Page 1

g

GE Energy

Industrial Solutions

DC OEM Module

For use with Gerapid DC Circuit Breaker

Installation and Maintenance Instructions

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 1

Page 2

2 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 3

INDEX

INTRODUCTION ............................ ................................ ................................ .........................5

1-1 General Notes ..................... ................. .................. ................. .................. ................. 5

TESTING AND INSPECTION............................................................................................. 15

6-1 General Notes .................... ........................................ ........................................ ..... 15

Prior to Test .............................. ................................................. ................................. 15

Connecting Control Circuits ............................... .............................. .................. 15

1-2 Instruction Book Arrangement ........................................... .............................. 5

1-3 Related Publications...............................................................................................5

RECEIVING, HANDLING AND STORAGE .......................................................................6

2-1 Receiving ................... ...................... ...................... ....................... ...................... ..........6

Module and Trolley Package ......................................... ............... ............... ..........6

Inspecting for Damage .................................................. ........................... ...............6

Filing a Claim .......... ............................................... ............................................. ..........6

2-2 Handling and unpacking ........................... ........................ ......................... ..........6

Module handling and unpacking .................... ................................... .................6

Trolley handling and unpacking ............................... ..........................................7

2-3 Storage ....................... ................. ................. .................. ................. .................. ............7

Circuit Breakers ................................... ........ ....... ....... ........ ....... ........ ....... ........ ....... .....7

Modules and Trolleys ....... .......... .......... ......... .......... .......... .......... .......... .......... .......... 7

GENERAL DESCRIPTION .....................................................................................................8

3-1 General Notes ..................... ................. .................. ................. .................. ................. 8

3-2 Summary Description ............... ...................... ......................... ....................... .......8

Ratings ................................................... ........................ ......................... ......................... 8

Interlocks ................................. ......................... ......................... ......................... ............8

Accessories .............. .................... .................... .................... .................... .................... ..8

3-3 The Module ............ ............... ............... ............... ................. ............... ............... ..........8

Breaker Compartment ...................................... .................... ....................... ............8

Cable Compartment ............................... ..... ..... ....... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... 9

Control Compartment ..... ............... .............. ............... ............... ............... ............... 9

3-4 The Trolley ............. ........................... ............................ ........................... ....................9

3-5 Gerapid Breakers ............................ ........................... ............................ .............. 10

INSTALLING THE MODULE ............................................................................................. 11

4-1 General Notes ..................... ................. .................. ................. ............... ................. 11

Environmental Requirements ............................ ........................................... .... 11

Foundation Requirements ................................... ........................................... .... 11

4-2 Module Configuration and Assembly ......................................................... 11

Multiple Modules Side by Side Assembly ........................ ............................. 11

Module Preparation ............................................................................................... 11

Module Rejection Interlock ............................. ......................... ......................... .. 12

Main Busbars Connection .... ..................................... ...................................... .... 12

Ground Bus Connection ........................................... .......................................... .. 12

Connecting Secondary Controls ........................................... ........................... 12

Device mounting on control compartment door .................................... 12

6-2 Field Testing Procedure ............. .................................................... .................... 15

Testing the Module with Remote Racking System .................................. 15

Testing the Module w/o Remote Racking System ................................... 15

High Potential Tests .......... ......................................................... ............................ 15

Grounding Circuit Check ............................ ......................... ............................ ..... 15

OPERATING THE MODULE .............................................................................................. 16

7.1 Mechanisms and Interlocks ........... .... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ... 16

Racking Mechanism................................................ ..... ..... ..... ..... ..... ..... ..... ..... ..... ... 16

Access Interlocks ............................... .................................................. .................... 16

Secondary Control Interlock ................................. ............................................. 16

Remote Racking .................................... ............. ............ ............. ............ ............. ..... 17

Trolley Operated Switches ......... ................................... ................................... ... 17

Padlocks................................. ..... ..... .... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... ... 17

7.2 Trolley with Manual Racking ...... .......... .......... .......... .......... .......... .......... .......... 18

Operational Positions ............................................... ................................ ............. 18

Racking – In Procedure .................................... ............................................. ........ 18

Rack-Out Procedure .............................. ................................... .............................. 19

7.3 Trolley with Remote Racking .. ............................................. ............................ 19

Operational positions. .............................................. ............ ............. ............ ........ 19

Remote Rack–In Procedure. .................................... ........................................... 20

Manual Rack-Out Procedure.

7.4 Operate the breaker. ........................................................................................... 21

TROUBLESHOOTING AND MAINTENANCE ............................................................... 22

8.1 Troubleshooting ........... ........................................ ........................................ .......... 22

Manually operated trolley ............... .................... .................... .................... ........ 22

Motor driven trolley .............................................. ............... ............... ............... ..... 22

8.2 Maintenance ........... ...................................................... ........................................... 22

CUSTOMER SUPPORT ....................................................................................................... 23

8.1 Warranty ..................... ............. ............ ............ ............. ............ ............. ............ ........ 23

8.2 Field Service Support ........ .................................................. ................................. 23

8.3 Publications and other support .......................................... ............. ............ ... 23

APPENDIX “A” – MODULE & TROLLEY DRAWINGS ................................................ 24

APPENDIX B – PRIMARY TERMINALS DRAWINGS .................................................. 26

APPENDIX C – LAYOUT DRAWINGS ............................................................................ 29

........................... ..... ..... ..... ..... ..... ..... ..... ..... ..... ..... 21

INSTALLING THE BREAKER ............................................................................................ 13

5-1 General Notes ..................... ................. .................. ................. ............... ................. 13

5-2 Installing Gerapid Breaker ............... ................................... ............................. 13

Prior to Installation ................................................................................................ 13

Installation Procedure .................................. ................................................. ....... 13

Configuration of the Rejection Interlock .............................................. ....... 14

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 3

APPENDIX D – TIGHTENING TORQUES TABLES...................................................... 30

APPENDIX E – ELECTRICAL DIAGRAMS...................................................................... 31

APPENDIX F – RATING TABLES ..................................................................................... 39

APPENDIX G – ACCESSORIES & INSTALLATION DRAWINGS ............................. 40

APPENDIX H – FIELD TEST PROCEDURE ................................................................... 43

Page 4

4 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 5

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 1 Introduction

Introduction

1-1 General Notes

This manual contains procedures for receiving, handling,

storage, operation, and maintenance of GE’s DC OEM Module

(called also the Module in this document) with withdrawable DC

OEM Trolley (referred to as Trolley in this document) for use with

Gerapid high speed DC circuit breaker (referred to as Breaker in

this document).

The OEM Module is designed to simplify the construction of a DC

switchgear assembly. Typical applications for such equipment

are Heavy and Light Rail Transit systems, commercial IT

systems (Data Centers), heavy industrial applications in mining

and metals. Other applications include equipment to supply DC

motors, excitation systems or high power DC testing and

research facilities.

DC OEM Module and Trolley described in this document are UL

Recognized components for use with GE’s UL listed Gerapid

high-speed circuit breaker.

NOTE: The personnel responsible for installing, operating,

and servicing this equipment should be thoroughly familiar

with the contents of this manual.

Before any installation work is performed, thoroughly read and

understand the material in this instruction manual. A copy of

the instruction manual is shipped with each module, in the

control compartment. When requesting additional information

from GE Energy, include the complete data appearing on the

equipment nameplate, including requisition number. The

module’s label is located inside the control compartment. The

trolley’s nameplate is located on the right side of the trolley,

next to doors.

When requesting information concerning any specific item

furnished with module and/or trolley, refer to that item by

description, part number, its location within this manual, and

any applicable drawing number. Any materials, which may be

required to meet local codes, such as mats, screens, railings,

etc., are not included, and not furnished by GE Energy.

If there are any questions or requirements not covered in this

manual or in the accompanying drawings, please contact the

local sales office of GE Energy.

Chapter 5 Installing and Removing the Breaker - gives a

step-by-step procedure for lifting the breaker from the

floor, and installing it on the trolley. Information on

configuring the Rejection Interlock on the trolley is

included.

Chapter 6 Testing and Inspection - reviews items which

should be field-tested or inspected prior to energizing and

operating the switchgear.

Chapter 7 Operating the Module - covers how to operate

the trolley, the module and the breaker. This section

contains information concerning drawout provisions, and

functions of various accessories.

Chapter 8 Energizing the Module - outlines the steps to be

taken before and during the electrical energization of the

completed equipment.

Chapter 9 Maintaining the Module - provides instructions

for recommended preventive maintenance, servicing, and

lubrication information for the module.

Appendixes - contains information covering ratings,

dimensional drawings, electric diagrams; screw and bolt

torque values, field testing procedures, and accessories.

1-3 Related Publications

Detailed Users Guides and Instruction Books for the Gerapid

breaker and other devices not fully described in this instruction

book are available at: http://www.geindustrial.com

Go to: Products -> Circuit Breakers -> Gerapid

1-2 Instruction Book Arrangement

Information and procedures in this instruction book are divided

into Chapters as follows:

Chapter 1 Introduction - provides applicable data for the

module and its components.

Chapter 2 Receiving, Handling and Storage - describes

procedures required for receiving, handling and storage

the module and trolley.

Chapter 3 Component Description - describes the module

and its various components. Included are the cable

compartment, breaker compartment, and instrument

compartment. This section also lists the electrical and

mechanical components and explains their assigned

functions.

Chapter 4 Module Installation - provides the information

needed prior to installation, site location and foundation

requirements, and how to anchor the equipment properly

and safely. It also covers information on electrical

connections and mechanical construction.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 5

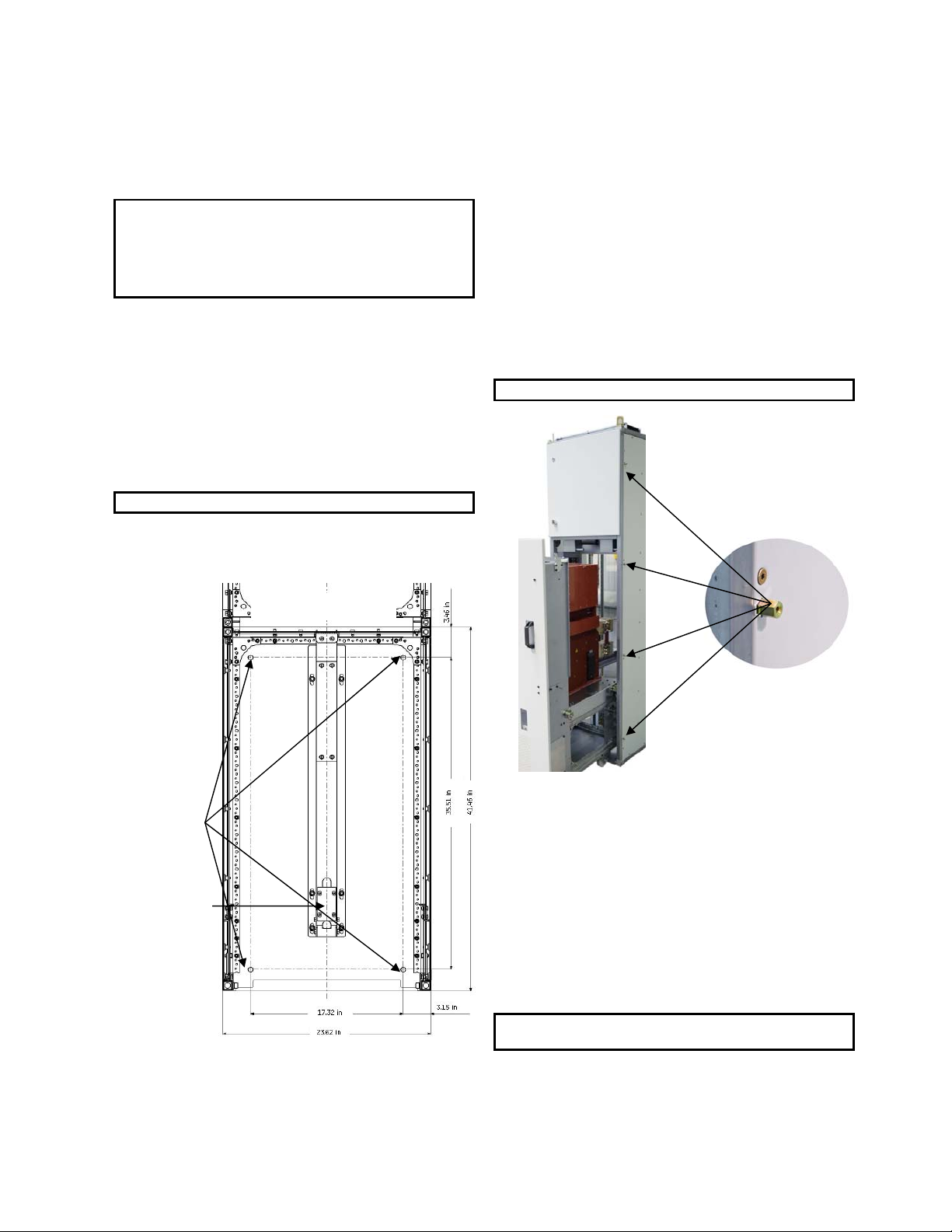

Fig. 11-1 DC OEM Module and Trolley with Gerapid High

Speed Circuit Breaker

Page 6

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 2 Receiving, handling and storage

Receiving, handling and storage

2-1 Receiving

Module and Trolley Package

Every package leaving the factory is plainly marked with the

case number, requisition number, and customer's order

number.

The Module and the trolley are shipped in separate wooden

crates. The contents of each shipping package are listed on

the crate.

NOTE: Breakers, Trolleys and Modules are ordered

individually and shipped separately. Module accessories, if

ordered, are shipped separately.

See Fig. 21-1 for crates dimensions. Crates load weights are:

Crate with module, 6.5x2.6x8.0 [ft] / ~850 [lbs],

Crate with trolley, 3.9x2.6x5.8 [ft] / ~ 500 [lbs],

D

W

Remove the carton box and check plastic covers for any

damages. Do not remove the plastic if the breaker will be

stored for long periods. (See. Fig. 21-2 and 21-3)

Fig. 21-2 Gerapid circuit breaker package

H

Fig. 21-1 Typical wooden module crate for shipment

Inspecting for Damage

All equipment leaving the factory is carefully inspected and

packed by personnel experienced in the proper handling and

packing of electrical equipment. Upon receipt of any

equipment, immediately perform a visual inspection to

ascertain if any damage has been sustained in shipping or if

there are any loose parts. Be sure to inspect all devices

mounted inside compartments of each section to see if any

have been dislodged or damaged.

Gerapid circuit breakers are shipped separately in individual

boxes with the breaker in the open position. (See Fig. 21-2)

Circuit breakers should be unpacked and visually inspected for

damage or loose parts as soon as possible after they have

been received.

Fig. 21-3 Breaker plastic shrink-wrap protection

Filing a Claim

If any damage is evident, or indication of rough handling is

visible, file a claim for damage at once with the transportation

company and notify the nearest GE Energy Sales Office

immediately. Information on damaged parts, part number,

case number, requisition number, etc., should accompany the

claim.

2-2 Handling and unpacking

Module handling and unpacking

NOTE: The Module should be transported and installed in

its final location prior to installing the trolley.

The module shipping crate should be transported using forklift

only. During transport, the module should remain in its original

package. To unpack the module, start by removing the top

cover, then remove sidewalls and all inner supports.

CAUTION: Never use a forklift to transport an unpacked

module, as the module is not bolted to the shipping

palette.

6 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 7

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 2 Receiving, handling and storage

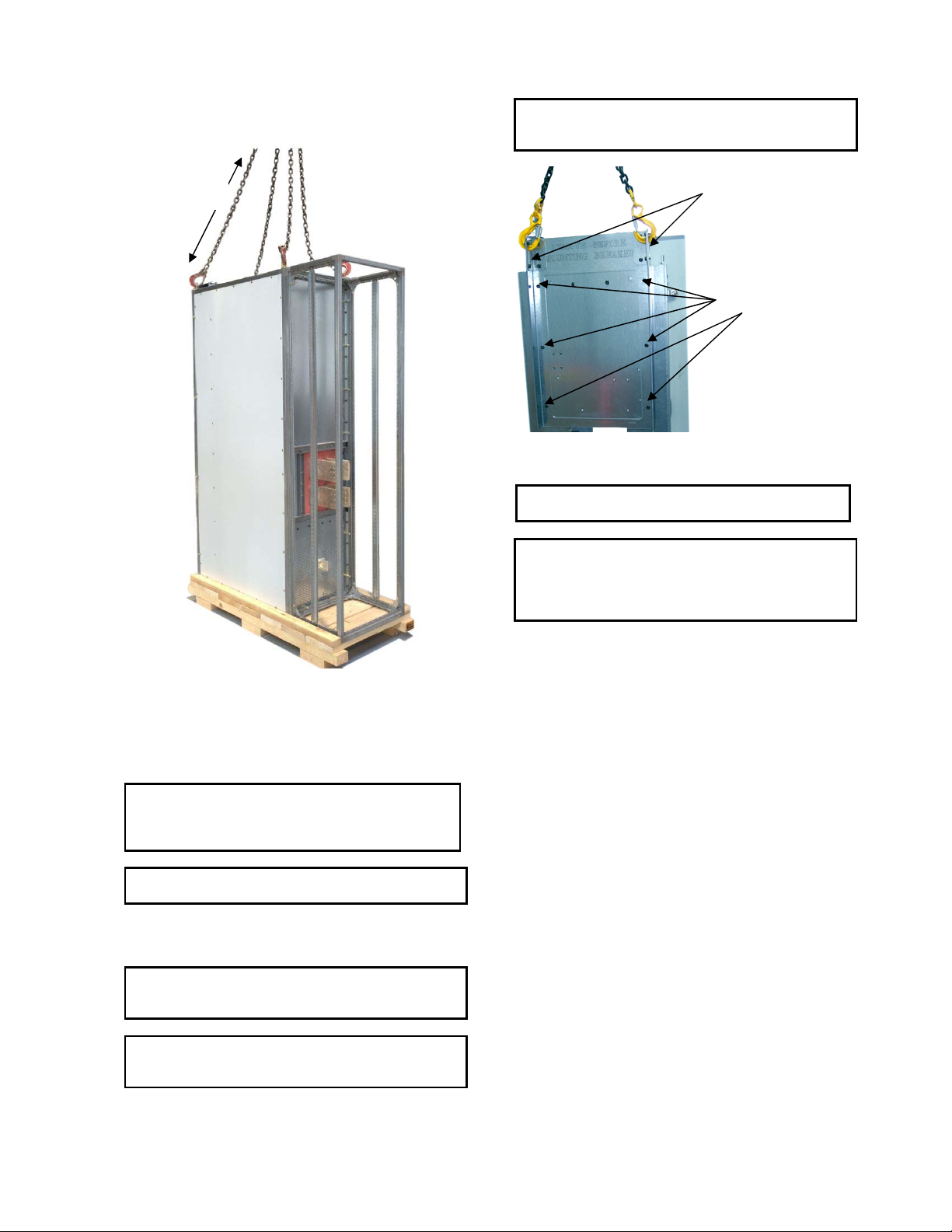

Removable lifting plates are provided on the top of each

module, as standard equipment. Using a crane or overhead

hoist, carefully lift the module from the palette using the four

lifting plates. (See Fig. 22-1)

Min. 4 ft

NOTE: After transportation, but before installing of the

breaker, loosen six attachment screws and remove lifting

frame from the trolley. Replace and tighten these screws!

Lifting slots.

Fixing screws.

Fig. 22-2 Lifting of the trolley

CAUTION: Never use forklift to transport unpacked trolley,

as it is not bolted or fixed to the shipping palette

NOTE: Do not lift or transport the trolley, using forklift.

Never lift the trolley with a breaker mounted. Never roll the

trolley on the floor with a breaker set in place, unless the

breaker is properly bolted to the trolley and arc chutes

properly secured to the breaker (if installed).

2-3 Storage

Fig. 22-1 Overhead lifting of the module

To preserve the external appearance of the equipment, it is

suggested that the lifting plates be left in place. Utilize four

equal length cables or slings, each with a minimum load rating

of twice the weight of the Module package. See section 2.1.

NOTE: The angle between the cables and the top of the

equipment must be at least 45 degrees. This requires the

use of chains/slings at least 4 ft long. If this is not possible,

spreader bars must be used.

NOTE: Do not move, lift or handle the module with a trolley

installed.

Take up the slack in the lifting device very carefully and

manually stabilize the module to prevent it from rotating.

WARNING: Do not stand under the module while it is being

moved. Serious injury may occur if the cables or lifting

device fail.

CAUTION: Gently lower the module onto the level site

location. If the module is roughly handled or jarred, it is

possible to damage or misalign internal components.

Trolley handling and unpacking

The trolley, in its original package, should be transported using

forklift only. To unpack the trolley, remove the top cover first,

and then remove sidewalls and all inner supports. To lift the

trolley, use special lifting frame available. See Fig. 22-2.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 7

Circuit Breakers

Open shipping cartons and thoroughly inspect shipping

materials for damage. If shipping plastic is in satisfactory

condition, leave the breakers in their shipping cartons for

storage. Do not remove the circuit breaker shipping material

(shrink wrap) at this time.

Store the circuit breakers in a clean, dry location in an upright

position. If shipping plastic is damaged, a plastic or canvastype cover should be provided to reduce the possibility of

damage or contamination to the breakers due to dust and

water. For details concerning Gerapid breakers handling

consult the breaker’s User Guide, S47183De.

Modules and Trolleys

Remove protective covering. Check thoroughly for damage.

Store in a clean, dry, rodent-free location with moderate

temperature and provide protective coverings to prevent dirt,

water, or other foreign substances from entering the

equipment.

If dampness or condensation may be encountered in the

storage location, heaters must be placed inside the module

breaker compartment (module must be without trolley) and in

the front of the trolley with trolley door open to prevent

condensation. Approximately 250 watts of heat in each

section is required. Incandescent lamps can be used and

located in the bottom of the breaker compartment and

supported so the bulbs will not touch adjacent materials.

Page 8

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 4 Installing the Module

General Description

3-1 General Notes

This section contains a description of the GE DC OEM Module and

Trolley for use with Gerapid high speed DC circuit breaker. It also

describes the functions of the electrical and mechanical systems.

3-2 Summary Description

The DC OEM Module is an individual, freestanding, metal-enclosed

switchgear section, designed to be used in conjunction with the

withdrawable trolley, containing a Gerapid circuit breaker,

auxiliary contacts, primary finger clusters and secondary

disconnect.

Ratings

The module is designed to be used on DC systems operating up to

800VDC and 6000A continuous.

The module is available in two continuous current ratings:

4000A for use with 2500A and 4000A Gerapid breaker,

6000A for use with 5000A and 6000A Gerapid breaker,

NOTE: See Appendix “F” for complete ratings of the Module

and the breaker.

Interlocks

Module and trolley are equipped with variety of safety interlocks

that minimize risk of incorrect operations. The following interlocks

are incorporated into the module and trolley:

Positive Interlock preventing movement of the trolley to or

from CONNECTED position when breaker is closed.

Negative Interlock preventing breaker closing unless the

trolley is in CONNECTED or TEST position.

Access Interlock – ensures breaker opening before any

manual operations.

Secondary Control Interlock preventing movement of the

trolley from TEST position to CONNECTED position unless

secondary disconnect is connected. The same interlock

prevents the trolley from being fully withdrawn from the

module unless the secondary disconnect is unplugged.

Breaker Disconnected Padlock Provisions allows padlocking

the trolley in DISCONNECTED position.

Control Compartment Padlock Provisions allows for

padlocking of the controls compartment door.

Rejection Interlock prevents trolley coded for particular

breaker current rating from being inserted into the module

that is coded to different rating.

Shutter Safety Padlock allows padlocking of the safety

shutters in closed position.

Accessories

Several accessories are available with the module and the trolley

for user convenience:

Side Covers for cable compartment,

Crank Handle for trolley racking operations,

Cable Channel connectors and covers,

Attachment Hardware Kits for different components,

Hinges for user furnished compartment doors,

NOTE: See Appendix “G” for full list of accessories, their codes

and illustrations.

NOTE: Detailed description of all accessories functions is given

in Chapter 7.

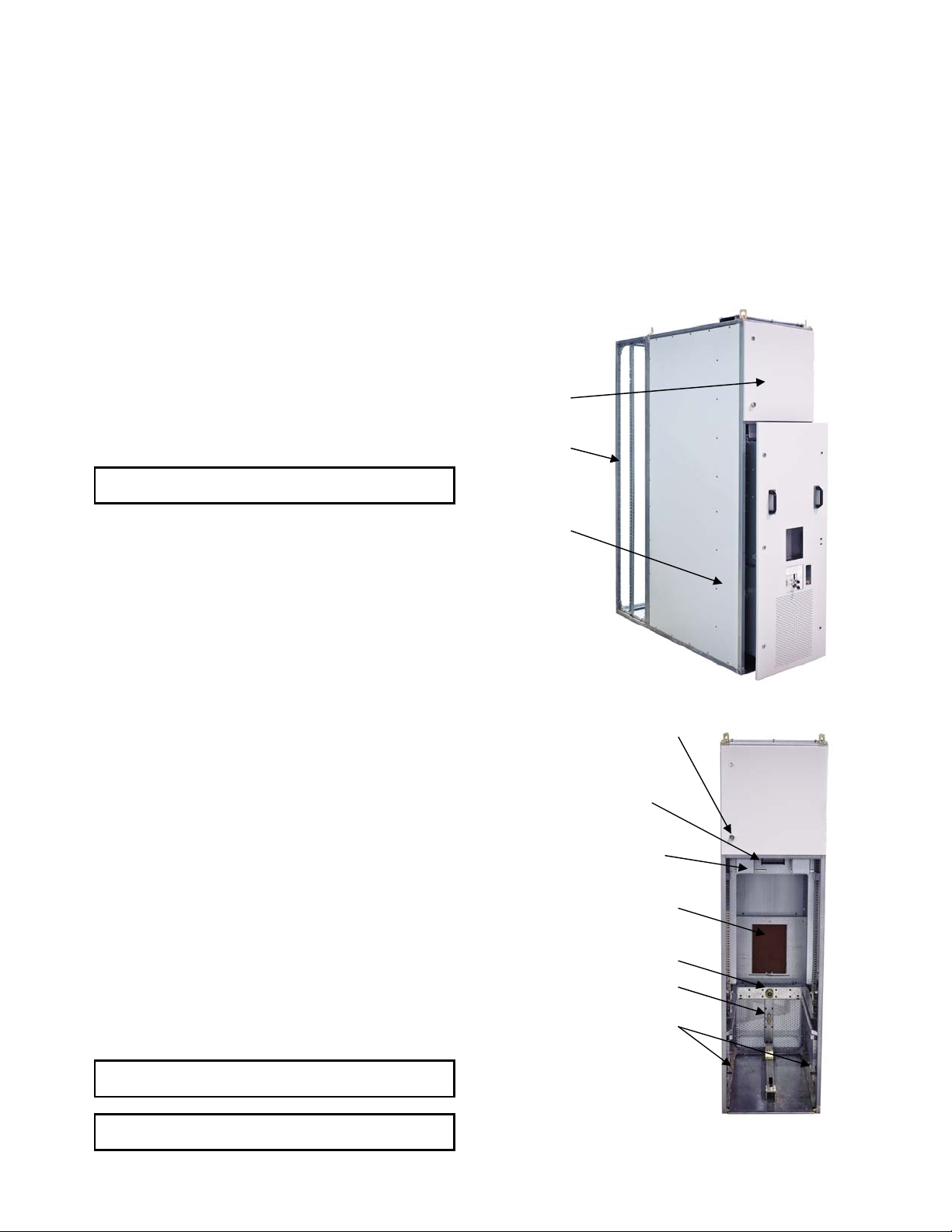

3-3 The Module

Breaker Compartment

The module is metal-enclosed construction, and consists of the

front breaker compartment, upper controls compartment and

rear cable compartment. Fig. 33-1 shows the location of the

module compartments.

Dead-front, drawout circuit breaker compartment is a standard

construction feature with all modules. The breaker compartment

door remains closed and latched while the breaker is racked out

from the CONNECTED position through TEST position, to the

DISCONNECTED position. See chapter 7.

Control

Compartment

Cable

Compartment

Breaker

Compartment

Fig. 33-1 Front view of the Module with Trolley inside

Control Compartment

Padlock Provisions

Secondary Disconnect

Secondary Control Interlock

Primary Disconnect Shutters

In front of Primary Stabs

Racking Drive Socket

Grounding Circuit Stab

Rejection Interlocks

Fig. 33-2 Front view of the module

8 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 9

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

g

Rej

Chapter 4 Installing the Module

Grounded steel barriers on the top, sides, bottom, and front

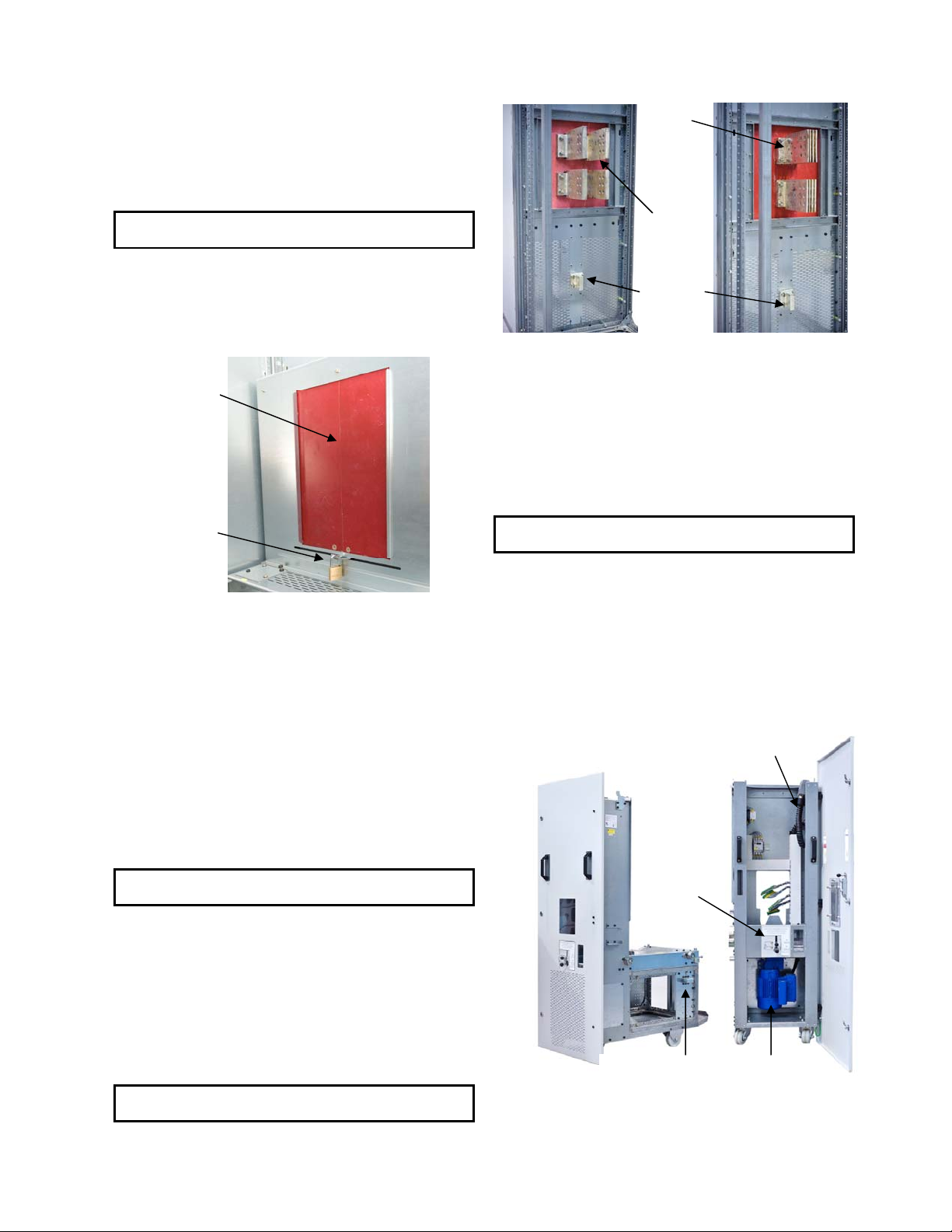

enclose the breaker compartment. In the back, a flame-retardant,

track resistant, glass-filled polyester base minimizes the possibility

of fault communication between compartments or to the bus.

Breaker compartment has primary stabs for connecting the

breaker. Insulated shutters cover primary stabs. See Fig 33-2.

NOTE: See Appendix A for all dimensional drawings of the

breaker Compartment.

Primary disconnect shutters are provided as standard feature to

provide protection against contact with the energized stationary

primary stabs when the trolley is removed from its compartment.

The shutters are constructed from fiberglass reinforced thermoset

polyester. A padlock can lock the shutters in the closed position.

See Fig. 33-3.

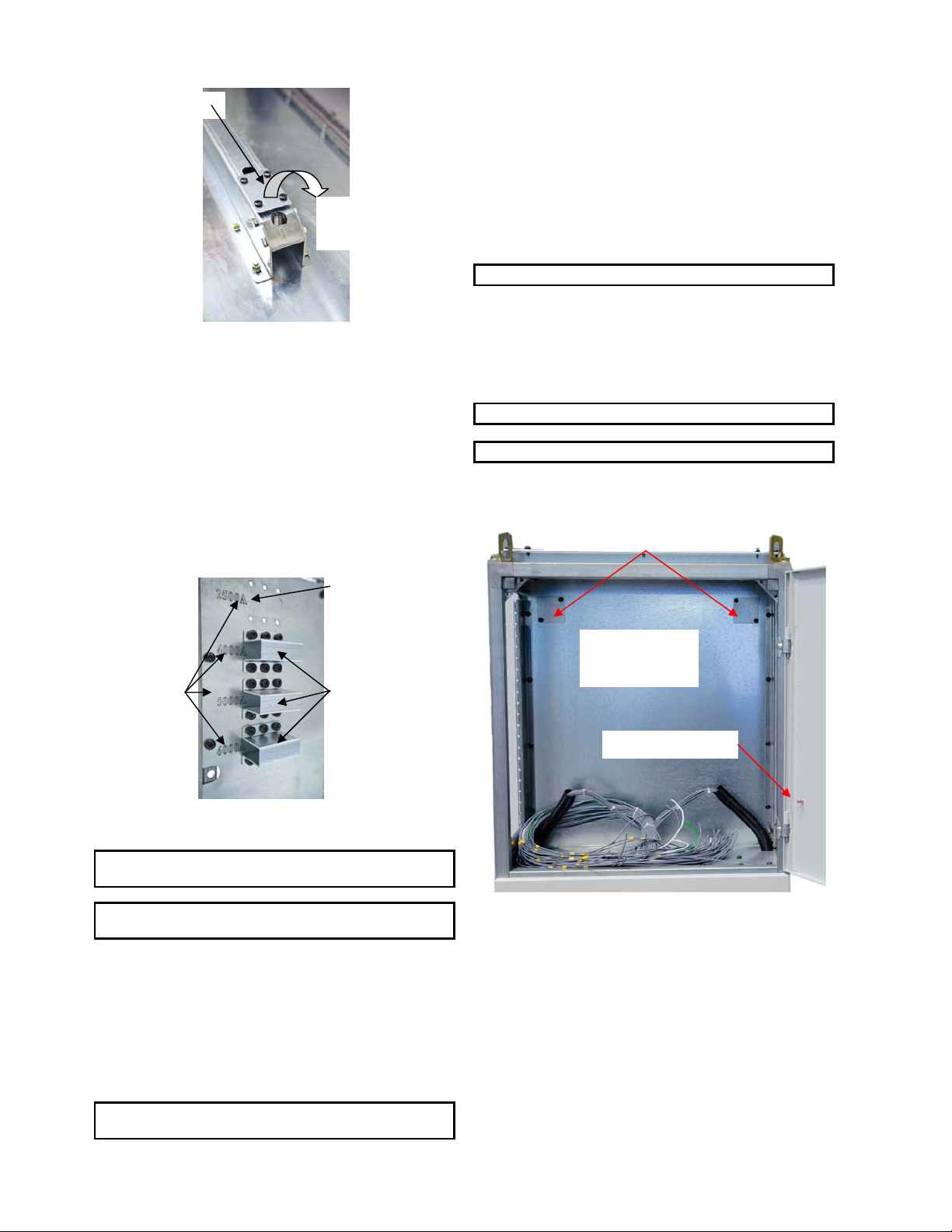

4000A

Terminals

6000A

Terminals

Ground

Bus

Connection

Fig. 33-4 Rear views of 4000A and 6000A Modules

Shutters

Padlock

Fig. 33-3 Safety padlock on the shutters

Every module is equipped with rejection Interlock that must be

properly configured by the OEM. This interlock allows

configurations for all current ratings. It is placed on both sides of

the breaker compartment. See Fig. 33-2.

Cable Compartment

The primary stabs extend into the cable compartment and are

suitable for connection with ANSI type busbars. Fig 33-4 shows

primary terminals for 4000A and 6000 A rated modules. Ground

bus connection in the cable compartment is the same on all

module types. Cable compartment is provided without side

covers. See Fig. 33-1. Painted and pre-punched side covers can

be ordered as separate accessories.

NOTE: See Appendix A for all dimensional drawings of the

primary terminals and cable compartment.

Module is also equipped with trolley-operated contacts that are

activated in CONNECTED and TEST position as well as with some

other limit switches that are used for internal interlocks.

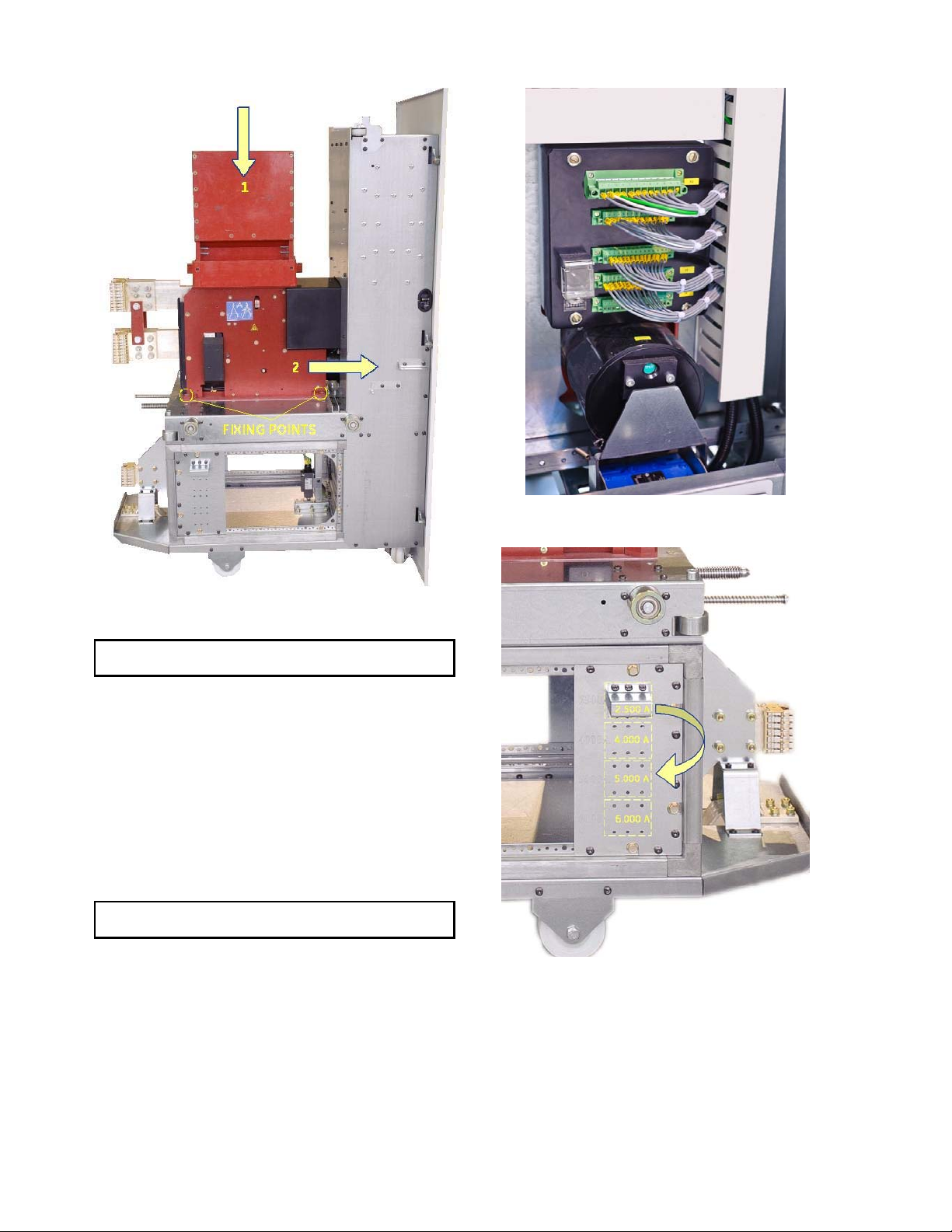

3-4 The Trolley

The module is designed to be used with Gerapid high-speed

circuit breaker installed on the withdrawable trolley. The trolley

can be ordered in two different versions, with manual racking or

with motor operated remote racking system.

Remote racking trolley equipped with motor drive can also be

operated manually by the crank handle.

NOTE: The crank handle is an accessory and has to be

ordered separately.

Trolley structure is compatible with all the modules and all

Gerapid circuit breakers listed in Section 3-5. The OEM must

correctly configure the rejection Interlock on the trolley and in the

module for the specific rating of breaker being installed.

All breaker controls, control power supply and auxiliary contacts

are extended to the control compartment via the secondary

disconnect and harness. Negative and positive interlocks are

operated from access console at the front of the trolley. The

access opening for the manual crank handle is there as well.

Secondary Disconnect Plu

Access

Console

Control Compartment

The secondary control plug located in the breaker compartment

is prewired, with a 3ft tagged wire harness brought into the

controls compartment for User’s connections. The matching

secondary disconnect plug is mounted on the trolley.

NOTE: See Appendix A for all dimensional drawings of the

Control Compartment.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 9

Fig. 34-1 Trolley features (motorized racking shown)

ection Interlock

Motordrive

Page 10

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 4 Installing the Module

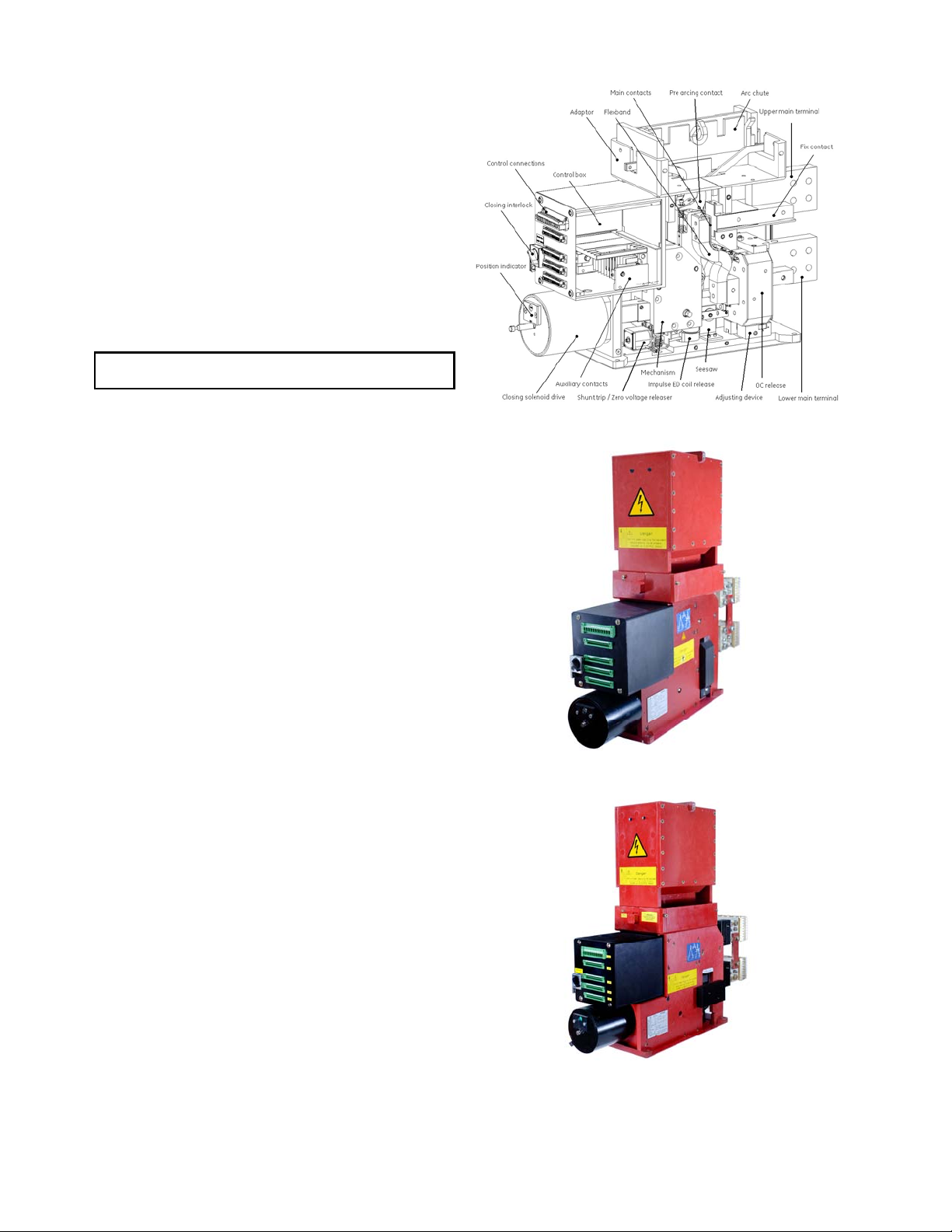

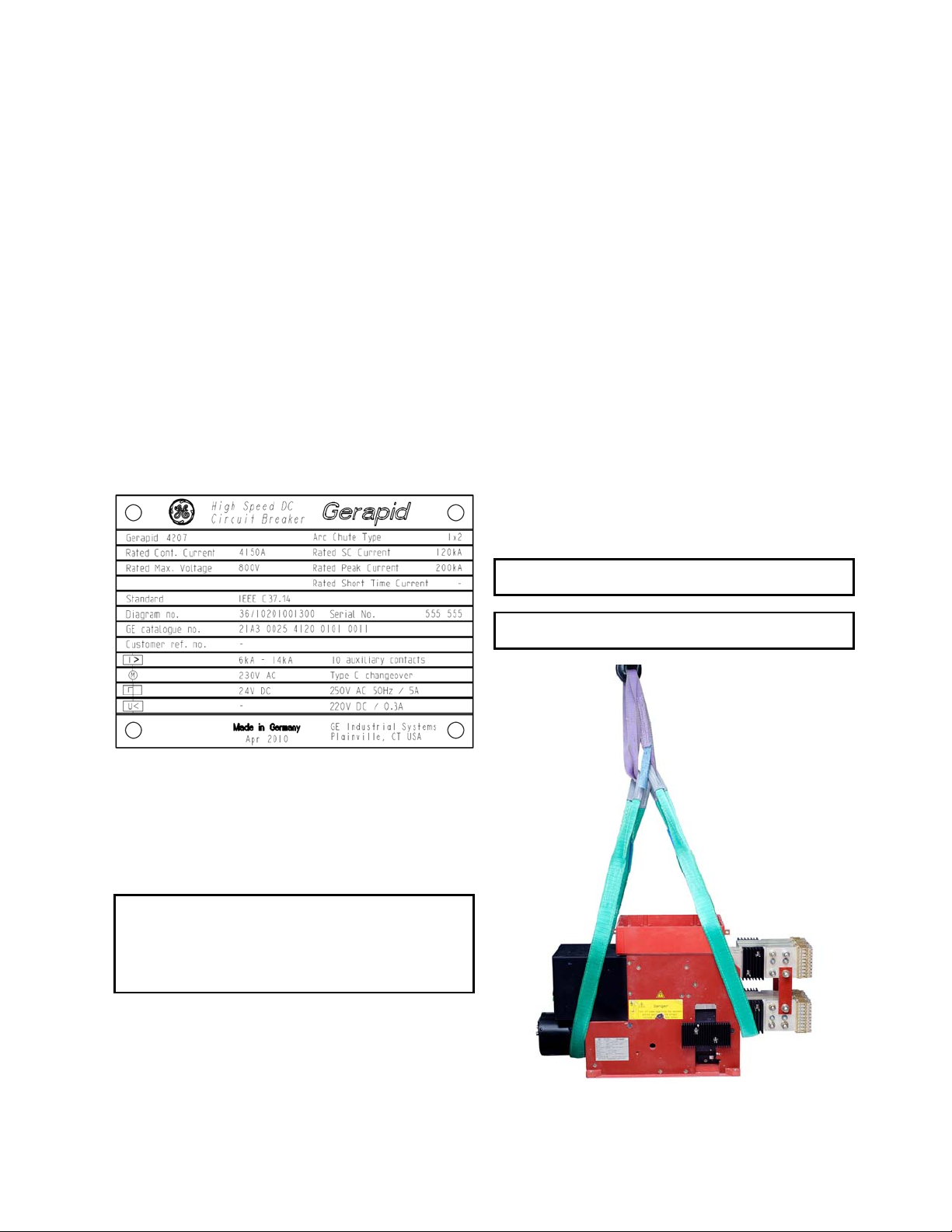

3-5 Gerapid Breakers

The GE Gerapid DC Circuit Breaker is a high speed, single pole breaker

used for protection of high power DC supply systems. The main features

of the Gerapid circuit breaker are:

Modular construction, easy to inspect and maintain

Non-flammable and non-toxic insulation materials

High speed, current limiting short circuit characteristics

Up to 24kA tripping threshold for OC release

High speed remote impulse release for distant faults

Shunt or zero voltage releases for opening operation

Powerful closing solenoid enables quick closing operation

Easy and safe remote and local control of the breaker,

Wide variety of accessories, such as counter, indicators,

interlocks, manual handle, etc..

See Fig. 35-1 for overview of the breaker construction.

NOTE: See Appendix F for all ratings and see User Manual

S47183De for breaker details and accessories.

Four current ratings of Gerapid circuit breakers are available for

mounting on the trolley and used in the module. These circuit

breakers are UL Listed and type tested in accordance with

IEEE/ANSI C37.14-2000 Standards. Continuous current ratings

range from 2500 to 6000 ampere frame size. All Gerapid circuit

breakers of the same type and rating may be interchanged,

provided the breaker accessories have the same ratings.

Gerapid 2508 (See Fig. 35-2)

2500A frame size

Standard 200kA peak interrupting current at 800VDC

3700V power frequency withstand level

Current limiting characteristic

Tested for duty type a, b, c and d according to ANSI C37.14

Trip-free capability according to ANSI C37.100

Gerapid 4008 (See Fig. 35-2)

4000A frame size

Standard 200kA peak interrupting current at 800VDC

3700V power frequency withstand level

Current limiting characteristic

Tested for duty type a, b, c and d according to ANSI C37.14

Trip-free capability according to ANSI C37.100

Gerapid 5008 (See Fig. 35-3)

5000A frame size

Standard 200kA peak interrupting current at 800VDC

3700V power frequency withstand level

Current limiting characteristic

Tested for duty type a, b, c and d according to ANSI C37.14

Trip-free capability according to ANSI C37.100

Gerapid 6008 (See Fig. 35-3)

6000A frame size

Standard 200kA peak interrupting current at 800VDC

3700V power frequency withstand level

Current limiting characteristic

Tested for duty type a, b, c and d according to ANSI C37.14

Trip-free capability according to ANSI C37.100

Fig. 35-1 Gerapid circuit breaker construction

Fig. 35-2 Gerapid 2508 and 4008 circuit breakers

Fig. 35-3 Gerapid 5008 and 6008 circuit breakers

10 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 11

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 4 Installing the Module

Installing the Module

4-1 General Notes

This chapter contains instructions for installing the GE DC OEM

Module.

CAUTION: Personnel installing this equipment must be

thoroughly familiar with this instruction manual and all articles

of the National Electrical Code applicable to the installation of

this equipment. In addition, all drawings, both mechanical

installation and electrical, must be understood and strictly

followed to prevent damage to the module.

Environmental Requirements

The module as provided is designed for indoor installations only

and should be placed in an indoor area where clean, dry air is free

to circulate around and above it. Since air is taken into the

equipment at the bottom of each section and exhausted at the

top, a location with good airflow must be provided for efficient

operation.

A minimum of 30 inches of clear space above the equipment is

recommended. In order to properly withdraw the trolley there

should be at least 7 foot of space in the front of the module.

NOTE: See Appendix C for sketches concerning layout.

The foundation must be flat and level in all planes with maximum

deviation of 0.8 inch at the length of 3 foot. The module should be

anchored to the floor through holes shown on Fig. 41-1 using

7/16” or metric M12 grade 5 steel bolts.

4-2 Module Configuration and Assembly

Multiple Modules Side by Side Assembly

Modules can be connected together to form switchgear lineups.

To bolt two modules together, edge trim strips must be removed.

Special connection spacers must be used and are inserted into 12

hex shaped cut outs visible in the sidewalls. Fig. 42-1 shows the

location of the front 4 connection spacer openings. Location of all

openings and installation tips are shown in Appendix G.

A Module Coupling Kit can be ordered under Cat. No.: 289169.

Each kit consists of 12 Connection spacers, bolts and washers

necessary to connect two adjacent modules.

NOTE: See Appendix D for connection drawings.

Foundation Requirements

The foundation requirements detailed in this chapter should be

strictly adhered to.

Top View on the floor.

Anchor Points

Use M12 or

7/16” grade 5

bolts.

Locking Plate

Fig.41-1 Module anchor bolt hole locations

The foundation must be strong enough to prevent sagging due to

the weight of the completed switchgear structure and to

withstand the impact loading caused by the opening of the

breakers under fault conditions. The impact loading is

approximately 1-1/2 times the static load.

Connection Spacers

12 per side-by-side.

Fig. 42-1 Location of front module connection spacers

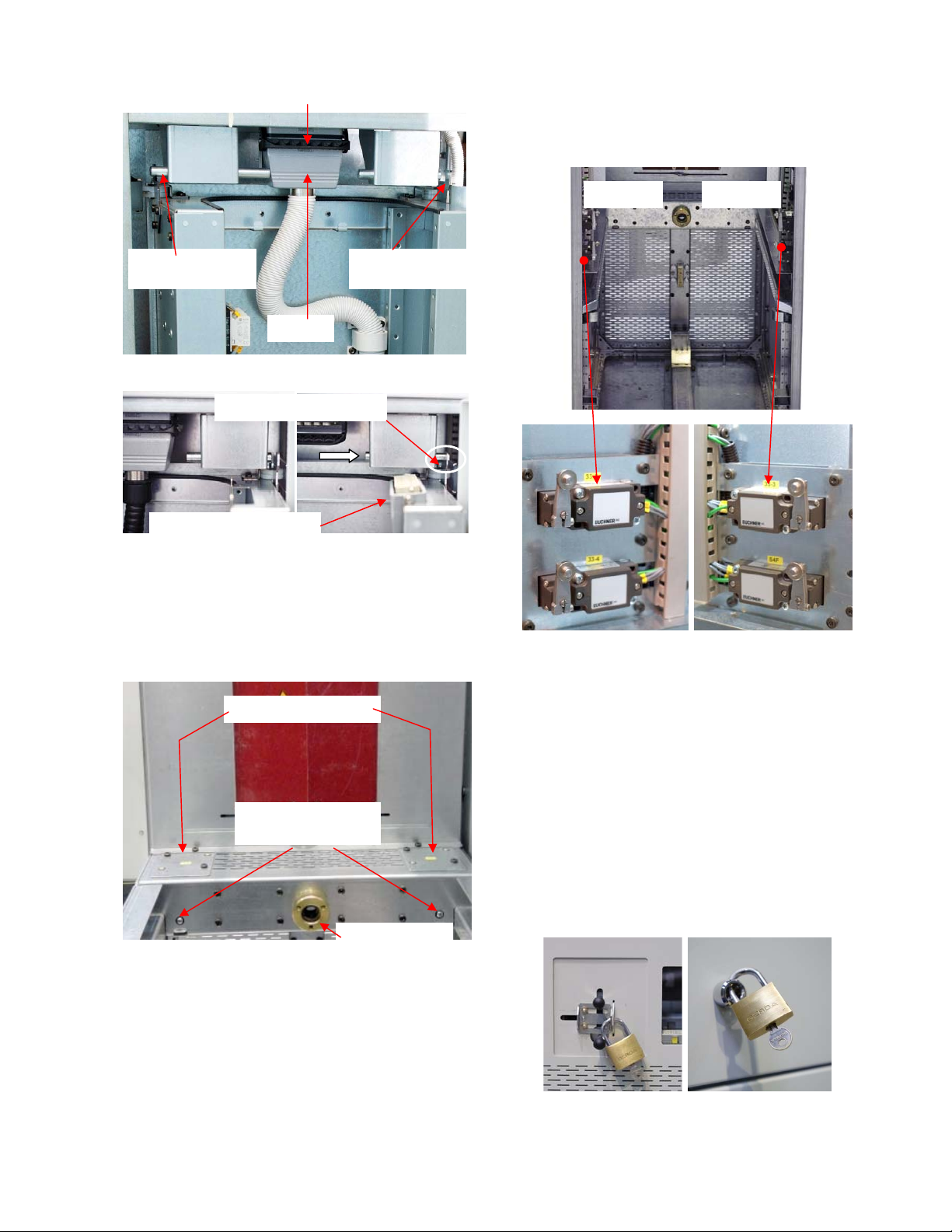

Module Preparation

Every module is suitable for operating either with manually or

motor operated trolley. Depending on the type of trolley being

utilized, a locking plate in the module may need to be removed:

If motor operated trolley is going to be used with the

Module, remove the locking plate.

If manually operated trolley is going to be used with the

module, keep the locking plate in place

See Fig. 41-1 and Fig. 42-2 to locate locking plate.

NOTE: Look for the yellow warning label placed on the

module’s floor to find bottom guide rail and the plate.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 11

Page 12

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Rej

Chapter 4 Installing the Module

Locking Plate

Remove for motor

operated trolley !

Fig. 42-2 Locking Plate

Module Rejection Interlock

OEM must configure the rejection interlock in the module, before

its usage. Four different configurations are possible: 2500A,

4000A, 5000A or 6000A. In the module, rejection markers must be

screwed in place aligned with all current ratings except the one

that module is dedicated to. This should be done on the right and

left side of the module.

Fig. 42-3 illustrates a correctly configured module rejection

Interlock for a 2500A rated Gerapid breaker. Rejection markers

must be fixed on both right and left sides of the breaker

compartment, aligned with ratings: 4000A, 5000A and 6000A.

Installed Breaker

Ground Bus Connection

Ground bus connection terminal is located at the bottom of the

module in the cable compartment. See Fig. 33-4. Circuit

connections to a ground bus are made so that it is not necessary

to open-circuit the ground bus to remove any connection made

to the ground bus. Ground connections are provided for all

removable elements to ensure that the frame and mechanism are

grounded until the primary circuit is disconnected and the

removable element is moved a safe distance.

NOTE: See Appendix B for ground terminal drawings.

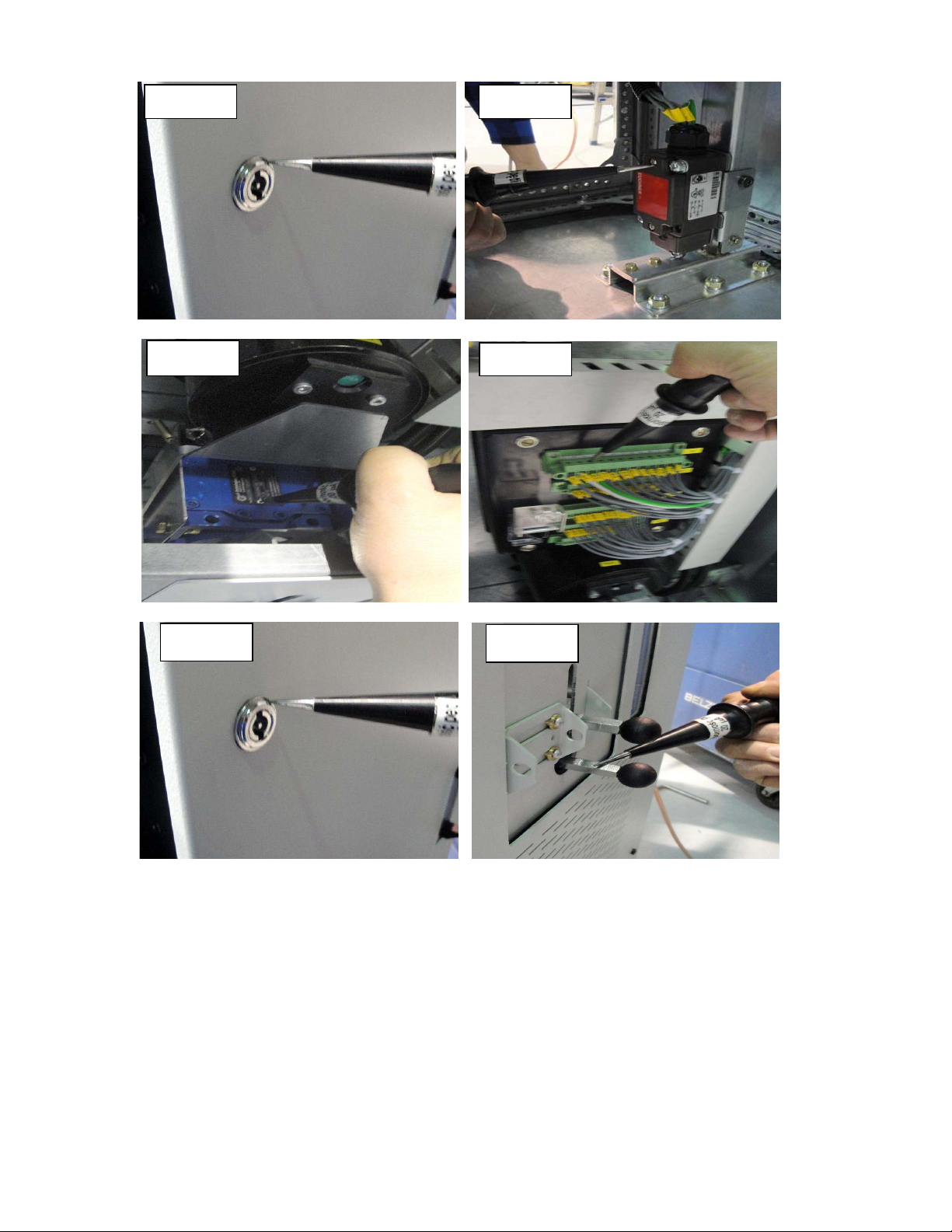

Connecting Secondary Controls

Secondary disconnect plug in the module is pre-wired with the

harness going into control compartment. All wires that should be

used by OEM for completing the module and breaker control are

numbered and accessible inside the Control Compartment.

NOTE: See Appendix E for electrical schemes for connections.

NOTE: See Appendix A for control compartment dimensions.

All trolley control commands and supply connections are also

available thru the harness in the Control Compartment.

Top mounted wire way

access covers

Rating

Markers

Fig.42-3 Rejection interlock set up for rating of 2500A

NOTE: Always verify that the rating on rejection interlock is not

higher that the module rated current.

NOTE: Always configure rejection interlock on both sides of the

module breaker compartment.

ection Markers

Main Busbars Connection

Module primary terminals are silver plated copper and are

suitable to connect to copper bus bars as per IEEE Std. C37.14

Table 6. Connected bus bars should not have cross sections less

that recommend in Table 6.

Gerapid circuit breakers are not polarized. Therefore the load and

the supply line can be connected to either top or bottom terminal.

See Fig. 33-4 for primary terminals views.

NOTE: See Appendix B for primary terminals drawings and

recommend bus bar dimension.

Components

Mounting Plate

Grounding Stud

Fig.42-4 Control compartment

Device mounting on control compartment door

Control compartment’s door should be removed before making

any cutouts. To remove the door, open and remove grounding

connection. Lift the door up until the pins are free from hinges.

All auxiliary devices can be attached to the mounting plate

provided at the back of the control compartment. However it is

recommend prefabricating a separate metal sheet and installing

it in the control compartment using frame supports.

There are two cover plates that provide access to the top

mounted wire way (cable channel). Remove the covers to use

them. See Fig. 42-4.

12 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 13

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 5 Installing the Breaker

Installing the Breaker

5-1 General Notes

Before installing, operating, or removing a circuit breaker, refer to

the Gerapid breaker instruction manual S47183De for

preparation, inspection, and test. Check thoroughly for damaged

or loose parts and for any dirt or foreign matter, which may be in

the breaker.

To install the breaker, proceed as follows:

1) Before installing a breaker, check the contact areas

on each primary disconnect cluster of fingers for foreign

matter that may have accumulated. Clean these areas if

necessary. Be sure that a thin film of the red lubricating

grease “MOBIL GREASE 28” covers the fingers areas before

putting a breaker in the compartment.

2) Check to see that the breakers match their respective

trolley and compartment. Each breaker is assigned a serial

number and ratings. These are shown on the breaker’s

nameplate. The breaker may also be identified using the 20digit PST catalog number. See Fig 51-1.

5-2 Installing Gerapid Breaker

Prior to Installation

Prior to placing a breaker in its intended location on the trolley,

please check following precautions:

1) Find the foil bag with breaker bolting kit no. 700701

that is attached to the trolley’s platform. Remove it.

2) Ensure that the breaker is OPEN.

3) Ensure that arc chute is NOT on the breaker.

4) Ensure that lifting device can carry ~300 lbs and that

lifting slings are min. 6 ft long.

Installation Procedure

To install the Gerapid circuit breaker, proceed as follows:

1) Ensure that the lifting frame has been removed from

the trolley. See Fig. 22-2.

2) Place the lifting slings in position. See Fig. 52-1.

Carefully lift the breaker and place it on the trolley.

3) Slide in the breaker toward the front of the trolley,

until four attachment bolt holes in platform match the holes in

breaker baseplate. Install bolts provided and tighten with

torque listed in Table D-1. The fixing kit is attached to the

trolley’s platform.

4) Plug in all connectors to correct terminals at the front

of breaker’s control box. Tight the connectors. See Fig. 52-3.

WARNING: Do not stand under the circuit breaker during the

lifting and transport operations.

NOTE: Do not transport the circuit breaker with arc chute

installed.

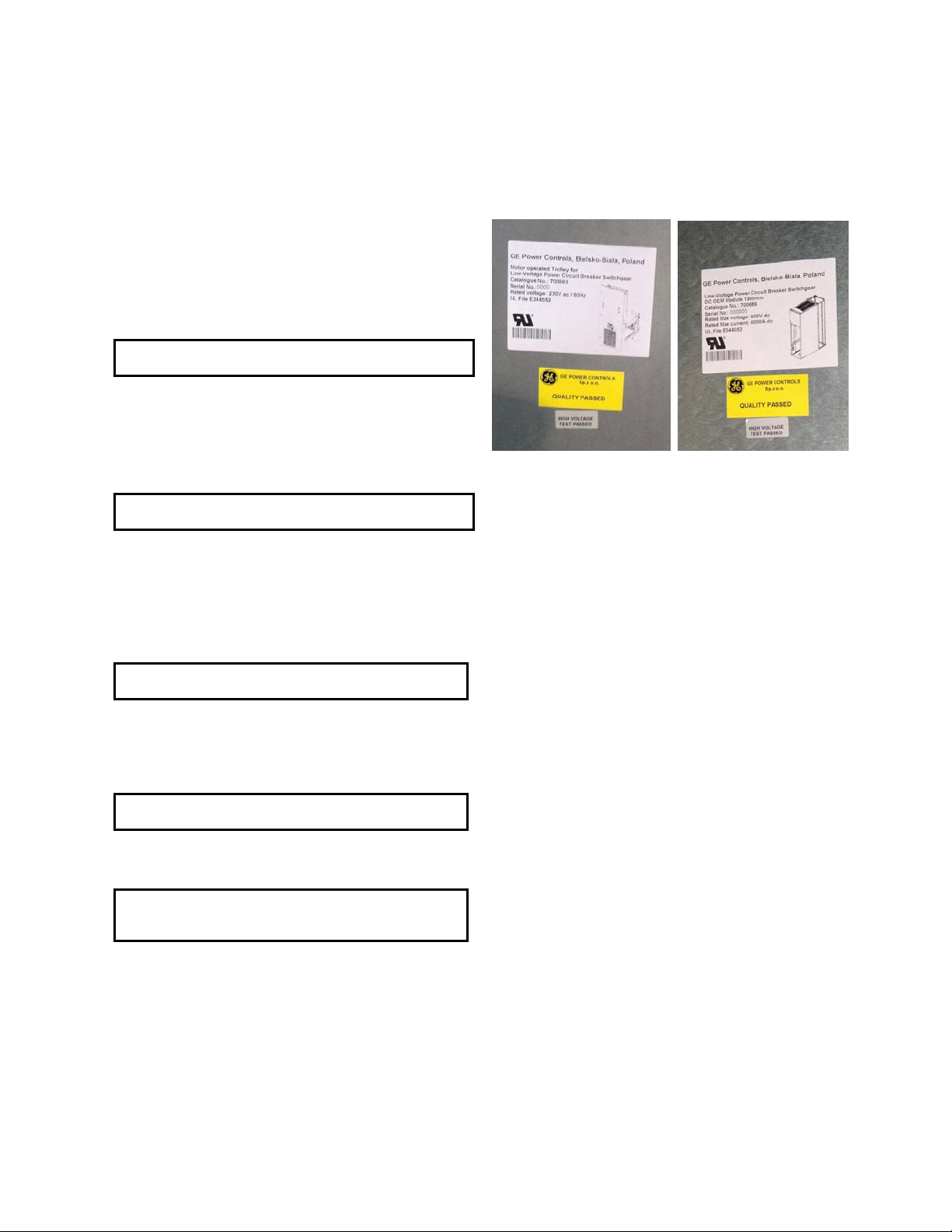

Fig. 51-1 Nameplate of Gerapid breaker

Breakers of the same rating are interchangeable in their

equipment compartments, as long as they have the same

accessories equipped.

The trolley design is the same and universal, regardless of the

Gerapid breaker type intend to operate with.

WARNING: A breaker with different rating fit into any of the

trolleys. If the trolley’s rejection interlock does not match the

breaker’s rating, but it does match the compartment’s

rejection interlock, it is possible to rack-in an incorrect breaker

into the compartment. This may lead to serious damages and

could result in death or serious injury for operator!

Fig. 52-1 Lifting the breaker

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 13

Page 14

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 5 Installing the Breaker

Fig. 52-2 Breaker on the trolley

NOTE: Do not use attachment screws longer than ~1.2 in.

Longer screws may damage trolley’s components.

Configuration of the Rejection Interlock

It is strongly recommended to check and set up correct position

of the rejection interlock immediately after breaker is installed on

the trolley.

All trolleys have their rejection interlock set at 2500A, by default. If

the breaker has a different rating, the rejection interlock has to be

configured accordingly.

1) Remove both rejection markers from default positions.

2) Reattach them in to the positions which correspond to

the breaker’s current rating. In example from 2500A to 5000A,

see Fig. 52-4

CAUTION: Make sure both rejection markers on both sides of

the trolley match the breaker current rating.

Fig. 52-3 Control connectors for Gerapid breaker

Fig. 52-4 Rejection Interlock of the trolley

14 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 15

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 5 Installing the Breaker

Testing and Inspection

6-1 General Notes

After the equipment has been installed and all connections made,

equipment must be tested and inspected before it is put in

service. Although each module and each breaker have been

tested at the factory, a final field test must be made to be sure

that the equipment has been properly installed and that all

interlocks operate correctly.

Directions for inspection and testing breakers are given in the

instruction book S47183De, furnished with each breaker. The

extent of the tests on the equipment as a whole is given below.

NOTE: See Appendix H for corresponding Field Test Procedure,

where all steps are listed in Tables H-2, H-3 and H-4.

Prior to Test

Before any operation on the module, it is required to check if

corresponding trolley is remote or manual racking type. Remote

racking trolley includes motor drive installed in a bottom-front

compartment of the trolley. See Fig. 34-1.

NOTE: Make sure that locking plate has been removed, if the

trolley is manual racking type. See section 4.2.

Connecting Control Circuits

Some of the field test procedures require control circuits to be

active and energized. Therefore it is necessary to connect the

wiring harness of the module to a dedicated system, which

enables control of the module. To see recommended connections,

please refer to Appendix H, Fig. H-1.

CAUTION: All wires, which are not connected, must be

insulated while test is running.

The Remote Racking option is available only with ~230 V 60 Hz

control voltage. For other values please contact GE Industrial

Solutions representatives. Supply source should be capable to

carry ~3 A permanent current.

NOTE: See Appendix F for details concerning electric

characteristics of auxiliary loads.

High Potential Tests

High-potential tests, to check the integrity of the insulation, are

not necessary if the installation instructions are carefully followed.

Each module and each trolley undergo High Potential Tests

before shipment. Passing of compete Factory Acceptance Test

sequence is marked by sticker note. See Fig. 61-1.

Fig. 61-1 Quality check markings after FAT tests

If local codes demand this test, or the purchaser wishes to make

high-potential tests, the voltage should not exceed, for the power

circuit, 2.8 kV RMS or 3.9 kV DC and for the control circuit

1.2 kV RMS. Testing procedure is described in Appendix H, Table

H-7.

Grounding Circuit Check

If local codes demand this test, or the purchaser wishes to make

earthing system test, refer to procedure described in Appendix H,

Table H-8.

Minimum current required for checking of grounding connections

is 10 A. Resistance for each measured grounding connection

must be less than 0.1 Ohm.

6-2 Field Testing Procedure

NOTE: Extended descriptions of the module operating modes

with illustrations are given in Chapter 7. Refer to these during

Field Testing execution.

Testing the Module with Remote Racking System

Proceed with steps 1.1 to 1.9 from Appendix H, Table H-4.

Testing the Module w/o Remote Racking System

Proceed with steps 1.1 to 1.9 from Appendix H, Table H-5.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 15

Page 16

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 7 Operating the Module

Operating the Module

7.1 Mechanisms and Interlocks

Racking Mechanism

The racking mechanism is designed for moving the trolley

between two (2) positions, TEST and CONNECTED. Clockwise

rotation of the racking shaft, Fig. 71-1, results in Trolley

movement toward the CONNECTED position. Counterclockwise

rotation of the racking mechanism results in trolley movement

from the CONNECTED to the TEST position.

Racking Shaft

Indicator Shaft

Access Interlocks

Front door Access Interlock, see Fig. 71-4, ensures tripping of

the breaker before the Crank Handle can be inserted for

racking. Lifting up of the Trip Lever causes breaker to trip open,

and additionally enable access to manual racking slot.

NOTE: The Access Lever is locked in lower position when

the breaker is closed.

Trip Lever

Fig. 71-1 Racking system

The racking mechanism can be manually or remotely

operated, closed-door drawout, designed to prevent overtravel, and equipped with guides for alignment of the breaker

in the module. The Crank Handle has a torque clutch. See

Fig. 71-2. This clutch protects the racking system against

damages caused by applying excessive force when Trolley is in

CONNECTED position.

Clutch

Fig 71-2 Crank Handle

An indicator is provided to show breaker position within the

compartment. See Fig. 71-3. The indicator is visible from the

exterior of the switchgear.

Access Lever

Fig. 71-4 Front door Access Interlock

Trip Lever is mechanically coupled with a vertical interlock

under the trolley. This interlock mechanically locks the trolley in

TEST or CONNECTD position.

When the Tri Lever is lifted up, the “Crank Lock” stop switch

(S3F) electrically cuts-off the closing circuit of the breaker and

blocks remote racking. This ensures no remote command

activates the trolley or closes the breaker with the Crank

Handle is inserted. See Fig. 71 5 and wiring circuit in Appendix

D.

Operating

Rod

-S3F stop

Lower position

switch

Upper position

Fig. 71-5 Locking rod with S3F end switch “Crank Lock”

Secondary Control Interlock

TEST CONNECTED

Fig. 71-3 Position Indicator

Trolley is equipped with integral wheels for moving the trolley

in and out of a cubicle and sized to carry the weight without

deforming or cutting into the concrete surface. The wheels roll,

but not slide, and guide the trolley to correctly align and

engage the racking mechanism.

16 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Secondary Disconnect consist of a receptacle installed in the

stationary cell and removable plug, which is a part of the

trolley. See Fig. 71-6. This disconnect is equipped with Rack-in

Interlock preventing movement of the trolley from TEST

position to CONNECTED position unless Secondary Disconnect

is connected. Rack-out Interlock prevents the trolley from

being fully withdrawn from the Module unless the secondary

disconnect is unplugged. See Fig. 71-6.

After removing the plug, both interlocks move to the right and

reset. This enables withdrawal operation and blocks rack-in

operation as shown at Fig. 71-7.

Page 17

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

(

)

(

Chapter 7 Operating the Module

Receptacle Snap Lock

Trolley Operated Switches

Stationary part of the Module is equipped with set of trolley

position switches. See Fig. 71-9 for location.

Rack-Out Interlock

active)

Plug

Fig. 71-6 Secondary Disconnect with two interlocks

Rack-In Interlock activated

Park position for the plug.

Fig. 71-7 Operation of Rack-in Interlock

Rack-In Interlock

release

Remote Racking

A motor drive 230V 60 Hz and 250 W (0.34 Hp) is available for

Remote Racking option. The gear-motor is installed in the

front-bottom compartment of the trolley. See Fig. 34-1.

Complete rack-in or rack-out operation lasts ~8 seconds.

Access to 33-1 & 33-2

33-5/33-4

Fig. 71-9 Position switches 33-3, S4F, 33-4, 33-5

Following signal switches are available with the Module:

Switch S4F: NC dry contact available at (Y64 Y65).

Indicate coupling of the racking shaft with racking socket.

Switch 33-4: NO and NC dry contacts available at

(Y66 Y67) and (Y68 Y69). Indicate TEST position.

Switch 33-5: NO and NC dry contacts available at

(Y70 Y71) and (Y72 Y73). Indicate CONNECTED position.

33-3/S4F

Actuator Pins of 33-1

& 33-2

Racking Socket

Fig. 71-8 Limit switches 33-1 and 33-2.

The motor is protected by 2.5 A fuse element. Two

independent limit switches, 33-1 and 33-2, switch off the

motor drive’s supply when the trolley reaches CONNECTED

position. Limit switch 33-3 stops the trolley in TEST position.

See Fig. 71-9.

All three switches are wired to block the breaker CLOSE

operation if the trolley is between CONNECTED and TEST

positions. See circuit diagram E-2, Appendix E.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 17

Padlocks

There are three interlocks, which can be padlocked. Padlock’s

diameter shall not exceed 1/3 inch. Padlocks are not included.

Safety Shutters, see Fig. 33-3,

Access Console, see Fig. 71-10,

Control Compartment, see Fig. 71-10.

Fig. 71-10 Padlock set at Access Console (left) and

Control Compartment (right).

Page 18

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 7 Operating the Module

7.2 Trolley with Manual Racking

Operational Positions

The trolley has four separate operating positions:

1. CONNECTED position – Primary Disconnects and

Secondary Disconnect in full contact, breaker ready for normal

operation. Position Interlock, see Fig. 72-1, keeps the trolley in

this position.

Secondary Disconnect

Secondary Disconnect

2. TEST position - Primary Disconnect separated by a safe

distance and shutters closed. The Secondary Disconnect is in

full contact. Trolley is withdrawn ~5 inches and locked by

Position Interlock. See Fig. 72-2.

3. DISCONNECTED position - Primary Disconnects separated

by a safe distance and shutters closed. Secondary Disconnect

is disengaged. Trolley positioned in the TEST position.

4. WITHDRAWN position – Trolley outside of the Module.

Position Interlock

Fig. 72-1 CONNECTED position of the trolley

NOTE: Manual racking-in and racking-out does not

require control voltage to be present. Although, switching

ON/OFF the breaker will not possible in such case.

Primary Disconnects

Position Interlock

Fig. 72-2 TEST position of the trolley

Primary Disconnects

Racking – In Procedure

NOTE: Crank Handle is necessary for racking operations.

Crank Handle has to be ordered separately.

1. Trolley WITHDRAWN. Push trolley toward the module until

it stops at DISCONNECTED position.

2. Open the trolley’s door and install Secondary Disconnect.

Now the trolley is at the TEST position.

NOTE: .Use the Door Key to open all Door Locks and

release Door Interlock. See Fig. 72-3.

NOTE: Make sure that Receptacle Snap Lock is engaged.

3. Lift up the Access Lever (Fig. 71-4) and push the trolley in

further until racking shaft (Fig. 71-1) couples with socket

(Fig. 71-8).

NOTE: S4F contact should indicate the coupling position if

connected (Y64 Y65) to any external indication device.

18 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 19

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

y

Chapter 7 Operating the Module

Lift to release

Door Interlock

Door Ke

Door Locks

Rack-Out Procedure

NOTE: Crank Handle is necessary for racking operations.

Crank Handle has to be ordered separately.

1. Trolley CONNECTED. Open the breaker either using OPEN

command or pulling up the Trip Lever (Fig. 71-4).

2. Lift up the Access Lever (Fig. 71-4) and insert Crank

Handle. Rotate the crank counterclockwise until trolley

stops. Breaker is now at TEST position.

NOTE: TEST position is indicated by Position Indicator,

(Fig. 71-3) or by contacts of the switch 33-4 (Fig. 71-9).

3. Open the trolley’s door and disconnect the Secondary

Disconnect. Hang it on the frame to the right (Fig. 71-7).

Now the trolley is at the DISCONNECTED position.

NOTE: Use the Door Key to open all Door Locks and

release Door Interlock. See Fig. 72-3.

4. Remove the crank. Lift up the Access Lever (Fig. 71-4) and

pull the trolley out from the module.

Fig. 72-3 Door locks positions

4. Insert Crank Handle into the Access Console slot, Fig. 72-4

and rotate the crank clockwise until trolley reaches

CONNECTED position.

NOTE: CONNECTED position is indicated by Position

Indicator, (Fig. 71-3) or by contacts of the switch 33-5.

5. Remove the Crank Handle. Push down the Trip Lever,

(Fig. 71-4), to make sure that both levers of the Access

Console are in their maximum lower positions.

NOTE: If the Access Lever is not at its maximum lower

position, closing of the breaker will not be possible.

7.3 Trolley with Remote Racking

Operational positions.

The trolley has distinguished four operational positions:

Secondary Disconnect

Fig. 72-4 Crank Handle installed

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 19

Position Interlock

Fig. 73-1 CONNECTED position for the remote racking

trolley

Primary Disconnects

Page 20

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 7 Operating the Module

1. CONNECTED position – Primary Disconnects and

Secondary Disconnect in full contact, breaker ready for normal

operation. Position Interlock, see Fig. 73-1, keeps the trolley in

this position.

2. TEST position - Primary Disconnect open and separated by

a safe distance with shutters closed. The Secondary

Disconnect is in full contact. The Trolley is withdrawn ~4 inches

and locked by Position Interlock. See Fig. 72-3.

Secondary Disconnect

Secondary Disconnect

Position Interlock

Fig. 73-2 TEST position for remote racking trolley

3. DISCONNECTED position - Primary Disconnects open and

separated by a safe distance with shutters closed. Secondary

Disconnect is open. Trolley is withdrawn ~5 inches. See Fig. 72-

3.

4. WITHDRAWN position – Trolley outside of the module.

NOTE: Remote racking-operations require control voltage

and control commands to be provided. See Appendix E for

electrical circuit drawings.

Primary Disconnects

Fig. 73-3 DISCONNECTED position for remote racking

trolley.

Position Interlock

Primary Disconnects

Remote Rack–In Procedure.

NOTE: Crank Handle is necessary for completing racking

operations. Crank Handle has to be ordered separately.

WARNING: EMERGENCY RACKING STOP circuit (Y58 Y59)

must be wired to a pushbutton (furnished by OEM). It is

recommended the STOP PB be installed on the control

compartment door. See example Fig. 73-4.

Use this pushbutton for immediate interruption of racking

operation and stop the trolley regardless of its position.

EMERGENCY RACKING STOP

Fig. 73-4 EMERGENCY STOP pushbutton (by OEM)

20 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 21

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

y

Chapter 7 Operating the Module

1. Trolley WITHDRAWN. Push trolley toward the module

until it stops at DISCONNECTED position.

2. Open the trolley’s door and install Secondary

Disconnect.

NOTE: Use the Door Key provided to open all Door Locks

and release Door Interlock. See Fig. 73-4.

NOTE: Make sure that Receptacle Snap Lock is engaged.

3. Lift up the Access Lever (Fig. 71-4) and push the

trolley in further until racking shaft (Fig. 71-1) couples with

socket (Fig. 71-8).

NOTE: S4F contact should indicate the coupling position if

connected (Y64 Y65) to any external indication device.

4. Insert Crank Handle into the Access Console slot,

Fig. 72-4 and rotate Crank Handle clockwise until trolley

reaches TEST position.

NOTE: TEST position is indicated by Position Indicator,

(Fig. 71-3) or by indication of switch 33-4 (Fig. 71-9).

5. Remove Crank Handle. Push the Trip Lever down,

(Fig. 71-4), making sure that both levers of the Access

Console are in their maximum lower positions.

NOTE: If the Access Lever is not at its maximum lower

position, closing of the breaker or remote rack-in will not

be possible.

6. Use RACK BREAKER-IN command (Y60 Y61) to start

motor for rack in operation. Trolley will stop at

CONNECTED position.

WARNING: Use EMERGENCY STOP pushbutton in case of

emergency situation. See Fig.73-4.

Lift to release

Door Interlock

Manual Rack-Out Procedure.

NOTE: Crank Handle is necessary for completing of

racking operations. Crank Handle has to be ordered

separately.

1. Trolley CONNECTED. Open the breaker either using

OPEN command or pulling up the Trip Lever (Fig. 71-

4).

2. Use RACK BREAKER-OUT command (Y62 Y63) to start

motor for rack out operation. Trolley will stop at TEST

position.

NOTE: TEST position is indicated by Position Indicator,

(Fig. 71-3) or by indication of switch 33-4 (Fig. 71-9).

3. Open the trolley’s door and disconnect the

Secondary Disconnect. Hang it on the frame to the

right (Fig. 71-7).

NOTE: Use the Door Key to open all Door Locks and

release Door Interlock. See Fig. 73-4.

4. Lift up the Access Lever (Fig. 71-4) and insert Crank

Handle. Rotate Crank Handle counterclockwise until

trolley stops. Now the trolley is in the DISCONNECTED

position.

5. Remove Crank Handle. Lift up the Access Lever

(Fig. 71-4) and pull the trolley out from the module.

7.4 Operate the breaker.

Gerapid circuit breakers can be operated electrically and

manually.

NOTE: Manual CLOSE operation at the breaker is possible

only at WITHDRAWN position of the trolley. Manual closing

should only be performed for maintenance.

Manual OPEN operation at CONNECTED or TEST positions is

possible by means of Trip Lever. For maintenance purposes

breaker can be operated by means of dedicated hand lever at

WITHDRAWN position.

NOTE: See User Manual S47183De for breaker operation

details and accessories.

All electric control commands and signals are wired thru

available harness (Y01 Y54). See Appendix E for details of

available commands and signals.

Door Ke

Door Locks

Fig. 73-4 Door locks

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 21

Page 22

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 9 Customer Support.

Troubleshooting and Maintenance

8.1 Troubleshooting

Troubleshooting section describes potential issues that user

may experience during operation of the trolley. Contact GE

Energy service in case the problem is not resolved.

NOTE: See User Manual S47183De for breaker

troubleshooting information.

Manually operated trolley

A. Cannot lift Access Lever to insert Crank Handle

Check if the breaker is OPEN. When CLOSED,

breaker’s drive rod activates interlock, which

locks the Access Lever.

Check the length of four M8 mounting screws

for the breaker. Screws may limit the movement

of the Access Lever if are longer than 25 mm

(1”).

B. Cannot trip the breaker by means of Trip Lever

Check the length of four M8 mounting screws

for the breaker. Screws may limit the movement

of the Trip Lever if are longer than 25 mm (1”).

Check the Forced Tripping Release pin under the

breaker’s base. The pin should be able to be fully

pressed against base. If this does not work, the

pin may be damaged inside the breaker.

C. Cannot move the trolley using Crank Handle

Check if Crank Handle is properly and fully

inserted into Access Slot. The crank engages

fully with the shaft only with proper orientation

of the handle.

Check if Crank’s clutch is set at minimum 50 Nm.

D. Cannot rack-in the trolley into DISCONNECT / TEST

position

Check point C.

Check if rating Rejection Interlock of the trolley

and the module match.

Check if Racking Shaft is bent.

Check if Indicator Shaft is jammed.

E. Cannot rack-in the trolley into CONNECTED

position.

Check point C.

Check if Secondary Disconnect is connected.

Check if shutters are jammed or closed.

F. Cannot rack-out the trolley from TEST position.

Check if Secondary Disconnect is disconnected.

Check if Access Lever is lifted up.

8.2 Maintenance

NOTE: See User Manual S47183De for complete breaker

inspection and maintenance routines.

Expected service life of the OEM module is 20 years, with MTBF

exceeds 2,000 racking operations. The module and trolley

construction is nearly maintenance free. The system is

designed to operate during specified period and in prescribed

conditions without functional part replacement. Only simple

preventive maintenance is recommended to be performed

every two years:

Check the racking shaft of the trolley and grease it with

molybdenum based grease, such as MOLYKOTE G4700

or NYE Rheolube® 373. Also grease racking socket in

the structure.

Check the Primary Disconnect clusters. Clean and

apply a light coating of red Mobile 28 grease,

manufactured by ExxonMobil.

Perform testing routine as listed in Appendix H, tables

H3 or H4.

Motor driven trolley

NOTE: Check points A thru F are also valid for motor driven

trolley. Refer to them in case of related issues.

G. Cannot rack-in the trolley to CONNECTED position.

Check if Access Lever is in down position.

Check if motor thermal overload protection

GPS1B is activated.

Check if end switch S4F is activated.

Check if end switch S3F is activated.

H. Cannot rack-out the trolley from CONNECTED

position.

Make sure the breaker contacts are OPEN.

Check point G.

22 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 23

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX A Module & Trolley Drawings.

Customer support

8.1 Warranty

For warranty issues or other after sales service, contact

the GE Energy GE Resolve Customer support line at :

1-888-437-3765.

8.2 Field Service Support

To request and schedule GE Energy Service Engineering

support, call :

1-800-533-5885.

8.3 Publications and other support

Instruction Books, Drawings and other technical

documents can be found and downloaded from the

GE Energy web site at

http://www.geindustrial.com

Go to: Products -> Circuit Breakers -> DC High Speed

Circuit Breakers -> Gerapid.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 23

Page 24

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX A Module & Trolley Drawings.

APPENDIX “A” – Module & Trolley Drawings

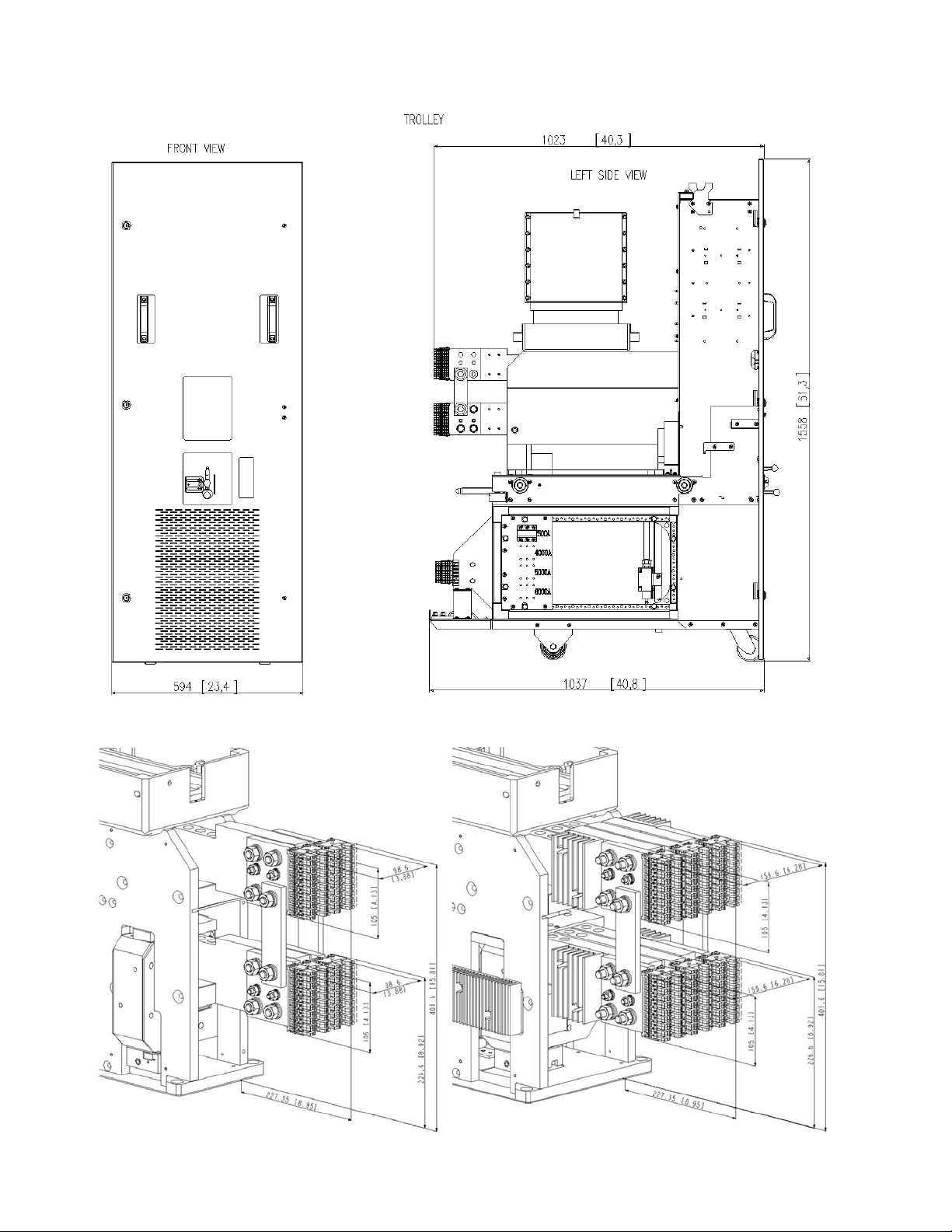

Fig. A-1 Outline dimensions of the trolley. Units are mm [inches]

Fig. A-2 Primary disconnect clusters for 2508, 4008 (left) and 5008, 6008 (right) Gerapid breakers. Units are mm [inches]

24 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 25

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX A Module & Trolley Drawings.

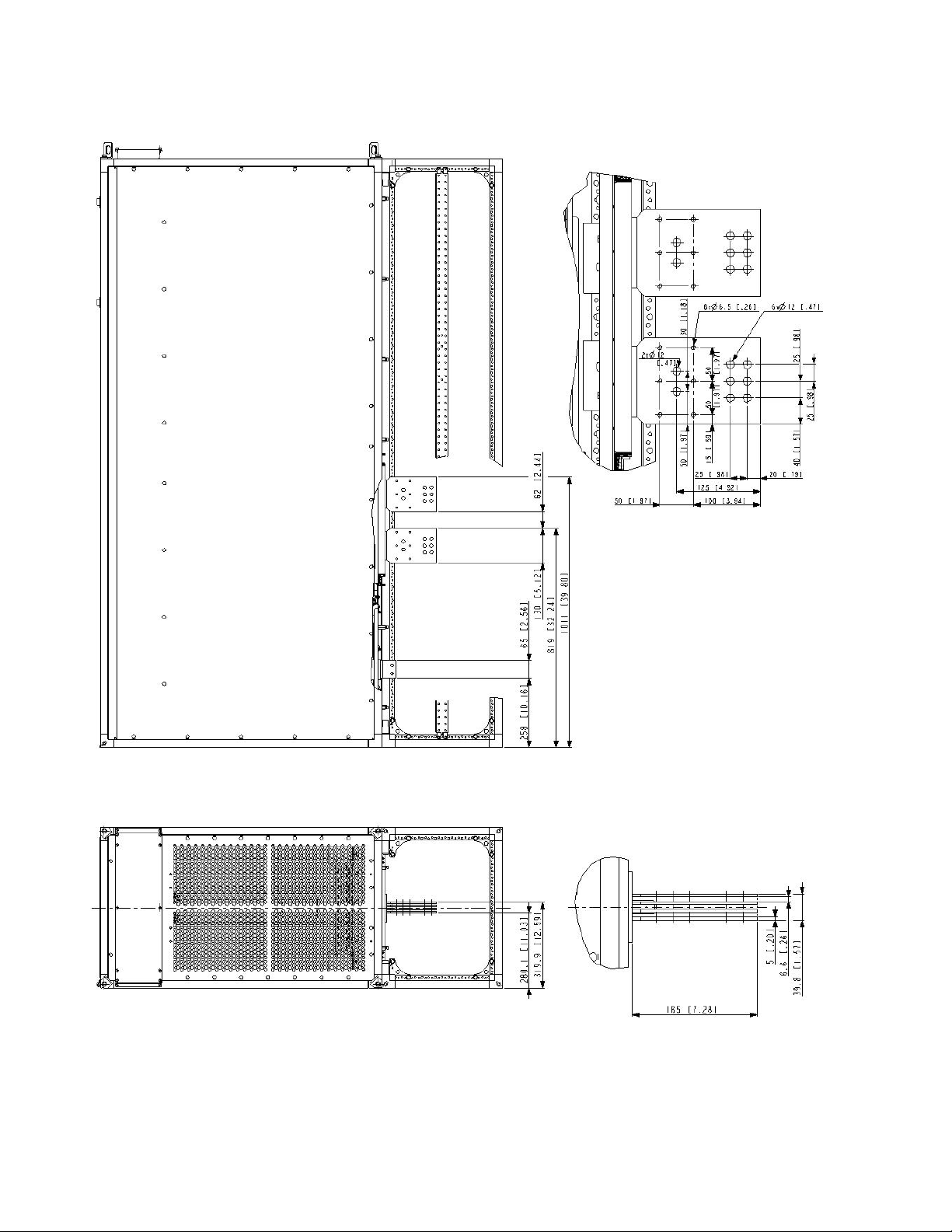

Fig. A-3 Outline dimensions for OEM Module with 750 mm [ 29.53 inches ] Cable Compartment

Fig. A-4 Outline dimensions for OEM Module with 450 mm [ 17.72 inches ] Cable Compartment

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 25

Page 26

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX B Primary Terminals Drawings.

APPENDIX B – Primary Terminals Drawings

Fig. B-1 2500A and 4000A Primary Terminals of OEM DC Module. Units are mm [inches]

26 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 27

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX B Primary Terminals Drawings.

Fig. B-2 5000A and 6000A Primary Terminals of OEM DC Module. Units are mm [inches]

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 27

Page 28

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX B Primary Terminals Drawings.

Side View

Fig. B-3 Ground bus main connection

Top View

28 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 29

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX B Primary Terminals Drawings.

APPENDIX C – Layout drawings

TOP VIEW :

Dimension A:

Dimension B:

Dimension C:

NOTE: Minium free space over the Module’s roof should be 1.5 ft.

- min. 0.3 ft

- min. 7 ft

- min. 0.3 ft in case of no need for rear access,

- min. 1.5 ft in case of need for rear access.

Trolley

Fig. C-1 Minimum required distances for installing the DC OEM Module

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 29

Page 30

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX C Layout Drawings.

APPENDIX D – Tightening Torques Tables

All the tightening torques listed below are applicable for Module, Trolley and Breaker.

Table D-1 Tightening torques for mechanical construction elements

Screw size Hex-head screws

Class 5.8

Inch-pounds Inch-pounds Inch-pounds

Less M3 3 – 4 5 - 6 -

M3 7 – 8 10 - 11 -

M3.5 9 - 10 15 - 17 8 - 10

M4 14 - 15 22 - 24 15 - 17

M5 26 - 29 44 - 49 62 - 68

M6 47 - 51 75 - 83 132 - 146

M8 106 - 117 177 - 194 177 - 194

M10 230 - 253 362 - 398 -

M12 362 - 398 620 - 681 -

M16 885 – 973 1500 - 1650 -

Hex-head screws

Class 8.8

Self-tapping

screws

Table D-2 Tightening torques for electric circuits connections

Screw size Auxiliary & control

circuits

Inch-pounds Inch-pounds

Less M3 - -

M3 9 - 10 -

M3.5 10 - 11 -

M4 13 - 15 -

M5 26 - 29 -

M6 52 - 58 71 - 78

M8 124 - 136 177 - 194

M10 230 - 253 354 - 390

M12 354 - 390 620 - 681

M16 531 - 584 1240 - 1360

Copper bus bar

connections

30 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 31

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX E Electrical Diagrams.

APPENDIX E – Electrical Diagrams

Fig. E-1 Remote Racking Module - Gerapid connections

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 31

Page 32

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX F Rating Tables.

Fig. E-2 Remote Racking Module – Control diagram

32 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 33

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX E Electrical Diagrams.

Fig. E-3 Remote Racking Module – Secondary Disconnect coding

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 33

Page 34

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX F Rating Tables.

Fig. E-4 Remote Racking Module – Wiring Harness coding

34 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 35

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX E Electrical Diagrams.

Fig. E-5 Manual Racking Module - Gerapid connections

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 35

Page 36

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX F Rating Tables.

Fig. E-6 Manual Racking Module – Control diagram

36 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 37

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX E Electrical Diagrams.

Fig. E-7 Manual Racking Module – Secondary Disconnect coding

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 37

Page 38

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX F Rating Tables.

Fig. E-8 Manual Racking Module – Wiring Harness coding

38 Design and specifications are subject to change without notice S47183Ee rev.01 2011-04-26

Page 39

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX G Accessories and Installation Drawings..

APPENDIX F – Rating Tables

Breaker Rating Gerapid 2508

Arc chute type 1x2 1x2 1x2 1x2

Rated continuous current 2,500 A 4,000 A 5,000 A 6,000 A

Rated short circuit peak/sustained current 200/120 kA 200/120 kA 200/120 kA 200/120 kA

Short circuit characteristics Duties a b, c, d Duties a b, c, d Duties a b, c, d Duties a b, c, d

Rated maximum system voltage 800 V 800 V 800 V 800 V

Power frequency withstand voltage 3,700 V / 60 sec 3,700 V / 60 sec 3,700 V / 60 sec 3,700 V / 60 sec

Maximum arc voltage 1,500 V 1,500 V 1,500 V 1,500 V

Mechanical endurance w/o maintenance* 20,000 cycles 20,000 cycles 20,000 cycles 20,000 cycles

Breaker weight 310 lbs 310 lbs 480 lbs 480 lbs

Table F-1 UL listed Gerapid Ratings according to IEEE Std. C37-14-2002

Module Rating DCOEM 4000

Rated continuous current of the primary circuit 4,000 A 6,000 A

Type of Gerapid breaker for installation 2508 & 4008 5008 & 6008

Rated short circuit peak/sustained current 200/120 kA 200/120 kA

Rated maximum voltage 800 V 800 V

Rated insulation level of the primary circuit 5,200 V d.c. 5,200 V d.c.

Rated insulation level of the secondary circuits

Mechanical endurance w/o maintenance* 500 cycles 500 cycles

Weight of the trolley without Gerapid breaker 300 lbs 300 lbs

Weight of the Module without Trolley 550 lbs 580 lbs

1,500 V

Gerapid 4008

DCOEM 6000

1,500 V

Gerapid 5008 Gerapid 6008

Table F-2 UL listed DC OEM Module. Ratings according to IEEE Std. C37.20.1-2002

No functional parts replaced during the listed number of operations. Breakers require servicing at recommended intervals.

Servicing consists of adjusting, cleaning, lubricating, tightening and similar procedures as recommended in Users Guide

S47183De.

2011-04-26 S47183Ee rev.01 Design and specifications are subject to change without notice 39

Page 40

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX G Accessories and Installation Drawings.

APPENDIX G – Accessories & Installation Drawings

Accessories