Page 1

Installation Guide

for Galaxy Power Systems

Note: Instructions in this manual reference installation and setup of GPS

systems with Galaxy Millennium Controllers and 596 or 596 rectifiers.

For installation and setup with other controllers and rectifiers refer to

these product manuals.

GalaxyMillennium II Product Manual 167-792-181

GalaxyPulsar Plus Product Manual CC848815341

NE Rectifiers

GPS2436 Product Manual 850022020

GPS4827 Product Manual 850022019

Installation Guide

Select Code 167-792-157

Comcode 108327362

Issue 12

August 2012

Page 2

Page 3

Installation Guide

Select Code 167-792-157

Comcode 108327362

Issue 12

August 2012

for Galaxy Power Systems

Installation Guide

Notice:

The information, specifications, and procedures in this manual are

subject to change without notice. Lineage Power assumes no

responsibility for any errors that may appear in this document.

© 2011 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 4

Page 5

Installation Guide for Galaxy Power Systems

Table of Contents

1 Introduction

Product Documentation 1-1

This Installation Guide 1-1

Revisions 1-1

Related Documentation 1-1

Customer Service Contacts 1-3

Customer Service, Technical Support, Product Repair and Return,

and Warranty Service 1-3

Customer Training 1-3

Downloads and Software 1-3

2 Safety

Safety Statements 2-1

Warning and Safety Symbols 2-3

Precautions 2-4

Special Installation Notes 2-9

Deutsch - German 2-9

Español - Spanish 2-11

3 Getting Started

Tools and Hardware 3-1

Torque Settings for Hardware 3-3

Unpacking 3-4

Location 3-4

4 System Electrical Architecture Overview

Introduction 4-1

Bonding Network 4-1

Facility 4-1

Single Cabinet System 4-2

Distributed Architecture 4-3

Centralized Architecture 4-6

5 Cabinet Floor Mounting and Battery Stand

Connection

Cabinet Installation 5-2

Mounting Plates for Unigy Batteries 5-13

Mounting Specifications 5-14

Procedure 5-15

Cabinet Ground and Central Office Ground 5-17

5-17

Issue 12 August 2012 Table of Contents - 1

Page 6

Installation Guide for Galaxy Power Systems

Cabinet Ground Procedure 5-17

Central Office Ground Procedure 5-17

Recommended Cable Rack Layout 5-20

6 Centralized or Distributed Architecture

Connections

Multiple-Cabinet Installations 6-1

Special Requirements 6-1

Centralized Architecture 6-2

DC Power Connections to Central Bus Bar 6-2

Remote Voltage Sense and System Shunt

for Galaxy Millennium Controller 6-4

Remote Voltage Sense and System Shunt

for Galaxy Vector Controller 6-6

Distributed Architecture 6-8

Intercabinet DC Power Bus Connections 6-8

Intercabinet Alarm and Serial Bus Connections 6-10

BLJ2/3 to BLJ2/3 (Millennium Controller) 6-10

BLJ3 to BLJ3 (Vector Controller) 6-12

7 AC Connection and Wiring

Safety 7-1

Reference Information 7-1

Wire Sizing and Ampacity 7-2

AC Input Schemes 7-3

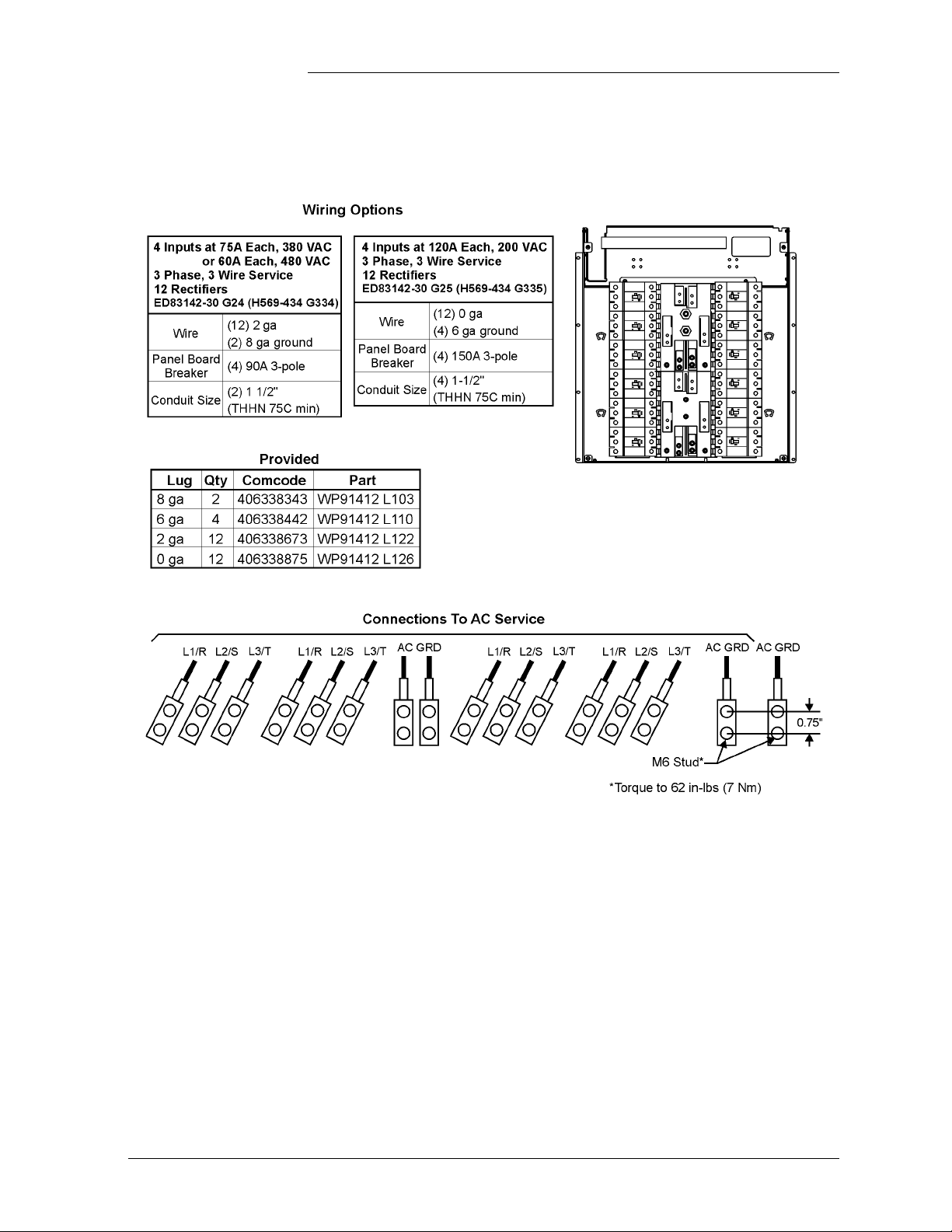

595 Rectifiers (48V, 200A) and 595LT Rectifiers (48V, 220A) 7-3

596 Rectifiers (24V, 100A/125A and 48V, 50A/100A) 7-3

AC Cable Routing 7-4

Rectifier Positions 7-6

AC Input Panels Cross Reference 7-8

AC Input Panels 7-10

7-26

Field Modification of the 1-Phase Circuit Breaker AC Panel for use with

Phase-Neutral Input Circuits - ED83142-30 G-6, G7, G19, G21, or

G23 7-27

Bottom Cable Feed Options for GPS 4848/100 7-28

Completing the AC Connection 7-29

8 DC Distribution Assembly and Connections

Overview 8-1

DC Distribution Panels Cross Reference 8-2

Connecting Loads 8-3

Cable Routing Strategy 8-3

Capacitor Charge Unit 8-3

Mounting Large Circuit Breakers 8-4

2 - Table of Contents Issue 12 August 2012

Page 7

Installation Guide for Galaxy Power Systems

Mounting Small Plug-in Circuit Breakers and Fuses 8-4

Disrtibution Panels 8-5

Low Voltage Disconnect Feature 8-20

EBV Circuit Pack 8-20

9 Converters

Introduction 9-1

Installing the Converter Carrier 9-2

Setting the CIC ID 9-4

Converter Wiring 9-5

10 Remote Peripheral Monitoring

Overview 10-1

RPM Modules 10-1

Current Limiting Resistors 10-2

Mounting Locations 10-2

RPM Installation 10-3

11 Battery Connection Panels

Connecting and Disconnecting Batteries 11-1

Battery Connection Panels Cross Reference 11-2

Additional Battery Leads 11-3

Battery Connection Panel Options 11-4

Connecting (+) and (-) Conductors 11-7

+24-volt Systems 11-7

-48-volt Systems 11-7

Installing Battery Connection Panels 11-8

Contactor Control Board 11-9

Full-Height Cabinet 11-9

Half-Height Cabinet 11-10

Battery and Alarm Fuses and Circuit Breakers 11-11

12 Thermal Probe and 210E Connections

Introduction 12-1

Cable Letter Codes 12-2

Connecting Thermal Probe Cable Assembly 12-3

Millennium Controller 12-3

Vector Controller 12-4

Wiring Schematic for Extender Cable 12-5

Cable Routing 12-5

Connecting Thermal Probe Assembly 12-6

BLJ Board 12-6

Millennium Controller 12-7

Connecting a 210E Module to the Controller or BLJ Board 12-8

Connecting Cable Assembly to the 210E 12-11

Issue 12 August 2012 Table of Contents - 3

Page 8

Installation Guide for Galaxy Power Systems

Connecting Cable Assembly to Thermal Probes 12-12

Monitoring a 210E Alarm Signal, BLJ-BIC7/8 with Millennium 12-13

13 Fascia Cover Installation

Introduction 13-1

Installing the Fascia Covers 13-2

14 Connection of Office Alarms

Introduction 14-1

Connecting Controller Alarms 14-1

15 Power Up and Installation Completion

Initial System Checkout and Preparation for Power Up 15-1

Controller Front Panels 15-1

Millennium 15-2

Vector 15-3

Initial Power Up of the System 15-4

Rectifier Installation Notes 15-4

Install First Rectifier 15-5

Install Converter Cards 15-6

Verify Controller 15-6

Set Rectifier ID 15-7

Installing Rectifiers and Converters 15-9

Lamp Test 15-11

Voltage Calibration 15-12

Setting the System Float Voltage 15-13

Setting the System Shunt 15-14

Setting the Low-Voltage Battery Disconnect Feature 15-15

Setting the Low-Voltage Load Disconnect Feature 15-17

Connecting Batteries 15-19

Testing Rectifiers and Load Share 15-21

Testing Temperature Compensation (Optional Feature) 15-22

Testing Additional Alarms 15-23

Testing the BD Alarm and High Voltage Shutdown 15-24

Galaxy Millennium Controller System Alarm Test 15-25

Connecting to Load 15-25

16 Addition or Modification to a Galaxy Power

System

Upgrading a GPS4848 System to a GPS4848/100 System 16-1

Adding an ED83143-31 Distribution Panel to a GPS 16-2

Installing an LVLD Contactor (if required) 16-5

Adding a Cabinet to an Existing GPS System with

Distributed Architecture. 16-6

4 - Table of Contents Issue 12 August 2012

Page 9

Installation Guide for Galaxy Power Systems

Replacing the Bay Interface Card (BIC) or BLJ3

Terminal Board 16-7

Issue 12 August 2012 Table of Contents - 5

Page 10

Installation Guide for Galaxy Power Systems

6 - Table of Contents Issue 12 August 2012

Page 11

Installation Guide for Galaxy Power Systems

List of Figures

Figure 2-1: Short Circuit Current Calculations 2-5

Figure 4-1: Single-Cabinet Configurations 4-2

Figure 4-2: Two-Cabinet Configuration,

Distributed Architecture 4-4

Figure 4-3: Three-Cabinet (or more) Configuration,

Distributed Architecture 4-5

Figure 4-4: Centralized Architecture 4-6

Figure 5-1: Footprint for Galaxy Power System Cabinets

(without a Battery Stand) 5-2

Figure 5-2: Footprint for a European Battery Stand 5-3

Figure 5-3: Half-Height Cabinet on a European Battery Stand 5-4

Figure 5-4: Footprint for a 12IR125/12IR125LP (Low Profile)

Battery Stand 5-5

Figure 5-5: Half-Height Cabinet on a 12IR125 Battery Stand 5-6

Figure 5-6: Half-Height Cabinet on a 12IR125LP

(Low Profile) Battery Stand 5-7

Figure 5-7: Footprint for a 2VR375 Battery Stand 5-8

Figure 5-8: Half-Height Cabinet on a 2VR375 Battery Stand 5-9

Figure 5-9: Footprint for a 2VR250 Battery Stand 5-10

Figure 5-10: Half-Height Cabinet on a 2VR250 Battery Stand 5-11

Figure 5-11: Half-Height Cabinet on a Unigy Battery

Module Assembly 5-12

Figure 5-12: Cabinet Installation Procedure 5-16

Figure 5-13: Full-Height Cabinet and System Central Office

Ground 5-18

Figure 5-14: Half-Height Cabinet and System Central Office

Ground 5-19

Issue 12 August 2012 List of Figures - 1

Page 12

Installation Guide for Galaxy Power Systems

Figure 5-15: Various Cable Rack Arrangements 5-20

Figure 6-1: DC Power Connections to Centralized Bus Bars 6-3

Figure 6-2: System Shunt and Remote Voltage Sense

for Galaxy Millennium Controller 6-5

Figure 6-3: System Shunt and Remote Voltage Sense

for Galaxy Vector Controller 6-7

Figure 6-4: Distributed Architecture Intercabinet DC Power

Bus Connections (Full-Height Cabinets Only) 6-9

Figure 6-5: BLJ2 or BLJ3 Board Connections,

Millennium Controller 6-10

Figure 6-6: BLJ2/3 DIP Switch Settings When Using a

Millennium Controller 6-11

Figure 6-7: BLJ3 to BLJ3 Board Connections,

Vector Controller 6-13

Figure 6-8: BLJ3 DIP Switch Settings When Using a

VectorController 6-15

Figure 7-1: Attaching AC Conduit 7-5

Figure 7-2: 595 and 596 Series Rectifier Positions 7-6

Figure 7-3: Dual Shelf Rectifier Positions 7-7

Figure 7-4: ED83142-30 Group 2 (H569-434 G22, G322)

AC Input Panel for 595A or LTA Series Rectifiers 7-10

Figure 7-5: ED83142-30 Group 3 (H569-434 G20, G220, G320)

AC Input Panel for 595B, LTB, or C (DA) Series Rectifiers 7-11

Figure 7-6: ED83142-30 Group 4 (H569-434 G21, G23, G321, G323,

G421)

AC Input Panel for 595A, B, LTA, LTB, or C (DA) Series Rectifiers

7-12

Figure 7-7: ED83142-30 Group 24 or 25 (H569-434 G334, G335)

AC Input Panel for 595LTA or LTB Series Rectifiers 7-13

Figure 7-8: ED83142-30 Group 5

(H569-434 G24, G25, G26, G27, G224, G226, G324, G325, G326,

G327, G425, G429)

AC Input Panel for 595A, B, or C (DA) Series Rectifiers 7-14

2 - List of Figures Issue 12 August 2012

Page 13

Installation Guide for Galaxy Power Systems

Figure 7-9: ED83142-30 Groups 6/6M

(H569-436/H569-437 G71H, G73F, G74H, G74F)

AC Input Panel for 596A or B Series Rectifiers 7-15

Figure 7-10: ED83142-30 Group 7 (H569/436/H569-437 G72F)

AC Input Panel for 596A Series or 596B Series Rectifiers 7-16

Figure 7-11: ED83142-30 Group 8 or 9

(H569-436 G76H, G77F, G78F, G79F; H569-437 G76H, G77F,

G78F)

AC Input Panel for 596A Series or 596B Series Rectifiers 7-17

Figure 7-12: Wire Termination for ED83142-30 G-8, G9, G20, G22

(H569-436 G76H, G77F, G78F, G79F, G175H, G176H, G177F,

G178F, G179F;

H569-437 G76H, G77F, G78F) 7-18

Figure 7-13: ED83142-30 Group 10 (H569-434 G70, G270, G370)

AC Input Panel for 595A Series Rectifiers 7-19

Figure 7-14: ED83142-30 Group 11 (H569-434 G71, G371, G471)

AC Input Panel for 595A Series Rectifiers 7-20

Figure 7-15: ED83142-30 Group 18 (H569-434 G128, G129, G130,

G131, G224, G226, G330, G331)

AC Input Panel for 595A or 595B Series Rectifiers 7-21

Figure 7-16: ED83142-30 Group 26 (H569-434 G328, G329, G332,

G333)

AC Input Panel for 595LTA or 595LTB Series Rectifiers 7-22

Figure 7-17: ED83142-30 Group 19 (H569-436 G172F)

AC Input Panel for 596D Series Rectifiers 7-23

Figure 7-18: ED83142-30 Group 20, 22 (H569-436 G175H, G176H,

G177F, G178F, G179F)

AC Input Panel for 596D Series Rectifiers 7-24

Figure 7-19: ED83142-30 Group 21 (H569-436 G171H)

AC Input Panel for 596D series Rectifiers 7-25

Figure 7-20: ED83142-30 Group 23 (H569-436 G173F)

AC Input Panel for 596D Series Rectifiers 7-26

Figure 7-21: Neutral AC Input for ED83142-30 G6, G7, G19, G21 or

G23 H569-436 G71H, G72F, G73F, G171H, G172F, G173F;

H569-437 G71H, 72F, or G73F 7-27

Figure 7-22: Bottom Cable Feed Option for GPS4848/100 7-28

Issue 12 August 2012 List of Figures - 3

Page 14

Installation Guide for Galaxy Power Systems

Figure 8-1: Installation of Large Circuit Breakers

and Capacitor Charge Unit 8-3

Figure 8-2: ED83143-31 Group 1 DC Distribution Panel 8-5

Figure 8-3: ED83143-31 Group 2 DC Distribution Panel 8-6

Figure 8-4: ED83143-31 Group 5 DC Distribution Panel 8-7

Figure 8-5: ED83143-31 Group 11 DC Distribution Panel 8-8

Figure 8-6: ED83143-31 Group 12 DC Distribution Panel 8-9

Figure 8-7: ED83143-31 Group 15 DC Distribution Panel 8-10

Figure 8-8: ED83143-31 Group 16 (14 position) and

Group 17 (22 position) DC Distribution Panels 8-11

Figure 8-9: ED83143-31 Group 21 DC Distribution Panel 8-12

Figure 8-10: ED83143-31 Group 22 DC Distribution Panel 8-13

Figure 8-11: ED83143-31 Group 53 DC Distribution Panel 8-14

Figure 8-12: ED83143-31 Group 54 (5 position) DC Distribution Panel

8-15

Figure 8-13: ED83143-31 Group 55 DC Distribution Panel 8-16

Figure 8-14: ED83143-31 Group 56 DC Distribution Panel 8-17

Figure 8-15: ED83143-31 Group 58 (6 positionGMT) DC Distribution

Panel 8-18

Figure 8-16: ED83143-31 Groups 71 and 171

DC Distribution Panel 8-19

Figure 8-17: EBV Circuit Pack for Load Disconnect 8-20

Figure 9-1: Converter Position 9-3

Figure 9-2: Installing a Second Carrier 9-3

Figure 9-3: Setting the CIC ID Switch 9-4

Figure 9-4: Converter Connection for System Ground 9-6

Figure 9-5: Connection Point for System Ground Wire 9-7

Figure 9-6: Installation of Load Circuit Breakers into 597A

Converter Carrier 9-8

Figure 10-1: Possible RPM Mounting Locations 10-2

4 - List of Figures Issue 12 August 2012

Page 15

Installation Guide for Galaxy Power Systems

Figure 10-2: Connection of Voltage, Shunt, Transducer,

and Binary Modules 10-5

Figure 10-3: Connection of Temperature Module 10-6

Figure 10-4: Connection of Control Relay Module 10-7

Figure 10-5: Connection to the Controller (All Modules) 10-8

Figure 10-6: RPM Module Assembly 10-9

Figure 11-1: Additional Battery Leads 11-3

Figure 11-2: H569-434 Battery Connection Panel Options 11-4

Figure 11-3: H569-436 Battery Connection Panel Options 11-5

Figure 11-4: H569-437 Battery Connection Panel Options 11-6

Figure 11-5: BJN Low Voltage Battery Disconnect

Contactor Control Board (Full-Height Cabinet) 11-9

Figure 11-6: BJN Low Voltage Battery Disconnect

Contactor Control Board (Half-Height Cabinet) 11-10

Figure 12-1: Thermal Probe Cable Assembly Connection

to Millennium Controller 12-3

Figure 12-2: Thermal Probe Cable Assembly Connection

to Vector Controller 12-4

Figure 12-3: Wiring Schematic for Extender Cable 12-5

Figure 12-4: Thermal Probe and 210E Cable Routing 12-5

Figure 12-5: Thermal Probe Connection to BLJ Board 12-6

Figure 12-6: Thermal Probe Connection to Millennium

Controller 12-7

Figure 12-7: 210E Connection to Vector Controller or BLJ 12-9

Figure 12-8: 210E Connection to the Millennium Controller 12-10

Figure 12-9: Cable Assembly Connection to 210E 12-11

Figure 12-10: Cable Assembly Connection to Thermal Probes 12-12

Figure 12-11: Monitoring a 210E Alarm off the BLJ-BIC7/8 in a

Millennium System 12-13

Figure 13-1: Fascia Cover Installation 13-2

Issue 12 August 2012 List of Figures - 5

Page 16

Installation Guide for Galaxy Power Systems

Figure 14-1: Galaxy Millennium Controller

with Insulation Displacement Alarm Board 14-2

Figure 14-2: Galaxy Millennium Controller

with Wire Wrap Alarm Board 14-3

Figure 14-3: Galaxy Vector Controller With Insulation

Displacement Alarm Board 14-4

Figure 15-1a: Galaxy Millennium Controller Front Panel , Square Keys

(DA) 15-2

Figure 15-1b: Galaxy Millennium Controller Front Panel, Round Keys

15-2

Figure 15-2a: Galaxy Vector Controller Front Panel, Square Keys (DA)

15-3

Figure 15-2b: Galaxy Vector Controller Front Panel, Round Keys

15-3

Figure 15-3: Installing 595A/B Rectifiers, 596 Rectifiers, and 597A

Converter Carriers 15-9

Figure 15-4: Installing 595LTA and 595LTB Rectifiers 15-10

Figure 15-5: Battery Connection Panel 15-20

Figure 16-1: Adding an ED83143-31 Distribution Panel to GPS 16-3

Figure 16-2: Adding an LVLD to a Distribution Panel 16-5

Figure 16-3: BLJ3 Terminal Board 16-7

Figure 16-4: BIC/BLJ3 Mounting on a GPS 16-8

6 - List of Figures Issue 12 August 2012

Page 17

Installation Guide for Galaxy Power Systems

List of Tables

Table 2-A: Cable Run Lengths 2-6

Table 2-B: Interrupt Current Ratings for Fuses

and Circuit Breakers 2-7

Table 3-A: Torque Settings for Hardware 3-3

Table 5-A: Mounting Plates for Unigy Batteries 5-13

Table 5-B: GPS Mounting Specifications 5-14

Table 7-A: Wire Sizing and Ampacity 7-2

Table 7-B1: AC Panels Cross Reference - GPS4848/100 7-8

Table 7-B2: AC Panels Cross Reference - GPS4812/24 and GPS2424/

30 (208/240Vac) 7-9

Table 8-A: DC Distribution Panels Cross Reference 8-2

Table 10-A: RPM Modules and Connection Units 10-1

Table 11-A: Battery Connection Panels Cross Reference 11-2

Table 12-A: Cable Letter Codes 12-2

Issue 12 August 2012 List of Tables - 1

Page 18

Page 19

Installation Guide for Galaxy Power Systems

1 Introduction

Product Documentation

This Installation Guide

This Installation Guide provides instructions for installing Lineage

Power Galaxy Power Systems that use 595A or 595B series

(-48V/200A), 595LTA or 595LTB series (-48V/220A), 596A series

(-48V/50A), 596B series (+24V/100A or 125A), or 596D series

(-48V/100A) rectifiers.

Revisions For information on systems components that are no longer available

(Discontinued Availibility DA) see earlier issues of this manual:

Galaxy RC or SCF Controllers - see Issue 5

Plastic Door - see Issue 8

595C Rectifier - see Issue 8

Related Documentation

Ordering Guide H569-437

Manufacturing Drawings ED83142-30 (AC)

Wiring Diagram T83314-30

User’s Guide 167-792-159

GPS2424/30

ED83143-31 (DC)

J85582E-1 (System)

GPS4812/24

Ordering Guide H569-436

Manufacturing Drawings ED83142-30 (AC)

ED83143-31 (DC)

J85582E-1 (System)

Wiring Diagram T83314-30

User’s Guide 167-792-161

GPS4848/100

Ordering Guide H569-434

Manufacturing Drawings ED83142-30 (AC)

ED83143-31 (DC)

J85582C-1 (System)

Wiring Diagram T83314-30

User’s Guide 167-792-155

Issue 12 August 2012 Introduction 1 - 1

Page 20

Installation Guide for Galaxy Power Systems

Product Documentation, continued

Related Product

Manuals,

continued

Manufacturing Drawing J85501K-1

Wiring Diagram T83413-30

Product Manual 167-792-180

Wiring Diagram T83314-30

Product Manual (BIC2, BIC3) 167-792-112

Product Manual (GCM2, GCM3) 167-792-115

Manufacturing Drawing J85501G-1

Wiring Diagram T83275-30

Schematic Drawing SD-83275-01

Product Manual Select Code 167-790-063

Galaxy Millennium Controller

Galaxy Vector Controller

Remote Peripheral Monitoring System

EasyView Software

Product Manual 193-104-105

Galaxy Gateway Card (Internet)

Product Manual 193-104-106

1 - 2 Introduction Issue 12 August 2012

Page 21

Installation Guide for Galaxy Power Systems

Customer Service Contacts

Customer Service, Technical Support, Product Repair and Return, and Warranty Service

For customers in the United States, Canada, Puerto Rico, and the US

Virgin Islands, call 1-800-THE-1PWR (1-800-843-1797). This number

is staffed from 7:00 am to 5:00 pm Central Time (zone 6), Monday

through Friday, on normal business days. At other times this number is

still available, but for emergencies only. Services provided through this

contact include initiating the spare parts procurement process, ordering

documents, product warranty administration, and providing other

product and service information.

For other customers worldwide the 800 number may be accessed after

first dialing the AT&T Direct country code for the country where the

call is originating, or you may contact your local field support center or

your sales representative to discuss your specific needs.

Customer Training Lineage Power offers customer training on many Power Systems

products. For information call 1-972-284-2163. This number is

answered from 8:00 a.m. until 4:30 p.m., Central Time Zone (Zone 6),

Monday through Friday.

Downloads and Software

To download the latest product information, product software and

software upgrades, visit our web site at

http://www.lineagepower.com

Issue 12 August 2012 Introduction 1 - 3

Page 22

Installation Guide for Galaxy Power Systems

1 - 4 Introduction Issue 12 August 2012

Page 23

Page 24

Installation Guide for Galaxy Power Systems

1 - 6 Introduction Issue 12 August 2012

Page 25

Installation Guide for Galaxy Power Systems

2 Safety

Safety Statements

Please read and follow all safety instructions and warnings before

installing, maintaining, or repairing a Galaxy Power System. Reference

the individual module product manuals for additional safety statements

specific to the modules.

• The Galaxy Power System is Underwriters Laboratories (UL)

Listed per Subject Letter 1801, DC Power Distribution Centers for

Telecommunications Equipment, and VDE Licensed to EN60950

(H569-436 and H569-437 only). Rectifiers are individually UL

Recognized and/or CSA Certified to UL1950 and CSA C22.2 No.

234/950. Rectifiers are also approved to IEC-950/EN60950 by an

EC Notified Body and have outputs classified as SELV.

• Install only in restricted access areas (dedicated equipment rooms,

equipment closets, or the like) in accordance with articles 110-16,

110-17, and 110-18 of the U.S. National Electric Code (NEC),

ANSI/NFPA No. 70, and pursuant to applicable local codes.

• Use this equipment in a controlled environment (an area where the

humidity is maintained at levels that cannot cause condensation on

the equipment, the contaminating dust is controlled, and the

steady-state ambient temperature is within the range specified).

GPS4848/100 has been evaluated for use in a continuous ambient

temperature not to exceed 40°C. Short-term excursions to 45°C are

acceptable. GPS4848/100 with Dual Rectifier Shelf has been

evaluated for use in a continuous ambient temperature not to

exceed 40°C. Short-term excursions to 50°C are acceptable.

GPS2424/30 and GPS4812/24 have been evaluated for use in a

continuous ambient temperature not to exceed 45°C. Short-term

excursions to 50°C are acceptable.

• Do not install this equipment over combustible surfaces.

Issue 12 August 2012 Safety 2 - 1

Page 26

Installation Guide for Galaxy Power Systems

Safety Statements, continued

• Fuses/circuit breakers may not be provided with the equipment.

Refer to the Galaxy Power System documentation for the proper

hardware. Use only the parts specified in the Galaxy Power

System (GPS) documentation. Installing fuses or circuit breakers

not specified for use in this equipment may result in injury to

service personnel or equipment damage.

• For installations in the U. S. or Canada, use Listed/Certified

compression connectors to terminate Listed/Certified field-wire

conductors where required. For all installations, apply the

appropriate connector to the correct size conductor as specified by

the connector manufacturer, using only the connector

manufacturer’s recommended tooling or tooling approved for that

connector. If the proper connector for the country of installation is

not provided, obtain appropriate connectors and follow

manufacturer’s and all local requirements for proper connections.

Follow all national and local rules and regulations when making

field connections.

• Torque electrical connections to the values specified on labels or in

the product documentation.

• Battery input cables must be dressed to avoid damage to the

conductors (caused by routing around sharp edges or routing in

areas where wires could get pinched) and undue stress on the

connectors.

• Either external fuses or external circuit breakers must be sized as

required by the National Electric Code (NEC) and/or local codes.

Refer to the equipment ratings to assure rating of equipment will

not exceed 80% of the value of the protector chosen. Refer to the

system T-drawing (wiring diagram) for recommended circuit

protection for the different options.

• The ac input distribution has been evaluated for connection of

minimum 90°C conductors sized according to the US National

Electrical Code using the 90°C ampacity tables. Torque electrical

connections to the values specified on labels or in the product

documentation.

• Provide an accessible ac disconnect/protection device to remove ac

power from the equipment in the event of an emergency. This

device must open all poles and be connected together. When

connecting to 3-wire plus neutral supply systems, the neutral must

be readily earthed at the supply, i.e., this equipment is not intended

to be connected to IT supply systems.

2 - 2 Safety Issue 12 August 2012

Page 27

Installation Guide for Galaxy Power Systems

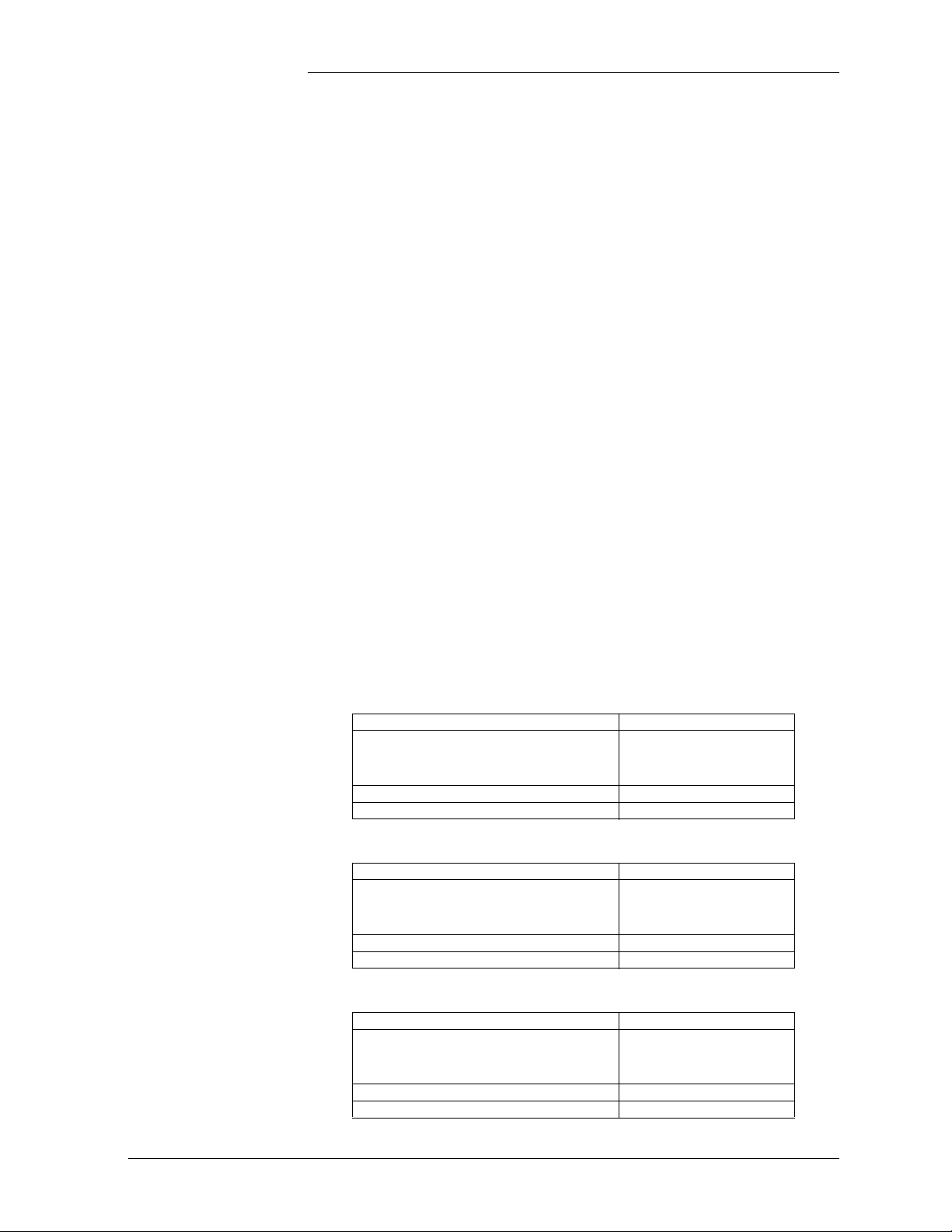

Warning and Safety Symbols

The symbols may sometimes be accompanied by some type of statement; e.g., “Hazardous voltage/energy inside. Risk

of injury. This unit must be accessed only by qualified personnel.” Signal words as described below may also be used

to indicate the level of hazard

DANGER

WARNING

CAUTION

Indicates the presence of a hazard that

hazard is not avoided.

Indicates the presence of a hazard that can cause death or

is not avoided.

Indicates the presence of a hazard

damage if the hazard is not avoided.

This symbol identifies the need to refer to the equipment instructions for important

information.

These symbols (or equivalent) are used to identify the presence of hazardous ac mains voltage.

This symbol is used to identify the presence of hazardous ac or dc voltages. It may also be

used to warn of hazardous energy levels.

One of these two symbols (or equivalent) may be used to identify the presence of rectifier

and battery voltages. The symbol may sometimes be accompanied by some type of

statement, for example: “Battery voltage present. Risk of injury due to high current. Avoid

contacting conductors with uninsulated metal objects. Follow safety precautions.”

will cause death or severe personal injury if the

severe personal injury if the hazard

that will or can cause minor personal injury or property

One of these two symbols may be used to identify the presence of a hot surface. It may also

be accompanied by a statement explaining the hazard. A symbol like this with a lightning

bolt through the hand also means that the part is or could be at hazardous voltage levels.

This symbol is used to identify the protective safety earth ground for the equipment.

This symbol is used to identify other bonding points within the equipment.

This symbol is used to identify the need for safety glasses and may sometimes be

accompanied by some type of statement, for example: “Fuses can cause arcing and sparks.

Risk of eye injury. Always wear safety glasses.”

Issue 12 August 2012 Safety 2 - 3

Page 28

Precautions

Installation Guide for Galaxy Power Systems

When working on or using this type of equipment, the following

precautions should be noted:

• The Galaxy Power System must be installed, serviced, and operated

only by skilled and qualified perso

nnel who have the necessary

knowledge and practical experience with electrical equipment and

who understand the hazards that can arise when working on this type

of equipment.

• The Galaxy Power System may be powered by multiple ac inputs.

Make sure that the appropriate circuit protection device for each ac

input being serviced is disconnected before servicing the equipment.

• If batteries are connected to the Galaxy Power System, disconnecting

the ac alone will not necessarily remove power to the equipment.

Make sure the equipment is not also powered by the batteries or the

batteries are not connected to the output of the equipment.

• High leakage currents may be possible on this type of equipment.

Make sure the equipment is properly safety earth grounded before

connecting power.

• Hazardous energy and voltages are present in the Galaxy Power

System and on the interface cables that can shock or cause serious

injury. Exercise care and follow all safety warnings and practices

when servicing this equipment.

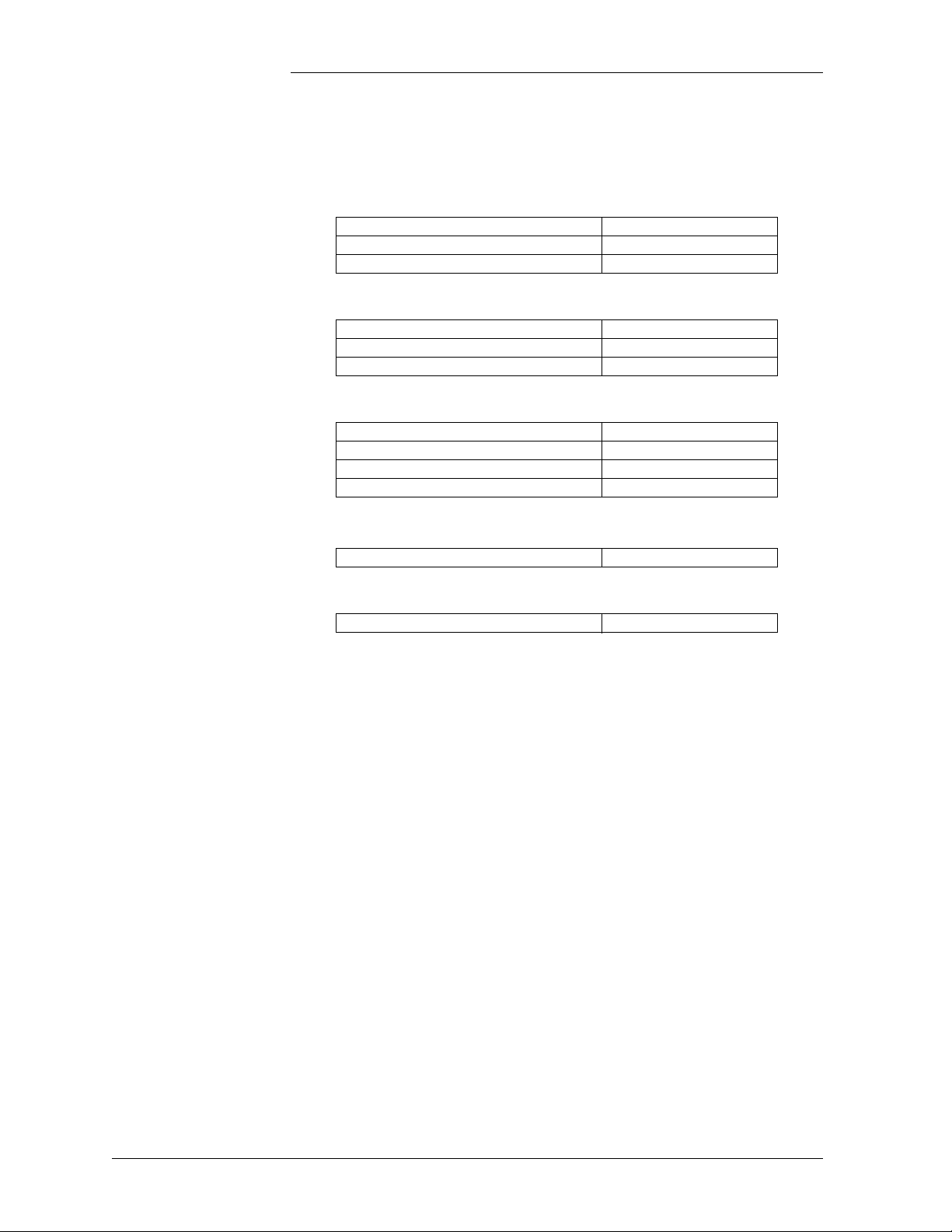

• Load cables must be sized in accordance with the cable lengths

shown in T

able 2-A and Figure 2-1 to keep short circuit currents less

than the interrupt ratings of dc protectors in each panel (as shown in

Table 2-B).

2 - 4 Safety Issue 12 August 2012

Page 29

Installation Guide for Galaxy Power Systems

Precautions, continued

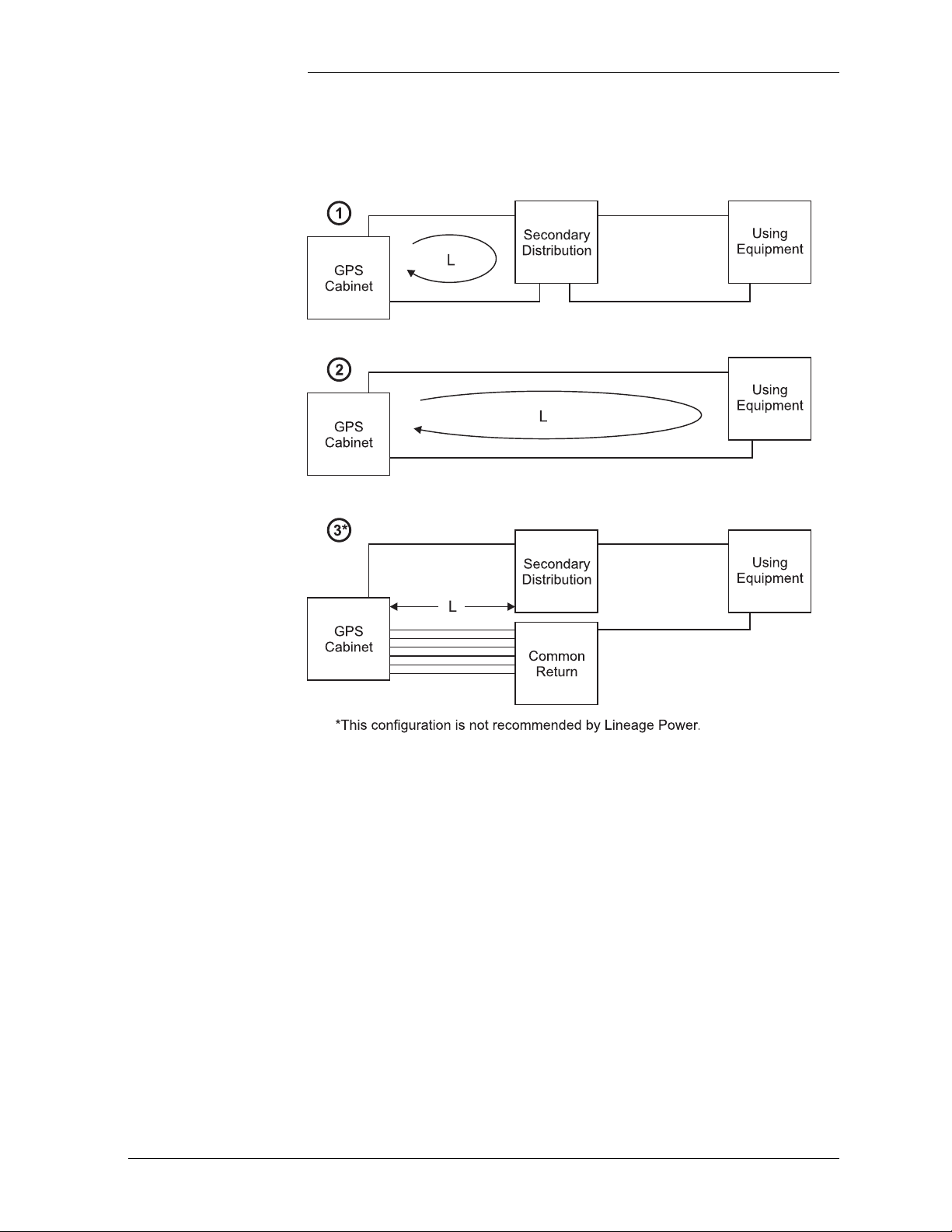

Figure 2-1: Short Circuit Current Calculations

Issue 12 August 2012 Safety 2 - 5

Page 30

Installation Guide for Galaxy Power Systems

Precautions, continued

Note: Provide cable run lengths as least as long as the minimum length

indicated in Table 2-A to assure that the short circuit currents are less

than the interrupt current rating of the fuse or circuit breaker chosen.

1. Find the interrupt current rating of the chosen fuse or circuit

breaker from Table 2-B.

2. See Table 2-A for the minimum length (L) for the engineered cable

size to be run at the interrupt rating found in Step 1.

A minimum cable length for a given cable size and protector type must

be used to ensure proper short circuit protection in the case of a bolted

fault.

Table 2-A: Cable Run Lengths

Minimum Length “L” Required to Limit the Current to an

Cable Size

100KA 25KA 10KA

10 GA

2

8 GA

6 GA

4 GA

2 GA

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

(6mm

(10 mm

(16 mm

(25 mm

(35 mm

1/0 GA

(50 mm

2/0 GA

(70 mm

4/0 GA

(120 mm

(2) 4/0 GA

((2) 120 mm

(3) 4/0 GA

((3) 120 mm

350 MCM 17 feet 63 feet -(2) 350 MCM 32 feet 125 feet -(3) 350 MCM 47 feet 188 feet --

-- -- 5 feet

-- -- 8 feet

-- 5 feet 12 feet

-- 8 feet 19 feet

3 feet 12 feet 30 feet

5 feet 19 feet --

6 feet 24 feet --

10 feet 38 feet --

19 feet 76 feet --

29 feet 113 feet --

Interrupt Rating

of:

2 - 6 Safety Issue 12 August 2012

Page 31

Installation Guide for Galaxy Power Systems

Precautions, continued

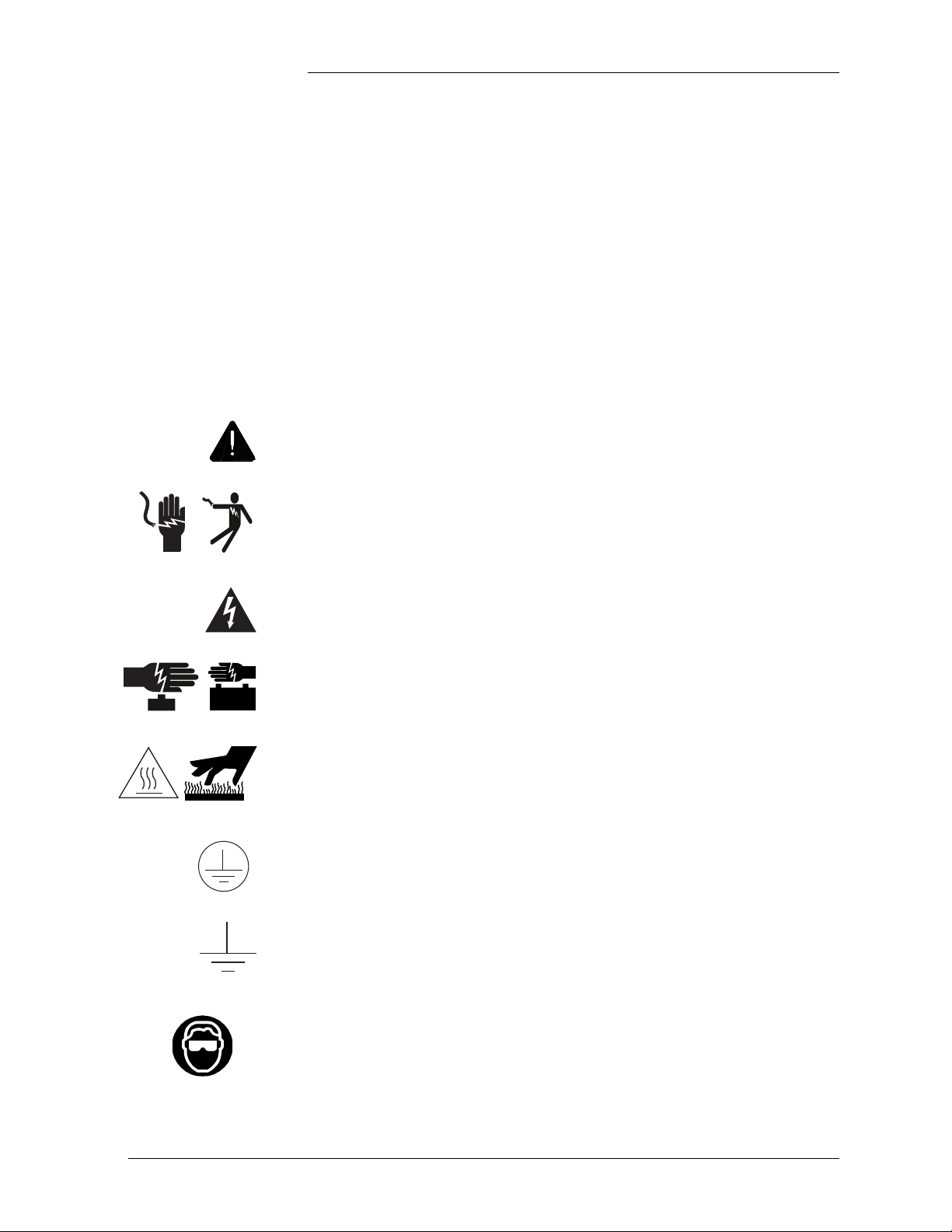

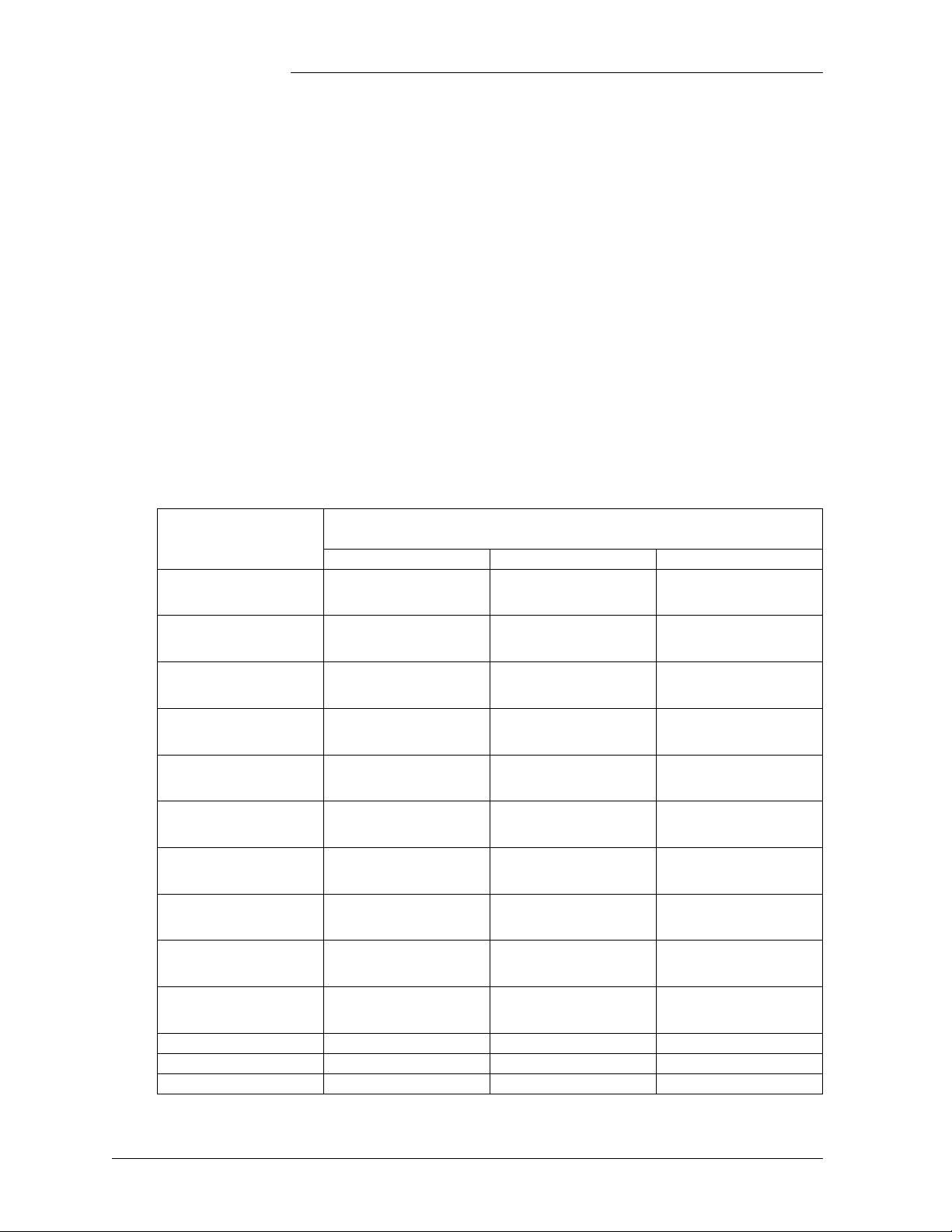

Table 2-B: Interrupt Current Ratings for Fuses

Description

Large bolt-in circuit breakers

Small plug-in circuit breakers

Small bullet-style circuit breakers

Large fuse (TPL)

Medium fuse (TPS)

Small plug-in fuse (TPA)

DIN-style fuses Not available from Lineage Power.

DIN-style circuit breakers Not available from Lineage Power.

and Circuit Breakers

ED83143-31

Groups

1, 2, 5 25,000

11, 12 10,000

15 - 17 10,000

54 - 55 100,000

11, 12 100,000

Contact fuse or circuit breaker manufacturer.

Contact fuse or circuit breaker manufacturer.

Interrupt

Current

Rating

(amps)

53 100,000

Issue 12 August 2012 Safety 2 - 7

Page 32

Installation Guide for Galaxy Power Systems

Precautions, continued

• Electricity produces magnetic fields that can affect implanted

medical electronic devices, such as pacemakers. The strength of the

magnetic field depends on the amount of current in the circuit, as

well as other conditions (such as number of conductors, placement,

and distance from the conductor). DC power and distribution

systems, including the batteries, that are typically used in

telecommunications utility rooms can operate at high current levels.

Personnel with electronic medical devices need to be aware of their

restrictions when working around electricity.

• In addition to proper job training and safety procedures, the

following are some basic precautions that should always be used:

– Batteries may be connected in parallel with the output of the

rectifiers. Turning off the rectifiers will not necessarily remove

power from the bus. Make sure the battery power is also

disconnected and/or follow safety procedures while working on

any equipment that contains hazardous energy/voltage.

–Use only properly insulated tools.

– Remove all metallic objects (key chains, glasses, rings, watches,

or any other jewelry).

– Wear safety glasses.

– Test circuits before touching.

– Lock out and tag any circuit breakers/fuses when possible to

prevent accidental turn on.

– Be aware of potential hazards before servicing equipment.

– Identify exposed hazardous electrical potentials on connectors,

wiring, etc. (note the condition of these circuits, especially any

wiring).

– Use care when removing or replacing any covers; avoid

contacting any circuits.

Note: Refer to Section 15, Power Up and Installation Completion, for

precautions and proper methods for handling rectifiers and converters.

2 - 8 Safety Issue 12 August 2012

Page 33

Installation Guide for Galaxy Power Systems

Special Installation Notes

Deutsch - German Installationsanleitung (Installation Instructions)

• Eingangsspannung (Voltage):

200-240 phase to phase or phase to neutral (H569-436, H569-437)

200-240, 380-480 (H569-434)

• Eingangsstrom (Current):

120A max., 20A/rectifier (H569-436, H569-437)

385A max. (H569-434)

• Nennfrequenz (Frequency):

50/60Hz

• Abmessungen sind nur zur referenz:

(Dimensions are for reference only)

600mm x 500mm (H569-436, H569-437)

600mm x 600mm (H569-434)

• Max. Umgebungstemperatur:

(Max. operation temperature)

40°C (104°F) for H569-434

45°C (113°F) for H569-436 and H569-437

• Achtung: Für kontinuierlichen Feuerschutz sollte die Sicherung nur

mit einer des gleichen Types ersetzt werden.

(Warning: For continued protection against fire replace with same

type and rating of fuse)

• Das Schaltnetzteil ist ein Gerät der Schutzklasse I

(Power Supply is a Class I Equipment)

Issue 12 August 2012 Safety 2 - 9

Page 34

Installation Guide for Galaxy Power Systems

Special Installation Notes, continued

Deutsch - German,

continued

• Ausgangsspannungen und -stöme

(Output Voltage and Current)

Ausgangsspannungen und -stöme

H569-434 -48 14,080

H569-436 -48 2400

H569-437 +24 3000

• Das Gerät darf nur in Räumen mit beschränktem Zutritt aufgestellt

werden.

(Nur ausgebildetes Personal) (Restricted access)

• Das Gerät muß mindestens mit einer Anschlußleitung 4 x mm oder 5

x mm versehen sein.

(Suitable for 4 conductor or 5 conductor systems)

• Das Gerät hat keinen eigenen Ausschalter, es muß daher mit einem

Ein- und Ausschalter im Versorgungskreis versehen sein.

(Mains disconnect switch required in the installation)

• Das Gerät hat kein Brandschutzgehäuse es darf daher nur auf nicht

brennbaren Untergrund aufgestellt werden. (Beton, Metall usw.)

(No fire enclosure, non-combustible floor)

• Das Gerät wird fest am Boden installiert (siehe weitere Anleitung)

(Must be bolted to the floor)

• Modellnummer H569-436, H569-437: Beim Aufstellen des Gerätes

ist daraf zu achten das alle Anforderungen gemäß EN60950

eingehalten werden.

(Evaluated to EN60950)

2 - 10 Safety Issue 12 August 2012

Page 35

Installation Guide for Galaxy Power Systems

Special Installation Notes, continued

Español - Spanish Notas especiales para instalaciones en países de habla hispana

Instrucciones de instalación (Installation Instructions)

• Voltaje (Voltage):

200-240, 350-415 (H569-436, H569-437)

200-240, 380-480 (H569-434)

• Corriente (Current):

120A máx., 20A/rectificador (H569-436, H569-437)

385A máx. (H569-434)

• Frecuencia (Frequency):

50/60Hz

• Las dimensiones son únicamente para referencia:

(Dimensions are for Reference only)

600mm x 500mm (H569-436, H569-437)

600mm x 600mm (H569-434)

• Temperatura máxima de operación:

(Max. operation temperature)

40°C (104°F) for H569-434

45°C (113°F) for H569-436 and H569-437

• Advertencia: Para una protección continua contra incendios,

reemplace por el mismo tipo y clasificación de fusible.

(Warning: For continued protection against fire replace with same

type and rating of fuse.)

• La fuente de alimentación es un equipo clase I

(Power Supply is a Class I Equipment)

• Voltaje y corriente de salida

(Output Voltage and Current)

• (Acceso restringido) (Restricted access)

– Adecuado para sistemas de 4 conductores o de 5 conductores.

(Suitable for 4 conductor or 5 conductor systems)

– Se requiere un interruptor de desconexión de la línea principal

en la instalación (Mains disconnect switch required in the

installation.)

– Sin cabina contra incendios, suelo no combustible (No fire

enclosure, non-combustible floor)

– Debe estar anclado al piso (Must be bolted to the floor)

– Número de modelo H569-436, H569-437: Evaluado en

EN60950 (Evaluated to EN60950)

Issue 12 August 2012 Safety 2 - 11

Page 36

Page 37

Installation Guide for Galaxy Power Systems

3 Getting Started

Tools and Hardware

You will need the following tools and hardware to install the Galaxy

Power System:

• Material-handling equipment to unload the cabinet at the installation

site, remove from shipping container, and set in final position

[minimum lifting capacity: 900 lbs. (410Kg)] Note: Use the

equipment weights and dimensions as a guideline for choosing

material-handling equipment.

• Drill and drill bits to install floor anchors

• 3/16-inch (5mm) Allen-head wrench (provided)

• Insulated hand tools

• Screw drivers (flat-blade and Phillips)

• Wire cutters and stripper

• Torque wrenches (see Table 3-A)

35-513 in·lbs (4-58 N·m)

• Sockets:

Metric English Equivalent Hardware

8mm 5/16" M5

10mm -- M6

13mm 1/2" M8

17mm 11/16" M10

19mm 3/4" M12

-- 3/8" 1/4"

-- 9/16" 3/8"

Issue 12 August 2012 Getting Started 3 - 1

Page 38

Installation Guide for Galaxy Power Systems

Tools and Hardware, continued

• Crimp tools

– 22-16 gauge

– 10-500 MCM (5-120mm2)

• Jeweler’s screwdriver

• Digital multimeter (DMM) with 0.05% accuracy on dc scale

• Load box (100 amperes @ 24V)

• Load box (200 amperes @ 48V)

• Laptop or personal computer (PC) loaded with Windows 3.1 or later

(optional)

• ESD wrist strap*

*Equipment is ESD sensitive. It is required that an ESD wrist strap

be worn during installation and repair. An ESD wrist strap

(408157105) is provided with each controller.

3 - 2 Getting Started Issue 12 August 2012

Page 39

Installation Guide for Galaxy Power Systems

Torque Settings for Hardware

Table 3-A: Torque Settings for Hardware

Screw Size Torque (N·m) Tor qu e (i n· l bs )

M2 0.24 2

M2.5 0.48 4

M3 0.9 8

M3.5 1.4 12

M4 2 18

M5 4 35

M6 7 62

M8 18 145

Metric

M10 34 300

M12 58 513

English

Screw Size Torque (N·m) Tor qu e (i n· l bs )

6-32 1.1 10

8-32 2.3 20

10-32 2.8 25

12-24 4 35

1/4-20 7 65

5/16-18 15 135

3/8-16 27 240

Issue 12 August 2012 Getting Started 3 - 3

Page 40

Installation Guide for Galaxy Power Systems

Unpacking Before opening the packaging, carefully inspect the outside in the

presence of shipping personnel for signs of damage. Carefully open the

packaging to verify that the contents are complete and undamaged. If

damaged, follow the shipping carrier’s procedure for filing a damage

claim. If the equipment must be returned, it should be repacked in the

original shipping crate.

Location Before continuing, verify that the following conditions exist at the

installation site:

• Floor is conditioned and clean (refers to removal of any combustible

flooring, e.g., carpet, wood, etc.).

• Batteries and associated stands are in place.

• Cable rack not supported by cabinets is in place.

• Job Site Documentation is available that details cabinet locations, dc

distribution assignments, and Remote Peripheral Monitoring System

module location and assignment.

3 - 4 Getting Started Issue 12 August 2012

Page 41

Installation Guide for Galaxy Power Systems

4 System Electrical Architecture

Overview

Introduction This section is a basic system overview of the architecture of Galaxy

Power Systems. The overview provides information about the

connections and physical considerations of the systems that must be

understood before the installation process begins.

The GPS individual cabinets may be connected together in two basic

architectures, distributed or centralized, to form systems. These two

architectures contain the same basic modules, but are arranged in

different cabinet configurations.

Single cabinet systems are considered neither distributed nor

centralized.

Bonding Network GPS systems are suitable for installation as part of a Common Bonding

Network (CBN) or an Isolated Bonding Network (IBN).

In this manual Battery Return grounds labeled "System (CO) ground"

are "Isolated DC return (DC-I)".

Installation as part of a Common Bonding Network (CBN) or an

Isolated Bonding Network (IBN) is determined by the point external to

the GPS system connected to GPS "System (CO) ground".

Facility GPS systems are suitable for installation in Network

Telecommunication Facilities and locations where NEC applies.

Issue 12 August 2012 System Electrical Architecture Overview 4 - 1

Page 42

Installation Guide for Galaxy Power Systems

Half Height Cabinet Full Height Cabinet

Control

and

Monitor

AC

Battery String(s)

Mounted Below

Half Height Cabinet

To Loads

AC

Ground

Cabinet

Ground

System (CO)

Ground

Battery

Shunt

AC

Ground

Cabinet

Ground

System (CO)

Ground

Control

and

Monitor

Battery

String

To Loads

Battery

Shunt

AC

Single Cabinet System

Available in both half-height and full-height configurations, the single

cabinet systems are illustrated in Figure 4-1.

Figure 4-1: Single-Cabinet Configurations

4 - 2 System Electrical Architecture Overview Issue 12 August 2012

Page 43

Installation Guide for Galaxy Power Systems

Distributed Architecture

A distributed architecture is best thought of as small systems combined

together to form a much larger system. Each small system (cabinet)

contains an entire dc power system that includes ac input, rectifiers,

battery connection modules (with external batteries), and dc distribution

modules.

The dc power generated by the rectifiers and supported by the batteries

in a given cabinet will approximately equal the dc power distributed to

the loads from that cabinet. The dc power of each cabinet is electrically

interconnected so that power may be shared (up to 1200A) between the

cabinets. This sharing allows the system of cabinets to handle

imbalances in cabinet loads (due to improper sizing or to rectifier or

battery module failure).

Distributed architecture is summarized as follows: Each cabinet

(system) generates and distributes all the dc power it needs but is able to

borrow, or give up, power (up to 1200A) from other cabinets in the

system. Growth of the system is accomplished by adding another

cabinet (system) and interconnecting it to the original cabinets (system).

Multiple-cabinet configurations are shown in Figure 4-2 (two-cabinet

configuration) and Figure 4-3 (three-cabinet (or more) configuration).

Issue 12 August 2012 System Electrical Architecture Overview 4 - 3

Page 44

Installation Guide for Galaxy Power Systems

Control

and

Monitor

Battery

String

Shared DC Power

Battery

String

AC

AC

Initial Cabinet SupplementalCabinet

To LoadsTo Loads

Battery

Shunt

Battery

Shunt

AC

Ground

AC

Ground

Cabinet

Ground

Cabinet

Ground

System (CO)

Ground

Distributed Architecture, continued

Figure 4-2: Two-Cabinet Configuration,

Distributed Architecture

4 - 4 System Electrical Architecture Overview Issue 12 August 2012

Page 45

Installation Guide for Galaxy Power Systems

Control

and

Monitor

To LoadsTo Loads

Battery

String

Battery

String

ACAC

Controller

Rectifier

Battery

Distribution

Cabinet

Rectifier

Battery

Distribution

Cabinet

Rectifier

Battery

Distribution

Cabinet

AC

Ground

AC

Ground

Cabinet

Ground

Cabinet

Ground

To Loads

Battery

String

AC

AC

Ground

Cabinet

Ground

System (CO)

Ground

Shared DC PowerShared DC Power

Distributed Architecture, continued

Figure 4-3: Three-Cabinet (or more) Configuration,

Distributed Architecture

Issue 12 August 2012 System Electrical Architecture Overview 4 - 5

Page 46

Installation Guide for Galaxy Power Systems

Charge Bus Charge Return Bus Discharge Return Bus

Battery Strings

Controller

Rectifier

Cabinet

Rectifier

Only

Cabinet

Rectifier

Only

Cabinet

Distribution

Only

Cabinet

System

Shunt

Control

and

Monitor

To Loads

Cabinet

Ground

AC AC AC

Cabinet

Ground

Cabinet

Ground

Cabinet

Ground

System (CO)

Ground

Centralized Architecture

The centralized architecture is best thought of as all the rectifiers and all

the batteries in the system connected together at a central point and then

taken from that central point to the distribution modules and then in turn

to the system loads. Since all the system power is brought together at a

central point, the central point must be sized for the ultimate capacity of

the system. Growth of the system is accomplished by adding rectifiers

(either to an existing cabinet or in a new cabinet), adding distribution

panels (either to an existing cabinet or in a new cabinet), and adding

batteries.

Figure 4-4 illustrates the centralized architecture.

Figure 4-4: Centralized Ar

4 - 6 System Electrical Architecture Overview Issue 12 August 2012

chitecture

Page 47

Installation Guide for Galaxy Power Systems

5 Cabinet Floor Mounting and

Battery Stand Connection

Refer to the following figures for the procedures in this section:

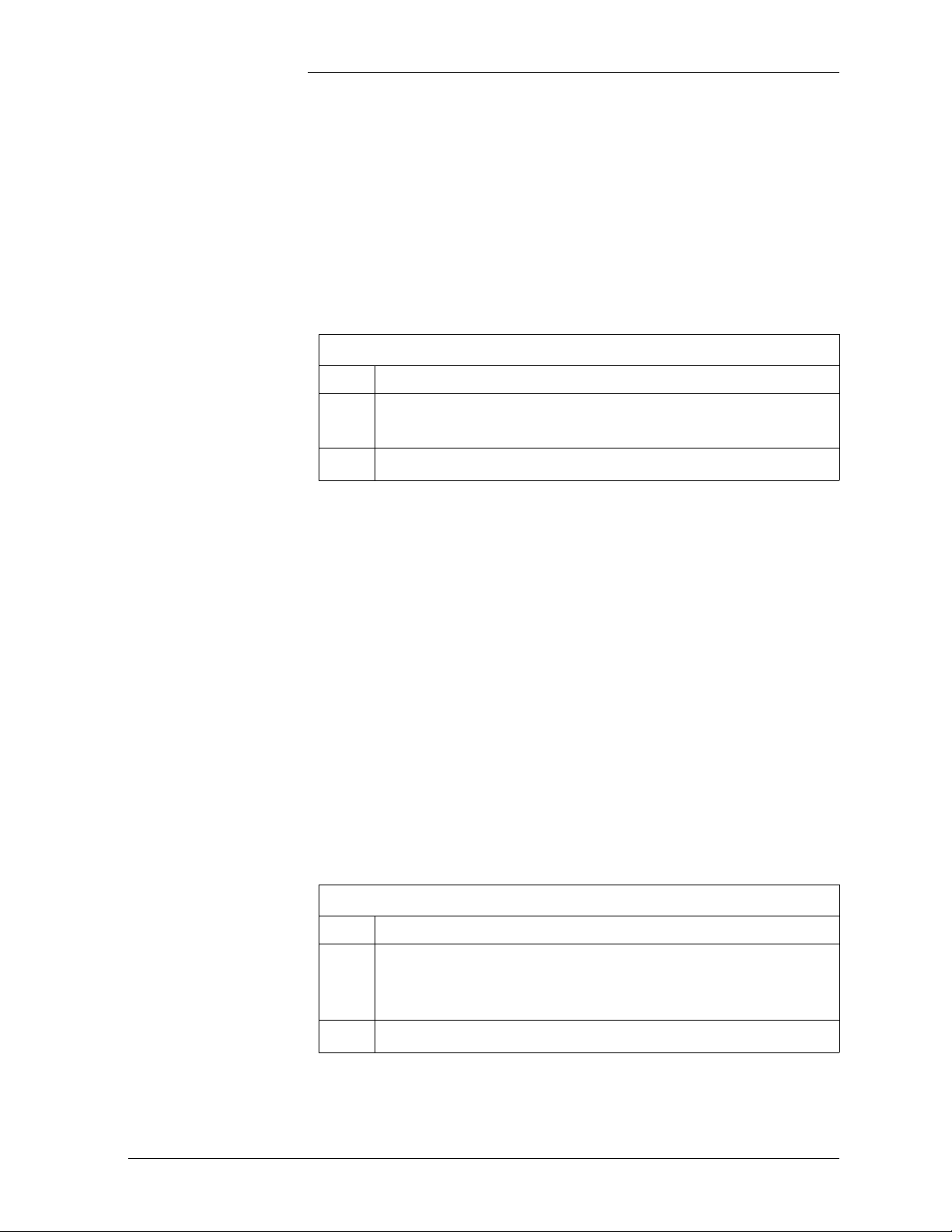

Figure No. Illustrates

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

Footprint for Galaxy Power System (GPS) without a

battery stand

Footprint for European battery stand

Half-height cabinet on a European battery stand

Footprint for 12IR125/12IR125LP battery stand

Half-height cabinet on a 12IR125 battery stand

Half-height cabinet on a 12IR125LP (Low Profile)

battery stand

Footprint for 2VR375 battery stand

Half-height cabinet on a 2VR375 battery stand

Footprint for 2VR250 battery stand

Half-height cabinet on a 2VR250 battery stand

Half-height cabinet on a Unigy module assembly

Details of the cabinet installation procedure

Central office ground for full-height cabinet

5-14

5-15

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 1

Central office ground for half-height cabinet

Cable rack arrangements

Page 48

Installation Guide for Galaxy Power Systems

19.6"

(498 mm)

23.6"

(600 mm)

(549 mm)

1.00" typ

(25.4 mm)

0.50" typ

(12.7 mm)

2"

(51 mm)

2.5"

(64 mm)

GPS4848/100

19"

(482 mm)

GPS4848/100

23.6"

(600 mm)

GPS2424/30

GPS4812/24

(without battery

stands)

15.3"

(389 mm)

GPS2424/30

GPS4812/24

(without battery

stands)

19.7"

(500 mm)

0.75" x 1" Slots

(19 x 25 mm)

Bottom View

Front

33.4”

(849 m m)

1.0”

(25 mm)

1.0”

(25 mm)

0.5”

(13 mm)

1.0”

(25 mm)

FRONT

BOTTOM VIEW

1.0”

(25 mm)

16.2”

(412 m m)

35.4”

(900 mm)

19.0”

(483 mm)

23.7”

(603 mm)

0.75 x1.0” Slots

(19 x 25 mm)

36” Wide

Distribution Cabinet

Cabinet Installation

21.6"

Figure 5-1: Footprint for Galaxy Power System Cabinets

(without a Battery Stand)

5 - 2 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 49

Installation Guide for Galaxy Power Systems

Figure 5-2: Footprint for a European Battery Stand

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 3

Page 50

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-3: Half-Height Cabinet on a European Battery Stand

5 - 4 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 51

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-4: Footprint for a 12IR125/12IR125LP (Low Profile)

Battery Stand

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 5

Page 52

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-5: Half-Height Cabinet on a 12IR125 Battery Stand

5 - 6 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 53

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-6: Half-Height Cabinet on a 12IR125LP

(Low Profile) Battery Stand

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 7

Page 54

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-7: Footprint for a 2VR375 Battery Stand

5 - 8 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 55

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-8: Half-Height Cabinet on a 2VR375 Battery Stand

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 9

Page 56

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-9: Footprint for a 2VR250 Battery Stand

5 - 10 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 57

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-10: Half-Height Cabinet on a 2VR250 Battery Stand

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 11

Page 58

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-11: Half-Height Cabinet on a Unigy Battery

Module Assembly

5 - 12 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 59

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Mounting Plates for Unigy Batteries

Table 5-A: Mounting Plates for Unigy Batteries

Module Type

6A-75-9

3A-75-17

3A-75-19

6A-75-11

3A-75-21

3A-75-23

6A-75-13

3A-75-25

3A-75-27

6A-75-15

3A-75-29

6A-75-31

Capacity,

8-hour Rate

12V, 310Ah

6V, 630Ah

6V, 700Ah

12V, 390Ah

6V, 785Ah

6V, 865Ah

12V, 470Ah

6V, 945Ah

6V, 1025Ah

12V, 550Ah

6V, 1100Ah

6V, 1175Ah

Comcode

848275509

848275517

848275533

848275558

3A-85-33 6V, 1400Ah 848299673

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 13

Page 60

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Mounting Specifications

Table 5-B: GPS Mounting Specifications

Seismic

Zone(s)

Comcode

0, 1 847135720

0, 1 847135712

0, 1, 2 847135662

0, 1, 2 847135654

0, 1, 2, 3, 4 847135670

0, 1, 2, 3, 4 847135688

4* 847221074

*IR Battery Stand only

Anchor Type

(HILTI)

(4) 3/8"

drop in

(4) 3/8"

self drill

(4) 1/2"

drop-in

(4) 1/2"

self drill

(4) 12mm

self drill

(4) 12mm

cap bolts

(4) 16mm

cap bolts

Hole Size Wrench To rq ue

1/2" bit

1-9/16" deep

-- --

5/8" bit

2" deep

-- 3/4"

-- 19mm

18mm

100mm deep

24mm

125mm deep

--

3/4"

19mm

30mm

85 in·lbs

(7.1 ft·lbs)

85 in·lbs

(7.1 ft·lbs)

216 in·lbs

(18 ft·lbs)

216 in·lbs

(18 ft·lbs)

720 in·lbs

(60 ft·lbs)

720 in·lbs

(60 ft·lbs)

1800 in·lbs

(150 ft·lbs)

9.6 N·m

9.6 N·m

24.5 N·m

24.5 N·m

81.6 N·m

81.6 N·m

204 N·m

5 - 14 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 61

Installation Guide for Galaxy Power Systems

Comcode of

Tem pl at e

For:

847891280 GPS4812/24, GPS2424/30, or GPS4848/100

846898708 2VR375 Battery Stand

846736841 2VR250 Battery Stand

847733342 12IR125LP Battery Stand

Cabinet Installation, continued

Procedure Refer to Figure 5-12 for this procedure.

Cabinet Installation

Step Action

1

Position the appropriate drill template where the cabinet is

to be located.

2

Using a drill bit, drill anchor holes to the depths specified in

Table 5-B.

3

Locate the cabinet in position using two or four anchor

bolts and hold-down washers.

4

Shim under cabinet corners to level.

5

Torque anchors as specified in Table 5-B.

6

Secure cabinets together using the hardware provided.

Note: See H569-407 for more details.

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 15

Page 62

Installation Guide for Galaxy Power Systems

Cabinet Installation, continued

Figure 5-12: Cabinet Installation Procedure

5 - 16 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 63

Installation Guide for Galaxy Power Systems

Cabinet Ground and Central Office Ground

Cabinet Ground Procedure

Central Office Ground Procedure

The next step is to ground the cabinet framework. Local grounding

practices will determine the grounding method and the size of cable

connected to the cabinet. A 2-gauge pigtail (847992070), as shown in

Figures 5-13 and 5-14, is provided for this purpose.

Cabinet Ground

Step Action

1

Run and connect the framework ground lead as shown in

Figure 5-13 or 5-14.

2

Torque connection as specified in Figure 5-13 or 5-14.

The system ground should be connected to the building’s principal

ground point (Central Office Ground). The conductor size must conform

to local standards.

Centralized Architecture

Follow local practice for Centralized Architecture.

Distributed Architecture

Connection to the power system is through the M10 studs located on the

distribution return bus. See Figure 5-13 (full-height cabinet) or 5-14

(half-height cabinet).

Central Office Ground for Distributed Architecture

Step Action

1

Run and connect the system ground lead to the initial

cabinet return bus. This connection will connect the return

side of the dc system to earth ground.

2

Torque connections as specified in Figure 5-13 or 5-14.

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 17

Page 64

Installation Guide for Galaxy Power Systems

Cabinet Ground and Central Office Ground, continued

Figure 5-13: Full-Height Cabinet and System Central Office

Ground

5 - 18 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 65

Installation Guide for Galaxy Power Systems

Cabinet Ground and Central Office Ground, continued

Figure 5-14: Half-Height Cabinet and System Central Office

Ground

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 19

Page 66

Installation Guide for Galaxy Power Systems

Recommended Cable Rack Layout

Figure 5-15: Various Cable Rack Arrangements

5 - 20 Cabinet Floor Mounting and Battery Stand Connection Issue 12 August 2012

Page 67

Installation Guide for Galaxy Power Systems

Issue 12 August 2012 Cabinet Floor Mounting and Battery Stand Connection 5 - 21

Page 68

Page 69

Installation Guide for Galaxy Power Systems

6 Centralized or Distributed

Architecture Connections

Multiple-Cabinet Installations

Special Requirements

This section covers the special requirements for multiple-cabinet

installations. These are:

• Centralized Architecture

– DC power connections to central bus bar

– Remote voltage sense (regulation) and system shunt for the

Galaxy Power System controller

• Distributed Architecture

– Intercabinet dc power bus connections

• All Types

– Intercabinet alarm and serial bus connections

Issue 12 August 2012 Centralized or Distributed Architecture Connections 6 - 1

Page 70

Installation Guide for Galaxy Power Systems

Centralized Architecture

Introduction This section covers the field assembly for Centralized Architecture

(H569-434 G2). For Distributed Architecture (H569-434 G1, all

H569-437 Groups, and all H569-436 Groups), skip these procedures.

DC Power Connections to Central Bus Bar

Refer to Figure 6-1 for this procedure.

DC Power Connections to Central Bus Bar

Step Action

1

Install optional plates if more than 8 connections are needed.

(See Figure 6-1.)

2

Run and connect new wires from positive and negative bus

bars in each cabinet to charge and charge return centralized

bus bars located outside the equipment.

Note: In centralized architectures all return wires from the

load must be terminated to the external discharge return bus.

These return wires may not be terminated in the cabinet.

6 - 2 Centralized or Distributed Architecture Connections Issue 12 August 2012

Page 71

Ground Bus Bar

To Centralized

Charge Battery Bus Bar

Rectifier Output

Negative for 48V systems

Positive for 24V systems

Return

Positive f or 48 V systems

Negative for 24V systems

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

Bat/Rtn

1/0

2/0

--

4/0

--

350

--

500

--

750

--

-1/0

2/0

-4/0

--

350

--

500

--

750

50

70

--

--

120

--

--

--

--

--

--

(One or two

required per

connection.)

Lugs and Hardware

Std Wire Ga

(Class B)

Metric

Wire Size

(mm )

2

Hardware Kit

(Grade 2)

Flex Wire Ga

(Class I)

Lug

Comcode

405348228

405348236

406021725

405348251

405347923

407890763

407890748

407850833

407890755

406335141

407890730

Optional Rectifier Output Bus Bars

848285847

(GPS4848/100 only)

Torque: 300 in-lbs (34 Nm)

(Note)

Note:

To Centralized

Rectifier Output

Positive for 24V systems

Installation Guide for Galaxy Power Systems

Centralized Architecture, continued

Torque: 300 in-lbs (3 4 Nm)

To Centralized Charge

Charge Battery Bus Bar

Negative for 48V systems

Type

Limited to 4 terminations maximum per bus or 8 maximum

(back-to-back) per 848285847 extension bus bar.

847867132

Figure 6-1: DC Power Connections to Centralized Bus Bars

Issue 12 August 2012 Centralized or Distributed Architecture Connections 6 - 3

Page 72

Installation Guide for Galaxy Power Systems

Centralized Architecture, continued

Remote Voltage

Sense and System

Shunt

for Galaxy

Millennium

Controller

These procedures convert the Galaxy Millennium Controller to external

battery sense (voltage sense at the central charge and discharge buses)

and a single system shunt for load current.

Refer to Figure 6-2 for these procedures.

Remote Voltage Sense for Galaxy Millennium Controller

Step Action

1 Cut the regulation wires that run from the controlle

bars in the cabinet (RB and RG, Slate and Black wires, respectively).

2 Remove and discard the ends of the wires that run to the cabinet bus

bars

.

3 Run new wires from the central bus bars; butt splice to th

that remain connected to the controller.

Note: If central bus bars have LVBD, sense leads must be on

rectifier side of the contactor.

System Shunt for Galaxy Millennium Controller

r to the rear bus

e cut wires

the

Step Action

1 Run new wires (installer-provided) from the system shunt to

connection

board. Limit the resistance of this wiring to 1 ohm maximum.

Typically, this may be accomplished with 22 AWG conductors 25 ft

long (1-way) or 20 AWG conductors 45 ft long (1-way). If the cabling

distance to the shunt exceeds these lengths, then 12 AWG conductors

may be used and spliced down to 22 AWG within the wiring gutter

above the BLJ card to permit termination onto the insulation

displacement terminals of M1 and M2. Note: For -48V systems, the

SH- connection is to the load side of the shunt (if it is in the return

path), and the SH+ connection is to the battery/rectifier side of the

shunt. For +24V systems, these leads are reversed.

Caution: Do not

connected to M1 and M2 from the controller. Adding the external

shunt wiring to these same M1 and M2 points completes the

connection from the shunt to the controller.

2 If the system shunt is located in the “h

chandelier, it will also be necessary to move the BL lead designated

“CG” (T83314-30 Figure 3F) of the Millennium Power/Sense P6-9

cable set off its default termination on the return bus at the top of the

cabinet, to the hot bus instead.

points M1 (SH-) and M2 (SH+) on the BLJ termination

remove the Violet and White wires that are already

ot” or ungrounded side of the

6 - 4 Centralized or Distributed Architecture Connections Issue 12 August 2012

Page 73

Installation Guide for Galaxy Power Systems

BLJ Board

Violet and White Wires

on Terminals M1 and M2

To System Shunt

To System Bus Bars

Original Path of Slate and

Black Voltage Sense Wires

(dashed line)

Butt Splice

Centralized Architecture, continued

Figure 6-2: System Shunt and Remote Voltage Sense

for Galaxy Millennium Controller

Issue 12 August 2012 Centralized or Distributed Architecture Connections 6 - 5

Page 74

Installation Guide for Galaxy Power Systems

Centralized Architecture, continued

Remote Voltage

Sense and System

Shunt

for Galaxy Vector

Controller

These procedures convert the Galaxy Vector Controller to external

battery sense (voltage sense at the central charge and discharge buses)

and a single system shunt for load current.

Refer to Figure 6-3 for these procedures.

Remote Voltage Sense for Galaxy Vector Controller

Step Action

1 Remove the regulation wires that run

controller (V1+ and V1-, Black and Slate wires) to the cabinet bus

bars.

2 Run new wires (installer provided,

in-line fuses required) from the central bus bars to the BLJ

terminals (V1+ and V1-).

Note: If central bus bars have LVBD, sense leads must be on the

rectifier side of the contac

System Shunt for Galaxy Vector Controller

Step Action

tor.

from the BLJ terminals on the

22-gauge maximum with 3A

1

Remove shunt wires that have been factory connected to the

BLJ terminals (SH1+ and SH1-, White and Black wires).

2

Retrieve current limiting resistors from the removed wireset.

3

Placing resistors near the shunt, connect a resistor to each of

the shunt sense terminals.

4

Run new wires (installer-provided) from the system shunt to

connection points SH1+ and SH1- on the BLJ termination

board. Limit the resistance of this wiring to 1 ohm maximum.

Typically, this may be accomplished with 22 AWG conductors

25 ft long (1-way) or 20 AWG conductors 45 ft long (1-way).

If the cabling distance to the shunt exceeds these lengths, then

12 AWG conductors may be used and spliced down to 22

AWG within the wiring gutter above the BLJ card to permit

termination onto the insulation displacement terminals of

SH1+ and SH1-. Note: For -48V systems, the SH-

connection is to the load side of the shunt (if it is in the

return path), and the SH+ connection is to the battery/

rectifier side of the shunt. For +24V systems, these leads

are reversed.

6 - 6 Centralized or Distributed Architecture Connections Issue 12 August 2012

Page 75

Installation Guide for Galaxy Power Systems

BLJ Board

To System Shunt

To System Bus Bars

Black and White

Shunt Wires

Yellow and White

Regulation Wires

Centralized Architecture, continued

Figure 6-3: System Shunt and Remote Voltage Sense

for Galaxy Vector Controller

Issue 12 August 2012 Centralized or Distributed Architecture Connections 6 - 7

Page 76

Installation Guide for Galaxy Power Systems

Distributed Architecture

Intercabinet DC Power Bus Connections

Refer to Figure 6-4 for this procedure.

Intercabinet DC Power Bus Connections

Step Action

1

Install the intercabinet bus bars as shown.

2

Install the bus bar shield as shown.

3

Torque connections as specified in Figure 6-4.

6 - 8 Centralized or Distributed Architecture Connections Issue 12 August 2012

Page 77

Distributed Architecture, continued

847720802 Bus Bars

Hardware provided:

901249839 Nut M8

901249821 Lock Washer M8

901249813 Flat Washer M8

(8 places each bus)

848414611 Bus Bar Shield

(1 per Supplemental Cabinet)

847760204 Short "T" Bus Bar

Negative for 48V systems

Positive for 24V systems

847760196 Long "T" Bus Bar

Positive for 48V systems

Negative for 24V systems

Hardware provided:

901263327 Screw M8 x 25mm

901249821 Lock Washer M8

901249813 Flat Washer M8

(4 places each "T")

Torque: 145 in-lbs (16 Nm)

Installation Guide for Galaxy Power Systems

Issue 12 August 2012 Centralized or Distributed Architecture Connections 6 - 9

Figure 6-4: Distributed Architecture Intercabinet DC Power

Bus Connections (Full-Height Cabinets Only)

Page 78

Installation Guide for Galaxy Power Systems

J6

J7

J6

J7

J5 J5

Millennium

Controller

BLJ2/3

1st Cabinet

BLJ2/3

2nd Cabinet

Rectifier Interface Cable Assembly

Leave Resistor In

Place If Last Cabinet

or

Remove Resistor and

Connect to J6 of Next

Cabinet

To Rectifiers

in This Cabinet

To Rectifiers

in This Cabinet

To Next Cabinet

As Required

Factory Installed

Intercabinet Alarm and Serial Bus Connections

BLJ2/3 to BLJ2/3 (Millennium Controller)

The cable used in this procedure is:

• Rectifier Interface Cable Assembly

(provided with cabinet)

BLJ2/3 to BLJ2/3 (Millennium Contr

Ste p Action

1

Connect the Rectifier Interface Cable Assembly from J5 of one

BLJ2/3 board to J6 of the BLJ2/3 board in the next cabinet.

Note: Remove and discard any resistors that are blocking

access to J6 or J5 connection points, except for those in J5 of

the last cabinet.

847690799 (10 feet)

oller)

6 - 10 Centralized or Distributed Architecture Connections Issue 12 August 2012

Figure 6-5: BLJ2 or BLJ3 Board Connections,

Millennium Controller

Continued on next page.

Page 79

Installation Guide for Galaxy Power Systems

S1.1 - S1.3: Bay ID

S1.4, S1.5, S1.6: Shunt Size*

S1.7, S1.8: Bay ID

0

1

0

0

1

1

0

0

1

1

0

0

0

0

1

1

1

1

0

1

0

1

0

1

0

1

1000

600

150

1500

2000

3000

Invalid

User-Defined

(shown)

S1.1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

S1.2

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

S1.7

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

S1.3

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

S1.8

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

(shown)

*Shunt size settings for distributed

architecture only.

Bay ID

Shunt Size (Amps)*

S1.4 S1.5 S1.6

Intercabinet Alarm and Serial Bus Connections, continued

BLJ2/3 to BLJ2/3

(Millennium

Controller),

continued

BLJ2/3 to BLJ2/3 (Millennium Controller), continued

Ste p Action

2

Set the DIP switch on the BLJ2/3 board for the bay ID number.

(Factory default is Bay 1.)

Figure 6-6: BLJ2/3 DIP Switch Settings When Using a

Millennium Controller

Issue 12 August 2012 Centralized or Distributed Architecture Connections 6 - 11

Page 80

Installation Guide for Galaxy Power Systems

Intercabinet Alarm and Serial Bus Connections, continued

BLJ3 to BLJ3 (Vector Controller)

This procedure is for the Vector Controller only.

The cable used in this procedure is:

• Rectifier Interface Cable Assembly 847690799 (10 feet)

(provided with cabinet)

BLJ3 to BLJ3 (Vector Controller)

Ste p Action

1

Remove the GCM daughter board from the BLJ3 termination

board in the supplemental cabinet. It is not used with a Vector

controller in the initial cabinet.

2

Using 22-gauge wire (installer provided), make discrete alarm

connections from the terminals designated in Figure 6-7 on one

BLJ3 board to corresponding terminals on the BLJ3 board in

the next cabinet.

3

Connect the Rectifier Interface Cable Assembly from J5 of one

BLJ3 board to J6 of the BLJ3 board in the next cabinet.

Note: Remove and discard any resistors that are blocking

access to J6 or J5 connection points, except for those in J5 of

the first cabinet and J6 of the last cabinet.

4

If there is a battery shunt terminated onto the SH1+ or SH1–

terminals in the supplemental cabinet:

• Remove the WH strap from across an usused set of SH1 or

SH2 +/– terminals in the initial cabinet.

• Use 22 AWG (installer provided) to extend the shunt pair

from the supplemental cabinet to the unused SH1 or SH2

terminals on the BLJ3 termination board of the initial

cabinet.

Note: Vector monitor only 2 shunts maximum, SH1 and SH2.

Continued on next page.

6 - 12 Centralized or Distributed Architecture Connections Issue 12 August 2012

Page 81

BLJ3 in 1st Cabinet

SH1

SH2

SH3

SH4

–

+

–

+

–

+

–

+

BLJ3 in 2nd Cabinet

SH1

SH2

SH3

SH4

–

+

–

+

–

+

–

+

J6

J7

J6

J7

J5 J5

BLJ3 With

Vector Controller

1st Cabinet

BLJ3

2nd Cabinet

Rectifier Interface Cable Assembly

see above