Page 1

CPS6000-M2 Frame-Mounted Battery Plant

Model H5694720

Product Manual

Select Code 167-793-112

Comcode CC848802595

Issue 8

January 2008

Page 2

Notice:

The information, specifications, and procedures in this manual are subject to change

without notice. Lineage Power assumes no responsibility for any errors that may appear

in this document.

© 2008 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 3

CPS6000-M2 Installation Guide H5694720

Table of Contents

1 Introduction.................................................................................................................... 5

Document Objectives...................................................................................................... 5

Additional Product Documentation ................................................................................ 5

Customer Service Contacts............................................................................................. 6

2 Product Description....................................................................................................... 7

Architecture..................................................................................................................... 8

Millennium II Controller................................................................................................. 9

Rectifier Shelves ........................................................................................................... 10

QS-Series Rectifiers...................................................................................................... 12

QS-Series Ringers......................................................................................................... 12

AC Input........................................................................................................................ 14

Battery Options and Monitoring Features..................................................................... 14

DC Distribution and Battery Termination .................................................................... 15

Specifications................................................................................................................ 16

3 Safety............................................................................................................................. 21

Safety Statements.......................................................................................................... 21

Warning Statements and Safety Symbols..................................................................... 23

Precautions.................................................................................................................... 24

Handling Batteries ........................................................................................................ 25

Special Installation Notes ............................................................................................. 26

4 Installation.................................................................................................................... 28

Preparation .................................................................................................................... 28

Anchoring Frame .......................................................................................................... 31

Connecting Frame Ground............................................................................................ 32

Connecting Central Office Ground (COG)................................................................... 33

Connecting AC Utility .................................................................................................. 34

Installing Batteries ........................................................................................................ 35

Installing and Wiring DC Loads................................................................................... 40

Installing QS-Series Rectifiers...................................................................................... 44

Installing QS-Series Ringers......................................................................................... 46

Controller Connections ................................................................................................. 48

Installing Optional Circuit Packs.................................................................................. 55

5 Controller User Interface............................................................................................ 63

Controller Display Menu Maps .................................................................................... 70

Minimum Controller Configuration.............................................................................. 74

Controller Defaults........................................................................................................ 79

Web Interface................................................................................................................ 84

6 Acceptance Testing ...................................................................................................... 89

7 Troubleshooting ........................................................................................................... 92

Troubleshooting Controller Circuit Pack...................................................................... 99

Modem and Data Switch Cards .................................................................................... 99

Controller Alarm Descriptions.................................................................................... 100

Clear Events................................................................................................................ 104

Issue 8 January 2008 3

Page 4

CPS6000-M2 Installation Guide H5694720

Uninstall Devices........................................................................................................ 105

Troubleshooting QS-Series Rectifiers ........................................................................ 105

Troubleshooting QS-Series Ringers ........................................................................... 107

Troubleshooting VT-Probes........................................................................................ 109

8 Ordering Information and Spare Parts .................................................................. 110

9 Product Warranty...................................................................................................... 118

Appendix A: Battery Functions................................................................................... 120

Appendix B: EasyView for Windows®........................................................................ 127

Appendix C: Upgrading Software Through Network Connection Or Craft Port.. 130

Revision History............................................................................................................ 134

Issue 8 January 2008 4

Page 5

CPS6000-M2 Installation Guide H5694720

1 Introduction

Document Objectives

This manual provides installation and maintenance information for the Lineage Power

CPS6000-M2 power system:

• Product Description

• Safety Information

• Installation Procedures

• Test and Acceptance

• Troubleshooting

• Controller and Rectifier Operations

• Product Warranty

Audience

Equipment Installers – Instructions for installation, test, and acceptance.

Equipment Users – Plant basics and troubleshooting.

CAUTION: This unit must be installed, serviced, and operated only by

skilled and qualified personnel who have the necessary knowledge and

practical experience with electrical equipment and who understand the

hazards that can arise when working on this type of equipment.

Applications

The 48V CPS6000-M2 is ideally suited for small central office (CO) applications and high end

huts and vaults.

Additional Product Documentation

For additional specification, engineering and installation information, refer to the following

drawings as needed. These drawings may be accessed on our web site at

http://lineagepower.com/. Click on Energy Systems Products/CPS6000 Plants.

Drawing Description

H5694720 Ordering Guide

167-790-063 Remote Peripheral Monitoring (RPM)

157-010-202 210E Thermal Probe Multiplexer Module

167-792-182 Advanced Features User Guide For The

Millennium II

Issue 8 January 2008 5

Page 6

CPS6000-M2 Installation Guide H5694720

Customer Service Contacts

Customer Service, Technical Support, Product Repair and Return, and Warranty Service

For customers in the United States, Canada, Puerto Rico, and the US Virgin Islands, call 1-800THE-1PWR (1-800-843-1797). This number is staffed from 7:00 am to 5:00 pm Central Time

(zone 6), Monday through Friday, on normal business days. At other times this number is still

available, for emergencies only. Services provided through this contact include initiating the

spare parts procurement process, ordering documents, product warranty administration, and

providing other product and service information.

For other customers worldwide the 800 number may be accessed after first dialing the AT&T

Direct country code for the country where the call is originating, or you may contact your local

field support center or your sales representative to discuss your specific needs.

Customer Training

Lineage Power offers customer training on many Power Systems products. For information call

1-972-284-2163. This number is answered from 8:00 a.m. until 4:30 p.m., Central Time Zone

(Zone 6), Monday through Friday.

Downloads and Software

To download the latest product information, product software and software upgrades, visit our

web site at

http://lineagepower.com/

Issue 8 January 2008 6

Page 7

CPS6000-M2 Installation Guide H5694720

2 Product Description

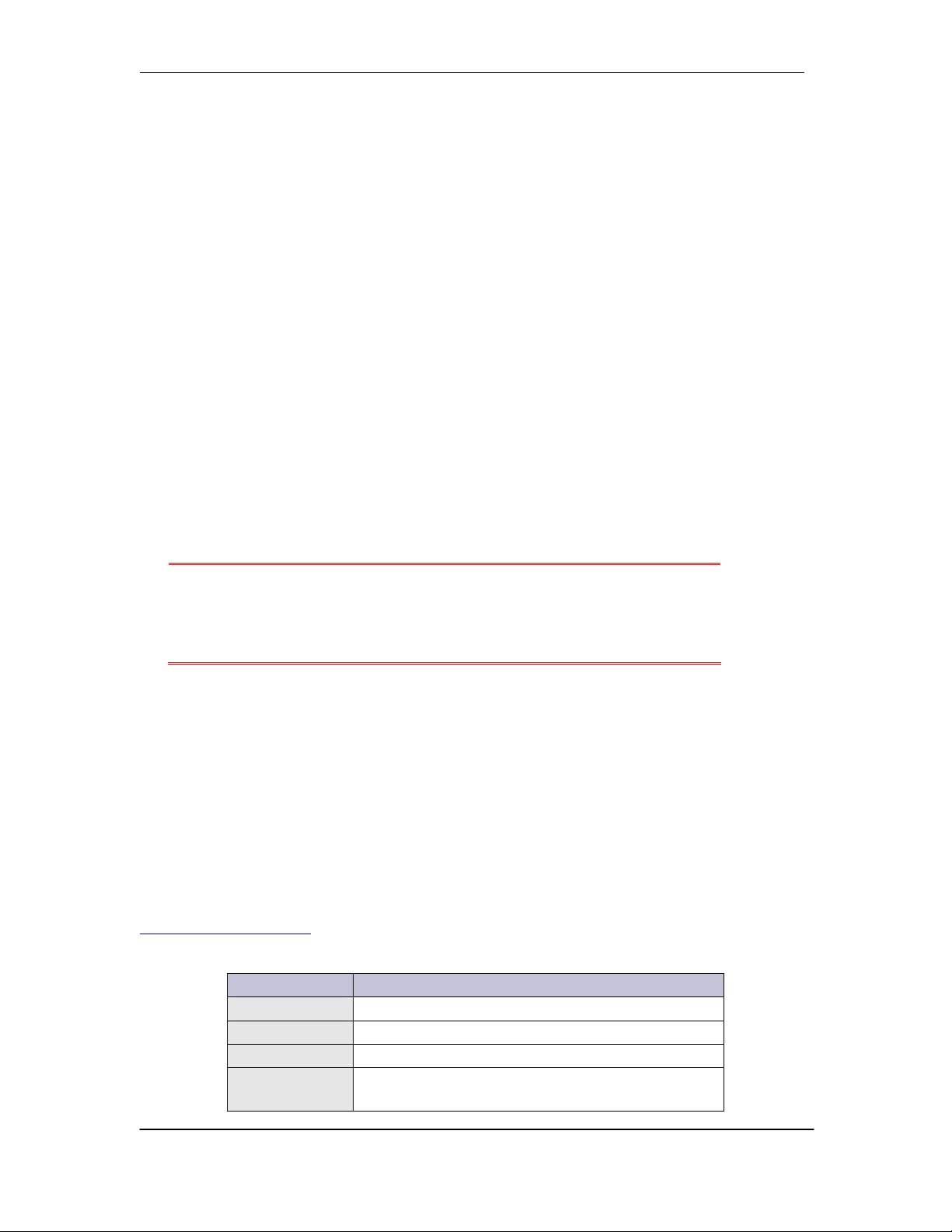

The 48V CPS6000-M2 Power Plant is a 23 inch wide, front access, frame mounted battery plant.

The system integrates QS series vertical airflow rectifiers and ringers, dc distribution options,

battery connections and the Galaxy Millennium II controller in 500A and 1000A capacity

systems. System dimensions are 25.5 inches wide, 15 inches deep and 29.8 inches tall (500A

system) or 38.5 inches tall (1000A system). This allows the system to be mounted in either a 42

inch (1/2 height) frame for mounting on a battery stand or Unigy battery stack or in a 7 foot (full

height) framework with battery trays.

The system operates directly from commercial power in 208/220/240Vac single phase @

50/60Hz. 110Vac operation is also available with some rectifiers. AC connects to a terminal

block panel at the top of the system.

48V CPS6000-M2 DC Power System Configuration

Issue 8 January 2008 7

Page 8

CPS6000-M2 Installation Guide H5694720

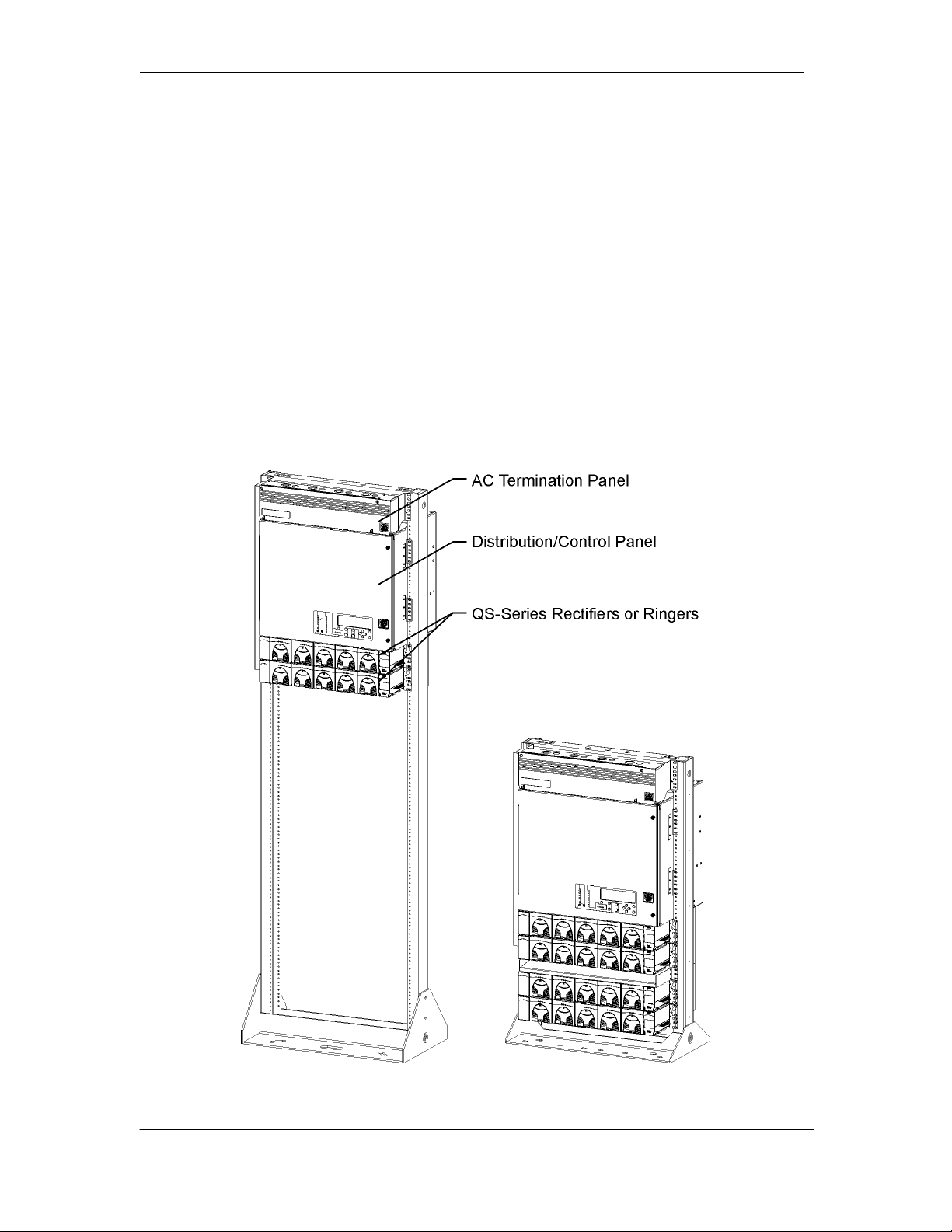

Architecture

The plant architecture is shown in the diagram below. The CPS6000-M2 System rectifiers accept

alternating current (ac) power and produce a regulated dc -48V nominal voltage distributed to

float the batteries, power the controller and power the loads through distribution circuit breakers

or fuses. Batteries are used to provide backup dc power when the ac is lost. They are connected in

parallel with the rectifiers through either optional battery breakers or a low voltage disconnect

(LVD). AC power is distributed to each rectifier through ac terminal blocks located in the ac

termination panel at the top of the frame. The Millennium II system controller monitors and

controls system operation.

CPS6000-M2 Block Diagram

Issue 8 January 2008 8

Page 9

CPS6000-M2 Installation Guide H5694720

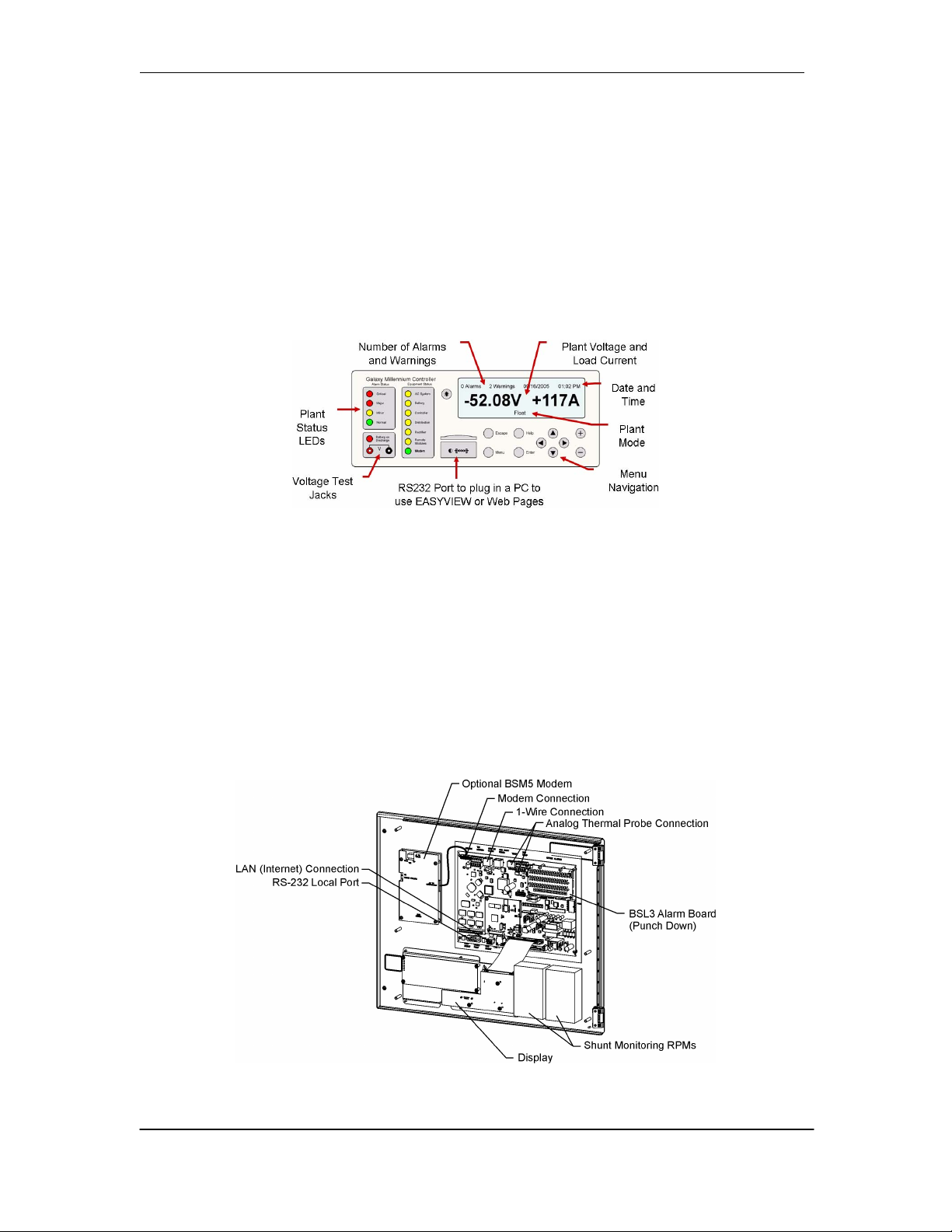

Millennium II Controller

The Millennium II controller is located on the door of the dc distribution. It uses an RS485 bus to

serially monitor and control rectifiers, ringers and peripheral modules called RPM’s. It can also

monitor and control external power equipment, including standby generators, converter plants,

and inverters.

Local viewing and setting of system parameters and various alarm thresholds, user-definable

alarm inputs and relays can be accessed either by a LCD graphics display with intuitive

navigation mounted on the front door of the system or by the local RS-232 port connected to a

notebook computer.

Remote access is available through a 10/100 Base-T network connection to the world wide web

(internet) or your enterprise network (intranet) using standard browsers such as Microsoft Internet

Explorer® or Netscape® Navigator. There is also an optional BSM5 56k bps modem available.

The controller performs various battery management functions to ensure peak performance and

protection from thermal issues. In addition to monitoring for open battery breakers, measuring

current from the battery shunt and monitoring and control of a optional low voltage battery

disconnect contactor, the controller also measures battery string temperature and voltage with

either traditional analog thermistor based temperature probes or digital QS873 Voltage/Thermal

Probes (VT Probes) for slope thermal compensation. The VT probes connect in a daisy-chain

fashion with one probe mounted to the negative post of each mid-string battery using the serial 1Wire® bus.

Issue 8 January 2008 9

Page 10

CPS6000-M2 Installation Guide H5694720

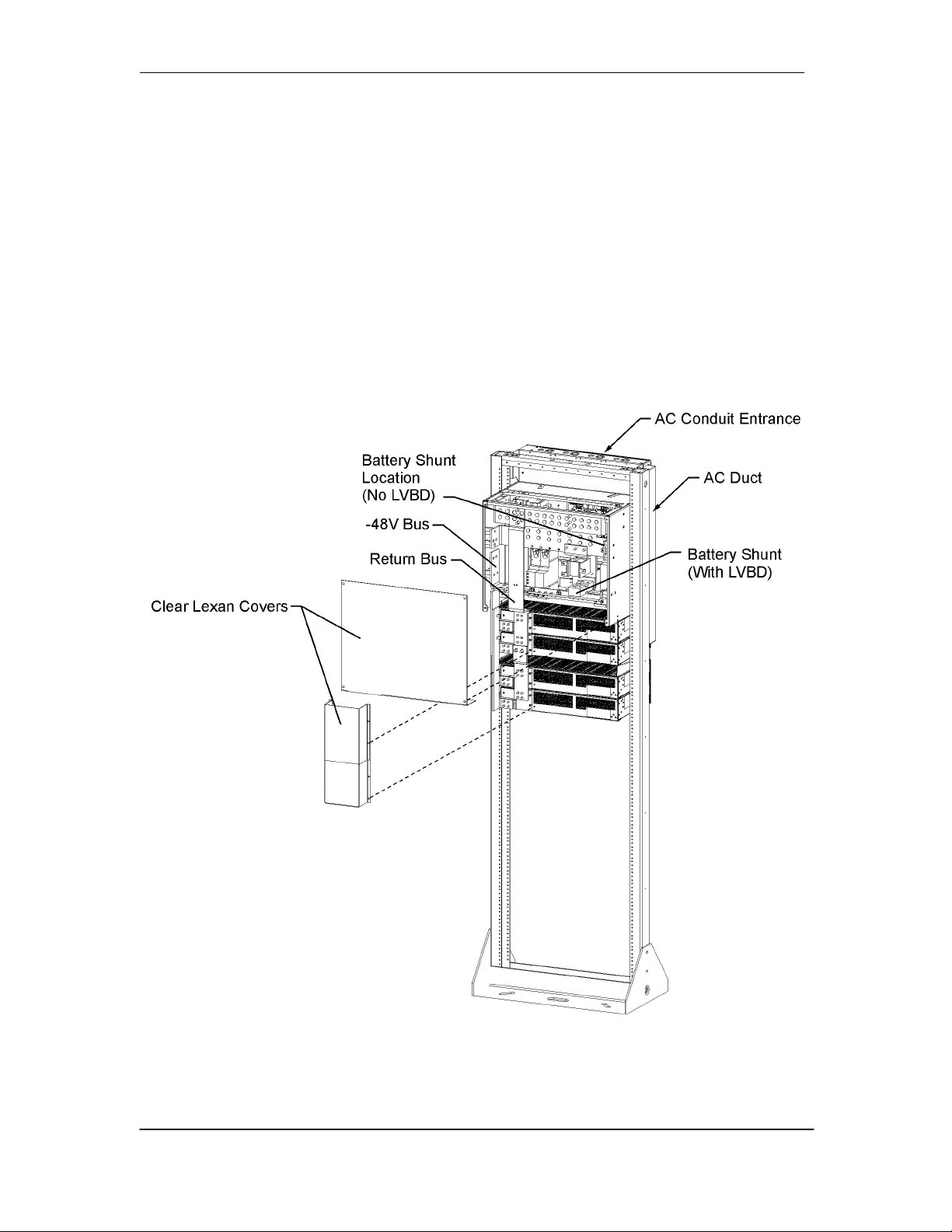

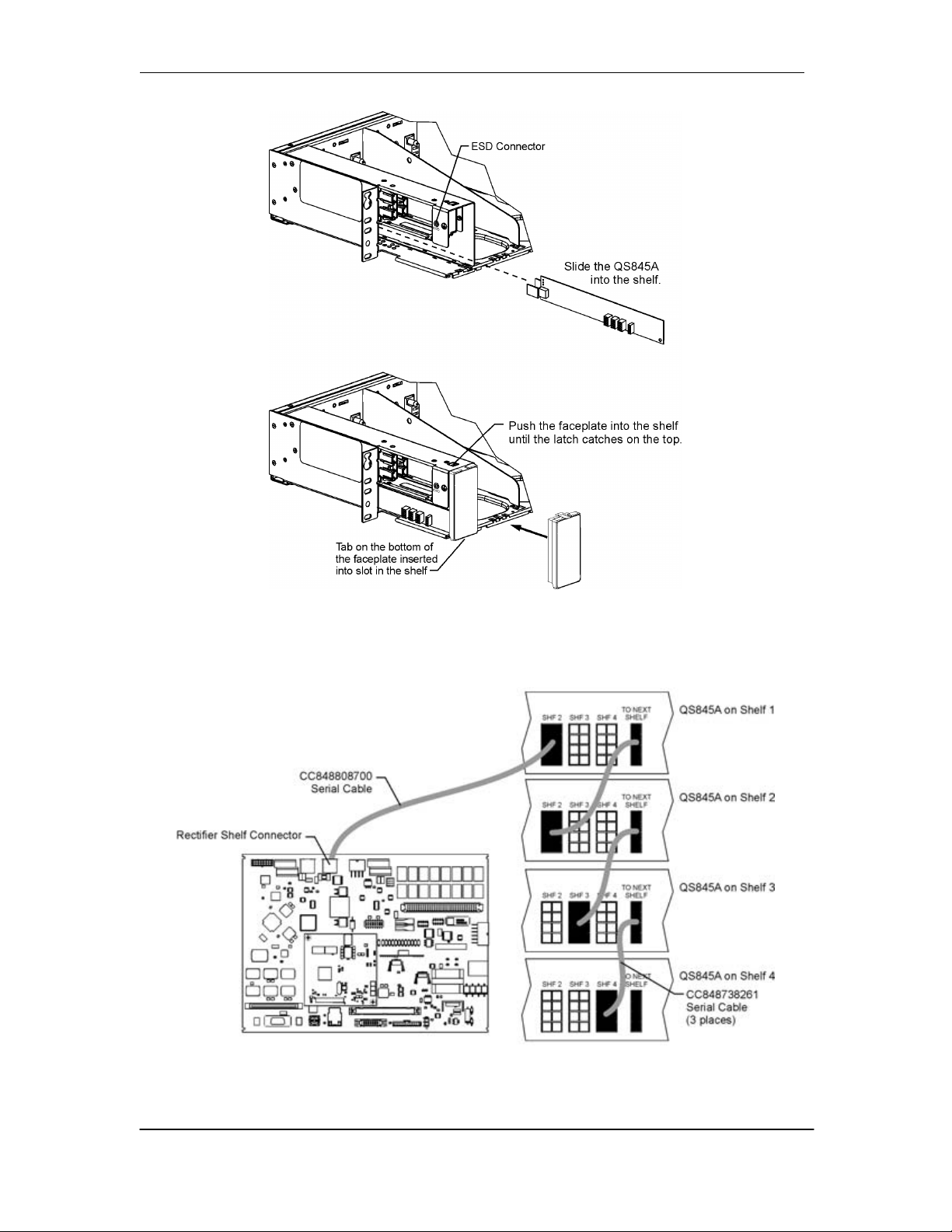

Rectifier Shelves

Rectifier shelves are equipped in either two shelf (500A system) or four shelf (1000A

system) arrangements. DC output from each rectifier is bused up the back to the

distribution and protected by clear lexan covers. Individual AC feeds from terminal

blocks in the ac box route down the ac duct to a connector on each shelf. Serial

communication cables daisy-chain from QS845A interface boards on the left side of each

shelf and up to the controller.

The system is designed to allow field upgrades from two shelf to four shelf systems. This

can be safely accomplished on working systems because the new shelves are first

installed and then bus and cable links added.

DC Bussing to Rectifier Shelves (Rear View)

Issue 8 January 2008 10

Page 11

CPS6000-M2 Installation Guide H5694720

QS845A Rectifier Interface Board Access

Rectifier Communication Connections

Issue 8 January 2008 11

Page 12

CPS6000-M2 Installation Guide H5694720

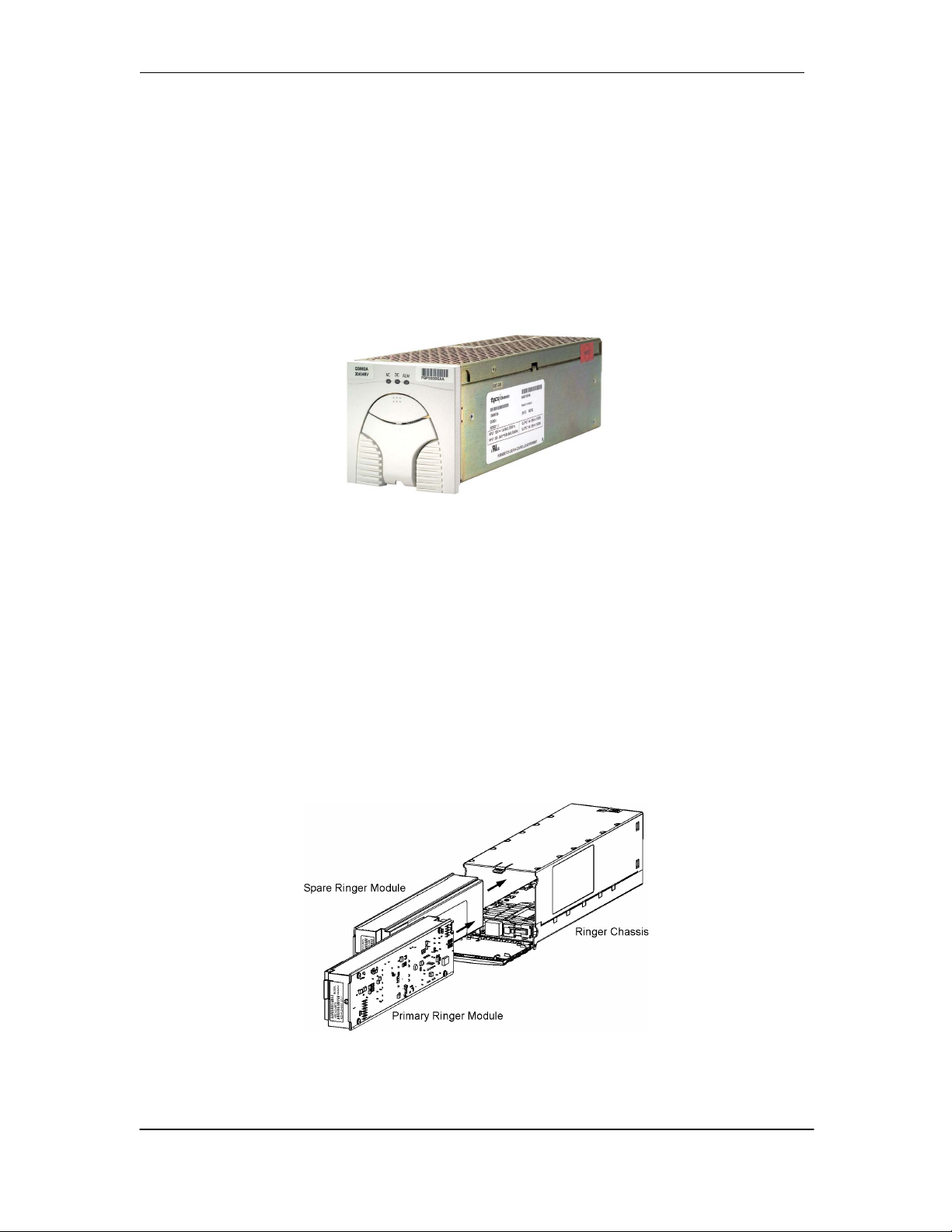

QS-Series Rectifiers

These constant power rectifiers are hot pluggable for quick installation. All interconnections (AC

input, DC output, and control) are made automatically during insertion. The rectifiers

communicate with the controller via a digital RS-485 serial cable allowing all rectifier settings to

be made automatically by the controller. Load-share circuits allow all rectifiers to apportion the

plant load equally, reducing the stress on individual units. The rectifier uses temperature

dependent variable speed fans to provide vertical flow cooling. QS-series of rectifiers are

available in 15A and 25A operating from 85VAC to 275VA and 20A, 30A, 40A, and 50A

operating from 150VAC to 275VAC.

QS-Series Rectifier

QS-Series Ringers

QS820A Ringers convert -48Vdc to a 100VA ringing power output with configurable ac voltage,

ac frequency, and dc offset. A ringer chassis may be installed in the two rightmost positions of

any rectifier shelf. Each ringer chassis includes two vertical airflow fans, accepts up to two

QS820A ringers, a primary and a spare, and provides a single ringing output. Install one ringer

for non-redundant (simplex) operation and two ringers for redundant (duplex) operation. Should

the primary ringer fail or be removed, the ringer output is provided by the spare ringer. The

controller provides ringer output voltage and frequency settings, status and alarm communication.

If communication is lost, the ringers continue to operate with the last received configuration.

QS820A Ringers and QS820M Chassis

Issue 8 January 2008 12

Page 13

CPS6000-M2 Installation Guide H5694720

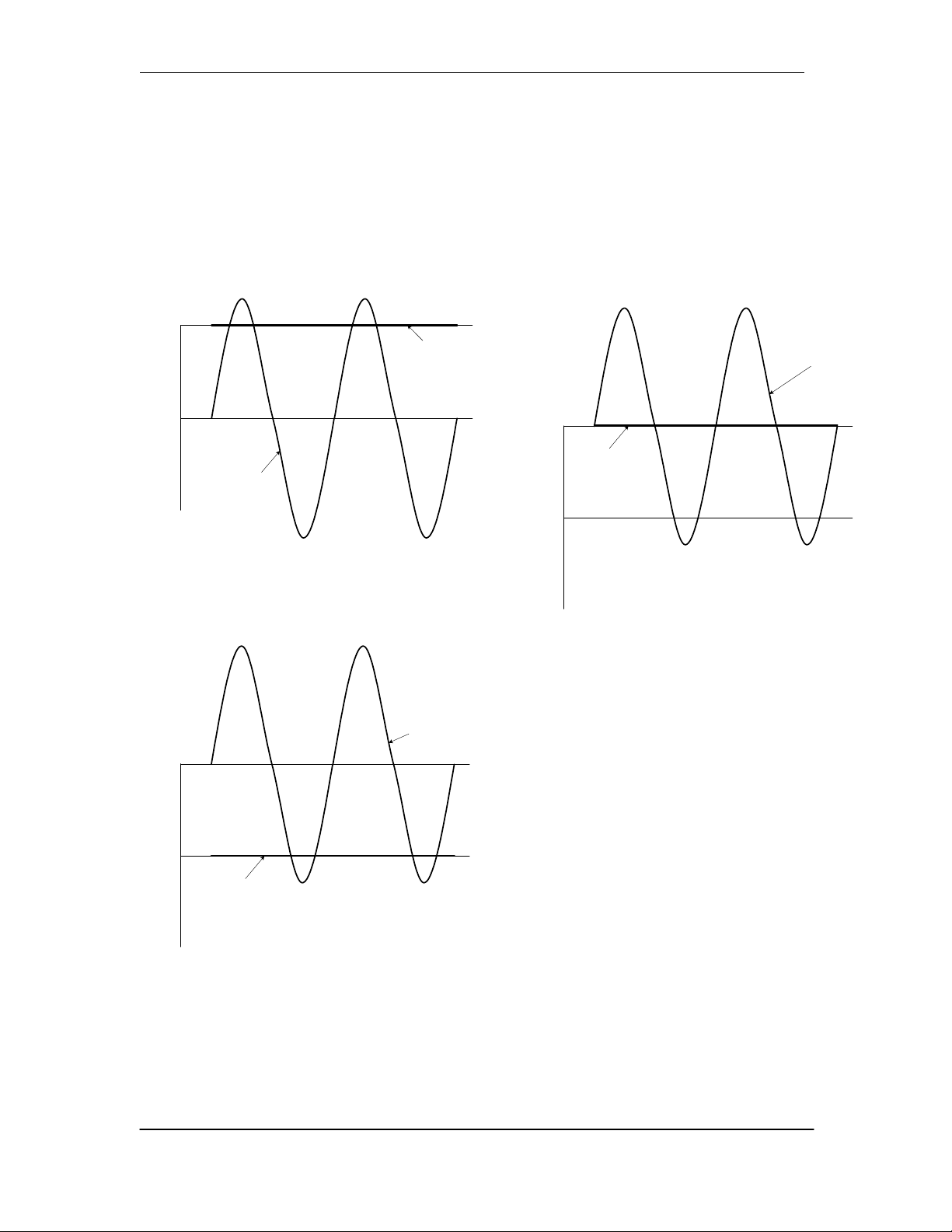

Types of Ringing

QS820 Ringers can be configured to provide one of three types of ringing: Battery Backed,

Ground Backed, and Ground Backed-no dc. Ringing type is selected with jumper J12 on the

chassis and by enabling or disabling dc Offset in the controller

Ground

(VBUS+)

Ring Return

tied to VBUS+

Voltage

(Tip wire)

Ring

(Ring wire)

-48Vdc

(VBUS-)

Ground

(VBUS+)

-48Vdc

(VBUS-)

Voltage

Ring

(Ring wire)

Battery Backed

(Common in USA)

Ring

(Ring wire)

Ground

(VBUS+)

-48Vdc

(VBUS-)

Ring Return

tied to VBUS+

(Tip wire)

Voltage

Ground Backed

No dc

Ring Return

tied to -48Vdc

(Tip wire)

Ground Backed

Ring Signaling Types

Issue 8 January 2008 13

Page 14

CPS6000-M2 Installation Guide H5694720

AC Input

• Connects to AC termination

panel at the top of the

system.

• One 1-inch conduit per

shelf.

• Each rectifier fed

individually by 10 gage wire

protected with a 20A circuit

breaker or fuse.

Battery Options and Monitoring Features

Battery Options

• Designed for operation with Flooded, VRLA,

NiCad, and Lithium batteries (Nickel metal

Hydride in the future).

• Half-height systems mount on Unigy II

batteries, Full Height systems may be

equipped with battery trays.

• Battery trays available for up to 170Ahr

batteries with Anderson PowerPole®

connectors or circuit breaker disconnects.

Battery Monitoring Features

• Open String (OS) Alarms

• Emergency Power Off (EPO) for

disconnecting batteries from the system

• Temperature/voltage probes (up to 16) used in

Battery Management options

Slope Thermal Compensation

Battery High Temp Disconnect

• Battery Discharge Test

• Battery Shunt

Low Voltage Battery Disconnect/Reconnect Contactor (LVBD)

Issue 8 January 2008 14

Page 15

CPS6000-M2 Installation Guide H5694720

DC Distribution and Battery Termination

Group 660 Option

• Two 19 position bullet

distribution panels each

rated at 400A.

• 12 pair of battery landings

for battery cables up to

350Kcmil. (6 pair with

750Kcmil cable) 3/8” studs

on 1” centers

• 8 position center section for

optional 800A Low Voltage

Battery Disconnect

(LVBD), GJ type circuit

breakers with 25mV shunts

or TPL-C fuse blocks with

1500A, 50mV shunts.

Group 661 Option

• One 19 position bullet

distribution panel rated at

400A.

• One fuse panel rated at

600A equipped with 4 TPS

fuses with 100A, 50mV

shunt monitoring and 4

TPL-B fuses with 600A,

50mV shunt monitoring

• RPM shunt monitoring for

fuse panel and up to 4

center TPL-C fuse blocks

with 1500A, 50mV shunt

monitoring

• 12 pair of battery landings

for battery cables up to

350Kcmil. (6 pair with

750Kcmil cable) 3/8” studs

on 1” centers

• 8 position center section for

optional 800A Low Voltage

Battery Disconnect

(LVBD), GJ type circuit

breakers with 25mV shunt

or TPL-C fuse blocks with

1500A, 50mV shunt.

Issue 8 January 2008 15

Page 16

CPS6000-M2 Installation Guide H5694720

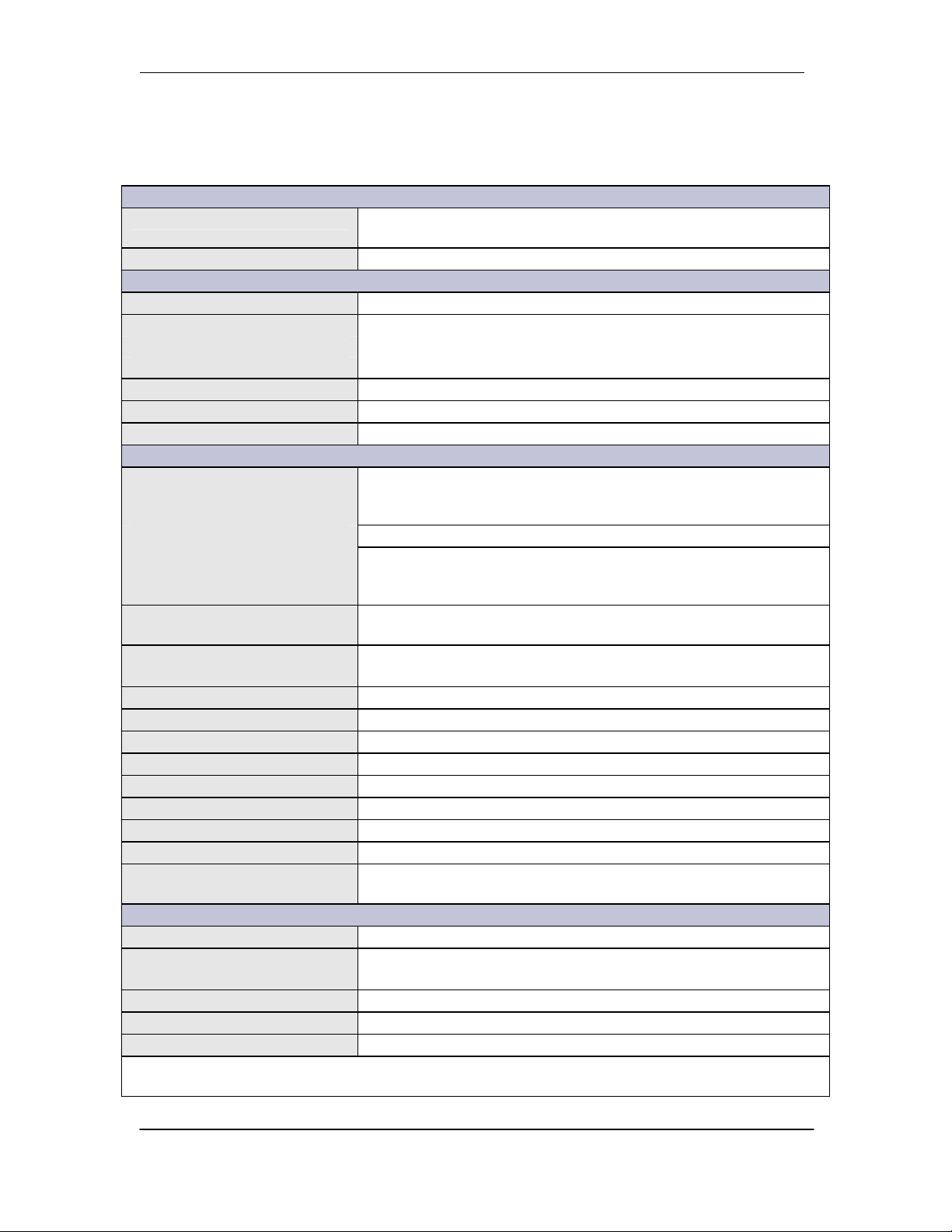

Specifications

AC Input

Input Distribution

Wire Size 10 AWG minimum for individual feeds.

System Voltage -48V

Maximum Output Current:

Two Rectifier Shelves (G255) 450A charge, 500A discharge

Four Rectifier Shelves (G256) 800A charge, 1000A discharge

Maximum Recharge Current Installed rectifier capacity minus plant -48V load

Low-Voltage Disconnect 39 to 50 Vdc

Low-Voltage Reconnect 39 to 55 Vdc

Safety Agency Approvals

VDE licensed to VDE0805/EN60950

European Economic Community

(EEC) Directives

Radiated and Conducted

Emissions

Harmonics EN61000-3-2 (IEC61000-3-2)

Voltage Fluctuations EN61000-3-3 (IEC61000-3-3)

Electromagnetic Immunity Meets Telcordia GR-1089-CORE

Electrostatic Discharge EN61000-4-2 Level 3

RF Immunity IEC61000-4-3 Level 3, 10 V/m

EFT IEC61000-4-4 Level 3, No Error; Level 4, No Damage

Surge IEC 61000-4-5 Level 3, No Error; Level 4, No Damage

Conducted Immunity IEC 61000-4-6 Level 3, 10V

Voltage Dips, Interruptions, and

Variations

Operating Ambient Temperature -20 to 45 °C

Altitude -200 to 13,000 feet (-61 to 3962 meters)

Humidity 10% to 95% non-condensing

Audible Noise < 60 dBA

Earthquake Rating Zone 2 or Zone 4, upper floors, depending on battery configuration

Note 1: For altitudes above 5000 feet, derate the temperature by 3.6 °F per 1000 feet. For altitudes above

1524 meters, derate the temperature by 0.656 degrees Celsius per 100 meters.

Terminal Blocks per rectifier fed from 20A breaker or fuse at the AC

service panel.

System Output

Safety / Standards Compliance

Underwriters Laboratories (UL) Listed per Subject Letter 1801: Power

Distribution Center for Communications Equipment, and cUL Certified

(CSA 22.2 950): Safety of Information Technology Equipment

Rectifiers are individually UL Recognized (UL1950), cUL Certified

(CSA 22.2 234) or evaluated to EN60950 by an EC Notified Body, as

appropriate.

EMC Directive 89/336/EEC, Low Voltage Directive 73/23/EEC as

amended by Marking Directive 93/68/EEC

FCC Part 15, Class A

EN55022 (CISPR22), Class A

IEC 61000-4-11

Environmental

See Note 1

Issue 8 January 2008 16

Page 17

CPS6000-M2 Installation Guide H5694720

Installation Category

CPS6000-M2 is suitable for connection to ac utility systems where the expected level of lightning

surges complies with ANSI C62.41 Category B or IEC 60664-1 Overvoltage Category II.

A service entrance surge protector is required in applications where the installation categories can

not be classified as being compliant to either ANSI C62.41 Category B or IEC 60664-1

Overvoltage Category II.

CPS6000-M2 rectifiers have been tested for repeated lightning surges typically found in an

Overvoltage Category III installation; however, a service entrance surge protector is

recommended in cabinet applications to bring the power feeds in compliance to the installation

categories above. The service entrance protection should be coordinated with the protection

provided in the power modules.

The power module provides common-mode protection via a 320V MOV in series with a 2500V

gas-discharge device and differential-mode protection via a 320V MOV in series with a 3.5A fuse

Issue 8 January 2008 17

Page 18

CPS6000-M2 Installation Guide H5694720

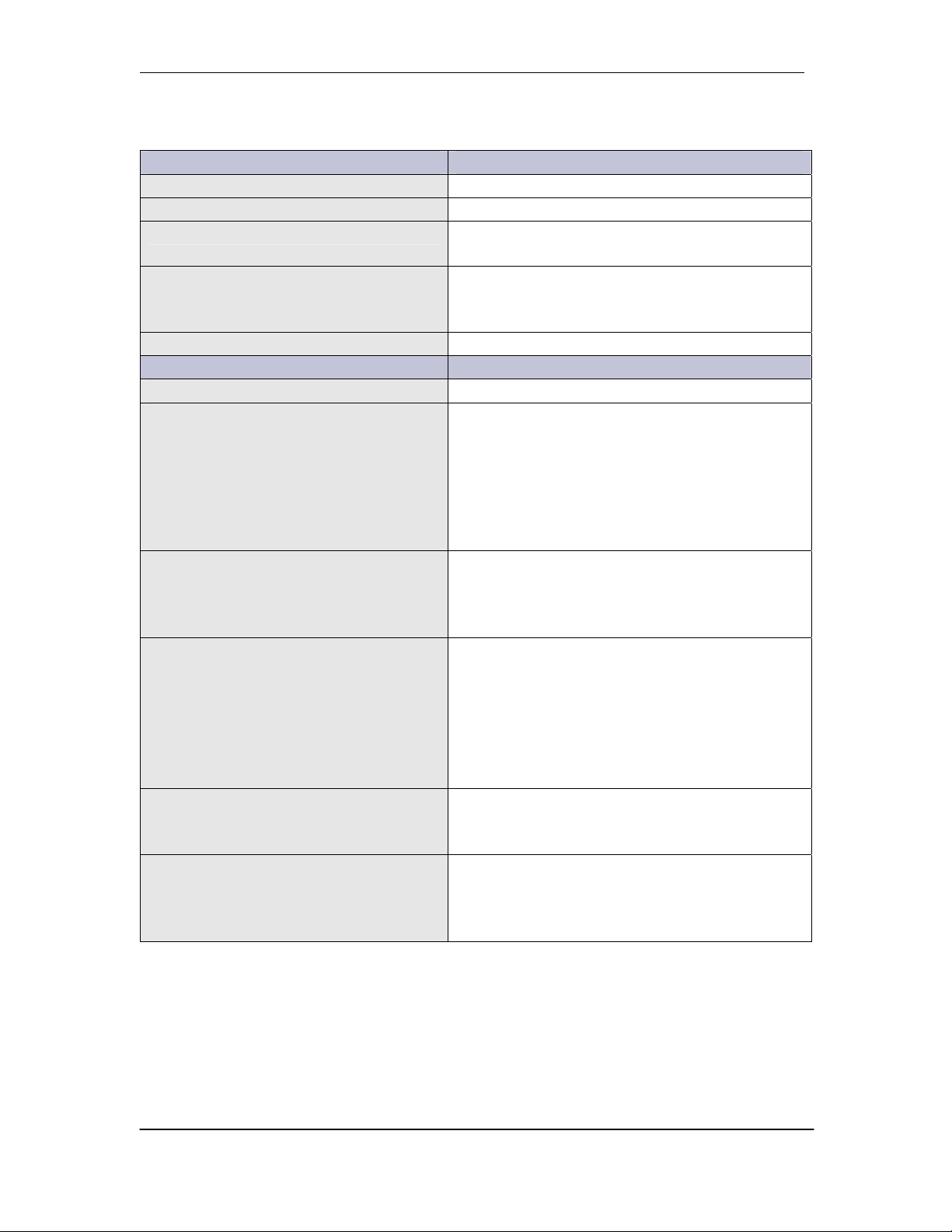

Millennium II Controller

General Specifications

Input Voltage Range -48 Vdc (Range: 18-60V)

Maximum Input Power 36W depending upon options

Display Graphic displayed arranged to

8-line by 40-character backlit LCD

Configuration Method Through front panel LCD display and menu keys

Through IBM compatible PC with RS-232 port

Through LAN internet connection

Mounting Requirements Door mounted

Input/Outputs Specifications

Form C Alarm Output Contact Ratings 60VDC at 0.5A

Plant Voltage Measurement

Accuracy

0 to 50 °C (±.05% of full scale + 1

count)

-40 to 85 °C (±0.1% of full scale + 1

count)

Resolution

Plant Current Measurement

Accuracy

Resolution

Temperature Measurement

Accuracy

Thermistor temperature

One-Wire Serial probes

Resolution

4-20mA Input Monitor

Accuracy

Resolution

General (0-5V) Input

Accuracy

Resolution

48V Systems: ±40 mV

48V Systems: ±70 mV

0.01V

0 to +50 °C : ±0.5% of full scale

-40 to +85 °C: ±1.25% of full scale

1A

-5 to +55 °C: ±2°C

-40 to +85 °C: ±3°C

-5 to +55 °C: ±1°C

-40 to +85 °C: ±3°C

0.1°C

±100µA

±10.0µA

0 to +50 °C: ±0.5% of full scale

-40 to +85 °C: ±1.0% of full scale

0.01VDC

Issue 8 January 2008 18

Page 19

CPS6000-M2 Installation Guide H5694720

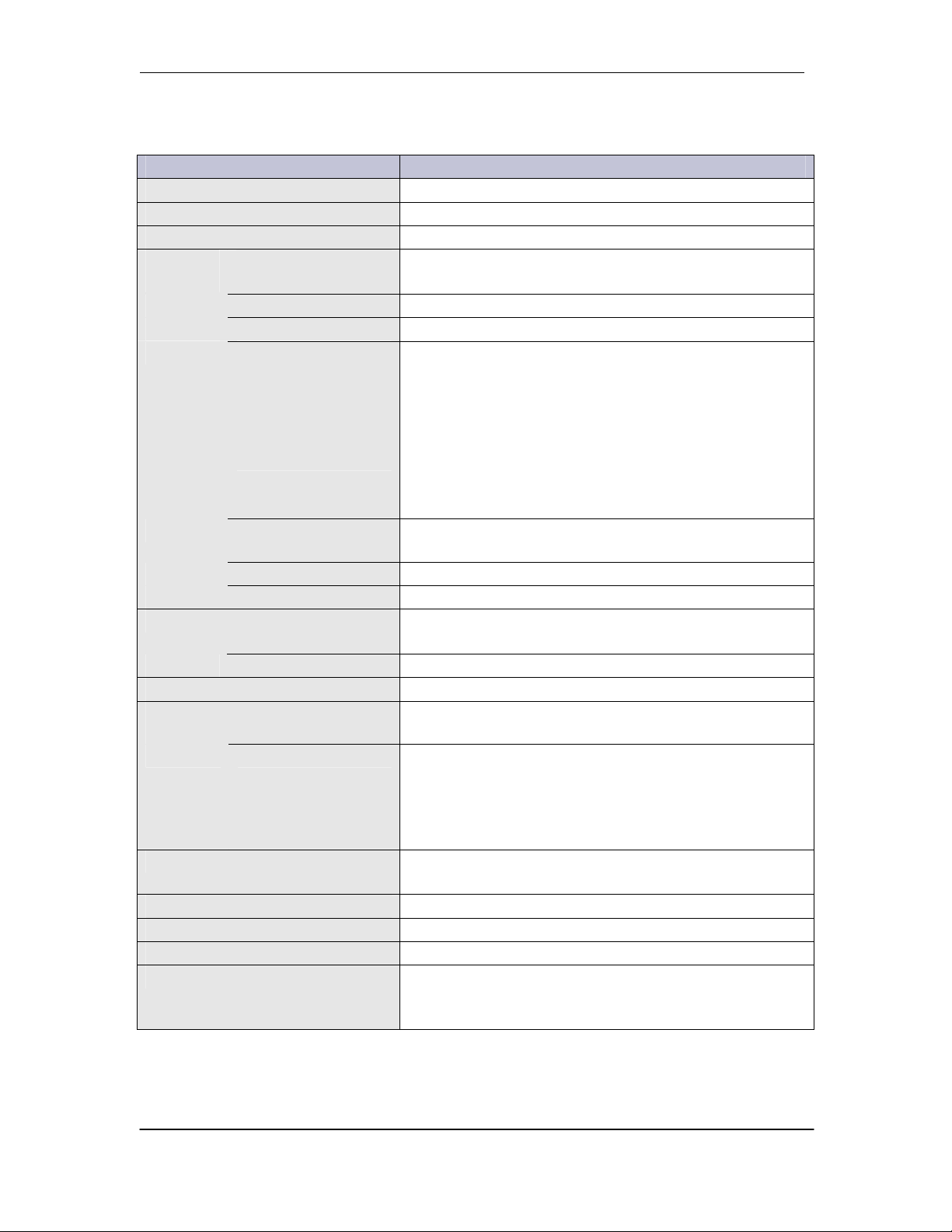

Rectifiers

Item Specification

Nominal Output Voltage 48/52/54.5 Vdc

Operating Output Voltage

42 to 58 Vdc

Ranges

Boost Voltage 48 to 58 Vdc

Output Current QS861A: 0 to 15A at 54.5V

QS862A: 0 to 30A at 54.5V

QS852A: 0 to 20A at 54.5V

QS853A: 0 to 25A at 54.5V

QS864A: 0 to 40A at 54.5V

QS865A: 0 to 50A at 54.5V

Nominal Input Voltage QS861A: 100/120/208/240

Vac

QS862A: 100/120/208/240

Vac

Input Voltage Ranges QS861A: 85 to 275 Vac

(Shutdown from 135 to

150V)

QS862A: 85 to 275 Vac

QS852A: 208/240 Vac

QS853A: 208/240 Vac

QS864A: 208/240 Vac

QS865A: 208/240 Vac

QS852A: 150 to 275 Vac

QS853A: 150 to 275 Vac

QS864A: 150 to 275 Vac

QS865A: 150 to 275 Vac

(Shutdown from 135 to

150V)

Input Current QS861A: 8A at 120 Vac

4.4A at 208 Vac

QS862A: 13A at 120 Vac

8.8A at 208 Vac

QS852A: 7.4A at 208 Vac

QS853A: 7.4A at 208 Vac

QS864A: 11.8A at 208 Vac

QS865A: 14.5A at 208 Vac

Operating Frequency Range 45 to 66 Hz

Operating Temperature -40 to +65 °C

Output Voltage Regulation ±0.5%

Output Noise, Ripple 250 millivolts peak to peak maximum, over the range dc to

100 MHz

Load Share Accuracy 1.5A maximum deviation between rectifiers

Heat Dissipation at Full Load QS861A: 141W (480 BTU) per rectifier at 120 Vac operation

160W (546 BTU) per rectifier at 240 Vac operation

QS862A: 177W (604 BTU) at 100 to 120 Vac operation

212W (724 BTU) at 200 to 240 Vac operation

QS852A: 133W (454 BTU) per rectifier at 240 Vac operation

QS853A: 151W (515 BTU) per rectifier at 240 Vac operation

QS864A: 240W (819 BTU) per rectifier at 240 Vac operation

QS865A: 267W (911 BTU) per rectifier at 240 Vac operation

Selective High-Voltage

Above 58 Vdc

Shutdown

Backup High-Voltage

Above 60 Vdc for 1 millisecond

Shutdown

Issue 8 January 2008 19

Page 20

CPS6000-M2 Installation Guide H5694720

Ringers

Item Specification

Input Voltage -40 to -57 Vdc See Output VA Thermal Limiting.

Nominal Input Voltage -48 Vdc

Input Current 5 A max.

Output

Voltage

ac tolerance ± 5 Vac

Regulation ±5% ac component only

dc Offset

dc Offset Tracking

Harmonic Distortion 5% THD

Crest Factor 1.21 to 1.51

Output Frequency 15 to 50 Hz

Frequency tolerance ± 1 Hz

Output

VA

Thermal Limiting Output VA may be reduced by reducing Vac when

Load Power Factor Operating: 0.5 Leading to 0.9 Lagging

Operating Temperature -40 to +75 °C See Output VA Thermal Limiting.

Heat Dissipation 50 W (170 BTU / hr)

Under Voltage Shutdown 50% of Output Vac Set Point

ac Component

Type of ringing

Battery Backed

Ground Backed

Ground Backed no-dc

65 to 100 Vac

Factory Default: 100Vac

• -40 to +57 Vdc Battery Backed

• +40 to +57 Vdc Ground Backed

• 0 Vdc Offset Disabled

• dc Offset tracks dc Input Voltage

• Factory Default: Enabled

• Battery or Ground Backed is selected by Ringer

Chassis jumper J12 or by external connection of Ring

Rtn to Battery or to Ground. Factory Default: Battery

Backed by Jumper

± 3 Vdc

Error

Factory Default: 20 Hz

100 VA

operating simultaneously above 50°C and less than

-50Vdc input.

Vac is reduced only sufficiently to prevent damage to the

ringer.

No Damage: 0 Leading to 0.7 Lagging

While shutdown due to external fault, restart will be

performed at approximately 2 minute intervals.

Issue 8 January 2008 20

Page 21

CPS6000-M2 Installation Guide H5694720

3 Safety

Safety Statements

Please read and follow all safety instructions and warnings before installing, maintaining, or

repairing the CPS6000-M2 System:

• The CE Mark demonstrates compliance with the European Union Council Directives for

Low Voltage and EMC.

• The CPS6000-M2 platform is Underwriters Laboratories (UL) Listed per Subject Letter

1801, DC Power Distribution Centers for Telecommunications Equipment.

• CPS6000-M2 shelves equipped with QS820A ringers have hazardous secondary voltages

on the secondary bus output connectors.

• Install only in restricted access areas (dedicated equipment rooms, equipment closets, or the

like) in accordance with articles 110-16, 110-17, and 110-18 of the U.S. National Electric

Code (NEC), ANSI/NFPA No. 70, and pursuant to applicable local codes.

• This equipment is to be used in controlled environments (an area where the humidity is

maintained at levels that cannot cause condensation on the equipment, the contaminating

dust is controlled, and the steady-state ambient temperature is within the range specified).

• This equipment has been evaluated for continuous use in ambient temperature from -40°C

to 65°C.

• This equipment must not be installed over combustible surfaces.

• For installations in the United States, Listed compression connectors are to be used to

terminate Listed field-wired conductors where required. For all installations, the

appropriate connector is to be applied only to the correct size conductor as specified by the

connector manufacturer, using only the connector manufacturer's recommended tooling or

tooling approved for that connector.

• If the proper connector for the country of installation is not provided, obtain appropriate

connectors and follow manufacturer’s and all local requirements for proper connections.

All national and local rules and regulations should be followed when making field

connections.

• The main output voltage (48V) meets SELV requirements.

• Insulation on field-wired conductors should be rated no less than 90° Celsius. Wire

conductor size should be sized per electrical codes for 75° Celsius wire, and based on the

ampacity of the associated protection device. Wiring internal to enclosed equipment

cabinets should be rated at 105° Celsius (minimum).

Issue 8 January 2008 21

Page 22

CPS6000-M2 Installation Guide H5694720

• Torque electrical connections to the values specified on labels or in the product

documentation.

• Battery input cables must be dressed to avoid damage to the conductors (caused by routing

around sharp edges or routing in areas where wires could get pinched) and undue stress on

the connectors.

• Alarm contacts on the office alarm board are not fused; therefore, current limiting

protection for these contacts must be provided by external circuits. Maximum ratings for

alarm connections are 60Vdc and 0.5 amperes. Exceeding these maximum ratings could

result in fire or damage to the unit.

• Fuse and/or circuit breaker loads must not exceed 80% of the fuse and/or circuit breaker

current rating. Distribute loads across the panel.

• The short circuit current capability of the battery input to the distribution panel must not

exceed 10,000A.

• AC branch circuits to this equipment must be protected with either fuses or circuit breakers

sized as required by the National Electric Code (NEC) and/or local codes. The maximum

size of the over-current protector is based on the type of shelf. Refer to the equipment

ratings to assure rating of equipment will not exceed 80% of the value of the protector

chosen.

• High leakage currents are possible due to contribution from simultaneous multiple AC

input connections. Earth ground connection is essential before connecting the ac source to

the shelf. This connection must be achieved by ensuring that the C.O. grounding stud is

connected as shown in the Installation Section, or quality service personnel shall ensure

that the rack system is bonded per the provision below.

• An accessible ac disconnect/protection device to remove power from the equipment in the

event of an emergency must be provided. Disconnect all AC branch circuits prior to making

AC connections.

• Installing fuses or circuit breakers not specified for use in these distribution modules may

result in injury to service personnel or equipment damage. Use only replacement parts

listed in this manual and on the equipment drawings.

• The telecom-type (e.g., GMT type) fuses can produce sparks during interruption or clearing

of a fault on a high energy circuit. Use only fuses provided with safety caps for this type of

circuit. Installing telecom-type fuses not equipped with safety caps may result in injury to

service personnel.

• While installing batteries, follow all safety precautions outlined in the appropriate battery

product manuals.

Issue 8 January 2008 22

Page 23

CPS6000-M2 Installation Guide H5694720

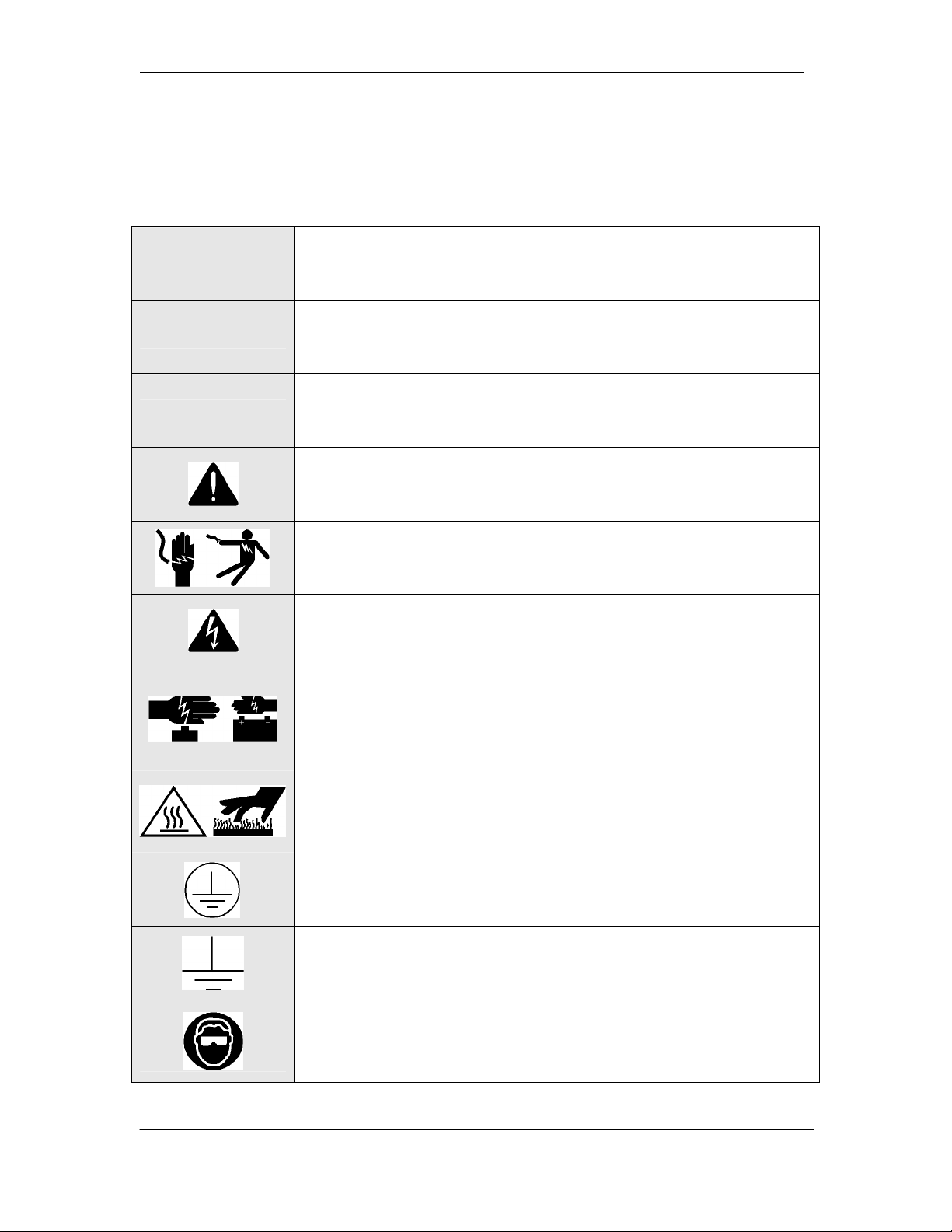

Warning Statements and Safety Symbols

The symbols may sometimes be accompanied by some type of statement; e.g., “Hazardous

voltage/energy inside. Risk of injury. This unit must be accessed only by qualified personnel.”

Signal words as described below may also be used to indicate the level of hazard.

Indicates the presence of a hazard that will cause death or severe personal

DANGER

WARNING

CAUTION

injury if the hazard is not avoided.

Indicates the presence of a hazard that can cause death or severe personal

injury if the hazard is not avoided.

Indicates the presence of a hazard that will or can cause minor personal

injury or property damage if the hazard is not avoided.

This symbol identifies the need to refer to the equipment instructions for

important information.

These symbols (or equivalent) are used to identify the presence of

hazardous ac mains voltage.

This symbol is used to identify the presence of hazardous ac or dc

voltages. It may also be used to warn of hazardous energy levels.

One of these two symbols (or equivalent) may be used to identify the

presence of rectifier and battery voltages. The symbol may sometimes be

accompanied by some type of statement, for example: “Battery voltage

present. Risk of injury due to high current. Avoid contacting conductors

with non-insulated metal objects. Follow safety precautions.”

One of these two symbols may be used to identify the presence of a hot

surface. It may also be accompanied by a statement explaining the hazard.

A symbol like this with a lightning bolt through the hand also means that

the part is or could be at hazardous voltage levels.

This symbol is used to identify the protective safety earth ground for the

equipment.

This symbol is used to identify other bonding points within the

equipment.

This symbol is used to identify the need for safety glasses and may

sometimes be accompanied by some type of statement, for example:

Issue 8 January 2008 23

“Fuses can cause arcing and sparks. Risk of eye injury. Always wear

safety glasses.”

Page 24

CPS6000-M2 Installation Guide H5694720

Precautions

When working on or using this type of equipment, the following precautions should be noted:

• This unit must be installed, serviced, and operated only by skilled and qualified personnel

who have the necessary knowledge and practical experience with electrical equipment and

who understand the hazards that can arise when working on this type of equipment.

• The equipment could be powered by multiple ac inputs. Ensure that the appropriate circuit

protection device for each ac input being serviced is disconnected before servicing the

equipment. Do not disconnect permanent bonding provisions unless all ac inputs are

disconnected.

• High leakage currents may be possible on this type of equipment. Make sure the equipment

is properly safety earth grounded before connecting power.

• Batteries may be connected in parallel with the output of the rectifiers. Turning off the

rectifiers will not necessarily remove power from the bus. Make sure the battery power is

also disconnected and/or follow safety procedures while working on any equipment that

contains hazardous energy/voltage.

• Hazardous energy and voltages are present in the unit and on the interface cables that can

shock or cause serious injury. Follow all safety warnings and practices when servicing this

equipment. When equipped with ringer modules, hazardous voltages will be present on the

ringer output connectors.

In addition to proper job training and safety procedures, the following are some basic precautions

that should always be used:

• Use only properly insulated tools.

• Remove all metallic objects (key chains, glasses, rings, watches, or other jewelry).

• Wear safety glasses. Fuses can produce sparks. High energy levels on buses and

distribution components can produce severe arcing.

• Test circuits before touching.

• Lock out and tag circuit breakers/fuses when possible to prevent accidental turn on.

• Be aware of potential hazards before servicing equipment.

• Identify exposed hazardous electrical potentials on connectors, wiring, etc. (note the

condition of these circuits, especially wiring).

• Use care when removing or replacing covers; avoid contacting circuits.

Issue 8 January 2008 24

Page 25

CPS6000-M2 Installation Guide H5694720

Handling Batteries

• To direct attention to the possible source of danger from battery gases, post one or more

warning signs, lettered in large characters, in a conspicuous location near the battery. For

example:

• Fully brief anyone who is permitted access to battery areas on the hazards of handling lead-

acid batteries. Make it clear to anyone handling, unpacking, or installing lead-acid batteries

that they contain electrolyte (sulfuric acid and water). Everyone must wear protective

equipment such as rubber gloves, rubber aprons, full face mask, and splash-proof goggles

when performing any activity involving handling of batteries or cells containing electrolyte.

• A storage battery gives no indication by its appearance of the potential energy stored in it.

All lead-acid storage cells/batteries have enormous short circuit capability which can result

in serious burns. Use extreme care to avoid shorting out cell and/or battery terminals.

Shorting a cell or battery with a non insulated tool can vaporize or throw the tool.

• All lead-acid batteries generate hydrogen gas, even under open circuit conditions. If not

permitted to escape, this gas can build up to explosive concentrations. NEVER tamper with

or block the vent caps of the 12IR125 battery modules. A damaged gas vent cap could

become clogged, resulting in an explosion due to internal pressure. Such an explosion could

short circuit other battery modules and result in a fire. ALWAYS place batteries in a wellventilated area. NEVER place battery modules in a sealed environment.

• In case of electrolyte contact with the skin, remove the electrolyte immediately by flushing

the affected area with large amounts of plain tap water. In case of electrolyte in the eye,

pour water into the inner corner of the eye and allow at least one quart of water to run over

the eye and under the eyelid. Eye injuries should be treated by a physician immediately.

Issue 8 January 2008 25

Page 26

CPS6000-M2 Installation Guide H5694720

Special Installation Notes

Deutsch

• Installationsanleitung

• Eingangsspannung ( Voltage ) : 120/200-240VAC , DC 54VDC

Eingangsstrom ( Current ) : <15A per rectifier, DC 15A-1000A

Eingangsleistung ( Watts ) :

Nennfrequenz ( Frequency ) : 50 / 60 Hz

• Seriennummer ( Assembly No. ): J5694720

• Modellnummer (Modell No. ) : H5694720

• Abmessungen sind nur zur Referenz : 978mm x 648mm x 381mm

( Dimensions are for reference only )

• Max. Umgebungstemperatur : max. 45 deg. C

( Max. Operation temperatur )

• Achtung: Für kontinuierlichen Feuerschutz sollte die Sicherung nur mit einer des

gleichen Types ersetzt werden.

Sicherungswert :

( Warning : For continued protection against fire replace with same type and rating of

fuse )

• Das System ist ein Gerät der Schutzklasse I / Überspannungs Kategorie II

( Power Supply is a Class I equipment / overvlotage category II )

• Ausgangsspannungen und -stöme: DC 58 V / SELV

( Output Voltage and Current )

• --Das Gerät darf nur in Räumen mit beschränktem Zutritt aufgestellt werden.

( Nur ausgebildetes Personal )

• --Nur für Aufstellung auf Boden oder einer anderen brennbaren Oberfläche

geeignet.

• --Das Gerät hat keinen eigenen Ausschalter, es muß daher mit einem Ein- und

Ausschalter im Versorgungskreis versehen sein.

• --Das Gerät ist für den Einbau in IT- Geräte in einem Rahmen bestimmt (siehe weitere

Anleitung)

• --Beim Einbau des Gerätes ist daraf zu achten das alle Anforderungen gemäß EN60950

eingehalten werden.

ACHTUNG: HOHER ABLEITSTROM

VOR ANSCHLUSS AN DEN VERSORGUNGSSTROMKREIS

UNBEDINGT ERDUNGSVERBINDUNG HERSTELLEN

Issue 8 January 2008 26

Page 27

CPS6000-M2 Installation Guide H5694720

Espanol

Notas especiales para instalaciones en países de habla hispana

• Instrucciones de instalación (Installation Instructions)

• Voltaje (Voltage): 120/200-240VAC

• Corriente (Current): <15A per rectifier

Frecuencia (Frequency): 50/60Hz

• Voltaje y corriente de salida (Output Voltage and Current): 54VDC, 15A-1000A

Temperatura máxima de operación (Maximum Operation Temperature):

45°C (113°F)

• Sin cabina contra incendios, suelo no combustible

(No fire enclosure, non-combustible floor)

• Evaluado en EN60950

(Evaluated to EN60950)

Issue 8 January 2008 27

Page 28

CPS6000-M2 Installation Guide H5694720

4 Installation

This section describes the following installation sequence for the CPS6000-M2 power system.

1. Preparations

2. Anchoring frame

3. Connecting frame ground

4. Connecting CO ground

5. Connecting ac utility

6. Installing batteries

7. Wiring dc loads and installing fuses/circuit breakers

8. Installing rectifiers and converters

9. Controller Connections

10. Starting Up System

Preparation

Safety

Please review all safety warnings in Section 3 before beginning the installation process. Observe

all warnings and labels on the equipment.

WARNING: Due to the possibility of working on energized circuits during these

procedures, all tools and test equipment must be insulated in an approved manner.

Proper ESD protection is required in order to prevent ESD damage to the

equipment.

WARNING: Only qualified personnel should install and service the power

system and plug-in modules. Hazardous energy and voltages are present in the

unit and on the interface cables and will shock or cause serious injury or death if

safety precautions are ignored. Follow all safety warnings and practices when

servicing this equipment.

Issue 8 January 2008 28

Page 29

CPS6000-M2 Installation Guide H5694720

Wiring Guidelines

• All electrical connections should be made using the proper crimping tools and dies and

should be torqued to values specified.

• All building wiring should comply with the NEC and other applicable local codes.

• The temperature rating of the wire must be 90°C minimum.. Wire gauge must be sized based

on 75°C wire and the ampacity of the associated branch-circuit protection.

• Wiring internal to enclosed equipment cabinets must be rated no less than 105° Celsius.

Packaging

• All packages should be opened with a box cutter with the blade minimally exposed so that

only the sealing tape is cut.

• Save all packaging material until the system has been powered up and all parts are operating

within specifications.

Installation Tools

You will need the following tools to install and test the CPS6000-M2 System.

• Wire cutters and strippers

• Heat shrink gun

• 5/16-inch (8 mm) hex driver

• Digital meter with an accuracy of

±0.02%

• Screw drivers (flat-blade and Phillips)

• ESD wrist strap

• 48V test load

• Calibrated clamp-on dc current meter

(0.1 ADC sensitivity)

• Torque wrench

• Socket wrenches:

− 7/16” and 9/16” for load and

battery connections;

− 19 mm for anchor bolts;

− 12" extension for socket

• Masonry drill kit as required

• Compression for installation of various

compression lugs

• Protective canvas

• Insulating rubber mat

• Standard insulated installation tools,

screwdrivers, etc.

• Windows-based personal computer

laptop (PC) and cable to connect the PC

communications port to the local port of

the controller OR a CAT5 LAN cable.

Issue 8 January 2008 29

Page 30

CPS6000-M2 Installation Guide H5694720

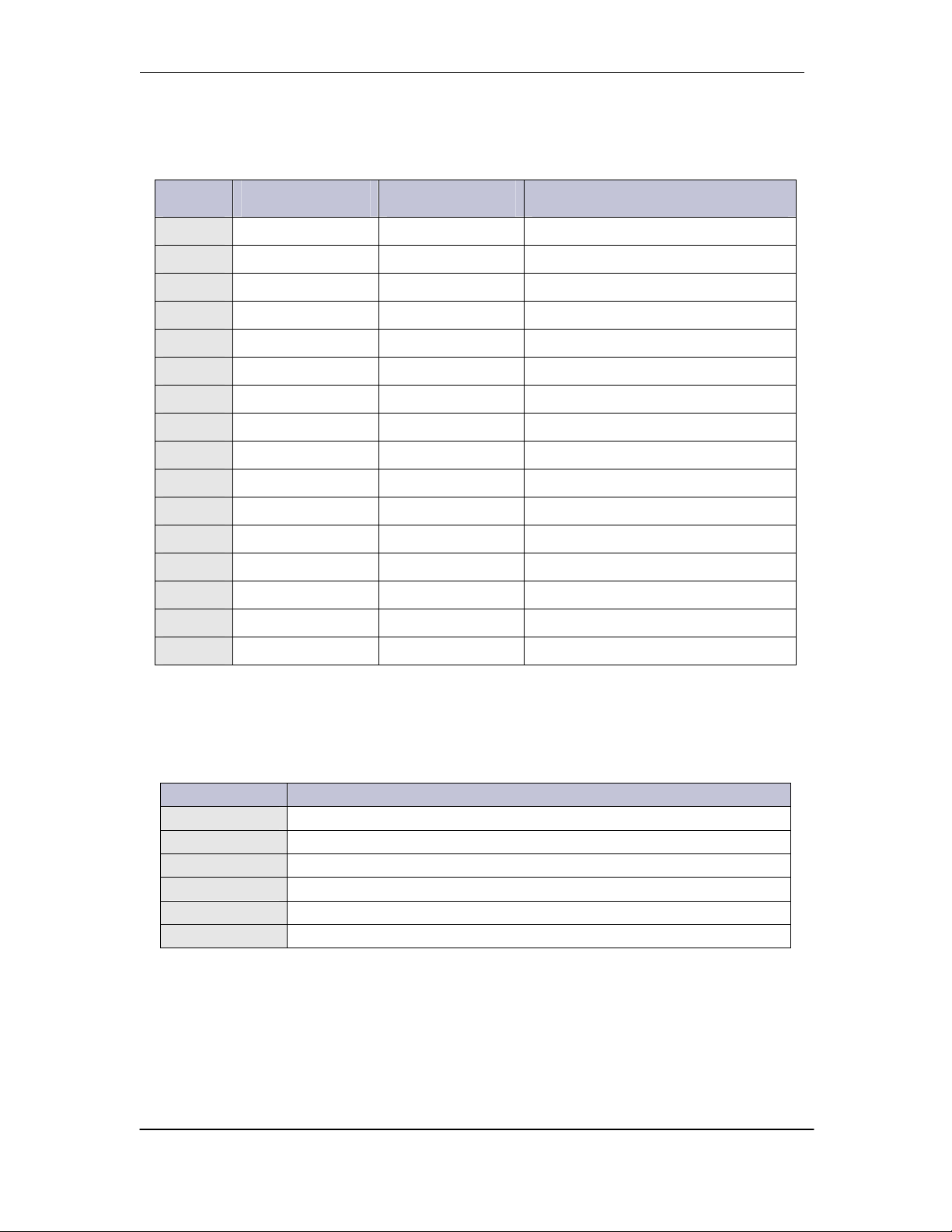

Accounting for Ship Loose Materials

QTY H5694720 Group COMCODE DESCRIPTION

60 660, 661 802841635 Flat Washer, 3/8

60 660, 661 801829607 Lock Washer, 3/8

60 660, 661 841064777 Nut Hex, 3/8

40 660, 661 230707-1 Amp Barrel Terminal

144 660, 661 901352617 Nut ¼ - 20

3 441, 451, 471 406954222 Cable ties for securing battery cables

1 441, 451, 471 CC848809104 2 gauge battery cable

2 440-471 901281444 Phillips flat head screws 10-32 x 3/8

3 440-471 848466884 Battery separators

1 440, 441, 451, 471 CC848768201 Front battery bracket

1 441, 451, 471 CC848770248 Clear cover for battery breaker

2 441, 451, 471 845143858 Screw 6-32 x ¼

2 101-104 CC408575947 ¼-20 x ¾-inch HH bolt

2 101-104 801829557 ¼-inch lockwasher

2 101-104 CC408576012 ¼-inch flat washer

1 104 CC848795385 Drill template

Torque Requirements

Torque (in-lb) Connection

10 AC terminal block screws

35 10-32 screw for dc rear covers and ac duct

35 12-24 frame-mounting screws

65 1/4-20 nuts for bullet panel loads

135 M8 bolts for large breaker and fuse kits and LVBD connections

240 3/8-16 nuts for large breaker and fuse load leads and all battery leads

Issue 8 January 2008 30

Page 31

CPS6000-M2 Installation Guide H5694720

Anchoring Frame

Floor Mounted Frames

Using the 847135688 Floor Anchor Kit (recommended):

Anchor Type (Hilti) Wrench Hole Size Torque

(4) 12 mm Cap Bolts 19 mm

Note: For systems with tray mounted batteries at sites requiring Seismic Zone 4 rating, (2)

847135688 kits are required to provide (8) floor anchors.

Note: If using Equivalent Floor Anchors, make sure the floor anchors are rated for this

application.

18mm

100mm deep

Step Action

Mark floor anchor locations, using the provided Floor Template.

720 in·lbs

60 ft·lbs

81.6 N·m

1

G103 7ft Standard Frames

G104 7ft Heavy Duty Frames

Drill anchor holes.

2

Caution: Follow safe floor drilling procedures to prevent possible asbestos exposure.

Place frame and install floor anchors according to manufacturer requirements.

3

Issue 8 January 2008 31

Page 32

CPS6000-M2 Installation Guide H5694720

Battery or Battery Stand Mounted Half-Height Frames:

Step Action

Place and secure frame to battery or battery stand per instructions provided with the

battery stand or adapter.

1

Connecting Frame Ground

Select a Frame Ground landing on the top of the frame and clean.

Step Action

Secure Frame Ground connection with

provided hardware:

(2) 801256165 ¼-20 x 3/4" HH bolt

(2) 801829557 ¼-inch lockwasher

(2) 802841577 ¼-inch flat washer

1

If required by local code or practice,

treat with an oxidation inhibitor such as

NO-OX.

Use 7/16” socket. Torque to 65 in·lbs.

Note: Landings are compatible with lugs

with 5/8” hole spacing for ¼” or 6mm

hardware.

Issue 8 January 2008 32

Page 33

CPS6000-M2 Installation Guide H5694720

Battery or Battery Stand Mounted Frames:

If required by local code or practice, battery or battery stand mounted frames may be grounded to

the frame or chassis of the other equipment. Select a Frame Ground landing at the side of the

frame and clean.

Step Action

Secure Frame Ground connection with

provided hardware:

(2) 801256165 ¼-20 x 3/4" HH bolt

(2) 801829557 ¼-inch lockwasher

(2) 802841577 ¼-inch flat washer

1

If required by local code or practice,

treat with an oxidation inhibitor such as

NO-OX.

Use 7/16” socket. Torque to 65 in·lbs.

Note: Landings are compatible with lugs

with 5/8” hole spacing for ¼” or

6mm hardware.

Connecting Central Office Ground (COG)

Action

• COG lead landing is as shown.

• If required by local code or practice,

treat with an oxidation inhibitor such

as NO-OX.

• Secure COG connection with provided

hardware:

(2) 841064777 3/8-16 nut

(2) 801829607 3/8-inch lockwasher

(2) 814251898 3/8-inch flat washer

• Use 9/16” socket. Torque to 240 in·lbs.

Note: Landings are compatible with lugs with

1” hole spacing for 3/8” hardware.

Issue 8 January 2008 33

Page 34

CPS6000-M2 Installation Guide H5694720

Connecting AC Utility

WARNING: Disconnect all AC branch circuits prior to making AC connections

to the CPS6000 Plant System. When connecting to utility source, ensure

compliance to all local and national wiring rules.

Step Action

• AC is connected to terminal blocks located at the top of the equipment frame.

• Route and attach conduit or other commercial fitting. A 1-inch conduit is required per

rectifier shelf.

1

• Pull and terminate AC wire.

• Terminal blocks are provided for up to twenty rectifiers (four shelves).

2

• Each rectifier must be fed by 10 gauge wire protected by a 20A circuit breaker or

fuse.

• Terminate ground connection on terminal blocks or optional lugs.

Issue 8 January 2008 34

Page 35

CPS6000-M2 Installation Guide H5694720

Installing Batteries

Installing Battery Trays

Optional battery trays are suitable for use with general trade VRLA batteries. VRLA batteries

come in two jar widths; approximately 4.25” width, typically used in 19” frame applications and

approximately 5” width, typically used in 23” frame applications. These battery trays

accommodate both types.

Step Action

Position the battery tray in the frame as

shown. Secure with provided (Comcode

1

901078717) rack screws.

Installing Tray Mounted Batteries

The system can be configured with battery trays sized for various batteries and may include

optional factory installed battery disconnect or battery mid-string voltage and temperature

monitoring units.

WARNING: All batteries contain hazardous electrical energy. Lead-acid

batteries contain sulfuric acid and explosive hydrogen gas. Follow all precautions

noted in the literature accompanying the batteries. Use only insulated tools.

CAUTION: Equipment frame anchoring, load rating, and seismic zone rating

should be verified before field installing trays and batteries.

Issue 8 January 2008 35

Page 36

CPS6000-M2 Installation Guide H5694720

Typical Battery Installation on Trays with Battery Disconnect

Step Action

Ensure disconnect switch is in

the OFF position (downward)

prior to making any

connections.

1

Remove the two 6/32 screws to

remove the plastic cover.

Does system have larger batteries?

Yes – Proceed to Step 2. No – Go to Step 3.

Reposition the battery

disconnect switch to the

outside of the battery tray as

shown using (2) provided

2

901281444 Flathead 10-32 x

3/8” Phillip screws.

Issue 8 January 2008 36

Page 37

CPS6000-M2 Installation Guide H5694720

Step Action

Place front bracket on battery

tray. Batteries sit on flange of

bracket holding it in place.

3

Note: For systems with larger

batteries the front bracket is

mounted to extend beyond the

front of the tray.

Connect one end of the 2 gage

cable to the input bus of the

disconnect switch. Secure with

4

1/4-20 hex nuts (901352617)

provided.

Torque to 65 in-lb.

Re-attach clear plastic cover to

disconnect switch and secure

5

with 6-32 screws.

Place four batteries on each

battery tray.

6

Position three Battery Spacers

between the batteries.

Interconnect three inter-cell bus

bars to configure one 48V

battery string per the battery

7

manufacturer’s instructions.

Issue 8 January 2008 37

Page 38

CPS6000-M2 Installation Guide H5694720

Step Action

Attach the battery securing top

rail. Secure with provided

8

(Comcode 901078717) rack

screws

Connect the 2 gage cable

between the V- post of the leftmost battery and the input bus

9

of the disconnect switch.

Torque to battery

manufacturer’s specification.

Is the system equipped with a factory installed QS873 VT thermal probe?

Note: The Millennium II can support up to 16 QS873VT 1-Wire probes. It also

has the capability of directly monitoring up to (4) analog temperature probes.

Temperature measurements are also available through the use of Remote

Peripheral Modules (RPM’s).

Connect the QS873 VT thermal

probe to the inter-cell busbar at

the V- post in the middle of the

battery string.

Cable-tie to front bracket along

10

with the battery cable.

See “Installing Thermal Probes”

later in this chapter if field

installing Thermal Probes

No – Proceed to Step 11. Yes – Proceed to Step 10.

Issue 8 January 2008 38

Page 39

CPS6000-M2 Installation Guide H5694720

Step

11

Action

Connect the factory-wired battery

cable to the V+ post of the rightmost battery. Torque to battery

manufacturer’s specification.

Battery installation is complete.

Attaching Battery Cables to CPS6000-M2 Busses

• Battery Cable landings are as shown. If

required by local code or practice, treat

with an oxidation inhibitor such as

NO-OX.

• Secure Battery Cable connections with

provided hardware (per cable):

(2) 841064777 3/8-16 nut

(2) 801829607 3/8-inch lockwasher

(2) 814251898 3/8-inch flat washer

• Use 9/16” socket. Torque to 240 in·lbs.

Action

Note: Landings are compatible with lugs with

1” hole spacing for 3/8” hardware.

Issue 8 January 2008 39

Page 40

CPS6000-M2 Installation Guide H5694720

Installing and Wiring DC Loads

Installing DC Bullet Style Distribution

Bullet Terminal distribution panels accept Bullet Terminal Circuit Breakers, TPS Fuse Holders,

and GMT Fuse Modules.

CAUTION: Ensure Circuit Breakers are in the OFF position prior to installation. Ensure

Fuse Holders are empty prior to installation.

• CAUTION: In order to meet UL Listing temperature limits, GMT Fuses on the bullet fuse

module must meet these layout restrictions:

• All 12A rated fuses must have an unused position to at least one side.

• All 15A rated fuses must not be installed next to another fuse. Leave empty position.

• CAUTION: In order to meet UL Listing temperature limits, bullet distribution panels

must meet the following layout restrictions

• Panel is rated 400A but derates to 350A if Large Breakers or Fuses are installed in the

Center Section of distribution.

• bullet circuit breakers rated 80A, 90A and 100A require one adjacent position be left

unoccupied.

Step Action

Loosen screws and swing hinged retainer cover clear of the distribution devices (if

present).

1

Vertical distribution panel

Insert distribution devices into the panel load busses as shown in the figure above.

2

Connect loads.

3

Note: To allow for future growth start from the top most position and work down the

panel. This will allow orderly and managed cable dressing as loads are added.

Issue 8 January 2008 40

Page 41

CPS6000-M2 Installation Guide H5694720

Step Action

Secure GMT Module Return bus bars to the distribution panel Return bus bar with

4

provided (901352617) 1/4-20 nuts.

Secure the hinged retainer cover if removed in step 1 above.

5

Single- and Two-Pole, Breakers and TPS Fuses:

Secure Two-Pole adapter busses to the distribution Load and Return busses with

6

provided (901352617) 1/4-20 nuts.

Secure Load and Return Cable connections with provided (901352617) 1/4-20 nuts.

7

Use 7/16” socket. Torque to 65 in·lbs.

Verify (using a voltmeter) polarity of the voltage between the Return bus and the

8

distribution input bus.

Verify wiring polarity at the input of the load equipment.

9

Leave breaker switches in the OFF position and do not install load fuses until the load

equipment is ready to be energized.

• WARNING: Do not install load fuses until the load equipment is ready to be energized.

Three-Pole Breakers:

Secure Three-Pole adapter busses to the distribution Load and Return busses with

10

provided (901352617) 1/4-20 nuts.

Use 7/16” socket. Torque to 65 in·lbs.

Secure Load Cable connections with provided hardware (per cable):

(2) 841064777 3/8-16 nut

11

(2) 801829607 3/8-inch lockwasher

(2) 814251898 3/8-inch flat washer

Use 9/16” socket. Torque to 240 in·lbs.

12

13

Using a voltmeter, verify polarity of the voltage between the Return bus and the

distribution input bus.

Verify wiring polarity at the input of the load equipment.

Leave breaker switches in the OFF position until the load equipment is ready to be

energized.

• WARNING: Do not install circuit breakers until the load equipment is ready to be

energized.

GMT Bullet Fuse Modules:

14

15

16

17

Issue 8 January 2008 41

Strip load wire 3/8” and secure in the GMT module terminal block.

Use #1 slot screwdriver. Torque to 13 in·lbs.

Dress and wire tie with service loop to provide strain relief.

Using a voltmeter, verify polarity of the voltage between the RTN and distribution input

bus.

Verify wiring polarity at the input of the load equipment.

• WARNING: Do not install load fuses until the load equipment is ready to be energized.

Page 42

CPS6000-M2 Installation Guide H5694720

Installing TPL-C Fuse Holders and Panels

TPL-C Fuse holders can either be factory or field installed per kit CC109129129128. The

following figure shows the installation of this kit and corresponding fuse installation. Note that

the fuse snaps into the fuse handle which is then pushed into the holder.

Step Action

Ensure Fuse Holders are empty prior to making any connections.

1

Secure Load Cable connections with provided hardware (per cable):

(2) 841064777 3/8-16 nut

(2) 801829607 3/8-inch lockwasher

2

(2) 814251898 3/8-inch flat washer

Use 9/16” socket. Torque to 240 in·lbs.

WARNING: Do not install load fuses until the load equipment is ready to be energized.

Issue 8 January 2008 42

Page 43

CPS6000-M2 Installation Guide H5694720

Installing Large Circuit Breakers

KS22012 Circuit Breakers can either be factory installed or field installed per the following kits:

• CC109127635 150A Single Pole Breaker

• CC109127627 250A Single Pole Breaker

• CC109127486 Two Pole Breaker

Step Action

Ensure Circuit Breakers are in the OFF (down) position prior to making any

connections.

1

Issue 8 January 2008 43

Page 44

CPS6000-M2 Installation Guide H5694720

Installing QS-Series Rectifiers

Action

Rectifiers are installed or removed with the rectifier handle in the open position as shown.

Use the above rectifier installation procedure as needed in the following steps:

Step Action

Turn on ac service circuit breakers to apply power to the system rectifier positions.

1

Install a rectifier in an available rectifier position.

2

Wait until the rectifier establishes communications with the controller (the red Fail

3

LED stops flashing).

Verify green Norm LED is lit.

4

Issue 8 January 2008 44

Page 45

CPS6000-M2 Installation Guide H5694720

Step Action

Apply 10 amperes of load to the system.

5

If equipped, verify the contactor closes and connects the battery strings.

6

If an audible alarm is present, press the ENTER key to MUTE the audible alarm.

7

Verify all LEDs are green on the controller and the display is visible with the proper

8

voltage shown.

Increase the plant load current to 20 amperes.

9

10

11

12

13

14

15

16

17

18

19

Install rectifier in the next position.

Wait until the rectifier establishes communications with the controller (the red Fail

LED stops flashing).

Verify green Norm LED is lit.

Verify the two rectifiers are present and verify the rectifier output currents by using the

front panel:

MENU > STATUS > RECTIFIERS > RECTIFIER CURRENTS.

Increase the plant load current to 50 amperes.

Continue to add rectifiers until the system is fully equipped or has a maximum of 20

rectifiers.

Verify the rectifiers share the load and the voltage regulation is correct. Rectifiers

should load share after 2 minutes to within 2% of the total average output.

Verify front panel display voltage is within 0.5% of the Float Set-point.

Remove a rectifier and ignore the request to remove missing equipment.

Verify the controller identifies the rectifier as missing to verify that the Minor

Communication Fail alarm is operational.

20

For more information on QS Rectifiers, see the Troubleshooting section.

Re-install the rectifier and verify that the alarm clears.

Issue 8 January 2008 45

Page 46

CPS6000-M2 Installation Guide H5694720

Installing QS-Series Ringers

Step Action

• Up to two Ringer Chassis’s may be installed per rectifier shelf, one in each of the two

right-most power slots. Each Ringer chassis accepts up to two ringer modules, a

primary and a spare.

• For redundant ringing, install both Primary and Spare Ringers in each Ringer Chassis.

WARNING: Consider the Ring signal as hazardous voltage. When

1

rectifiers and/or battery power is present, all installed QS820M ringer

chassis and QS820A ringer modules will be powered.

• Note: Ringer output connections are made after ringers are seated in the Ringer

chassis.

• Note: The primary and spare Ringer modules install facing opposite directions. No

rectifiers may be installed to the right of a Ringer Chassis. Slots dedicated to Ringers

do not require an ac input circuit in the AC Termination Panel

• Slide the ringer chassis into

the power slot.

• Press firmly until the

connector on the rear of the

ringer chassis engages with

the connector at the back of

the power slot on the shelf.

• Verify the hook under the

front left of the ringer chassis

2

hooks under the shelf.

• Press down on the faceplate

latch and open the faceplate.

• Secure the ringer chassis to

the shelf using one #4 screw,

hand tight to approximately 5

in-lbs.

• Repeat if a second ringer

chassis is required.

Issue 8 January 2008 46

Page 47

CPS6000-M2 Installation Guide H5694720

Step Action

• Locate connector on rear of

ringer module and the mating

connector on the inside rear of

the ringer chassis.

• Align the ringer module

connector with the ringer

chassis connector. Place the

ringer module in the guides

3

4

and slide the ringer in until it

fully engages with the

connector at the back of the

ringer chassis.

• Note: The Ringer modules

install facing opposite

directions

• Repeat until all Ringer

modules are installed.

• Use Tip Jumper J12 to set the Ringer output type.

• Note: Ringer output type is determined by connecting Ring Return (Tip) to Battery or

Ground. External connection of Ring Return (TIP) to Battery or Ground may be used

with J12 in EXTERNAL position. Ringer output is disabled if Ring Return is not

connected to Battery or to ground.

Ringing Type

Ground Backed 1. TIP BAT

Battery Backed 2. TIP GND

Ground Backed – no-dc 2. TIP GND

Externally Selected 3. EXTERNAL

Tip Jumper

J12 Position

Comments

Also requires Controller

configuration of dc Offset: Disabled

Requires external connection of Tip

to Battery or Ground.

Repeat until all Ringer modules are installed

Issue 8 January 2008 47

Page 48

CPS6000-M2 Installation Guide H5694720

Step Action

• Connect Ringer loads using Molex 39-01-4031 connector, Socket Terminal to the

HDR13 plug located inside the Ringer Chassis at the bottom-front

WARNING: Consider the Ring signal as hazardous voltage.

5

Controller Connections

Issue 8 January 2008 48

Page 49

CPS6000-M2 Installation Guide H5694720

The MCR1/MCR1B control board contains the connections for all the input and outputs. The

following table provides a list of the connections with their respective reference designators and

brief description of the particular connection.

Interface

Reference Description

P1

P2

P3

P6

P7

P8

P9

P13

P14

P15

P201

P202

P205

TB1

TB2

J10

Connectorized interface for large parallel format 8x40 LCD assembly

10/100 Base-T LAN/Ethernet interface

Connectorized interface for 10K/30K thermistor probe options or 210E

Connectorized input for input power, monitoring of two shunts, plant sense voltage,

and Major Fuse alarm (Same connection as on the Millennium)

RJ45 receptacle for ground referenced Auxiliary RS485 circuit and One-Wire

monitoring devices

BSL1-4 circuit pack Interface connector for Input/Output to controller

RJ45 receptacle for isolated RS485 system component monitoring and control of

rectifiers, converters, low voltage disconnect contactors, and bay level alarm inputs

(Serial Rectifier bus)

Factory test connector (not used in the field)

Connectorized interface for future smaller serial format LCD

Connectorized interface for future smaller serial format LCD

Connectorized interface for optional Modem

Ground referenced DB-9 for local RS232 serial port

Option board connector

Terminal block interface for RS232/RS485 Auxiliary port and Remote Peripheral

Module (RPM) connections

Terminal block interface for three additional 10K thermistor probe or 210E connection

options

USB interface (reserved for future use)

Fuses

Two Fuses, located on the MCR1/MCR1B board, provide protection for the controller input

power and Alarm Battery Supply (ABS). ABS is used to power alarm panels or other devices

requiring the power system voltage at no more than 1.3A.

Fuse Description Fuse Size

F1 Controller Input Power 3A

F2 Alarm Battery Supply (ABS) 1.3A

Issue 8 January 2008 49

Page 50

CPS6000-M2 Installation Guide H5694720

Network (LAN) Connections

Step Action

Note

1

2

3

The LAN port P2 is an IEEE 802.3 compliant 10/100Base-T Ethernet interface.

This port can be used for remote monitoring or configured as local Craft port.

Factory default is to be a DHCP client where the network will serve the controller

and IP address.

Since the cable length required to connect to the network is variable, this cable must

be supplied by the user.

At the controller, connect one end of the network interface cable to P2. This

connector is located at the bottom center of the MCR1 board, and immediately

below the MCR2 board.

Connect the other end to an IEEE 802.3 compatible network.

Configure the network parameters by contacting the customer’s network

administrator.

BSL Alarm Outputs and Control Inputs

The following tables provide the input/output signal assignments for the BSL alarm interface

board. Use 18-26 gage wire for alarm board terminations. Form-C Alarm contact ratings are

60VDC, 0.3A

Issue 8 January 2008 50

Page 51

CPS6000-M2 Installation Guide H5694720

BSL Alarm Outputs

Signal Name Pin

Power Critical

Alarm -Audio

Power Critical

Alarm -Visual

Power Critical

Alarm-External

Power Major

Alarm-Audio

Power Major

Alarm –External

Power Major

Alarm–Visual

Power Minor

Alarm-Audio

Power Minor

Alarm –Visual

Power Minor

Alarm –External

Major Fuse Alarm

Number

1 PCRAO 34 MNFR

2 PCRAC 35 MNFC

3 PCRAR

4 PCRVR 37 BDO

5 PCRVC 38 BDC

6 PCRVO

7 PCREO 40 ACFR

8 PCREC 41 ACFC

9 PCRER

10 PMJAR 43 RFAO

11 PMJAC 44 RFAC

12 PMJAO

13 PMJEO 46 HVR

14 PMJEC 47 HVC

15 PMJER

16 PMJVR 49 UR1O

17 PMJVC 50 UR1C

18 PMJVO

19 PMNAO 52 CTLRR

20 PMNAC 53 CTLRC

21 PMNAR

22 PMNVR 55 UR2O

23 PMNVC 56 UR2C

24 PMNVO

28 PMNER 58 VLVR

29 PMNEC 59 VLVC

30 PMNEO

31 MJFO

32 MJFC

33 MJFR

Signal

Reference

Signal Name Pin Number Signal

Minor Fuse Alarm

36 MNFO

Battery On

Discharge Alarm

AC Fail Alarm

Rectifier Fail

Alarm

High Voltage

Alarm

User Relay 1

Controller Fail

Alarm

User Relay 2

Very Low Voltage

39 BDR

42 ACFO

45 RFAR

48 HVO

51 UR1R

54 CTLRO

57 UR2R

60 VLVO

Reference

Issue 8 January 2008 51

Page 52

CPS6000-M2 Installation Guide H5694720

BSL Alarm and Control Inputs

Alarm Pin

Number

61 LVD2 Low Voltage 2 Disconnect State Detect

62 LVD2R

Fuse Alarm Major 63 FAJ

Fuse Alarm Minor 65 FAN

Auxiliary Alarm Major 64 AMJ

Auxiliary Alarm Minor 66 AMN

Timer Float Control 67 TFLT

Timer Boost Control 68 TBST

Timer Control Return 69 TRTN

Plant Battery Test

Open String Detect 72 OS

Transfer Rectifier 1 73 TR1

General Purpose Input 4 74 IN-4 (previously TEQ)

General Purpose Input -5 (Previously

Engine Transfer)

Reserve Operation

Transfer Rectifier 2 79 TR2

Transfer Rectifier 4 80 TR4

Reserve Battery-Emergency Power Off 81 RBRPO

General Purpose Input 1 82 IN-1

BTP or General Purpose Input 2 83 IN-2/BTP

Low Voltage 1 Disconnect State Detect 84 LVD1

Transfer Rectifier 3 85 TR3

General Purpose 4-20mA Measuring

Circuit

General Purpose 4-20mA Measuring

Circuit-RTN

BTPFLT or Generic Input 3 89 IN-3/ BTPFLT

Low Voltage 3 Disconnect State Detect

Also Battery Thermal Protect Major

General Purpose 0-5Vdc Measuring

Circuit

General Purpose 0-5Vdc Measuring

Circuit-RTN

70 PBTR

71 PBT

75 IN-5 (Previously ETR)

77 RO

78 ROR

87 4-20mA

88 4-20mAR

90 LVD3/ BTMJ

91 0-5V

92 0-5VR

Signal Name

Issue 8 January 2008 52

Page 53

CPS6000-M2 Installation Guide H5694720

Following are additional details concerning the alarm and control input signals.

BSL-63 FAJ: Fuse Alarm Major

An optional “battery” or non-grounded potential input, must use an external 1K ohm 2W current

limiting resistor at the source. A Fuse Alarm Major is generated when battery potential is

received.

BSL-65 FAN: Fuse Alarm Minor

An optional “battery” or non-grounded potential input, must use an external 1K ohm 2W current

limiting resistor at the source. A Fuse Alarm Minor is generated when battery potential is

received.

BSL-72 OS: Open String Alarm

An optional “battery” or non-grounded potential input, must use an external 1K ohm 2W current

limiting resistor at the source. This circuit is used to signal the controller that a battery string

protective device or switch is in the open position. An Open String Alarm is generated when

battery potential is received.

BSL-64 AMJ: Aux Major

An optional “battery” or non-grounded potential input, must use an external 1K ohm 2W current

limiting resistor at the source. This circuit is used to allow the controller to monitor another

power device and provide alarms for it. An Aux Major Alarm is generated when battery potential

is received.

BSL-66 AMN: Aux Minor

An optional “battery” or non-grounded potential input, must use an external 1K ohm 2W current

limiting resistor at the source. This circuit is used to allow the controller to monitor another

power device and provide alarms for it. An Aux Minor Alarm is generated when battery potential

is received.

LVD1: BSL-84 Low Voltage Disconnect Active

An optional “battery” or non-grounded potential input, must use an external 1K ohm 2W current

limiting resistor at the source if not using standard

controller. This circuit is used to inform the controller that the monitoring circuit of a Low

Voltage Disconnect device has failed.

LVD2/LVD2R: BSL-61/62 Low Voltage Disconnect Active

A closure between these points or a ground signal into LVD2/ BSL-61 is used to inform the

controller that a Low Voltage Disconnect device has opened.

External Boost Option

A variety of external devices may be used to initiate boost in the controller. Wiring is required

from positions 67/68/69 on the BSL board for operation of this feature. Providing a contact

closure between TBST and TRTN initiates the boost feature. A contact closure between TFLT

and TRTN returns the plant to float.

Rectifier Sequence Option

The controller is capable of sequencing rectifiers on line after detecting AC is being provided by

emergency generator. Internal Rectifier Sequencing requires external wiring to ETR/ETRR on

BSL pin numbers 75/76, and optionally RO/ROR on BSL pin numbers 77/78, in order to

Lineage Power LVD circuit boards or

Issue 8 January 2008 53

Page 54

CPS6000-M2 Installation Guide H5694720

function. The controller can also accept ground signals onto TR1 to TR4 on BSL 73/79/ 85/80

from an external device to control the sequencing of plant rectifiers in groups as follows:

TR leads and Associated Rectifiers

TR

Signal

TR1 G01, G02, G09, G10, G17, G18, G25, G26, G33, G34, G41, G42, G49, G50, G57,

G58

TR2 G03, G04, G11, G12, G19, G20, G27, G28, G35, G36, G43, G44, G51, G52, G59,

G60

TR3 G05, G06, G13, G14, G21, G22, G29, G30, G37, G38, G45, G46, G53, G54, G61,