plant, or 24 for a 48V plant.) Press

<ENTER> to save.

2 - 28 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 41

Galaxy Power System Verification Procedures

Battery Discharge Test, continued

Discharge Menu,

continued

Configuration Configuration may be done locally at the front panel or remotely via

NUM STRING: Use the <+> and <-> keys to select the number of

strings installed on the site. (Range is 1 to 32 strings, default is 2.) Press

<ENTER> to save.

END V/CELL: Use the <+> and <-> keys to select the cell voltage at

the end of the discharge test. (Default value is 1.75V, and is adjustable

between 1.75V and 1.95V.) Press <ENTER> to save.

BAT CLASS: Use the <+> and <-> keys to select flooded or sealed.

Press <ENTER> to save. Note: Use this feature only is the basic

controller is present.

EasyView interface.

Basic: MENU → CONFIG.. → BAT TEST

Intelligent: MENU → CONFIG.. → BAT MNGR → BAT DISCH..

EasyView: CONFIG → BATTERY MANAGEMENT → RESERVE

To initiate the test, the plant must be operating in the Float mode with

no active alarms and only serial type rectifiers connected. The test can

be controlled either locally at the front panel or remotely via EasyView

interface by toggling the BAT DISCH TST software switch.

Basic: MENU → MAINT OPER.. → BAT DISCH TST

Intelligent: MENU → MAINT OPER.. → BAT DISCH TST

EasyView: CONTROL → BATTERY TEST

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 29

Page 42

Galaxy Power System Verification Procedures

Battery Discharge Test, continued

Procedure

Step Action

1

Enable BATT TEST:

MENU → BATTERY MANAGEMENT → BAT DISCH

Note: Once the other parameters on this screen are configured,

do not modify until any system changes are made.

2

Press <ENTER> to confirm test to proceed. Controller will

perform the battery discharge test.

3

Ve r if y :

• BD alarm will turn On and Status LED will show Green

(NORM).

• Controller display will show BATT TEST at bottom left

and RESERVE TEST IN PROGRESS on bottom right.

4

To abort Battery Discharge Test:

a. Follow menu path

MENU → ΜΑΙΝΤ ΟPER → BAT DISCH TST

b. Verify that display shows “Battery Discharge Test

Aborted.”

Note: The Battery Discharge Test is for informational and planning

purposes only. It does not constitute the basis for warranty resolutions.

If the test is aborted due to an alarm, the Reserve Time message is

displayed as “Alarm Abort” and a user clearable minor alarm is

generated. If the test is aborted due to any of the other conditions shown

above, the Reserve Time message is displayed as “Check Battery” and

a user clearable minor alarm is generated.

2 - 30 Galaxy SC Controller Performance Verification Procedures Issue 3 January 2008

Page 43

Galaxy Power System Verification Procedures

Battery Discharge Test, continued

Test Completion The test is completed when approximately 20 percent of anticipated

battery capacity is depleted.

At the completion of the test, BD and VLV alarm thresholds continue to

be inhibited for 3 additional minutes to allow the batteries to recharge.

A successful test displays the calculated value in the Reserve Time field;

default menu in the intelligent controller or menu path MENU →

MAINT OPER.. in the basic controller. Reserve time in EasyView is

displayed at menu path: STATUS → DC PLANT.

Issue 3 January 2008 Galaxy SC Controller Performance Verification Procedures 2 - 31

Page 44

Page 45

Galaxy Power System Verification Procedures

3 Galaxy Millennium Controller

Performance Verification

Procedures

Introduction The procedures in this section may be used to test the different alarms in

a live Galaxy Millennium Controller system.

Follow the steps of the procedures in the order they are given.

Tools The following tools are required to complete the tests described in this

section:

• Digital Voltmeter (DVM) with dc accuracy of at least 0.05%

• Short length of wire or clip lead for jumper

• Jeweler’s screwdriver

Precautions Before performing the test procedures, verify that the following

conditions exist:

• All rectifiers are functioning properly.

• Plant batteries are fully charged and are ready to support a load.

(See Caution below.)

Caution: When Alarm Tests are performed on a live plant, some of

the tests will cause a battery discharge to occur. In this case, ensure

that the plant batteries are capable of supporting the load. It is

recommended that a battery discharge test be performed before

proceeding with other tests.

Follow the steps of the procedures in the order they are given.

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 1

Page 46

Galaxy Power System Verification Procedures

Lamp Test Depress the <LAMP TEST> key on the controller’s front display

interface. All LEDs on the controller front panel, controller boards, and

Lucent serial rectifiers will turn on momentarily and then retire.

Alarm Test

Overview Alarm Test provides a method of testing the operation of all or any of

the plant alarm relays and their wiring to the connected alarm system.

This test cannot be done if any alarms are active. It may also be desirable

to perform this test occasionally after the plant is in service to verify the

integrity of the office alarms for the power plant. Alarm Test may be

performed locally or from a remote terminal.

The Alarm Test feature will, in succession, operate each of the controller

alarm relays. With the basic controller, the default duration is one

minute. With the intelligent option for the controller, the selection of the

relays to be operated and default duration can be changed using the

EasyView interface.

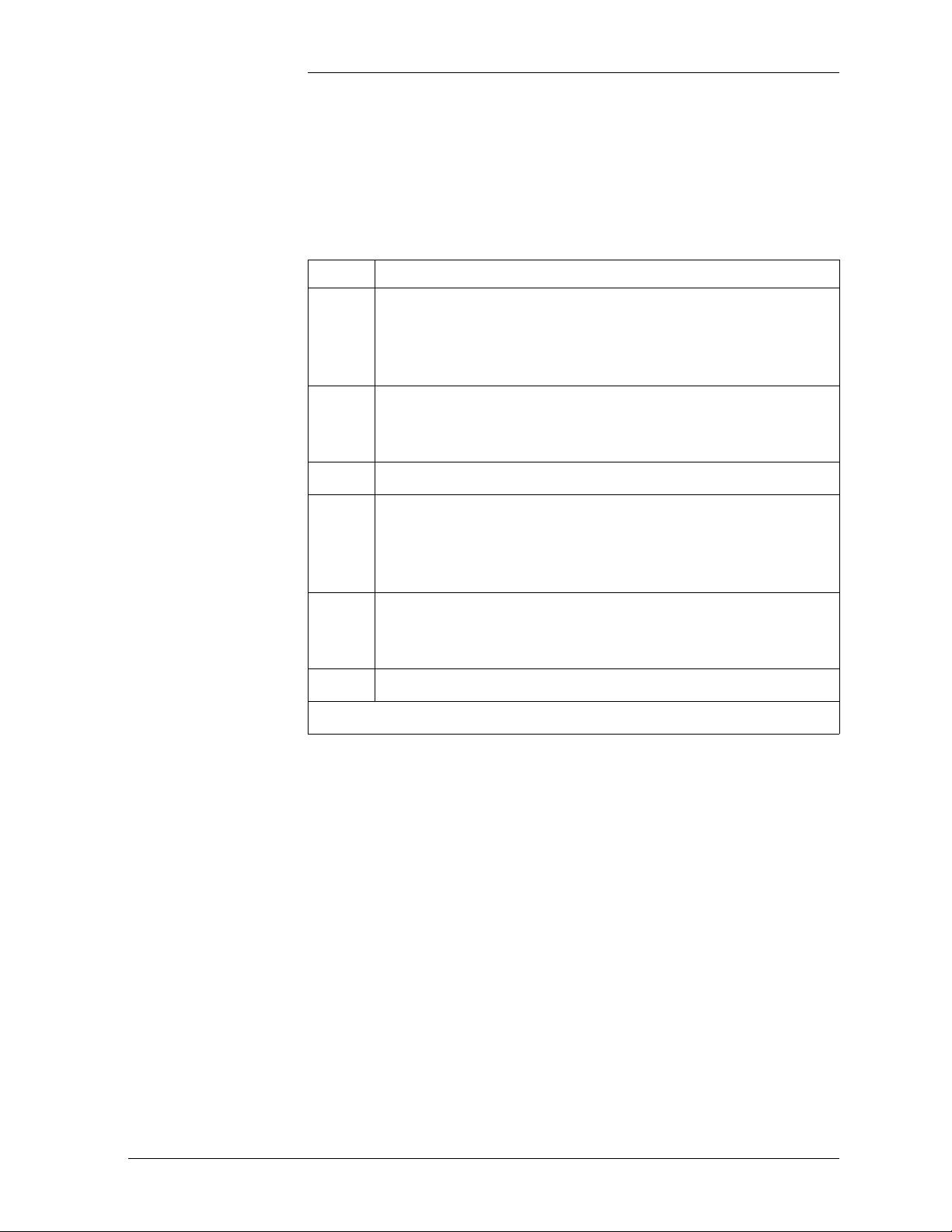

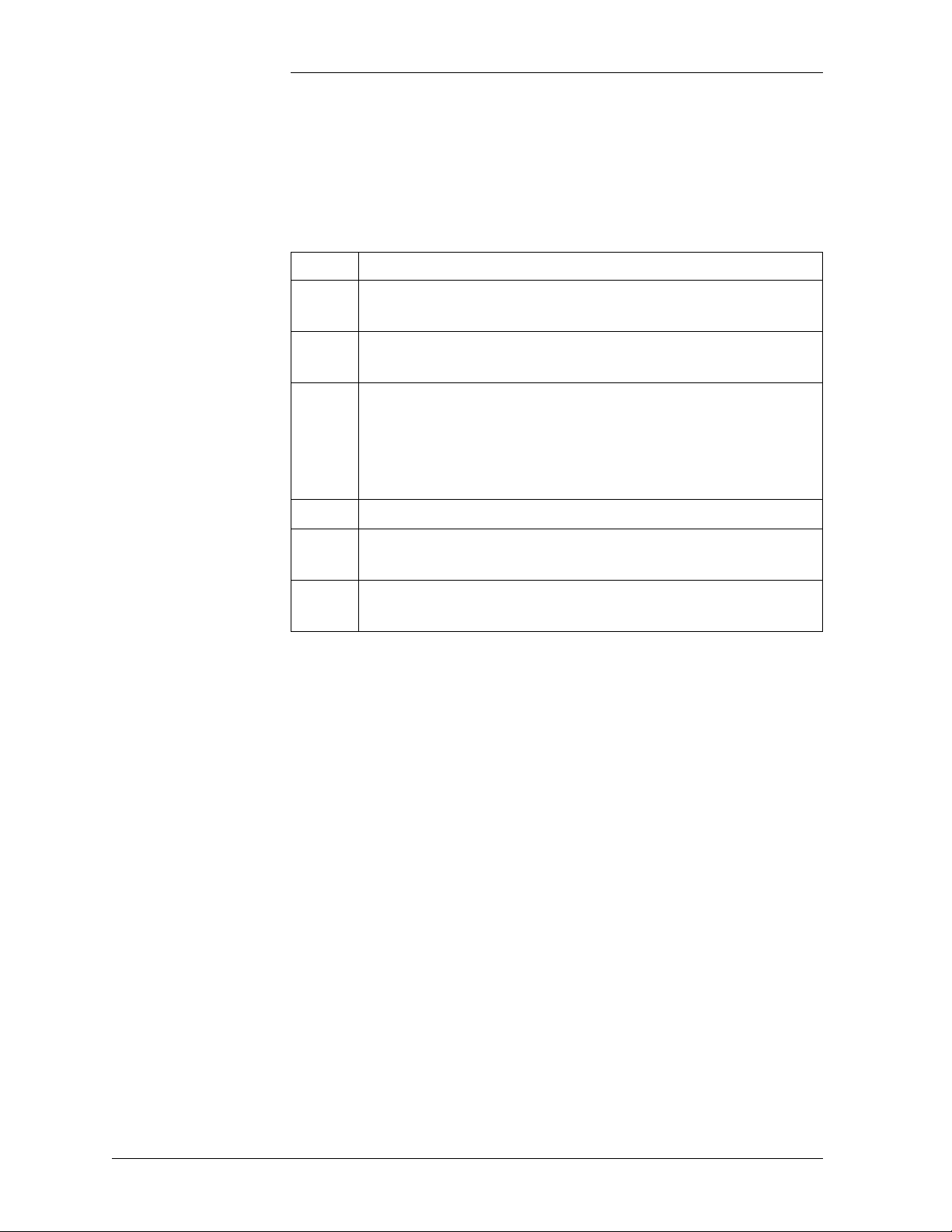

Switch Positions Figure 3-1 shows the switch positions referred to in these procedures.

Controller Fuses

F1 F2 F3 F4 F5

BSM Modem Board

BSH Basic Controller Board

BSJ Intelligent Controller Board

F1 - Option Power

F2 - Intelligent Power

F3 - Basic Power

F4 - Voltage Sense

F5 - Alarm Battery Supply (ABS)

BSL Alarm Termination Board

SW204 (on BSJ Board)

SW202 (on BSH Board)

BSW Data Switch Board

(mounting location)

Figure 3-1: Galaxy Millennium Controller Switch Positions

3 - 2 Galaxy Millennium Controller Performance Verification Procedures Issue 3 January 2008

Page 47

Galaxy Power System Verification Procedures

Alarm Test, continued

Local Alarm Test Refer to Figure 3-1 for the Millennium switch positions referred to in

this test.

Prior to performing an Alarm Test, hardware switch SW202-5 on the

BSH board must be enabled, in addition to the software switch located

at menu path:

Basic: <MENU> → CONFIG → ALARM → TEST ALM

Intelligent: <MENU> → CONFIG → ALARM → TEST ALM

If HVSD is desired during the test, BSH SW202-4 must also be enabled,

along with the appropriate software switch found on the front panel

under the path: MAIN → CONFIG → ALARM → TEST HV, and each

plant rectifier must have a load of at least 10% of its capacity.

To perform the Alarm Test from the front panel, follow the menu path:

Basic: <MENU> → MAINT OPER → ALARM TEST

Intelligent: <MENU> → MAINT OPER → ALARM TEST

As an alternative to the front panel configuration of the Alarm Test

software switch, it may be also configured within EasyView under the

path: CONFIGURE → DC PLANT → HARDWARE & SOFTWARE

CONFIGURED.

Pressing the <ENTER> key while the cursor is on the ALARM TEST

field will provide the message “ALARM TEST STARTED.” Use the

<ESC> key to return to the MAINTENANCE OPERATION screen and

follow the relay operation in the ALARM TEST STAT: field. Pressing

<ENTER> while the cursor is on the ALARM TEST field will restart

the test.

Note: Front panel LEDs do not activate during the Alarm Test. the

alarms can be monitored by checking on the BSL alarm board.

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 3

Page 48

Galaxy Power System Verification Procedures

Alarm Test, continued

Local Alarm Test,

continued

The Alarm Test will operate, in sequence, each of the relays shown

below for a default interval of approximately 60 seconds. This interval

for each relay’s activation during this test may optionally be set in an

intelligent controller via EasyView path: MAIN → CONFIGURE →

ALARM TEST.

Initiate Alarm Test locally by pressing the <MENU> key to bring up the

MAIN screen and following the path: MAINT OPER → ALARM

TEST. The ALM TEST STAT field of this same screen can then be used

to follow the progress of the alarm text.

The progress of the activated relays can also be followed during the test

by sensing for continuity on the appropriate positions of the BSL alarm

board if the connected alarm system is not yet processing.

High Voltage Shutdown - HVSD*

Rectifier Fail Alarm Test - RFAT**

Power Critical - PCR

Power Major - PMJ

Power Minor - PMN

Major Fuse - MJF

Minor Fuse - MNF

Battery on Discharge - BD

AC Fail - ACF

Rectifier Fail Alarm - RFA

User Relay 3 - UR3***

High Voltage - HV

Controller - CTLR

User Relay 1 - UR1***

User Relay 2 - UR2***

*HVSD is optional.

**RFAT is an alarm test intended for use with non-serial type rectifiers

and has no function in this test.

***UR1, UR2, and UR3 are inhibited if LVD Contactors have been

configured and a Bay Interface Card is not configured in the system.

Follow the status of the test remotely with EasyView path: STATUS →

ALARM TEST.

3 - 4 Galaxy Millennium Controller Performance Verification Procedures Issue 3 January 2008

Page 49

Galaxy Power System Verification Procedures

Alarm Test, continued

Remote Alarm Test Using EasyView to perform the Alarm Test, hardware switches

SW202-5 on the BSH board and SW204-2 on the BSJ board (Figure

3-1) must first be enabled, in addition to the software switches located

at menu path.

EasyView: CONFIGURE → DC PLANT → HARDWARE AND

SOFTWARE CONFIGURED

Both the Alarm Test and Remote Alarm Test fields must be enabled.

To start the Alarm Test in EasyView, follow the menu path:

EASYVIEW: CONTROL → ALARM TEST

A dialog box will appear with the status of the alarm relays being tested.

See above for the order in which the alarm relays will operate.

The selection of relays to be operated, as well as the duration of relay

operation, may be selected in EasyView by following the menu path:

EASYVIEW: CONFIGURE → ALARM TEST

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 5

Page 50

Galaxy Power System Verification Procedures

High Float Voltage Alarm Test

Introduction The High Voltage Alarm Test can be done by either raising the plant

voltage above the threshold set for HFV (High Float Voltage) or by

lowering the threshold for this condition to make it active.

Note: HFV is an alarm-only that can be used to notify users of an

impending HV condition before the need for a shutdown arises.

Raising the plant voltage on a working system is left to the discretion of

the user. This test could disrupt power to working equipment. If the test

is performed, verify that the plant is in FLOAT mode and that rectifier

voltage has been set to the normal level after completing the test.

Tests need to be done with batteries connected, or else when the

rectifiers shut down, the controller will also shut down.

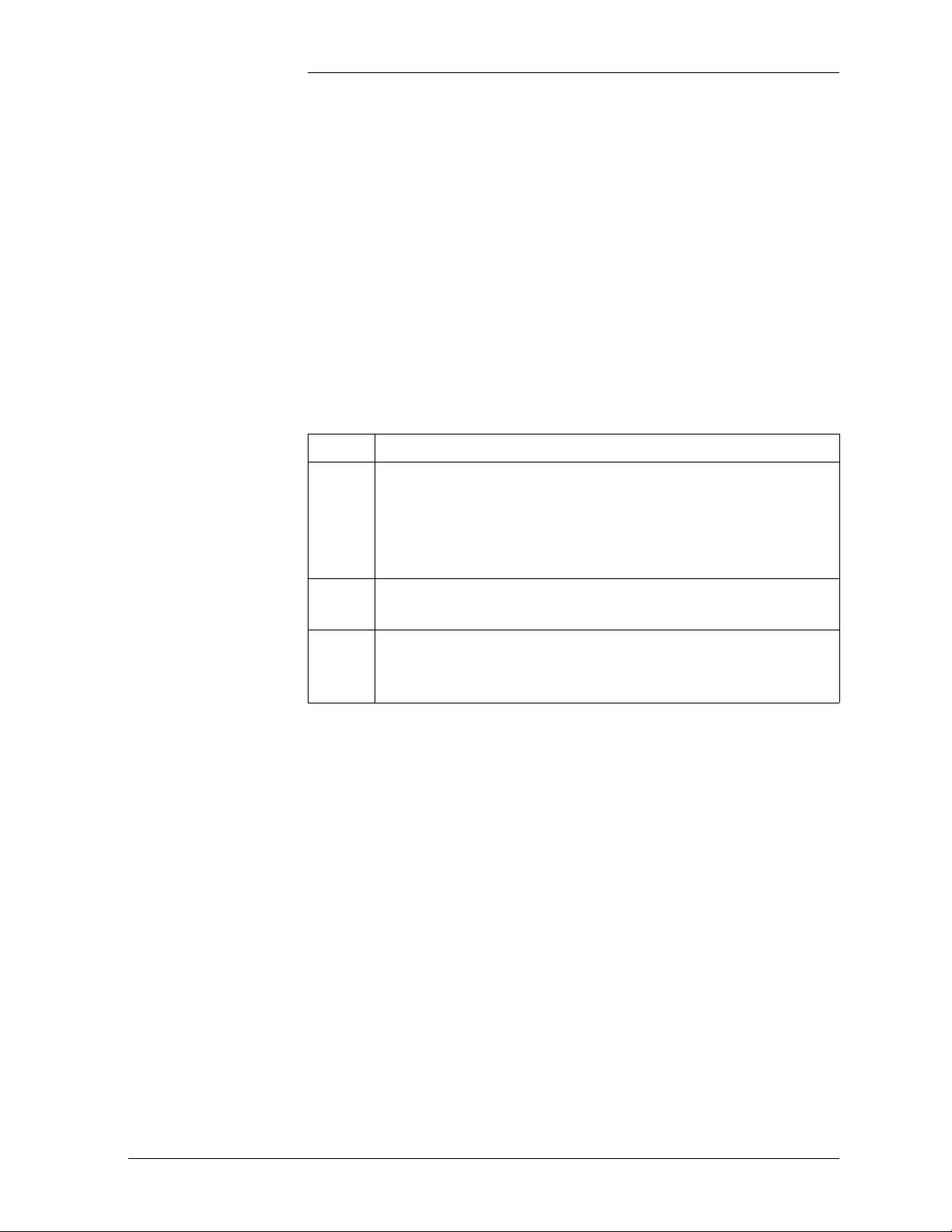

Preparations Note the value of plant voltage from the Default screen. Use the

following table to record settings before beginning the test procedures:

Plant Nominal Float

Voltage

HV HFV

Testing High Float Voltage Alarms

Step Action

1

From the front panel, follow the path <MENU> → CONFIG

→ THRESH → HFV (FLOAT). Use the <Adjust> keys to

change the value of the HFV threshold to a level below the

plant voltage noted above. Press <ENTER> to save the

change.

2

Observe that the controller initiates a Power Minor alarm

(PMN) and illuminates the RECT and MIN LEDs.

3

Follow the path <MENU> → CONFIG → THRESH →

HFV (FLOAT) and restore the threshold to it's original

setting. Press <ENTER> to save the change.

3 - 6 Galaxy Millennium Controller Performance Verification Procedures Issue 3 January 2008

Page 51

Galaxy Power System Verification Procedures

High Voltage Shutdown Test

Overview A High Voltage Shutdown signal (HVSD) may optionally be sent to the

rectifiers during the alarm test by enabling the hardware switch

SW202-4 on the BSH board and the software switch at menu path:

Basic: <MENU> → CONFIG → ALARM → TEST HV

Intelligent: <MENU> → CONFIG → ALARM → TEST HV

Use the ADJUST <+> <-> keys to change the value of the TEST HV

field, then press <ENTER> to save the change.

Note: The High Voltage Shutdown Test is not recommended for an

existing installation. However, if this test must be done, make sure that

the battery reserve can support the load for the period until the rectifier

is recycled.

Verify the Auto Restart hardware switch at SW202-7 on the BSH board

is set to 1 (Enabled). Verify the software switch for the Auto Restart

feature is enabled from the front panel. MAIN → CONFIG → RECT

CTR → AUTO RST

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 7

Page 52

Galaxy Power System Verification Procedures

High Voltage Shutdown Test, continued

Serial Rectifiers There are three requirements for a serial rectifier to shut down upon a

controller-initiated High Voltage Alarm:

• The plant voltage must be above the level set for HV at the front

panel path: <MENU> → CONFIG → THRESH.

• The rectifier must be delivering a current exceeding 10% of it's

capacity.

• The rectifier's current output must be unbalanced by more than 10%

from the average output currents of the other rectifiers. Because this

is difficult to achieve in a simulation test of properly functioning

serial rectifiers, even with load share disabled, rectifiers are tested

one at a time rather than as a group. Slightly different test

procedures are used for special applications in batteryless plants.

Note: In an active plant with serial rectifiers the plant High Voltage

(HVSD) test can be performed with only one rectifier in operation, in

order to satisfy all three conditions mentioned above.

Serial rectifiers have their own internal restart circuits that will function

3 times before the rectifier locks itself out and initiates a High Output

Rectifier Fail Alarm to the controller. If there is a sufficient interval

between restart and a subsequent shutdown the rectifier resets its restart

counter.

The controller initiates a restart signal a few seconds after the first RFA

(HO) alarm is received. After the second RFA (HO) is received, the

controller waits 5 minutes before sending one additional restart signal.

3 - 8 Galaxy Millennium Controller Performance Verification Procedures Issue 3 January 2008

Page 53

Galaxy Power System Verification Procedures

High Voltage Shutdown Test, continued

Battery Plant HVSD Test

Step Action

1

Turn Off all rectifiers except the rectifier under test by

operating their power switches to STANDBY. Perform these

tests when loads provide 10-90% of the rectifiers output

capacity.

2

From the front panel follow the path <MENU> → CONFIG

→ THRESH and note the value of the HV (FLOAT)

threshold.

3

Press the <ESC> key to return to the Configuration screen.

4

Follow the path RECT MNGR → [RECT OPER] →

PLANT V (FLOAT) from the Configuration screen.

Note: Menu item in [] used in intelligent controllers only.

5

Use the <ADJUST> keys to change the value of the plant

voltage to a level above the HV (FLOAT) setting noted

above.

6

Press <ENTER> to save the change.

Continued on next page.

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 9

Page 54

Galaxy Power System Verification Procedures

High Voltage Shutdown Test, continued

Battery Plant

HVSD Test,

continued

Step Action

7

Observe the following:

• When the voltage increases to the HV (FLOAT) level the

rectifier shuts down.

• The Green ON LED on the rectifier blinks, the ALM

LED on the rectifier is not lit.

• After 5-6 seconds the rectifier initiates its own restart

signal again, raising the plant voltage.

• The rectifier will shutdown and restart three additional

times.

• Upon the fourth shutdown, the rectifier’s ALM LED

lights and the rectifier’s display indicates “HO.”

• The controller receives the RFA signal from the rectifier

and initiates a restart signal 5-6 seconds later.

• The rectifier restarts again, raising plant voltage.

• The rectifier shuts down and restarts four additional

times.

• During these shutdowns the Green ON LED on the

rectifier blinks and the ALM LED on the rectifier is not

lit.

• Upon the fourth shutdown, the rectifier’s ALM LED

lights and the rectifier’s display indicates “HO.”

• An external RFA office alarm is generated

Continued on next page.

3 - 10 Galaxy Millennium Controller Performance Verification Procedures Issue 3 January 2008

Page 55

Galaxy Power System Verification Procedures

High Voltage Shutdown Test, continued

Battery Plant

HVSD Test,

continued

Step Action

8

The controller will wait 5-6 minutes and issue one final

restart signal, initiating the final sequence of shutdown and

restart events before the rectifier locks out, requiring

personnel intervention.

Prior to this occurring do the following:

a. From the front panel follow the path <MENU> →

CONFIG → RECT MNGR → [RECT OPER] → PLANT

V (FLOAT).

Note: Menu item in [] used in intelligent controllers only.

b. Use the <ADJUST> keys to change the value of the plant

voltage to its normal level. Press <ENTER> to save the

change.

c. Press <MENU> and select MAINT OPER → RECT

RESTART. Press <ENTER> to restart the rectifier.

Note: Restarting the rectifier from the front panel in this

manner, rather than toggling the rectifier's ON/STANDBY

switch, resets the HVSD timer so that another rectifier can

be tested immediately. Testing of the additional rectifiers in

the same manner is at the user’s discretion

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 11

Page 56

Galaxy Power System Verification Procedures

Battery on Discharge Alarm Test

Rectifier

Fail Alarm

If the BD alarm was observed during the High Voltage Shutdown test

this test can be disregarded.

If the BD alarm was not observed during the High Voltage Shutdown

test, do the following:

Step Action

1

From the front panel follow the path <MENU> → CONFIG

→ THRLD and observe the setting of the BD (FLOAT)

threshold.

2

Switch some of the rectifiers to STANDBY or OFF, until the

remaining rectifiers go into a current limit and plant voltage

drops below BD (FLOAT) threshold. Observe the active BD

and MAJ LEDs and asserted PMJ and BD relays.

3

Restart the rectifiers to retire alarms and return the plant

voltage to float.

If the RFA alarm was observed during the High Voltage Shutdown Test

no separate test is required.

Tes t

If the High Voltage Shutdown Test is not performed, generate an RFA

(Rectifier Fail Alarm) in each of the plant rectifiers individually, using

the following procedure:

Step Action

1

Turn the rectifier Off. Wait for the rectifier to power down.

2

Insert a plastic stick between the front panel grills to block

the fan rotation.

3

Turn the rectifier On. Wait for a few seconds; the rectifier

must issue an RFA alarm and the plant must generate a

PMN.

4

Remove the fan obstruction and toggle the power switch Off

and back On to restart the rectifier and retire the alarm.

5

Generate an RFA (Rectifier Fail Alarm) in each of the plant

rectifiers individually and verify that the RECT and MINOR

LEDs become active along with the Power Minor and RFA

alarm relays.

3 - 12 Galaxy Millennium Controller Performance Verification Procedures Issue 3 January 2008

Page 57

Galaxy Power System Verification Procedures

Terminate Rectifier (TR) Test

Introduction The TR test may be performed even if rectifier sequencing is not

planned to be utilized, as it provides a convenient means of testing that

the controller recognizes all plant rectifiers and is able to control each

over their assigned ports.

Refer to Figure 3-1 for location of the BSL board.

Procedure One at a time, connect a test lead on the BSL alarm interface terminal

block from position 76 (ETRR/Ground) to position 73 (TR1), 79 (TR2),

85 (TR3), and 80 (TR4). The rectifiers will shut down in groups as

depicted below and remain Off until the connection is removed at which

time they automatically restart.

TR1: G01, G02, G09, G10, G17, G18

TR2: G03, G04, G11, G12, G19, G20

TR3: G05, G06, G13, G14, G21, G22

TR4: G07, G08, G15, G16, G23, G24

Note: This function can be performed by using EasyView.

Caution: When this test is performed on a live plant, it may cause a

battery discharge (BD) to occur. Ensure that the battery reserve is able

to support the plant load.

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 13

Page 58

Galaxy Power System Verification Procedures

Fuse Alarm Test

Introduction If there are any site installed fuses, they can be tested for alarm

functionality by generating alarms for the controller at these points. If

this is not possible, they can be tested by simulating alarm conditions at

the BSL board (see Figure 3-1) on the Millennium Controller by

following the steps given below.

Major Fuse Alarm (FAJ)

Minor Fuse Alarm (FAN)

Connect a jumper (through a 1K resistor) between Pin 63 (FAJ) and

Pin 93 (ABS) on BSL Board (see Tables 3B, 3C and 3D in the

Millennium controller manual for details of these pin assignments).

DIST and MAJ LEDs will light up. MJF default relay will be activated.

For GPS cabinets, fuse alarms may be simulated at the BNL1 or BL7

alarm card by strapping FAJ on these cards to the hot bus (P4-1 for

BNL1, P5-6 for BNL7).

Connect a jumper (through a 1K resistor) between Pin 65 (FAN) and

Pin 93 (ABS) on BSL Board (see Tables 3B, 3C, and 3D in the

Millennium controller manual for details of these pin assignments).

DIST and MIN LEDs will light up. MNF default relay will be activated.

3 - 14 Galaxy Millennium Controller Performance Verification Procedures Issue 3 January 2008

Page 59

Galaxy Power System Verification Procedures

Modem/Data Switch

Remote Peripheral Monitoring

If the Modem (L-AE) and/or Data Switch (L-AH) options have been

provided, they can be tested after wiring and configuration is completed

by dialing into the modem port and, if equipped, passing through to the

devices wired to the equipped Data Switch ports. Refer to the controller

product manual for T1.317 Data Switch commands.

Note: If the controller is regularly accessed using a modem, from a

remote monitoring station, this test may not be necessary.

If J85501G-1 Remote Peripheral Monitoring units have been equipped,

each channel configured may be tested for accuracy with a clamp-on

ammeter (for Shunt Monitor channels), voltmeter (for Voltage Monitor

channels), or thermometer (for Temperature channels). If alarms have

been configured through the use of User Defined channels, they may

also be tested by adjusting their program line to move the thresholds or

by adjusting the channel programming to change the value reported for

the channel.

Once set, it is not recommended to change these UDE program lines,

unless it is attempted by a qualified and skilled professional. Refer to the

product manual if it is required to make any adjustments/changes to the

RPM modules or UDE.

Rectifier Sequencing

If Rectifier Sequencing in an intelligent controller has been enabled (via

EasyView path: MAIN → CONFIGURE → RECTIFIERS), testing can

be completed by temporarily using a shorting clip across BSL2 Alarm

Interface positions 75-76 (ETR/ETRR) This will cause all rectifiers

configured for Rectifier Sequencing control to shut Off. Releasing this

clip will then cause the rectifiers to restart sequentially in the manner in

which they have been programmed.

Issue 3 January 2008 Galaxy Millennium Controller Performance Verification Procedures 3 - 15

Page 60

Galaxy Power System Verification Procedures

Energy Management

Overview The Energy Management algorithm matches the number and ampacities

of all available battery plant rectifiers to the actual plant load

requirements, favoring the shutdown of rectifiers when plant load

requirements are low enough to warrant selected rectifier shutdown,

thus maintaining the battery plant at maximum efficiency without

sacrificing reliability or creating nuisance alarms. The Galaxy controller

continuously monitors the number of connected rectifiers, their

individual ampacities, the actual output current being delivered by each

and the actual office load-current demand.

The Energy Management algorithm exercises all rectifiers on a monthly

basis, guaranteeing that every connected rectifier is operated for at least

24 hours each month. All connected rectifiers that have not operated a

total of 24 hours in the previous monthly cycle will be turned On by the

controller on the first Wednesday of the next month at 10:00 a.m. for 24

hours.

Procedure

Energy Management is available only in the intelligent controller and

must be enabled in both hardware and software. Enable the hardware

switch by setting SW204-1 on the BSJ board to 1. From the front panel

follow the path: <MENU> → CONFIG → RECT CTR → EFFIC to

enable the software switch. Energy Management can be enabled in

EasyView by following the path: CONFIGURE → PLANT →