Page 1

Page 2

This book replaces the Instruction Books GEI-100332A Rev. 7.5 , GEI-100332B Rev.7.6 and GEI100332G REV. 9.2.0.

The up-to-dating is referred to SW version 9.2XX

These instructions do not purport to cover all details or variations in equipment, nor to provide every

possible contingency to be met during installation, operation, and maintenance. If further information

is desired or if particular problems arise that are not covered sufciently for the purchaser’s purpose,

the matter should be referred to GE Consumer & Industrial.

This document contains proprietary information of General Electric Company, USA and is furnished to

its customer solely to assist that customer in the installation, testing, operation, and/or maintenance

of the equipment described. This document shall not be reproduced in whole or in part nor shall its

contents be disclosed to any third party without the written approval of GE Consumer & Industrial.

© 2009 by General Electric Company, USA. All rights reserved.

Page 3

DV-300 Adjustable Speed Drives

TABLE OF CONTENTS

SAFETY SYMBOL LEGEND ................................................................................................... XIV

BLOCK DIAGRAM LEGEND .................................................................................................. XIV

1 - SAFETY PRECAUTIONS - PRECAUTIONS DE SECURITÉ ............................................1

2 - DESCRIPTION, COMPONENT IDENTIFICATION AND SPECIFICATIONS ...................1

2.1 GENERAL ......................................................................................................................................... 1

Functions and features (Overview) ......................................................................................... 3

2.2 UPON DELIVERY INSPECTION PROCEDURES ................................................................................... 4

Storage, Transport .................................................................................................................. 4

2.2.1 Device setting ................................................................................................................... 4

2.3 DRIVE KEYPAD DESCRIPTION ........................................................................................................... 6

Keypad ....................................................................................................................................... 6

LEDs ........................................................................................................................................... 7

2.4 SPECIFICATIONS .............................................................................................................................. 8

2.4.1 Standards .......................................................................................................................... 8

2.4.2 AC Input ............................................................................................................................ 8

2.4.3 Output ........................................................................................................................................................................ 10

Output current ...................................................................................................................... 10

Armature circuit ................................................................................................................... 10

Field circuit ........................................................................................................................... 11

Output voltage ...................................................................................................................... 12

Armature circuit ................................................................................................................... 12

Field circuit ........................................................................................................................... 12

2.4.4 Control section ................................................................................................................ 13

2.4.5 Accuracy ......................................................................................................................... 14

2.5 DIMENSION AND WEIGHTS ........................................................................................................... 15

2.6 WATT LOSS.................................................................................................................................... 18

2.7 MOTORS, ENCODER, TACHOMETER .............................................................................................. 19

2.7.1 Motors............................................................................................................................. 19

2.7.2 Encoder / Tachometer ...................................................................................................... 20

3 - INSTALLATION GUIDELINES .......................................................................................1

3.1 PERMISSIBLE AMBIENT CONDITION ............................................................................................... 1

3.2 DISPOSAL OF THE DEVICE ............................................................................................................... 2

3.3 INSTALLATION, MOUNTING CLEARANCE ........................................................................................ 2

Mounting the device ............................................................................................................... 2

4 - WIRING PROCEDURES ...............................................................................................1

4.1 REMOVING THE FRONT COVER ....................................................................................................... 1

—————— TABLE OF CONTENTS ——————

I

Page 4

GEI-100332Ga

Terminal Assignments/Cable Sections .................................................................................... 1

4.2 WIRING THE DRIVE .......................................................................................................................... 1

4.3 POWER SECTION ............................................................................................................................. 2

4.4 REGULATION SECTION .................................................................................................................... 6

4.4.1 R-TPD32-GE Regulation Card ............................................................................................. 6

4.5 SERIAL INTERFACE ........................................................................................................................ 12

4.5.1 Description ...................................................................................................................... 12

4.5.2 RS485 serial interface connector description ................................................................. 13

4.6 INPUT/OUTPUT EXPANSION CARD 6KCV300TBO .......................................................................... 13

4.6.1 Assignment of the plug-in terminal strip (terminals 1...15) for Option Card 6KCV300TBO ......14

4.6.2 Fitting the option card ..................................................................................................... 15

4.7 DIGITAL ENCODER INTERFACE 6KDV300DES ................................................................................. 16

4.7.1 Description ...................................................................................................................... 16

4.7.2 Terminal Assignment ....................................................................................................... 17

4.8 STANDARD CONNECTION DIAGRAMS .......................................................................................... 18

4.9 CIRCUIT PROTECTION .................................................................................................................... 23

4.9.1 Fuses ............................................................................................................................... 23

4.9.2 Fuses selection when the Overload function is activated ................................................ 26

4.9.3 Internal Fuses .................................................................................................................. 27

4.9.4 AC input contactors ......................................................................................................... 28

4.9.5 Control power protection ................................................................................................. 28

4.10 REACTORS / FILTERS ................................................................................................................... 29

4.10.1 AC input choke .............................................................................................................. 29

4.10.2 Interference suppression filters ..................................................................................... 30

4.11 ENGINEERING NOTES .................................................................................................................. 31

Potentials of the regulator section ........................................................................................ 31

External devices ................................................................................................................... 32

Connection cables ................................................................................................................ 32

5 - CONVERTER OPERATION ............................................................................................ 1

5.1 KEYPAD ............................................................................................................................................ 1

5.1.1 LEDs ................................................................................................................................. 1

5.1.2 Moving inside a menu ....................................................................................................... 2

5.1.3 Displaying parameters ....................................................................................................... 2

5.1.4. Changing / Saving parameters / Password ....................................................................... 3

Changing numerical values and text ....................................................................................... 3

Selection from predefined values............................................................................................ 4

Autotuning of Analog input ..................................................................................................... 4

Parameters Saving ................................................................................................................. 5

Entering a password ............................................................................................................... 5

II

—————— TABLE OF CONTENTS ——————

Page 5

DV-300 Adjustable Speed Drives

General unlocking of the password ......................................................................................... 6

5.1.5 Operating the drive via the Keypad .................................................................................... 6

5.1.5.1 Starting and stopping the drive ................................................................................... 7

Enabling the converter ............................................................................................................ 7

Disabling the converter ........................................................................................................... 7

Start / Stop ............................................................................................................................. 7

5.1.5.2 Failure register / Acknowledging alarms ..................................................................... 8

Clearing the failure register ..................................................................................................... 8

Acknowledging a failure alarm ............................................................................................... 9

Acknowledging when several failure alarms occur at the same time ..................................... 9

5.1.5.3 Motor potentiometer function ..................................................................................... 9

Acceleration, Deceleration ...................................................................................................... 9

Changing rotation direction................................................................................................... 10

Resetting the speed reference value ..................................................................................... 10

5.1.5.4. Jog function ............................................................................................................ 10

5.2. MENU STRUCTURE ....................................................................................................................... 11

5.3 COMMISSIONING .......................................................................................................................... 35

5.3.1 Setting jumpers and switch ............................................................................................. 35

5.3.2 Checking the wiring and the auxiliary voltages ............................................................... 36

5.3.3 Basic settings of the converter ........................................................................................ 36

5.3.4 START UP procedures ..................................................................................................... 37

Motor data ........................................................................................................................... 37

Limits .................................................................................................................................. 38

Speed feedback setting ........................................................................................................ 38

Alarms .................................................................................................................................. 38

Overload control .................................................................................................................. 38

Analog inputs 1, 2 and 3 ...................................................................................................... 38

5.3.5 Drive tuning ..................................................................................................................... 39

5.3.5.1 Self tuning of the current regulator .......................................................................... 39

5.3.5.1.1 Checking current regulator performance using parameter Eint .............................. 40

5.3.5.2 Self tuning of the speed regulator ............................................................................ 40

5.3.5.3 Field converter .......................................................................................................... 42

Selection of the functioning system ..................................................................................... 42

Setting the rated field current ............................................................................................... 42

Flux current min/max............................................................................................................ 43

5.3.6 Manual tuning of the regulators ....................................................................................... 43

Using the Test generator ....................................................................................................... 43

Manual tuning of speed regulator ......................................................................................... 44

Manual tuning of field current regulator ................................................................................ 45

Voltage regulator in the field converter ................................................................................. 47

5.3.7 Others tuning .................................................................................................................. 49

—————— TABLE OF CONTENTS ——————

III

Page 6

GEI-100332Ga

Flux / if curve tuning (Flux / if curve) .................................................................................... 49

Speed-up function ................................................................................................................ 51

Setting of the speed zero logic ............................................................................................. 51

Adaptive of the speed regulator ............................................................................................ 52

6 - FUNCTION DESCRIPTION ........................................................................................... 1

Functions and parameters ...................................................................................................... 1

Explanation of parameter tables ............................................................................................. 2

6.1 ENABLES.......................................................................................................................................... 3

6.1.1 Enable drive ....................................................................................................................... 4

6.1.2 Start / Stop ........................................................................................................................ 5

6.1.3 Fast stop ........................................................................................................................... 6

6.1.4 Quick Stop ......................................................................................................................... 7

6.1.5 External fault ..................................................................................................................... 7

6.2 BASIC START UP MENUS ................................................................................................................ 8

DRIVE STATUS ........................................................................................................................ 8

START UP ............................................................................................................................... 8

First basic setting ................................................................................................................... 8

Motor data .............................................................................................................................. 8

Limits ..................................................................................................................................... 9

Speed feedback ...................................................................................................................... 9

Alarms .................................................................................................................................... 9

Overload control ..................................................................................................................... 9

Analog inputs ....................................................................................................................... 10

Self tuning of current regulator ............................................................................................. 10

Self tuning of speed regulator ............................................................................................... 10

Final operation ...................................................................................................................... 11

TUNING ................................................................................................................................ 11

Current self tuning ................................................................................................................ 11

Speed self tune ..................................................................................................................... 11

Manual tuning of speed regulator, field regulator and voltage regulator ................................ 11

IV

6.3 MONITOR ....................................................................................................................................... 12

6.4 INPUT VARIABLES ......................................................................................................................... 16

6.4.1 Ramp ref .......................................................................................................................... 17

6.4.2 Speed ref ......................................................................................................................... 18

6.4.3 Torque current reference (T current ref) ........................................................................... 20

6.5 LIMITS ............................................................................................................................................ 21

6.5.1 Speed Limits.................................................................................................................... 21

6.5.2. Armature current limits (Current limits) .......................................................................... 23

6.5.3 Flux limits ........................................................................................................................ 25

6.6 RAMP ............................................................................................................................................. 26

6.6.1 Acceleration, Deceleration, Quick Stop ........................................................................... 27

—————— TABLE OF CONTENTS ——————

Page 7

DV-300 Adjustable Speed Drives

6.6.2 Ramp shape and control commands ...............................................................................28

6.7 SPEED REGULATION (SPEED REGULAT) ......................................................................................... 31

6.7.1 Speed regulator ............................................................................................................... 32

6.7.1.1 Self tuning of Speed regulator ................................................................................. 33

6.7.2 Spd zero logic .................................................................................................................. 34

6.7.3 Speed up ......................................................................................................................... 35

6.7.4. Droop function ................................................................................................................ 36

6.7.5 Inertia/Loss compensation .............................................................................................. 38

6.8 CURRENT REGULATION (CURRENT REGULAT) .............................................................................. 39

6.9 FLUX REGULATION ......................................................................................................................... 41

6.10 REG PARAMETERS ....................................................................................................................... 44

6.11 CONFIGURATION .......................................................................................................................... 46

6.11.1 Operating mode selection .............................................................................................. 46

6.11.2 Speed base value, Full load current ............................................................................... 48

6.11.3 Configuration of the OK relay (Terminals 35,36) ............................................................. 48

6.11.4. Configuration of the speed feedback circuit ................................................................. 49

Ind store ctrl parameter [92] ................................................................................................. 52

Index storing parameter [13] ................................................................................................ 53

6.11.5 “Standard / American” selection, Software Version ...................................................... 53

6.11.6. Dimension factor, Face value fator ............................................................................... 54

6.11.7. Programmable alarms................................................................................................... 56

6.11.8 Address for bus operation ............................................................................................. 62

6.11.9 Password ...................................................................................................................... 63

6.12 I/O CONFIG ................................................................................................................................... 64

6.12.1 Analog Ouputs ............................................................................................................... 65

6.12.2 Analog Inputs ................................................................................................................ 67

6.12.3 Digital Outputs ............................................................................................................... 73

6.12.4 Digital Inputs ................................................................................................................. 76

6.12.5 Speed reference from encoder input (Tach follower function) ....................................... 79

6.13 ADDITIONAL SPEED FUNCTIONS (ADD SPEED FUNCT) ............................................................... 81

6.13.1 Auto capture ................................................................................................................. 81

6.13.2 Adptive spd reg ............................................................................................................. 81

6.13.3 Speed control ................................................................................................................ 84

6.13.4 Speed zero ..................................................................................................................... 86

6.14 FUNCTIONS .................................................................................................................................. 87

6.14.1 Motorpotentiometer ...................................................................................................... 87

6.14.2 Jog function .................................................................................................................. 89

6.14.3 Multi speed function ...................................................................................................... 91

—————— TABLE OF CONTENTS ——————

V

Page 8

GEI-100332Ga

6.14.4 Multi ramp function ....................................................................................................... 94

6.14.5 Speed Draw function ..................................................................................................... 98

6.14.6 Overload control .......................................................................................................... 100

6.14.7 Stop control ................................................................................................................. 121

6.14.8 Brake control ............................................................................................................... 123

6.14.9 Current limitation according to the speed (I/n curve) ................................................... 126

6.15 SPEC FUNCTIONS ...................................................................................................................... 127

6.15.1 Test generator ............................................................................................................. 127

6.15.2 Saving parameters, loading default factory settings, life time ..................................... 128

6.15.3 Failure Register ............................................................................................................ 129

6.15.4. Signal adaptation ........................................................................................................ 130

6.15.5 Pads ............................................................................................................................ 132

6.16 OPTIONS .................................................................................................................................... 135

6.16.1 Option 1 ....................................................................................................................... 135

6.16.2 Option 2 ....................................................................................................................... 135

6.16.3 PID Functon ................................................................................................................. 137

6.16.3.1 General ................................................................................................................. 138

6.16.3.2 Inputs / Outputs .................................................................................................... 138

6.16.3.3 Feed - Forward ..................................................................................................... 139

6.16.3.4 PID function ......................................................................................................... 141

6.16.3.5 Proportional - integral block .................................................................................. 143

6.16.3.6 Proportional - Derivative control block .................................................................. 147

6.16.3.7 Output reference ................................................................................................... 149

6.16.3.8 Function of calculation for Initial diameter ........................................................... 151

6.16.3.9 Procedure of calculation for initial diameter .......................................................... 153

6.16.3.10 Examples of application ...................................................................................... 154

6.16.3.11 Generic PID ......................................................................................................... 171

6.16.3.12 Application note ................................................................................................ 173

6.17 TORQUE WINDER FUNCTION ..................................................................................................... 176

6.17.1 Diameter calculation .................................................................................................... 177

6.17.2 Torque calculation ....................................................................................................... 181

6.17.2.1 Compensations and closing of the tension loop .................................................... 182

6.17.2.2 Taper function ....................................................................................................... 185

VI

6.17.3 Calculation of the speed reference .............................................................................. 186

6.17.4 Typical connection diagrams ....................................................................................... 191

6.17.5 Control logic ................................................................................................................ 195

Diameter initialization ......................................................................................................... 195

Initial phase ........................................................................................................................ 195

Automatic switching .......................................................................................................... 196

Reel stop ............................................................................................................................ 196

—————— TABLE OF CONTENTS ——————

Page 9

DV-300 Adjustable Speed Drives

Jog function ....................................................................................................................... 197

6.17.6 Application example .................................................................................................... 198

Provisions ........................................................................................................................... 208

1. Drive used as a winder – winding side = up .................................................................. 208

2. Drive used as a winder – winding side = down ............................................................. 209

3. Drive used as an unwinder – unwinding side = up ........................................................ 209

4. Drive used as an unwinder – unwinding side = down ................................................... 210

6.17.7 Block diagram ............................................................................................................. 211

6.18 DRIVECOM ................................................................................................................................. 215

6.18.1 Control word, status word, malfunction code .............................................................. 215

6.18.2 Speed .......................................................................................................................... 216

6.18.3 Speed limitation .......................................................................................................... 217

6.18.4 Acceleration / Deceleration .........................................................................................218

6.18.5 Factor function ............................................................................................................ 219

6.19 SERVICE ..................................................................................................................................... 220

7- MAINTENANCE ............................................................................................................ 1

7.1 CARE ................................................................................................................................................ 1

7.2 SERVICE ........................................................................................................................................... 1

7.3 REPAIRS ........................................................................................................................................... 1

7.4 CUSTOMER SERVICE ....................................................................................................................... 1

8 - TROUBLESHOOTING ................................................................................................... 1

Failure alarms in the keypad display ...................................................................................... 1

Other faults ............................................................................................................................. 5

9 - BLOCK DIAGRAM ........................................................................................................1

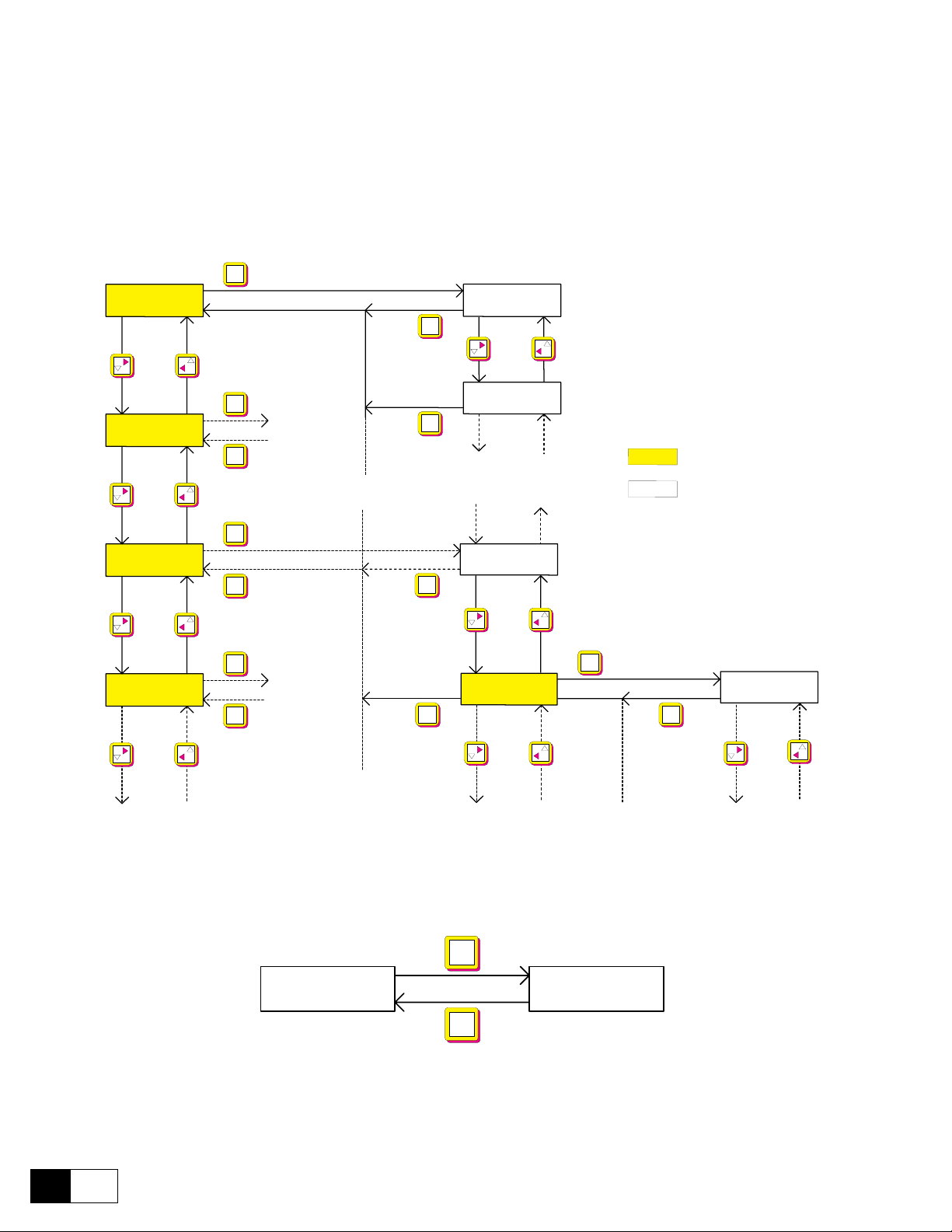

9.1 CONTROL BLOCK DIAGRAMS .......................................................................................................... 1

DV-300 Converter Overview ................................................................................................... 1

Digital Inputs /Outputs & Mapping Standard and TBO cards .................................................. 2

Analog Inputs/Outputs & Mapping.......................................................................................... 3

Speed Reference Generation .................................................................................................. 4

Ramp reference Block ............................................................................................................ 5

Speed / Current Regulator Overview ....................................................................................... 6

Speed Feedback setting ......................................................................................................... 7

Speed regulator ...................................................................................................................... 8

Speed regulator PI part ........................................................................................................... 9

Speed adaptive and Speed zero logic ................................................................................... 10

Current regulator .................................................................................................................. 11

Field current regulator .......................................................................................................... 12

Motor parameters ................................................................................................................. 13

Start and Stop management ................................................................................................. 14

Droop compensation ............................................................................................................ 15

—————— TABLE OF CONTENTS ——————

VII

Page 10

GEI-100332Ga

Inertia / Loss compensation.................................................................................................. 16

Speed Threshold / Speed control .......................................................................................... 17

PID function .......................................................................................................................... 18

Functions .............................................................................................................................. 19

LINKS Function ..................................................................................................................... 20

PAD parameters .................................................................................................................... 21

Taper Current Limits ............................................................................................................. 22

Dimension factor - Face value factor .................................................................................... 23

Test Generator ...................................................................................................................... 24

JOG function ......................................................................................................................... 25

Multispeed ........................................................................................................................... 26

Motor potentiometer ............................................................................................................ 27

Alarm mapping ..................................................................................................................... 28

9.2 POWER CIRCUIT BLOCK DIAGRAMS .............................................................................................29

9.3 REGULATION CARD ........................................................................................................................ 35

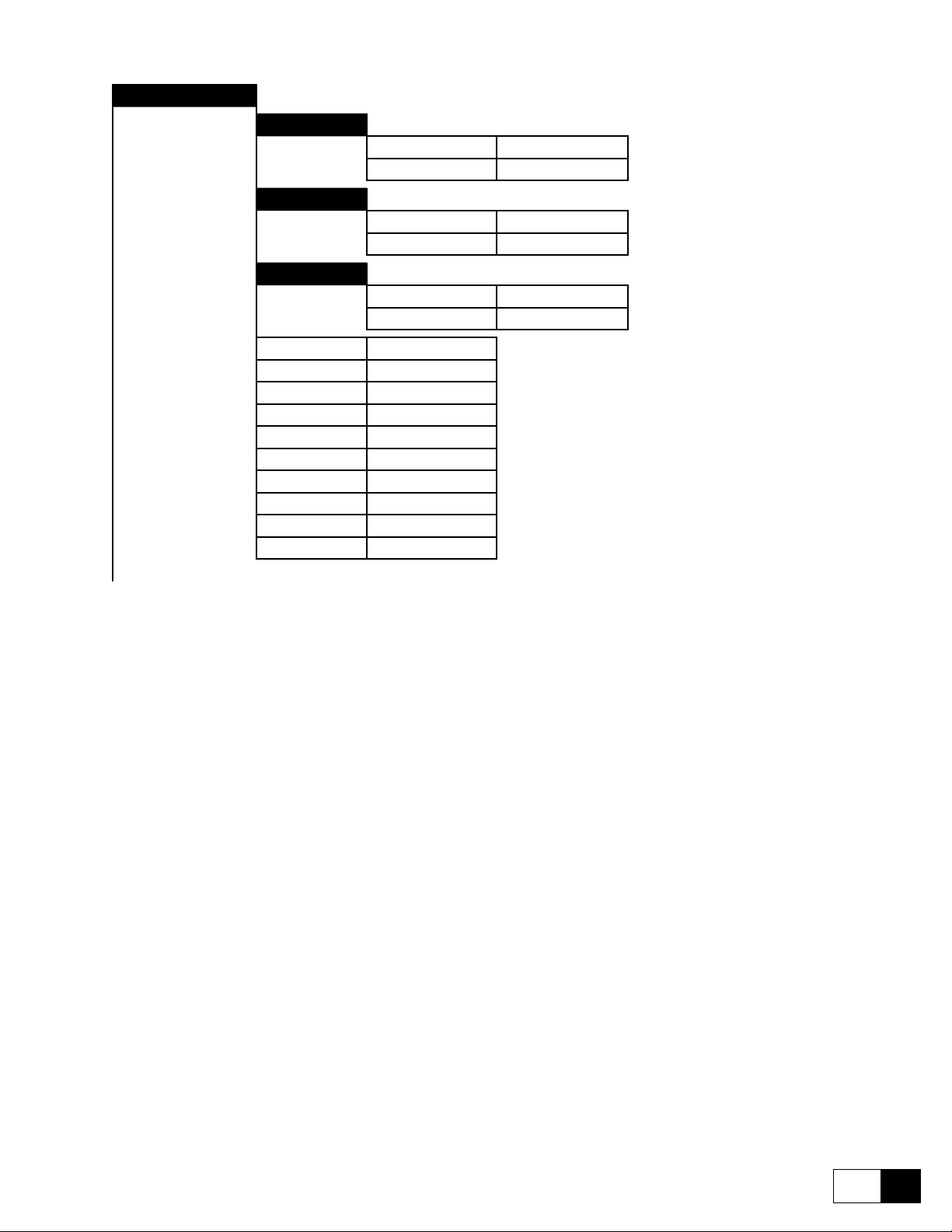

10 - PARAMETER LISTS ...................................................................................................1

10.1 COMPLETE MAIN MENU LIST ........................................................................................................ 1

10.2 NUMERICAL LIST ......................................................................................................................... 37

10.3 PARAMETERS IN ALPHABETICAL ORDER .................................................................................... 63

10.4 LIST OF HIGH PRIORITY PARAMETERS ........................................................................................ 81

11 - REPLACEMENT PARTS ............................................................................................. 1

11.1 HARDWARE CONFIGURATION (CARDS / DIP SWITCHES / JUMPERS) .......................................... 1

11.2. R-TPD32-GE REGULATION CARD .................................................................................................. 2

11.3 FIR1-... POWER/DRIVER CARDS.................................................................................................... 3

11.4 FIR2-... POWER/DRIVER CARD ...................................................................................................... 4

11.6 PBB POWER CONNECTION CARD ................................................................................................. 6

11.7 PFC1-32 FIELD CONVERTER .......................................................................................................... 6

11.8 PFC2-31 FIELD CONVERTER .......................................................................................................... 7

11.9 SN-FC FIELD SNUBBER ................................................................................................................. 7

11.10 SN4-31, SN5-31 SNUBBER .......................................................................................................... 8

11.11 SW1-31 POWER SUPPLY CARD ................................................................................................... 8

11.12 SW2-32 POWER SUPPLY CARD .................................................................................................. 9

11.13 FL-31 FILTER................................................................................................................................. 9

VIII

11.14 CN3 CONNECTION CARD ........................................................................................................... 10

11.15 I/O OPTION CARD 6KCV300TBO ................................................................................................. 10

—————— TABLE OF CONTENTS ——————

Page 11

DV-300 Adjustable Speed Drives

LIST OF FIGURES

1 - SAFETY PRECAUTIONS - PRECAUTIONS DE SECURITÉ ............................................ 1

2 - DESCRIPTION, COMPONENT IDENTIFICATION AND SPECIFICATIONS ...................1

Fig 2.1: Base diagram of a converter ......................................................................................................................................... 1

Fig. 2.5.1: Drive dimensions for 20 A ... 185 A sizes (form 1) .................................................................................................15

Fig. 2.5.2: Drive dimensions for 280 A ... 650 A sizes (form 2) ...............................................................................................16

Fig. 2.5.3: Drive dimensions for 770 A ... 1050 A sizes (form 3) .............................................................................................17

3 - INSTALLATION GUIDELINES .......................................................................................1

Figure 3.3.1: max Angle of Inclination .......................................................................................................................................2

Figure 3.3.2: Mounting Clearance ............................................................................................................................................3

4 - WIRING PROCEDURES ...............................................................................................1

Figure 4.1.1: Removing the Front Panel ....................................................................................................................................1

Figure 4.4.1: R-TPD32-GE regulation card ................................................................................................................................6

Figure 4.4.2: Disposition of terminals from 1 to 42 ....................................................................................................................9

Figure 4.5.1.1: RS485 serial interface ..................................................................................................................................... 12

Figure 4.6.2.1: Installing the option card ................................................................................................................................. 15

Figure 4.7.1.1: 6KDV300DES card .......................................................................................................................................... 16

Figure 4.8.1:Control sequencing .............................................................................................................................................. 18

Figure 4.8.2: Example for relay interface ................................................................................................................................19

Figure 4.8.3: Typical connections ...........................................................................................................................................20

Figure 4.8.4: Encoder and Tachometer Connections ...............................................................................................................21

Figure 4.8.5: Programmable Inputs/outputs (option 6KCV300TBO) with relay and contacts ................................................... 21

Figure 4.8.6: Programmable Inputs/outputs with PLC ..............................................................................................................22

Figure 4.8.7: 6KCV300DES connection .................................................................................................................................... 22

Figure 4.9.1.1: Position of the super fast fuses .......................................................................................................................23

Figure 4.11.1: Potentials of the regulator section ...................................................................................................................31

5 - CONVERTER OPERATION ............................................................................................ 1

Figure 5.1.2.1: Moving inside a menu ...................................................................................................................................... 2

Figure 5.3.6.1: Above: Actual spd; Below: Motor current. Speed P too low. ..........................................................................45

Figure 5.3.6.3: Above: Actual spd; Below: Motor current. Speed I too high. ..........................................................................45

Figure 5.3.6.2: Above: Actual spd; Below: Motor current. Speed P too high. .......................................................................... 45

Figure 5.3.6.4: Above: Actual spd; Below: Motor current. Speed P and Speed I set correctly. ............................................... 45

Figure 5.3.6.5: Above: Flux reference; Below: Flux current. The regulator behavior is not good. Jumps are due to field chan-

ging. ..................................................................................................................................................................................46

Figure 5.3.6.7: Above: Flux reference; Below: Flux current. The increment in the field current has no jump. Variation compa-

red to Fig. 4.5.7: Increase of Flux P from 2 to 10%. Flux I = 5%. ......................................................................................46

Figure 5.3.6.6: Above: Flux reference; Below: Flux current. The reduction of the field current depends on the field time con-

stant. The reg has no influence. ........................................................................................................................................46

Figure 5.3.6.8: Above: Flux; Below: Output voltage. After a speed change the field current (Flux) has some jumps. Voltage P

= 10%, Voltage I = 80%. ................................................................................................................................................. 48

Figure 5.3.6.10: Above: Flux; Below: Output voltage. After a short transient, the field current and armature voltage are con-

stant. Voltage P = 40%, Voltage I = 50%. ........................................................................................................................ 48

Figure 5.3.6.9: Above: Flux; Below: Output voltage. The gain is too low. The armature voltage increases. Voltage P = 3%,

Voltage I = 5%. ................................................................................................................................................................. 48

Figure 5.3.7.1: Curve convertion flux/current .........................................................................................................................49

Figure 5.3.7.2: Blocks diagrams of field current regulator ......................................................................................................50

Figure 5.3.7.3: Above: Actual spd; Below: Motor current jumps with the speed changes due to a high moment of inertia. The

function Speed-up is not active. ........................................................................................................................................51

Figure 5.3.7.4: Above: Actual spd; Below: Motor current. The same drive with Speed -up function active. ............................ 51

6 - FUNCTION DESCRIPTION ........................................................................................... 1

—————— TABLE OF CONTENTS ——————

IX

Page 12

GEI-100332Ga

Figure 6.1.1 Enables via potential free contacts and PLC .........................................................................................................3

Figure 6.4.1.1: Ramp references ............................................................................................................................................. 17

Figure 6.4.2.1: Speed reference ..............................................................................................................................................19

Figure 6.4.3.1: Torque current reference .................................................................................................................................20

Figure 6.6.1 : Ramp circuit ......................................................................................................................................................26

Figure 6.6.1.1: Accel, decel and Quick stop ............................................................................................................................27

Figure 6.6.2.1: Ramp shape ....................................................................................................................................................29

Figure 6.6.2.2: Ramp delay .....................................................................................................................................................29

Figure 6.6.2.3: Ramp control ................................................................................................................................................... 30

Figure 6.7.1: Speed regulation ................................................................................................................................................31

Figure 6.7.2.1: Speed zero logic ..............................................................................................................................................34

Figure 6.7.4.1: Droop compensation ........................................................................................................................................ 36

Figure 6.7.4.2: Droop function example ................................................................................................................................... 37

Figure 6.7.5.1: Inertia/Loss compensation .............................................................................................................................. 38

Figure 6.8.1: Torque current regulaton ....................................................................................................................................39

Figure 6.9.1: Motor control .....................................................................................................................................................41

Figure 6.11.4.1: Speed feedback .............................................................................................................................................50

Figure 6.11.4.2: Allowed area for Encoder 2 pulses and Motor max speed ............................................................................. 51

Figure 6.11.6.1: Calculation using dimension and face value factors.......................................................................................55

Figure 6.11.7.1: Drive enabling sequence: Main command = Terminals .............................................................................61

Figure 6.11.7.2 Drive enabling sequence: Main command = Digital ..................................................................................61

Figure 6.12.1: Arrangement of the programmable I/O ............................................................................................................64

Figure 6.12.1.1: Option card, analog output blocks .................................................................................................................66

Figure 6.12.2.1: Analog input .................................................................................................................................................. 71

Figure 6.12.2.2: Analog Input 1 window comparator ..............................................................................................................72

Figure 6.12.3.1: Digital outputs ...............................................................................................................................................74

Figure 6.12.4.1: Digital inputs .................................................................................................................................................76

Figure 6.12.5.1: Tach follower .................................................................................................................................................79

Figure 6.12.5.2: Example of application of the encoder reference ..........................................................................................80

Figure 6.13.2.1: Adaptive of the speed regulator.....................................................................................................................83

Figure 6.13.3.1: “Speed threshold” (up) and “Set speed” (down) messages .........................................................................85

Figure 6.13.4.1: Speed zero ....................................................................................................................................................86

Figure 6.14.1.1: Motor potentiometer .....................................................................................................................................88

Figure 6.14.2.1: Example of external activation in Jog mode ................................................................................................... 90

Figure 6.14.3.1: Selection of different references via terminals ...............................................................................................91

Figure 6.14.3.2: Multi speed function ......................................................................................................................................93

Figure 6.14.4.1: Multi ramp selection via terminals .................................................................................................................97

Figure 6.14.4.2: Multi ramp selection via signals .................................................................................................................... 97

Figure 6.14.5.1: Speed draw block diagram ...........................................................................................................................98

Figure 6.14.5.2: Rubber calender example ..............................................................................................................................99

Figure 6.14.6.1: Overload control (Overload mode = curr limited) ........................................................................................ 103

Figure 6.14.6.2: Overload control (Overload mode= curr not limited) ..................................................................................103

Figure 6.14.6.3: Example- Operating point of drive ................................................................................................................ 120

Figure 6.14.7.1: Start and stop management.........................................................................................................................121

Figure 6.14.8.1: Diagram of control .......................................................................................................................................124

Figure 6.14.8.2: Brake control diagram .................................................................................................................................125

Figure 6.14.8.1 Current limitation according to the speed ..................................................................................................... 126

Figure 6.15.1.1: Test generator output ..................................................................................................................................127

Figure 6.15.4.1: Structure of the signal adaptation ................................................................................................................131

Figure 6.15.5.1: Bus pads .....................................................................................................................................................134

Figure 6.16.3.1: Feed-forward block description ................................................................................................................... 139

Figure 6.16.3.2: PID blocks description .................................................................................................................................141

Figure 6.16.3.3: PI block description .....................................................................................................................................143

Figure 6.16.3.4: PD block description ................................................................................................................................... 147

Figure 6.16.3.5: Output reference block description ..............................................................................................................149

Figure 6.16.3.6: Diameter calculation block description .......................................................................................................151

Figure 6.16.3.7: Diameter calculation .................................................................................................................................... 152

X

—————— TABLE OF CONTENTS ——————

Page 13

DV-300 Adjustable Speed Drives

Figure 6.16.3.8: Nip-roll control with dancer .........................................................................................................................154

Figure 6.16.3.9: Nip-rolls control with load cell .....................................................................................................................157

Figure 6.16.3.10: Winder/Unwinder control with dancer ....................................................................................................... 161

Figure 6.16.3.11: Diameter calculation .................................................................................................................................. 165

Figure 6.16.3.12: Winder/unwinder control with sensor diameter ......................................................................................... 166

Figure 6.16.3.13: Relation between transducer signal and coil signal ...................................................................................166

Figure 6.16.3.14: Pressure control for pumps and extruder .................................................................................................. 168

Figure 6.16.3.15: Example with small and large diameter .....................................................................................................173

Figure 6.16.3.16: Relation between PI I gain PID and PI I output PID....................................................................................174

Figure 6.16.3.17: General description of the PID blocks ........................................................................................................ 175

Figure 6.17.1: Acceleration and deceleration indication ....................................................................................................... 183

Figure 6.17.2: Relation among the Taper function parameters .............................................................................................. 185

Figure 6.17.3: Operative sequence of the functioning status .................................................................................................188

Figure 6.17.4: Functioning with Jog TW enable .................................................................................................................... 190

Figure 6.17.5: Winder with an automatic switch and a closed loop tension regulation .........................................................191

Figure 6.17.6: Winder with an automatic switch and a closed loop tension regulation .........................................................192

Figure 6.17.7: Winder with an automatic switch and a closed loop tension regulation .........................................................193

Figure 6.17.8: Winder with an automatic switch and a closed loop tension regulation .........................................................194

Figure 6.17.9: Initial phase with a stopped line .....................................................................................................................195

Figure 6.17.10: Automatic switching between two coils during a winding/unwinding period ................................................ 196

Figure 6.17.11: Coil stop after the automatic switching ......................................................................................................... 197

Figure 6.17.12: Jog function to prepare the machine ............................................................................................................197

Figure 6.17.13: Drive used as a winder – winding side = up ...............................................................................................208

Figure 6.17.14: Drive used as a winder – winding side = down ........................................................................................... 209

Figure 6.17.15: Drive used as an unwinder – unwinding side = up ...................................................................................... 209

Figure 6.17.16: Drive used as an unwinder – unwinding side = down .................................................................................210

Figure 6.17.4.1: Acceleration and deceleration .....................................................................................................................219

7- MAINTENANCE ............................................................................................................ 1

8 - TROUBLESHOOTING ................................................................................................... 1

9 - BLOCK DIAGRAM ........................................................................................................1

Figure 9.2.1: Circuit block diagram: 6KDV3017Q4F ... to 6KDV3148Q4F - 6KDV3020Q4E ... to 6KDV3185Q4E .................... 29

Figure 9.2.2: Circuit block diagram: 6KDV3224Q4F ... to 6KDV3450Q4F - 6KDV3280Q4E ... to 6KDV3650Q4E .................... 30

Figure 9.2.3: Circuit block diagram: 6KDV3560Q4F ... to 6KDV3850Q4F - 6KDV3770Q4E ... to 6KDV310HQ4E ....................31

Figure 9.2.4: Circuit block diagram: 6KDV3017Q2B ... to 6KDV3148Q2B - 6KDV3020Q2A ... to 6KDV3185Q2A ...................32

Figure 9.2.5: Circuit block diagram: 6KDV3224Q2B ... to 6KDV3450Q2B - 6KDV3280Q2A ... to 6KDV3650Q2A ...................33

Figure 9.2.6: Circuit block diagram: 6KDV3560Q2B ... to 6KDV3850Q2B - 6KDV3770Q2A ... to 6KDV310HQ2A ..................34

10 - PARAMETER LISTS ...................................................................................................1

11 - REPLACEMENT PARTS ............................................................................................. 1

—————— TABLE OF CONTENTS ——————

XI

Page 14

GEI-100332Ga

LIST OF TABLES

1 - SAFETY PRECAUTIONS - PRECAUTIONS DE SECURITÉ ............................................ 1

2 - DESCRIPTION, COMPONENT IDENTIFICATION AND SPECIFICATIONS ...................1

Table 2.1.1: Converter size .......................................................................................................................................................2

Table 2.3.1: Keypad LEDs .........................................................................................................................................................7

Table 2.4.2.1: AC input votages ................................................................................................................................................. 8

Table 2.4.2.2: AC input curents .................................................................................................................................................9

Table 2.4.3.1: Output currents ................................................................................................................................................. 10

Table 2.4.3.2: Field current resistors .......................................................................................................................................11

Table 2.4.3.3: Armature circuit output votages ........................................................................................................................12

Table 2.4.3.4: Field circuit output votages ...............................................................................................................................12

Table 2.6.1: Power Dissipation ................................................................................................................................................18

3 - INSTALLATION GUIDELINES .......................................................................................1

4 - WIRING PROCEDURES ...............................................................................................1

Table 4.3.1: Terminals description .............................................................................................................................................2

Table 4.3.2: Cable size for power terminals U, V, W, C, D, PE ....................................................................................................2

Table 4.3.3: Cable section for UL approval ...............................................................................................................................3

Table 4.3.4: Wire adapter Kit and lugs suggested for UL approval ..........................................................................................4

Table 4.3.5: Cable size for power field terminals U1, V1, C1, D1 ..............................................................................................5

Table 4.3.6: Cable size for fans, signals, thermistors and regulation supply .............................................................................5

Table 4.4.1: LEDs on the R-TPD32-GE card ...............................................................................................................................6

Table 4.4.2: Dip-switch S15 adaptation of the regulation card to the device type ....................................................................7

Table 4.4.3 : Dip-switch S4 adaptation of the tachometer feedback to the input voltage ........................................................7

Table 4.4.4: Jumpers on the R-TPD32-GE card ......................................................................................................................... 8

Table 4.4.5: Test points on Regulator card ................................................................................................................................. 8

Table 4.4.6 - A: Terminal Assignment (terminals from 1 to 20) .................................................................................................. 9

Table 4.4.6 - B: Terminal Assignment (terminals from 21 to 42) ..............................................................................................10

Table 4.4.7: Cable size for fans, signals, and thermistors .......................................................................................................11

Table 4.4.8: Terminal strip for the connection of an analog tachometer ..................................................................................11

Table 4.4.9: Assignment of an XE1 connector for a sinusoidal encoder ...............................................................................11

Table 4.4.10: Assignment of the XE2 connector for a digital encoder ..................................................................................... 11

Table 4.5.2.1: Description of the XS connector for the RS485 serial interface ........................................................................13

Table 4.6.1.1: Terminal strip connections ................................................................................................................................ 14

Table 4.6.1.2: Cable size for terminals of the option card 6KCV300TBO .................................................................................15

Table 4.7.2.1: Terminal assignment (Terminals 0Venc and +Venc) .........................................................................................17

Table 4.7.2.2: Permissible cable cross section on the terminals of option card 6KDV300DES .................................................17

Table 4.7.2.3: XS1 9-pole connector ........................................................................................................................................ 17

Table 4.9.1.1: Recommended fuses (externally mounted) .......................................................................................................24

Table 4.9.2.1: Overload fuses ..................................................................................................................................................26

Table 4.9.3.1: Internal fuses ................................................................................................................................................... 27

Table 4.9.5: Control power protection .....................................................................................................................................28

Table 4.10.1.1: AC input choke ............................................................................................................................................... 30

5 - CONVERTER OPERATION ............................................................................................ 1

Table 5.3.5.3.1: Tuning resistances of the field current ............................................................................................................43

6 - FUNCTION DESCRIPTION ........................................................................................... 1

Table 6.14.2.1: Multi speed function ....................................................................................................................................... 93

Table 6.14.4.1: Ramp selection ...............................................................................................................................................96

Table 6.14.6.1: I2t derating ...........................................................................................................................102

7- MAINTENANCE ............................................................................................................ 1

XII

—————— TABLE OF CONTENTS ——————

Page 15

DV-300 Adjustable Speed Drives

8 - TROUBLESHOOTING ................................................................................................... 1

9 - BLOCK DIAGRAM ........................................................................................................1

10 - PARAMETER LISTS ...................................................................................................1

11 - REPLACEMENT PARTS ............................................................................................. 1

—————— TABLE OF CONTENTS ——————

XIII

Page 16

GEI-100332Ga

SAFETY SYMBOL LEGEND

Warning: Commands attention to an operating procedure, practice, condition, or statement which, if

not strictly observed, could result in personai injury or death.

Caution: Commands attention to an operating procedure, practice, condition, or statement which, if

not strictly observed, could result in damage or destruction of equipment.

note: Commands attention to an operating procedure, practice, condition, or statement that must

be highlighted.

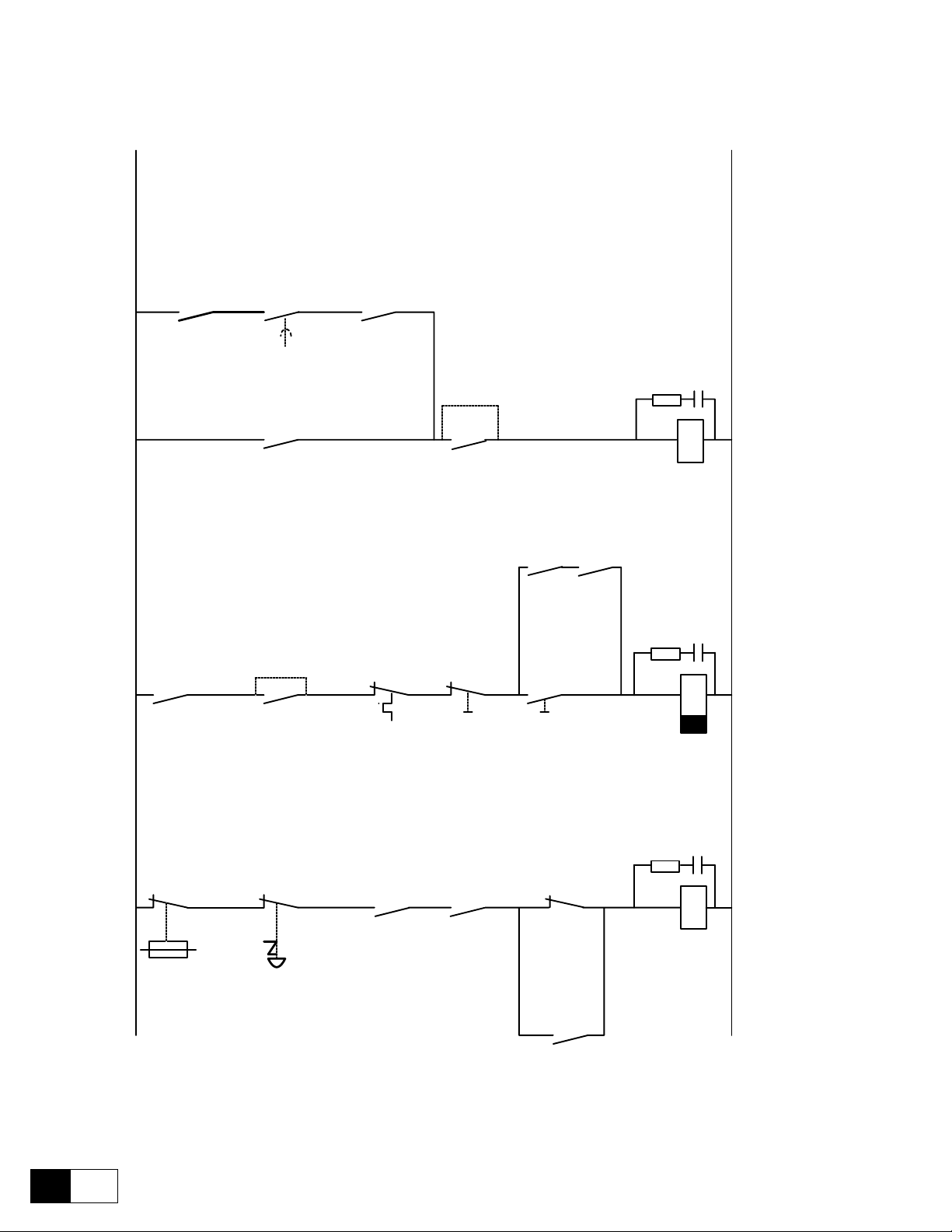

BLOCK DIAGRAM LEGEND

XIV

—————— TABLE OF CONTENTS ——————

Page 17

DV-300 Adjustable Speed Drives

1 - SAFETY PRECAUTIONS - PRECAUTIONS DE SECURITÉ

ATTENTION!

According to the EEC standards the DV-300 and accessories must be used only after checking that the machine has been produced

using those safety devices required by the 89/392/EEC set of rules, as far as the machine industry is concerned.

Drive systems cause mechanical motion. It is the responsibility of the user to insure that any such motion does not result in an

unsafe condition. Factory provided interlocks and operating limits should not be bypassed or modied.

Selon les normes EEC, les drives DV-300 et leurs accessoires doivent être employés seulement après avoir verié que la machine ait

été produit avec les même dispositifs de sécurité demandés par la réglementation 89/392/EEC concernant le secteur de l’industrie.

Les systèmes provoquent des mouvements mécaniques. L’utilisateur est responsable de la sécurité concernant les mouvements mécaniques. Les dispositifs de sécurité prévues par l’usine et les limitations operationelles ne doivent être dépassés ou modiés.

WARNING - ELECTRICAL SHOCK AND BURN HAZARD / ATTENTION – DÉCHARGE ÉLECTRIQUE ET RISQUE DE BRÚLURE :

When using instruments such as oscilloscopes to work on live equipment, the oscilloscope’s chassis should be grounded and a

differential amplier input should be used. Care should be used in the selection of probes and leads and in the adjustment of the

oscilloscope so that accurate readings may be made. See instrument manufacturer’s instruction book for proper operation and

adjustments to the instrument.

Lors de l’utilisation d’instruments (par example oscilloscope) sur des systémes en marche, le chassis de l’oscilloscope doit être

relié à la terre et un amplicateur différentiel devrait être utilisé en entrée.