Page 1

g

DEH203 R02

EntelliGuard™ Power Circuit Breakers

800–2000 A Frames, 240–600 Vac

Maintenance Manual

Page 2

Page 3

WARNINGS

CAUTIONS

NOTES

DEH203

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or

other conditions that could cause personal injury are present in this equipment or may be associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care is not taken.

Notes call attention to information that is especially significant to understanding and operating the

equipment.

This document is based on information available at the time of its publication. While efforts have

been made to ensure accuracy, the information contained herein does not cover all details or variations in hardware and software, nor does it provide for every possible contingency in connection

with installation, operation, and maintenance. Features may be described herein that are not present in all hardware and software systems. GE Consumer & Industrial assumes no obligation of

notice to holders of this document with respect to changes subsequently made.

GE Consumer & Industrial makes no representation or warranty, expressed, implied, or statutory,

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warrantees of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Company:

EntelliGuard™, EntelliGuard Messenger™, Entellisys™

© Copyright 2005 GE Company

All Rights Reserved

i

Page 4

EntelliGuard™ 800–2000 A Power Circuit Breakers

Table of Contents

Chapter 1. Introduction

1.1 Overview...................................................................................................................................................1

1.2 Inspection and Maintenance..................................................................................................................1

1.3 Renewal Parts...........................................................................................................................................1

Chapter 2. Description

2.1 Introduction ............................................................................................................................................3

2.2 Frame Sizes.............................................................................................................................................. 3

2.3 Operation ................................................................................................................................................3

2.4 Fused Models...........................................................................................................................................3

2.5 Mounting.................................................................................................................................................3

2.6 Trip Units................................................................................................................................................3

2.7 Interruption Ratings ...............................................................................................................................3

Chapter 3. Storage, Safety, and Maintenance

3.1 Storage.....................................................................................................................................................5

3.2 Safety........................................................................................................................................................5

3.3 Maintenance............................................................................................................................................5

Chapter 4. Breaker Operation

4.1 Operating Instructions............................................................................................................................7

Sequence of Operations ..................................................................................................................7

Operation of the Breaker................................................................................................................7

Padlock Operation...........................................................................................................................8

4.2 Control Wiring ........................................................................................................................................8

4.3 Breaker Interlocks ...................................................................................................................................8

Drawout Interlock............................................................................................................................ 8

Contact Interlock.............................................................................................................................8

Spring Discharge Interlock .............................................................................................................8

4.4 Equipment Interlocks.............................................................................................................................. 8

Chapter 5. Breaker Maintenance

5.1 Lubrication............................................................................................................................................11

5.2 Removing and Reinstalling the Breaker ..............................................................................................11

Removing the Breaker...................................................................................................................11

Installing the Breaker.................................................................................................................... 11

5.3 Slow Closing the Breaker ......................................................................................................................13

5.4 Separation and Reconnection of Front and Back Frames................................................................... 13

Separation of Front and Back Frames for EGS08, EGF08, and EGH08......................................13

Reconnection of Front and Back Frames for EGS08, EGF08, and EGH08.................................14

Separation of Front and Back Frames for EGX08, EGS16, EGF16, EGH16, EGS20, and

EGF20.............................................................................................................................................16

Reconnection of Front and Back Frames for EGX08, EGS16, EGF16, EGH16, EGS20, and

EGF20.............................................................................................................................................16

ii

Page 5

EntelliGuard™ 800–2000 A Power Circuit Breakers

5.5 Breaker Mechanism Operation and Adjustment.................................................................................18

Trip Latch Adjustment..................................................................................................................19

Chapter 6. Contact Maintenance

6.1 Introduction ..........................................................................................................................................20

6.2 Arc Chute Removal and Replacement .................................................................................................20

Arc Chutes in EGS08, EGF08, and EGH08 Breakers....................................................................20

Arc Chutes in EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20 Breakers............................20

6.3 Back Frame Assembly............................................................................................................................21

6.4 Replacement of Contacts ......................................................................................................................21

Contact Replacement on EGS08, EGF08, and EGH08 Breakers.................................................21

Contact Replacement on EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20 Breakers..........24

6.5 Adjusting the Contacts..........................................................................................................................26

Contact Adjustment on EGS08, EGF08, and EGH08 Breakers....................................................26

Contact Adjustment on EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20 Breakers............26

Chapter 7. Maintenance of Standard Parts and Assemblies

7.1 Primary Disconnects..............................................................................................................................28

Primary Disconnect Replacement on EGS08, EGF08, and EGH08 Breakers..............................28

Primary Disconnect Removal on EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20

Breakers..........................................................................................................................................28

Primary Disconnect Installation on EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20

Breakers..........................................................................................................................................29

7.2 Secondary Disconnect...........................................................................................................................31

Secondary Disconnect Removal....................................................................................................31

Secondary Disconnect Installation................................................................................................31

7.3 Flux Shifter ............................................................................................................................................32

Flux Shifter Adjustment.................................................................................................................32

Removing the Flux Shifter ............................................................................................................32

Installing the Flux Shifter..............................................................................................................32

7.4 Draw-Out Mechanism............................................................................................................................34

Draw-Out Mechanism Removal ....................................................................................................34

Draw-Out Mechanism Installation................................................................................................34

Draw-Out Mechanism Adjustment................................................................................................34

7.5 Escutcheon.............................................................................................................................................36

Escutcheon Removal .....................................................................................................................36

Escutcheon Installation.................................................................................................................36

7.6 Charging Handle...................................................................................................................................36

Removing the Charging Handle...................................................................................................36

Installing the Charging Handle....................................................................................................36

Table of Contents

Chapter 8. Accessory Maintenance

8.1 Bell Alarm with Lockout........................................................................................................................38

Removing the Bell Alarm with Lockout........................................................................................38

Installing the Bell Alarm with Lockout.........................................................................................39

8.2 Shunt Trip .............................................................................................................................................39

iii

Page 6

EntelliGuard™ 800–2000 A Power Circuit Breakers

Table of Contents

Removing the Shunt Trip............................................................................................................. 40

Installing the Shunt Trip ..............................................................................................................40

8.3 Charging Motor..................................................................................................................................... 41

Removing the Charging Motor.....................................................................................................41

Installing the Charging Motor...................................................................................................... 41

Removing the Motor Cut-Off Switch ............................................................................................41

Installing the Motor Cut-Off Switch..............................................................................................41

Adjusting the Motor Cut-Off Switch............................................................................................. 43

8.4 Remote Close......................................................................................................................................... 43

Removing the Remote Close......................................................................................................... 44

Installing the Remote Close.......................................................................................................... 44

8.5 Open-Fuse Lockout ...............................................................................................................................45

Removing the Open-Fuse Lockout, 800 A and 1600 A Breakers..................................................45

Installing the Open-Fuse Lockout, 800 A and 1600 A Breakers................................................... 45

Removing the Open-Fuse Lockout, 2000 A Breakers...................................................................45

Installing the Open-Fuse Lockout, 2000 A Breakers ....................................................................46

8.6 Remote Charge-Indication Switch........................................................................................................47

Removing the Remote Charge-Indication Switch........................................................................ 47

Installing the Remote Charge-Indication Switch.........................................................................47

8.7 Network Interlock..................................................................................................................................48

iv

Page 7

EntelliGuard™ 800–2000 A Power Circuit Breakers

List of Figures

1. Front of the EntelliGuard circuit breaker, showing the locations of standard and optional

features....................................................................................................................................................... 2

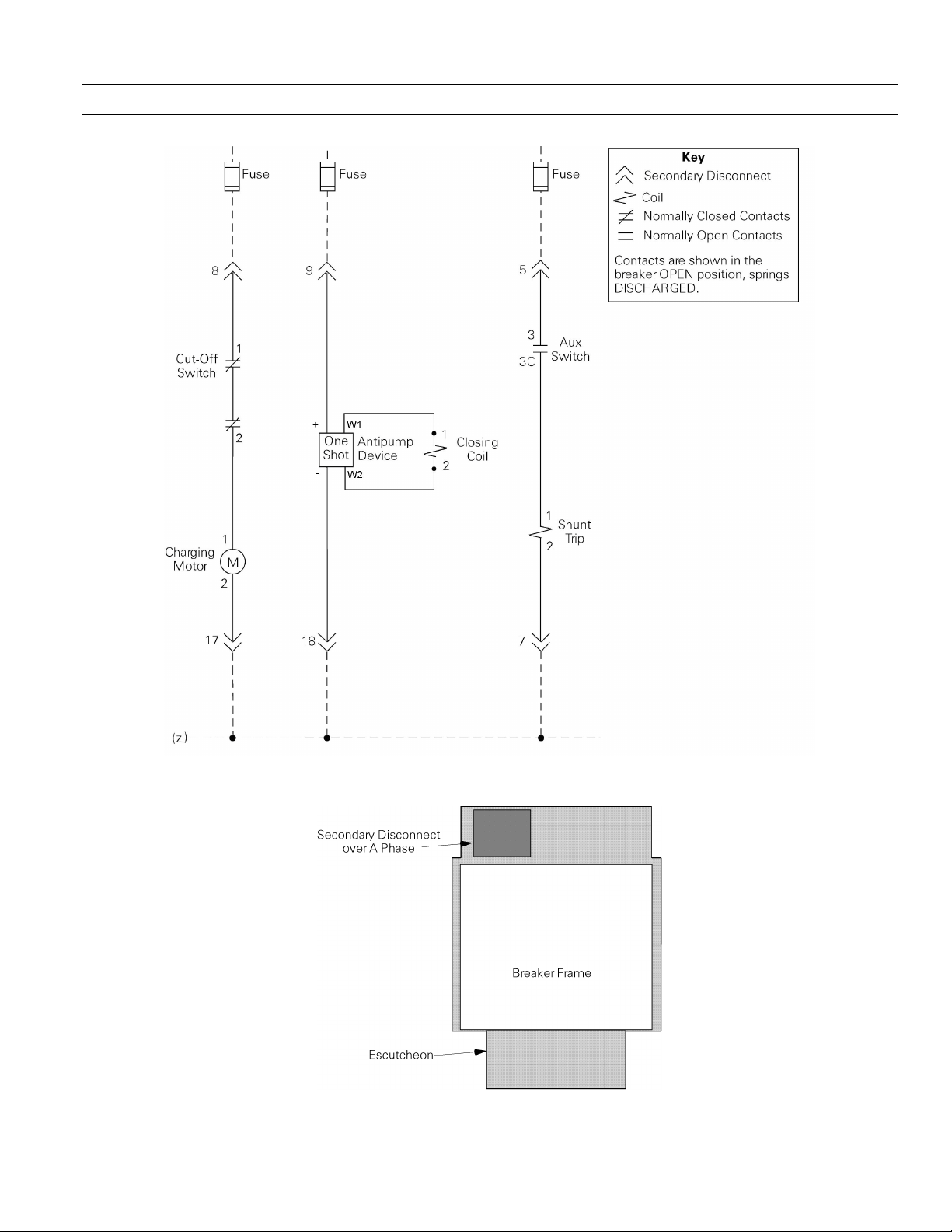

2. Elementary diagram of the breaker control circuits. ...............................................................................9

3. Location of the secondary disconnect...................................................................................................... 9

4. Installing the breaker into the compartment......................................................................................... 12

5. Disconnecting the closing spring assembly. ........................................................................................... 13

6. Removing or installing the secondary disconnect ................................................................................. 14

7. Movable contact connection to the breaker main shaft on EGS08, EGF08, and EGH08 breakers...... 14

8. Separating the front and back frames on EGS08, EGF08, and EGH08 breakers.................................. 15

9. Movable contact connection to the breaker main shaft on EGX08, EGS16, EGF16, EGH16,

EGS20, and EGF20 breakers. .................................................................................................................. 16

10. Separating the front and back frames on EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20

breakers.................................................................................................................................................... 17

11. Breaker mechanism in the CLOSED position. ...................................................................................... 18

12. Breaker mechanism in the TRIPPED position. ..................................................................................... 18

13. Breaker mechanism in the RESET position........................................................................................... 18

14. Adjusting the trip latch. .......................................................................................................................... 19

15. Typical back frame assembly, EGS08, EGF08, and EGH08. .................................................................. 21

16. Typical back frame assembly, EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20............................ 21

17. Upper (stationary) contact assembly for EGS08, EGF08, and EGH08 breakers................................... 22

18. Lower (movable) contact assembly for EGS08, EGF08, and EGH08 breakers...................................... 22

19. Removal and installation of contact assemblies on EGS08, EGF08, and EGH08 breakers .................. 23

20. Removal and installation of contact assemblies on EGX08, EGS16, EGF16, EGH16, EGS20, and

EGF20 breakers........................................................................................................................................ 25

21. Stationary main and intermediate contact styles. ..................................................................................25

22. Replacement of stationary arcing contacts............................................................................................. 25

23. Contact adjustment on EGS08, EGF08, and EGH08 breakers............................................................... 26

24. Contact adjustment on EGX08, EGS16, EGF16, EGH16, EGS20, EGF20 breakers. ............................. 27

25. Primary disconnect assembly for EGS08, EGF08, and EGH08 breakers ............................................... 28

26. Primary disconnect assembly for EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20 breakers........ 28

27. Primary disconnect removal and installation on EGS08, EGF08, and EGH08 breakers...................... 29

28. Primary disconnect removal and installation on EGX08, EGS16, EGF16, EGH16, EGS20, and

EGF20 breakers........................................................................................................................................ 30

29. Primary disconnect adjustment on EGX08, EGS16, EGF16, EGH16, EGS20 and EGF20 breakers. ....30

30. Secondary disconnect.............................................................................................................................. 31

31. Secondary disconnect terminal numbering. ..........................................................................................31

32. Removing or installing the secondary disconnect. ................................................................................ 31

33. Flux shifter............................................................................................................................................... 32

34. Flux shifter adjustment............................................................................................................................ 32

35. Removal or installation of a flux shifter ................................................................................................. 33

36. Draw-out racking mechanism. ................................................................................................................ 34

v

Page 8

EntelliGuard™ 800–2000 A Power Circuit Breakers

List of Figures

37. Draw-out mechanism adjustment............................................................................................................34

38. Draw-out racking mechanism removal and installation.........................................................................35

39. Escutcheon kit and related parts. ............................................................................................................36

40. Charging handle ......................................................................................................................................37

41. Charging handle removal and installation.............................................................................................37

42. Charging handle mounting detail ..........................................................................................................37

43. Bell Alarm with Lockout connections on the secondary disconnect. ....................................................38

44. Bell Alarm with Lockout accessory kit. ....................................................................................................38

45. Bell Alarm with Lockout installation or removal. ...................................................................................38

46. Front view of the Bell Alarm with Lockout installation, showing the breaker mechanism tab

engaging the mounting plate slot............................................................................................................39

47. Orientation of the label on the Bell Alarm module for installation. .....................................................39

48. Shunt Trip connections to the auxiliary switch and secondary disconnect. .........................................40

49. Shunt Trip accessory kit...........................................................................................................................40

50. Shunt Trip module removal and installation. ........................................................................................40

51. Charging Motor and cut-off switch..........................................................................................................41

52. Removal and installation of the Charging Motor and cut-off switch.....................................................42

53. Cut-off switch adjustment.........................................................................................................................43

54. Remote Close accessory kit.......................................................................................................................43

55. Remote Close installation and removal...................................................................................................44

56. Open-Fuse Lockout accessory ..................................................................................................................45

57. Open-Fuse Lockout connections to the secondary disconnect for EGF-20 breakers.............................45

58. Open-Fuse Lockout installation and removal .........................................................................................46

59. Remote charge-indication switch............................................................................................................47

60. Remote charge-indication switch removal and installation...................................................................47

61. Remote charge-indication switch side view.............................................................................................47

62. Network Interlock connections to the secondary disconnect. ................................................................48

63. Network Interlock assembly mounting to the circuit breaker bottom frame .........................................49

64. Network Interlock module fastening to the mounting plate. .................................................................49

65. Manual reset assembly mounting............................................................................................................49

66. Trip paddle and set lever gap calibration .............................................................................................49

vi

Page 9

EntelliGuard™ 800–2000 A Power Circuit Breakers

List of Tables

1. Recommended service intervals, in number of ON-OFF operations, for EntelliGuard breakers........... 1

2. Breaker interruption ratings..................................................................................................................... 4

3. Sequence of operations that may be performed with the EntelliGuard circuit breaker......................... 7

4. Secondary disconnect terminals with standard and optional connections. ......................................... 10

5. Key to numbered parts in Figure 11, Figure 12, and Figure 13 ............................................................. 18

6. Bell Alarm with Lockout wires and corresponding secondary disconnect terminals. ..........................39

7. Catalog number and operating voltage for the Shunt Trip accessory. ................................................. 40

8. Catalog number and operating voltage for the Charging Motor accessory.......................................... 41

9. Catalog number and operating voltage for the Remote Close accessory.............................................. 43

vii

Page 10

Page 11

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 1. Introduction

1.1 Overview

These instructions describe the procedures for maintenance and operation of EntelliGuard 800-2000 ampere

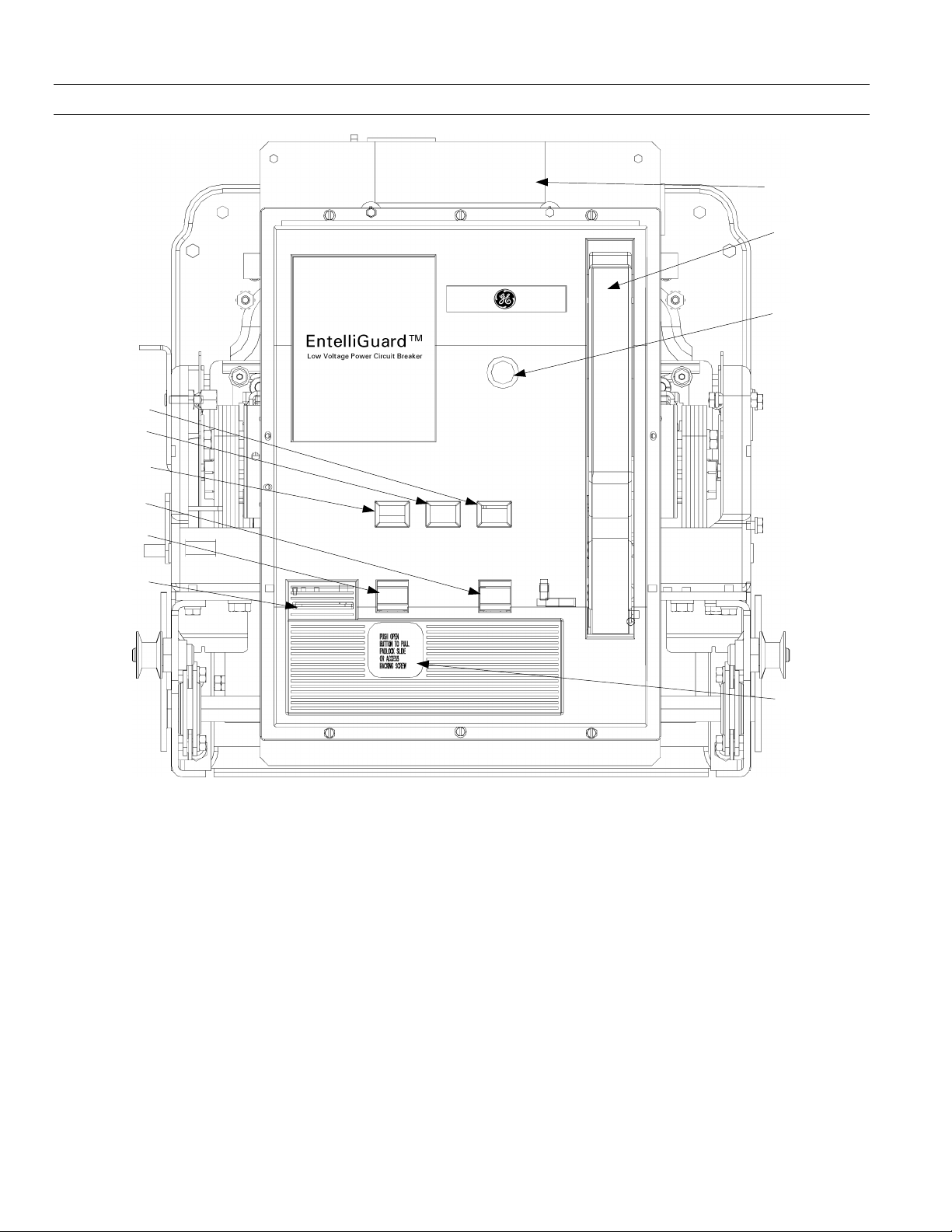

low-voltage power circuit breakers. Figure 1 is a front view

of the breaker, with key features indicated.

The proper use, care, and maintenance of these breakers

is important both from the safety aspect of protecting personnel and for minimizing equipment damage when

faults occur. Persons who apply, use, and service these

breakers should be familiar with the information presented in this publication.

WARNING: Before inspecting or beginning

any maintenance work on a circuit breaker, the

breaker must be in the OPEN position and dis connected from all voltage sources, both power

and control.

AVERTISSEMENT: Avant d’inspecter ou de

débuter tout travail de maintenance d’un disjoncteur, celui-ci dout être en position OPEN et

débranché de toutes les sources de voltage, à la

fois de puissance et de contrôle.

1.2 Inspection and Maintenance

Circuit breakers should be maintained under a systematic

program. Take each breaker out of service periodically for

inspection and maintenance to help establish high reliability in service. This policy is facilitated by keeping one

or more spare breakers to install in place of breakers

requiring maintenance. Keeping a stock of recommended

renewal parts ensures that maintenance work can be done

quickly.

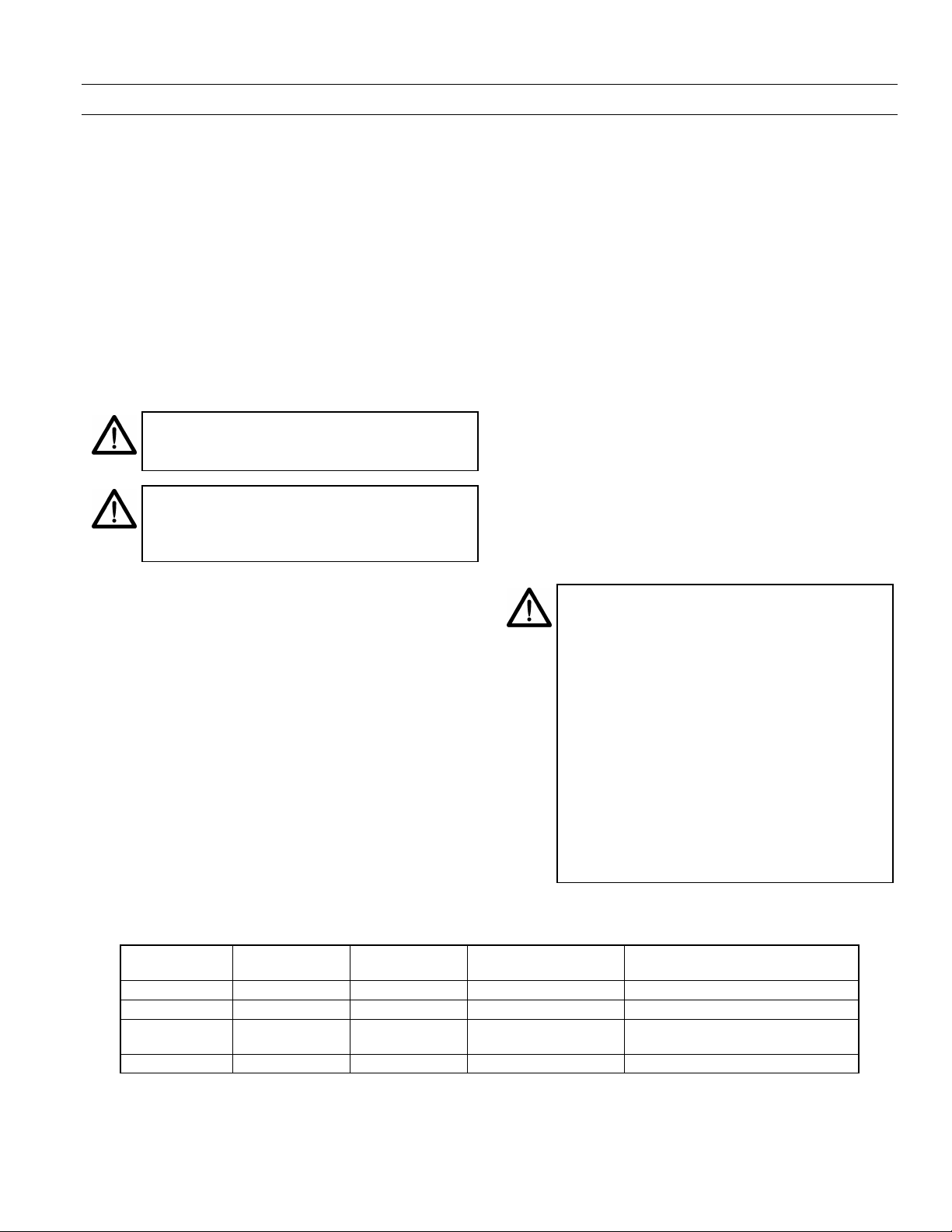

The frequency at which an individual breaker should be

inspected depends on the circumstances of its use. Table 1

lists the ANSI-recommended service interval with the GErecommended interval for EntelliGuard breakers.

EntelliGuard breakers should be inspected after every

short circuit interruption, after every number of ON-OFF

operations given in Table 1, or every two years, whichever

comes first. EntelliGuard breakers have been built and

tested to operate reliably with inspections at twice the

ANSI interval, thus saving time and money by reducing

breaker downtime.

Source of

Recommendation 800 A Frame

ANSI 1750 500

EntelliGuard, no

load

EntelliGuard, at

frame rating

Table 1. Recommended service intervals, in number of ON-OFF

operations, for EntelliGuard breakers.

If a breaker is installed in an area of high humidity or a

dusty atmosphere, it should be inspected more often.

Monthly inspections might be warranted for a breaker

operated under severe conditions.

Always inspect the breaker after it has interrupted a short

circuit or ground fault.

A standard inspection should consist of the following

steps:

1. Visual Check – Look for dirt, grease, or other

foreign material on all breaker parts. Check

insulating surfaces for conditions that could

degrade insulating properties, such as cracks or

evidence of overheating. Check for foreign objects

on the bottom of the breaker compartment. Check

for loose or damaged control wiring and for similar

problems.

2. Operation – Observe a few close-open operations

using the operating handle. If a breaker is seldom

operated, such that it remains open or closed for six

months or more, open and close the breaker several

times in succession.

3. Interlocks – During the operational check, verify

that the safety interlocks are working properly.

4. Arc Chutes and Contacts – Inspect the arc chutes

and contacts for excessive burning or breakage.

Check the amount of contact depression or wipe

when the breaker is closed.

5. Accessories – Verify that the various accessories are

working properly.

3500 1000

2800 800

1600 and

2000 A Frames

1.3 Renewal Parts

Many of the parts and assemblies contained in

EntelliGuard breakers are available as replacement parts.

See DEF004 for a complete listing.

1

Page 12

EntelliGuard™ 800–2000 A Power Circuit Breakers

A B C D E F G H J K

Chapter 1. Introduction

Figure 1. Front of the EntelliGuard circuit breaker, showing the locations of standard and optional features.

A Indicator: DISC (white)

TEST (white)

CONN (white)

B Indicator: CHARGED (yellow)

DISCHARGED (white)

C Indicator: CLOSED (red)

OPEN (green)

D CLOSE button (black)

E OPEN button (red)

F Padlock provision

G Catalog number, rating, and date code nameplate

H Manual charging handle

J Bell Alarm with Lockout target/RESET button

K Draw-out racking screw (behind cover)

2

Page 13

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 2. Description

2.1 Introduction

EntelliGuard low-voltage power circuit breakers control

and protect power circuits up to 600 volts. They will safely

switch loads and automatically clear circuits during abnormal conditions when used with the EntelliGuard

Messenger™. These include short circuits, sustained

overloads, and ground faults.

EntelliGuard breakers contain a “quick-make, quickbreak” mechanism, which stores energy in a closing spring

for quick release. During closing, some energy is

transferred to an opening spring to be used subsequently

for fast tripping.

The three main functional components of the breaker are

its mechanism, an assembly consisting of the conductive

components, and the interrupter.

The mechanism is designed to receive energy, store it, and

later deliver it to close the breaker contacts. It must be able

to reverse the closing operation at any point upon receipt

of a trip signal from the EntelliGuard Messenger (that is,

it must be “trip-free”). Finally, it must also open a closed

breaker quickly enough to minimize contact erosion and

to effectively transfer the arc to the arc chutes.

The current-carrying components are assembled on the

back frame, which provides the required mechanical support and insulating structure. The conductive components are the studs for external connections, the movable

and stationary contact sets, and the pivots for the movable

contacts.

The interrupter components are the arcing contacts, the

arc runners mounted on the back base, and the removable

arc chute assemblies.

In addition to these basic components, a breaker may be

equipped with a combination of accessories and interlocking devices.

breaker, and a Shunt Trip to open the breaker. External

control power is required to energize the motor and its

control circuit. All breakers are equipped with a manual

charging handle so that the closing springs can be

charged without motor control power.

2.4 Fused Models

Internally fused breakers are available in 800- and 1600ampere frame sizes. They are not interchangeable with

unfused breakers, since fused breakers require deeper

compartments to accommodate the fuses.

2.5 Mounting

EntelliGuard breakers are designed for draw-out

mounting. Draw-out breakers are easily installed into or

removed from their switchgear cubicle. They are

equipped with a racking mechanism, which is used to

insert or withdraw the breaker, and primary and

secondary disconnects, which connect and disconnect

automatically.

2.6 EntelliGuard Messenger™

EntelliGuard low-voltage power circuit breakers are

intended for use in Entellisys™ Low-Voltage Switchgear

only. The breaker frames do not contain trip units or

current transformers. Thus, the EntelliGuard circuit

breaker must be used in concert with the EntelliGuard

Messenger and the current transformers mounted within

the switchgear cubicle. For installation and operation of

the EntelliGuard Messenger, see DEH231 and DEH234.

2.7 Interruption Ratings

2.2 Frame Sizes

The EntelliGuard breakers covered in this manual are

available in 800-ampere, 1600-ampere, and 2000-ampere

frame sizes. These values represent the maximum

continuous-current rating of each frame. In addition,

each breaker carries a specific rating that is determined by

the current sensor ampere rating or the maximum setting

of the EntelliGuard Messenger™ with which it is used.

2.3 Operation

EntelliGuard breakers are available with either manual or

electric operation. The mechanism closing springs of

manually operated breakers are charged by operating the

charging handle on the front of the breaker.

Electrically operated breakers contain an electric

Charging Motor that charges the closing springs, a

Remote Close accessory with antipump to close the

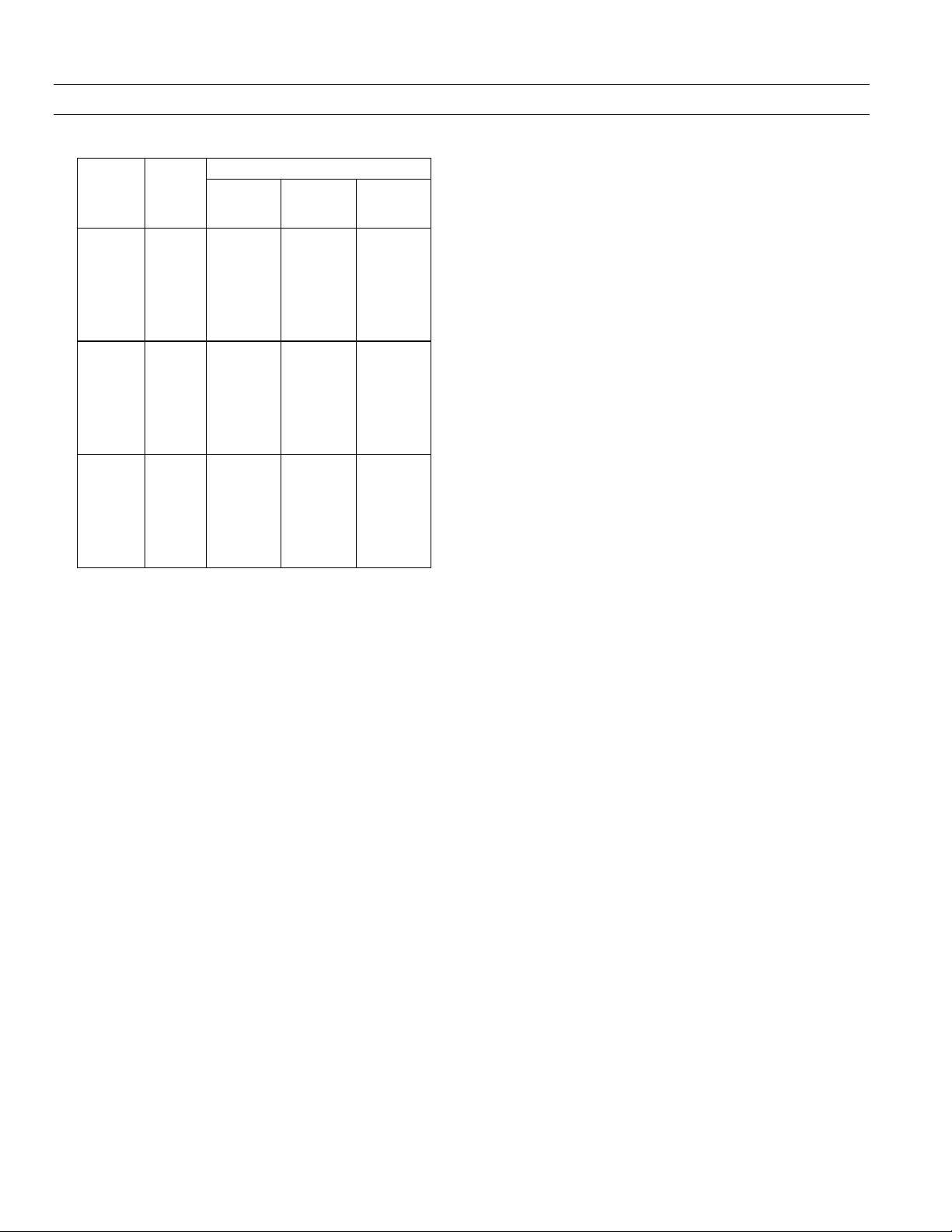

Table 2 lists the short-circuit current that each breaker

type is rated to interrupt for each maximum rated voltage.

3

Page 14

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 2. Description

Rated AC

Voltage,

Nominal

(max)

600

(635)

480

(508)

240

(254)

Short-Circuit RMS Symmetrical kA

Breaker

Type

EGS-08

EGH-08

EGX-08

EGS-16

EGH-16

EGS-20

EGS-08

EGH-08

EGX-08

EGS-16

EGH-16

EGS-20

EGS-08

EGH-08

EGX-08

EGS-16

EGH-16

EGS-20

Short-Time

Withstand

30

42

50

42

65

65

30

42

65

50

65

65

30

42

65

50

65

65

With

Inst. Trip

30

42

50

42

65

65

30

42

65

50

65

65

42

50

65

65

65

65

Without

Inst. Trip

30

42

50

42

65

65

30

42

65

50

65

65

30

42

65

50

65

65

Table 2. Breaker interruption ratings.

(EGF-08/16/20 rated at 200kA).

4

Page 15

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 3. Storage, Safety, and Maintenance

3.1 Storage

The breaker should be put into service immediately in its

permanent location. If this is not possible, the following

precautions must be taken to ensure proper storage of the

breaker

• Protect the breaker against condensation, preferably

by storing it in a warm, dry room, since water absorption has an adverse effect on the insulating parts.

• Store the breaker in a clean location free from corrosive gases or fumes. It is particularly important to

protect the equipment from moisture and cement

dust, as this combination is corrosive to many parts.

CAUTION: If the breaker is stored for any

length of time, inspect it periodically to ensure

that steel parts have not begun to rust and to

ensure good mechanical condition. If the

breaker has been stored under unfavorable

atmospheric conditions, it must be cleaned and

dried before being placed in service.

ATTENTION: Si le disjoncteur est remisé pour

peu importe la période de temps, inspectez-le

périodiquement afin de vous assurer que les

pièces d’acier n’ont pas commencé à rouiller et

de vous assurer de leur bonne condition

mécanique. Si le disjoncteur a été remisé à des

conditions atmosphériques défavorables, il doit

être nettoyé et séché avant d’être mis en service.

3.2 Safety

Each facility must maintain a safety program for the protection of personnel, as well as other equipment, from the

hazards associated with electrical equipment.

The following requirements are intended to augment a

facility’s safety program, not to supplant local responsibility for devising a complete safety program. The following

basic industry-accepted safety requirements are applicable

to all major electrical equipment, such as switchgear and

switchboards. General Electric neither condones nor

assumes any responsibility for practices that deviate from

these requirements.

1. All conductors must be assumed to be energized

unless their potential has been measured as ground

and suitable grounding conductors have been

applied to prevent energizing. Many accidents have

been caused by back feeds from various sources.

2. Although interlocks are provided to reduce some of

the risks, each individual’s actions are essential to

prevent accidents when performing service or main tenance. Each person’s knowledge, mental awareness, and planned and executed actions often

determine if an accident will occur. The most

important principle for avoiding accidents is that all

associated personnel carefully apply a thorough

understanding of the specific equipment with

regard to its purpose, its construction, its operation,

and situations that could be dangerous.

3. All personnel associated with installation, operation,

and maintenance of electrical equipment, such as

power circuit breakers and other power-handling

equipment, must be thoroughly instructed, with

periodic retraining, about power equipment in general and the specific equipment with which they will

be working in particular. Instruction books, actual

devices, and appropriate safety and maintenance

procedures, such as OSHA publications, the

National Electrical Safety Code (ANSI C2), the

National Electrical Code, and NFPA 7 OB Electrical

Equipment Maintenance, must be closely studied

and followed. During actual work, supervisors

should audit procedures to ensure conformance.

4. Excellent maintenance is essential for reliability and

safety of all electrical equipment. Industry publications of recommended maintenance practices, such

as ANSI/NFPA 70B, Electrical Equipment Maintenance,

are readily available.

3.3 Maintenance

Both long- and short-term maintenance of all electrical

equipment is essential for reliability and safety. Maintenance programs must be well-planned and carried out

consistently with both industry experience and the manufacturer’s recommendations. The local environment must

always be considered such programs, including such

variables as ambient temperature, extreme moisture,

number of operations, corrosive atmosphere, significant

insect problems, and any other unusual or abusive condition of the application.

One of the critical service activities, sometimes neglected,

is the calibration of various control devices. These monitor conditions in the primary and secondary circuits,

sometimes initiating emergency corrective action, such as

opening or closing circuit breakers. In view of the vital

roles of these devices, it is important to follow a periodic

test program.

General Electric recognizes that the interval between periodic checks will vary, depending on the environment, the

type of device, and the customer’s experience. GE recommends that, until the customer has accumulated sufficient

experience to select a test interval best suited to the local

requirements, all significant calibrations be checked at

one- to two-year intervals.

Operation and maintenance guides supplied by manufacturers normally address components that require service

or maintenance during the useful life of the equipment.

However, they cannot include every possible part that

could require attention, particularly over a long service

period or under adverse conditions. Maintenance

personnel must be alert to deterioration of any part of the

5

Page 16

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 3. Storage, Safety, and Maintenance

supplied switchgear, taking such action as necessary to

restore it to serviceable status.

If additional assistance is required in the planning and

performance of maintenance, contact GE Installation and

Field Service (1-888-434SERV / 1-888-434-7378) to

undertake the maintenance or to provide technical

assistance, such as the latest publications.

The performance and safety of this equipment may be

compromised by the modification or supplied parts or

their replacement by non-identical substitutes. All such

design changes must be qualified to ANSI/IEEE Standard

C37.59.

Each customer should methodically keep written maintenance records as an aid in future service planning and

equipment reliability improvement. Unusual experiences

should be promptly reported to General Electric (1-888GER-ESOLve).

6

Page 17

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 4. Breaker Operation

4.1 Operating Instructions

Sequence of Operations

The sequence of operations that may be performed on the

circuit breaker are listed in Table 3.

Operation of the Breaker

Manually Charging the Closing Springs

Pull the operating handle down about 90° (until it stops)

six times to fully charge the closing springs. This will

not close the breaker contacts. The charge indicator will

show CHARGED on a yellow background.

NOTE: The breaker cannot be closed unless

the springs are fully charged and the handle is

stored fully in.

NOTE: Le disjoncteur ne peut être fermé à

moins que les ressorts ne soient pleinement

chargés et que la poignée ne soit pleinement

rentrée.

Electrically Charging the Closing Springs

If the breaker is equipped with the (optional) Charging

Motor, the closing springs may also be charged with any

the following methods:

• With the breaker in the TEST position, install the

motor fuse in the fuse holder in the upper left corner

of the breaker compartment.

• Operate the Charging Motor by applying the rated

voltage to secondary disconnect terminals 8 and 17.

Power to the motor is removed automatically by a

cutoff switch when the springs are fully charged.

• If power is lost during the charging cycle, finish

charging the springs by cycling the charging handle

until the indicator shows CHARGED on a yellow

background.

The closing springs will automatically recharge after

closing if control power is maintained at terminals 8 and

17.

Open/Closed

Indicator

OPEN Open DISCHARGED Discharged Mechanism may be charged

OPEN Open CHARGED Charged Contacts may be closed

CLOSED Closed DISCHARGED Discharged

CLOSED Closed CHARGED Charged Contacts may be opened

Main Breaker

Contacts

Charge

Indicator

Condition of Close

Table 3. Sequence of operations that may be performed with the EntelliGuard circuit breaker

Closing the Breaker

Close the breaker contacts with any of the following

methods:

• Depress the CLOSE button on the front of the

breaker.

• Close the breaker using the Entellisys™ HMI.

• Energize the (optional) Remote Close accessory by

applying the rated voltage to secondary disconnect

terminals 9 and 18.

If the breaker is closed electrically and the closing voltage

is maintained, an antipump device prevents a second closing operation on the breaker in the event it is tripped

OPEN. The closing impulse must be released for 1 to 2.5

seconds and reapplied before a second closing operation

can occur.

If the closing voltage is applied while the closing springs

are not fully charged, the Remote Close coil energizes, but

operation of the closing mechanism is blocked. The

closing voltage must be removed and reapplied when the

springs are fully charged to close the breaker.

A mechanical interlock prevents the closing springs from

discharging if an attempt is made to close an already

CLOSED breaker.

NOTE: The main breaker contacts cannot be

closed if any of the following conditions apply:

• The draw-out mechanism is in any position other than TEST or CONN, as displayed on the breaker position indicator.

• The (optional) Bell Alarm with Lockout

was not reset after an overcurrent lockout.

• The (optional) Open Fuse Lockout was

not reset after replacement of a blown fuse.

• The (optional) Network Interlock was not

reset after a set operation.

These conditions must be corrected before the

breaker can be closed. Attempts to close the

breaker before these conditions are corrected

may result in discharge of the closing springs

without closing the main contacts.

Springs

Mechanism may be recharged or

Contacts may be opened

Next Permissible

Operating Function

7

Page 18

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 4. Breaker Operation

NOTE: Les contacts principaux du disjoncteur

ne peuvent être fermés si l’une ou l’autre des

conditions suivantes s’appliquent:

• Le mécanisme de retrait du ressort est en

tout autre position que: TEST ou DISC, tel

que montré à la position indicatrice du disjoncteur.

• L’alarme optionnelle avec cloche n’a pas

été remise en place après un blocage par

surintensité de courant.

• Le mécanisme optionnel de déclenchement par sous voltage n’a pas été

enclenché.

• Le verrouillage réciproque optionnel de

réseaun'était pas réenclenché après une

opération d'enclenchement.

Il faut que ces situations soient corrigées avant

de procéder à la fermeture du disjoncteur.

Opening the Breaker

Open the breaker contacts with any of the following

methods:

• Depress the OPEN button on the front of the breaker.

• Open or trip the breaker using the Entellisys™ HMI.

• Energize the (optional) Shunt Trip accessory by

applying the rated voltage to secondary disconnect

terminals 5 and 7.

Padlock Operation

The padlock provision prevents the breaker from closing

by holding the trip latch in the tripped position. Up to

three padlocks with 1/4" or 3/8" diameter shanks, or scissor-type safety lockout hasps may be inserted at one time.

To install a padlock, use the following procedure:

WARNING: Be sure to test for proper

operation of the mechanism, as described in

step 1, before using it to secure the breaker.

AVERTISSEMENT: Assurez-vous de tester que

le mécanisme opère correctement, tel que

décrit à l'étape 1, avant de l'utiliser pour fixer le

disjoncteur.

1. To check for proper installation of the padlock

mechanism, hold in the OPEN button, pull out the

padlock slide, insert a 1/8" rod or #10 gage solid

wire, and attempt to close the breaker.

The breaker must not close.

2. While holding the OPEN button in, slide the padlock plate out and hold it in place.

3. Put the padlock or safety lockout hasp into one of

the three holes in the padlock plate; this will

prevent the plate from returning to its unlocked

position and prevent the breaker from closing.

4.2 Control Wiring

Figure 2 is the wiring diagram for the breaker control

circuits. Table 4 lists the secondary disconnect terminals

and the items connected to each. The location of the

secondary disconnect is illustrated in Figure 3.

4.3 Breaker Interlocks

EntelliGuard breakers are equipped with a number of

safety interlocks to prevent improper operation of the

breaker.

Draw-Out Interlock

The draw-out interlock prevents the breaker from being

closed when the breaker is in neither the CONN or TEST

position, but is between these positions. A pin on the side

of the breaker engages a ramped cam in the switchgear

cubicle. When the pin is lifted 3/8" the breaker is held tripfree.

An additional interlock holds the breaker trip-free whenever the access door to the racking mechanism is open.

Contact Interlock

The contact interlock keeps the door to the draw-out

mechanism racking screw closed whenever the breaker

contacts are CLOSED. This prevents changes to the

breaker’s position with the main contacts CLOSED.

Spring Discharge Interlock

The spring discharge interlock functions in conjunction

with the circuit breaker’s draw-out interlock and a

compartment-mounted cam to discharge the closing and

opening springs before the breaker can be withdrawn

from the compartment.

4.4 Equipment Interlocks

Additional optional interlocks may be furnished with the

breaker enclosure. The Key Interlock prevents the breaker

from closing when the interlock is engaged and requires

one or more keys to operate. The Door Interlock prevents

opening of the enclosure door when the breaker is in the

CONN position. It can be defeated for authorized access.

The door can be opened by racking the breaker to the

TEST or DISC position.

8

Page 19

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 4. Breaker Operation

Figure 2. Elementary diagram of the breaker control circuits.

Figure 3. Location of the secondary disconnect (top view of the breaker).

9

Page 20

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 4. Breaker Operation

10 Aux Switch (NO contact)

1 Aux Switch

2 Aux Switch

11 Aux Switch (NC contact)

13 Flux Shifter

12 Flux Shifter common

5 Shunt Trip

7 Shunt Trip common

9 Close Circuit

18 Close Circuit common

8 Closing Spring Charging Motor

17 Closing Spring Charging Motor common

3 Remote Charge Indicator

4 Remote Charge Indicator

14 Bell Alarm Trip

6 Bell Alarm Trip Common

16 Bell Alarm Status

19 Bell Alarm Status Comon

OR

15 Network Interlock SET

20 Network Interlock RESET

21 Network Interlock SET/RESET common

16 Network Interlock Status

19 Network Interlock Status common

22 OFLO (phase A)

23 OFLO (phase A)

24 OFLO (phase B)

25 OFLO (phase B)

26 OFLO (phase C)

27 OFLO (phase C)

28 Spare

29 Spare

30 Spare

31 Spare

32 Spare

33 Spare

34 Spare

35 Spare

36 Spare

Table 4. Secondary disconnect terminals with standard and optional connections.

10

Page 21

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

WARNING: Before inspecting a breaker or

beginning any maintenance, the breaker must

be disconnected from all voltage sources, both

power and control, and the breaker must be in

the OPEN position.

AVERTISSEMENT: Avant d’inspecter ou de

débuter tout travail de maintenance d’un disjoncteur, celui-ci dout être en position OPEN et

débranché de toutes les sources de voltage, à la

fois de puissance et de contrôle.

5.1 Lubrication

Bearing points and sliding surfaces should be lubricated

with a thin film of GE Lubricant D6A15A1 (MobilGrease

28, catalog number 193A1751P1). Clean the surfaces to be

lubricated with an industry-approved solvent.

Note: Remove all excess lubricant with a clean, lint free cloth to avoid accumulation of dirt or dust.

The contact surfaces of the primary disconnect fingers

should be cleaned and lubricated with GE Lubricant

D6A15A1.

Note: Do not lubricate the main, intermediate, or

arcing breaker contacts or the outside diameters of

rollers. Also do not lubricate the ground radius on the

closing prop or trip latch, as this will cause

accumulation of dirt and dust.

5.2 Removing and Reinstalling the

Breaker

Maintenance or inspection should be performed with the

breaker removed from the compartment and placed on a

workbench. Figure 4 illustrates these procedures.

Removing the Breaker

1. With the compartment door closed and latched,

trip the breaker.

2. Push the OPEN button and slide the racking screw

access door to the right, exposing the racking screw.

3. Engage the Remote Racker accessory (WPEGRRLV)

or the Racking Handle (0324B4721G001) with the

racking screw. Rotate the screw counterclockwise

using either the Remote Racker or the Racking

Handle until the breaker travels from the

Connected position through the Test position (as

indicated by the legends CONN and TEST,

respectively, on the draw-out position indicator)

and comes to a solid stop in the Disconnected

position (as indicated by the legend DISC on the

position indicator). At this point, the primary and

secondary disconnects are disengaged.

4. Open the compartment door. Pull out the rails,

then pull the breaker out to the withdrawn position

at the track travel limit

5. Verify that the indicators on the front of the breaker

show that the springs are DISCHARGED and the

breaker is OPEN.

6. Attach the lifting bracket (catalog number

0324B4551G1) by locating the hooks in the slots on

the side of the breaker and on the closing spring

anchor pin. Raise the breaker until its mounting

wheels clear the rails.

7. Push the rails back into the compartment, then

move the breaker forward until the primary disconnects clear the compartment. Lower the breaker

onto a flat surface free of protrusions that could

damage the breaker’s internal parts. Close the compartment door.

8. Place the draw-out mechanism in the Connect position to deactivate the interlocks that would otherwise prevent the breaker mechanism or contacts

from closing. Engage the Racking Handle to the

racking screw and turn it clockwise until it stops, as

indicated by the legend CONN on the position indicator.

Installing the Breaker

Use the following procedure to install the draw-out

breaker into its compartment.

1. Before lifting a breaker to its intended compartment

location, observe the following precautions:

• Check the compartment to ensure that it is free of

foreign objects.

• Verify that the breaker is the correct type for the

compartment.

• Ensure that the breaker is OPEN.

• Apply a thin coat of GE lubricant D6A15A1 to the

breaker’s primary disconnects.

• Insert the racking handle and rotate it fully counterclockwise to ensure that the racking cams on

the breaker are correctly positioned for initial

engagement with the pins in the breaker cubicle.

The position indicator on the front of the breaker

should show DISC.

2. Attach the lifting bracket by locating the hooks in

the slots on the side of the breaker and on the closing spring anchor pin.

3. Pull the rails all the way out to their withdrawn position.

4. Slowly lower the breaker onto the rails so that the

grooves in the rollers on the side of the breaker

align with the rails.

11

Page 22

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

Figure 4. Installing the breaker into the compartment.

12

Page 23

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

5. Push the breaker into the compartment until it

reaches the stops. This is the Disconnect position

(as shown by the legend DISC on the draw-out position indicator). At this point the racking arms are

positioned to engage the fixed racking pins in the

compartment and are ready to begin the racking

motion. Push the rails back into the compartment.

6. Close the compartment door. Push the OPEN button

and slide the racking screw access door to the right,

exposing the racking screw.

7. Engage the Remote Racker accessory or the Racking

Handle with the racking screw. Rotate the screw

clockwise using either the Remote Racker or the

Racking Handle through the Test position, until

the racking screw comes to a solid stop. The breaker

is now in the Connected position, as shown by the

legend CONN on the position indicator flag. Note

that a loud click will be heard as the spring-loaded

secondary disconnect detent releases as the breaker

moves beyond the TEST position.

8. Depress the red OPEN button to close the racking

screw access door to permit breaker closing.

5.3 Slow Closing the Breaker

3. After the bolt is removed, use the maintenance

handle (catalog number 568B386P1) to rotate the

ratchet assembly roller onto the closing prop.

4. Remove the closing prop by either pushing the

CLOSE button or by pushing the solenoid armature

of the Remote Close.

5. Continue turning the camshaft until the contacts

and mechanism are in the fully closed position. The

cam then supports the cam roller and the contacts

develop maximum depression.

6. Push the TRIP button to release the mechanism and

open the contacts.

CAUTION: The mechanism and contacts will

open with normal speed and force.

ATTENTION: Le mécanisme et les contacts

s’ouvriront à une vitesse et une force normales.

When replacing the hex-head bolt, turn the camshaft with

the charging handle to align the mating holes in the

lower spring assembly and camshaft linkage. Tighten the

bolt to 360 lb-in.

Closing the breaker slowly, while observing the action of

the mechanism and contacts, is a good way to judge the

correctness of mechanical and contact relationships.

Some of the maintenance procedures described later

involve slow closing the breaker. Use the following procedure to slow close the breaker:

1. Remove the escutcheon. (See Section 7.5)

2. The closing spring must be isolated from the

mechanism camshaft. Make sure that the breaker

mechanism is DISCHARGED and the spring is at

minimum extension, then remove the hex-head bolt

shown in Figure 5 to disconnect the lower spring

assembly from the mating camshaft linkage.

Figure 5. Disconnecting the closing spring assembly.

5.4 Separation and Reconnection of

Front and Back Frames

Some repair operations require separation of the front

and back frames, per the following procedure. The

breaker must first be removed from its compartment, as

described in Section 5.2, and placed on a suitable work

surface.

Separation of Front and Back Frames for

EGS08, EGF08, and EGH08

The following procedure is illustrated in Figure 8.

1. Verify that the breaker contacts are open and that

the closing springs are discharged.

2. Remove the mounting bolt securing each of the arc

chutes and lift out the arc chutes. Remove the four

interphase barriers.

3. Remove the two screws and standoffs securing the

secondary disconnect to the mounting plate, taking

care to retain the spring washer from the pin on the

underside of the disconnect, as illustrated in Figure

6. Cut the wire ties securing the secondary disconnect leads to the mounting plate and to the breaker

back frame. Slide the secondary disconnect off the

support bracket. Secure the secondary disconnect to

the front frame assembly.

4. Remove the bolt, lock washer, and nut connecting

each tie bar to the front frame. Lift off the tie bars.

13

Page 24

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

5. Remove the four bolts, washers, and nuts that attach

the secondary disconnect mounting plate to the

back frame. Remove the mounting plate.

6. Remove one of the snap rings and slide out the pin

connecting each of the movable contact assemblies

to the breaker main shaft, as illustrated in Figure 7.

7. Carefully place the breaker on its back, resting on

the primary disconnects.

8. Remove the six bolts and lock washers attaching the

front and back frames on the side panels.

9. Lift the front frame straight off the back frame.

Reconnection of Front and Back Frames for

EGS08, EGF08, and EGH08

The following procedure is illustrated in Figure 8.

1. Carefully place the back frame on a suitable work

surface, resting on the primary disconnects.

2. Place the front frame assembly onto the back frame,

being careful to line up the mounting holes in the

side panels. Insert the six bolts and lock washers and

tighten them to 200 in-lb.

3. Carefully place the breaker upright, resting on its

bottom surface.

4. Reconnect the movable contact assemblies to the

breaker main shaft by inserting the connecting pin

and reattaching the snap ring, as illustrated in

Figure 7.

5. Place the secondary disconnect mounting plate in

position and secure with the four bolts, washers, and

nuts.

6. Connect the ends of the tie bars to the secondary

disconnect mounting plate and attach the other

ends to the front frame with the bolt, lock washer,

and nut removed earlier. Tighten to 96 in-lb.

7. Place the flexible washer on the molded pin on the

bottom of the secondary disconnect, then slide the

two feet into the slots on the mounting plate. Secure

with the two screws and standoffs, as illustrated in

Figure 6. Replace the wire bundle into the channel

on the top of the frame and secure with wire ties.

8. Insert the four interphase barriers into their mounting slots.

9. Slide the arc chutes into position, with the slots over

the movable contact arms. Secure with the bolts and

lock washers removed on disassembly.

10. Check that no wires are interfering with breaker

operation and that all bolts and nuts are tight.

Operate the breaker a few times to verify proper

operation.

Figure 6. Removing or installing the secondary disconnect.

Figure 7. Movable contact connection to the breaker main shaft on

EGS08, EGF08, and EGH08 breakers.

14

Page 25

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

Figure 8. Separating the front and back frames on EGS08, EGF08, and EGH08 breakers.

15

Page 26

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

Separation of Front and Back Frames for

EGX08, EGS16, EGF16, EGH16, EGS20, and

EGF20

The following procedure is illustrated in Figure 10.

1. Verify that the breaker contacts are open and that

the closing springs are discharged.

2. Remove the two bolts and lock washers that attach

the arc chute retainer to the front frame and

remove the retainer. Slide out the arc chutes and

interphase barriers. Note that there are three distinct types of phase barriers: right, inner (2), and

left.

3. Remove the two screws and standoffs securing each

secondary disconnect to the mounting plate, taking

care to retain the spring washer from the pin on the

underside of the disconnect, as illustrated in Figure

6. Cut the wire ties securing the secondary disconnect leads to the mounting plate and to the breaker

back frame. Slide the secondary disconnect off the

support bracket. Secure the secondary disconnect to

the front frame assembly.

4. Remove the three screws and washers that attach

the secondary disconnect mounting plate to the

back frame. Remove the mounting plate.

5. Remove one of the snap rings and slide out the pin

connecting each of the movable contact assemblies

to the breaker main shaft, as illustrated in Figure 9.

On the two outer poles, first remove the bolt and

cover over the outer end of the pin.

6. Carefully place the breaker on its back, resting on

the primary disconnects.

7. Remove the two nuts and lock washers attaching the

tie bars to the front frame.

8. Remove the six nuts and lock washers (the top connections also have spacers) connecting the front

and back frames.

9. Lift the front frame straight off the back frame.

Reconnection of Front and Back Frames for

EGX08, EGS16, EGF16, EGH16, EGS20, and

EGF20

The following procedure is illustrated in Figure 10.

1. Carefully place the back frame on a suitable work

surface, resting on the primary disconnects.

2. Carefully lower the front frame onto the back frame,

lining up the six studs in the sides of the back frame

with the corresponding holes in the front frame.

Attach the six nuts and lock washers, with the two

spacers on the top studs, and tighten to 250 in-lb.

Figure 9. Movable contact connection to the breaker main shaft on

EGX08, EGS16, EGF16, EGH16, EGS20, and EGF20 breakers.

3. Attach the two nuts and lock washers to secure the

tie bars to the front frame. Tighten to 250 in-lb.

4. Carefully place the breaker upright, resting on its

bottom surface.

5. Reconnect the movable contact assemblies to the

breaker main shaft by inserting the connecting pin

and reattaching the snap ring, as illustrated in

Figure 9. Reattach the cover and bolt on the two

outer poles.

6. Reattach the secondary disconnect mounting plate

with three screws and washers to the back frame.

7. Place the flexible washer on the molded pin on the

bottom of the secondary disconnect, then slide the

two feet into the slots on the mounting plate. Secure

with the two screws and standoffs, as illustrated in

Figure 6. Replace the wire bundle into the channel

on the top of the frame and secure with wire ties.

8. Insert the four interphase barriers into position,

noting the proper locations for the three different

types.

9. Slide the arc chutes into position. Place the arc

chute retainer in position and secure with the two

bolts and lock washers to the front frame. Tighten

securely.

10. Check that no wires are interfering with breaker

operation and that all bolts and nuts are tight.

Operate the breaker a few times to verify proper

operation.

16

Page 27

EntelliGuard™ 800–2000 A Power Circuit Breakers

left

Chapter 5. Breaker Maintenance

Figure 10. Separating the front and back frames on EGX08, EGPS16, EGF16, EGH16, EGS20, and EGF20 breakers (EGS20 illustrated).

17

Page 28

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 5. Breaker Maintenance

5.5 Breaker Mechanism Operation

and Adjustment

Figure 11, Figure 12, and Figure 13 show the mechanism

components in the CLOSED, TRIPPED, and RESET

conditions, respectively. Numbers in parentheses refer to

the indicated items in the figures listed in Table 5. The

closing spring is in the charged position for all of these

details.

Closed Position – The movable contacts are pushed against

the stationary contacts by the toggle linkage, as illustrated

in Figure 11. The toggle linkage is held in position

through the engagement of its cam roller (4), with the

prop (1), the secondary latch/roller (5), the secondary

latch (10), and the trip latch (7).

Tripped Position – The mechanism goes from the CLOSED

position to the TRIPPED position, illustrated in Figure 12,

when the trip shaft (6) is rotated by either the manual trip

button or one of the other trip devices. The trip latch (7)

is assembled to the trip shaft. When the trip shaft rotates,

the trip latch disengages from the secondary latch roller

(5). The secondary latch pivots, resulting in the collapse

of the toggle linkage. This collapse, along with the opening spring (11), shown in Figure 13, causes the breaker

contacts to open.

Reset Position – The closing cam (2), assembled to the

cam shaft (3), is rotated by the Charging Motor, manual

charging handle, or maintenance handle. The cam

engages the cam roller and partially extends the toggle

linkage. This allows the secondary latch (10) to pivot

against the front frame, as illustrated in Figure 13, leaving

a gap between the trip latch (7) and secondary latch roller

(5). The secondary latch is now in a position to engage

both the trip latch and cam roller (4).

The breaker closes when the closing springs discharge

and rotate the cam (2) against the cam roller (4). The

toggle linkage is fully extended, pivoting the secondary

latch (10) from the front frame and engaging it with the

trip latch (7) and cam roller (4), as shown in Figure 11.

When the breaker is closed and the closing spring is discharged, the upper cam roller (4) is supported by the cam

(2) rather than the prop (1). The mechanism must be in

this position to check contact adjustment, as described in

Chapter 6.

Figure 11. Breaker mechanism in the CLOSED position.

Figure 12. Breaker mechanism in the TRIPPED position.

Figure 13. Breaker mechanism in the RESET position.

1 Prop 7 Trip latch

2 Cam 8 Insulated coupling

3 Camshaft 9 Main shaft

4 Cam roller 10 Secondary latch

Secondary latch

5

roller

6 Trip shaft

Table 5. Key to numbered parts in Figure 11, Figure 12, and

11 Opening spring

Figure 13.

18

Page 29

EntelliGuard™ 800–2000 A Power Circuit Breakers

Trip Latch Adjustment

Use the following procedure to adjust the trip latch, as

illustrated in Figure 14.

1. Remove the breaker from its compartment and

place it on a suitable work surface.

2. Remove the arc chutes and phase barriers, as

described in Section 6.2.

3. Charge the closing springs with the manual charging handle and close the breaker.

4. Turn the trip latch adjustment screw in (clockwise)

until the breaker trips. Withdraw the screw

(counter-clockwise) 41/2 turns.

Chapter 5. Breaker Maintenance

Figure 14. Adjusting the trip latch.

19

Page 30

EntelliGuard™ 800–2000 A Power Circuit Breakers

Chapter 6. Contact Maintenance

6.1 Introduction

Breakers subjected to frequent interruption of high currents may eventually require replacement of their contacts. The general rule for determining if replacement is

required is the loss of one-half or more of the mass of the

contact tip material. Roughening or light pitting of the

contact surface does not indicate loss of ability to carry or

interrupt current.

When contacts are replaced, they must be adjusted to

ensure that the proper force and contact depression is

developed between the movable and stationary contacts

when the breaker is closed. This is called the wipe adjustment. Wipe is the distance through which the stationary

contacts move when the breaker closes. It is measured

between the point of contact on a stationary contact when

the breaker is open and the position of the same point

when the breaker is closed. The actual wiping motion is

greater than this measurement, since the contacts overtravel.

The wipe adjustment provides proper depression to assure

full current-carrying capacity without overheating and

influences proper current transfer during interruption of

fault currents. Transfer of the current is the forced

sequential movement from the main to the intermediate

contacts, then to the arcing contacts, to the arc runner,

and finally to the arc chutes, where energy is dissipated

and the arc is extinguished. Contact wipe should be

checked periodically during normal maintenance inspections and after any overcurrent trip.

CAUTION: Before performing any contact

adjustment or replacement, disable the closing

springs, as described in Section 5.3.

ATTENTION: Avant d’effectuer tout

ajustement ou remplacement de contact,

neutraliser les ressorts de fermeture, tel que

décrit à la Section 5.3.

6.2 Arc Chute Removal and

Replacement

The arc chutes should be removed and inspected at the

regular inspection period. Arc chutes and interphase barriers are available as renewal parts.

The breaker must be removed from its compartment, as

described in Section 5.2, and placed on a suitable work

surface.

There are two types of arc chutes used in these breakers,

depending on frame size.

Arc Chutes in EGS08, EGF08, and EGH08

Breakers

Use the following procedure to remove and replace the

arc chutes, as illustrated in Figure 8.

1. Verify that the breaker contacts are open and the

closing springs are discharged.

2. Remove the mounting bolt and lock washer securing each of the arc chutes and lift out the arc

chutes. Remove the four interphase barriers.

3. Check the arc chutes and barriers for damage and

replace them, if necessary.

4. Replace the four interphase barriers into their slots.

5. Slide the arc chutes into place, with the slots over

the movable contact arms.

6. Replace the mounting bolt and lock washer securing each arc chute to the breaker frame.

CAUTION: All insulating barriers must be in

place before the breaker is placed back into

service.

ATTENTION: Toutes les barriéres isolatrices

doivent être en place avant que le disjoncteur

ne soit replacé en service.

Arc Chutes in EGX08, EGS16, EGF16,

EGH16, EGS20, and EGF20 Breakers

Use the following procedure to remove and replace the

arc chutes, as illustrated in Figure 10.

1. Verify that the breaker contacts are open and the

closing springs are discharged.

2. Remove the two bolts and lock washers that attach

the arc chute retainer to the front frame and

remove the retainer.

3. Slide out the arc chutes and interphase barriers.

Note that there are three distinct types of phase barriers: right, inner (2), and left.

4. Check the arc chutes and barriers for damage and

replace them, if necessary.

5. Replace the four interphase barriers into their correct slots.

6. Slide the arc chutes into place, with the slots over

the movable contact arms.

7. Replace the arc chute retainer bar and secure it with

two bolts and lock washers.