Page 1

CPS6000

-48V Indoor/Outdoor Power Shelf

Product Manual

Select Code 167-102-105

Comcode 108992120

Issue 21

January 2008

Page 2

This document is relevant to the following equipment series:

Controllers: QS840A 1:1 E App version 1.9 and defaults version Std-1.0

Rectifiers:

QS841A 1:0D App version 1.4.1 and defaults version Std-1.0

15A QS861A 1:1F

20A QS852A 1:0E

25A QS853A 1:0A

25/30A QS862A 1:1H

40A QS864A 1:0E

50A QS865A 1:1E

Series

Notice:

The information, specifications, and procedures in this manual are subject to change

without notice. Lineage Power assumes no responsibility for any errors that may appear

in this document.

© 2008 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 3

CPS6000 –48V Indoor/Outdoor Power Shelf

Table of Contents

1 Introduction..............................................................................................................6

Overview...................................................................................................................6

Customer Service Contacts.......................................................................................8

2 Product Description.................................................................................................9

CPS6000 System Overview......................................................................................9

Block Diagrams ......................................................................................................10

Shelf Design............................................................................................................12

Configurations.........................................................................................................13

Distribution and Power Module Configurations.....................................................14

Battery Reserve System ..........................................................................................15

Specifications..........................................................................................................16

3 Engineering and Ordering ....................................................................................24

Engineering Information.........................................................................................24

Ordering Information..............................................................................................26

4 Safety.......................................................................................................................32

Safety Statements....................................................................................................32

Warning Statements and Safety Symbols...............................................................35

Precautions..............................................................................................................36

Special Installation Notes .......................................................................................37

5 Installation..............................................................................................................39

CPS6000 Installation ..............................................................................................39

Installing the CPS6000 Shelf..................................................................................40

Install the CPS6000 Shelf .......................................................................................42

Controller ................................................................................................................43

QS845A Supplementary Shelf Board .....................................................................45

Thermal Compensation Connections......................................................................47

Office Alarms..........................................................................................................51

Controller Connections ...........................................................................................52

AC Connections......................................................................................................52

C.O. Ground Conductor Installation.......................................................................57

Rectifier Installation................................................................................................58

Ringer Installation...................................................................................................59

Battery Strings Installation .....................................................................................63

Load Connections ...................................................................................................67

Circuit Breaker and Fuse Installation .....................................................................73

Terminate Load Connections - Direct to Bus Connections ....................................74

Load Connections - Bulk Output ............................................................................75

Battery and Load Connections - External DC Distribution Panel ..........................76

Initial Start-up .........................................................................................................82

6 AC, Alarm, and Control Cable Reference Information.....................................85

Overview.................................................................................................................85

AC Utility Connection ............................................................................................85

Controller Connections ...........................................................................................86

Issue 21 January 2008 3

Page 4

CPS6000 –48V Indoor/Outdoor Power Shelf

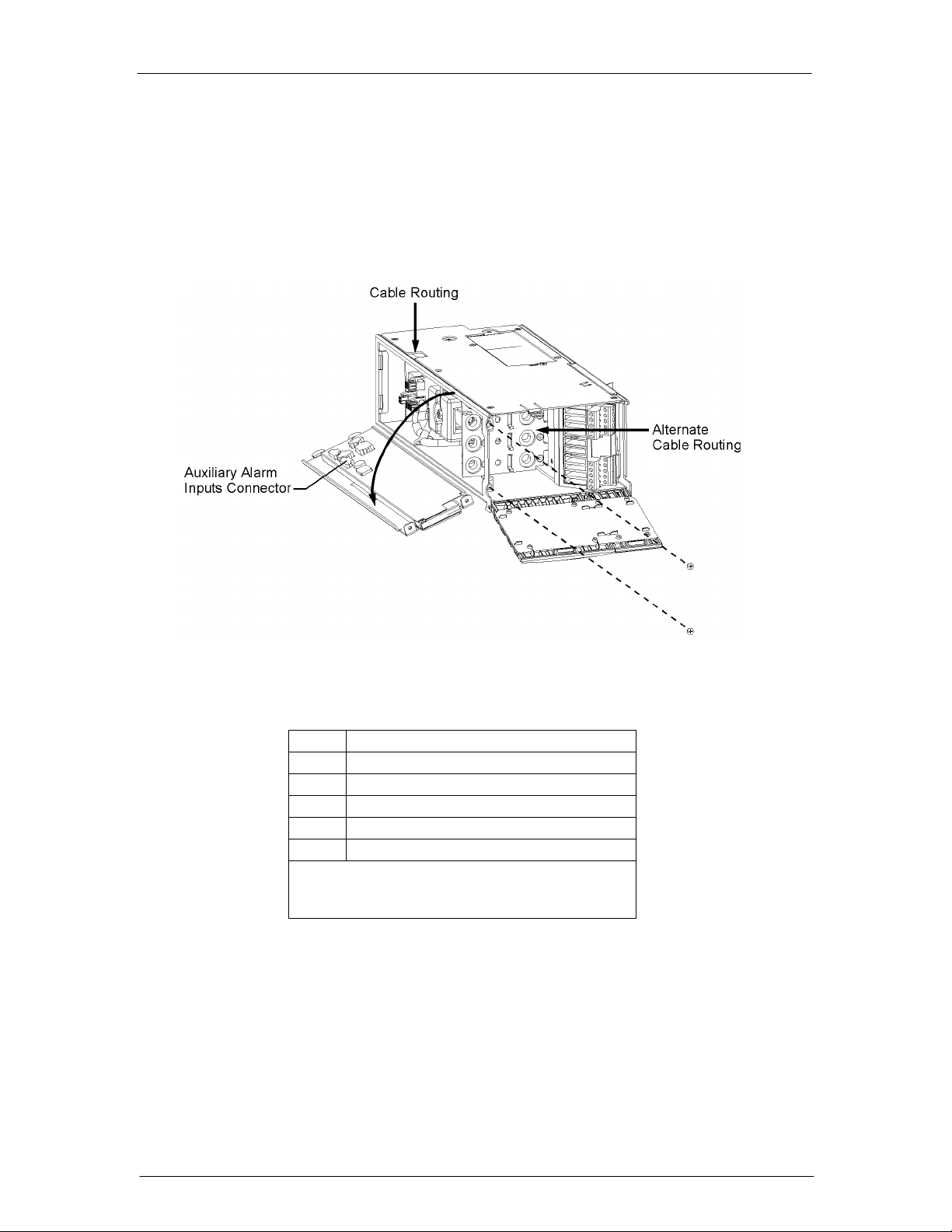

Auxiliary Alarms ....................................................................................................88

Additional Bulk Output Module Connections ........................................................89

7A QS840A System Controller ................................................................................90

Overview.................................................................................................................90

CPS6000 Controller Minimum Configuration........................................................96

User Interface and Display......................................................................................96

Minimum Configuration.........................................................................................96

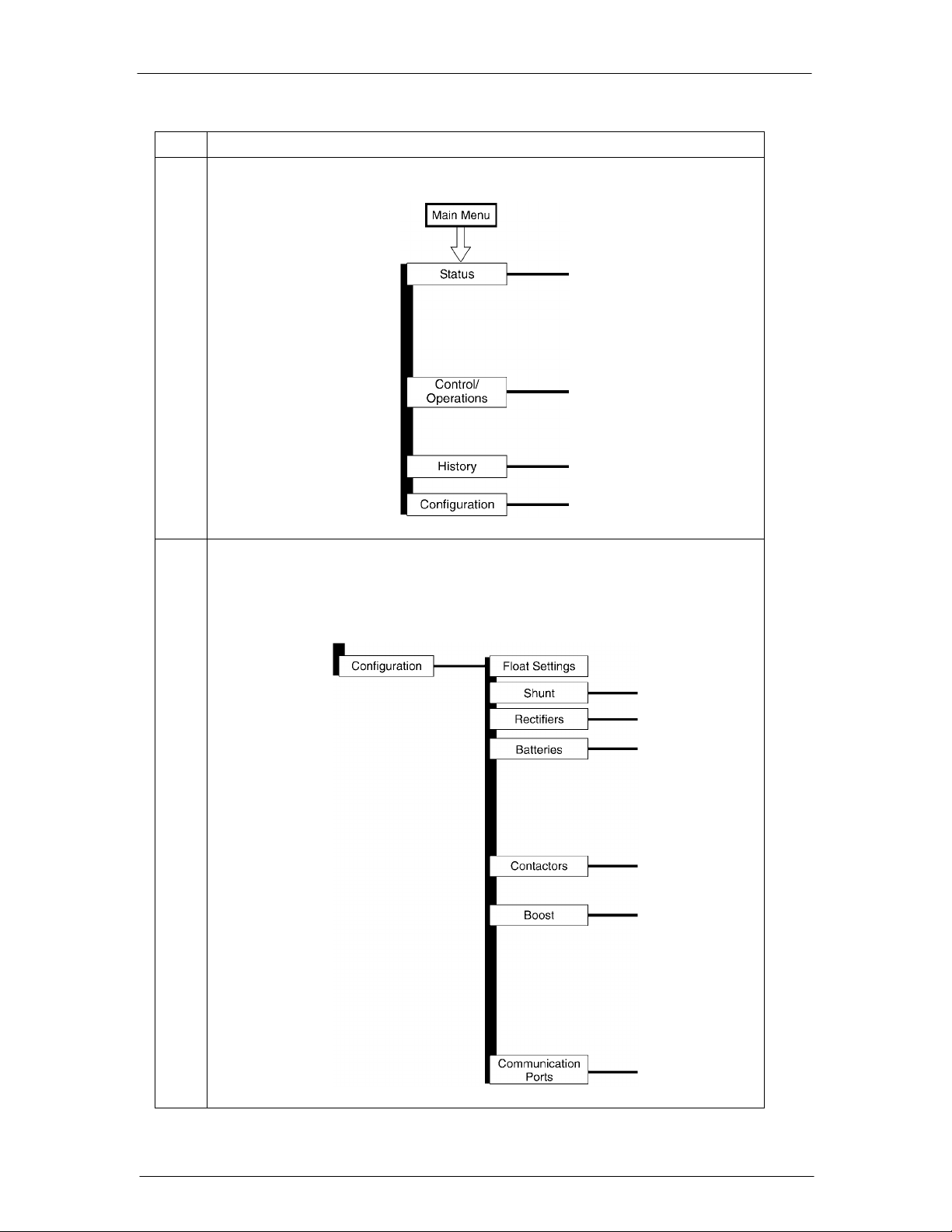

7B QS841A System Controller ..............................................................................107

Overview...............................................................................................................107

Status.....................................................................................................................116

Control/Operations................................................................................................119

Configuration ........................................................................................................121

10/100 Base-T Ethernet Port.................................................................................128

8 Rectifier.................................................................................................................135

Overview...............................................................................................................135

Alarms and Displays.............................................................................................136

Features and Functions .........................................................................................138

9 QS872A Distribution Monitoring Module.........................................................139

Overview...............................................................................................................139

10 Ringer Chassis and Ringers ..............................................................................141

Ringer Chassis ......................................................................................................141

Ringer....................................................................................................................142

Types of Ringing...................................................................................................143

11 Peripheral Devices .............................................................................................146

Voltage/Thermal Probes .......................................................................................146

Remote Voltage Monitor Module.........................................................................147

12 ES772A Remote Distribution Module..............................................................149

Overview...............................................................................................................149

Module Features....................................................................................................151

Module Connector Definitions .............................................................................152

22-position external distribution panel .................................................................159

13 Troubleshooting .................................................................................................160

Checking for Defective VT-Probes ......................................................................162

14 Product Warranty..............................................................................................163

Appendix A: T1.317 Command Language ...........................................................165

Initializing the QS840A Controller.......................................................................165

T1.317 Command Language.................................................................................166

Appendix B: Battery Functions .............................................................................190

Float Mode............................................................................................................190

Slope Thermal Compensation...............................................................................190

Plant Battery Test..................................................................................................193

Boost Mode...........................................................................................................194

Appendix C: Alarms and Relays ...........................................................................197

Alarm Relays ........................................................................................................197

Alarms...................................................................................................................197

Appendix D: EasyView for Windows® for the CPS6000 Controller.................202

Issue 21 January 2008 4

Page 5

CPS6000 –48V Indoor/Outdoor Power Shelf

Overview...............................................................................................................202

Loading the EasyView Application......................................................................202

Making the Connection.........................................................................................202

Configuring a Site.................................................................................................203

Serial Port Setup ...................................................................................................203

Connect to Site......................................................................................................203

Navigating Once Connected .................................................................................204

Appendix E: Pigtail Alarm Cable..........................................................................206

Appendix F: Operating Temperature Measurement and Vertical Spacing......209

Overview...............................................................................................................209

Revision History......................................................................................................210

Issue 21 January 2008 5

Page 6

CPS6000 –48V Indoor/Outdoor Power Shelf

1 Introduction

Overview

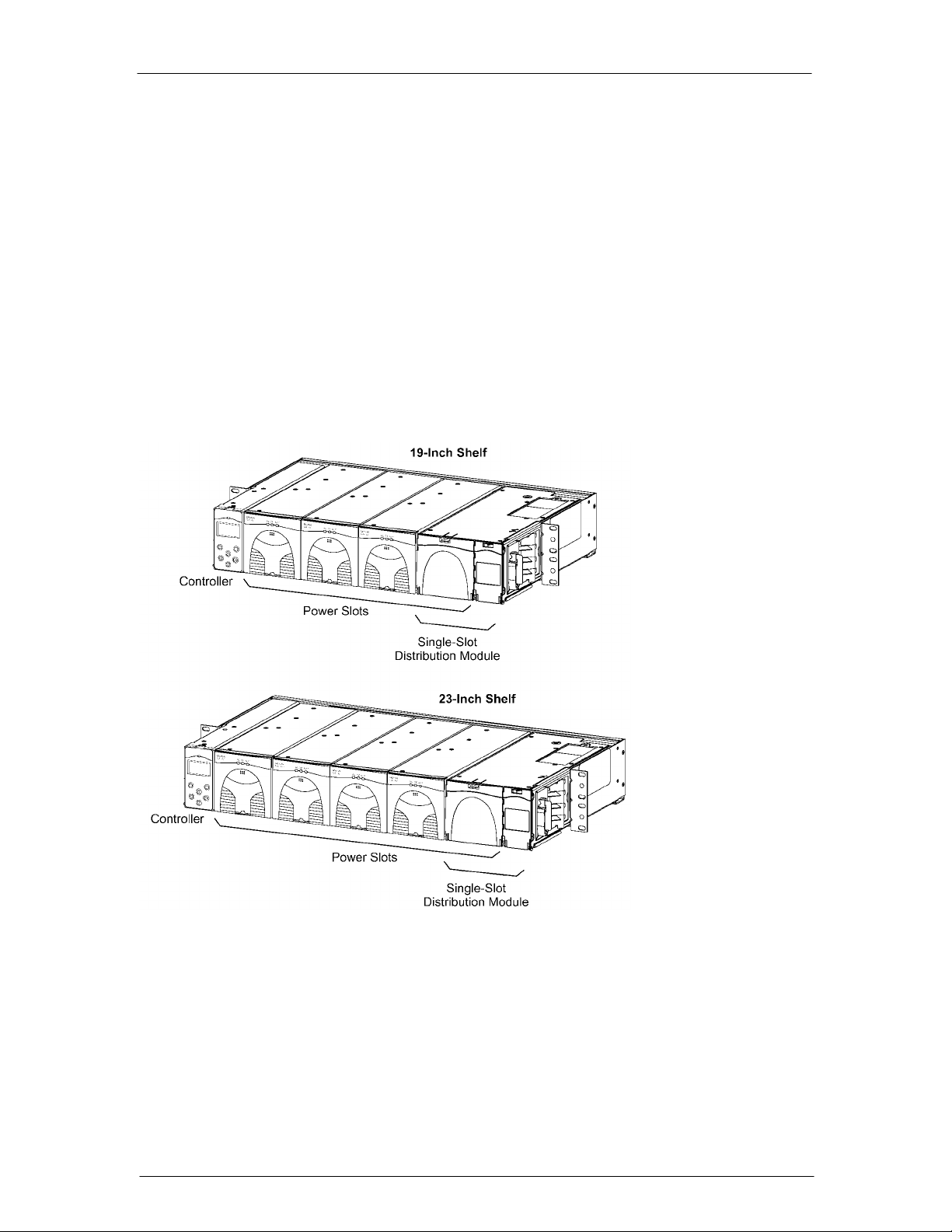

CPS6000 -48V Outdoor Power System is a modular power system designed for 19-inch

(483mm) and 23-inch (584mm) applications where reliability, space conservation and

environmental considerations are critical. This highly dense power system occupies minimum

space and its modular architecture enables an exact fit to custom needs.

The shelf architecture is based on the widely accepted and acclaimed CPS4000 systems. AC

power is brought in on the left side of the shelf. The first slot on the left side is occupied by

the controller. DC Output is aggregated on the right side of the shelf. Rectifiers/Ringers

occupy the slots available between the controller and the DC output

Figure 1-1: CPS6000 System with Distribution Module

The CPS6000 currently supports -48V primary loads up to 8.2kW of N+1 redundant power in

a single 19-inch shelf, and up to 10.9kW of N+1 redundant power in a 23-inch shelf with a

Bulk Output Module and 50A rectifiers.

Issue 21 January 2008 6

Page 7

CPS6000 –48V Indoor/Outdoor Power Shelf

CPS6000 systems may include up to 4 bulk-output shelves: an Initial shelf with controller,

and up to three supplemental shelves. External distribution is used with multi-shelf systems.

Ringer Chassis may be installed in Power Slots. Each Ringer Chassis supports one ringing

output in either non-redundant (simplex) or 1 + 1 redundant (duplex) operation. Ringer

distribution is direct from the Ringer Chassis.

The system controller card is powered by the system bus voltage and is located on the left

side of the shelf. The controller allows setting of system parameters, and various alarm

thresholds locally on the four-line LCD graphics display with intuitive navigation. The

controller can perform periodic battery tests and has a provision for user-definable alarm

inputs as well as alarm relays.

Applications

CPS6000 fits Outside Plant(OSP) applications, digital loop carrier, remote switch, fiber in the

loop, cable television cabinets, Intelligent Vehicle Highway System (IVHS), Personal

Communications Service (PCS), cellular, and customer premises applications.

Issue 21 January 2008 7

Page 8

CPS6000 –48V Indoor/Outdoor Power Shelf

Customer Service Contacts

Customer Service, Technical Support, Product Repair and Return,

and Warranty Service

For customers in the United States, Canada, Puerto Rico, and the US Virgin Islands, call 1800-THE-1PWR (1-800-843-1797). This number is staffed from 7:00 am to 5:00 pm Central

Time (zone 6), Monday through Friday, on normal business days. At other times this number

is still available, but for emergencies only. Services provided through this contact include

initiating the spare parts procurement process, ordering documents, product warranty

administration, and providing other product and service information.

For other customers worldwide the 800 number may be accessed after first dialing the AT&T

Direct country code for the country where the call is originating, or you may contact your

local field support center or your sales representative to discuss your specific needs.

Customer Training

Lineage Power offers customer training on many Power Systems products. For information

call 1-972-284-2163. This number is answered from 8:00 a.m. until 4:30 p.m., Central Time

Zone (Zone 6), Monday through Friday.

Downloads and Software

To download the latest product information, product software and software upgrades, visit our

web site at http://www.lineagepower.com/

Issue 21 January 2008 8

Page 9

CPS6000 –48V Indoor/Outdoor Power Shelf

2 Product Description

CPS6000 System Overview

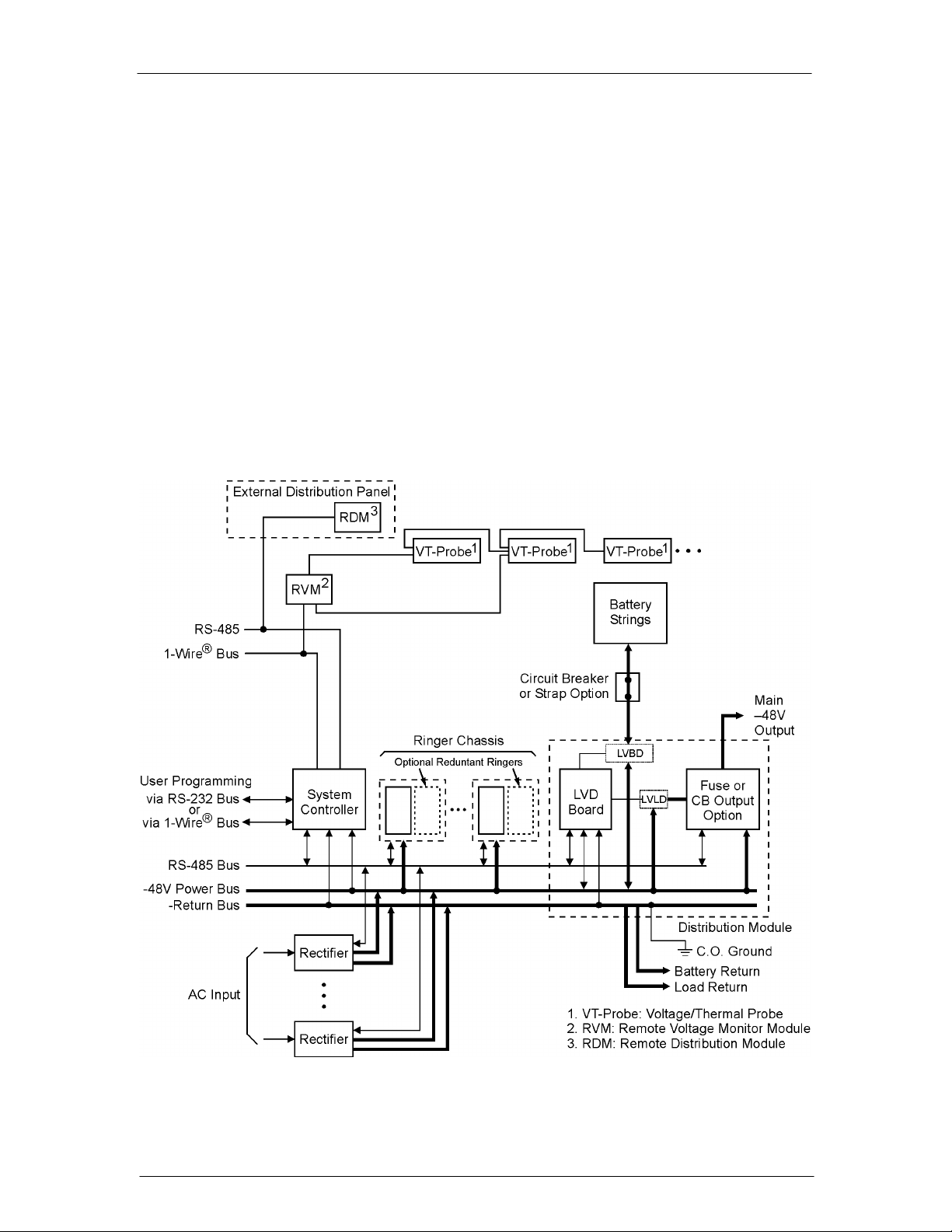

CPS6000 power systems are comprised of shelves, rectifiers, ringer chassis, ringers, and

distribution modules. Several types of distribution modules are available. The Bulk Output

Module provides connection to an external distribution without consuming a shelf power slot.

The CPS6000 is available as single-shelf systems and multiple-shelf systems with both 19inch and 23-inch shelves.

Single Shelf Systems

• With Distribution Module: all components contained in single shelf.

• With Bulk Output Module: uses external distribution, accommodates all other

components within the shelf.

Multi-Shelf Systems

• With Bulk Output Module: uses external distribution, accommodates all other

components within the shelves.

AC power is supplied to the rectifiers which produce regulated -48V dc output voltage. This

voltage is used to power all other system components including ringers, the system controller

and the LVD boards. Batteries are connected to distribution, internal or external. Some

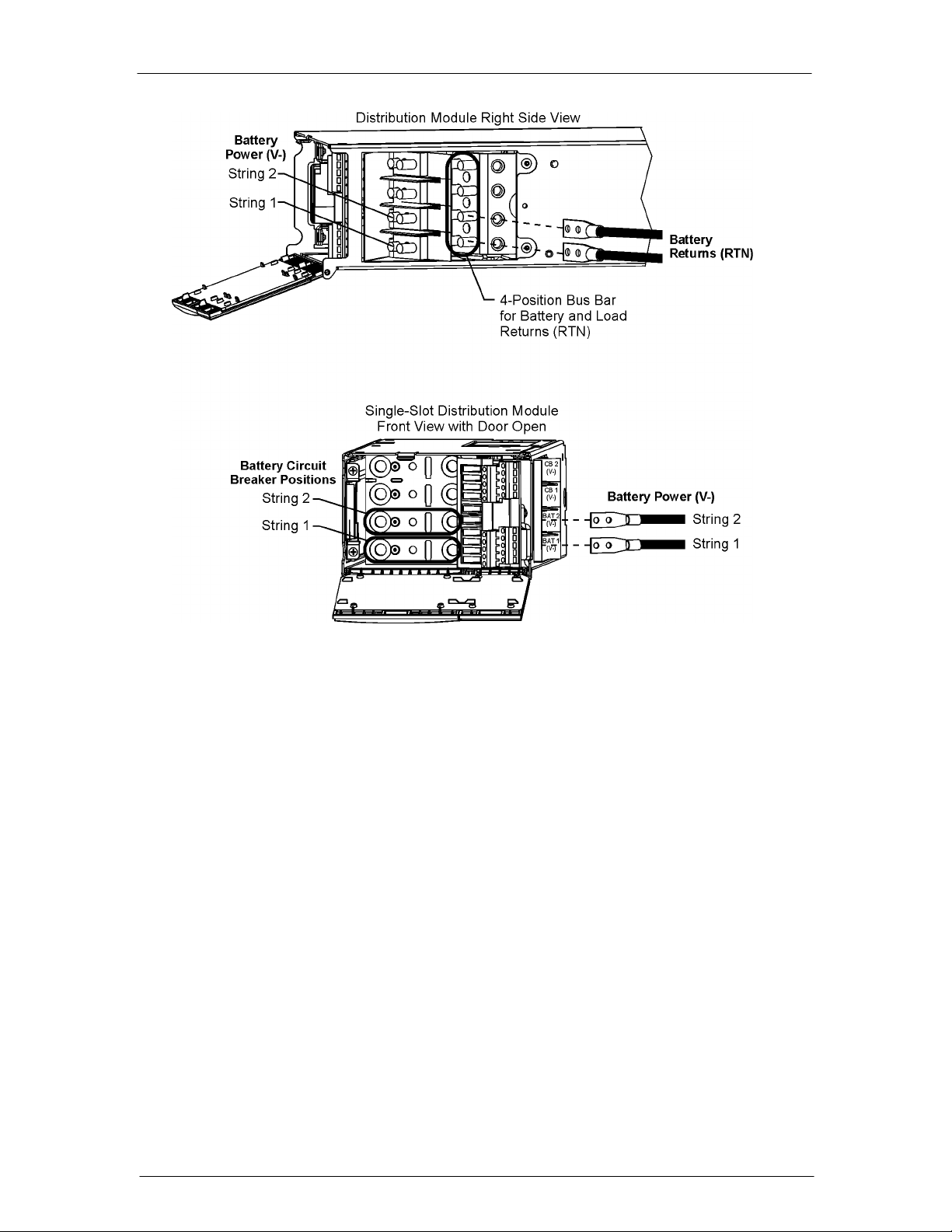

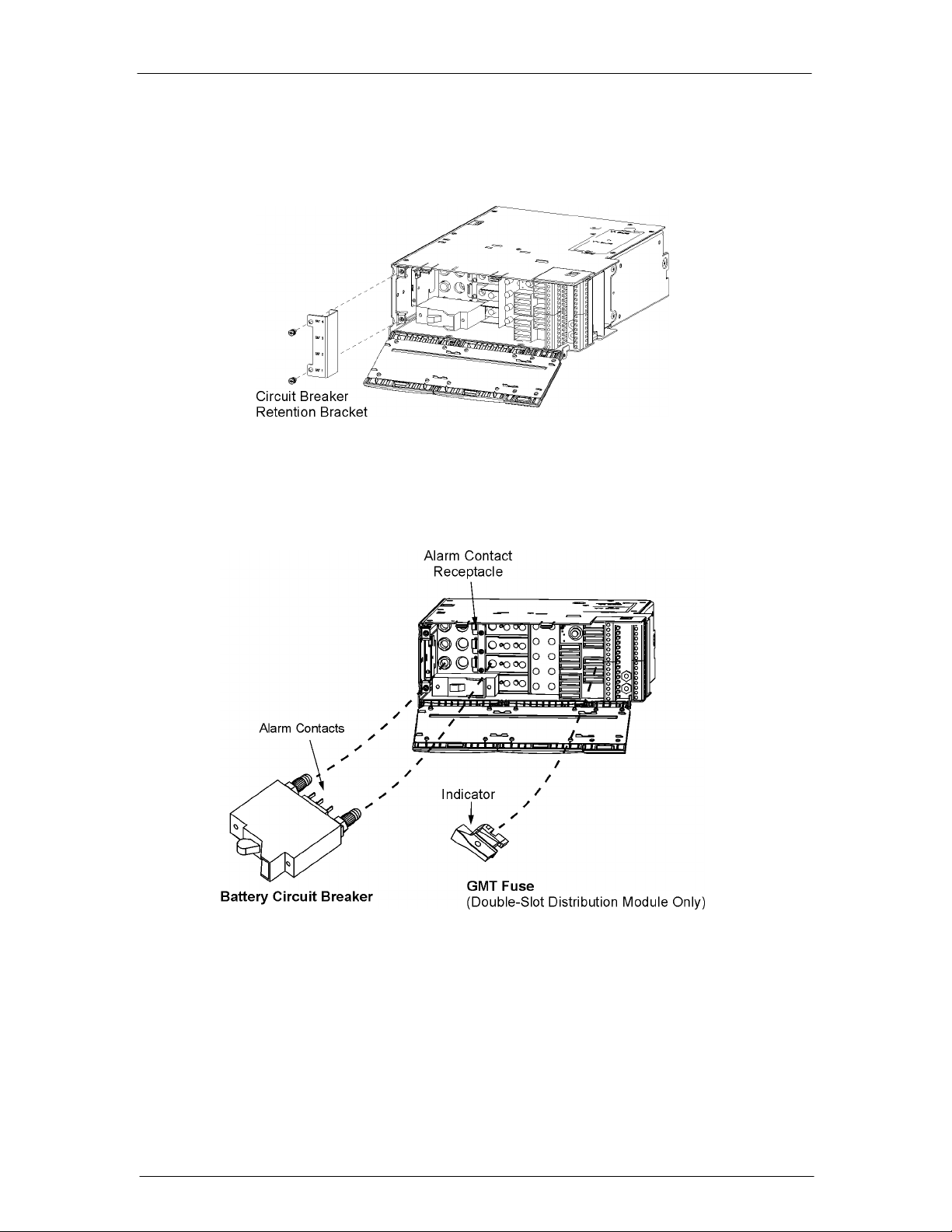

Distribution Modules provide battery circuit breakers. Single-Slot and Double-Slot

Distribution Module options include GMT-style fuses and bullet-style circuit breakers.

Ringer Chassis may be installed in Power Slots. Each Ringer Chassis supports one ringing

output in either non-redundant (simplex) or 1 + 1 redundant (duplex) operation. Ringer

distribution is direct from the Ringer Chassis. Ringers power ringing signaling outputs and

are powered by -48Vdc.

The batteries are monitored by the system controller to ensure their peak performance and

longevity against thermal issues. They are monitored via the Voltage/Thermal Probes (VTProbes), which are connected from the Distribution Module to the battery.

The Remote Voltage Monitor (RVM) module may be used with the VT-Probes in making

voltage measurements for battery string-voltage imbalance detection. Additional VT-Probes

may used by connecting them in a daisy-chain fashion.

The system controller monitors all system parameters and performs battery management

functions. It communicates with all devices using the RS-485 bus. The RVM and VT-Probe

communicate with the controller using the 1-Wire® from Maxim Integrated Products, Inc.

The LVBD contactor is used to connect the battery strings to the main power bus. Under ac

fail conditions, the battery current will be flowing through the contactor to the output

distribution in supporting the load. To prevent deep discharge of batteries, the CPS6000 can

disconnect the batteries from the load by opening the LVBD contactor.

Issue 21 January 2008 9

Page 10

CPS6000 –48V Indoor/Outdoor Power Shelf

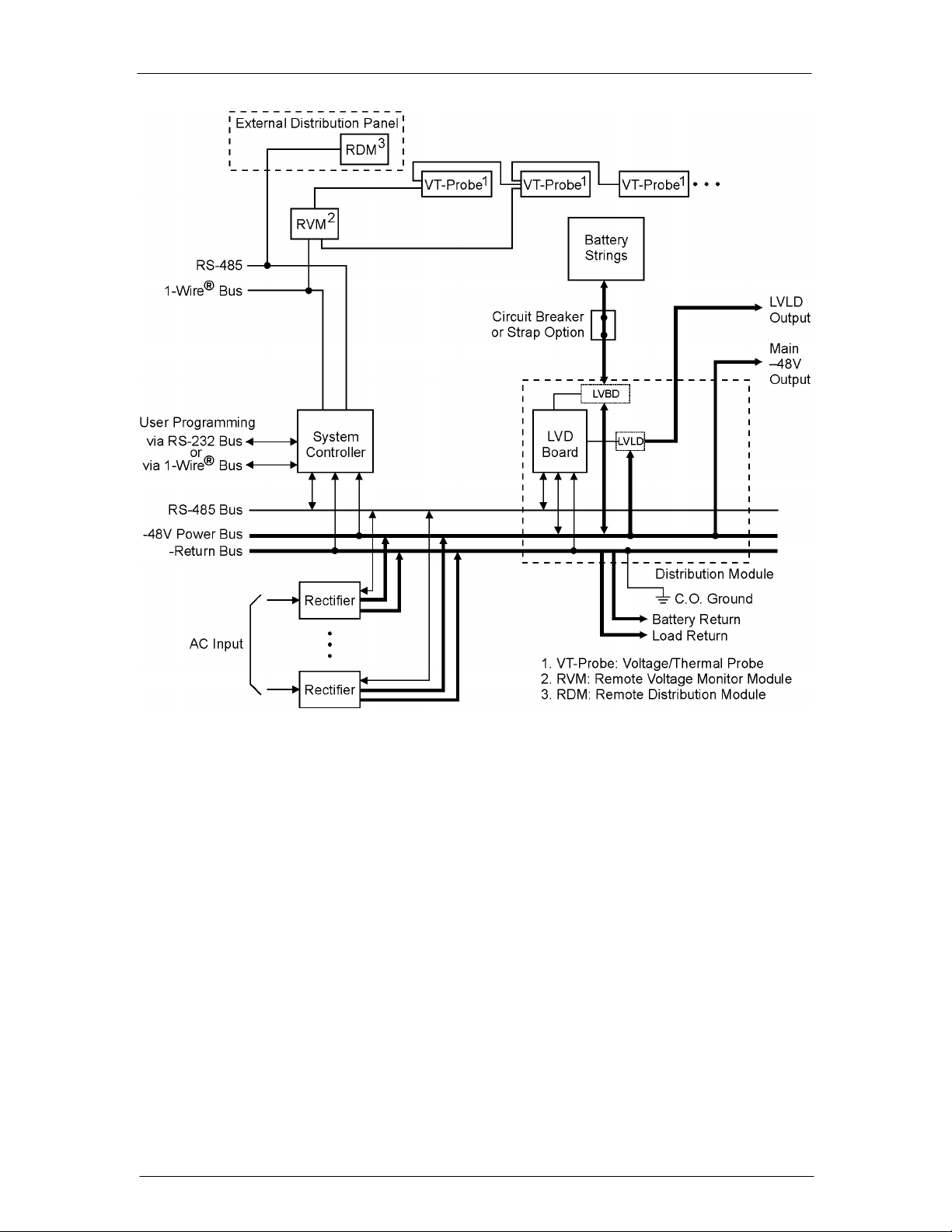

CPS6000 also offers an optional low voltage load disconnect (LVLD) contactor. Non-critical

loads and loads sensitive to low voltages can be connected to the system via the LVLD in the

Distribution Module. CPS6000 disconnects these loads at a set threshold during a battery

discharge. This reduces drain on the batteries and extends reserve time available for critical

loads.

With the Bulk Output Module, a supplementary shelf may be paralleled to the primary shelf

to create a larger plant. Only the primary shelf would contain the system controller. The

supplementary shelf only requires signal connections to the primary shelf, and power

connections to an external distribution panel. The controller can monitor for open protectors,

current from a battery shunt, and monitor and control a low voltage disconnect contactor via

the Remote Distribution Module (RDM).

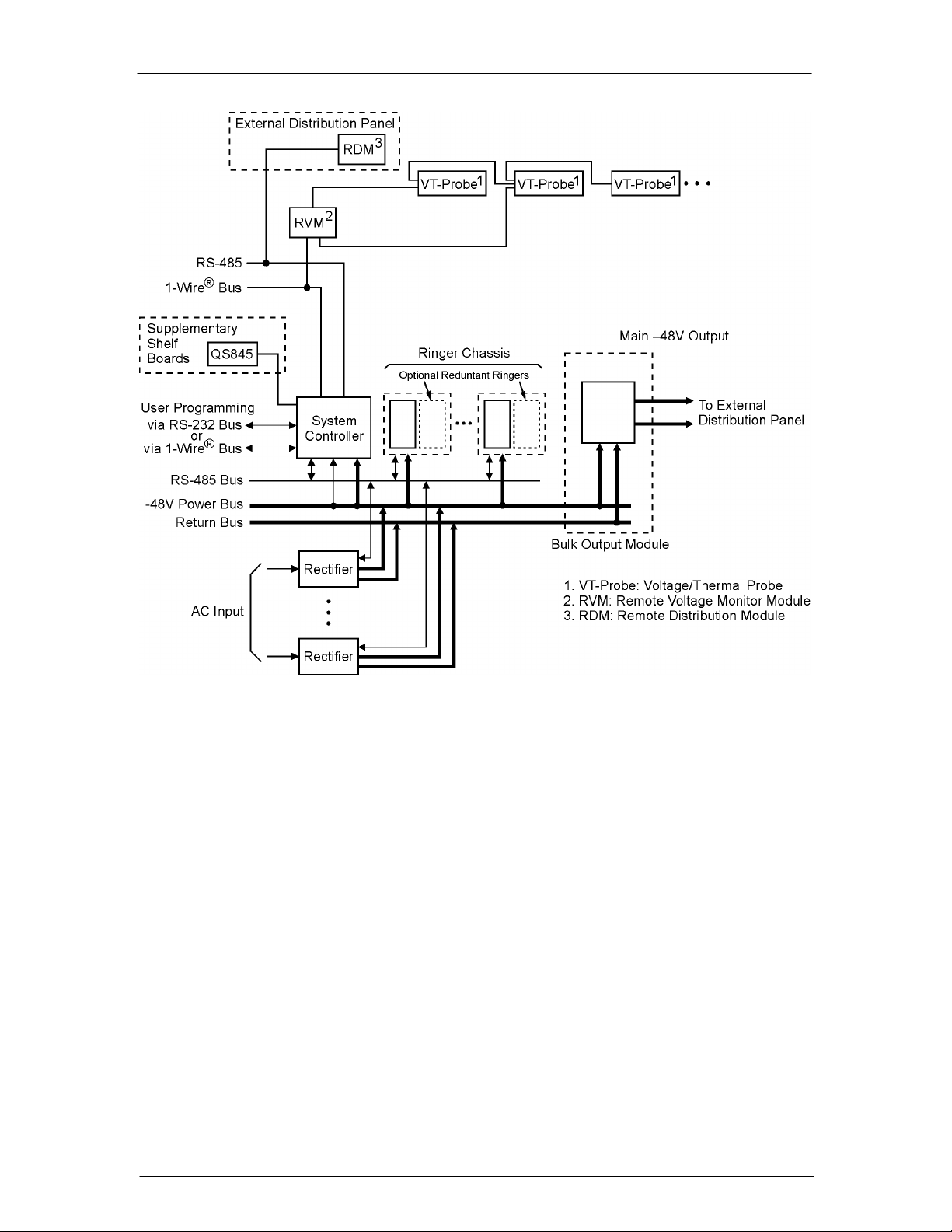

Block Diagrams

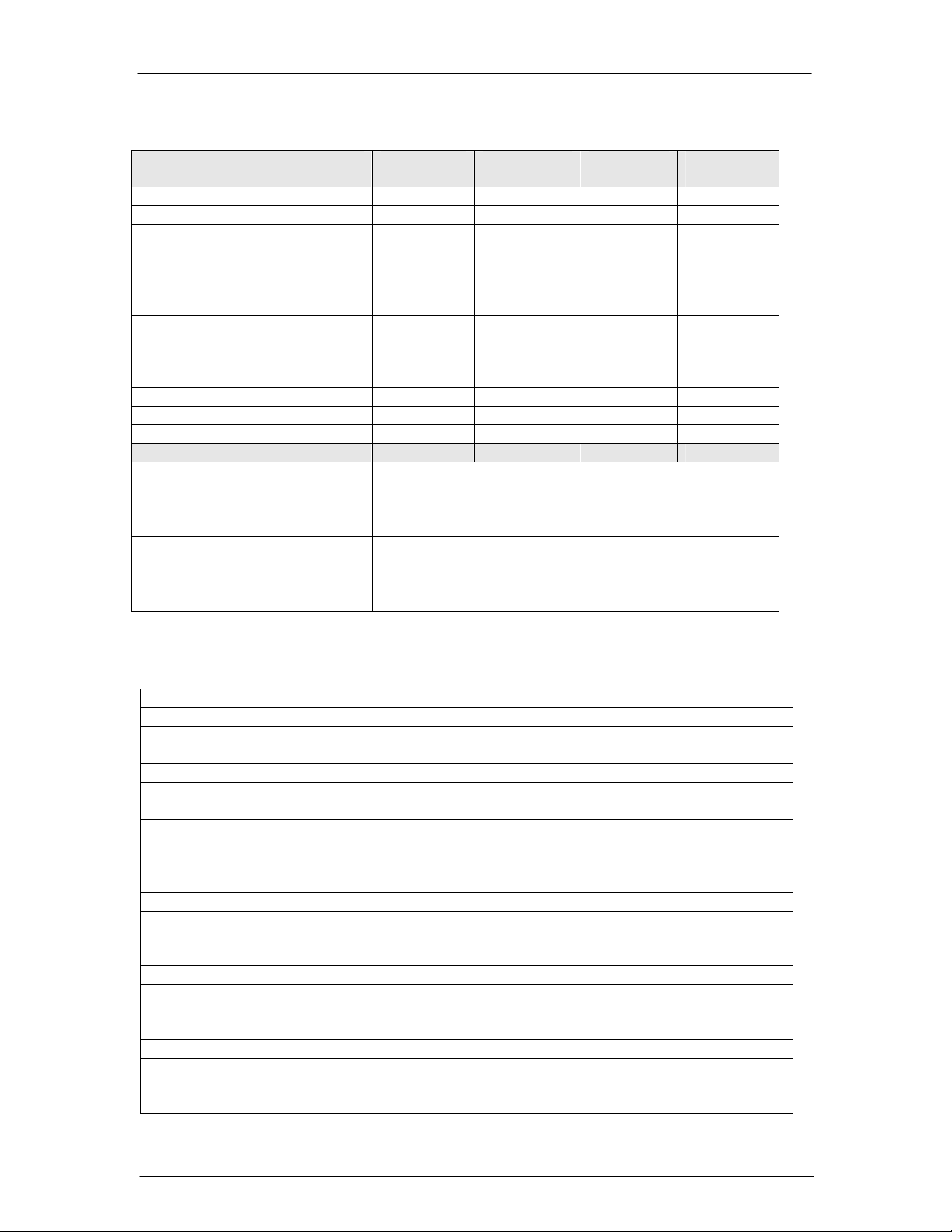

2-1a and 2-1b are basic block diagrams of the CPS6000 System in a single shelf with a

Distribution Module. Figure 2-2 shows the Bulk Output Module in place of the Distribution

Module.

Figure 2-1a: CPS6000 System with Distribution Module

Issue 21 January 2008 10

Page 11

CPS6000 –48V Indoor/Outdoor Power Shelf

Figure 2-1b: CPS6000 System with Distribution Module

Issue 21 January 2008 11

Page 12

CPS6000 –48V Indoor/Outdoor Power Shelf

Figure 2-2: CPS6000 System with Bulk Output Module

Shelf Design

Features

• The shelf is available in 19-inch (phase 2) and 23-inch standard widths and has the

following features:

• Accepts plug-in rectifier, ringer and Distribution Modules.

• 19-inch shelves provide 4 Power Slots.

• 23-inch shelves provide 5 Power Slots

• Rectifiers, Ringer Chassis, and Distribution Modules may be installed in Power Slots.

Permits growth of plant capacity and easy maintenance without service interruption.

Issue 21 January 2008 12

Page 13

CPS6000 –48V Indoor/Outdoor Power Shelf

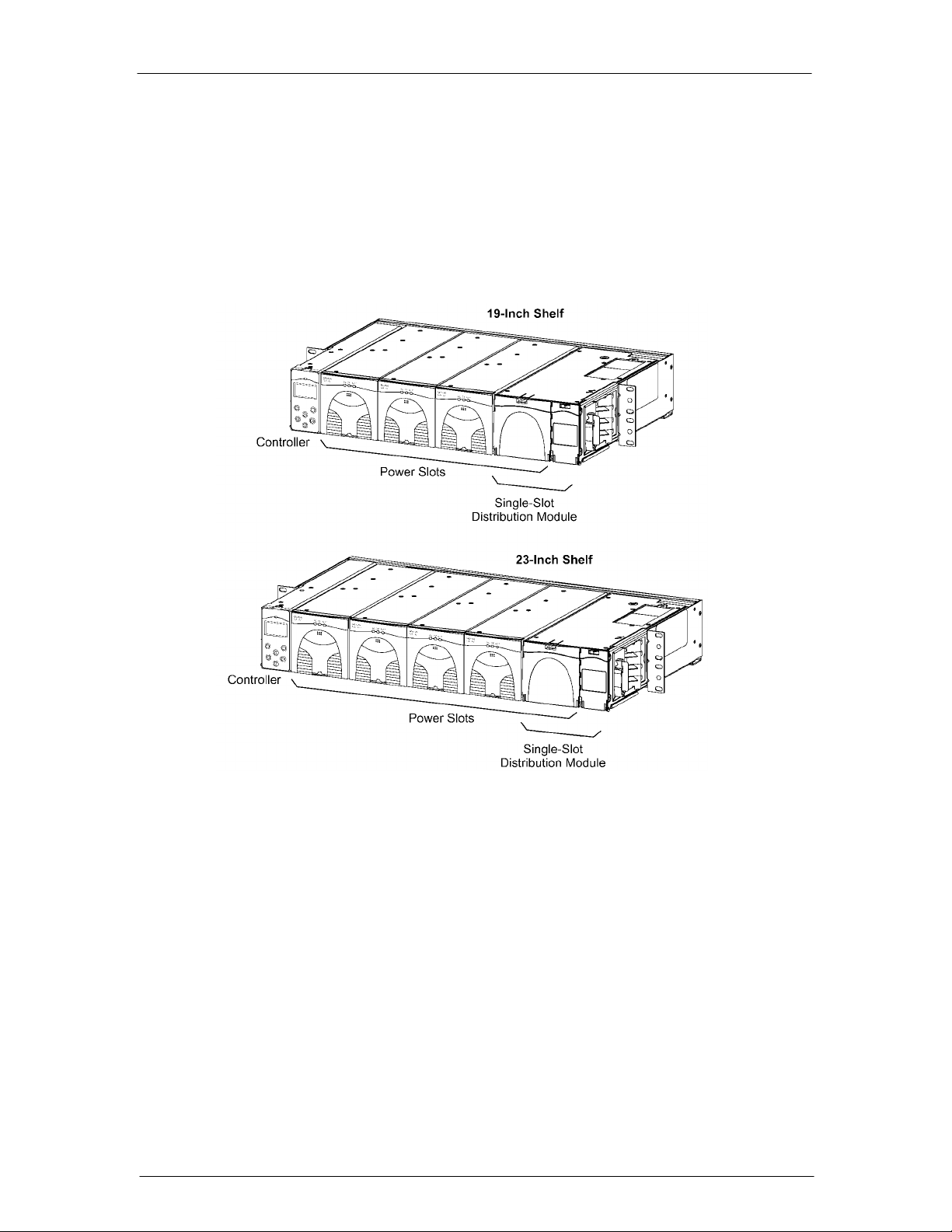

Configurations

The 19-Inch Shelf provides four Power Slots.

The 23-Inch Shelf provides five Power Slots.

Power Slots support Rectifiers, Ringer Chassis, and Distribution Modules. Figure 2-3 shows

the show the locations of the CPS6000 components in the19-inch and 23-inch shelves with

the Single-Slot Distribution Module.

Figure 2-3: CPS6000 Systems with Single-Slot Distribution Module

Issue 21 January 2008 13

Page 14

CPS6000 –48V Indoor/Outdoor Power Shelf

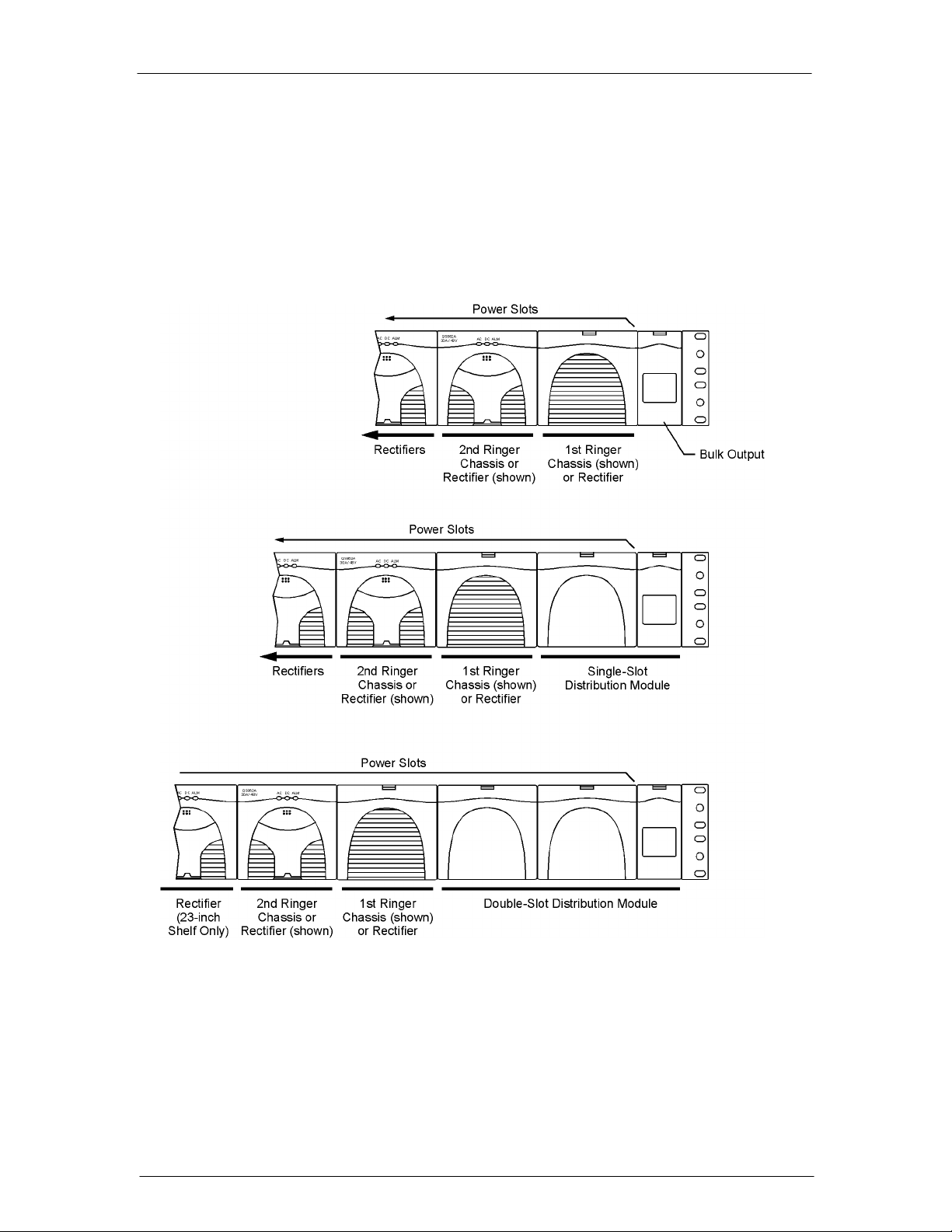

Distribution and Power Module Configurations

The 19-inch shelf has four Power Slots, and the 23-inch shelf has five Power Slots for power

modules (Rectifiers and up to two Ringer Chassis) and distribution options (See 2- 4). With

Bulk Output Distribution only, all slots are available for power modules. The Single-Slot

Distribution Module occupies the right-most Power Slot, and the Double-Slot Distribution

Module occupies the right-most two Power Slots, leaving the remaining Power Slots available

for power modules. Up to two Ringer Chassis can be installed in the right-most remaining

Power Slots.

Figure 2-4: Distribution and Power Module Configurations

Issue 21 January 2008 14

Page 15

CPS6000 –48V Indoor/Outdoor Power Shelf

Battery Reserve System

Introduction

A battery reserve system is a key component for a reliable power system. The CPS6000

provides a primary voltage of -48Vdc that drives load equipment. At the same time, it

provides float and recharge capability for the battery reserve system. If an ac power failure

occurs, the batteries provide power to the load equipment until the ac can be restored.

Types of Batteries

CPS6000 may be used with valve-regulated lead-acid (VRLA) batteries. Up to four strings of

VR-type batteries or equivalent general trade batteries may be connected directly to a

CPS6000 shelf.

Certain Nickel-Cadmium (Ni-Cd) and Lithium-Ion batteries may also be used with the

CPS6000. Please contact your sales representative for details. CPS6000 is also compatible to

Flooded lead-acid batteries.

See Appendix D for detailed descriptions of battery related functions; float and boost

charging, thermal compensation, and system battery test functions.

Issue 21 January 2008 15

Page 16

CPS6000 –48V Indoor/Outdoor Power Shelf

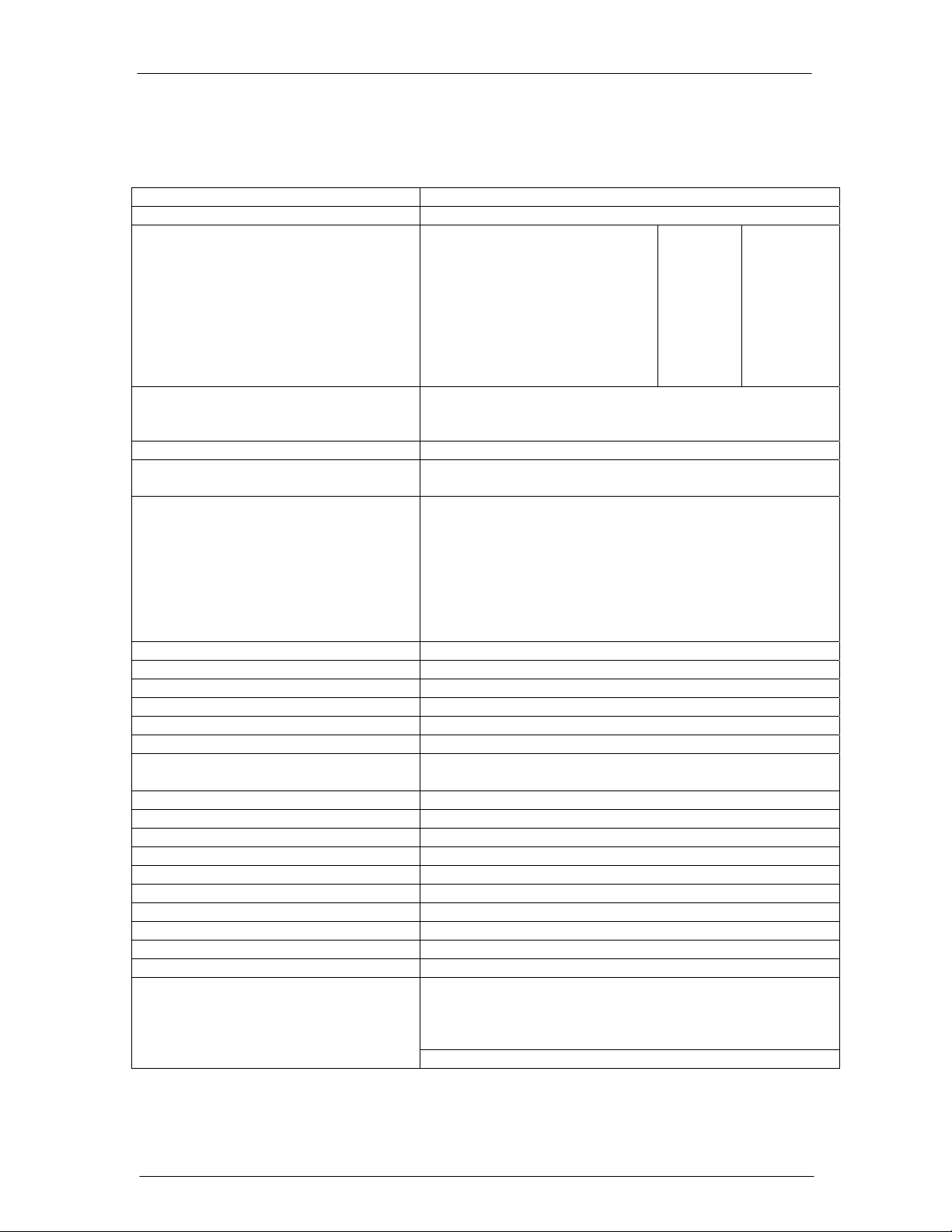

Specifications

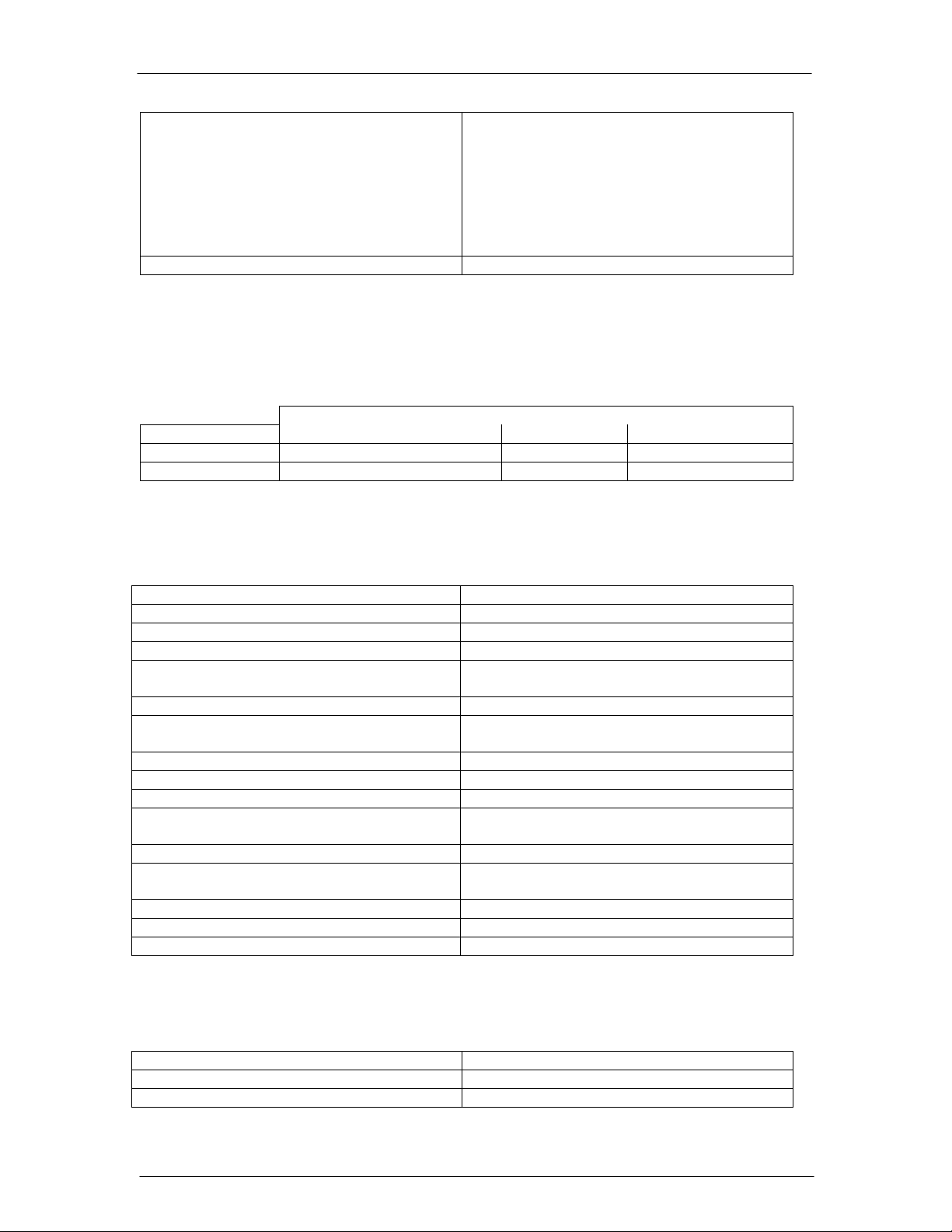

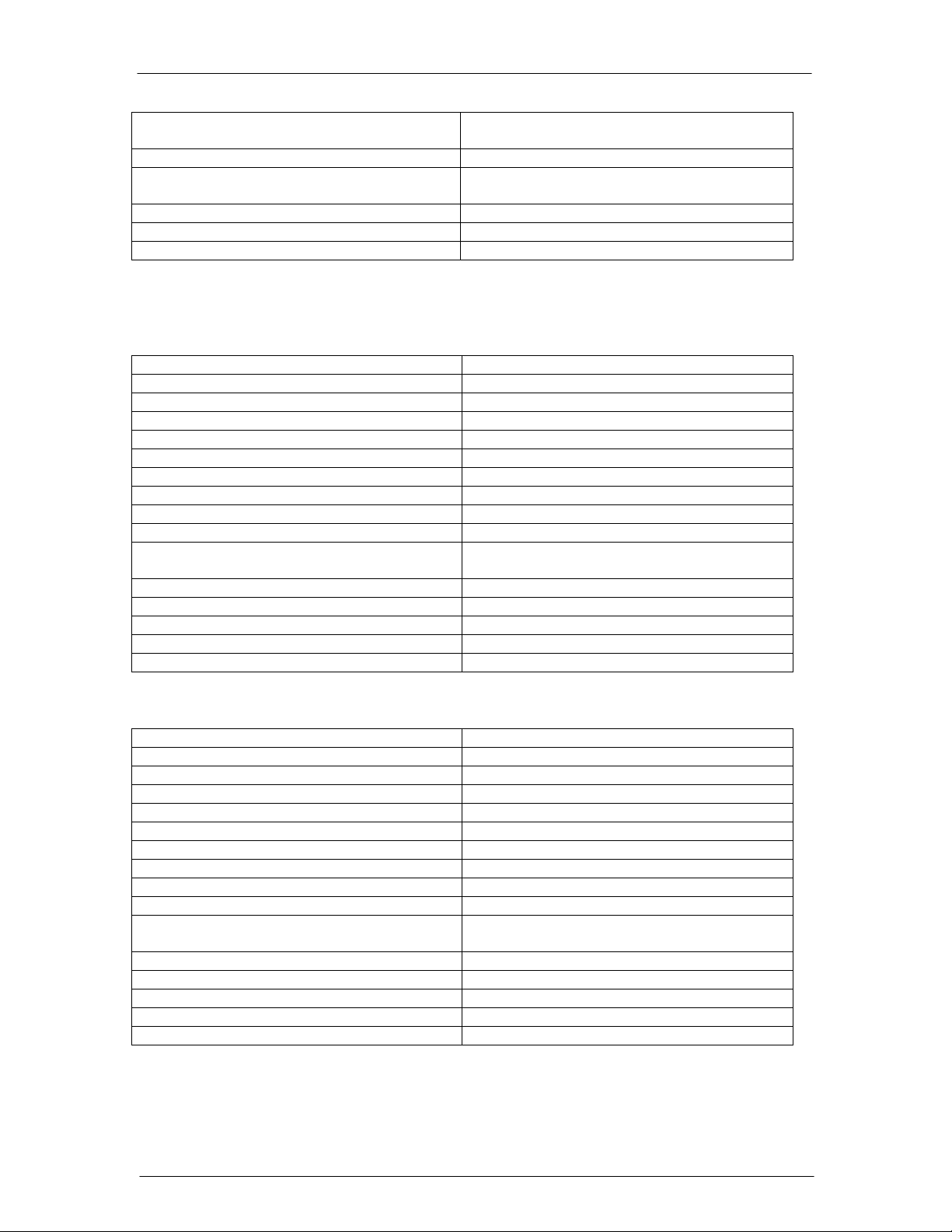

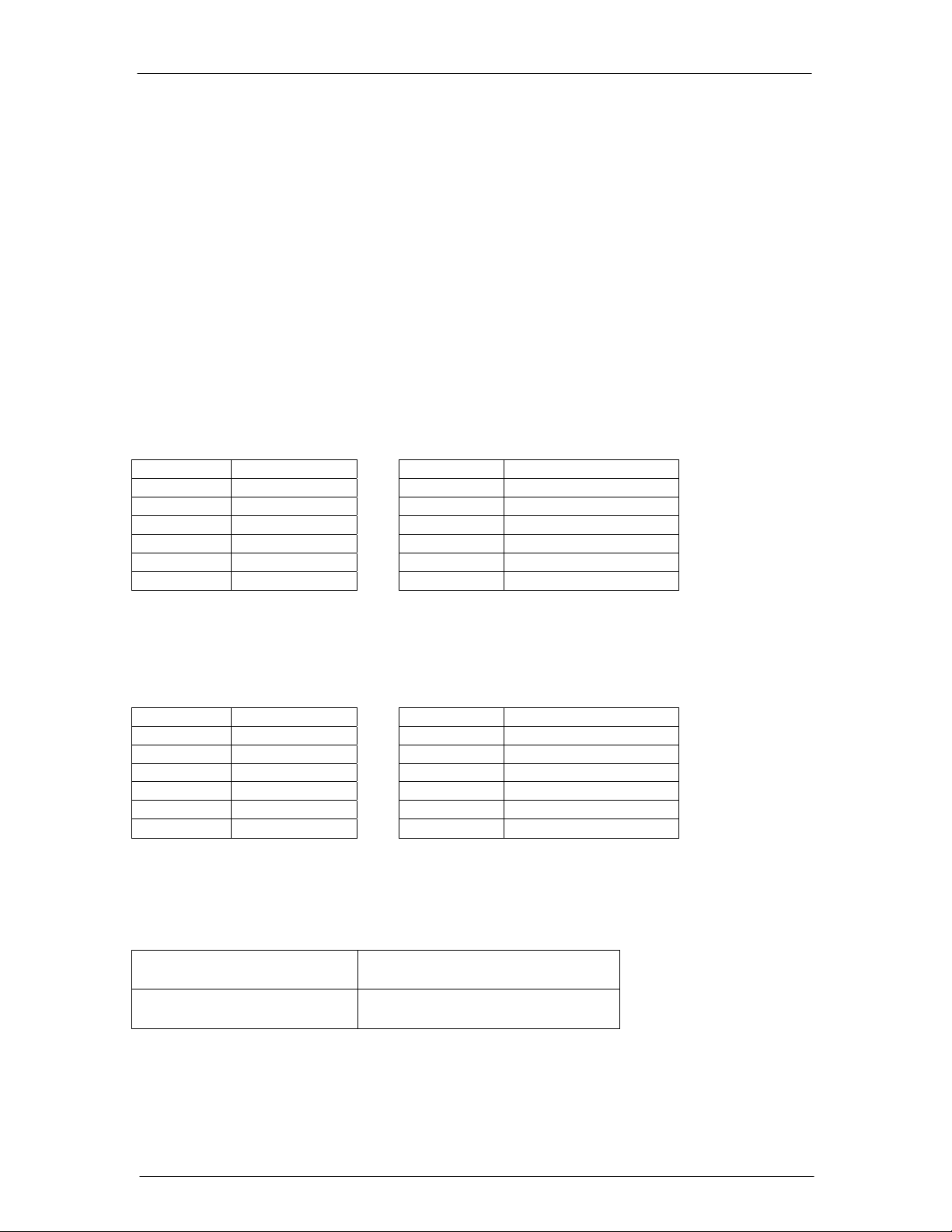

Table 2-A: CPS6000 System Specifications

Shelf Single 19-inch or 23-inch shelf

Power Slots per Shelf 4 (19-inch shelf), 5 (23-inch shelf)

Power Units

Installed Position

Installed from the Right

Bulk Output Module

Distribution Module

Ringer Chassis

Installed from the Left

Rectifier Input Distribution Dual ac input (19 and 23-inch shelves)

System Architecture Primary output: 1 primary output power bus per shelf

Primary Power Bus Current

with Bulk Output Module

Output Distribution Primary Bus

Bulk Output Module

Single-Slot and Double-Slot

Distribution Modules

Maximum Discharge Current Based on rectifier capacity. See Note 2

Maximum Recharge Current Installed shelf –48V rectifier capacity minus plant –48V load

Operating Ambient Temperature -40 to 75 °C (-40 to 167 °F), see Note 3

Altitude -200 to 13,000 feet (-61 to 3962 meters). See Note 4

Humidity 10% to 95% non-condensing

Audible Noise < 60 dBA

Radiated and Conducted Emissions FCC Part 15, Class B

Harmonics EN61000-3-2 (IEC61000-3-2)

Voltage Fluctuations EN61000-3-3 (IEC61000-3-3)

Electromagnetic Immunity Meets Telcordia GR-1089-CORE

Electrostatic Discharge EN61000-4-2 Level 3

RF Immunity IEC61000-4-3 Level 3, 10 V/m

EFT IEC61000-4-4 Level 3, No Error; Level 4, No Damage

Surge IEC 61000-4-5 Level 3, No Error; Level 4, No Damage

Conducted Immunity IEC 61000-4-6 Level 3, 10V

Voltage Dips, Interruptions, and Variations IEC 61000-4-11

Earthquake Rating Zone 4, upper floors

Safety Agency Approval

5

Rectifiers

Bulk Output Module

Single-Slot Distribution Module

Double-Slot Distribution Module

Ringer Chassis

Rectifiers (19-inch shelf)

(23-inch shelf)

Individual ac input (19 and 23-inch shelves)

Single ac input (19 and 23-inch shelves)

19-inch shelf: 227A

23-inch shelf: 283A

Battery connections: double-hole lugs to terminate battery

strings.

-48 Vdc bulk power outputs to loads or distribution

• Bullet-style circuit breakers

• GMT-style fuses

See Note 2.

EN55022 (CISPR22), Class B

Underwriters Laboratories (UL) Listed per Subject Letter 1801:

Power Distribution Center for Communications Equipment, and

cUL Certified (CSA 22.2 950): Safety of Information

Technology Equipment

VDE licensed to VDE0805/EN60950

Unit

Max. per

Shelf

1

1

1

2

4

5

Power Slots

Each

0

1

2

1

1

1

Issue 21 January 2008 16

Page 17

CPS6000 –48V Indoor/Outdoor Power Shelf

Rectifiers are individually UL Recognized (UL1950), cUL

Certified (CSA 22.2 234) or evaluated to EN60950 by an EC

Notified Body, as appropriate.

European Economic Community (EEC)

Directives

Note 1: CPS6000 can be used with four strings of batteries depending on Distribution Module

Note 2: When used with Single-Slot and Double-Slot Distribution Modules, maximum output is limited to

200A or the size of the LVD contactor installed (if smaller). See Section 3 for limitations on

maximum currents through Distribution Modules.

Note 3: Operating temperatures and required airflow are different when used with specific rectifiers. See

Tables 2-D through 2-F for rectifier information.

Note 4: For altitudes above 5000 feet, derate the temperature by 3.6 °F per 1000 feet. For altitudes above

1524 meters, derate the temperature by 0.656 degrees Celsius per 100 meters.

Note 5: Power Unit Install Positions:

• Install these units in order beginning with the right most Power Slot

First: Distribution Module

Second: Ringer Chassis

• Install these units in order beginning with the left most Power Slot

First: Rectifiers

EMC Directive 89/336/EEC

Low Voltage Directive 73/23/EEC as amended by Marking

Directive 93/68/EEC

Installation Category

CPS6000 is suitable for connection to ac utility systems where the expected level of lightning

surges complies with ANSI C62.41 Category B or IEC 60664-1 Overvoltage Category II.

A service entrance surge protector is required in applications where the installation categories

can not be classified as being compliant to either ANSI C62.41 Category B or IEC 60664-1

Overvoltage Category II.

CPS6000 rectifiers have been tested for repeated lightning surges typically found in an

Overvoltage Category III installation; however, a service entrance surge protector is

recommended in cabinet applications to bring the power feeds in compliance to the

installation categories above. The service entrance protection should be coordinated with the

protection provided in the power modules.

The power module provides common-mode protection via a 320V MOV in series with a

2500V gas-discharge device and differential-mode protection via a 320V MOV in series with

a 3.5A fuse.

Issue 21 January 2008 17

Page 18

CPS6000 –48V Indoor/Outdoor Power Shelf

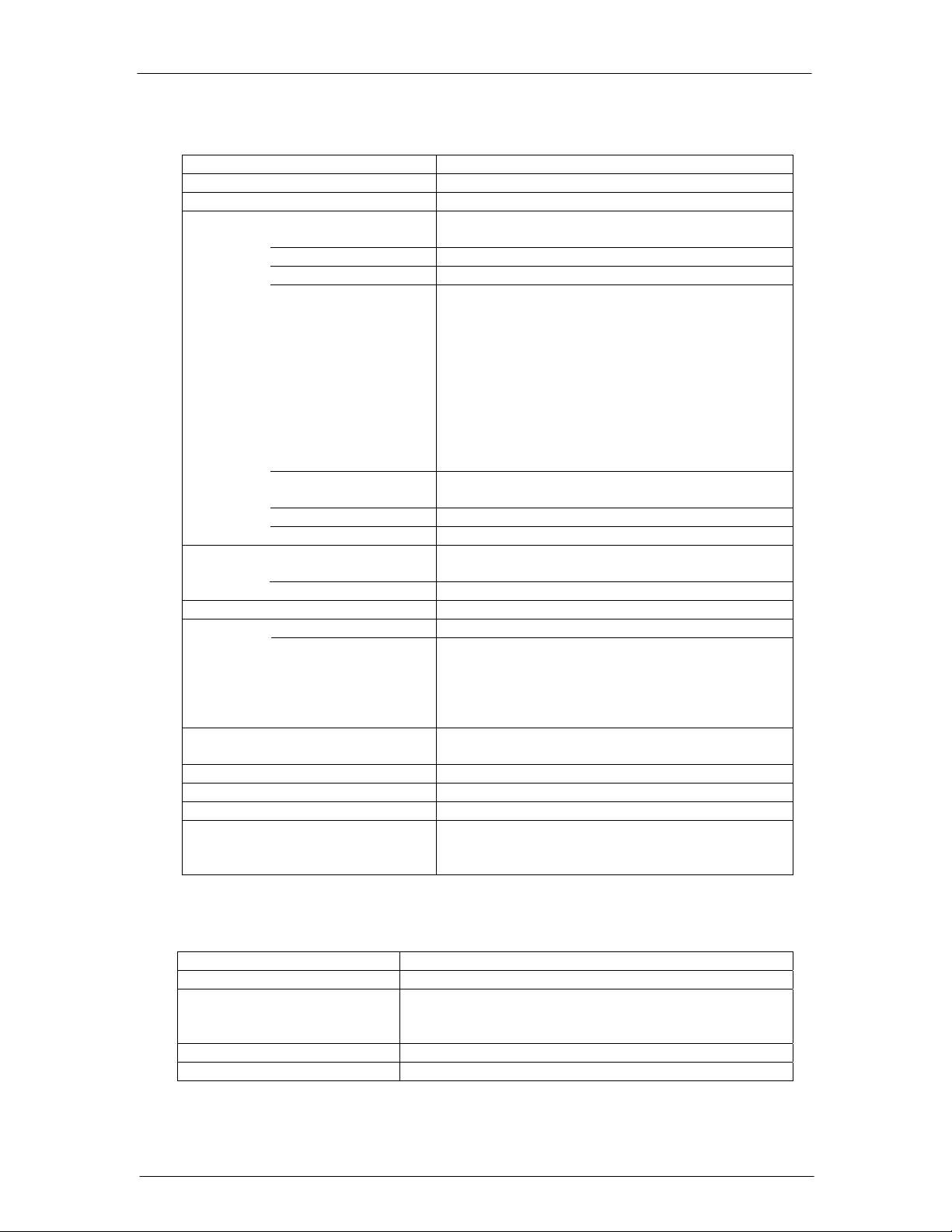

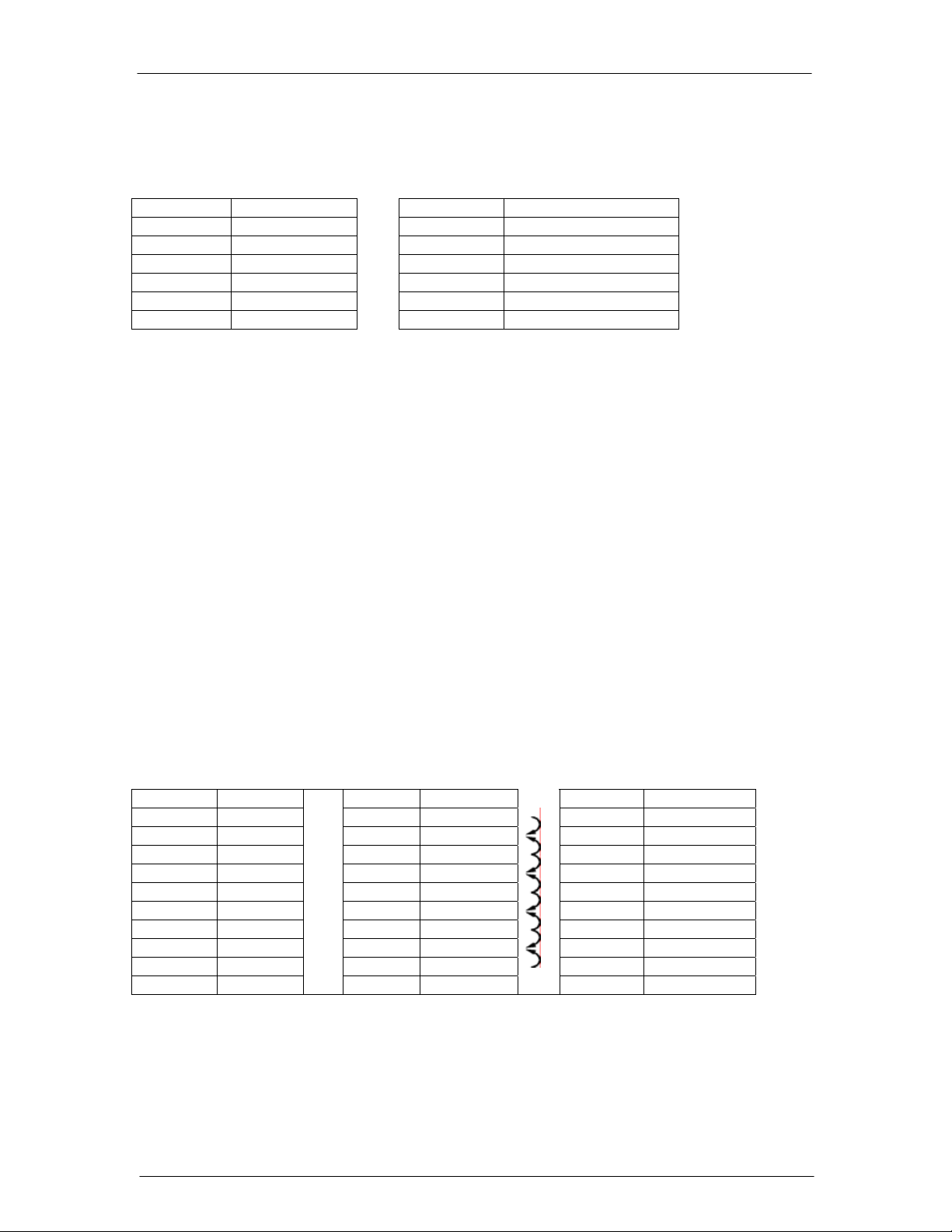

Table 2-B: CPS6000 Physical Specifications

Rectifier 3.41 (86.6) 3.4 (86.3) 11.2 (284.5) 5.75 (2.6)

Ringer Chassis 3.41 (86.6) 3.4 (86.3) 11.2 (284.5) 3.45 (1.6)

Ringer 2.4 (61.0) 1.51 (38.4) 9.9 (252) 1.25 (0.6)

19-Inch Shelf 3.41 (86.6) 17.37 (441.2) 12 (304) –

23-Inch Shelf 3.41 (86.6) 20.95 (532.1) 12 (304) –

Single-Slot Distribution Module 3.41 (86.6) 5.1 (129.5) 12 (304) 9 (4.1)

Double-Slot Distribution Module 3.41 (86.6) 8.5 (216) 12 (304) TBM

Bulk Output Module 3.41 (86.6) 1.59 (40.4) 12 (304) 4 (1.8)

23-Inch Frame Mounting

Requirements

19-Inch Frame Mounting

Requirements

Height

in. (mm)

Standard 23 and 26-inch relay racks:

•Vertical mounting centers: 1.0 in. (25 mm) and 1.75 in.

(44 mm)

•Horizontal mounting centers: 22.32 in. (567 mm)

Standard 19-inch relay racks:

•Vertical mounting centers: 1.0 in. (25 mm) and 1.75 in.

(44 mm)

•Horizontal mounting centers: 18.31 in. (465 mm)

Width

in. (mm)

Depth

in. (mm)

front access

13.25 (337)rear access

12.7 (5.77)

front access

13.25 (337)rear access

Weight

lb (kg)

7.5 (3.41)

Table 2-C: CPS6000 Shelf Specifications

Control Unit QS840A / QS841A

Nominal Output Voltages 48/52/54.5 Vdc

Operating Voltage Range 42 to 58 Vdc

Maximum Output Current 200A per 19-inch shelf; 250A per 23-inch shelf

(see Note 1)

Nominal Input Voltage 100/120/200/208/240 Vac

Input Voltage Ranges 85 to 275 Vac

Max Nominal Input Current per Rectifier (based

on 25A rectifier for low line ac, and 50A

rectifier for high line ac)

Boost Voltage 48 to 58 Vdc

Output Voltage Regulation ±0.5%

Output Noise:

Ripple

Wideband Noise

Load Share Accuracy 1.5A (maximum) for QS862A

Maximum Discharge Current

(see Note)

Maximum Recharge Current Installed rectifier capacity minus plant load

Low-Voltage Disconnect 39 to 50 Vdc

Low-Voltage Reconnect 39 to 55 Vdc

Heat Dissipation 177W (604 BTU) per QS862A at full load and

13A at 120 Vac

14.5A at 208 Vac

100 mVrms maximum, 10 Hz to 20 MHz

< 250 mV pk-pk over the range dc to 100 MHz

227A per 19-inch shelf; 284A per 23-inch shelf

120 Vac operation;

Issue 21 January 2008 18

Page 19

CPS6000 –48V Indoor/Outdoor Power Shelf

132W (450 BTU) per QS861A rectifier at full

load and 120 Vac operation;

212W (724 BTU) per QS862A at full load and

240 Vac operation;

130W (445 BTU) per QS861A rectifier at full

load and 240 Vac operation;

267W (911 BTU) per QS865A rectifier at full

load and 240 Vac operation;

Power Factor > 0.98 for loads > 50% of full load

Note: Maximum current is based on Bulk Output Module and 50A QS865A rectifier. System capacity

will decrease with lower rated rectifiers.

Power Slots Available for Rectifiers or Ringer Chassis

Shelf

19-Inch Shelf 4 3 2

23-Inch Shelf 5 4 3

None (Bulk Output Module)

Distribution Module

Single-Wide Double-Wide

Rectifiers

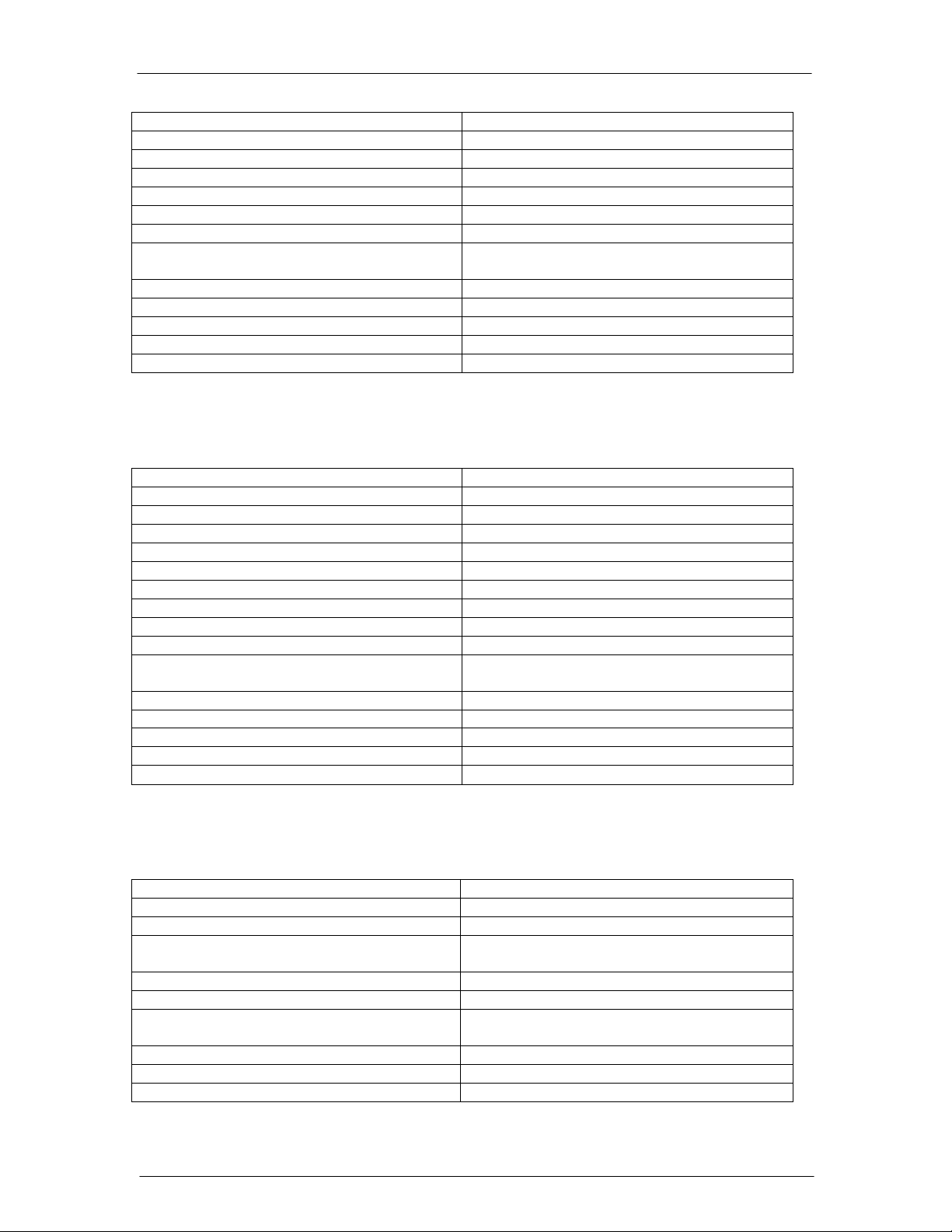

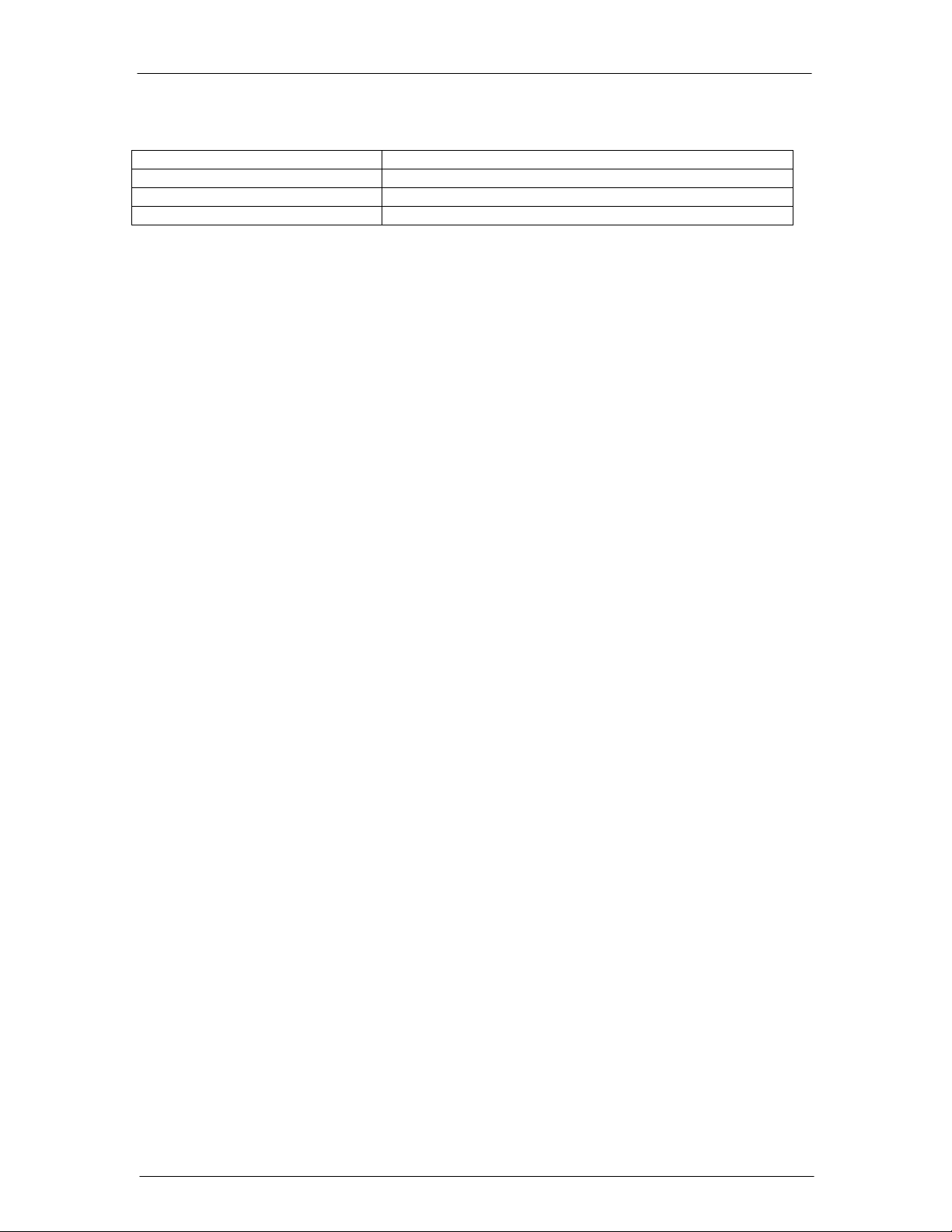

Table 2-D: QS861A Rectifier Specifications

Nominal Output Voltage 48/52/54.5 Vdc

Operating Output Voltage Ranges 42 to 58 Vdc

Boost Voltage 48 to 58 Vdc

Output Current 0 to 15A at 54.5V

Nominal Input Voltage 100/120/200/208/240 Vac (Shutdown from 135 to

150V)

Input Voltage Ranges 85 to 275 Vac

Input Current 8A at 120 Vac

4.4A at 208 Vac

Operating Frequency Range 45 to 66 Hz

Operating Temperature -40 to +75 °C

Output Voltage Regulation ±0.5%

Output Noise, Ripple 250 millivolts peak to peak maximum, over the

range dc to 100 MHz

Load Share Accuracy 1.5A maximum deviation between rectifiers

Heat Dissipation (per rectifier, full load) 132W (450 BTU) at 120 Vac operation

130W (445 BTU) at 240 Vac operation

Power Factor >0.99 (low-line), >0.98 (high line)

Selective High-Voltage Shutdown Above 58 Vdc

Backup High-Voltage Shutdown Above 60 Vdc for 1 millisecond

Table 2-E: QS852A Rectifier Specifications

Nominal Output Voltage 48/52/54.5 Vdc

Operating Output Voltage Ranges 42 to 58 Vdc

Boost Voltage 48 to 58 Vdc

Issue 21 January 2008 19

Page 20

CPS6000 –48V Indoor/Outdoor Power Shelf

Output Current 0 to 20A at 54.5V

Nominal Input Voltage 1200/208/240 Vac

Input Voltage Ranges 150 to 275 Vac

Input Current 6A at 208 Vac

Operating Frequency Range 45 to 66 Hz

Operating Temperature -40 to +75 °C

Output Voltage Regulation ±0.5%

Output Noise, Ripple 250 millivolts peak to peak maximum, over the

range dc to 100 MHz

Load Share Accuracy 1.5A maximum deviation between rectifiers

Heat Dissipation (per rectifier, full load) 133 W (454 BTU) at 240 Vac operation

Power Factor >0.98 (high line)

Selective High-Voltage Shutdown Above 58 Vdc

Backup High-Voltage Shutdown Above 60 Vdc for 1 millisecond

Table 2-F: QS853A Rectifier Specifications

Nominal Output Voltage 48/52/54.5 Vdc

Operating Output Voltage Ranges 42 to 58 Vdc

Boost Voltage 48 to 58 Vdc

Output Current 0 to 25A at 54.5V (100/120 Vac)

Nominal Input Voltage 200/208/240 Vac

Input Voltage Ranges 150 to 275 Vac (Shutdown from 135 to 150V)

Input Current 7.4A at 208 Vac

Operating Frequency Range 45 to 66 Hz

Operating Temperature -40 to +75 °C

Output Voltage Regulation ±0.5%

Output Noise, Ripple 250 millivolts peak to peak maximum, over the

range dc to 100 MHz

Load Share Accuracy 1.5A maximum deviation between rectifiers

Heat Dissipation (per rectifier, full load) 212W (724 BTU) at 200 to 240 Vac operation

Power Factor >0.98 for loads > 50% full load

Selective High-Voltage Shutdown Above 58 Vdc

Backup High-Voltage Shutdown Above 60 Vdc for 1 millisecond

Table 2-G: QS862A Rectifier Specifications

Nominal Output Voltage 48/52/54.5 Vdc

Operating Output Voltage Ranges 42 to 58 Vdc

Boost Voltage 48 to 58 Vdc

Output Current 0 to 25A at 54.5V (100/120 Vac)

0 to 30A at 54.5V (200/240 Vac)

Nominal Input Voltage 100/120/200/208/240 Vac

Input Voltage Ranges 85 to 275 Vac (Shutdown from 135 to 150V)

Input Current 13A at 120 Vac

8.8A at 208 Vac

Operating Frequency Range 45 to 66 Hz

Operating Temperature -40 to +75 °C

Output Voltage Regulation ±0.5%

Issue 21 January 2008 20

Page 21

CPS6000 –48V Indoor/Outdoor Power Shelf

Output Noise, Ripple 250 millivolts peak to peak maximum, over the

range dc to 100 MHz

Load Share Accuracy 1.5A maximum deviation between rectifiers

Heat Dissipation (per rectifier, full load) 177W (604 BTU) at 100 to 120 Vac operation

212W (724 BTU) at 200 to 240 Vac operation

Power Factor >0.98 for loads > 50% full load

Selective High-Voltage Shutdown Above 58 Vdc

Backup High-Voltage Shutdown Above 60 Vdc for 1 millisecond

Table 2-H: QS864A Rectifier Specifications (Preliminary)

Nominal Output Voltage 48/52/54.5 Vdc

Operating Output Voltage Ranges 42 to 58 Vdc

Boost Voltage 48 to 58 Vdc

Output Current 0 to 40A at 54.5V

Nominal Input Voltage 200/208/240 Vac

Input Voltage Ranges 150 to 275 Vac

Input Current 11.8A at 208 Vac

Operating Frequency Range 45 to 66 Hz

Operating Temperature -40 to +75 °C

Output Voltage Regulation ±0.5%

Output Noise, Ripple 250 millivolts peak to peak maximum, over the

range dc to 100 MHz

Load Share Accuracy 1.5A maximum deviation between rectifiers

Heat Dissipation (per rectifier, full load) 240W (819 BTU) at 240 Vac operation

Power Factor >0.98 for loads > 50% full load

Selective High-Voltage Shutdown Above 58 Vdc

Backup High-Voltage Shutdown Above 60 Vdc for 1 millisecond

Table 2-I: QS865A Rectifier Specifications

Nominal Output Voltage 48/52/54.5 Vdc

Operating Output Voltage Ranges 42 to 58 Vdc

Boost Voltage 48 to 58 Vdc

Output Current 0 to 50A at 54.5V

Nominal Input Voltage 200/208/240 Vac

Input Voltage Ranges 150 to 275 Vac

Input Current 14.5A at 208 Vac

Operating Frequency Range 45 to 66 Hz

Operating Temperature -40 to +65 °C

Output Voltage Regulation ±0.5%

Output Noise, Ripple 250 millivolts peak to peak maximum, over the

range dc to 100 MHz

Load Share Accuracy 1.5A maximum deviation between rectifiers

Heat Dissipation (per rectifier, full load) 267W (911 BTU) at 240 Vac operation

Power Factor >0.98 for loads > 50% full load

Selective High-Voltage Shutdown Above 58 Vdc

Backup High-Voltage Shutdown Above 60 Vdc for 1 millisecond

Issue 21 January 2008 21

Page 22

CPS6000 –48V Indoor/Outdoor Power Shelf

Table 2-J: QS820A Ringer Specifications

Input Voltage -40 to -57 Vdc See Output VA Thermal Limiting.

Nominal Input Voltage -48 Vdc

Input Current 5 A max.

Output

Voltage

ac tolerance ± 5 Vac

Regulation ±5% ac component only

dc Offset

dc Offset Tracking

Harmonic Distortion 5% THD

Crest Factor 1.21 to 1.51

Output Frequency 15 to 50 Hz

Frequency tolerance ± 1 Hz

Output VA 100 VA

Thermal Limiting Output VA may be reduced by reducing Vac when

Load Power Factor Operating: 0.5 Leading to 0.9 Lagging

Operating Temperature -40 to +75 °C See Output VA Thermal Limiting.

Heat Dissipation 50 W (170 BTU / hr)

Under Voltage Shutdown 50% of Output Vac Set Point

ac Component

Type of ringing

Battery Backed

Ground Backed

Ground Backed no-dc

Error

65 to 100 Vac

Factory Default: 100Vac

• -40 to +57 Vdc Battery Backed

• +40 to +57 Vdc Ground Backed

• 0 Vdc Offset Disabled

• dc Offset tracks dc Input Voltage

• Factory Default: Enabled

• Battery or Ground Backed is selected by Ringer

Chassis jumper J12 or by external connection of

Ring Rtn to Battery or to Ground. Factory Default:

Battery Backed by Jumper

See figures in the Ringer section.

± 3 Vdc

Factory Default: 20 Hz

operating simultaneously above 50°C and less than

-50Vdc input.

Vac is reduced only sufficiently to prevent damage to

the ringer.

No Damage: 0 Leading to 0.7 Lagging

While shutdown due to external fault, restart will be

performed at approximately 2 minute intervals.

Table 2-K: QS840A and QS841A Control Unit Specifications

Operating Input Voltage Range 38 to 60 Vdc

Input Power 6.0 watts maximum

Plant Parameter Setting Through front panel LCD display and menu keys or with

IBM compatible PC with RS-232 port. 841 also has 10/100

Baset-T network ability

Alarm Contact Ratings 60 Vdc, 0.5A, Form-C

Operating Temperature -40 to +75 °C

Issue 21 January 2008 22

Page 23

CPS6000 –48V Indoor/Outdoor Power Shelf

Table 2-L: QS845A Supplementary Board Specifications

Operating Input Voltage Range Input power through QS840A or QS841A

Plant Parameter Setting None, communicates with shelf components QS840A/QS841A

Alarm Contact Ratings None

Operating Temperature -40 to +75 °C

Issue 21 January 2008 23

Page 24

CPS6000 –48V Indoor/Outdoor Power Shelf

3 Engineering and Ordering

Engineering Information

Introduction

This section discusses the factors to be considered in determining the number of rectifiers and

ringers required in both non-redundant and redundant battery plants.

Rectifier Sizing (Non-Redundant Systems)

In non-redundant systems, the installed rectifier capacity of the battery plant must be

sufficient to provide the current required for the load during normal operations as well as the

current required to recharge the battery following ac power outages.

For the telecommunications industry, the system load current is known as the average busyhour current. (The average busy-hour current drain is defined as the average busy-hour

current drain during busy season with the plant operating at the normal voltage.) Therefore,

the minimum installed rectifier capacity (mirc) is the sum of the average busy-hour (abh)

current and the required battery recharge current, or

mirc = abh + recharge current

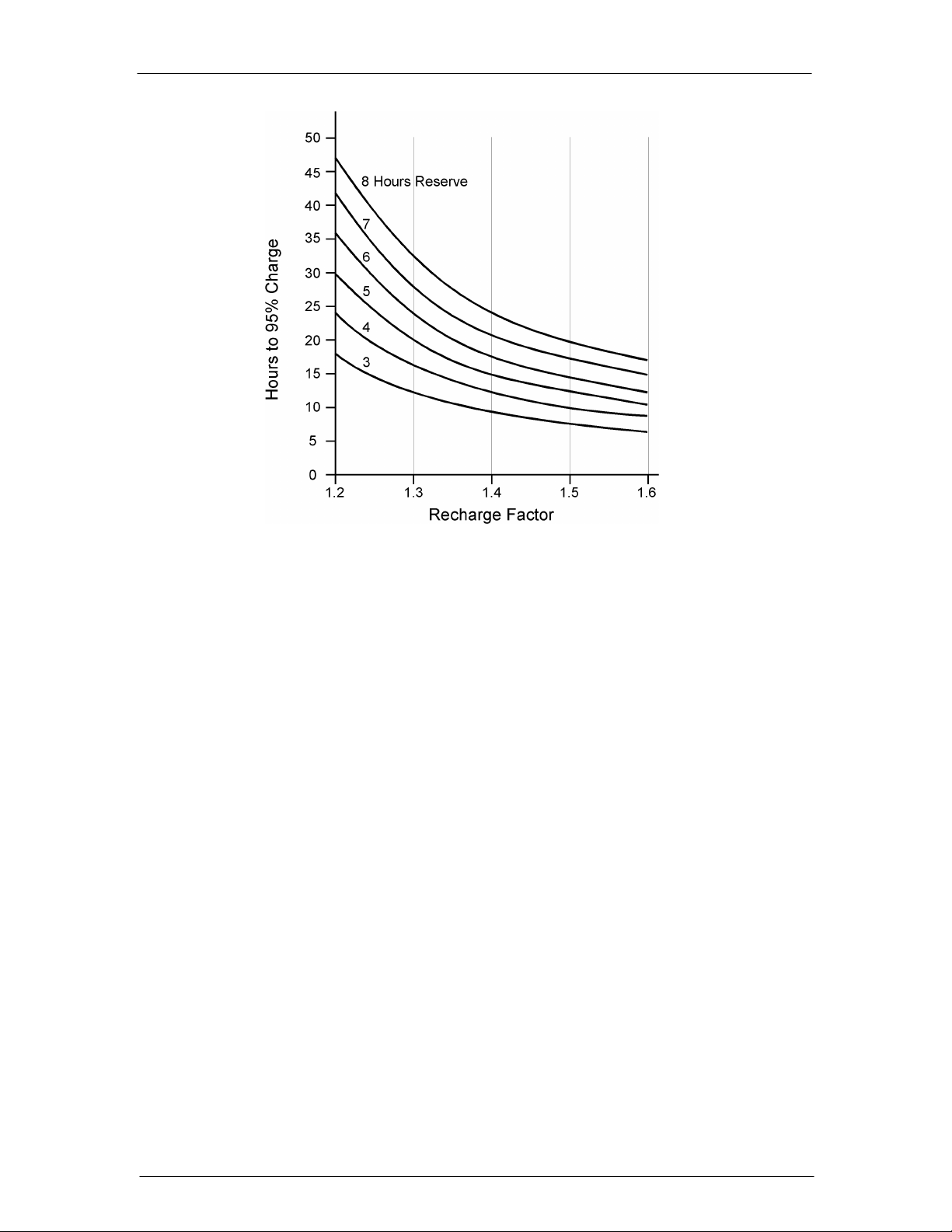

The battery recharge current is determined by two system considerations: the maximum time

the system is required to operate in the absence of ac power (reserve time), and the time

allocated to recharge the battery after ac power returns. These two times and Figure 3-1 may

be used to determine the recharge factor. This factor, when multiplied by the average busyhour current, determines the minimum installed rectifier capacity, or:

mirc = abh x recharge factor

The mirc divided by the individual rectifier capacity determines the number of rectifiers (of

equal capacity) required for a non-redundant system.

Rectifier Sizing (Redundant Systems)

In redundant systems, a spare on-line rectifier is included so that the loss of any one rectifier

will not cause the available plant capacity to fall below the required minimum installed

rectifier capacity. Thus, the loss of a rectifier will not affect the normal system operation nor

will it cause the batteries to discharge, and will allow the batteries to recharge in the required

time.

In cases where the additional spare rectifier will provide the required battery recharge current,

the mirc satisfies the requirements for both non-redundant and redundant systems. In other

cases, rectifiers in addition to the redundant rectifier may be required to provide the battery

recharge current. Typically, the number of spare rectifiers required for a redundant system is

the larger of one spare rectifier or 200% of the rated load.

Issue 21 January 2008 24

Page 25

CPS6000 –48V Indoor/Outdoor Power Shelf

Figure 3-1: Recharge Factor vs. Recharge Time

Plant Configuration Examples

1. To illustrate the relationships between mirc, abh current drains, the recharge factor, and

battery recharge current for non-redundant and redundant systems, consider the following

examples. Note that the QS862A rectifier provides 25A at 54.5 Vdc (100-120 Vac) and

30A at 54.5 Vdc (200-240Vac).

A battery plant is required to provide a load current of 50 amperes, have an 8-hour

discharge time (reserve time) and recharge to 95% of battery capacity in 24 hours.

Determine the number of rectifiers required for non-redundant systems.

From Figure 3-1, the recharge factor is 1.38.

mirc = abh x recharge factor

mirc = 50 x 1.38 = 69 amperes

For low line ac using QS862A 25A (100-120 Vac) rectifiers, three rectifiers (69/25 =

2.76) are required to provide the minimum installed capacity of 69 amperes for a nonredundant system. If one rectifier fails, the remaining rectifiers will provide the abh

capacity.

2. An alternate method to calculate the number of rectifiers necessary is to utilize power. In

the above example, the requisite current is 50A. As most battery plant loads are looking

into constant-power loads, the 50A would increase as the battery voltage decreases during

battery discharge. Assuming the 50A is the current being drawn from the load at the plant

float voltage of 54.5V, the total power being drawn by the load is 2725W (54.5V x 50A).

We can utilize the recharge factors from Figure 3-1 and use a modified mirc formula,

Issue 21 January 2008 25

Page 26

CPS6000 –48V Indoor/Outdoor Power Shelf

therefore:

mirc = power x recharge factor

mirc = 2725W x 1.38 = 3761W

In this high line ac example using QS862A 1635W (200-240 Vac) constant power

rectifiers, three rectifiers (3761/1635 = 2.3) are needed to support the load and recharge

the batteries within the requisite time.

Ringer and Ringer Chassis

Ringer Chassis each support one 100 VA ringing output. Redundant ringing outputs require

two Ringers in each Ringer Chassis.

Ordering Information

Ordering Guide

An ordering guide may be downloaded from the Lineage Power web site. This guide will

augment the information found here.

Note: Ordering information here is presented only from the viewpoint of miscellaneous

item ordering and may not be complete. Complete System ordering should done using

the ordering guide only.

Comcodes

The CPS6000 can be ordered by 9-digit numeric character sets called comcodes. The

following guides you through the comcode selection process in creating a power system.

Please refer to the product description section on the individual components for more details.

Power Shelves

Shelves are available in 23-inch (584 mm) and 19-inch (483 mm) rail widths. Mounting

hardware is provided. Refer to Ordering Guide for other shelf types.

Baffle

A 1U tall baffle is available to mount between shelves, below the shelf or above the shelf. See

Appendix F for application information.

Distribution Modules

The Platform has standard single slot, dual slot, front bulk and rear bulk output module

options. An external 23” distribution panel is also available for systems with the bulk output.

Battery breakers are available in lieu of the battery straps. However, maximum current

allowed through each battery breaker is 50A instead of the 100A through the battery strap.

For load breakers in a single slot distribution module, a max of two 60A load breakers can be

used. If only a single breaker is used in the topmost position, a 70A breaker may be used

Issue 21 January 2008 26

Page 27

CPS6000 –48V Indoor/Outdoor Power Shelf

Office Alarm Cable

WARNING

Disconnect alarm cable before cutting it to length. Cutting the alarm cable while it is

plugged into the controller will damage the controller.

A cable assembly is available that mates to the host-interface connector on the controller

allowing access to alarms. This cable is terminated on one end with a connector that mates to

the Distribution Module host-interface connector, and un-terminated on the other end. Refer

to the ordering guide for cable lengths available

Distribution Module Circuit Breakers

The following bullet-style circuit breakers, which have been accepted for use in dc load and

battery applications, are available for the current Distribution Module. These breakers only

alarm for a trip condition. For a single slot distribution module, a max of two 60A load

breakers can be used. If only a single breaker is used in the topmost position, a 70A breaker

may be used

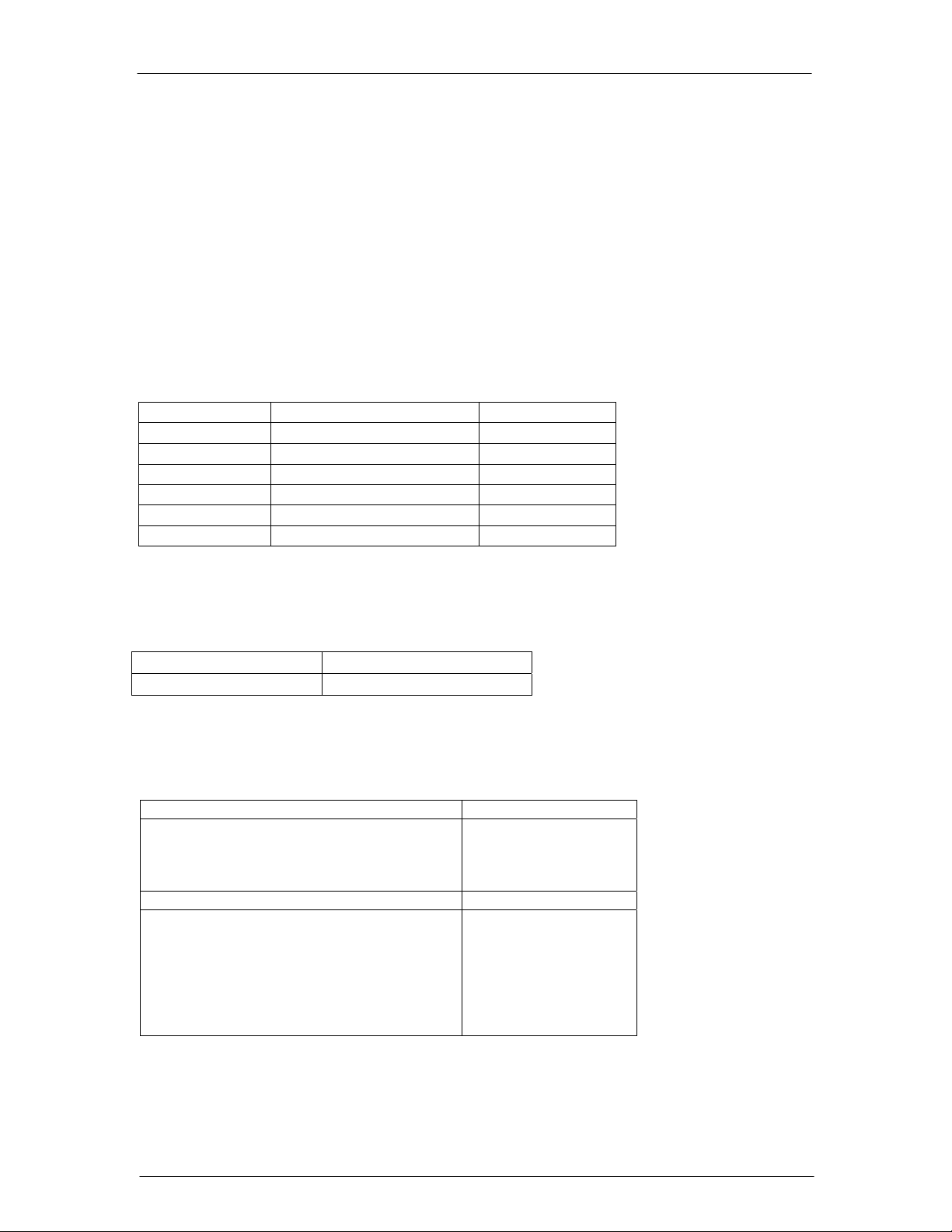

Size (Amps) Comcode Size (Amps) Comcode

3 407998137 25 407998194

5 407998145 30 407998202

10 407998152 45 407998210

15 407998160 50 407998228

16 407998178 60 407998236

20 407998186 70 407998244

Some versions of the distribution module accept breakers that alarm for trip or open

condition. The comcodes for such breakers are provided below. These breakers can ONLY be

used with specific distribution modules

Size (Amps) Comcode Size (Amps) Comcode

3 CC408606834 30 CC408606891

5 CC408606842 40 CC408606900

10 CC408606850 45 CC408606917

15 CC408606867 50 CC408606925

20 CC408606875 60 CC408606933

25 CC408606883

Caution - Please check the type of breaker the distribution module

accepts before using the above comcodes

Pluggable Strap

Size(Amps) Comcode

100A Pluggable Strap CC109106548

Issue 21 January 2008 27

Page 28

CPS6000 –48V Indoor/Outdoor Power Shelf

Distribution Module GMT Fuses

The following GMT fuses have been accepted for use in dc load applications, are available

for the current Distribution Module.

Size (Amps) Comcode Size (Amps) Comcode

0.25 405006222 7.5 405725433

0.5 406976894 10 406159236

1.33 405673146 12 407845197

2 405181983 15 406473959

3 406976985 20 408555453

5 406159061

The following shows the possible fuse loading scenario for the Single-Slot and Double-Slot

Distribution Modules. 20A fuse positions can be used only with factory wiring. When using

20A fuses, adjacent fuse positions must be left open.

For the Single-Slot Distribution Module with 10 GMT fuses, Field installation is only rated

for 10A fuses. No more than 80A may be carried through the 10 fuse positions, or 40A

through each half section. 15A and lower rated fuses may be used in any combination and

position, as long as they do not violate the previous 80A/40A rule.

For the Single-Slot Distribution Module with 5 GMT fuses, a maximum load of 32 A is

permitted with restrictions on the fuse positions. Specifically:

Position F1 defined as the bottom fuse position and F5 as the top fuse position.

1. Configuration #1 - F1+F2 <= 15A, F3<=15A, and F5+F4<= 10A

2. Configuration #2 - F1<=15A; F2=No Fuse; F3<=15A; F4=No Fuse; F5<=10A 3.

For the Double-Slot Distribution Module, each 8-fuse board can support a maximum of 80A.

Single-Slot Distribution Module

Position Max Fuse Position Max Fuse Position Max Fuse

10 10 15A 8 15A/20A

9 20A 9 7

8 8 15A 6 15A/20A

7 20A 7 5

6 6 15A 4 15A/20A

5 5 3

4 20A 4 15A 2 15A/20A

3 3 1

2 20A 2 15A

1 1 15A

(Arrows indicate

alternate positions)

Double-Slot

Distribution Module

Issue 21 January 2008 28

Page 29

CPS6000 –48V Indoor/Outdoor Power Shelf

Controller

There are two controller options for the CPS6000. The QS840A system controller allows for

control and monitoring of system functions and setting of all system parameters. The QS841

provides integrated Ethernet access and other enhanced features. Refer to Section 5 for more

controller details and Appendix A for programming information. The QS845A supplemental

kit allows up to 3 supplemental shelves to be controlled by the QS840A/QS841A controller

on the primary shelf.

Rectifiers

The constant-power rectifiers each occupy a single slot in the CPS6000 shelf. If a full

complement of rectifiers is not required, a rectifier slot filler may be to cover empty rectifier

slots. The slot filler is not necessary from an earthquake standpoint.

Model Amperage Comcode

QS861A Rectifier 15A low and high line ac 108993531

QS852A Rectifier 20A high line ac CC109106440

QS853A Rectifier 25A high line ac CC109121290

QS862A Rectifier 25A low line/30A high line ac 108986704

QS864A Rectifier 40A high line ac 108994513

QS865A Rectifier 50A high line ac 108990074

QS850 Slot Filler N/A 108994273

Ringer Chassis

Ringer Chassis each occupy a single Power Slot in the CPS6000 Shelf.

Ringer Chassis Comcode

QS820M Ringer Chassis 108991262

Ringer Output Cable

Ringer Cables one per Ringer Output (Ringer Chassis).

Item Comcode

Ringer Output Cable H569-470 G kit – 15’ cable

with connector for CPS6000/CPS2000 shelf on

one end and unterminated leads on the other

end.

Ringer Output Cable – 150 ft CC848804765

Commercial - Molex:

Plug 39-01-4031

Socket (3 per plug):

Terminal Type 5556

16 AWG 39-00-0079

18 AWG 39-00-0059

Tool 11-01-0197

847922101

Commercial

Ringers

Up to two Ringers plug into a Ringer Chassis.

Issue 21 January 2008 29

Page 30

CPS6000 –48V Indoor/Outdoor Power Shelf

One Ringer per Ringer Chassis is non-redundant (simplex).

Two Ringers per Ringer Chassis is 1 + 1 redundant (duplex).

Ringer Comcode

QS820A Ringer 108990082

AC Power Cables

An ac power cable must be ordered. A standard ac cable set will not fit in the CPS6000 shelf.

Verify that the sum of the input currents for all the rectifiers served by an ac circuit breaker

does not exceed 80% of the breaker’s rating.

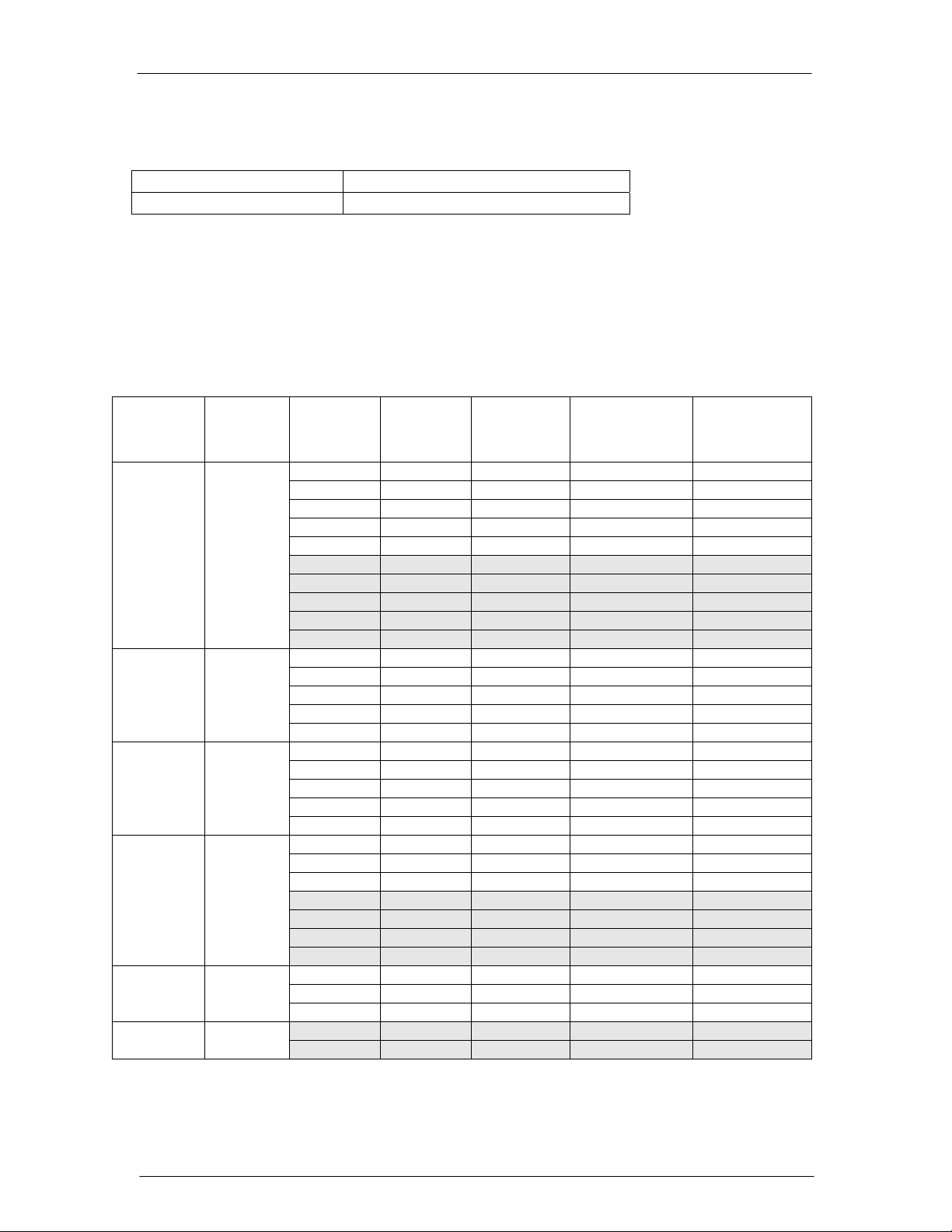

Table 3-A: Rectifier AC Input Current Table

Lineage

Power

Rectifier (A)

Model

Number of

Rectifier

Nominal

Input

Voltage

Number of

Rectifiers

per AC feed

Nominal AC

Current (A)

Minimum Circuit

Breaker value

recommended

(A)*

75°C Minimum

Recommended

Wire Gauge

(AWG)*

120 1 7.8 15 14

120 2 15.6 20 12

120 3 23.4 30 10

120 4 31.2 40 8

15A QS861A

120 5 39.1 50 8

208 1 4.4 15 14

208 2 8.8 15 14

208 3 13.2 20 12

208 4 17.6 25 10

208 5 22.0 30 10

208 1 6 15 14

208 2 12 15 14

20A QS852A

208 3 18 25 10

208 4 24 30 10

208 5 30 40 8

208 1 7.4 15 14

208 2 14.8 20 12

25A QS853A

208 3 22.2 30 10

208 4 29.6 40 8

208 5 37.0 50 8

120 1 13.0 20 12

120 2 26.0 35 8

120 3 39.1 50 8

25/30A QS862A

208 1 8.8 15 14

208 2 17.6 25 10

208 3 26.4 35 8

208 4 35.3 45 8

208 1 11.8 15 14

40A QS864A

208 2 23.5 30 10

208 3 35.3 45 8

50A QS865A

208 1 14.5 20 12

208 2 29.1 40 8

*Conduit and further temperature deratings may be required in some installations .Cross-check table with

local code and regulation requirements

Issue 21 January 2008 30

Page 31

CPS6000 –48V Indoor/Outdoor Power Shelf

Thermal Compensation

Thermal Compensation: For thermal compensation, the QS873A Voltage/Thermal probe

(VT-Probe) and its associated cables must be ordered. Refer to Section 5 for details on their

interconnection, and Section 9 for more information on VT-Probes. The probe is provided

with a weatherproof case.

Thermal Compensation/Voltage Monitoring: When voltage monitoring for battery string

voltage imbalance detection is to be implemented in addition to thermal compensation, the

VT-probe and its associated cables must be ordered. Refer to Section 5 for details on their

interconnection, and Section 9 for more information on VT-Probes and voltage monitoring.

Remote Distribution Monitor Module

The Remote Distribution Monitor Module allows the CPS6000 system controller to monitor

for open circuit breakers and fuses, monitor current through a battery shunt, and

monitor/control low-voltage disconnect contactors at an external distribution panel that is

bulk-fed from the CPS6000 system. See Section 11 for more details.

Inter-Shelf Kit for Multiple Shelves

Supplementary bulk-output shelves may be added to a bulk-output primary shelf to create a

larger plant. Only the primary shelf requires a controller. The inter-shelf kit contains a QS845

shelf controller (with blank faceplate) and a connecting cable with connectors on both ends.

Refer to Appendix F for thermal considerations while paralleling shelves.

Lugs

Please refer to ordering guide H569-470 for lugs specific to distribution modules. The

following table is generic and needs to be used in conjunction with the ordering guide.

Note: TEPS lugs in the WP91412 specification are Burndy parts. The Panduit and T&B (and

any others) may have different dimensions.

WP-91412

GA Description

2 Straight, STR 54 405348202 YA2CL-2TC14 LCD2-14A-Q 54207 (STR)

2 Straight, FLEX 8 405347683 YAV2C-L2TC14-FX LCDX2-14A-E 54208 (Flex)

2 45°, STR ? ? YA2CL-2TC14-45 LCD2-14AH-Q 54207UF (STR)

2 45°, FLEX 193 408210524 YAV2C-L2TC14-FX-45 LCDX2-14AH-E 54208UF (Flex)

4 Straight, STR / FLEX 5 405347576 YAV4C-L2TC14-FX LCDX4-14A-L (FLEX)

4 45°, STR / FLEX ? ? YAV4C-L2TC14-FX-45 LCDX4-14AH-L (FLEX)

6 Straight, STR / FLEX 3 405347519 YAV6C-L2TC14-FX LCDX6-14A-L (FLEX)

6 45°, STR / FLEX ? ? YAV6C-L2TC14-FX-45 LCDX6-14AH-L (FLEX)

8 Straight, STR / FLEX 75 406021626 YA8CL2TC14 LCDX8-14A-L (FLEX)

8 45°, STR / FLEX ? ? YA8CL2TC14-45 LCDX8-14AH-L (FLEX)

List

Comcode Burndy Equivalent Panduit Similar T&B Similar

54206 (STR)

LCD4-14A-L (STR)

LCD4-14AH-L (STR)

LCD6-14A-L (STR)

LCD6-14AH-L (STR)

LCD8-14A-L (STR)

LCD8-14AH-L (STR)

54206 (FLEX)

54206UF (STR)

54206UF (FLEX)

54205 (STR)

54205 (FLEX)

54205UF (STR)

54205UF (FLEX)

542040410 (STR)

542040410 (FLEX)

N/A

Issue 21 January 2008 31

Page 32

CPS6000 –48V Indoor/Outdoor Power Shelf

4 Safety

Safety Statements

Please read and follow all safety instructions and warnings before installing, maintaining, or

repairing the CPS6000 System:

• The CE Mark demonstrates compliance with the European Union Council Directives

for Low Voltage and EMC.

• The CPS6000 platform is Underwriters Laboratories (UL) Listed per Subject Letter

1801, DC Power Distribution Centers for Telecommunications Equipment.

• CPS6000 shelves equipped with QS820A ringers (in development) have hazardous

secondary voltages on the secondary bus output connectors.

• Install only in restricted access areas (dedicated equipment rooms, equipment closets,

or the like) in accordance with articles 110-16, 110-17, and 110-18 of the U.S.

National Electric Code (NEC), ANSI/NFPA No. 70, and pursuant to applicable local

codes.

• This equipment is to be used in controlled environments (an area where the humidity is

maintained at levels that cannot cause condensation on the equipment, the

contaminating dust is controlled, and the steady-state ambient temperature is within

the range specified).

• This equipment has been evaluated for continuous use in ambient temperature from -

40°C to 75°C when used with the QS862A rectifier.

• This equipment must not be installed over combustible surfaces.

• For installations in the United States, Listed compression connectors are to be used to

terminate Listed field-wired conductors where required. For all installations, the

appropriate connector is to be applied only to the correct size conductor as specified

by the connector manufacturer, using only the connector manufacturer's recommended

tooling or tooling approved for that connector.

• If the proper connector for the country of installation is not provided, obtain appropriate

connectors and follow manufacturer’s and all local requirements for proper

connections. All national and local rules and regulations should be followed when

making field connections.

• Load connections to Bulk Output Modules should be made in close proximity to the

power shelf.

• The main output voltage (48V) meets SELV requirements.

Issue 21 January 2008 32

Page 33

CPS6000 –48V Indoor/Outdoor Power Shelf

• Insulation on field-wired conductors should be rated no less than 90° Celsius. Wire

conductor size should be sized per electrical codes for 75° Celsius wire, and based on

the ampacity of the associated protection device. Wiring internal to enclosed

equipment cabinets should be rated at 105° Celsius (minimum).

• Torque electrical connections to the values specified on labels or in the product

documentation.

• Battery input cables must be dressed to avoid damage to the conductors (caused by

routing around sharp edges or routing in areas where wires could get pinched) and

undue stress on the connectors.

• Alarm contacts on the office alarm connector (J1) are not fused within the distribution

panel; therefore, current limiting protection for these contacts must be provided by

external circuits. Maximum ratings for alarm connections are 60Vdc and 0.5 amperes.

Exceeding these maximum ratings could result in fire or damage to the unit.

• Fuse and/or circuit breaker loads must not exceed 80% of the fuse and/or circuit

breaker current rating. Distribute loads across the panel.

• The short circuit current capability of the battery input to the distribution panel must

not exceed 10,000A.

• AC branch circuits to this equipment must be protected with either fuses or circuit

breakers sized as required by the National Electric Code (NEC) and/or local codes.

The maximum size of the over-current protector is based on the type of shelf. Refer to

the equipment ratings to assure rating of equipment will not exceed 80% of the value

of the protector chosen.

• An accessible ac disconnect/protection device to remove ac power from the equipment

in the event of an emergency must be provided.

• High leakage currents are possible due to contribution from simultaneous multiple AC

input connections. Earth ground connection is essential before connecting the ac

source to the shelf. This connection must be achieved by ensuring that the C.O.

grounding stud is connected as shown in the Installation Section, or quality service

personnel shall ensure that the rack system is bonded per the provision below.

• In enclosed equipment cabinets, the CPS6000 mounting framework must be connected

directly to the cabinet ac service ground bus. For applications in huts, vaults, and

central offices, the CPS6000 mounting framework must be connected to the system

integrated ground grid.

• Installing fuses or circuit breakers not specified for use in these distribution modules

may result in injury to service personnel or equipment damage. Use only replacement

parts listed in this manual and on the equipment drawings.

• The telecom-type (e.g., GMT type) fuses can produce sparks during interruption or

clearing of a fault on a high energy circuit. Use only fuses provided with safety caps

for this type of circuit. Installing telecom-type fuses not equipped with safety caps

may result in injury to service personnel.

Issue 21 January 2008 33

Page 34

CPS6000 –48V Indoor/Outdoor Power Shelf

• While installing batteries, follow all safety precautions outlined in the appropriate

battery product manuals.

• The terminal block for the GMT fuse panel is rated for 20A with factory wiring, but

only 10A for field installation.

• All ac inputs for the J85470S1 L12 and L13 must be connected to maximum 60A panel

board breakers from maximum two ac conduit connections.

• CPS6000 outputs are not connected to earth. Earthing of rectifier outputs may be

performed externally to the shelf at a “ground window” or “mesh ground”. Connection

of Ringer tip outputs to CPS6000 Battery or Ground is optional via Ringer Chassis

jumper or external connection.

• The QS841 has an IEEE 802.3 compliant 10Base-T network interface with a

grounded connector shield.. Where intra building lightning surge protection is of

concern, Lineage Power recommends the use of a shielded cable, where both ends are

tied to ground. This cable must be supplied by the user. (example: CAT 5 E STP)

Issue 21 January 2008 34

Page 35

CPS6000 –48V Indoor/Outdoor Power Shelf

Warning Statements and Safety Symbols

The symbols may sometimes be accompanied by some type of statement; e.g., “Hazardous

voltage/energy inside. Risk of injury. This unit must be accessed only by qualified

personnel.” Signal words as described below may also be used to indicate the level of hazard.

Indicates the presence of a hazard that will cause death or severe personal

DANGER

WARNING

CAUTION

injury if the hazard is not avoided.

Indicates the presence of a hazard that can cause death or severe personal

injury if the hazard is not avoided.

Indicates the presence of a hazard that will or can cause minor personal

injury or property damage if the hazard is not avoided.

This symbol identifies the need to refer to the equipment instructions for

important information.

These symbols (or equivalent) are used to identify the presence of hazardous

ac mains voltage.

This symbol is used to identify the presence of hazardous ac or dc voltages.

It may also be used to warn of hazardous energy levels.

One of these two symbols (or equivalent) may be used to identify the

presence of rectifier and battery voltages. The symbol may sometimes be

accompanied by some type of statement, for example: “Battery voltage

present. Risk of injury due to high current. Avoid contacting conductors with

uninsulated metal objects. Follow safety precautions.”

One of these two symbols may be used to identify the presence of a hot

surface. It may also be accompanied by a statement explaining the hazard. A

symbol like this with a lightning bolt through the hand also means that the

part is or could be at hazardous voltage levels.

This symbol is used to identify the protective safety earth ground for the

equipment.

This symbol is used to identify other bonding points within the equipment.

This symbol is used to identify the need for safety glasses and may

sometimes be accompanied by some type of statement, for example: “Fuses

can cause arcing and sparks. Risk of eye injury. Always wear safety glasses.”

Issue 21 January 2008 35

Page 36

CPS6000 –48V Indoor/Outdoor Power Shelf

Precautions

When working on or using this type of equipment, the following precautions should be noted:

• This unit must be installed, serviced, and operated only by skilled and qualified

personnel who have the necessary knowledge and practical experience with electrical

equipment and who understand the hazards that can arise when working on this type of

equipment.

• The equipment could be powered by multiple ac inputs. Ensure that the appropriate

circuit protection device for each ac input being serviced is disconnected before

servicing the equipment. Do not disconnect permanent bonding provisions unless all ac

inputs are disconnected.

• Batteries may be connected in parallel with the output of the rectifiers. Turning off the

rectifiers will not necessarily remove power from the bus. Make sure the battery power

is also disconnected and/or follow safety procedures while working on any equipment

that contains hazardous energy/voltage.

• Hazardous energy and voltages are present in the unit and on the interface cables that

can shock or cause serious injury. Follow all safety warnings and practices when

servicing this equipment. When equipped with ringer modules, hazardous voltages will

be present on the ringer output connectors.

In addition to proper job training and safety procedures, the following are some basic

precautions that should always be used:

• Use only properly insulated tools.

• Remove all metallic objects (key chains, glasses, rings, watches, or other jewelry).

• Wear safety glasses. Fuses can produce sparks. High energy levels on buses and

distribution components can produce severe arcing.

• Test circuits before touching.

• Lock out and tag circuit breakers/fuses when possible to prevent accidental turn on.

• Be aware of potential hazards before servicing equipment.

• Identify exposed hazardous electrical potentials on connectors, wiring, etc. (note the

condition of these circuits, especially wiring).

• Use care when removing or replacing covers; avoid contacting circuits.

Issue 21 January 2008 36

Page 37

CPS6000 –48V Indoor/Outdoor Power Shelf

Special Installation Notes

Deutsch

Installationsanleitung

Eingangsspannung ( Voltage ) : 2x AC 120/200-240V V

Eingangsstrom ( Current ) : QS801A, max 45A, QS800A, max 30A

Eingangsleistung ( Watts ) :

Nennfrequenz ( Frequency ) : 50 / 60 Hz

Seriennummer ( Assembly No. ):--

Modellnummer (Modell No. ) : QS801A, QS 800A

Abmessungen sind nur zur Referenz : 150mm x 22.5mm x 77.5mm

( Dimensions are for reference only )

Max. Umgebungstemperatur : max. 75 deg. C

( Max. Operation temperatur )

Achtung: Für kontinuierlichen Feuerschutz sollte die Sicherung nur mit einer des

gleichen Types ersetzt werden.

Sicherungswert :

( Warning : For continued protection against fire replace with same type and rating of

fuse )

Das System ist ein Gerät der Schutzklasse I / Überspannungs Kategorie II

( Power Supply is a Class I equipment / overvlotage category II )

Ausgangsspannungen und -stöme: DC 58 V / SELV

( Output Voltage and Current )

--Das Gerät darf nur in Räumen mit beschränktem Zutritt aufgestellt werden.

( Nur ausgebildetes Personal )

--Nur für Aufstellung auf Boden oder einer anderen brennbaren Oberfläche geeignet.

--Das Gerät hat keinen eigenen Ausschalter, es muß daher mit einem Ein- und

Ausschalter im Versorgungskreis versehen sein.

--Das Gerät ist für den Einbau in IT- Geräte in einem Rahmen bestimmt (siehe

weitere Anleitung)

--Beim Einbau des Gerätes ist daraf zu achten das alle Anforderungen gemäß

EN60950 eingehalten werden.

ACHTUNG: HOHER ABLEITSTROM

VOR ANSCHLUSS AN DEN VERSORGUNGSSTROMKREIS

UNBEDINGT ERDUNGSVERBINDUNG HERSTELLEN

Issue 21 January 2008 37

Page 38

CPS6000 –48V Indoor/Outdoor Power Shelf

Espanol

Notas especiales para instalaciones en países de habla hispana

• Instrucciones de instalación

(Installation Instructions)

• Voltaje (Voltage):

Vea tabla 2-A

• Corriente (Current):

Vea tabla 2-A

• Frecuencia (Frequency):

50/60Hz

• Voltaje y corriente de salida (Output Voltage and Current):

Vea tabla 2-A

• Temperatura máxima de operación (Maximum Operation Temperature):

75°C (167°F)

• Sin cabina contra incendios, suelo no combustible

(No fire enclosure, non-combustible floor)

• Evaluado en EN60950

(Evaluated to EN60950)

Issue 21 January 2008 38

Page 39

CPS6000 –48V Indoor/Outdoor Power Shelf

5 Installation

CPS6000 Installation

Purpose

CPS6000 Shelf Installation guide for generic installations. Additional requirements are

needed for application specific installations. Refer to Appendix F for spacing requirements.

Audience

Field application personnel.

Precautions

Observe ESD protection while installing circuit packs

Safety

• Always consider personal safety.

• Make sure the system is properly grounded per the National Electrical Code and local

building codes.

• Remove all metal jewelry before beginning the installation.

Installation Tools

•Wire cutters and strippers •Digital meter, +/- 0.02%

•Heat shrink gun •Screw Drivers (flat-blade and Phillips)

•Torque wrench (0-240 in-lb / 28 Nm) •ESD wrist strap

•48 Volt test load

Parts List

Single-Wide

Distribution Module

Double-Wide

Distribution Module

Ringer Chassis

Shelf

Comcode Qty Description

801085119

802286773

802841635

407646330

408515823

7-22050-2

801085119

802286773

802841635

407646330

7-22050-2

848702007

7-22050-2 1 #4 Screw

901078717 8 12-24 mounting screw

2

3/8-inch bolt

2

3/8-inch lock washer

2

3/8-inch flat washer

2

Shelf plastic bushing

1

Fuse puller

2

#4 screw

2

3/8-inch bolt

2

3/8-inch lock washer

2

3/8-inch flat washer

2

Shelf plastic bushing

4

#4 screw

1

Spacer

Issue 21 January 2008 39

Page 40

CPS6000 –48V Indoor/Outdoor Power Shelf

Installing the CPS6000 Shelf

CPS6000 Unpacking and Installation

There are two distribution options for the CPS6000, a Single-Slot Distribution Module and a

Bulk Output Module. Only one distribution box can be used in a CPS6000 shelf. This

hardware assembly is field installable, however in most cases the factory will have already

installed the distribution module when it is required.

Step Action

1. Unpacking. Inspect the shipping container for any signs of damage. If damage

exists, have the carrier’s representative sign a note acknowledging the damage.

2. Carefully cut the sealing tape and remove the shelf from the carton. Use the

parts list to verify all materials are included. Save the shipping package until all

parts are operating within specifications.

3. Is there a Distribution Module already installed in the right-most shelf

position?

Yes - Go to the Install the

CPS6000 shelf section.

4. Remove the Distribution Module Assembly from the carton. The Assembly and

the shelf will be shipped in separate cartons.

5. Is the Single-Slot or the Bulk Output Distribution Module being installed?

Bulk Output Distribution

Module - Go to Step 8.

6. Slide the Assembly into the rightmost slot.

7. Verify the hook on the front engages under the shelf. See Figure 5-1.

No – Continue

Single-Slot or Double-Slot Distribution

Module - Continue.

Figure 5-1: Distribution Module

Issue 21 January 2008 40

Page 41

CPS6000 –48V Indoor/Outdoor Power Shelf

Step Action

8. Insert one #4 Screw inside the left side of the Bulk Output Module, hand tight

to approximately 5 in-lb. See Figure 5-2.

9. Insert one #4 Screw on the right side of the shelf, hand tight to approximately

5 in-lb. See Figure 5-3.

10. Put a 3/8-inch lock washer and a flat washer on the 3/8-inch bolt. Locate the

two access holes on the rear of the shelf. Attach the Distribution Module to the

shelf with the washers and two bolts. Torque to 240 in-lb.

11. Cover the two access holes with the Black Plastic Covers shown.

Figure 5-2: Bulk Output Module

Figure 5-3: Distribution Module

Issue 21 January 2008 41

Page 42

CPS6000 –48V Indoor/Outdoor Power Shelf

Install the CPS6000 Shelf

Important Note

The following procedures are in order for a typical application. If the left side of the shelf will

be blocked after the shelf is installed in the framework, the following procedures should be

done before installing the shelf:

• Inter-Shelf Connections (multi-shelf installations only)

• AC Connections

• Office Alarm Cable

• Thermal Probe Connection

Leave a sufficient service loop on these cables.

Install the CPS6000 Shelf

Follow the steps in the table below to mount the CPS6000 shelf into a 19-inch or 23-inch

frame.

Step Action

1. Locate the 2 mounting brackets, one on each side of the CPS shelf; align the

holes in the shelf-mounting bracket with the holes in the mounting frame. See

Figure 5-4.

2. Attach the CPS shelf to the frame using a minimum of four (two on each side)

of the 12-24 screws included in the supplied parts bag. Refer to the table

below for Torque Specifications.

Hardware

Torque

Nm In-lbs.

Metric M5 4 35

12-24 4 35

Metric M6 7.3 65

Figure 5-4: CPS6000 Frame Mounting

Issue 21 January 2008 42

Page 43

CPS6000 –48V Indoor/Outdoor Power Shelf

Controller

Controller Installation

The Controller mounts in the controller housing located on the left side of the CPS shelf,

Figure 5-5. The Controller is field installable, however in most cases it will be factory

installed.

Warning: You must properly protect the Controller against ESD discharge.

Note: There is an ESD cord connection located on the left side of the shelf.

Step Action

1. Does the CPS shelf have the Controller already installed?

Yes - Proceed to the Rectifier

installation section

2. Slide the controller into the shelf until it is fully seated in the connector on the

rear of the CPS shelf. See Figure 5-5.

3. Connect one end of the display cable to the connector on the controller.

Connect the display faceplate to the other end of the display cable. Carefully