Page 1

Definite Purpose

Contactors & Starters

CR453A Series Contactors

CR454A Series Starters

Description

GE’s CR453A magnetic contactors provide a 2- or 3-pole

device for use in air conditioning units or other general

purpose applications. These instructions give information

about ratings, installation, accessories and wiring, overload

relay may be added if needed. Factory assembled starters

CR454A include overload relay.

Motor branch circuit and control circuit overcurrent

protection should be supplied in accordance with the

National Electrical Code or local code as required. CR453A

contactors are suitable for use on a circuit capable of

delivering not more than 5,000 RMS symmetrical amperes,

600 volts maximum when protected by fuses or a circuit

breaker having an interrupting rating not less than 5,000

RMS symmetrical amperes.

Use 75° C copper conductors only.

Ratings – Full Voltage, Non-Reversing

Frame

Ratings Resistive

Size

VAC

FLA LRA

Horsepower Rating Per

1 PH 3 PH Pole

120 150 2 –

CR453AB

240

25

150 3 7.5

35

480 125 – 10

600 100 – 10

120 180 2 –

CR453AC

240

30

180 5 10

40

480 150 – 15

600 120 – 15

120 240 3 –

CR453AD

240

40

240 7.5 10

50

480 200 – 20

600 160 – 20

Caution: Before installing in a nuclear application, determine that the product is intended for such use.

Warning: Disconnect power before installing or servicing.

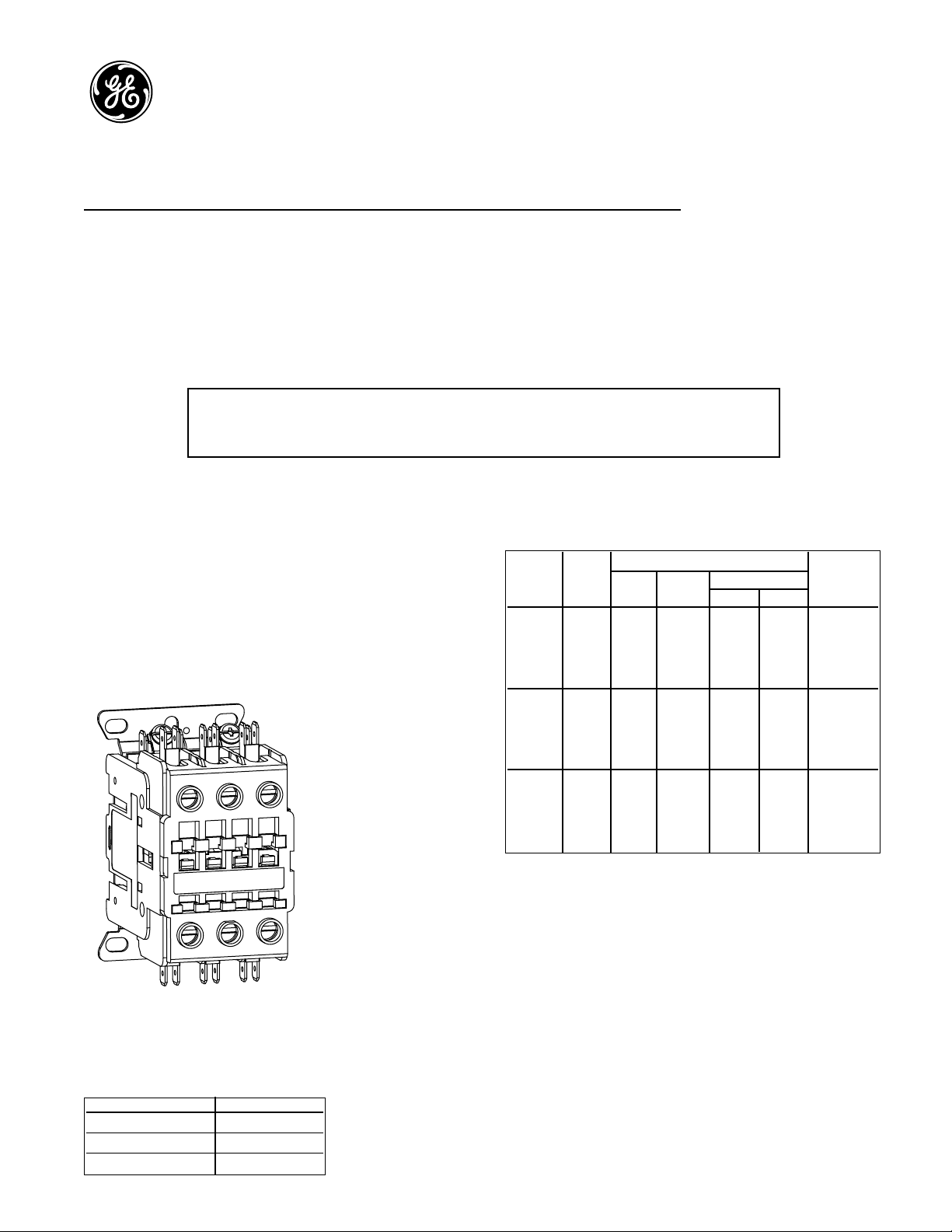

Typical CR453A Series contactor

Power Terminal Tightening Torque (lbs.-in.)

Terminal Type Torque Values

Box Lug 40

Pressure Plate 20

Binding Screw 20

Page 2

Contactor Installation

Before connecting to power supply:

1. Remove all packing.

2. Operate movable magnet and operating arm by

pressing down on the operating arm from the front

or side of the contactor to assure free movement.

3. Mount starter on a sturdy vertical support.

4. Make electrical connections as per wiring diagram.

For quick connect wiring, use UL recognized insulated

terminals.

Starter Installation

1. Remove all packing.

2. Motors with service factor of 1.15 or greater.

• Select overload relay as per the FLA shown in the

motor nameplate.

• Adjust the front mounted tripping current setting

dial to the motor FLA.

2. Motors with service factor less than 1.15

• Select overload relay as per the formula: Motor FLA

(shown in the motor plate) x 0.09.

• Adjust the front mounted tripping current setting dial

to the result of the above mentioned motor FLA.

3. Operate movable magnet and operating arm by pressing

down on the operating arm from the front or side of the

contactor to assure free movement.

4. Mount starter on a sturdy vertical support.

5. Make electrical connections as per wiring diagram.

For quick connect wiring, use UL recognized insulated

terminals.

6. Select the four modes by means of a front selector

lever.

7. Overload relays features tripping indicator, independent

& double break auxiliary tripping contacts (1NO+1NC)

with welding check lever.

8. Overload relay features thermal protection against

balanced overload, differential protection against

unbalanced overloads and also ambient temperature

compensation.

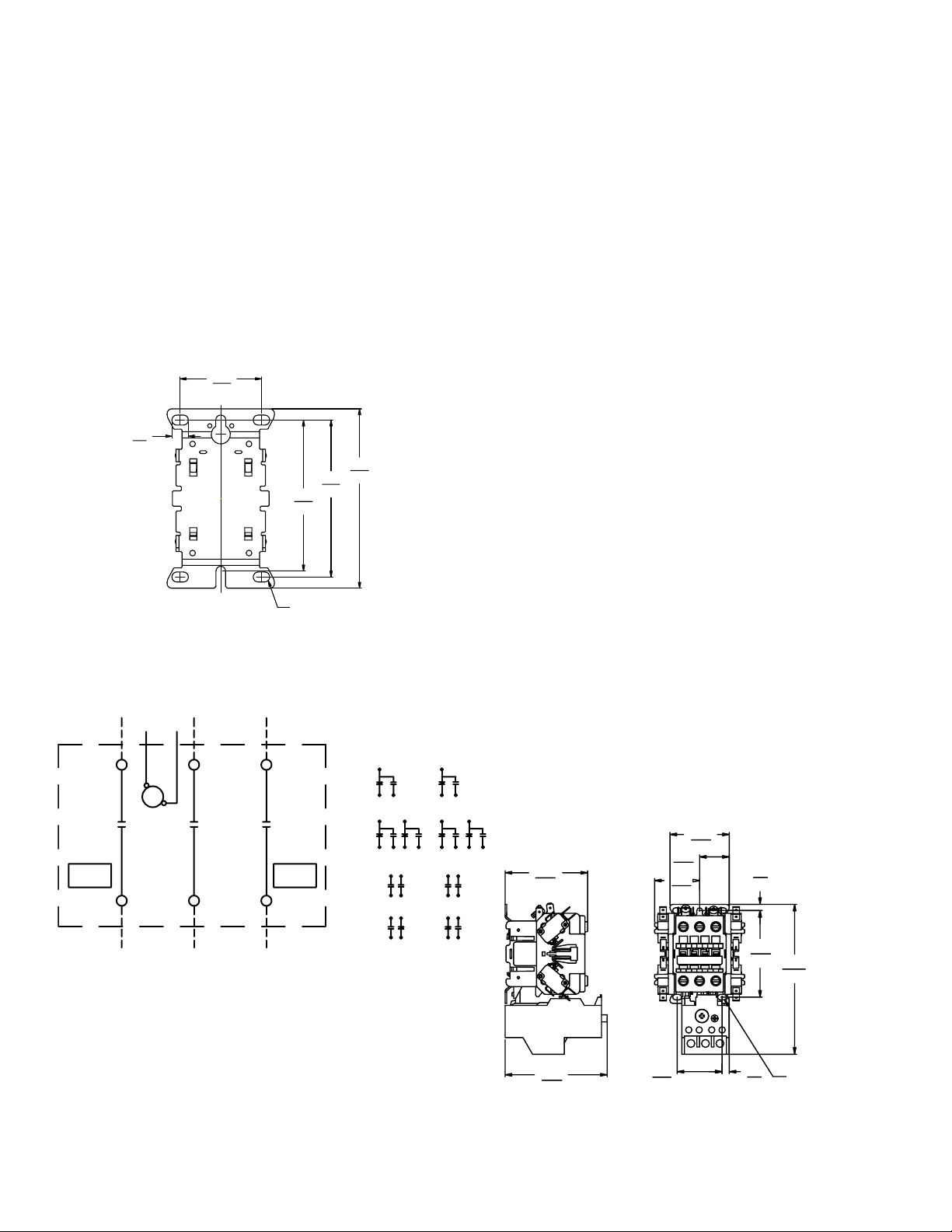

Mounting Hole Dimensions

Contactor Wiring Diagram

CR454A Series Starter Dimensions

1.70

43,2

.35

8,9

3.75

95,3

3.28

83,3

3.16

80,3

MOUNTING HOLES FOR

#10 SCREWS(6 PLACES)

3 PHASE LINE CONNECTION

CONTROL

L1 L2 L2

OPTIONAL

AUX

CONTACTS

VOLTAGE

M

T1 T2 T2

3 PHASE LINE CONNECTION

FRONT VIEW

OPTIONAL

AUX

CONTACTS

NOMENCLATURE

M-LINE CONTACTOR

NO-NORMALLY OPEN

NC-NORMALLY CLOSED

AUX CONTACT OPTONS

TYPE

LEFT

SIDE

C

1 SPDT

NC N

2 SPDT

NC N NC N

2 NO

1 NO-1 NC

RIGHT

SIDE

C

NC N

CC

C

NC N NCCN

13 23

24

131421

2214

33

34 44

31

32

2.25

57,0

1.12

43

43

44

3.13

79,4

1.71

43,3

28,5

.24

6,0

3.28

83,3

5.68

144,3

3.87

98,2

1.70

43,2

.27

6,9

MOUNTING HOLES FOR

#10 SCREWS(6 PLACES)

Page 3

CR453A Accessories Standard

Accessory Contacts (with quick connects on C-2000

side-mount accessories) accessories

600V side-mount aux. 1NO-1NC CR453XC611 BCLL11

contact block 2NO CR453XC620 BCLL20

250V side-mount aux 1 SPDT CR453XC211 —

contact block 2 SPDT CR453XC222 —

600V front-mount aux. 1NO BCLF10 BCLF10

contact block 1NC BCLF01 BCLF01

Mechanical interlock,

side-mount

2NC CR453XM602 BEL02

Accessories

Check for Welded Contacts in Overload Relay

Disconnect power from device and control wiring from the

terminals of the relay. Connect the bell set or resistance-

measuring instrument across the relay terminals. Depress

and release the reset arm to ensure the relay is reset. In this

condition there should be continuity between the terminals.

In the tripped condition, the circuit between the terminals

should be open indicating the contacts are operating

normally. Remove the bell set or resistance measuring

apparatus, rewire the relay terminals and reset the relay for

normal operation.

For further technical details on overload relays, refer to

installation instructions GEH-6237A.

Accessory Kit Installation

Overload Relays

Starter Wiring Diagram

Installation

Catalog No.

Current Range (A)

Contactor

Class 10 Class 20

RT1B RT12B 0.16-0.26

RT1C RT12C 0.25-0.41

RT1D RT12D 0.4-0.65

RT1F RT12F 0.65-1.1

RT1G RT12G 1.0-1.5

RT1H RT12H 1.3-1.9

RT1J RT12J 1.8-2.7

CR453AB, RT1K RT12K 2.5-4.1

AC, AD RT1L RT12L 4.0-6.3

RT1M RT12M 5.5-8.5

RT1N RT12N 8-12

RT1P RT12P 10-16

RT1S RT12S 14.5-18

RT1T RT12T 17.5-22

RT1U RT12U 21-26

CR453AC, AD RT1V RT12V 25-32

CR453AD RT1W RT12W 30-40

Typical 250V side auxiliary contact kit.

Typical 600V side auxiliary contact kit.

L1

WIRE B

REMOTE

CONTROL

1

OPTIONAL

AUX

CONTACTS

L1

M

96

95

98

97

T1 T2 T3

CONTROL CIRCUIT FUSING

(IF USED)

L2

L1

96

1

NOTE: ADDITIONAL CONTROL CIRCUIT PROTECTION

MAY BE REQUIRED.PREFER TO NATIONAL

ELECTRIC CODE OR LOCAL CODES.

FOR SEPERATE CONTROL SOURCE-OMIT WIRES A AND B.

CONNECT CONTROL SOURCE TO 1 ON CONTROL DEVICE.

AND 96 ON OVERLOAD RELAY.

L2

WIRE A

L2

MOTOR

L3

FRONT VIEW

L3

OPTIONAL

AUX

CONTACTS

AUX CONTACT OPTONS

TYPE

1 SPDT

2 SPDT

2 NO

1 NO-1 NC

NOMENCLATURE

M-LINE CONTACTOR

OL-THERMAL OVERLOAD RELAY

SPDT-SINGLE POLE DOUBLE THROW

NO-NORMALLY OPEN

NC-NORMALLY CLOSED

L1 L2

1

REMOTE

CONTROL

LEFT

SIDE

C

NC N

C

NC N NC N

NC N NCCN

13 23

24

131421

2214

ELEMENTARY

M

RIGHT

SIDE

C

NC N

CC

OL

33

34 44

31

32

43

43

44

9695

Page 4

GE Industrial Systems

General Electric Company

41 Woodford Avenue, Plainville, CT 06062

www.GEindustrial.com

© 2001 General Electric Company

e-DEH-40445 0801

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection

with installation, operation or maintenance. Should particular problems arise which are not covered sufficiently for the Purchaser’s purposes the

matter should be referred to the nearest GE Industrial Systems sales office.

Front-Mount Auxiliary Contacts Side-Mount Auxiliary Contacts

Overload Relays

Disassembly

Mechanical

interlock

2-Speed Controllers

Assembly

1

2

Loading...

Loading...