Page 1

TM

Page 2

This book is referred to SW version 9.2X00.

This book replaces the Instruction Book GEH-6129 Rev. 7.1

These instructions do not purport to cover all details or variations in equipment, nor to provide every possible contingency

to be met during installation, operation, and maintenance. If further information is desired or if particular problems

arise that are not covered sufficiently for the purchaser’s purpose, the matter should be referred to GE Consumer &

Industrial.

This document contains proprietary information of General Electric Company, USA and is furnished to its customer

solely to assist that customer in the installation, testing, operation, and/or maintenance of the equipment described.

This document shall not be reproduced in whole or in part nor shall its contents be disclosed to any third party without

the written approval of GE Consumer & Industrial..

© 2008 by General Electric Company, USA. All rights reserved.

Page 3

Table of Contents

1. PRECAUTIONS AND WARNINGS ........................................................................................5

2. PREFACE...............................................................................................................................7

2a. Important Introduction.................................................................................................................................... 7

2b. Drive Memory ................................................................................................................................................ 7

2c. Basic control wiring and starting .......................................................................................... .......................... 7

2d. GE Control System toolbox VS keypad setup............................................................................................... 8

3. PRE POWER CHECKS.......................................................................................................... 9

3a. Grounds/grounding........................................................................................................................................ 9

Regulator board terminals ................................................................................................................................... 9

3b. Meggering...................................................................................................................................................... 9

3c. Connections ................................................................................................................................................... 9

3d. motor data tabulation................................................................................................................................... 10

Nameplate dual speed rating............................................................................................................................. 10

3e. field current calibration dipswitch S14 ..........................................................................................................11

3f. Regulation card jumper settings ................................................................................................................... 13

4. POWER UP CHECKS AND INITIAL CONFIGURING ......................................................... 14

4a. Don’t turn on power yet.....check power input ............................................................................................. 14

4b. Power up..................................................................................................................................................... 14

4c. Loading default settings............................................................................................................................... 14

5. INITIAL PARAMETER SETUP............................................................................................. 15

6. CURRENT REGULATOR SELF TUNE................................................................................ 18

7. CHECK MOTOR/ROLL ROTATION, SPEED FEEDBACK POLARITY, AND

CALIBRATIONS................................................................................................................... 19

7a. Check motor/roll rotation.............................................................................................................................. 19

7b. Calibrations.................................................................................................................................................. 19

7c. Checking current regulator performance using parameter Eint................................................................... 19

8. SETUP SPEED FEEDBACK................................................................................................ 20

8a. Check speed feedback polarity ................................................................................................................... 20

8b. Setup ENC 2 for digital encoder for speed feedback ................................................................................. 20

8c. ENC 1 for digital encoder for speed feedback............................................................................................. 21

8d. Analog tachometer....................................................................................................................................... 21

8e. Save setup................................................................................................................................................... 22

9.CONFIGURE ADDITIONAL MOTOR FIELD PARAMETERS ............................................... 23

9a. Configure field weakening operation ........................................................................................................... 23

9b. hints on Flux regulator stability .................................................................................................................... 23

Page 4

10. SPEED SELF TUNE........................................................................................................... 24

11. SAVE PARAMETERS TO RETAIN IN PERMANENT MEMORY....................................... 24

12. OTHER COMMON SETUP PARAMETERS....................................................................... 25

12a. Terminal board input control VS keypad .................................................................................... ................ 25

12b. Configurable I/O.......................................................................................................... ............................... 25

12c. Configure jog operation.............................................................................................................................. 26

13. INTERNAL REPLACEMENT FUSES ................................................................................. 27

14. BASIC OPERATING DESCRIPTIONS...............................................................................28

14 a. standard inputs functional description ...................................................................................................... 28

14b. Regulation card LEDs................................................................................................................................ 28

14c. Keypad programmer LED description........................................................................................................ 28

14 d. Keypad menu structure............................................................................................................................. 29

15. QUICK TROUBLESHOOTING........................................................................................... 30

15a. Regulation card testpoints ......................................................................................................................... 30

15b. Failure messages and troubleshooting hints............................................................................................. 30

Page 5

DV-300 Adjustable Speed Drives

1. PRECAUTIONS AND WARNINGS

According to the EEC standards the DV300 and

accessories must be used only after checking that the

machine has been produced using those safety devices

required by the 89/392/EEC set of rules, as far as the

machine industry is concerned.

Drive systems cause mechanical motion. It is the responsibility of the user to insure that any such motion

does not result in an unsafe condition. Factory provided

interlocks and operating limits should not be bypassed

or modified.

WARNING - ELECTRICAL SHOCK AND BURN

HAZARD:

When using instruments such as oscilloscopes to work

on live equipment, the oscilloscope’s chassis should

be grounded and a differential amplifier input should

be used. Care should be used in the selection of probes

and leads and in the adjustment of the oscilloscope so

that accurate readings may be made. See instrument

manufacturer’s instruction book for proper operation

and adjustments to the instrument.

WARNING - FIRE AND EXPLOSION HAZARD:

Fires or explosions might result from mounting drives

in hazardous areas such as locations where flammable

or combustible vapors or dusts are present. Drives

should be installed away from hazardous areas, even if

used with motors suitable for use in these locations.

Improper installation of motors or drives may therefore

cause the failure of the device as well as serious injury

to persons or material damage.

Follow the instructions given in this manual and observe

the local and national safety regulations applicable.

CAUTION:

Do not connect power supply voltage that exceeds the

standard specification voltage fluctuation permissible.

If excessive voltage is applied to the Drive, damage to

the internal components will result.

CAUTION:

Do not operate the drive without the ground wire

connected. The motor chassis should be grounded to

earth through a ground lead separate from all other

equipment ground leads to prevent noise coupling.

The grounding connector shall be sized in accordance

with the NEC or Canadian Electrical Code. The

connection shall be made by a UL listed or CSA certified

closed-loop terminal connector sized for the wire gauge

involved. The connector is to be fixed using the crimp

tool specified by the connector manufacturer.

CAUTION:

Do not perform a megger test between the Drive

terminals or on the control circuit terminals.

WARNING - STRAIN HAZARD:

Improper lifting practices can cause serious or fatal

injury . Lift only with adequate equipment and trained

personnel.

WARNING:

Replace all covers before applying power to the drive.

Failure to do so may result in death or serious injury.

WARNING:

Adjustable speed drives are electrical apparatus for use

in industrial installations. Parts of the drives are

energized during operation. The electrical installation

and the opening of the device should therefore only be

carried out by qualified personnel.

—————— Quick Start up guide ——————

CAUTION:

Because the ambient temperature greatly affects drive

life and reliability, do not install the drive in any location

that exceeds the allowable temperature. Leave the

ventilation cover attached for temperatures of 40° C

(104° F) or below.

CAUTION:

If the drive’s Fault Alarm is activated, consult the

TROUBLESHOOTING section of the instruction book,

and after correcting the problem, resume operation. It

is not recommended to reset the alarm automatically

by external sequence, etc.

5

QS

Page 6

GEH-6129

CAUTION:

Be sure to remove the desicant dryer packet(s) when

unpacking the Drive. (If not removed these packets may

become lodged in the fan or air passages and cause the

Drive to overheat).

CAUTION:

The Drive must be mounted on a wall that is constructed

of heat resistant material. While the drive is operating,

the temperature of the Drive’s cooling fins can rise to a

temperature of 90° C (194°F).

NOTE! The terms “converter”, “controller” and

“drive” are sometimes used interchangably

throughout the industry. W e will use the term

“drive” in this document

NOTE! 1. Never open the device or covers while the

AC input power supply is switched on.

Minimum time to wait before working on the

terminals or inside the device is listed in the

instruction book

2. Do not touch or damage any components

when handling the device. The changing of

the isolation gaps or the removing of the

isolation and covers is not permissible. If the

front plate has to be removed because of a

room temperature higher than 40 degrees, the

user has to ensure that no accidental contact

with live parts may occur.

3. Protect the device from extreme

environmental conditions (temperature,

humidity, shock etc.)

4. No external voltage should be connected

to the output of the converter (terminals C &

D).

5. When engaging a running motor, the Auto

capture function (Auto capture in the ADD

SPEED FUNCT menu) must be activated.

6. Only an standard inductive DC motor load

should be connected to the output of the drive

(terminals C & D).

7. Always connect the Drive to the protective

ground (PE) via the marked connection

terminals (PE2) and the housing (PE1). The

discharge current to earth may be greater than

3.5 mA. A fixed (non disconnectable) ground

connection must be provided for this, to

comply with EN 50178 (VDE 0160). It is

aso recommended that the ground cable

should have a cross section of at least 10 mm

8. The electrical commissioning should only

be carried out by qualified personnel, who

are also responsible for the provision of a

suitable ground connection and a cable

protection for the power supply in accordance

with the local and national regulations. The

motor must be protected against overloads.

9. No dielectric tests using meggers or hi pots

should be carried out on the drive. A suitable

measuring instrument (internal resistance of

at least 10 kΩ/V) should be used for

measuring the signal voltages.

10.It is recommended to disconnect the drive

from the AC input feeder to prevent

unintentional running in the event of a failure,

even if the drive is disabled.

NOTE! The DV-300 operates from the inputs: start

and enable. If the enable input / signal is

removed, the start signal is not automatically

removed. Re establishing the enable signal

with the start signal already present can cause

motor rotation.

This guide highlights simplified steps to

program and tr oubleshoot the DV -300 drive.

In is intended to be used as a aid for trained

personnel, and to complement the DV-300

Instruction Book, after the drive is installed

in accordance with the DV-300 Instruction

Book.

2

.

QS

6

—————— Quick Start up guide ——————

Page 7

2. PREFACE

DV-300 Adjustable Speed Drives

2a. Important Introduction

This startup guide is based on starting up the DV-300

out of the box from the factory , based on factory default

settings.

This guide will walk the user through sequential steps

and checkpoints for startup. It is recommended to follow

this guide sequentially without skipping steps unless

this guide instructs the user to do so.

Parameter menus and names will be shown in a keypad

screen symbol, for example:

SPEC FUNCTIONS

Save parameters

parameter names will also be shown in brackets [save

parameters]

2b. Drive Memory

There are two memories for drive parameters. One is

the active memory which is always the one currently

in use by the drive. The other is the permanent memory

which is the drive accesses on power up. This is the

ONL Y time when the drive looks at permanent memory .

All file uploads and downloads, all changes, etc. are

made only to the active memory and read from the active

memory. The only time permanent memory is used in

any way is that when it is booted into active memory

on power up, and when it is stored using the “Save

Parameters” command.

When parameters are changed during set up, the

changes are not permanent. The parameters changes

are temporarily used, but unless [SAVE

P ARAMETERS] is executed, after recycling power, the

changes are lost. This is an advantage to “experiment”

with a parameter change to see how the change works,

and not modify the permanent set-up.

As parameters are entered it is recommended to

occasionally save entered data. The [SAVE

PARAMETER]command is located at the end of the

START UP, TUNING, and under the SPEC

FUNCTIONS menu.

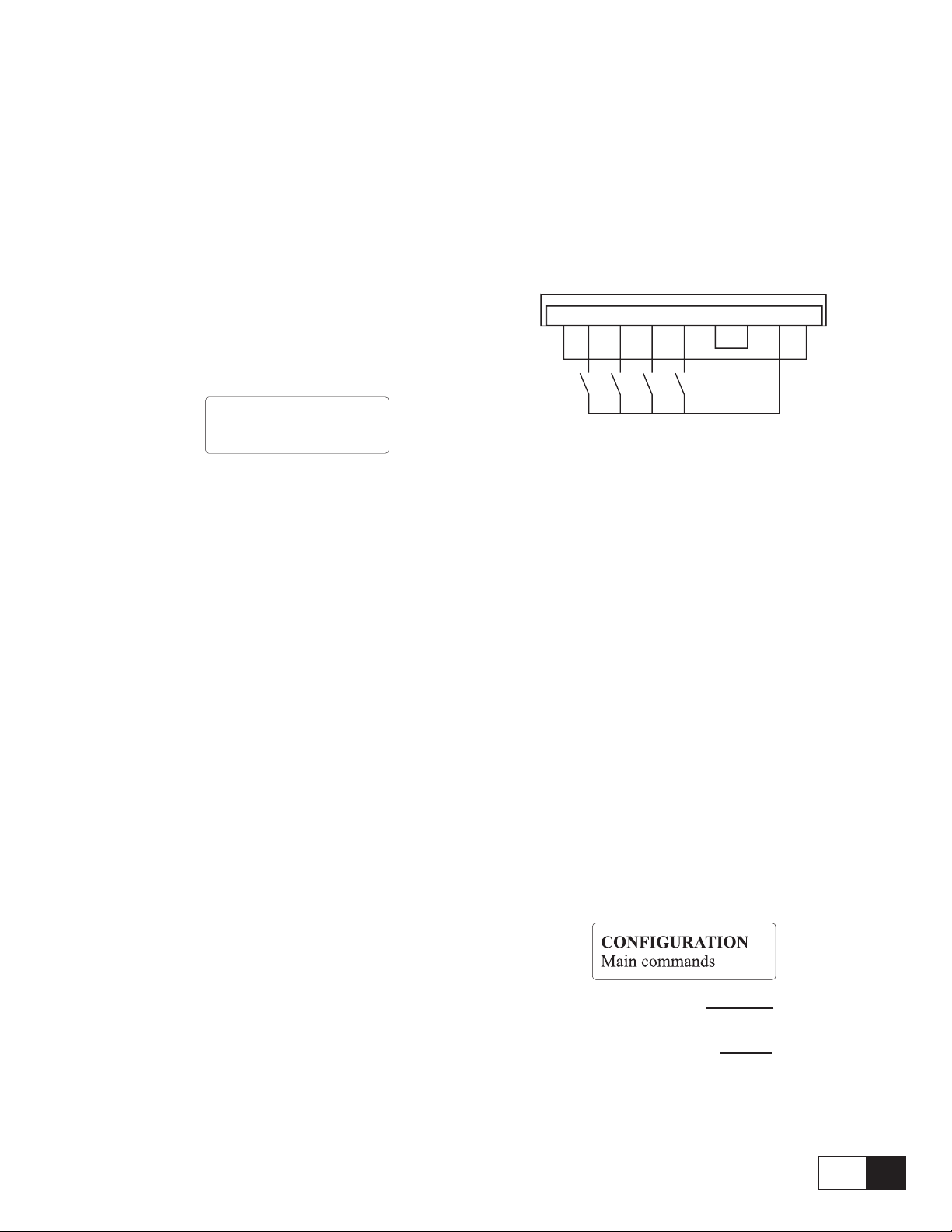

2c. Basic control wiring and starting

The terminal board inputs provide the user a hardwired

control means to sequence the drive.

For testing, the inputs can be wired using a local switch

box per the drawing below.

The actual control interface can be used if it has been

checked out, and is a convenient and reliable control

means.

11 12 13 14 15 16 18 19 20

11 - power supply common

12 - enable (close to activate)

13 - start (close to activate)

14 - fast stop (open to activate)

15 - external fault (open to activate)

16 - common for TB pts 11 -15

18 - + 24 V common

19 - + 24 VDC

20 - ground

After the control circuits are wired, and proven to

operate, repower the DV-300.

Close only the switch for EXTERNAL FAULT input.

Reset external drive fault with the keypad’s CANC key .

The default DV-300 configuration sets the control

inputs in a “digital” mode, which is for keypad and

PC control. In this mode, the terminal board inputs

must be connected to 24 VDC as well as commanded

from the keypad or PC.

This mode is set by parameter:

When this parameter is set to terminals, the terminal

board inputs control the drive.

When this parameter is set to

digital, the keypad,

PC, or bus controls the sequencing, but opening the

terminal board input will also cause the signal to

drop out.

—————— Quick Start up guide ——————

7

QS

Page 8

GEH-6129

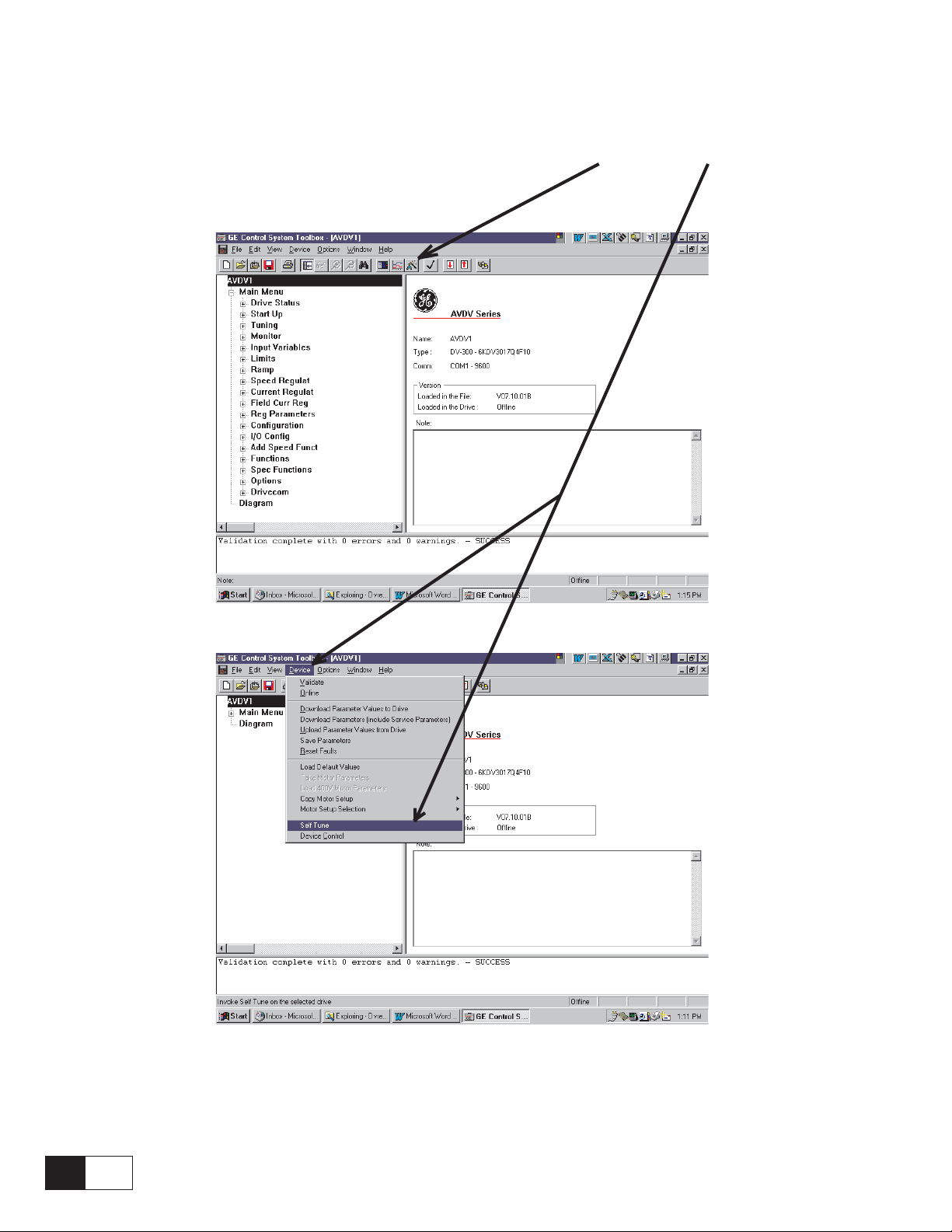

2d. GE Control System toolbox VS keypad setup

After following the suggestions for startup using Hints, pre power checks , and power up checks, a user

configuring the drive with the GE Control System toolbox can follow the wizards and self tune menus

to complete the setup.

QS

8

—————— Quick Start up guide ——————

Page 9

3. PRE POWER CHECKS

3a. Grounds/grounding

DV-300 Adjustable Speed Drives

Verify an AC power ground wire exists from the incoming power / isolation transformer to the DV-300

input ground terminal.

Verify the ground lead of the DV-300 output terminal is

wired to the motor, or the motor is properly grounded.The

DV-300 power supply, terminal point 11, may be

referenced to ground through a different ground circuit,

or may be wired to the same ground by connecting terminal

point 11 to terminal point 10 or 20.

V erify the AC input leads, DC output armature and field

leads, and control wiring to and from the drive terminals

are not grounded.

Use a digital voltmeter or equivalent to take these

readings if the wiring is attached to the drive. Remember

that the 0V terminal may be intentionally grounded.

Isolated field wiring generally reads at least 2-3 MW

to ground.

3b. Meggering

Cabling must be disconnected or isolated from the DV 300 drive when meggered or hi potted. Drive damage

could result if this advice is not followed.

3c. Connections

Without applying power , double check all connections

and wire terminals to make sure they are tight.

V erify each connection is wired per wiring diagrams,

and are appropriate for the current and voltage

levels specified.

Regulator board terminals

1,2 = programmable analog input 1,

3,4 = programmable analog input 2,

5,6 = programmable analog input 3

7 = + 10 V , 8 = -10V, 9 = +/- 10 V supply common ,

10 = ground,

11 = common

12 = enable input, 13 = start input,

14 = fast stop input, 15 = external fault input,

16 = common point for terminals 12 through 15,

—————— Quick Start up guide ——————

17 = no connection,

18 = common for the 24V power supply,

19 = + 24 VDC output, 20 = ground

XE1 ( ENC1) 9 pin sinusoidal encoder input

XE2 ( ENC2) 9 pin incremental encoder input

DC tach input: - , + terminals for DC tach. max volts ≤ 108 no jumper,

108 ≤ max volts ≤ 188 VDC jumper B & C

188 ≤ max volts ≤ 340 VDC jumper A & C

20 = Screen connection (PE) (connected w/housing)

9

QS

Page 10

GEH-6129

3d. motor data tabulation

Before commissioning, it is recommended to record the actual motor nameplate data. Also record gearbox, and

attached roll diameter, or any appropriate mechanical data that may be needed during setup.

This table may be used as a guide to record motor nameplate and application data

Typical DC Motor Nameplate

HP (kW) RPM Volts

Arm Amps

Fld Amps Fld ohms 25 C

Fld is an abbreviation for field

Gear in speed

· gear in speed is the top motor rpm to achieve rated machine speed

Acceleration time · : seconds

Deceleration time

Field control

(circle one)

tachometer type

and calibration

(circle one)

· : seconds

: constant current, (fixed field current)

field weakening (see example below)

: analog V / RPM

digital tacho into Encoder 2 PR

see jumpers note in 3.f.

None

· : rpm

P

see jumpers in 3.f.

see jumpers in 3.f.

Nameplate dual speed rating

The value for RPM may be represented with two values, the first representing base speed , which is the rpm at

nameplate volts and nameplate field current.

A second RPM value, if shown, corresponds to rated top speed, which is achieved at rated nameplate volts, and

a weak field setting. The weak field setting would correspond to the second value of field amps.

For the nameplate below, base speed is 1750 rpm @ 3 amps field and top speed is 2300 rpm @ 1 amp field

Typical DC Motor Nameplate

HP (kW) 20 RPM 1750 / 2300 Volts 500

Arm Amps 32

Fld Amps 3.0 / 1.0 Fld ohms 25 C 72

Verify the motor data matches the drive power rating, output voltages, and required motor speed is achievable.

If files in the GE Control System Toolbox were predefined off-line, verify the entered data is correct before

downloading to the drive

QS

10

—————— Quick Start up guide ——————

Page 11

DV-300 Adjustable Speed Drives

3e. field current calibration dipswitch S14

The DV-300 regulation card is shipped with the field current feedback resistor dipswitches calibrated for the

maximum rating of the field package capacity for each size DV-300.This maximum field package rating is

incorporated in the DV- 300 catalog number.

For example: 6KDV3017Q4F

Compare the actual motor field data, recorded in step 3d., to the maximum rating of the field package

of the DV-300 model supplied (in the instruction book) , and to the field calibration dipswitch S14, as shown

below Table 3e1, 3e2, 3e3.

· For fixed field current operation, if the actual motor (base) field current = 10% of the maximum rating of the

field package it is required to calibrate the field current feedback scaling using dipswitch S14.

· For weak field operation, also referred to CEMF field control or crossover field control, if the actual top

speed motor field current = 10% of the maximum rating of the field package it is required to calibrate the

field current feedback scaling using dipswitch S14.

Calibration to the exact field current setting is not required, as long as the above conditions are met.

Calibration is not required if the field control is provided from a source other than the DV-300.

10D1 The 10 represents a 10 A field exciter.

Example:

For the nameplate below , base speed is 1750 rpm @ 2.9 amps field and top speed is 2300 rpm @ 2.1 amp field.

The motor is desired to run at 2300 rpm, so the minimum field is 1 amp.

Typical DC Motor Nameplate

HP (kW) 20 RPM 1750 / 3000 Volts 500

Arm Amps 32

Fld Amps 2.9 / .9 Fld ohms 25 C 72

For DV-300, 6KDV3035..., the field package is rated for 10 A. The motor is needed to run at 3000 rpm, so

requires a minimum field setting of .9 amps. .9 A is less than 10% of the 10 A default dipwitch setting therefore

it needs changed.

A good setting for field curr scaling is 3.0 amps, S14-5 = ON, all others = Off.

The parameter [field curr scaling] also needs set for 3.0 amps.

RECORD REQUIRED S14 DIPSWITCH SETTING and FIELD SCALING AMPS

from the tables on the next page

Field curr scale S14 -1 S14 -2 S14-3 S14-4 S14-5 S14-6

—————— Quick Start up guide ——————

Tqs310

11

QS

Page 12

GEH-6129

Table 3e1: DV-300 Rev 7.1 or greater, field current calibration resistor dipswitch settings for

model numbers 6KDV3017...-3850, (European model numbers 6KDV3020..-310H)

Resistance = 1667 / field current amps

Switch ohms 168.5 ohm 333 ohm 182 ohm 36.4 ohm 845 ohm 1668 ohm

Field curr scale S14-1 S14-2 S14-3 S14-4 S14-5 S14-6 S14-7 S14-8

1.0 A OFF OFF OFF OFF OFF ON 1685 ohm

2.0 A OFF OFF OFF OFF ON OFF 845 ohm

3.0 A OFF OFF OFF OFF ON ON 558.8 ohm

5.0 A OFF ON OFF OFF OFF OFF 333 ohm

10.0 A ON OFF OFF OFF OFF OFF 168.5 ohm

12.9 A ON OFF OFF OFF ON ON 129.2 ohm

17.2 A OFF ON ON OFF ON ON 97 ohm

20.0 A ON OFF ON OFF OFF ON 83 ohm

24.1 A ON ON ON OFF OFF OFF 69 ohm

Not used

1=dipswitch in ON position

Table 3e2: DV-300 Rev 7.1 or greater, field current calibration resistor dipswitch settings for

model numbers 6KDV30900...-31500, (European model numbers 6KDV31200..-32000)

Resistance = 3332 / field current amps

Field current scale S14-1 S14-2 S14-3 S14-4 S14-5 S14-6 Equivalent resistance

40A ON OFF ON OFF OFF OFF 83

20A ON OFF OFF OFF OFF OFF 168

10A OFF ON OFF OFF OFF OFF 332

W

W

W

Equivalent

resistance

DV0032g

1=dipswitch in ON position

Tqs330

Table 3e3 : DV-300 Rev 7.1 or greater, field current calibration resistor dipswitch settings for

model numbers 6KDV31800...-32350, (European model numbers 6KDV32400..-33300)

Resistance = 1667 / field current amps

Field current scale S14-1 S14-2 S14-3 S14-4 S14-5 S14-6 Equivalent resistance

70A ON OFF ON ON OFF OFF 23.8

46A OFF OFF OFF ON OFF OFF 36.4

24A ON ON ON OFF OFF OFF 69.2

14A OFF ON ON OFF OFF OFF 117.6

1=dipswitch in ON position

W

W

W

W

Tqs340

Setting all dipswitch settings to 0 (OFF) allows a custom calculated resistor to be used in terminals LA and LB,

on the regulation board, using the formulas listed above.

QS

12

—————— Quick Start up guide ——————

Page 13

DV-300 Adjustable Speed Drives

3f. Regulation card jumper settings

Jumper settings to use 6KCV300PIU PC Interface Unit - ( RS232 isolator )

Jumpers S18 & S19 = B, Jumper S29 & S30 = ON Jumper S15 = Off

or the 6KCV300CTI PC configurator Interface Unit - ( RS232/RS485 )

Jumpers S18 & S19 = B, Jumper S29 & S30 = On Jumper S15 = On

Jumper Factory Description Record

default settings:

S4 Matching of the input voltage of the tachogenerator reaction, see table 4.4.3 (User manual)

Speed feedback channel selection

A = Enc 1 speed feedback channel

S5,S6 B

B = analog tachometer

Analog input 1 setup

S9 Off

S10 Off

S11 Off

S12,S13 Off

S15 On Adaptation of the regulation card to the device type, see table 4.4.2 (User manual)

S18,S19 B

S20 Off

S21,S22,

S23

ON Mounted Jumpers

OFF Non mounted Jumpers

Off = 0-10 V/ -10 V to + 10 V input

ON = 4-20mA/0-20mA input

Analog input 2 setup

Off = 0-10 V/ -10 V to + 10 V input

ON = 4-20mA/0-20mA input

Analog input 3 setup

Off = 0-10 V/ -10 V to + 10 V input

ON = 4-20mA/0-20mA input

RS 485 programming port (XS) termination resistors

Off - no termination resistors

ON - termination resistors in

Selection of the internal/external supply of the RS485 serial interface

OFF - Serial interface supplied from the outside (PIN 5 and 9) and galvanic divided form the

regulation section.

ON - Serial interface supplied from the inside and connected to the potential reference point of the

regulation. PIN 5 and 9 are used to supply the adaptor of the serial interface (for use of

6KDV300PIU).

Encoder 2 input (XE2) marker channel ( also called index , or C channel) input

Off - marker channel (also called index , or C channel) input not used

ON - marker channel (also called index , or C channel) input monitored

Encoder 2 input (XE2) A, /A, B, /B voltage

Off

Off - 15 ... 30 V

ON - 5 V

( XE1 connector with sinusoidal encoder, or digital encoder with 6KCV300DES )

for digital encoder into XE2, or armature feedback (tachless) this jumper position has no effect

Tqs350

NOTE! For sizes 6KDV3280... (American P/N) 6KDV3350... (European P/N) and higher, 1 15 VAC operation

requires a jumper between terminals SA & SB. These points are located on a terminal board on the top

of the converter module.

—————— Quick Start up guide ——————

13

QS

Page 14

4. POWER UP CHECKS AND INITIAL CONFIGURING

4a. Don’t turn on power yet.....check power

input

GEH-6129

To load factory default settings, go to:

Make sure the AC incoming voltage at the input side of

the disconnect switch(s) is/are correct for the main

converter, field control (460 VAC max), and control

power (115 - 230 VAC).

Disconnect drive connectors from option cards DGF

and SBI ( LAN interface cards ) if supplied.

This will keep other potential sources of control and

referencing from interfering with the initial setup.

To make absolutely sure motor motion is not possible

from any source on initial power up, pull out the I/O

connectors for Regulator terminal board points 1 - 20.

If the DV-300 is much larger than the actual motor

rating, the default field current setting may be higher

than the actual motor field. T o prevent overloading and

heating of the motor field circuit in this situation, it

may be advisable to disconnect the field circuit

connector (with the wiring attached) until the calibrated

data is entered.

4b. Power up

If possible, turn control power on separately first, check

that everything looks OK visually.

If one single disconnect switch is provided , turn on

power at this time.

The keypad LED should show “external fault” if the

terminal board connector points 11-20 are pulled out.

If other faults are present, ignore them for now.

SPEC FUNCTIONS

Load default

to permanently save the default settings, press the up

arrow to

SPEC FUNCTIONS

Save parameters

Press CANC, then hold down the up arr ow to return to

the top of the main menus.

Press ENT

Press ENT

DEFAULT NOTE:

Regulation card Dipswitch S15 sets the

converter size and type, and is set properly

from the factory.

In the event of card replacement, the

dipswitch may need changed. Refer to the

DV-300 Instruction book for the dipswitch

table.

Dipswitch S15 - 7 = off; identifies to the DV 300 firmware: 400 V European defaults

Dipswitch S15 - 7 = on; identifies to the DV 300: 460 V American defaults.

4c. Loading default settings

The DV-300 contains appropriate default settings for

typical 500 VDC GE motors, right out of the box.

If the drive has been powered before by persons

unknown, or the exact programming condition of the

drive is unknown, or for just getting a fresh

configuration start, executing a “load default”

parameters may be in order.

If the drive has been supplied from a third party as an

engineered package, many of the settings may be

already set, so loading default may be inappropriate.

QS

14

—————— Quick Start up guide ——————

Page 15

DV-300 Adjustable Speed Drives

START UP

Acc delta time

START UP

Dec delta speed

START UP

Dec delta time

START UP

Motor data

Motor data

Motor nom flux

Motor data

Flux reg mode

5. INITIAL PARAMETER SETUP

This part of the procedure sets up the DV-300 for

CEMF feedback (open loop) with constant field

current.

The enable input and start input ( TB 12 and 13)

should be open circuit, i.e. not tied to 24 VDC.

GE DRIVE DV-300

DRIVE STATUS

Using the keypad, press the down arrow to go to the

START UP menu .

GE DRIVE DV-300

START UP

START UP

Speed base value

Press ENT

Press ENT

Enter the same rpm as entered for Speed base value

( rated machine motor rpm recorded from section

3 d., corresponding to the maximum desired motor

rpm ), press ENT

Press the down arrow to go to the next parameter.

Press ENT

Enter the desired acceleration time in seconds as

recorded in section 3d., press enter

Press the down arrow to go to the next parameter.

Press ENT

Enter the same rpm as entered for speed base value(

rated motor rpm recorded from section 3 d.,

corresponding to the maximum desired motor rpm

), press enter

Enter the rated motor rpm recorded fr om section 3

d., ”gear in speed” corresponding to the maximum

desired motor rpm., press ENT

This parameter sets the value of speed reference that is

used as 100%, 1 per unit, in other words, the “base

value”.

Press the down arrow to go to the next parameter

START UP

Field curr scale

Enter the field current scale amps corresponding to

the S14 dipswitch setting recorded from section 3

e., press ENT

Press the down arrow to go to the next parameter.

START UP

Speed base value

Press ENT

Default = on,

Press the down arrow to go to the next parameter.

Press ENT

Enter the desired acceleration time in seconds as

recorded in section 3d., press enter

Press the down arr ow to go to the next parameter menu.

Press ENT

Press ENT

Enter the nameplate base field current amps as

recorded in section 3d, press ENT

Press the down arrow to go to the next parameter.

Press the down arrow to go to the next parameter.

START UP

Acc delta speed

Press ENT

—————— Quick Start up guide ——————

Press ENT

Use the + and - keys to select the desired flux

regulation control. The default setting = Constant

current = fixed field

15

QS

Page 16

Press the down arrow to go to the next parameter.

Motor data

Full load current

Press ENT

GEH-6129

The list below shows some possible applications requiring user changes to “Limits” parameters:

Enter the nameplate armature amps as recorded

in section 3d. . press ENT

Press the down arrow to go to the next parameter.

Motor data

Motor max speed

Enter the same rpm as entered for speed base value(

rated motor rpm recorded from section 3 d.,

corresponding to the maximum desired motor rpm

), press ENT

Press the down arrow to go to the next parameter.

Motor data

Max output volts

Default = 500 VDC press ENT to change

Enter the nameplate output volts as recorded from

section 3 d, if different from default, press ENT

Press ENT

- For weak field operations:

top speed field current

If

then “START UP \ Limits \ Flux current min “

will need adjusted

- 230 VAC operation - also change [prog alarms

\ undervoltage threshold] , and Motor data ....

- Overload capacities dif ferent than 150% for 60

seconds, [Overload contr] and [ T curr limit]

Press the down arr ow to go to the next parameter menu.

START UP

Speed feed-back

Speed feed-back

Speed feed-back sel

Use the + arrow to select speed feedback type =

armature, press ENT

Press CANC to return to

speed field currentbase

<.7

Press ENT

Press ENT

Press CANC to return to Motor data menu, and press

the down arrow to go to the next parameter menu.

START UP

Limits

The default settings for these are adequate for most

applications @ 500 VDC and 150% OL for 1 minute.

START UP

Speed feed-back

the default settings are already set for speed control

using a potentiometer wired to analog input, skip to

SAVE PARAMETERS.

For keypad control of speed reference, go to menu

selection.

START UP

Analog inputs

Analog inputs

Analog input 1

Analog inputs

Analog input 1 sel

Hold in the - key until entry shows OFF,

Press ENT

Press ENT

Press ENT

QS

16

—————— Quick Start up guide ——————

Page 17

DV-300 Adjustable Speed Drives

Analog input 1 sel

Off

Press CANC twice to get back to

START UP

Analog inputs

Speed reference is contr olled from the keypad using:

DRIVE STATUS

Ramp ref 1

OR

INPUT VARIABLES

Ramp Ref

Press ENT

Press ENT

Press ENT

Ramp Ref

Ramp ref 1

enter the desired rpm reference using the

and the + - keys, press ENT

SAVE PARAMETERS

Hold down the down arrow until the [Save

parameters] is seen, press ENT.

START UP

Save parameters

Power down the drive, and reconnect the field circuit

connector if it was removed for the initial

configuration of the drive per section 4a.

Press ENT,

arrow keys

Press ENT

—————— Quick Start up guide ——————

17

QS

Page 18

GEH-6129

6. CURRENT REGULATOR SELF TUNE

Per the setup in the previous section, a current regulator

self tune can now be executed from the keypad or PC.

The setting of parameter [main commands] must be =

digital, this is the default setting.

This parameter can be found under the menus:

START UP

Main commands

The terminal board inputs 12, 13, 14, and 15 must then

be connected to TB 19 (24 VDC), either through

jumpers, switches, or contacts.

It is recommended to have a switch wired from terminal

input 12 to 19 that is readily accessible to the user, so

under the drive can be stopped quickly during

commissioning.

CONFIGURATION

Main commands

When the self tune is complete , and only when the test

is complete, the drive will automatically set the

parameter [ST AR T UP\ Cur reg self tune] = OFF , enable

and start commands will be turned off.

The results of this test are temporarily stored in

[CURRENT REGULAT \ Arm resistance], and

[CURRENT REGULAT \ Arm inductance]

The motor must NOT be allowed to rotate during this

test. If the motor shaft moves during this test, the shaft

must be physically locked in place.

After completion of the self tune, save the parameters.

START UP

Save parameters

SPEC FUNCTIONS

Save parameters

Press ENT

The field current will be automatically set to zero during

the current reg self tune, and returned to its normal

setting when complete.

START UP

R&L Search

Press the + key to select ON, press ENT

Press the down arrow to get to

START UP

Enable drive

Press + to enable, Press ENT

The drive enable light will not turn on, and the

enable parameter will still show disabled.

This is normal operation for the drive with the

default setting of parameter STOP CONTROL.

Press the green START button on the keypad.

Autotuning can take a few minutes. For 4 Quadrant

regenerative drives, the torque + and torque - will flash

alternately during the test.

For 2 Quadrant non regenerative drives, only the torque

+ will light during the test.

Press ENT.

Press ENT,

If the self tune does not initiate, check to see the

above entered parameters are set correctly , and also

check

Press ENT

Press ENT

This screen shows the digital input status on the top line and

output status on the bottom line. If a number is shown, the

status is ON for the digital inputs and outputs.

E is Enable input ( TB 12) , S is the start input ( TB 13), and

F is the Fast stop input (TB 14).

Loss of the External fault input (TB 15) lights the red alarm

LED. This example shows a default configuration, where TB

12, 13, and 14 are tied to + 24, and digital outputs 3-8 are high

( the signals are high even though there may not be a TBO

card).

To execute the self tune the top line must have ESF

showing and there can not be any alarms. Check the

hardware interlocking.

QS

18

—————— Quick Start up guide ——————

Page 19

DV-300 Adjustable Speed Drives

7. CHECK MOTOR/ROLL

ROTATION, SPEED FEEDBACK

POLARITY, AND CALIBRATIONS

7a. Check motor/roll rotation

CAUTION: Execution of this test will turn the motor shaft.

Use and take all safety precautions to protect

personnel from the hazards of rotating

equipment.

Any and all safeguards and interlocks should

be tested, and be operational before executing

this test.

A DC motor will rotate counterclockwise as viewed

from the commutator end, if the armature and field are

wired with the following polarity conventions:

menus.

Scroll up using the up arr ows until the ST ART UP menu

screen is shown. pr ess ENT.

Press the down arrow until the [Enable drive]

parameter is seen. press ENT.

Press the + key to set the enable, press ENT.

Press the green START key

While running the drive forward, verify the rotation of

the is forward, swapping the motor field leads if

incorrect (after stopping the drive, and removing power

).

At this time the speed regulation may not be smooth

and stable. This is OK. Stop and disable the drive.

7b. Calibrations

These conventions should have been verified before

power up, and now is the time to verify rotation with the

mechanical load attached if possible.Make sure all safety

issues are resolved before running and rotating

equipment.

If the DV-300 is using a pot for speed reference into

analog input 1, turn the pot to about 10% of full speed.

If using the keypad for speed reference, go to

DRIVE STATUS

Ramp ref 1

INPUT VARIABLES, press ENT

Ramp Ref , press ENT

[Ramp ref 1], press ENT

Use the left and right arrow keys to select a digit of

the value, and use the + and - keys to change the

value.

Enter a rpm reference value approximately equal

to 10% of rated speed. press ENT.

Press CANC 3 times to get back to the main parameter

While running the drive at a low speed to check for

rotation direction:

- V erify the field current is at the desired setting, with

a clamp on DC ammeter, shunt , or series ammeter

(for example DVM, or Simpson style analog meter)

Check parameter

agreement with the measured reading.

- V erify the armature voltage is approximately where

expected (for instance, if running at 10% speed,

check for 10% volts for a constant current field ).

Check parameter

agreement with the measured readings.

STATUS \ field current amps for

STATUS\ output volts for

7c. Checking current regulator performance using parameter Eint

While running the drive , monitor the parameter [Eint],

located under menu heading “Current Regulator”.

This measures an average internal current error.

Its value should be close to zero, but values dynamically

changing between -40 and 40 are acceptable.

The drive must have at least 30% load for this

reading to be considered as a valid performance

measurement.

If adjustments are needed, make small changes to the

parameter [Current Regulator \ Arm inductance] to fine

tune [Eint] to an acceptable value.

Refer to the DV-300 Instruction Book for detailed

information on fine tuning regulators.

—————— Quick Start up guide ——————

19

QS

Page 20

GEH-6129

8. SETUP SPEED FEEDBACK

If the DV -300 is intended for final use with armature

control (no tach or encoder), go directly to step 10 ,

speed self tune.

8a. Check speed feedback polarity

Repeat the previous procedure 7a. to run the motor and

drive forward again. Now verify speed feedback polarity:

For enc1 or enc2 inputs:

go to the keypad menu, press the down arrow until:

Press ENT

press down arrow twice to menu heading:

While running forward, simply read the analog tach

output voltage at the drive tach terminal board + and .

The polarity should match the terminal labels.

8b. Setup ENC 2 for digital encoder for speed feedback

- check hardware jumpers S21, S22, and S23 are

set = OFF for a 5 V encoder

ON for a 15 - 30 V encoder

- hardware jumper S28 = ON

- hardware jumper S20 = ON if the C channel (also

called marker or index channel ) is used.

Press CANC until the main menu, shown in all capital

letters in the keypad, is reached.

Use the up or down keys to find the main menu ST ART

UP. Press ENT.

Press the down key until the menu shown is:

Press ENT

Press ENT

press the down arrow twice to get to the menu

Press ENT

press the down key 4 times to see parameter Enc 1 speed

( if using encoder 1 for speed feedback)

press the down key 5 times to see parameter Enc 2 speed

(if using encoder 2 for a digital encoder feedback)

It is not necessary at this time for the speed feedback

value to be exactly correct, but this is to check for +

polarity , and to see the value is non zero and is stable if

the motor speed is stable.

A zero value, or an intermittent value in the

corresponding display means the encoder is not being

read. The wiring, connections, power supplies,

hardware jumpers, etc. must be verified and a value

read in the display for proper final operation.

For an analog DC tach:

START UP

Speed feed-back

Speed feed-back

Speed feed-back sel

Press the - key until Encoder 2 is shown,

Press the down arrow 3 times to show the menu:

enter the encoder nameplate PPR (pulses per

revolution) as recorded in section 3d., press ENT

Press the down arrow twice to get to the menu:

Press ENT

Press ENT

Press ENT

Press ENT

Speed feed-back

Refresh enc 2

press the + key to enable, press ENT.

Press ENT

QS

20

—————— Quick Start up guide ——————

Page 21

DV-300 Adjustable Speed Drives

START UP

Speed feed-back

Speed feed-back

Speed feed-back sel

8c. ENC 1 for digital encoder for speed feedback

ENC1 input connector us primarily used for sinusoidal

encoders. If a digital encoder is used a 6KDV300DES

module must be used as a signal conditioner.

- hardware jumper S27 = ON, S5 and S6 = position A

Press CANC until the main menu, shown in all capital

letters in the keypad, is reached.

Use the up or down keys to find the main menu

CONFIGURA TION. Press ENT.

Press the down key until the menu shown is:

Press ENT

Speed feed-back

Speed feed-back sel

Press ENT

The analog DC tach are wired to regulator board

terminals: + and - found at the bottom left of the

regulator board. With forward CCW rotation of the

motor, the positive output of the tach is wired to the +

tach input terminal .

Calculate tach calibration, from data recorded in section

3d:

Jumper range:

for DC tach. max volts £ 108 no jumper, (jumper range volts

= 108)

108 ≤ max volts ≤ 188 VDC jumper B & C, (jumper range

volts = 188)

188 ≤ max volts ≤ 340 VDC jumper A & C, (jumper range

volts = 340)

Press the - key until Encoder 1 is shown,

Press ENT

Press the down arrow until the menu is shown:

Press ENT

enter the encoder nameplate PPR (pulses per

revolution) as recorded in section 3d., press ENT

Press the down arrow twice to get to the menu:

Speed feed-back

Refresh enc 1

Press ENT

press the + key to enable, press ENT.

8d. Analog tachometer

For example:

analog tach = 100 V/1000 RPM, motor top running

speed = 1500 RPM

Install a jumper between points B & C for the 188

VDC range. Set START UP\ Speed feedback\

Tacho scale = 188 V/150 V = 1.25

Press CANC until the main menu, shown in all capital

letters in the keypad, is reached. Use the up or down

keys to find the main menu ST ART UP. Press ENT.

Press the down key until the menu shown is:

Press ENT

Press ENT

Press the + key until [tacho] is shown,

hardware jumper on the regulator board : S5 and S6 =

position B

—————— Quick Start up guide ——————

Press ENT

21

QS

Page 22

GEH-6129

Press the down arrow to show the menu:

Press ENT

enter the tacho scale calculated above, press ENT

8e. Save setup

After completion of the setups, save the parameters.

START UP

Save parameters

SPEC FUNCTIONS

Save parameters

Press ENT

QS

22

—————— Quick Start up guide ——————

Page 23

DV-300 Adjustable Speed Drives

START UP

Motor data

9.CONFIGURE ADDITIONAL

MOTOR FIELD PARAMETERS

9a. Configure field weakening operation

Field weakening can only be used with an encoder or

tachometer for speed feedback. Make sure that the speed

feedback is enabled and configured as per the previous

section.

Press CANC until the main menu, shown in all capital

letters in the keypad, is reached. Use the up or down

keys to find the main menu STAR T UP. Press ENT.

Press the down key until the menu shown is:

START UP

Motor data

Press the down arrow to:

Motor data

Flux reg mode

Press ENT

Press ENT

Press CANC to get back to

9b. hints on Flux regulator stability

- if the field feedback calibration dipswitch is

changed from default, rescale the default Flux

regulator gains by the factor the field current scaling

was reduced.

For example: the field scaling dipswitches are set for 1

amp on a DV3017EQ4F10

base field current regulator

TUNING

Flux P default = 2% change to .2%

TUNING

Flux I default = 1% change to .1%

Press the + key to select “Voltage control”

Flux reg mode

Voltage control

Press the down arrow key 4 times to get to:

Motor data

Flux weak speed

calculate Flux weak speed in % from the motor data

table in section 3d. The formula is:

Flux weak speed = 100 *

enter the Flux weak speed % as calculated above. Press

ENT

Press ENT

Press ENT

base speed motor rpm

top speed motor rpm

NOTE: Parameter [max output voltage] * parameter

[ Out vlt level %] sets the actual CEMF level

for crossover (field weakening point).The

[Flux weak speed] parameter merely

calibrates the calculation of speed feedback

error ( CEMF vs speed feedback) in the event

[Enable fbk contl] is enabled and used for

speed feedback loss.

weak field current regulator

TUNING

Voltage P gain default = 30% change to 3%

TUNING

Voltage I gain default = 40% change to 4%

- If the Field reg mode = constant current, the default

settings are adequate for a vast majority of

applications.

- If flux regulator instability is suspected, stop here,

and review and execute the complete flux regulator

tuning procedures in the DV-300 Instruction

manual.

—————— Quick Start up guide ——————

23

QS

Page 24

GEH-6129

10. SPEED SELF TUNE

CAUTION: Execution of this test will turn the motor

shaft. Use and take all safety precautions

to protect personnel from the hazards of

rotating equipment.

Any safeguards and interlocks should be

tested, and be operational before executing

this test.

The drive needs to have parameter ST ART UP \ Speed

self tune \ [ Main commands] = digital, and the terminal

board inputs 12, 13, 14, and 15 should still be tied to

TB 19. The drive should be disabled.

Press CANC until the main menu, shown in all capital

letters in the keypad, is reached.

Use the up or down keys to find the main menu ST AR T

UP. Press ENT.

11. SAVE PARAMETERS TO

RETAIN IN PERMANENT

MEMORY

Press CANC to get back to

GE DRIVE DV-300

START UP

Hold down the down arrow until the parameter [Save

parameters] is seen. Press ENT.

[Save parameters] can also be found under menus:

After completion of the setups, save the parameters.

START UP

Save parameters

Press ENT

Hold the down key until the menu:

Press ENT

Press the down arrow twice to get to

Press ENT

prompt will read Start ? , press ENT

After self test completion, press the down arrow 9 times

to get to parameter “Take val”, press ENT

Go to step 11. Save parameters ...

SPEC FUNCTIONS

Save parameters

Press ENT

QS

24

—————— Quick Start up guide ——————

Page 25

DV-300 Adjustable Speed Drives

12. OTHER COMMON SETUP PARAMETERS

12a. Terminal board input control VS keypad

For the standard terminal board inputs to have sole

control over the drive operation, (enable, start, fast stop,

and external fault) parameter [main commands] must

be set = terminals.

This parameter is found at keypad locations:

CONFIGURATION

Main commands

The drive can operate enable and start/stop control from

the keypad by setting parameter [main commands] =

digital. The terminal board inputs must be tied to 24

VDC for this operation. If the terminal board inputs

are opened, they will deactivate the command.

This setting does not effect additional digital inputs on

the TBO cards.

The drive can operate enable and start/stop control from

the terminal board inputs and still have keypad control

over references such as ramped speed reference. For

the keypad to provide this feature, it is merely needed

to access the reference in the menu area:

12b. Configurable I/O

Digital inputs, digital outputs, analog inputs, analog

outputs, and encoder inputs are picklist driven

selections.

DV-300

TBO

option

Under this menu, select the I/O to be configured. Use

the + and - keys to make a selection, then press ENT.

Selecting an input automatically removes its selected

function from the other input picklists. For instance, if

analog input 1 is selected to be for RampRef1,

RampRef1 is removed from the picklist of analog input

2 and 3.

- TBO position B, (connector XBB) digital inputs

5- 8, digital outputs 5-8, analog outputs 3 & 4

- analog inputs 1, 2, 3 and 4

TBO Position B

Analog input 1,2,3 and 4

For the keypad to control the referencing from INPUT

VARIABLES, there must not be any other input

assigned tocontrol that variable, from analog input or

LAN connection. If the reference value entered using

INPUT VARIABLE is permanently saved using the

[save parameter] command.

—————— Quick Start up guide ——————

Analog outputs can be scaled for the desired voltage

output. A default scale value of 1.0 sets speed related

variables = 10 volts of parameter [speed base value] ,

and current related variables = 10 V of parameter [ full

load current ].

Analog inputs can also be scaled. A default scale value

of 1.0 sets speed related variables 100% of parameter

[speed base value] @ 10 volts input, and current related

variables 10 V = 100% of parameter [ full load current ].

25

QS

Page 26

GEH-6129

12c. Configure jog operation

Jog is setup using TBO discrete inputs (unless a LAN

is being used). Jog can be setup with several options:

ramped or step, analog reference or internal setpoint.

First the jog function must be enabled.

Press ENT

Press the down arrow key three times to show :

Press ENT

press the down arrow

Press ENT

Press ENT

press the + key to enable. Press ENT.

For internal jog speed reference, now press the down

arrow twice to show:

using the + and - keys, select Speed input for a step

reference, select Ramp input for a ramped jog using

the main ramp, press ENT.

For internal jog speed reference, now press the down

arrow to show:

Press the + key to set [Jog stop control] = ON.

Press ENT.

This setting operates the jog the same as the default

stop control for the drive. When the jog is commanded

the relay 2 output picks up ( to pickup the AC or DC

contactor ) and allow to run.

Now, the commands for jog need to be configured.

Press the CANC button twice, and then the up arrow

twice to get to menu:

Press ENT

press the down arrow thrice to get to:

Press ENT

Arrow down key to the digital input desired to be used

for jog + (jog forward), press ENT

Press CANC to get back to:

enter the desired rpm reference, using the arrow keys

and + and - key, press ENT.

If an analog jog reference is desired, review section

12.b.Press the CANC key to get back to:

Press the down arrow key until this screen is shown:

Press ENT

QS

26

—————— Quick Start up guide ——————

Press ENT

Arrow down key to the digital input desired to be used

for jog - (jog reverse), press ENT.

Follow steps repeated previously to SAVE parameters.

Page 27

DV-300 Adjustable Speed Drives

13. INTERNAL REPLACEMENT FUSES

DV-300 Power Supply fuse

cat # card type designation function Fuse type

6KDV3017-3148 SW1-31 F1 24 V power supply out IEC 250 V 1 A slo-blo

6KDV3020 - 3185 5mm X 20 mm, .2 X .8 inches

6KDV30900-33300

replacement vendor sources - equivalent to meet above ratings

Omega (Europe) ST 520210, Littlefuse 218 001 ( Littlefuse 239 1.25 may also be substituted )

DV-300 Power Supply fuse

cat # card type designation function Fuse type

6KDV3224-3450 SW2-32* F1 24 V power supply in IEC 250 V 3.15 A fast acting

6KDV3280-3650 SW2-32* 5mm X 20 mm, .2 X .8 inches

6KDV3560-3850 SW3-32*

6KDV3770-310H SW3-32* F2 24 V power supply in IEC 250 V 2.5 A slo blo

5mm X 20 mm, .2 X .8 inches

* F1 and F2 are used in both cards SW2-32 and SW3-32

replacement vendor sources - equivalent to meet above ratings

F1 - Omega (Europe) SF520231, Littlefuse 217 3.15 F2 - Omega (Europe) ST520225, Littlefuse 218 2.5

DV-300 Power Supply fuse

cat # card type designation function Fuse type

6KDV3020-3185 FIR1-... none

6KDV3017-3148 FIR1-... none

6KDV3280-3650 FIR2-... F1,F2,F3 Varistor fuse IEC 500 V 16 A fast acting

6KDV3224-3480 6 X 32 mm. 24 X 1.26 inches

replacement vendor sources - equivalent to meet above ratings

Omega (Europe) FF632316, Cooper/Bussman FWH-016A6F

6KDV31200-33300 FIR45 F11,F21,F31 IEC 500 V 4 A fast acting

6KDV30900-32350 6 X 32 mm. 24 X 1.26 inches

replacement vendor sources - equivalent to meet above ratings

Omega (Europe) GF632240

6KDV3770-10H FL-31 F1,F2,F3 Varistor fuse IEC 500 V 25 A fast acting

6KDV3560-3850 6 X 32 mm. 24 X 1.26 inches

replacement vendor sources - equivalent to meet above ratings

Omega (Europe) FF632325, Cooper/Bussman FWH-025A6F

Internal field exciter fuses (American version only)

fuse fuse fuse equivalent fuse

DV-300 Cat # QTY volts amps type Cooper/Bussman P/N

6KDV3017 - 3148 2 500 15 fast FWH-015A6F

6KDV3224 - 3850 2 500 25 fast FWH-025A10F

6KDV30900 - 31500 2 500 50 fast FWP50

6KDV31800 - 32350 2 500 80 fast FWP80

—————— Quick Start up guide ——————

27

QS

Page 28

GEH-6129

14. BASIC OPERATING DESCRIPTIONS

14 a. standard inputs functional description

Enable The input is activated when terminal 12

is connected to + 15 to +30 VDC and mains

commands = terminals. The enable also may be

internally interlocked with other DV-300 signals

using the stop control parameter.

Refer to the DV -300 Instruction book for details of

enable status with the [stop control] parameter.

If mains commands = digital, enable becomes

active if terminal 12 is connected + 15 to 30 VDC

and enable is set to 1 using a LAN command, using

the PC configurator Control Window, or through

the keypad.

When the enable signal becomes active in the drive,

speed and current regulators are released, but

referencing is not. External referencing into ramp

ref 1and 2, speed ref 1 and 2, or T curr ref 1 and 2

may cause the drive to output , and cause the motor

to rotate.

Enable does not effect the field control.

Start Ramp referencing is released when

terminal 13 is connected + 15 to +30 VDC and

mains commands = terminals.

If mains commands = digital, start becomes active

if terminal 13 is connected + 15 to +30 VDC and

start is set to 1 using a LAN command, using the

PC configurator Control Window, or through the

keypad by pressing the STAR T key.

The drive will not START unless ENABLE input

is picked up.

The start signal also may be internally interlocked

with other DV-300 signals using the

parameter.

Refer to the DV -300 Instruction book for details of

enable status with the [stop control] parameter.

Fast stop Fast stop is initiated if terminal 14 is

DISconnected from + 15 to +30 VDC.

If mains command = digital , fast stop is initiated

if terminal 14 is DISconnected + 15 to +30 VDC

or fast stop is transitioned from 1 to 0 using a

LAN command, or using the PC configurator

Control Window.

Fast stop is a ramped stop to zerospeed. The fast

stop ramp is adjusted using parameters

stop control

RAMP\Quick stop\QStp delta speed and

RAMP\Quick stop\QStp delta speed. The default

setting is 1000 rpm/sec.

If mains commands = terminals , when fast stop is

initiated (by drop out of signal) the drive decelerates

according to the Qstp ramp rate.

If mains commands = digital , when fast stop is

initiated by opening terminal 14 (drop out of signal)

the drive decelerates according to the Qstp ramp rate.

For example, if enable, or the enable & start bus

signals are still picked up after fast stop is initiated

by disconnecting terminal 14, when the fast stop

input transitions back to 1 (picks back up), the drive

will continue to operate as per the enable and start

input states.

The fast stop signal also may be internally

interlocked with other DV-300 signals using the

stop control parameter.

External fault Is initiated if terminal 15 is

DISconnected from + 15 to +30 VDC.

The action of external fault is programmable by

Configuration\prog alarms\External fault. Default

programming of External fault disables the DV300 (coast stop) and causes a latched trip.

14b. Regulation card LEDs

color nomenclature function

green PWR +5 volt power supply OK when lit

red RST when lit, card miprocessors are

undergoing a power up and reset

green RS485 jumpers S18 & S19 are in the B

position to supply 5 VDC on pins

5 & 9 of the RS485/232 PC

configuration port, XS

ACT It is lit when the SCR driving

system is active

RUN The LED blinks during the

regulation phase

14c. Keypad programmer LED description

Alarm -> when lit, an alarm or trip condition is present.

Enable -> when lit, the enable command is active.

The actual Enable status can be controlled

internally by the DV -300 with the programming of

the Stop control parameter. Refer to section II.g.

for details on that parameter setting.

The input is commanded when terminal 12 is

connected + 15 to +30 VDC and mains commands

QS

28

—————— Quick Start up guide ——————

Page 29

DV-300 Adjustable Speed Drives

GE DRIVE DV-300

RAMP

GE DRIVE DV-300

CURRENT REGULAT

GE DRIVE DV-300

FLUX REGULATION

= terminals.

If mains commands = digital, enable is commanded

if terminal 12 is connected to + 15 to +30 VDC

and enable is set to 1 using a LAN command, using

the PC configurator Control Window, or through

the keypad by pressing START UP, press ENT,

press the down arrow until Enable drive is shown,

press ENT twice.

press the down key

press the down key

Ilimit -> when lit, the drive is in current limit, or torque

current limit.

Zero speed -> when lit, the drive speed feedback is

detected to be below the adjustable zero speed

threshold.

+ torque LED -> when lit, the LED signals that the

current feedback magnitude is in a direction to

provide positive motor output torque.

Under light load conditions, the LEDs may flicker

between + and - torque.

This is the speed regulator generating + and - torque

current to accurately regulate speed.

- torque LED -> when lit, the LED signals that the

current feedback magnitude is in a direction to

provide negative motor output torque.

14 d. Keypad menu structure

The drive keypad menu structure is similar to DOSä

and Windowsä file structures.

There is a list of main menu headings. Selecting a

heading allows the user to funnel down to a select a

finer defined group of headings or parameters.

press the down key

press the down key

press the down key

press the down key

press the down key

press the down key

press the down key

The major menu structure of the DV-300 is, in

capital letters:

GE DRIVE DV-300

DRIVE STATUS

GE DRIVE DV-300

START UP

press the down key

press the down key

press the down key

press the down key

—————— Quick Start up guide ——————

press the down key

press the down key

press the down key

press the down key

press the down key

29

QS

Page 30

GEH-6129

15. QUICK TROUBLESHOOTING

15a. Regulation card testpoints

T est point name and description notes

XY5 +5V , processor power supply

XY6 GNDD, +5V processor power supply ground

XY7 GNDD, +5V processor power supply ground

XY8 +24V, 24 VDC power supply

XY9 GNDV, 24 VDC power supply common

XY10 GNDA, 15 V power supply common

XY11 -15 V power supply

XY12 +15 V power supply

XY17 current feedback, scaling .61V = 1 P.U. of the drive rating

XY18 common

XY19 armature voltage feedback

XY20 select output

XY21 attenuated AC input signal, V-U

XY22 attenuated AC input signal, V-W

15b. Failure messages and troubleshooting hints

Message Possible causes Hints

Failure Supply blown power supply fuse, bad power supply check 24 V I/O for shorts to ground replace power

supply fuse, remove I/O connectors to isolate

wiring

Undervoltage Parameter [ Undervoltage thres] set too high check parameter [Undervoltage thres] setting

AC line has excessive noise or ringing missing an incoming reactor

AC line is soft too much incoming reactor/transformer impedance

bad power connections check all power connections

the drive has been enabled without bridge power AC input contactor didn’t pick up

Overvoltage Too much voltage on the DC output parameter [max output voltage] set too low

field current set too high for speed check field current parameters

this trip occurs at 1.2 times parameter [max crossover % set too high

output voltage]

Heatsink heatsink temperature is too hot failure of a door fan, or drive fan

heatsink is dirty or clogged

loss of fan power

failed sensor

Overtemp motor failure in the motor overtemp circuit input TB 79 & 79 is open circuit,

bad wiring , thermistor, or klixon

motor is too hot motor blower is failed, or off

ventilation is blocked

overloaded motor, improper setup

ambient temperature is too high

self cooled motor running at low speeds at high

loads

QS

30

—————— Quick Start up guide ——————

Page 31

DV-300 Adjustable Speed Drives

Message Possible causes Hints

Enable seq error enable input circuit, TB 12, is closed the enable input can not be tied to +24 V with

before the drive is finished powering up. parameter [main commands = terminals] while the

drive powers up. This is to prevent unintentional

automatic restarting.

External fault external fault circuit, TB point 15, is control circuit is open

open circuit, not tied to +24 V blown 24 V fuse

Overcurrent overcurrent setting is too low check parameter [ overcurrent thr ]

current regulator is mistuned check Eint and regulator tuning

short circuit or ground fault in armature circuit check motor circuit integrity

Field loss no field current blown fuse in field package AC input

field current parameters are wrong

open field circuit

field current below min field settings check min field setting, field weakening

parameters

unstable flux regulator, check output current

stability and parameters [Flux P], [Flux I ],

[voltage P gain], [voltage I gain]

Speed fbk loss loss of encoder input check encoder power supplies, connections, and

wiring

check encoder jumper settings

misadjustment of encoder loss detection

misadjustment of [enable fbk contrl] parameters

Opt2 failure DGF card failure Option 2 is enabled with the DGF card ribbon

cable disconnected. Card is failed

DGF software error A software error has occurred, for instance, a

divide by zero error.

Improper DGF card parameter settings have been

entered.

Reset the DGF card using jumper S17, also trying

cycling power.

Bus loss Problem with the bus wiring check wiring, termination resistors, etc...

excessive noise on the bus check wiring, grounding practices

improper bus configuration check bus info, data size, data type, addressing,

configuration data

replace card

Opt 1 failure bad option 1 card replace card

—————— Quick Start up guide ——————

31

QS

Page 32

1S4G59

REV. 9.2.0

Loading...

Loading...